Wireless temperature measuring device for rotational molding equipment

A technology of wireless temperature measurement and equipment, applied in the direction of coating, etc., can solve the problems of low product quality accuracy, low efficiency of rotational molding, high energy consumption, etc., to ensure the temperature measurement environment and accuracy, and improve the efficiency of rotational molding , the effect of improving quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

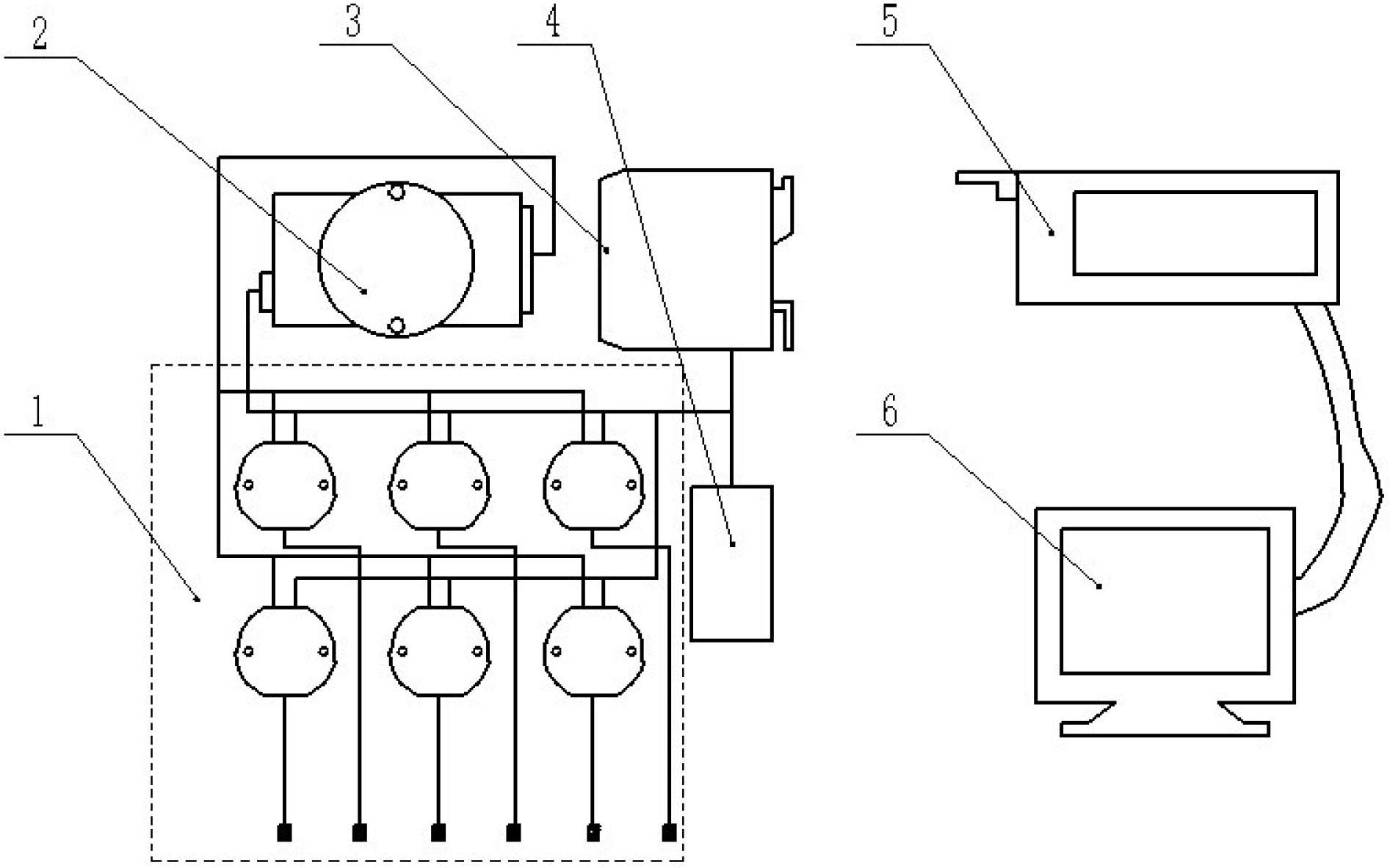

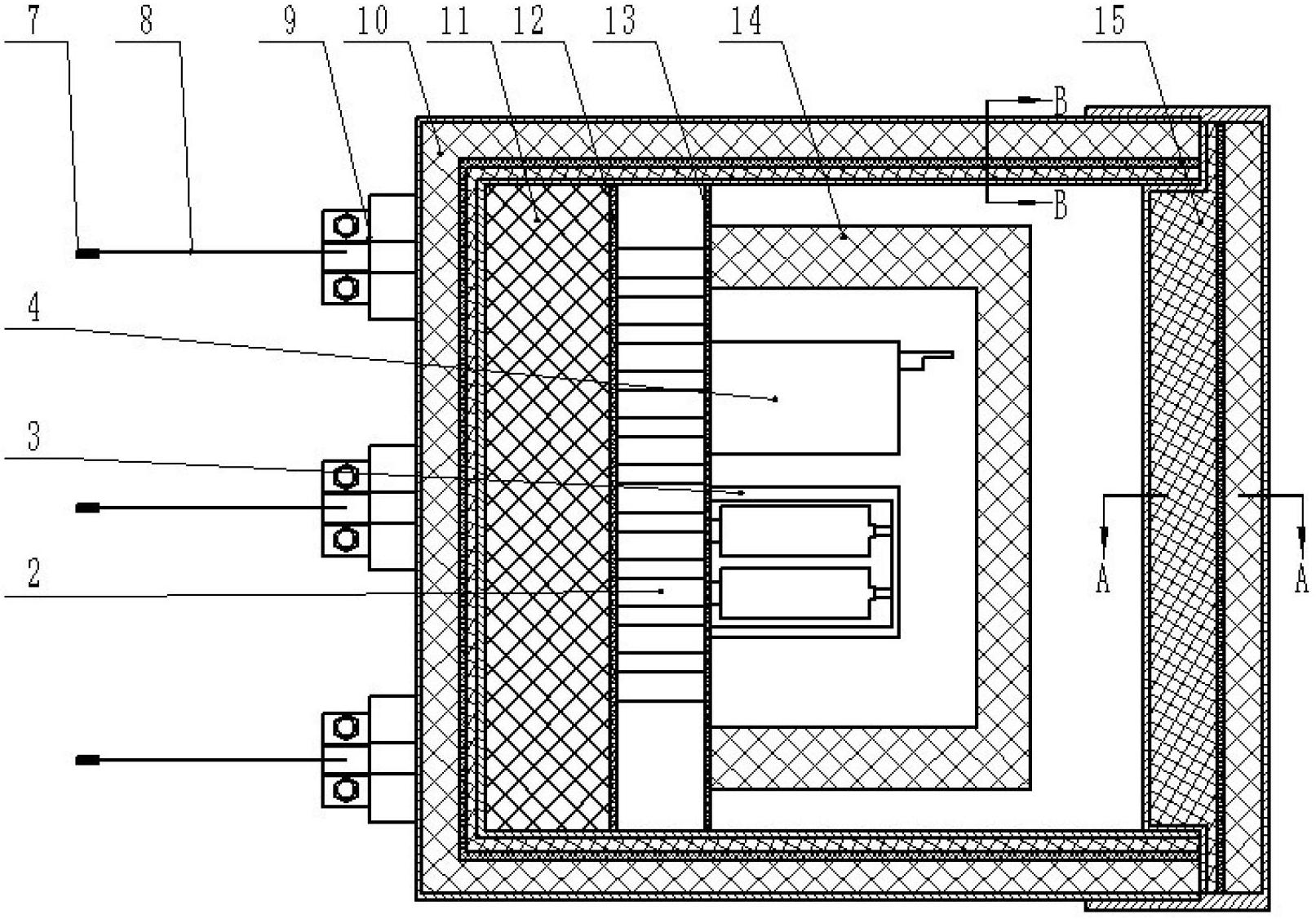

[0017] The present invention is a wireless temperature measuring device for rotomolding equipment, and the schematic diagram of equipment connection is as follows figure 1 , the wireless temperature measuring device includes an information collection module 1, an information processing module 2, an FSK radio frequency transmitter 3, a power supply 4, an FSK radio frequency receiver 5, and a data processing system 6, and the information collection module 1, the information processing module 2, The FSK radio frequency transmitter 3 and the power supply 4 are arranged inside the oven of the rotational molding equipment, the FSK radio frequency receiver 5 and the data processing system 6 are arranged outside the oven of the rotational molding equipment, and the information collection module 1 mainly collects each temperature measurement in the rotational molding equipment The temperature change of the point, and transmit the temperature signal, the information processing module 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com