Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Low hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

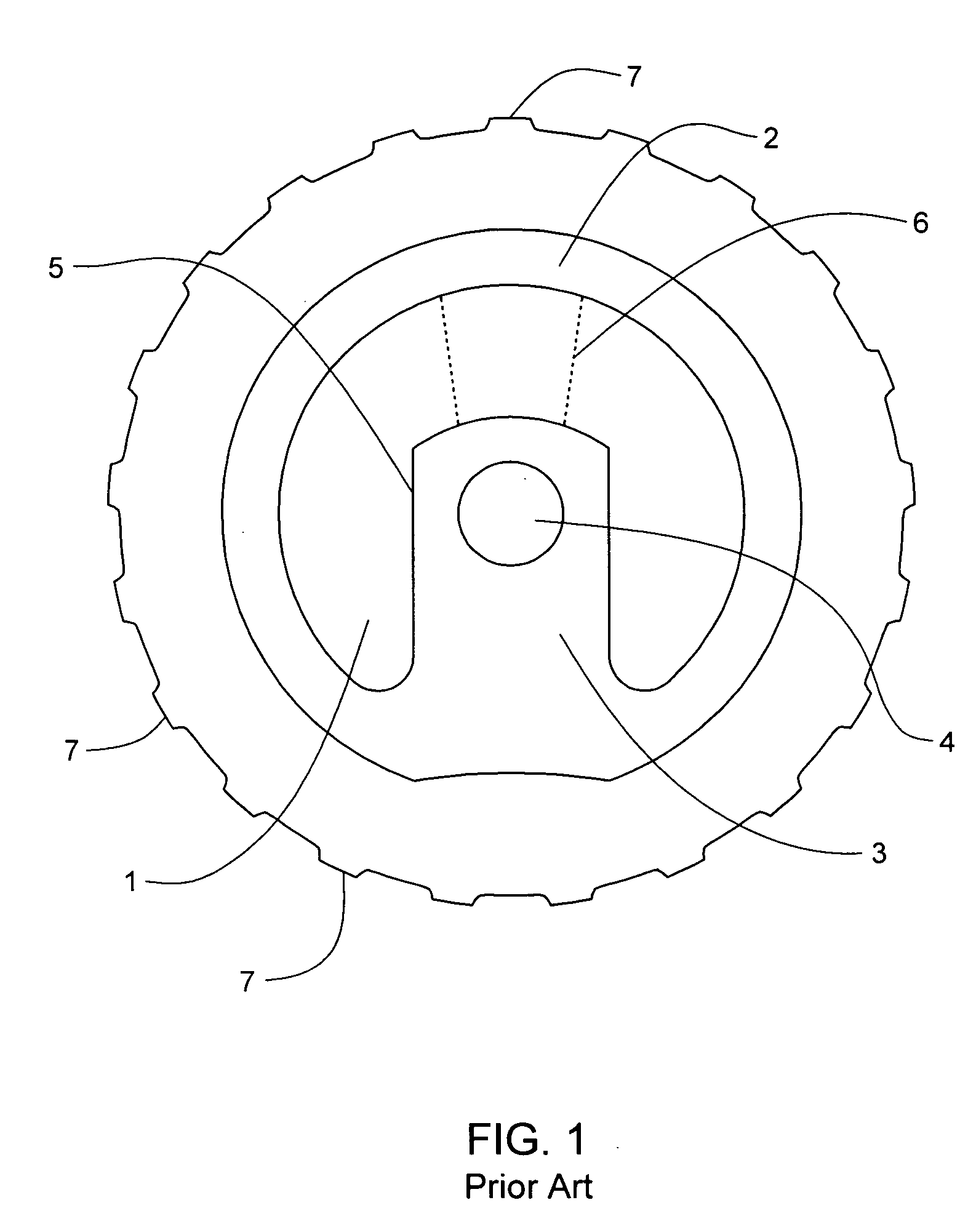

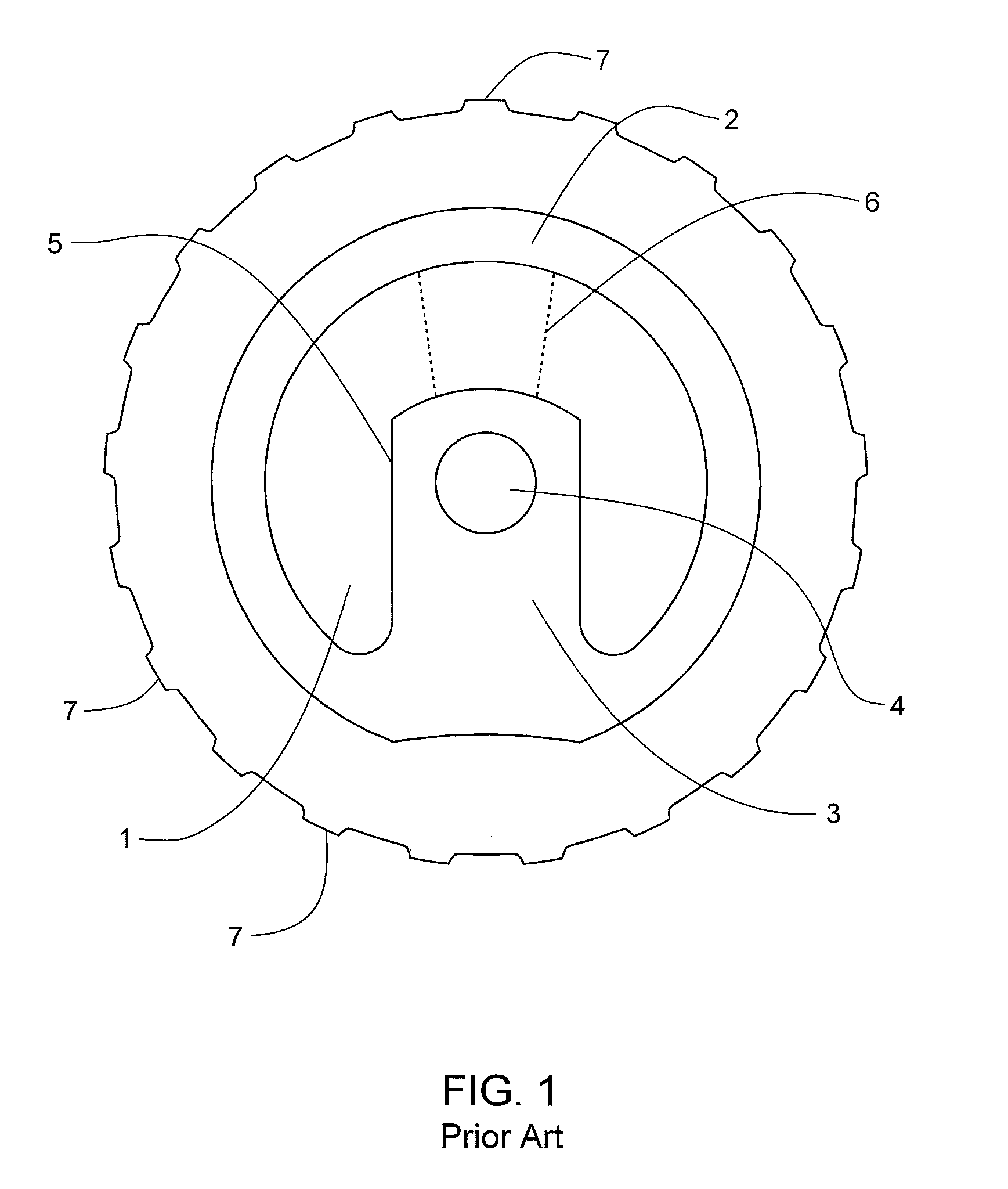

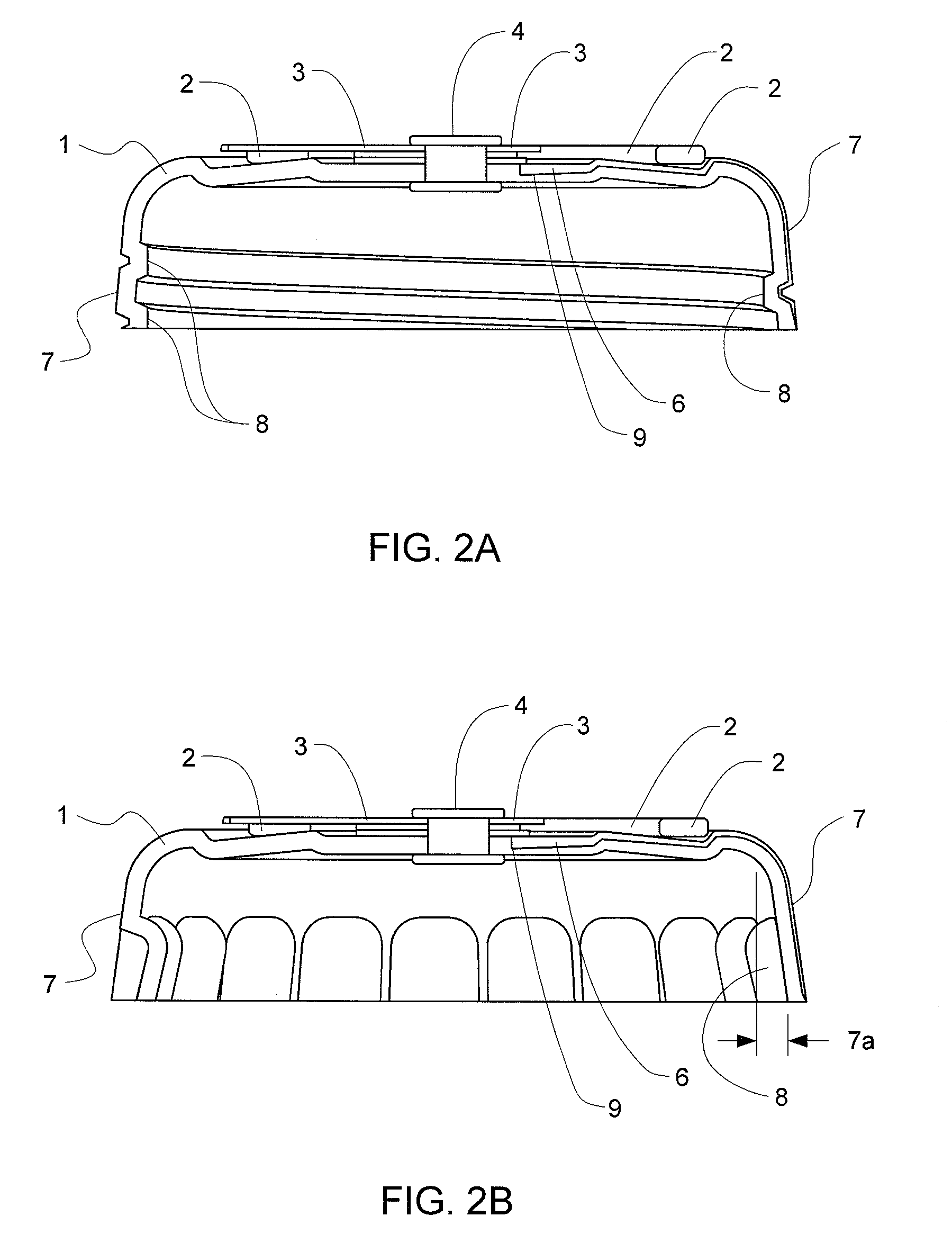

Easy-pull bottle cap

A crown for a bottle or other container, the crown comprised of a pull tab ring and a pull tab secured to the crown by a rivet and one or more cut lines between the rivet and the rim of the crown. The crown may be formed from tinplate with a hardness of T4 as measured by the Rockwell 30T Hardness Scale so that the crown may be opened and removed from the container the a force of approximately 2.5 Kg.

Owner:SWEENEY BART +1

Titanium dioxide pigment and method for producing the same and resin composition using the same

InactiveUS20050228112A1High opacityLow hardnessInorganic pigment treatmentTitanium dioxideColor toneChemistry

The titanium dioxide pigment of the present invention contains an anatase type crystal in an amount of 98-100% and has an average particle diameter of 0.2-0.4 μm and a whiteness of 95-97 in terms of L value of linseed oil. The titanium dioxide pigment of the present invention has characteristics peculiar to anatase type, for example, optical characteristics such as bluish color tone and physical characteristics such as low hardness, and furthermore has high opacity which is not possessed by conventional anatase type titanium oxide pigments.

