Battery management system suitable for low-temperature operation

A battery management system and working technology, applied in secondary batteries, secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve problems such as hindering the movement of charge carriers, battery failure to discharge, failure to start, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

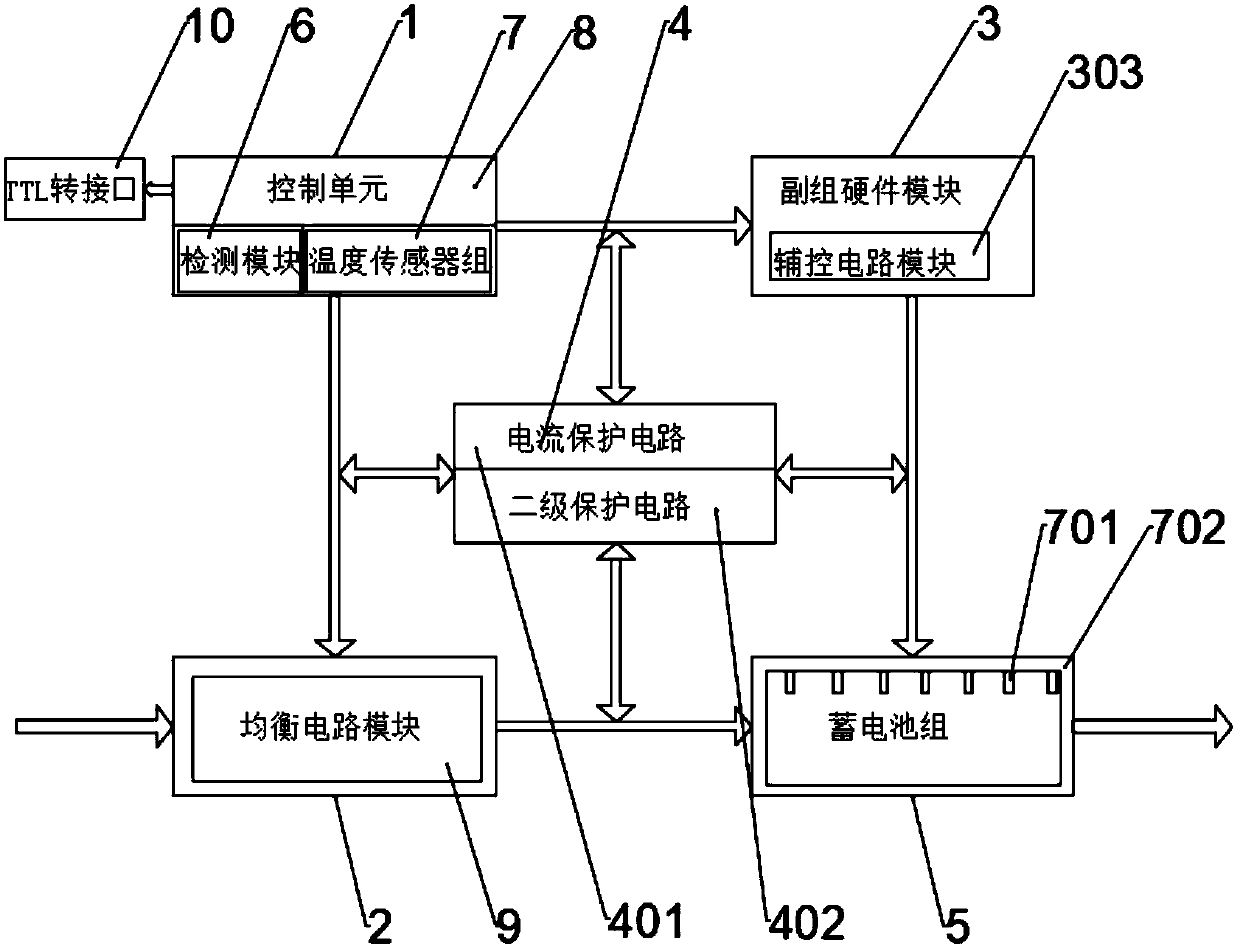

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention provides a battery management system suitable for low-temperature operation, including a detection and control module 1, a charging and adjustment module 2, a sub-group hardware module 3, and a protection module 4. The detection and control module 1 includes a battery pack 5 The voltage and current detection module 6 and the temperature sensor group 7, the data signal of the detection module 6 is analyzed by the control unit 8 in the detection and control module 1, and compared with the preset data value, the control unit 8 will execute the comparison The signal is transmitted to the equalizing circuit module 9 in the charging and adjusting module 2, and the control unit 8 analyzes the detection data of the temperature sensor group 7 and then drives the hardware module 3 of the sub-group through electrical signals to work, and at the same time detects and monitors the charging and adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com