Concrete temperature control early warning system

An early warning system and concrete technology, applied in the direction of thermometers, thermometer parts, measuring devices, etc., can solve the problem of untimely temperature recording, avoid quality accidents, improve timeliness, and solve real-time effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

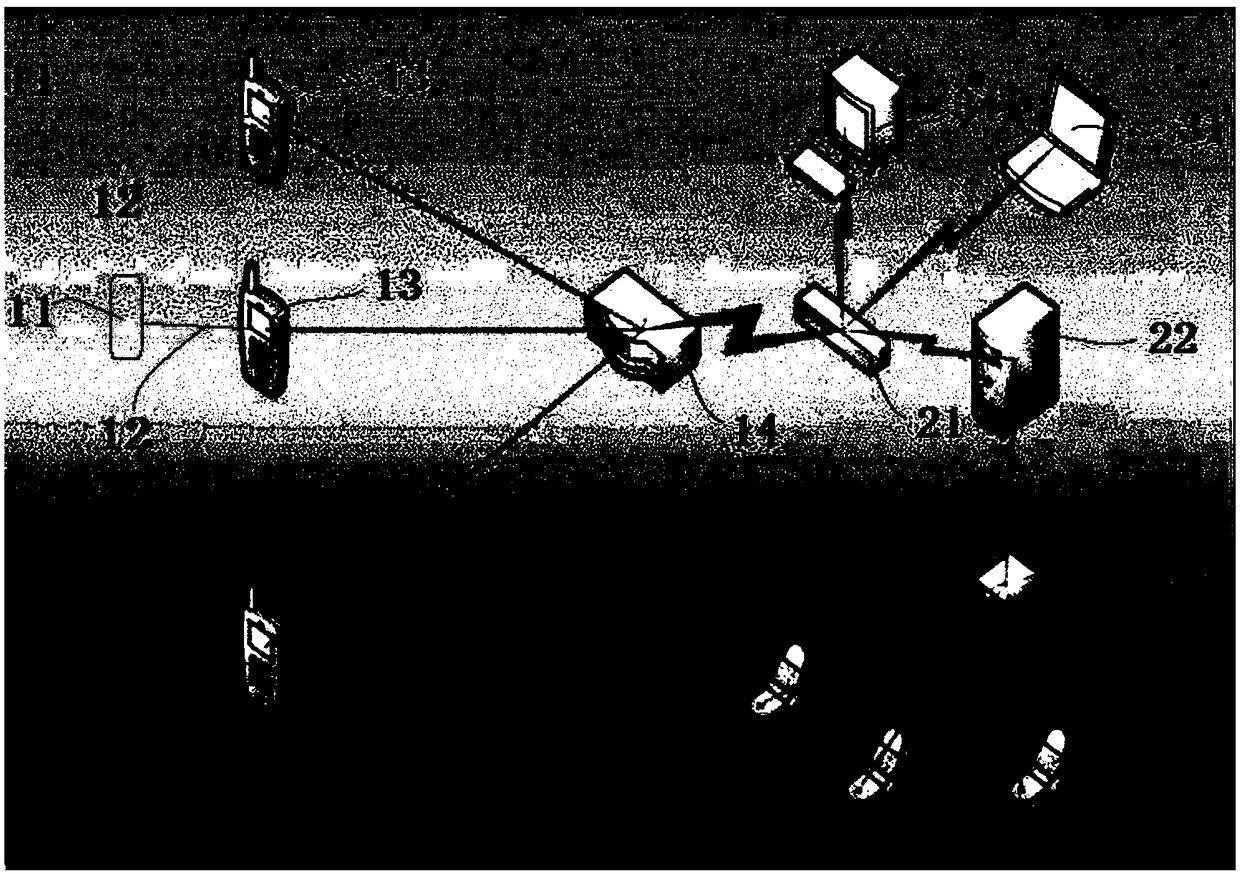

[0022] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0023] The maintenance method of concrete is the sub-project that takes the longest time and has the greatest impact on the quality of concrete in the entire concrete project. Generally speaking, the start time of concrete curing should be determined according to the local climatic conditions and the type of cement used in concrete engineering. After concrete pouring, the beam body is closed with a curing cover, and steam is input to control the humidity and temperature around the beam body. In order to ensure that the concrete has suitable hardening conditions and its strength continues to grow, the concrete must be maintained, that is, the temperature inside and on the surface of the concrete must be monitored and warned.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com