Owner:ISHIHARA SANGYO KAISHA LTD

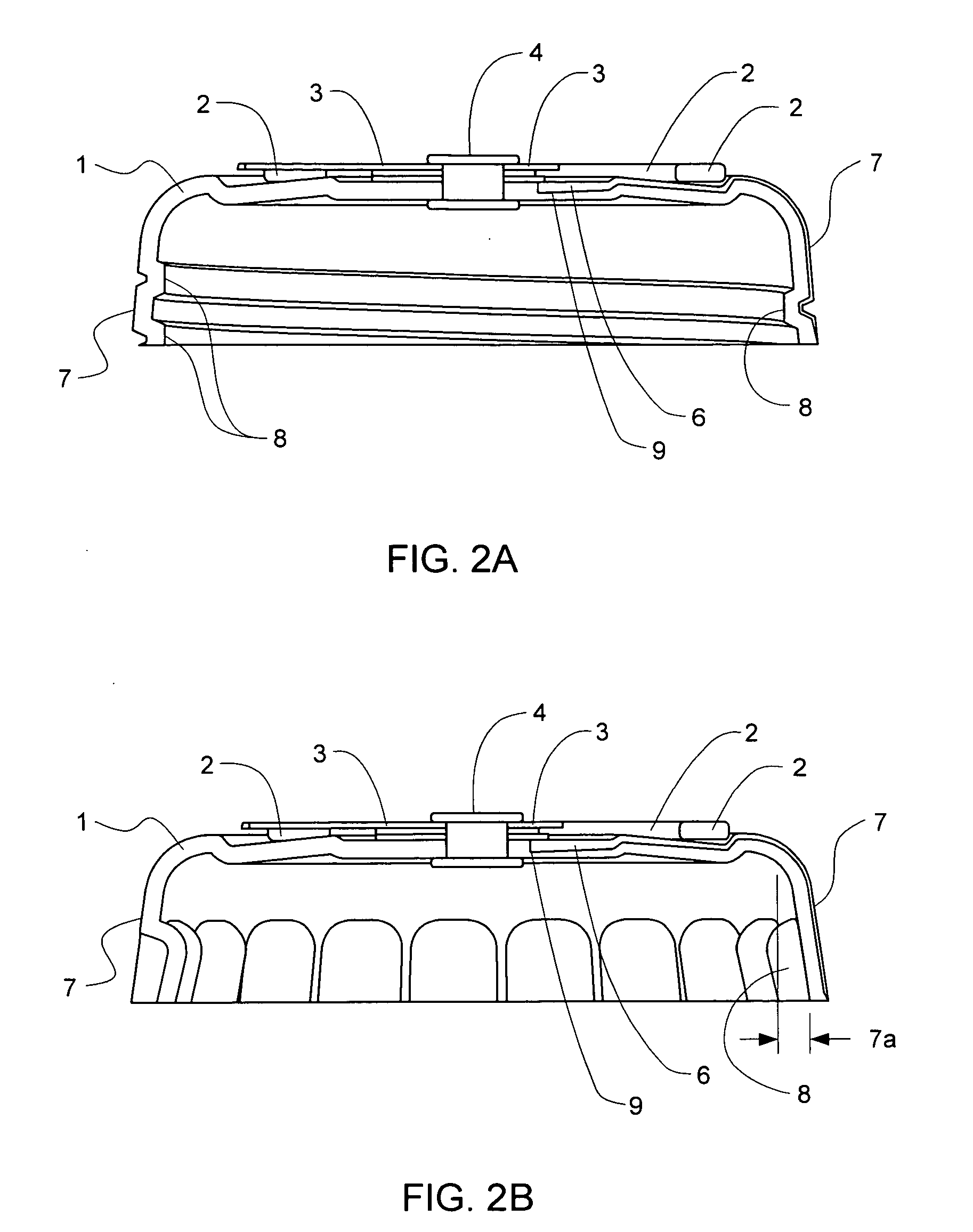

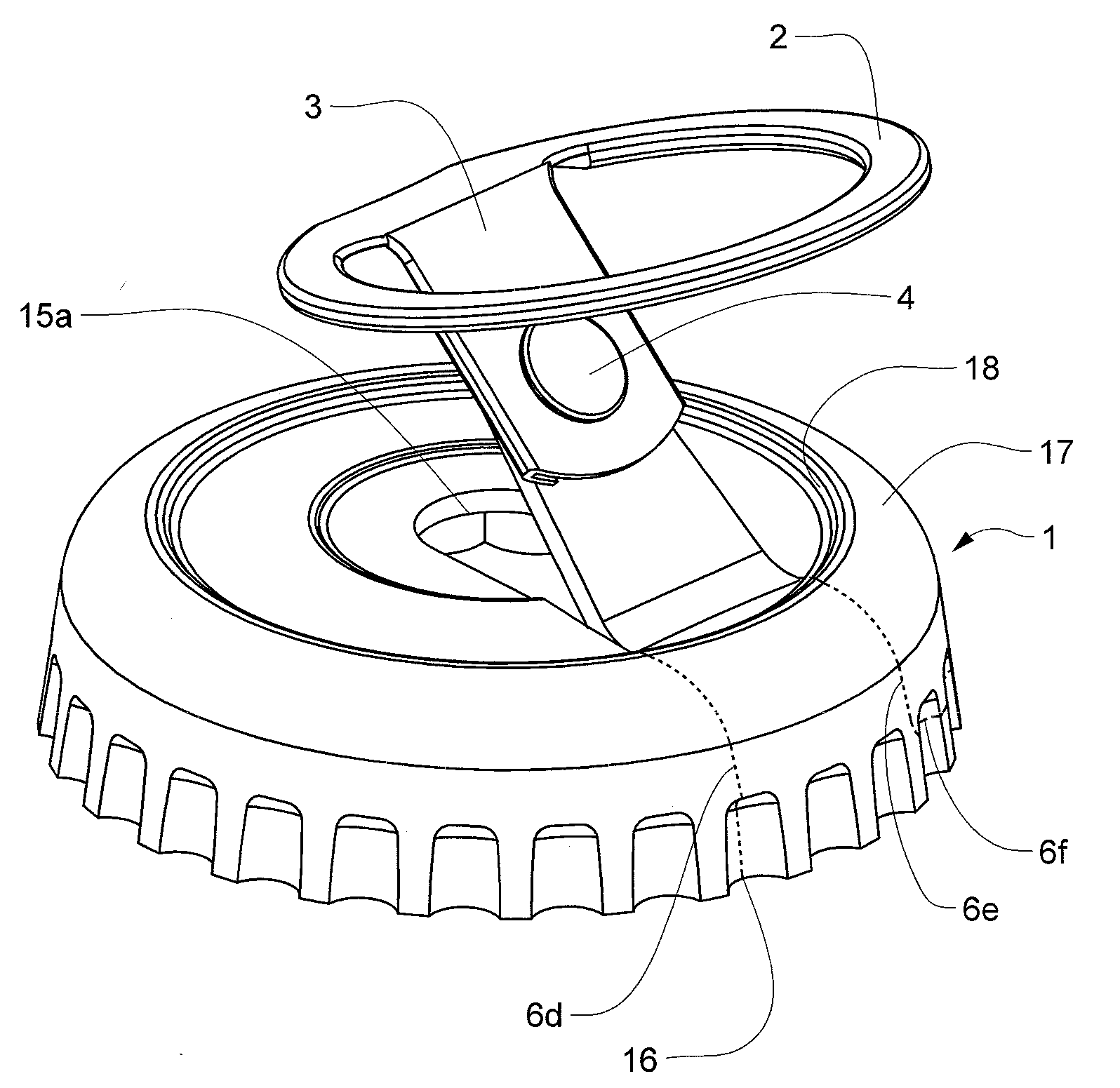

Easy pull bottle cap

A crown for a bottle or other container, the crown comprised of a pull tab ring and a pull tab secured to the crown by a rivet and one or more cut lines between the rivet and the rim of the crown. A pull tab ring seat is formed in the top of the crown such that the pull tab ring disposed in the seat is substantially flush with the top of the crown. Cut or tear lines are configured to reduce the production of sharps. The crown may be formed from tinplate with a hardness of T4 as measured by the Rockwell 30T Hardness Scale so that the crown may be opened and removed from the container the a force of approximately 2.5 Kg.

Owner:SWEENEY BART +1

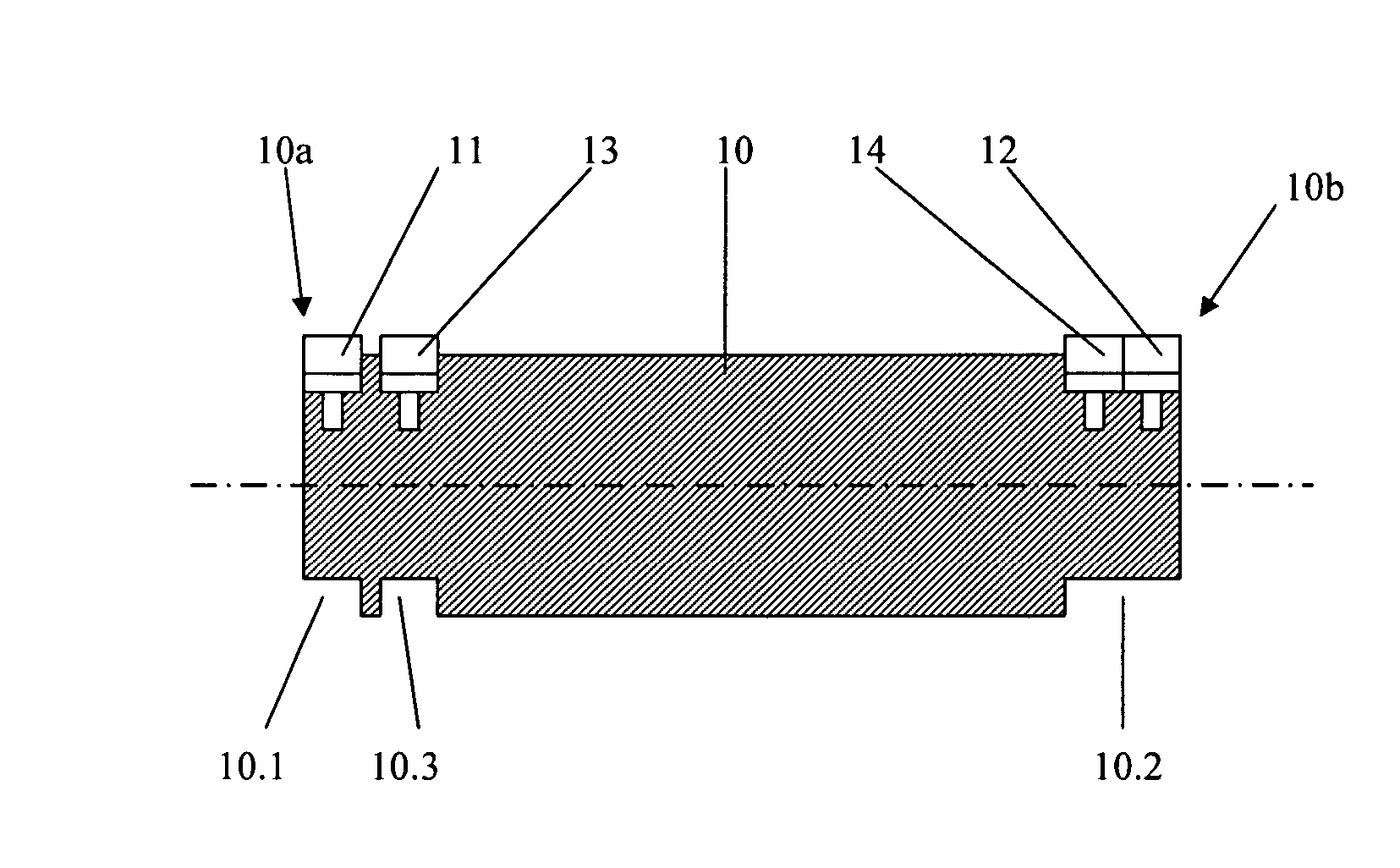

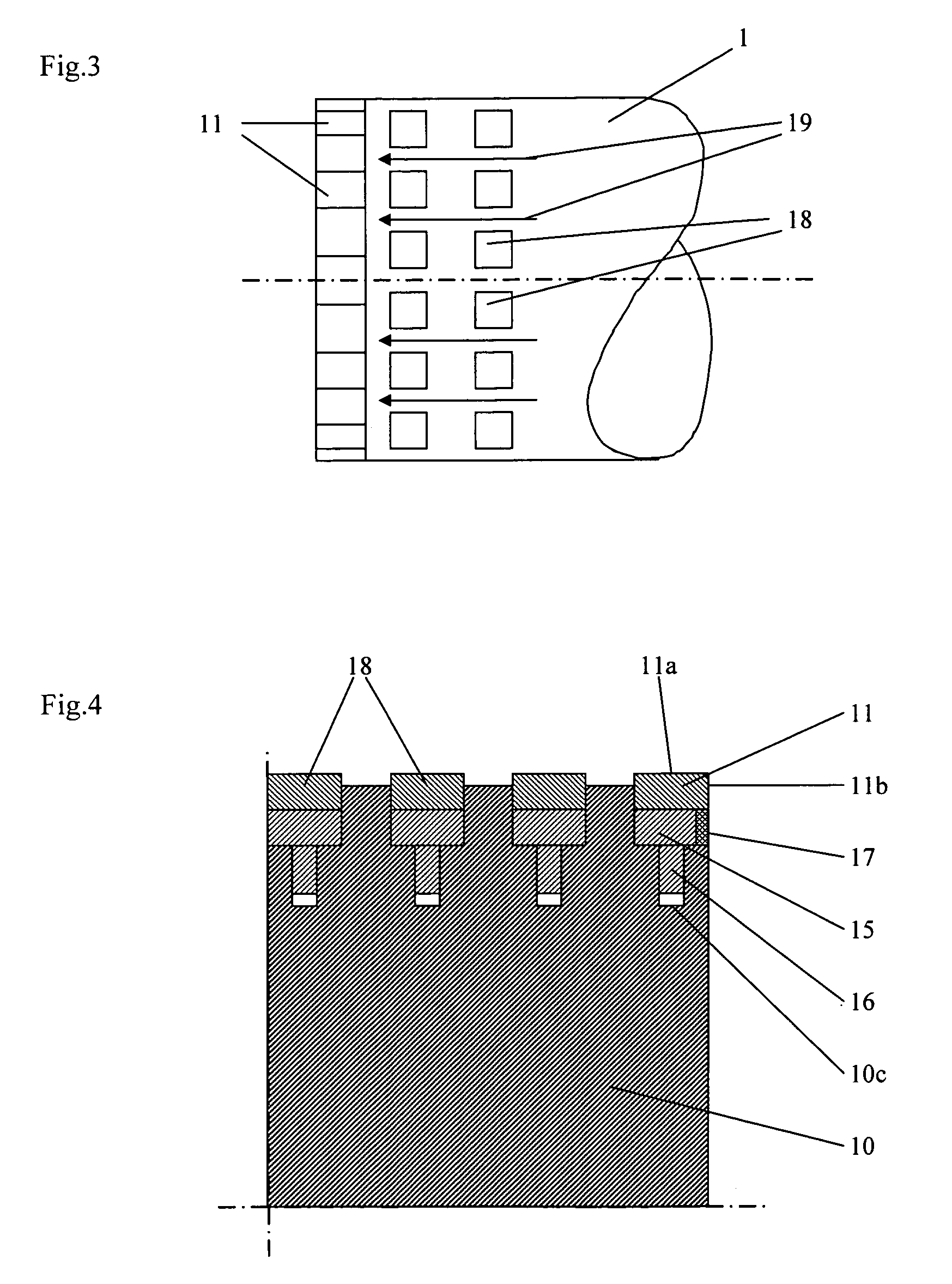

Grinding roll

The invention relates to a grinding roll with a basic roll body as well as a plurality of wear protection elements made from hard metal which form at least a part of the roll surface. The basic roll body has recesses extending in the circumferential direction, a plurality of wear protection elements being disposed one behind the other in the circumferential direction in each recess.

Owner:FLSMIDTH AS +1

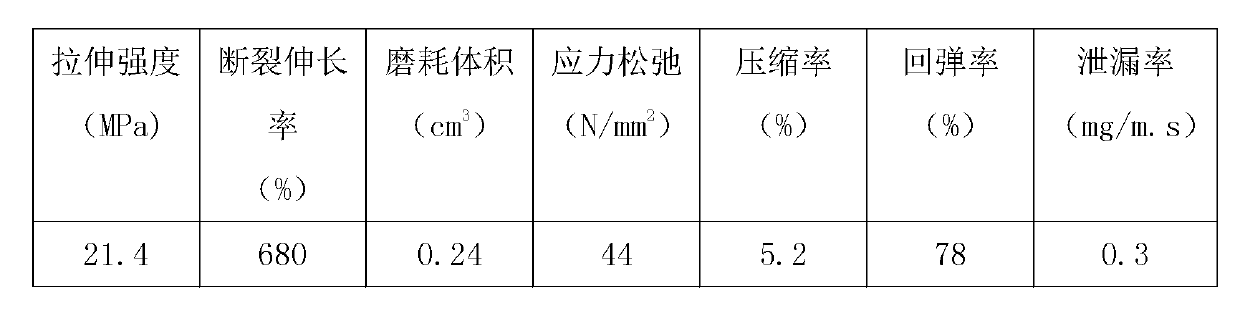

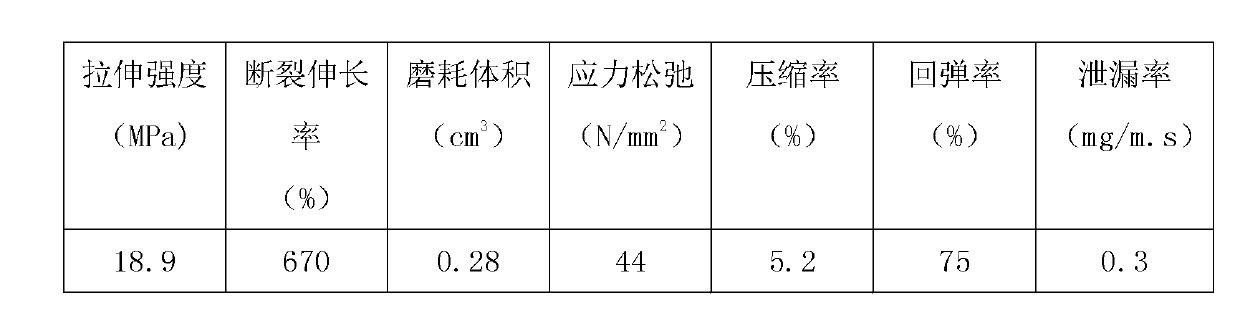

Chloroprene rubber gasket with high abrasion resistance and preparation method thereof

InactiveCN102993517AImprove flame retardant performanceAccelerated corrosionLow-density polyethylenePolymer science

The invention discloses a chloroprene rubber gasket with high abrasion resistance. The chloroprene rubber gasket comprises the following raw materials in parts by weight: 135-145 parts of chloroprene rubber (CR)121, 10-15 parts of butyl rubber CBK139, 20-25 parts of low density polyethylene, 3-5 parts of acetyl triethyl citrate, 2-5 parts of dibutyl maleate, 1-2 parts of isooctyl dimercaptoacetate di-n-octyl tin and the like. The chloroprene rubber gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such medias as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

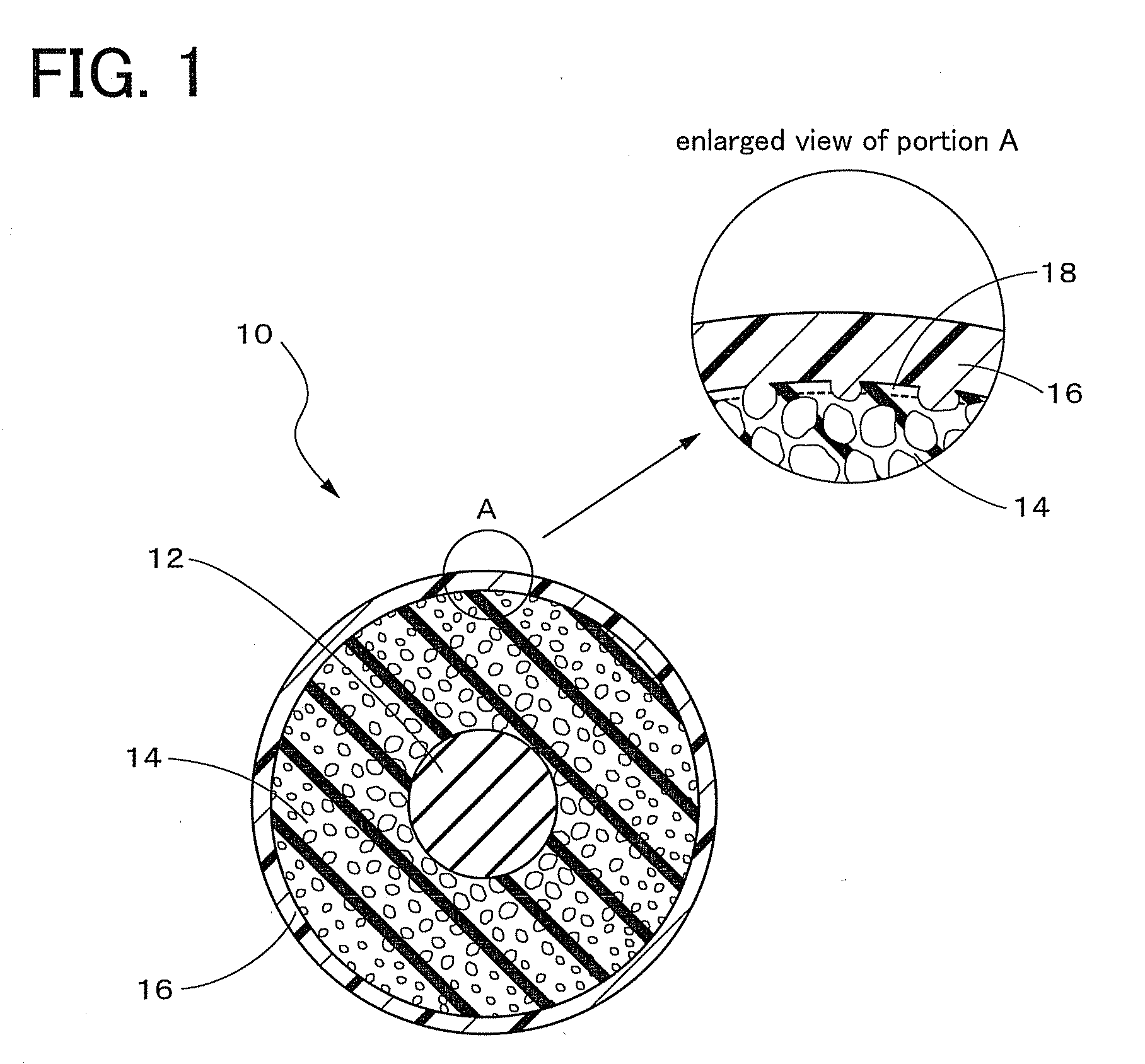

Thermoplastic elastomer composition, formed article and sealing material having low hardness

InactiveUS20070173591A1Excellent rubber elasticity and mechanical strengthLow hardnessOrganic dyesSolventCompression set

A thermoplastic elastomer composition comprising the following components [A], [B], [C], and [D]: [A] 5 to 60 mass % of an ethylene-α-olefin-based copolymer having a limiting viscosity of 3.5 dl / g or more measured in a decalin solvent at 135° C., [B] 1 to 20 mass % of a polyolefin-based resin, and [C] 30 to 94 mass % of a mineral oil-based softening agent, provided that the total of the components [A], [B], and [C] is 100 mass %, and for 100 parts by mass of the components [A], [B], and [C], [D] 0.1 to 50 parts by mass of a hydrogenated diene-based polymer, at least [A] the ethylene-α-olefin-based copolymer and [B] the polyolefin-based resin being dynamically treated with heat in the presence of a cross-linking agent, or the above thermoplastic elastomer composition wherein [A] is replaced with an oil-extended rubber comprising [A1] 20 to 80 mass % of an ethylene-α-olefin-based copolymer having a limiting viscosity of 3.5 dl / g or more measured in a decalin solvent at 135° C. and [C1] 20 to 80 mass % of a mineral oil-based softening agent, provided that the total of [A1] and [C1] is 100 mass %. This thermoplastic elastomer composition excels in molding processability, has low hardness, is free from bleed-out of a mineral oil-based softening agent, has high flexibility and superior rubber elasticity (rebound resilience and compression set), and excels in recycling efficiency.

Owner:JSR CORPORATIOON

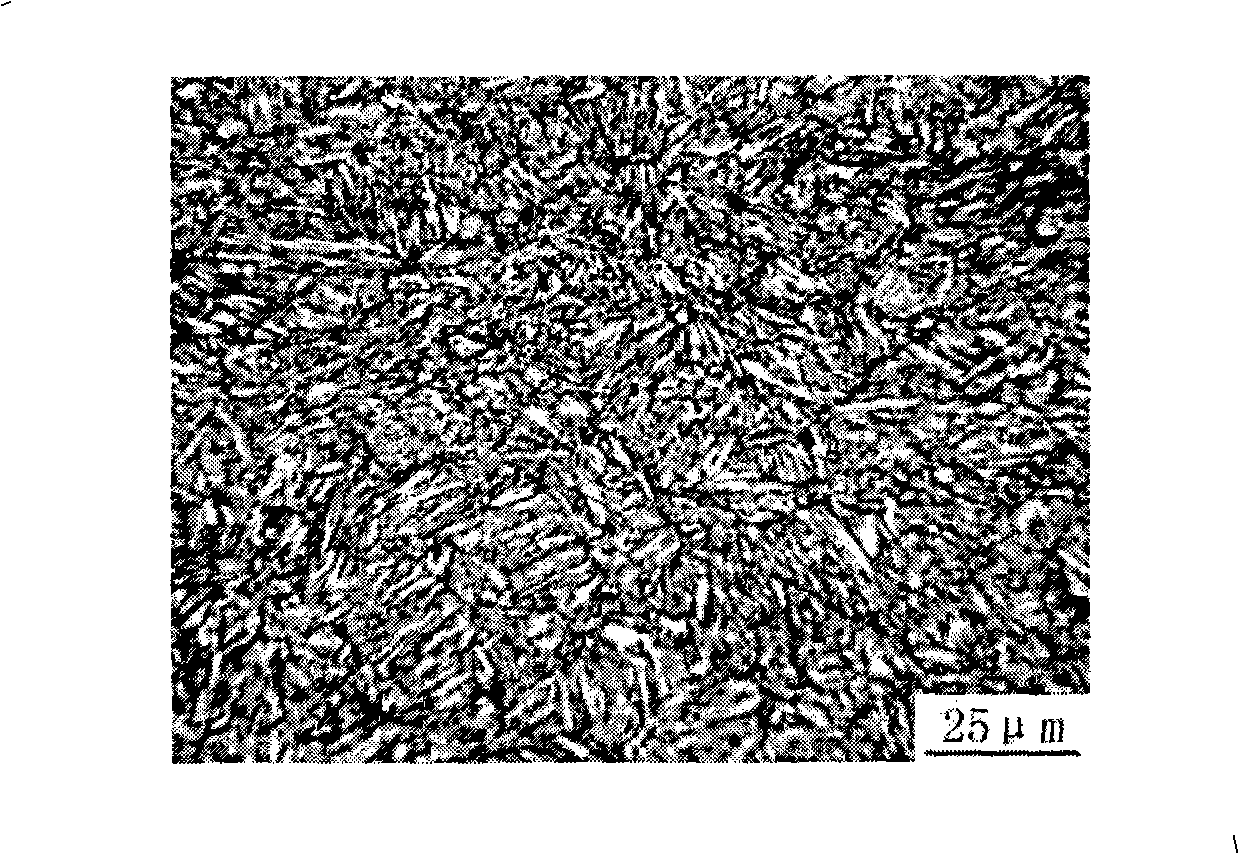

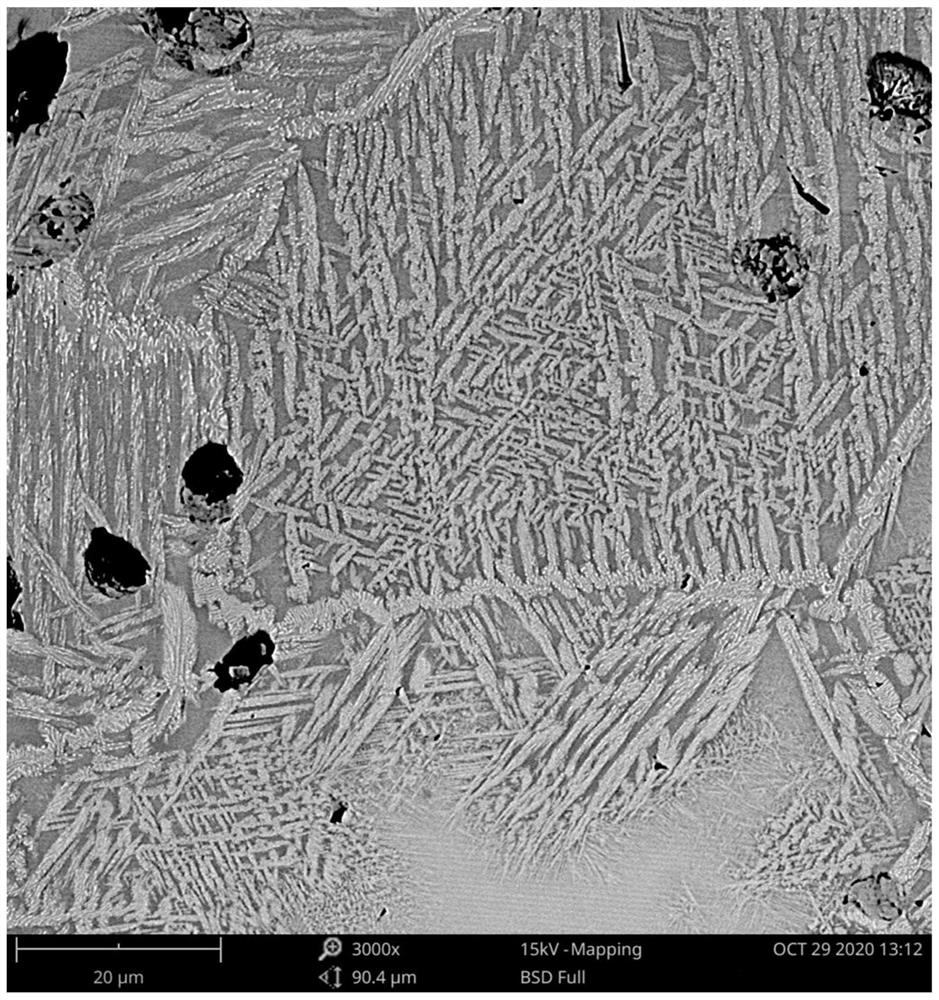

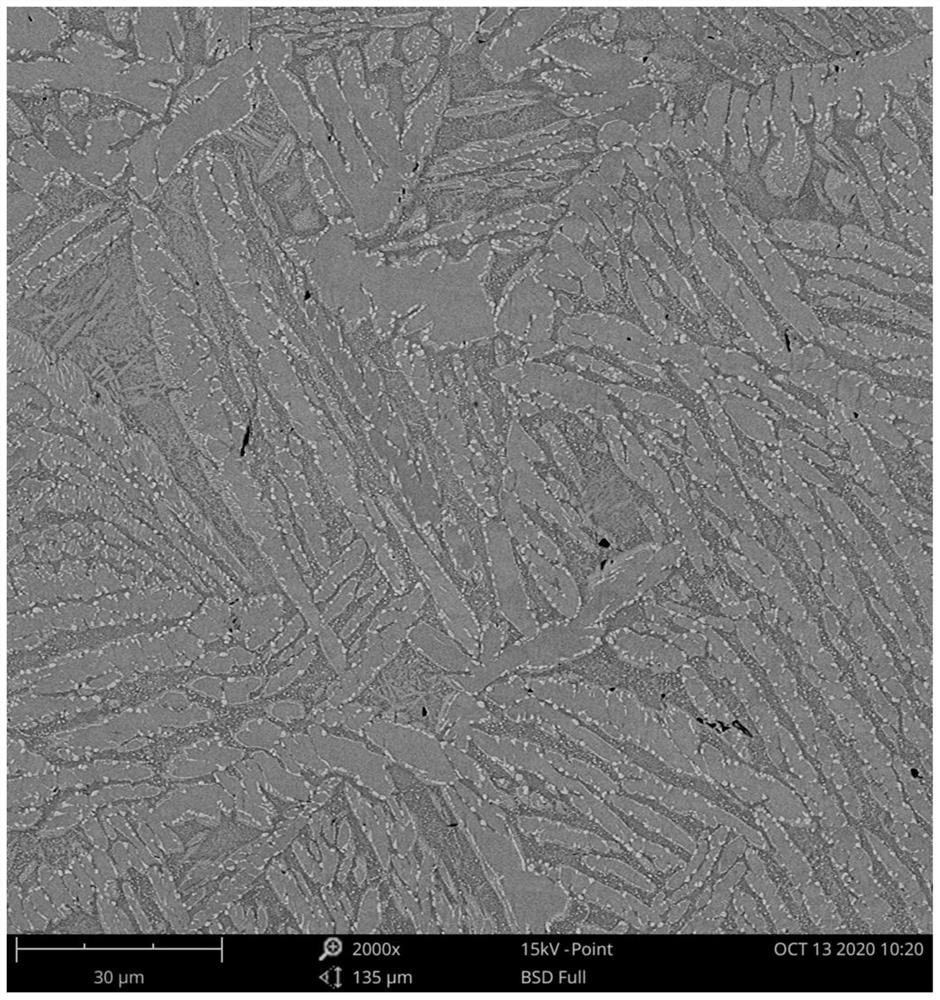

Carbides-free bainite wear resistant steel plate and production process thereof

ActiveCN101338399AImprove hardenabilityHigh strengthTemperature control deviceProduction lineWear resistant

The invention relates to a steel and a production technique thereof, in particular to a non-carbide bainite wear-resistant steel plate and a production technique thereof; the component weight percentages are: 0.15 to 0.25 percent of C, 1.50 to 2.00 percent of Mn, 0 to 0.015 percent of P, 0 to 0.006 percent of S, 1.30 to 2.00 percent of Si, 0.20 to 0.60 percent of Al, 0.60 to 1.00 percent of Cr, 0.25 to 0.50 percent of Mo, 0.010 to 0.035 percent of Nb and the rest is Fe. The production technique is carried out according to the following working procedures: (1) feeding a continuous casting plate to a heating furnace for heating; (2) feeding the continuous casting plate after being heated into a hot rolling production line to carry out the rolling of controlled rolling and controlled cooling; (3) carrying out middle-low temperature drawing temper on a rolling steel plate after the rolling is finished. The non-carbide bainite wear-resistant steel plate can be produced by the working procedures without carrying out online or offline hardening and tempering thermal processing which not only can simplify the working procedures of production, but also can improve the performance and the quality of a product as well as obtain the bainite wear-resistant steel with high intensity and high toughness.

Owner:NANJING IRON & STEEL CO LTD

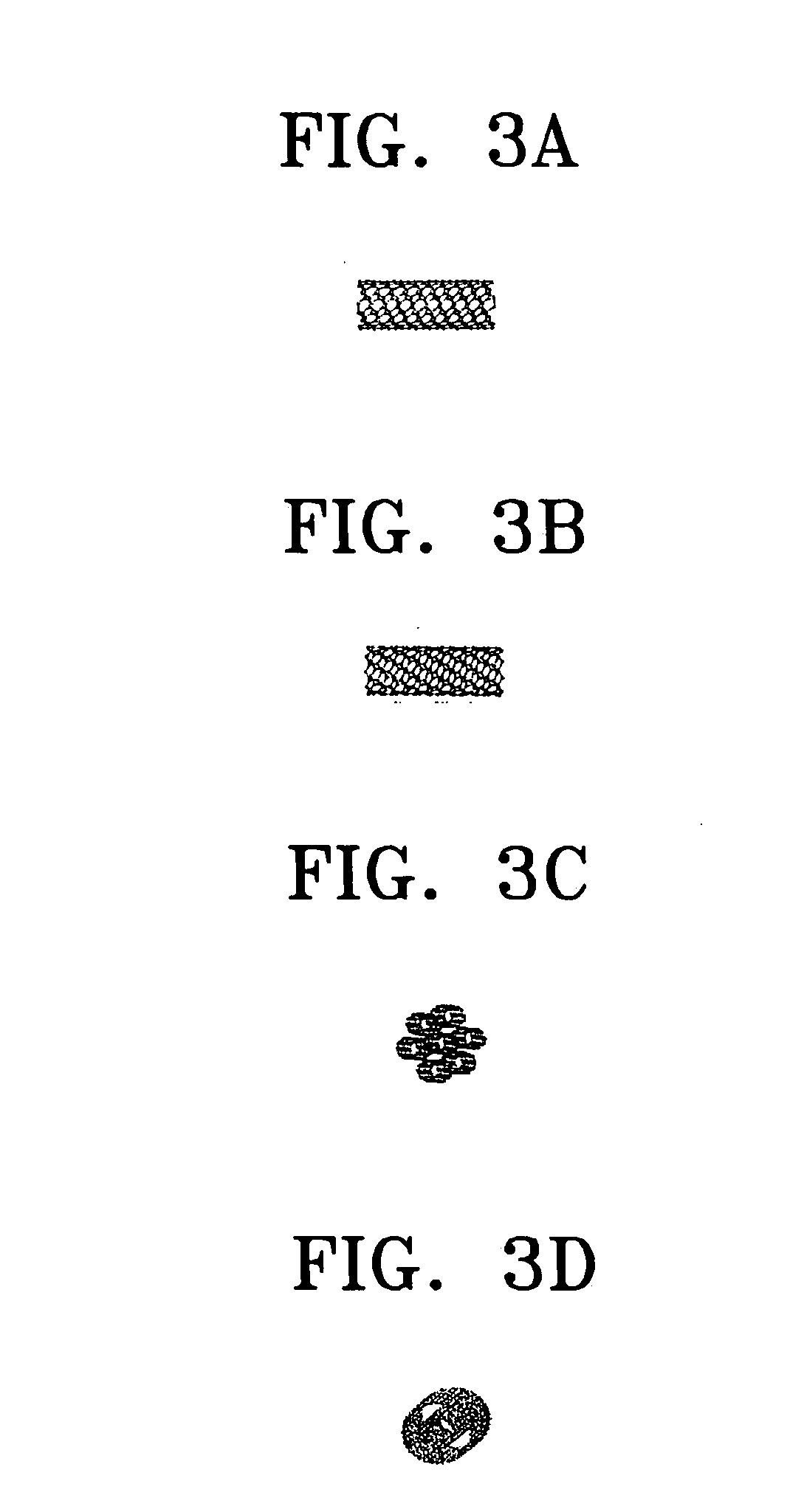

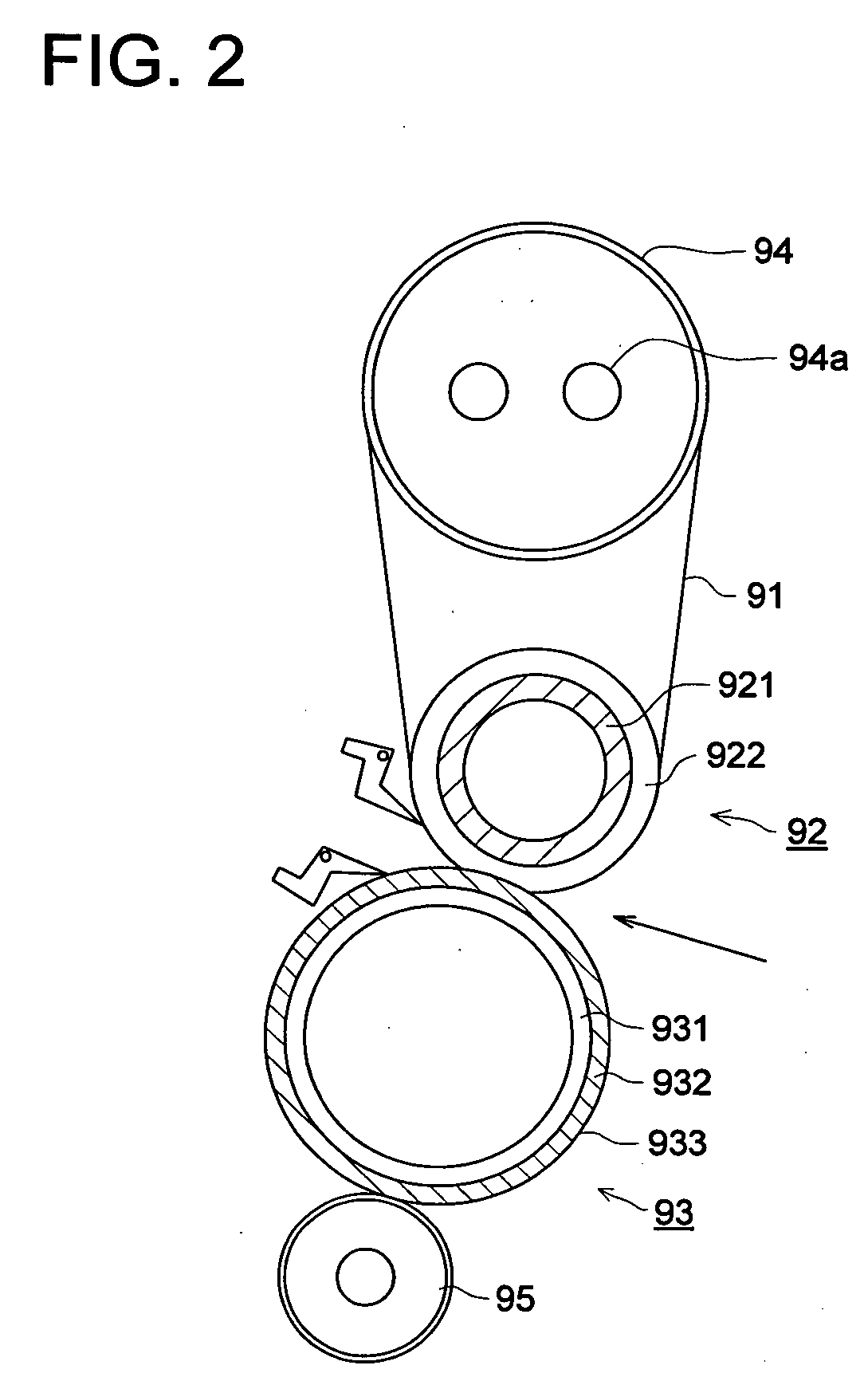

Developing roller including carbon nanotubes for electrophotographic device and method for fabricating the developing roller

ActiveUS20070003329A1High qualityLow hardnessMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeHigh definition

A development roller for electrophotographic device and a method of making the development roller are disclosed. The development roller according to the present invention includes a central shaft and a roller body. The roller body is composed of an elastic polymer material as a primary material and carbon nanotubes in an amount to provide the conductivity of the roller body. According to the present invention, the development roller can exhibit a low hardness and a low resistance at the same time, produce images having high sharpness, and does not contaminate images.

Owner:HEWLETT PACKARD DEV CO LP

Foaming material of propylene based elastomer

The invention discloses a foaming material of a propylene based elastomer. The foaming material is prepared from the following raw materials in parts by weight: 40-80 parts of a propylene based elastomer, 10-30 parts of modified resin, 20-40 parts of a filler, 0.8-1.4 parts of a cross-linking agent, 0.5-1.5 parts of a cross-linking accessory ingredient, 6-10 parts of a foaming agent, 0-1.6 parts of a foaming accessory ingredient and 0-1.6 parts of a lubricating agent. The foaming material of the propylene based elastomer prepared by using the above technical scheme is excellent in comprehensive properties, has the characteristics of high flexibility, high elasticity, low hardness, light weight, great foaming ratio and simple production process and can be widely used in the fields of shoe materials, sports auxiliary materials and package.

Owner:泉州三盛橡塑发泡鞋材有限公司

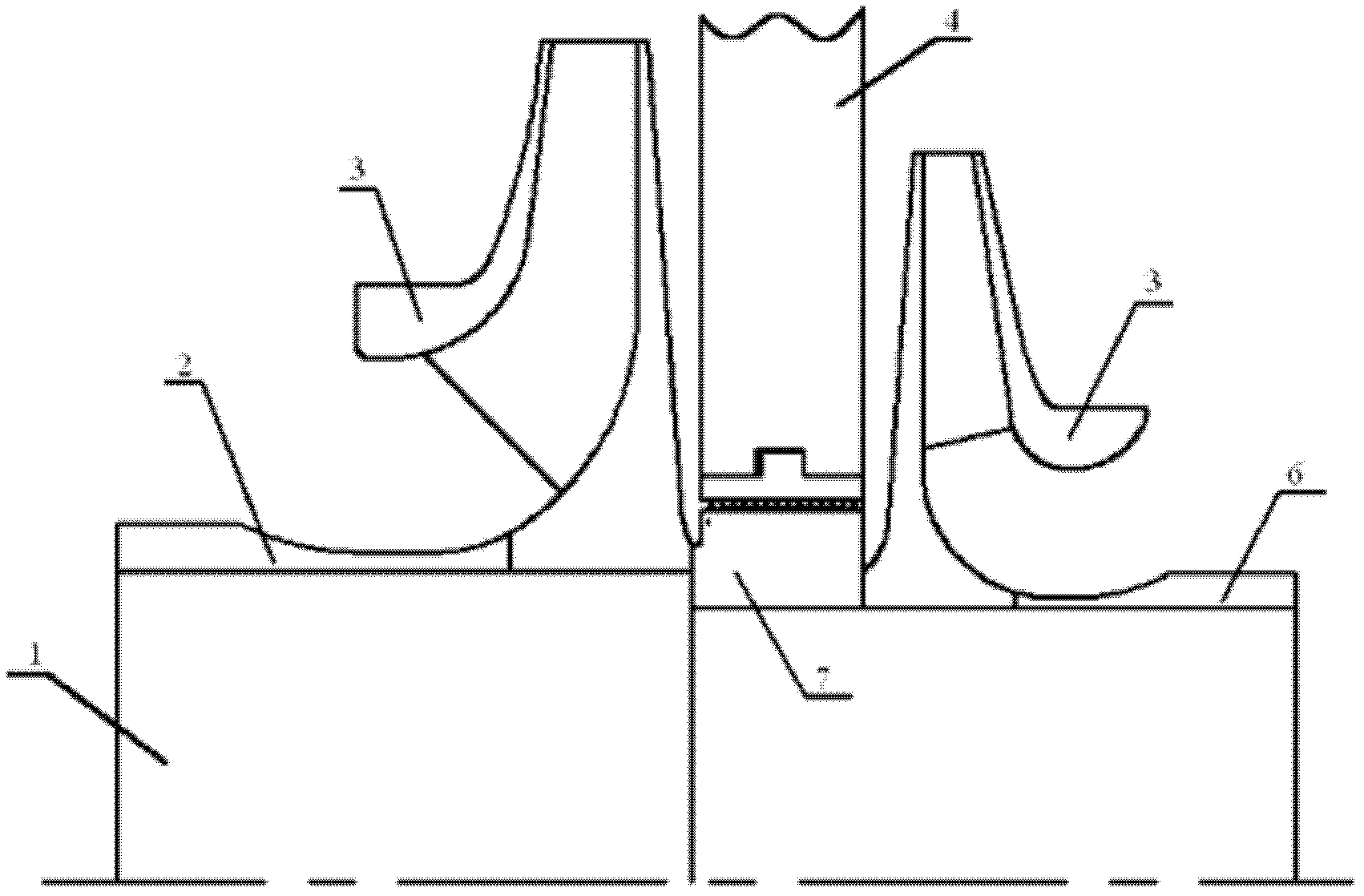

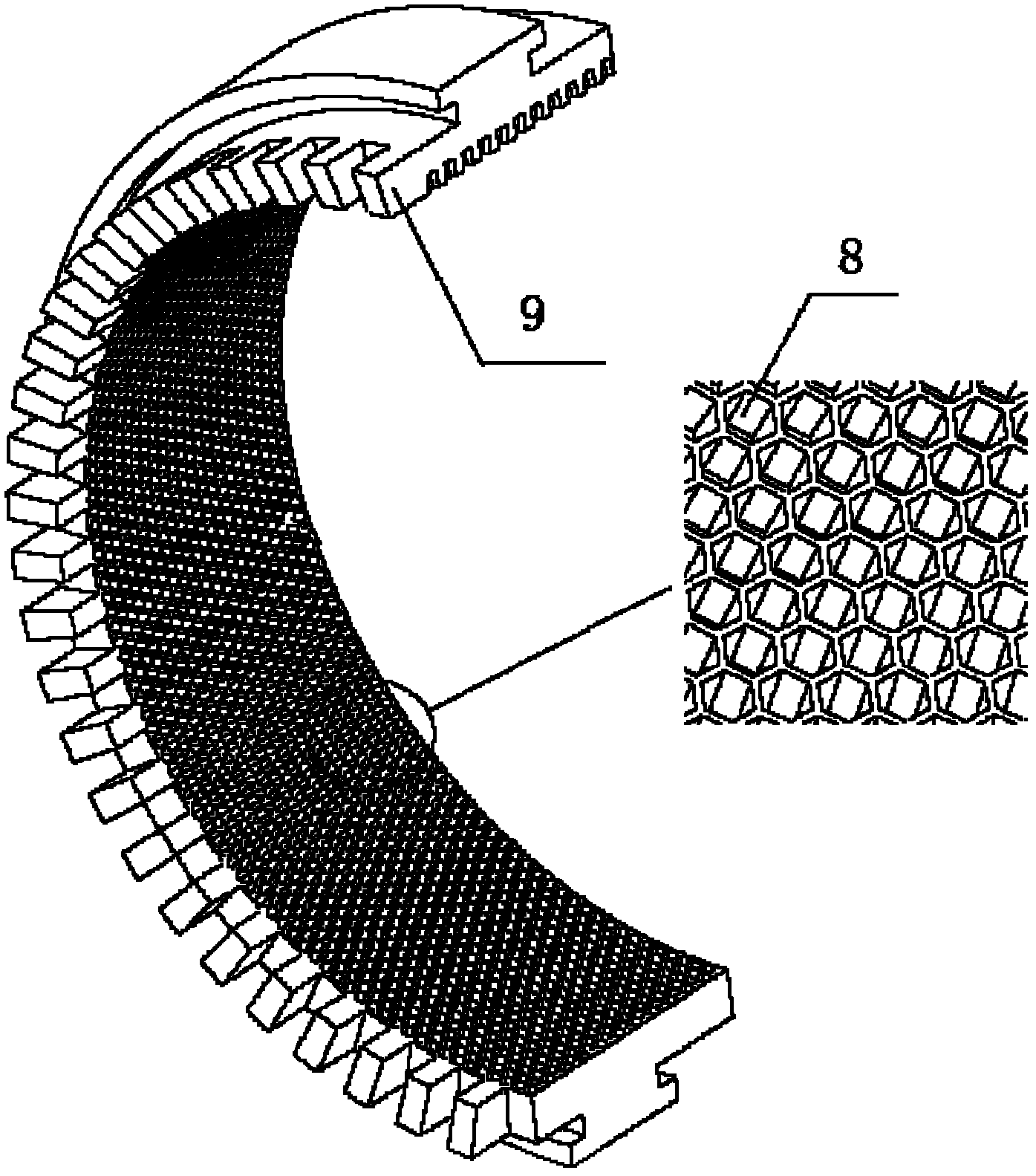

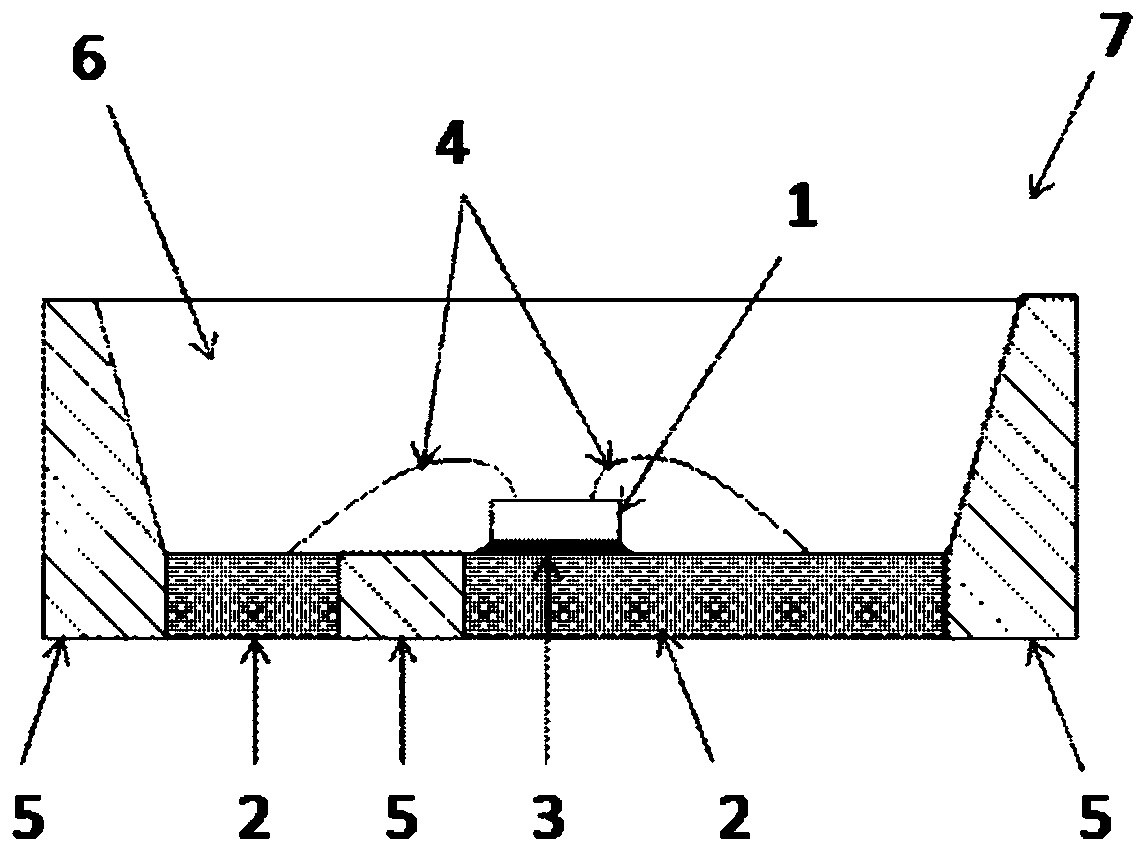

Centrifugal compressor provided with damping seal

The invention relates to a centrifugal compressor provided with damping seal. The damping seal is adopted at a balancing disc position and an impeller ring position and is formed by integratedly processing aluminum and an aluminum alloy material or copper and a copper alloy material; a plurality of regular hexagonal counter holes are arranged in the inner surface of the damping seal; a plurality of teeth are arranged on the periphery of one side of the damping seal; the inner surface of the damping seal is a conical surface; and the gap between high-pressure sides of the damping seal is larger than the gap between low-pressure sides of the damping seal. By adopting the sealed centrifugal compressor, the circumferential speed of fluid in the sealing gap is lower than that of the ordinary labyrinth sealed compressor, the disturbance of the fluid in the seal to a compressor rotor can be effectively reduced, and higher damping is input into a rotor system to improve the stability of the compressor.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT +1

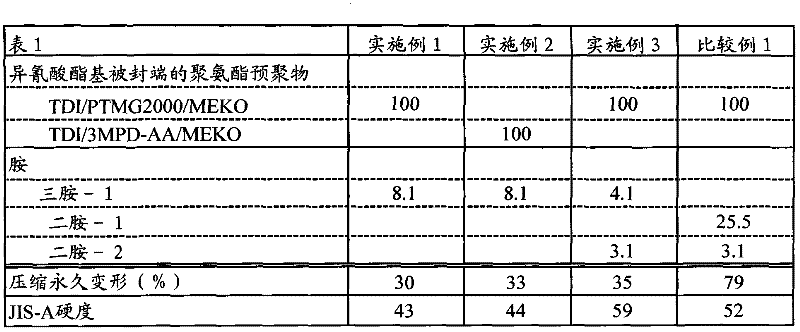

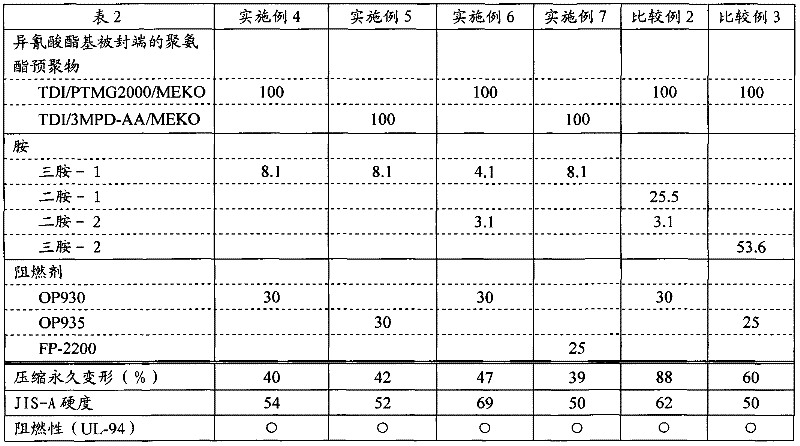

Heat-curable polyurethane resin composition and urethane elastomer molded article using the same

The invention aims at providing a heat-curable polyurethane resin composition and a urethane elastomer molded article using the same advantaged by excellent compression set resistance performance and low hardness. The invention relates to a heat-curable polyurethane resin composition and a urethane elastomer molded article using the same, which are characterized in that, the heat-curable polyurethane resin composition comprises a polyurethane prepolymer (1) with an isocyanate group terminated and a triamine with an amine equivalent of 50-350, the polyurethane prepolymer is obtained via polyhydric alcohol (A), polyisocyanates (B), and terminating agents (C) as necessary raw materials.

Owner:DAINIPPON INK & CHEM INC

Super-thick steel plate and production technology thereof

The invention belongs to the technical field of steel rolling and particularly relates to a super-thick steel plate and a production technology thereof. The super-thick steel plate includes, by weight, 0.31%-0.37% of C, 0.41%-0.59% of Si, 1.42%-1.59% of Mn, less than or equal to 0.007% of P, less than or equal to 0.004% of S, 1.91%-2.16% of Cr, 0.51%-0.63% of Mo, 0.17%-0.29% of Ni, and the balance Fe and inevitable impurities. The production technology includes the technical processes of electric furnace smelting, ladle furnace (LF) refining, vacuum degassing (VD), constant-speed die casting under argon shield, high-temperature demoulding, liquid core rolling, slow cooling, heating, rolling, online quenching and tempering. The Brinell hardness of the steel plate ranges from 291 HB to 329 HB, the value of difference between the surface hardness and the core hardness of the steel plate is smaller than 15 HB, the maximum thickness of the steel plate can reach 430 mm, and the steel plate can meet the I-class flaw detection requirement of the test standard of JB / T4730.3-2005 forge pieces and the requirement for high-quality interiors of high-class super-thick steel plates.

Owner:SHANDONG IRON & STEEL CO LTD

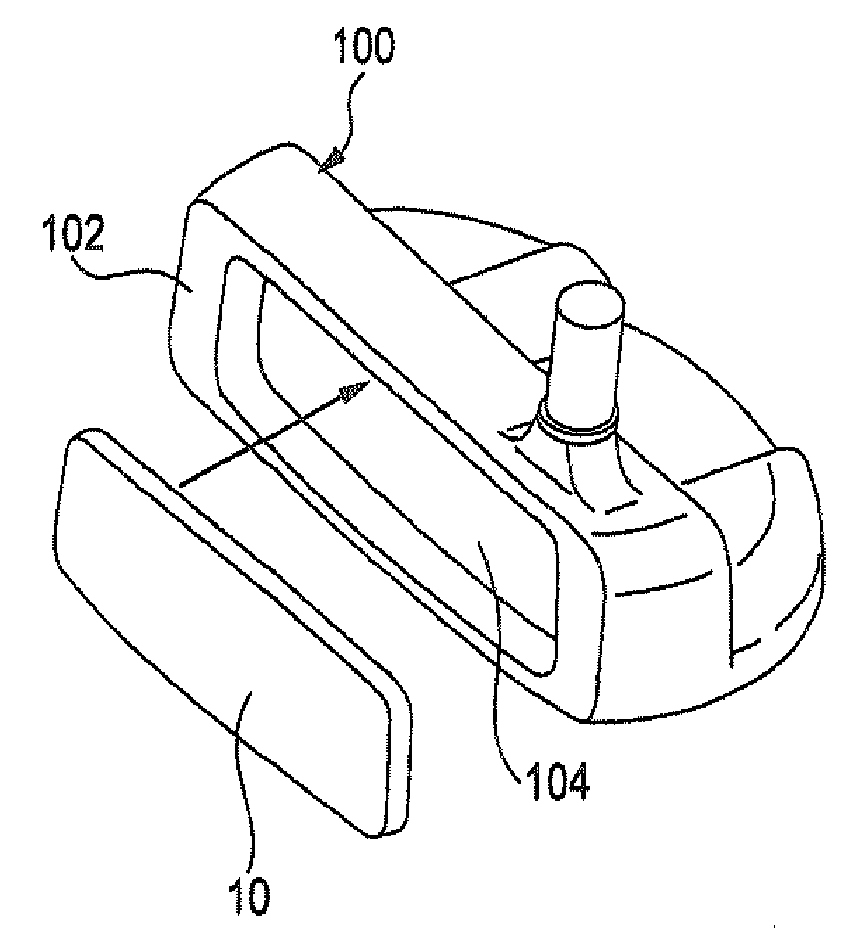

Charging roll and method of producing the same

InactiveUS20100267537A1Low hardnessReduce loadElectrographic process apparatusCoatingsElectrically conductiveElectrical and Electronics engineering

A charging roll is provided which does not cause image defects even when being used for a long period of time and does not allow a surface layer to be separated when an electrophotographic machine is operated after the charging roll installed therein is left under high temperature and humidity conditions. A charging roll includes a shaft, an electrically conductive rubber foam layer formed on an outer circumferential surface of the shaft, and a surface layer formed radially outwardly of the electrically conductive rubber foam layer. The electrically conductive rubber foam layer includes a skin layer having an opening area ratio of from 0.5 to 20% at a superficial layer of the electrically conductive rubber foam layer, and the surface layer is formed of a synthetic resin composition mainly composed of a synthetic resin material having a glass transition temperature of from 0 to 45° C.

Owner:TOKAI RUBBER IND LTD

Preparation technology of metal composite magnesium silicon carbide bulletproof ceramic

ActiveCN106631028AHigh strengthImprove flexural strengthPersonal protection gearCarbide siliconMetallic aluminum

The invention relates to a preparation technology of a metal composite magnesium silicon carbide bulletproof ceramic. The preparation technology comprises the following steps: 1) pre-mixing metal aluminium, nano alumina and cerium oxide for standby; 2) taking silicon carbide and high-purity sintering magnesium oxide as main raw materials, adding a proper amount of phenolic resin and stirring, adding pre-mixed mixed powder of metal aluminium, nano alumina and cerium oxide and stirring the material to prepare the metal composite magnesium silicon carbide bulletproof ceramic powder material; and 3) filling a low-carbon steel package sheathing with the metal composite magnesium silicon carbide bulletproof ceramic powder material, using nitrogen as a medium, employing an hot isostatic pressure mode for pressurization and insulation to obtain a base substrate having a corresponding shape, and obtaining the bulletproof ceramic with the required shape through linear cutting. According to the invention, metal aluminium and an aluminium magnesium alloy are introduced, nano alumina and cerium oxide are employed as a composite stabilizing agent, high purity sintering magnesium oxide substitutes practical silicon carbide, through heat isostatic compaction and sintering, so that the current bulletproof ceramic combines two processes of cold isostatic compaction and sintering as one heat isostatic compaction process.

Owner:新乡市炬能耐材有限公司

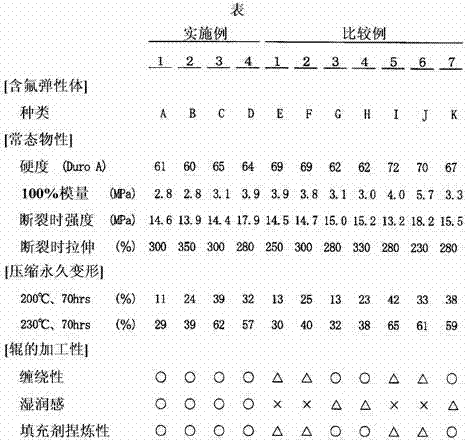

Blend of fluorine-containing elastomers

ActiveCN103180380AEasy to processLow hardnessOther chemical processesMiddle molecular weightFluorine containing

Provided is a blend of fluorine-containing elastomers comprising 5-60 wt% of a high-molecular-weight fluorine-containing elastomer having a number average molecular weight Mn (liquid chromatography, a tetrahydrofuran developing solvent, a polymer concentration of 0.5 wt%, a measurement temperature of 35 DEG C) of 3,000,000 or more, 20-80 wt% of a middle-molecular-weight fluorine-containing elastomer having an Mn of 100,000-1,000,000, and 10-50 wt% of a low-molecular-weight fluorine-containing elastomer having a Mn of 7,000-13,000. The blend of fluorine-containing elastomers achieves low hardness and low modulus, as well as an improved rolling processability.

Owner:UNIMATEC CO LTD

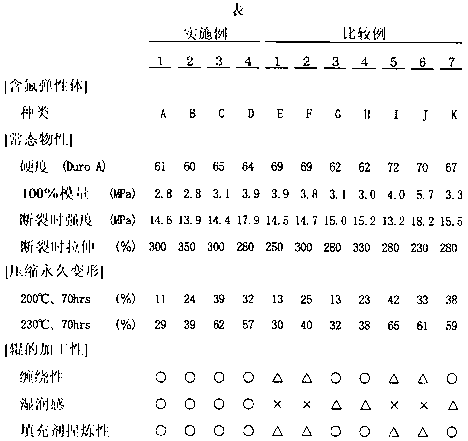

Chloroprene rubber/butyl rubber sealing gasket and its preparation method

The invention discloses a chloroprene rubber / butyl rubber sealing gasket. The sealing gasket comprises the following raw materials, by weight, 135-145 parts of chloroprene rubber CR121, 10-15 parts of butyl rubber CBK139, 10-15 parts of brominated butyl rubber 1066, 3-5 parts of propanediol sebacate polyester, 2-5 parts of n-butyl methacrylate, 1-2 parts of imarcaptoacetate dioctyltin and 1-2 parts of zinc stearate. The sealing gasket has the advantages of good high-temperature resistance, good sealing performance, good flame retardation, good corrosion resistance, realization of long-term working in mediums comprising acids, alkalis, oils and the like, small volume and hardness changes, no adhesion on metal surfaces, small friction coefficient, good abrasion resistance, good bonding flexibility with the sealing surface, good weather ageing resistance, good ozone ageing resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

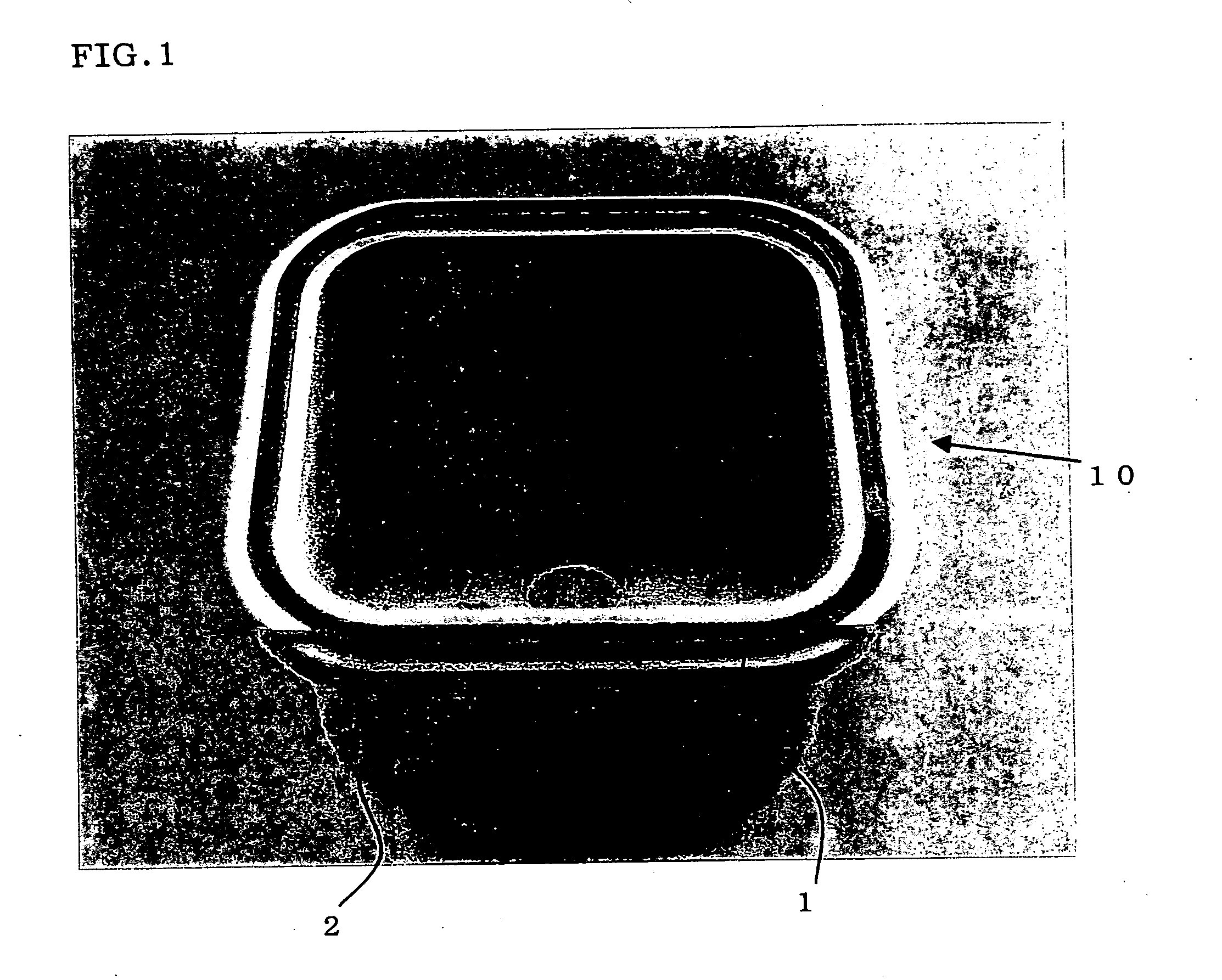

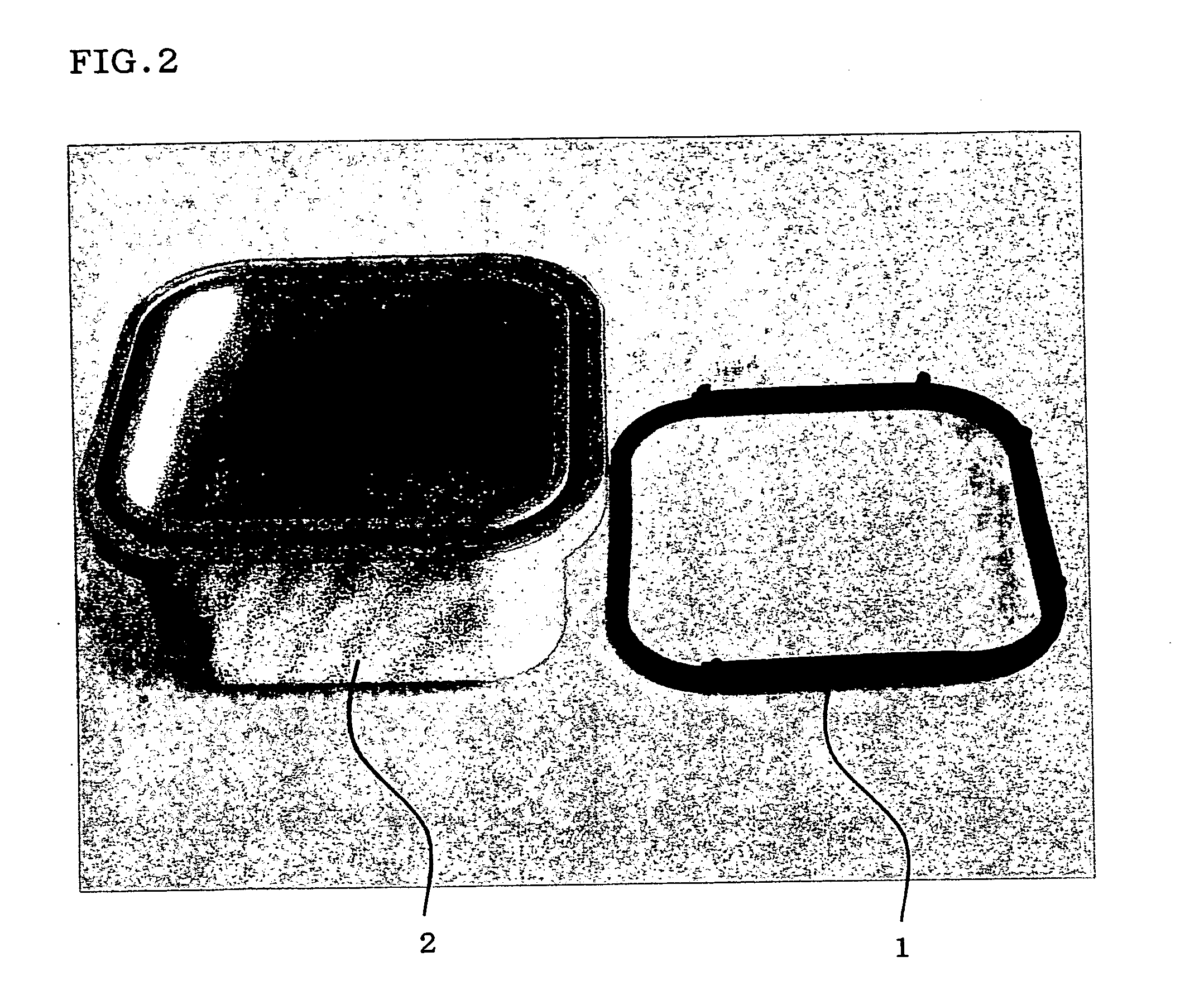

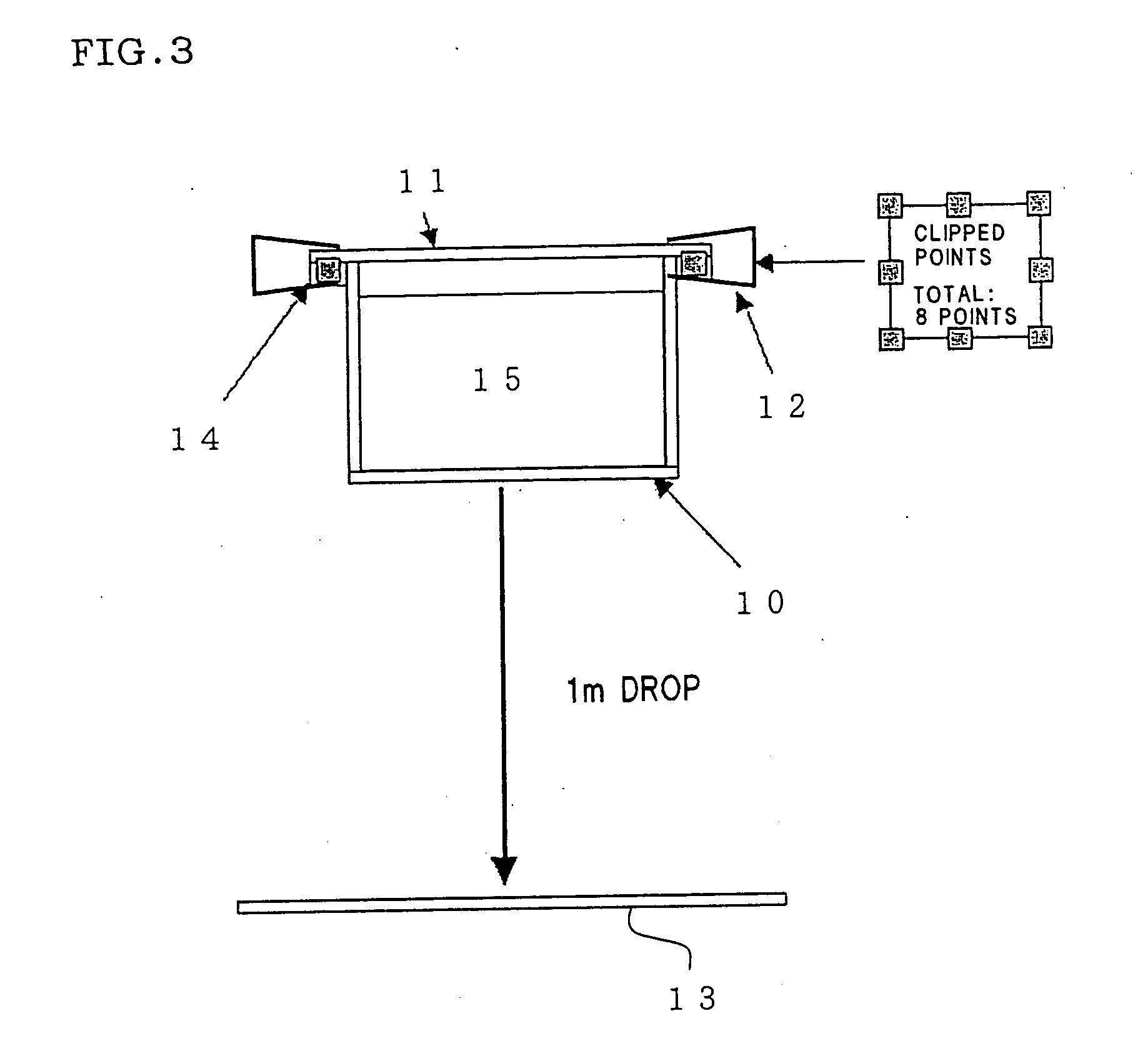

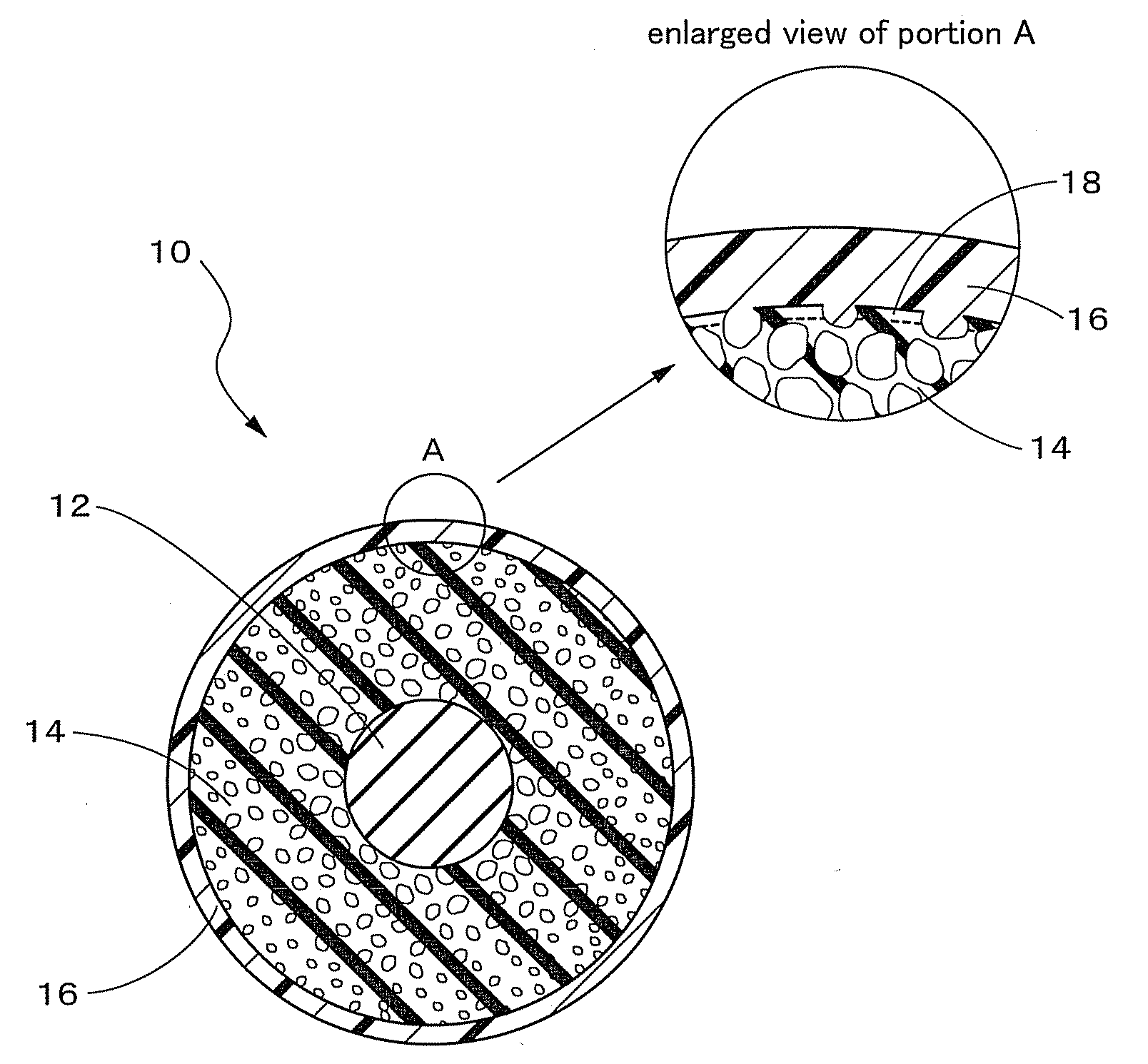

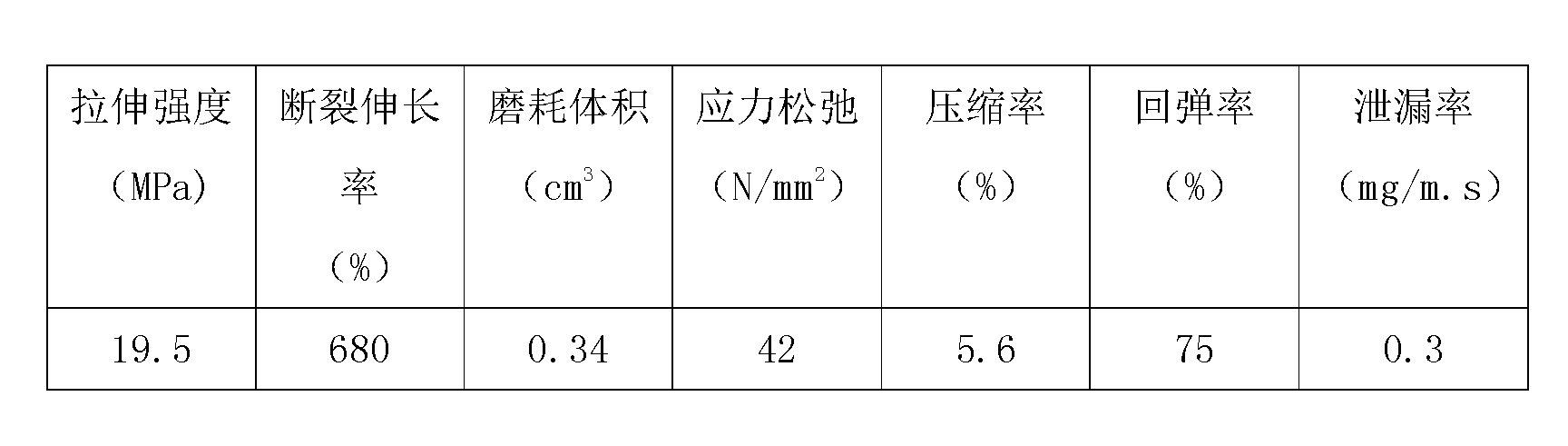

Foamed rubber member

ActiveUS20100036005A1Low hardnessExcellent durabilityClosuresLayered productsCompression setFoam rubber

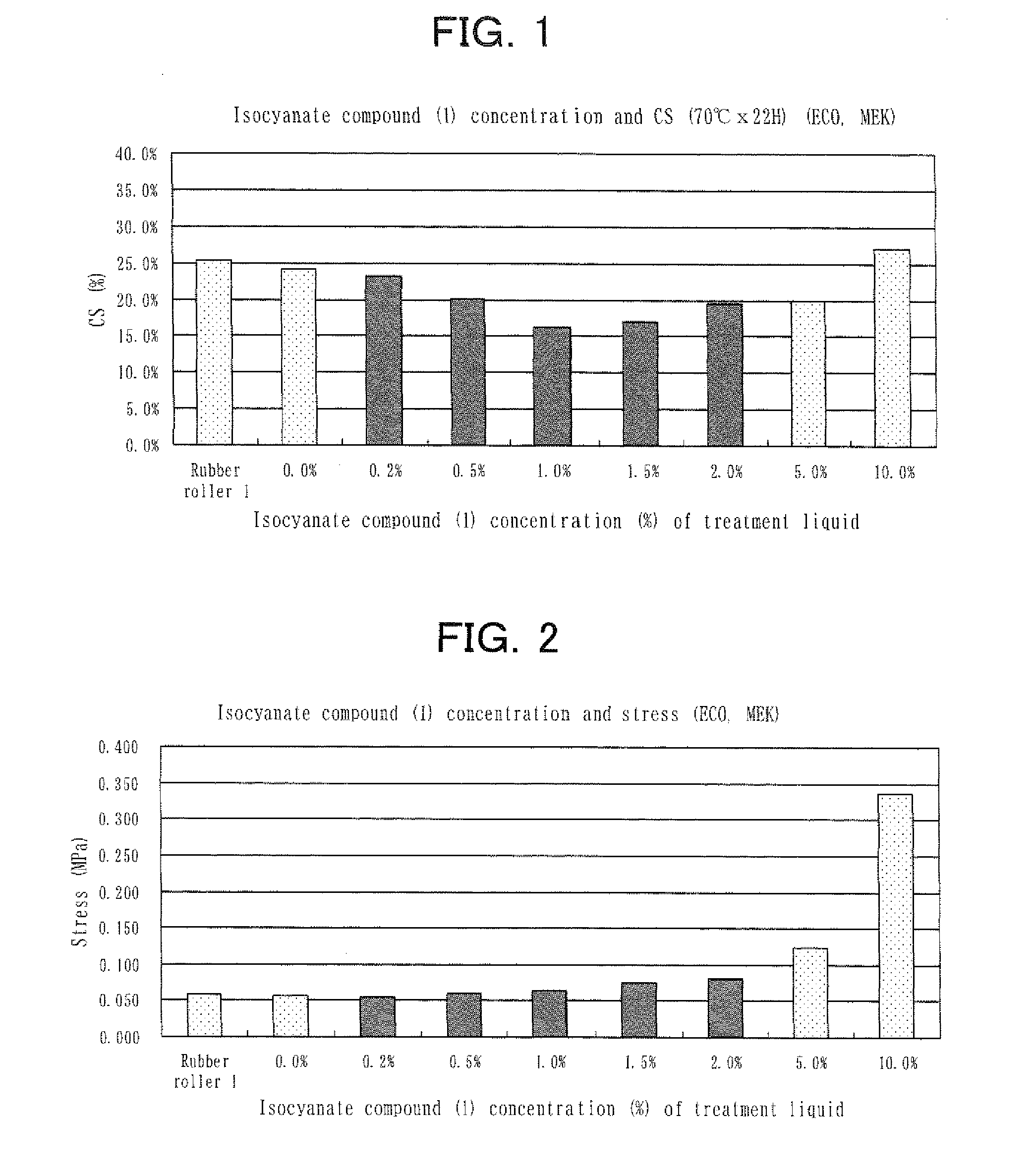

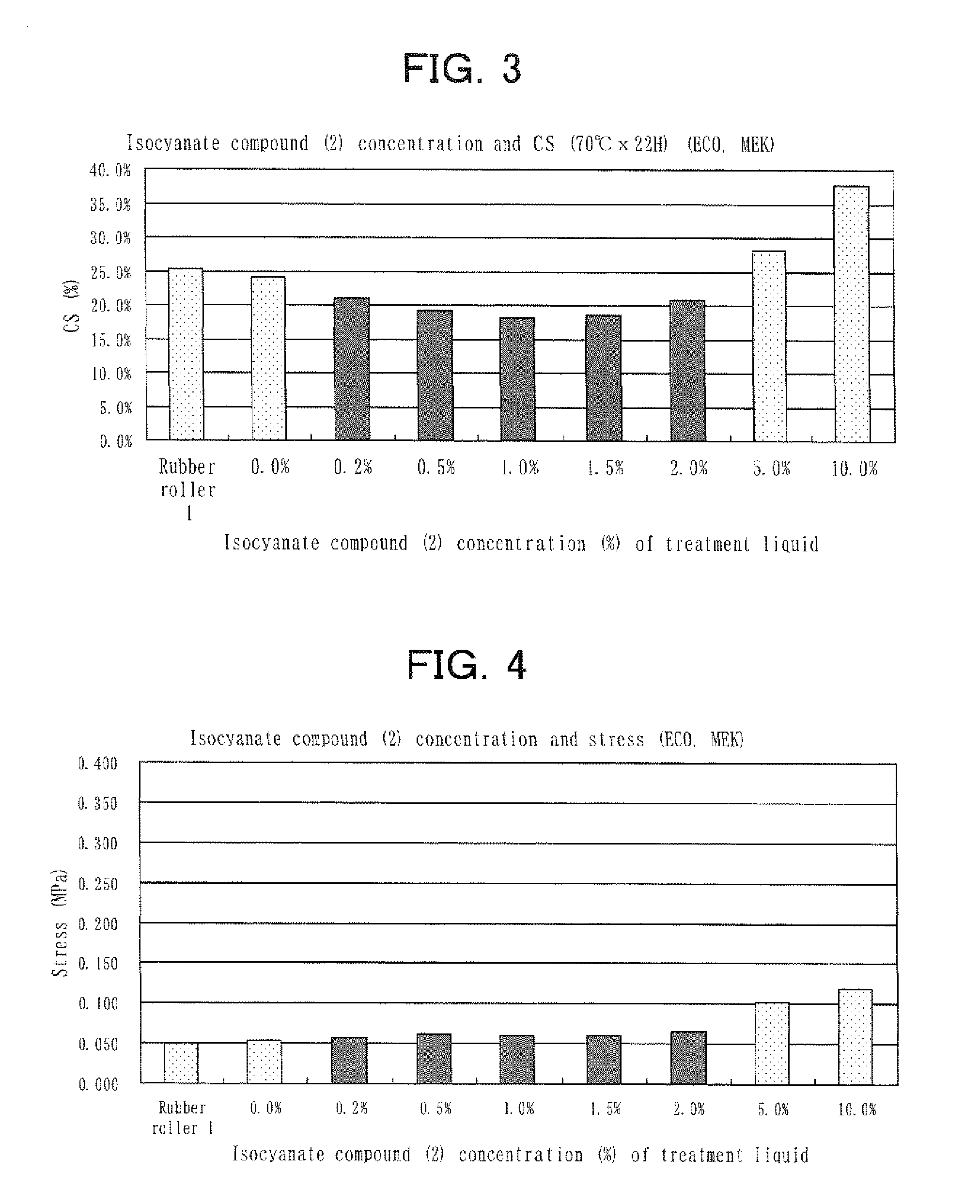

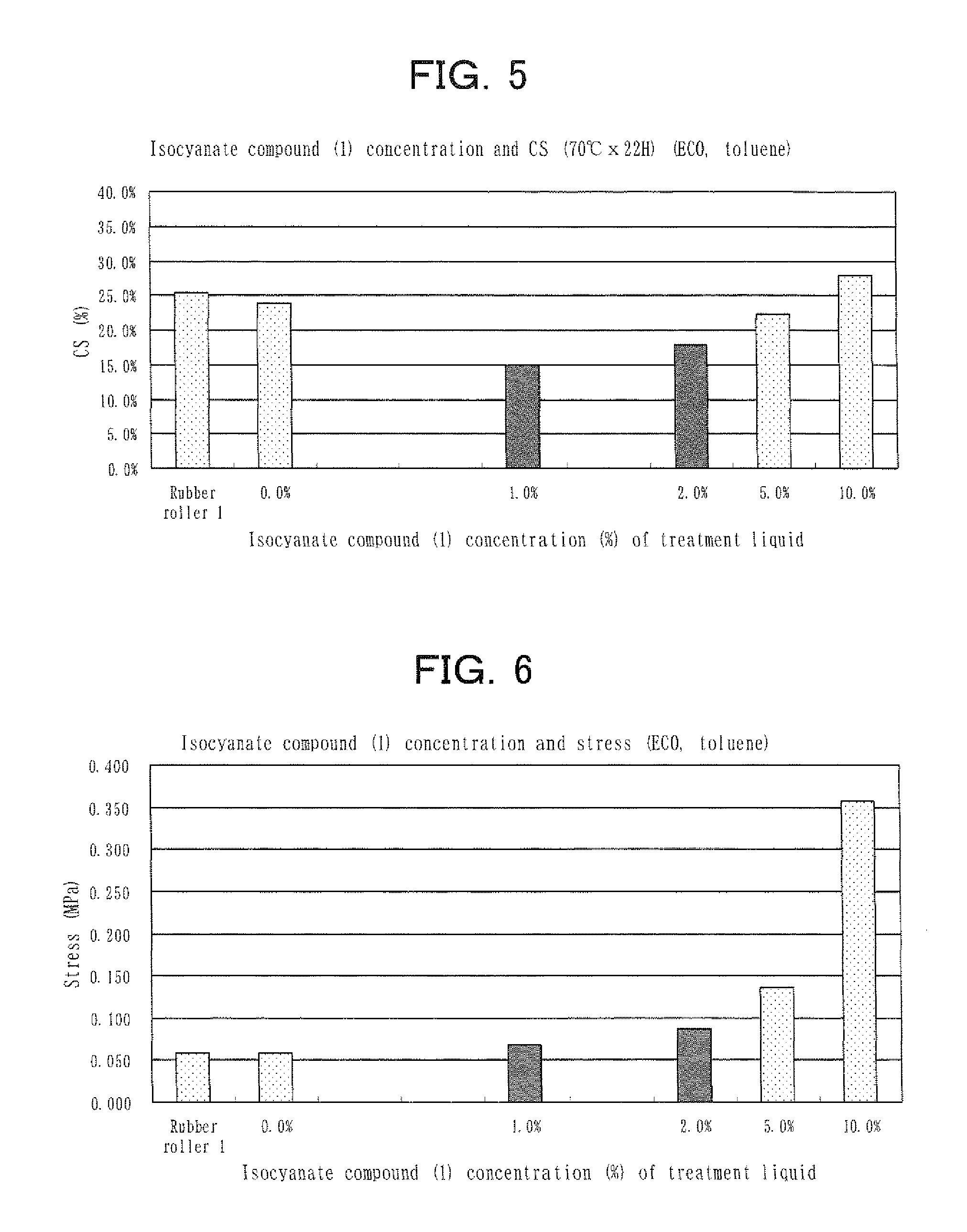

An object of the present invention is to provide a foamed rubber member which has low hardness and excellent durability. The foamed rubber member of the invention, produced through an impregnation treatment of a foamed elastic body with a treatment liquid containing an isocyanate compound and an organic solvent, the foamed elastic body being produced by foaming a base rubber, exhibits a compression set smaller than that of the foamed elastic body before undergoing the impregnation treatment, and exhibits a percent increase in stress, with respect to the stress of the foamed elastic body before undergoing the impregnation treatment, of 50% or less.

Owner:SYNZTEC

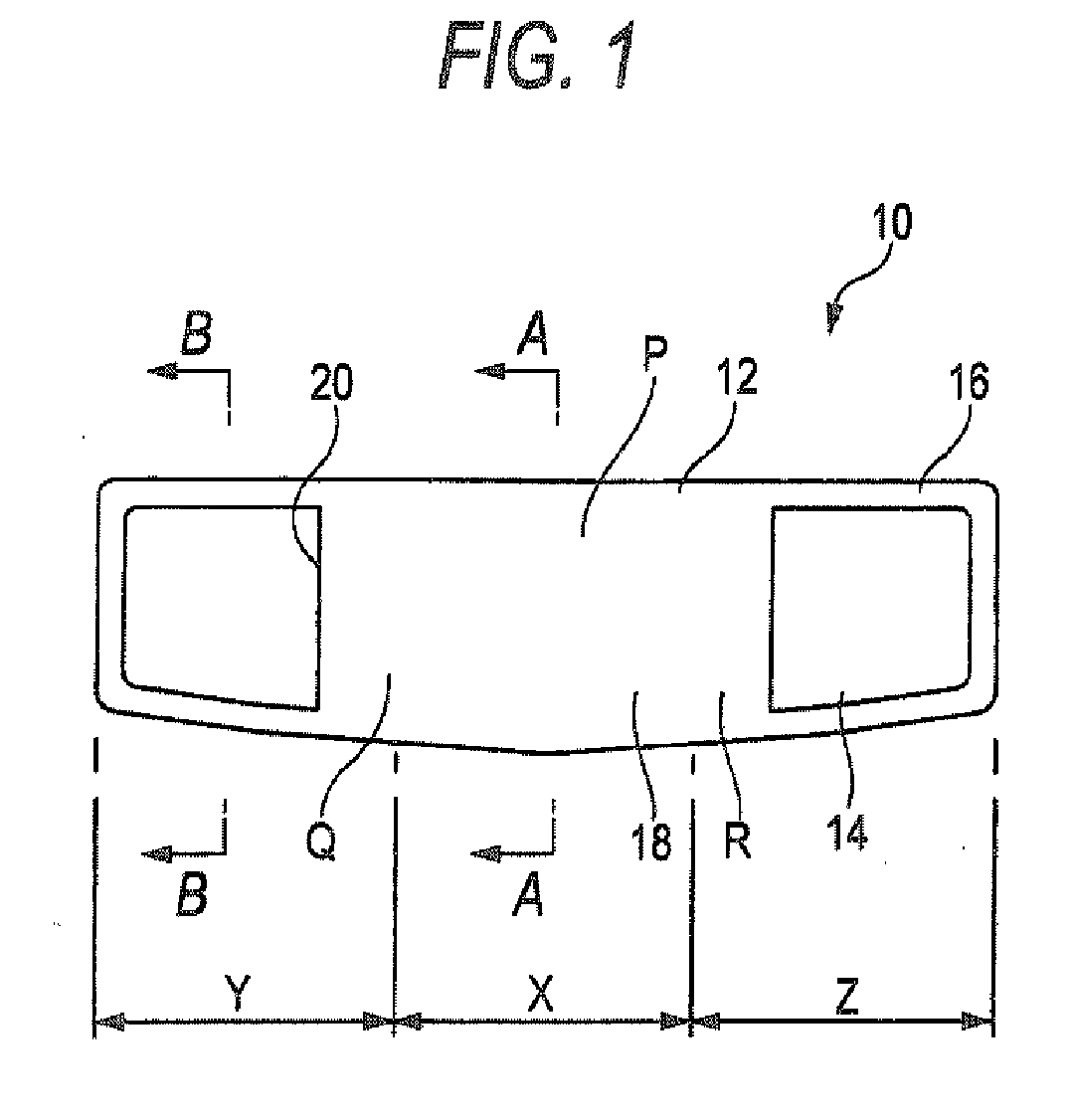

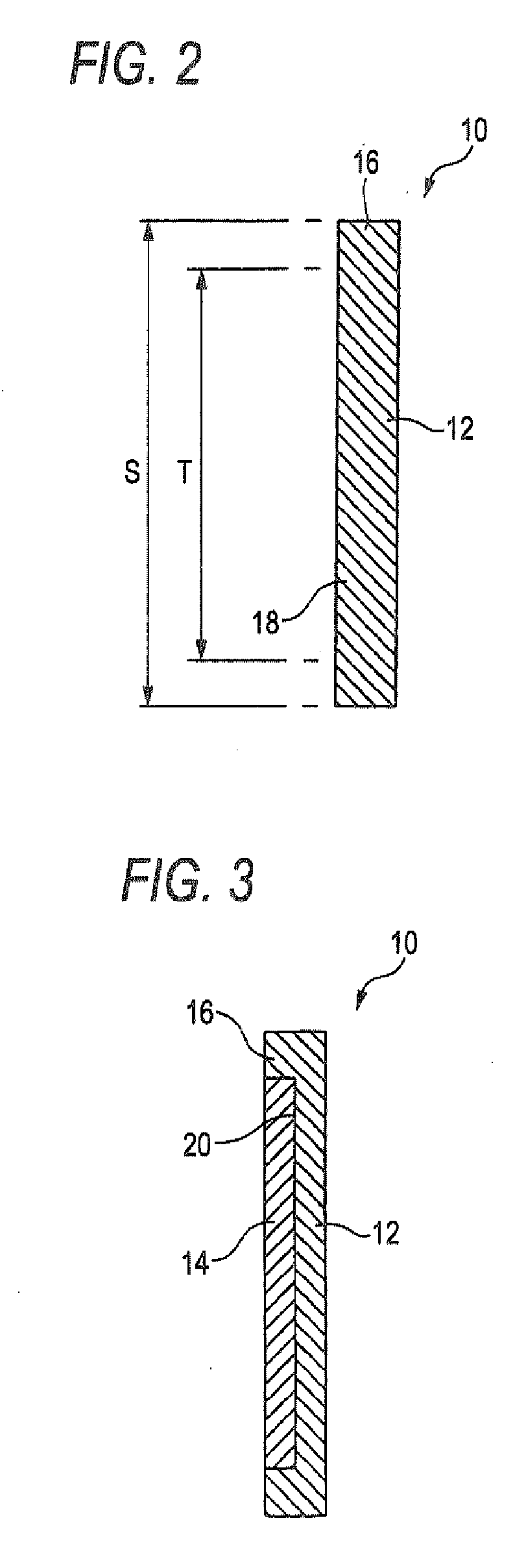

Putter head

A putter head that includes: a head body having a face portion; and a face insert fitted in the face portion, the face insert including a high-hardness portion that forms a hitting surface, a low-hardness portion jointed to the high-hardness portion and having a hardness lower than that of the high-hardness portion, and a projecting portion formed at least on a central portion of the high-hardness portion, the low-hardness portion filling a recessed portion formed by the projecting portion.

Owner:BRIDGESTONE SPORTS

Highly oil-resistant chloroprene rubber sealing gasket and preparation method thereof

The invention discloses a highly oil-resistant chloroprene rubber sealing gasket comprising the following raw materials in parts by weight: 35-145 parts of chloroprene rubber CR1211, 20-25 parts of epichlorohydrin rubber, 10-20 parts of SG-2 type PVC (Polyvinyl Chloride) resin, 2-5 parts of tri(2-ethylhexyl)acetocitrate, 3-5 parts of dioctyl epoxy tetrahydrophthalate, 3-5 parts of dibutyl maleate, 1-2 parts of sodium alcohol ether sulphate, 30-40 parts of nano argil, 30-35 parts of carbon black N220, 30-35 parts of nano calcium carbonate powder and the like. The chloroprene rubber sealing gasket has excellent oil resistance and solvent resistance, is capable of satisfying the sealing requirement on an engine sump, and is easy to peel after being solidified, and cleanable and repairable without affecting dismounting and repairing.

Owner:ANHUI RONGDA VALVE

Silicon carbide-based composite circuit board and preparation method thereof

The invention discloses a silicon carbide-based composite circuit board and a preparation method thereof and belongs to the technical field of circuit boards. The silicon carbide-based composite circuit board comprises a silicon carbide-based composite base board and a circuit printed on the silicon carbide-based composite base board, wherein the silicon carbide-based composite circuit board is prepared from raw materials of, by weight part, 50-60 parts of silicon carbide, 20-28 parts of glass powder, 5-10 parts of filler, 3-7 parts of adhesives and 7-12 parts of additives. The silicon carbide-based composite circuit board is prepared by taking the silicon carbide and the glass powder as the main component and matching with the filler, the adhesives and the additives through ball milling,ultrasonic treatment, spray granulation and three sintering processes. Through dispersion and adhesion of the raw materials, the prepared silicon carbide-based composite base board can be low in thermal expansion coefficient, high in mechanical strength, good in stability and capable of effectively improving the qualification rate, thereby being high in promotional significance.

Owner:国网河南省电力公司社旗县供电公司

Rubber seal ring

The invention discloses a rubber seal ring which is prepared from, by weight, 50-80 parts of butadiene-acrylonitrile rubber, 20-30 parts of butadiene styrene rubber, 10-12 parts of epoxy butyl oleate, 3-5 parts of n-butyl methacrylate, 5-8 parts of n-butyl methacrylate, 3-4 parts of zinc stearate, 2-3 parts of flint clay powder, 5-8 parts of talcum powder, 3-5 parts of bamboo charcoal fibers, 2-3 parts of hollow microbeads, 10-12 parts of chlorinated paraffin, 3-4 parts of aluminium hydroxide, 5-8 parts of paraffinic oil, 1-3 parts of accelerant CBS, 0.5-0.8 part of a vulcanizing agent, 1-2 parts of an anti-aging agent RD and 1-2 parts of a titanate coupling agent TMC-TTS. The rubber seal ring has excellent wear resistance and high temperature resistance and meanwhile has acid and alkaline corrosion resistance, stripping is easy to conduct, after curing is conducted, the rubber seal ring can be cleaned, disassembling, assembling and repairing are not affected, compressibility and rebound resilience are good, and the rubber seal ring is not softened, decomposed or subjected to brittle rupture at a high temperature, can work for a long time in an acid medium, an alkali medium and the like and is durable in use.

Owner:TONGLING BAIRUI EQUIP PARTS CO LTD

Modified PVC (polyvinyl chloride) foaming building material product and processing method thereof

The invention relates to a modified PVC (polyvinyl chloride) foaming building material product, and belongs to the technical field of a building material. The modified PVC foaming building material product consists of polyvinyl chloride, light calcium carbonate, heavy calcium carbonate, additive and a modifying agent, wherein the mass ratio of the polyvinyl chloride to the light calcium carbonate to the heavy calcium carbonate to the additive to the modifying agent is (95 to 110) to (20 to 30) to (20 to 30) to (15 to 20) to (0.4 to 0.8). The additive consists of a stabilizer, glycerin monostearate, titanium oxide, color powder, a lubricating agent, a foaming agent, a foaming adjusting agent and a catalyst, and the modifying agent consists of PE wax and an ultraviolet absorption agent. After the ultraviolet absorption agent 531 is added, the novel modified PVC foaming building material product is good in aging resistance and good in hardness; the foaming rate is higher than that of products of the same kind, thus the mass per meter is light, and the convenience in installation and transportation is realized. Meanwhile, the PE wax is added into the formula, so that appearance precision and brightness of the product are improved.

Owner:绍兴市万维塑业有限公司

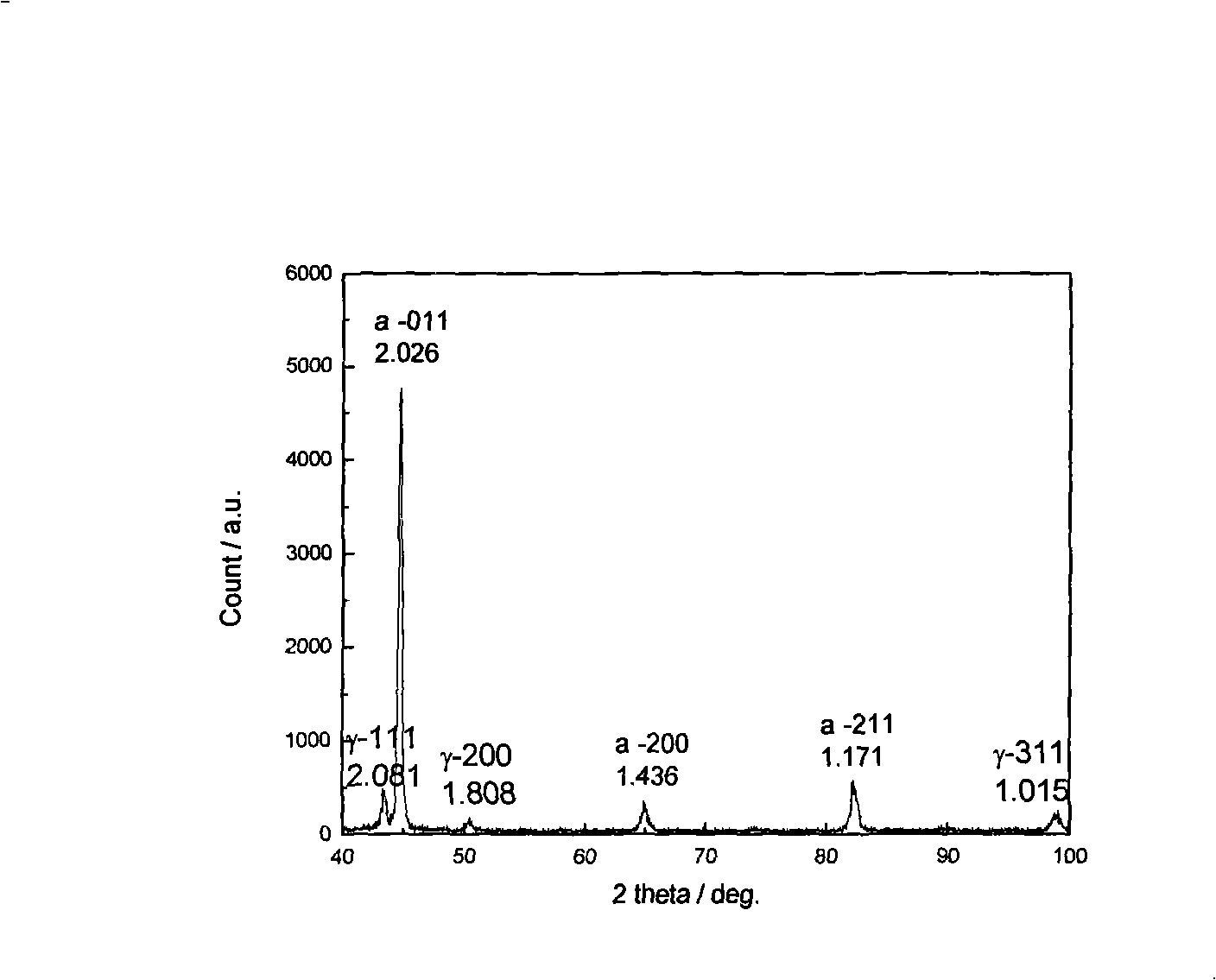

Powder metallurgy refractory multi-principal-element high-entropy alloy and preparation method thereof

The invention relates to the technical field of powder metallurgy preparation of refractory metal materials, and specifically discloses a preparation method of a powder metallurgy refractory multi-principal-element high-entropy alloy. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy specifically comprises the following steps: step S1, refractory metal element powder is sieved through a 300-mesh sieve and mixed in a multi-element powder mixing mode, so that a mixture is obtained; the mixture comprises at least four elements of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W; the atomic percent of each element in the mixture is 5%-35%; and the total percentage is 100%; step S2, pressing forming is carried out, and a pressed blank is obtained; and S3, vacuum high-temperature solid-phase sintering is carried out to obtain a sintered block. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy has the advantages that the components are easy to regulate and control, the production efficiency is high, and near-net forming is achieved; the prepared powder metallurgy refractory multi-principal-element high-entropy alloy is stable in structure and performance and low in cost; and the powder metallurgy refractory multi-principal-element high-entropy alloy has remarkable advantages in research and development of high-performance powder metallurgy refractory multi-principal-element high-entropy alloy and flexible batch production of products of various shapes and varieties.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of high-strength ceramic material

The invention relates to a preparation method of a high-strength ceramic material. The preparation method includes the steps: weighing 35-95% of alpha-Al2O3, 1-35% of silica fume, 3-35% of bauxite and1-50% of iron powder in weight percent; mixing and grinding materials into 1-100 micrometer fine powder, adding a nitrogen-containing compound into the fine powder, uniformly mixing the fine powder with the compound, pressing or rolling the mixture by a 600 tons / cm<2> press machine, and calcining the mixture in a calcining kiln for 8-72 hours at the temperature of 1350-1500 DEG C to finally formthe high-strength ceramic material containing silicon nitride and silicon micro-crystals. The method can be used for preparing high-strength wear-resistant ceramic balls, the high-strength wear-resistant ceramic balls have the advantages of light weight of ceramics and high strength and wear resistance of steel balls and are used for replacing traditional common ceramic balls or steel balls in a tube mill, on one hand, the high-strength wear-resistant ceramic balls are not easily broken, on the other hand, power consumption is reduced, electricity can be saved by 16 billion kilowatts only in acement industry, and the service life of the tube mill is greatly prolonged as the specific weight of the high-strength wear-resistant ceramic balls is smaller than that of the steel balls.

Owner:洛阳中伟环保科技有限公司

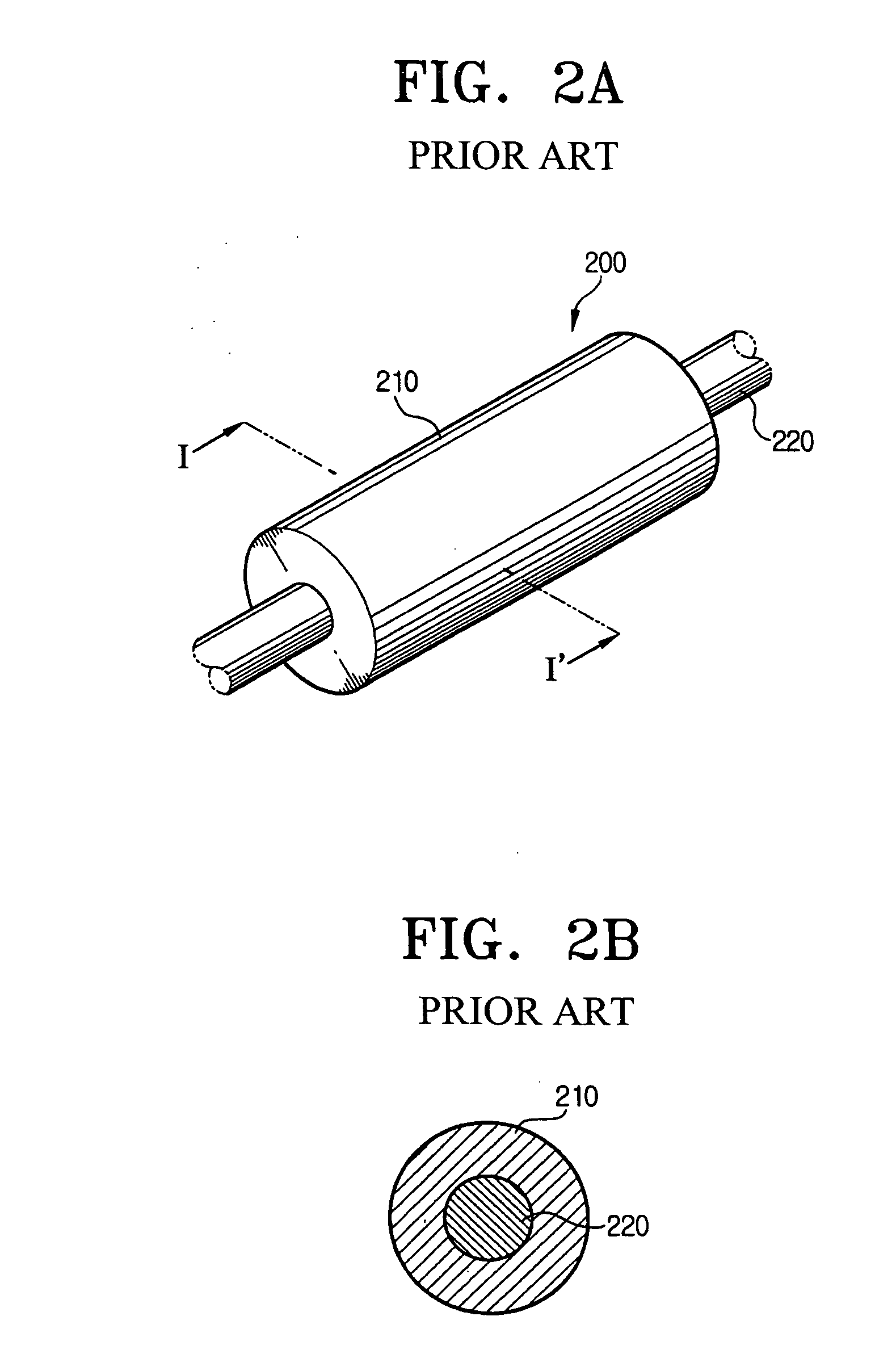

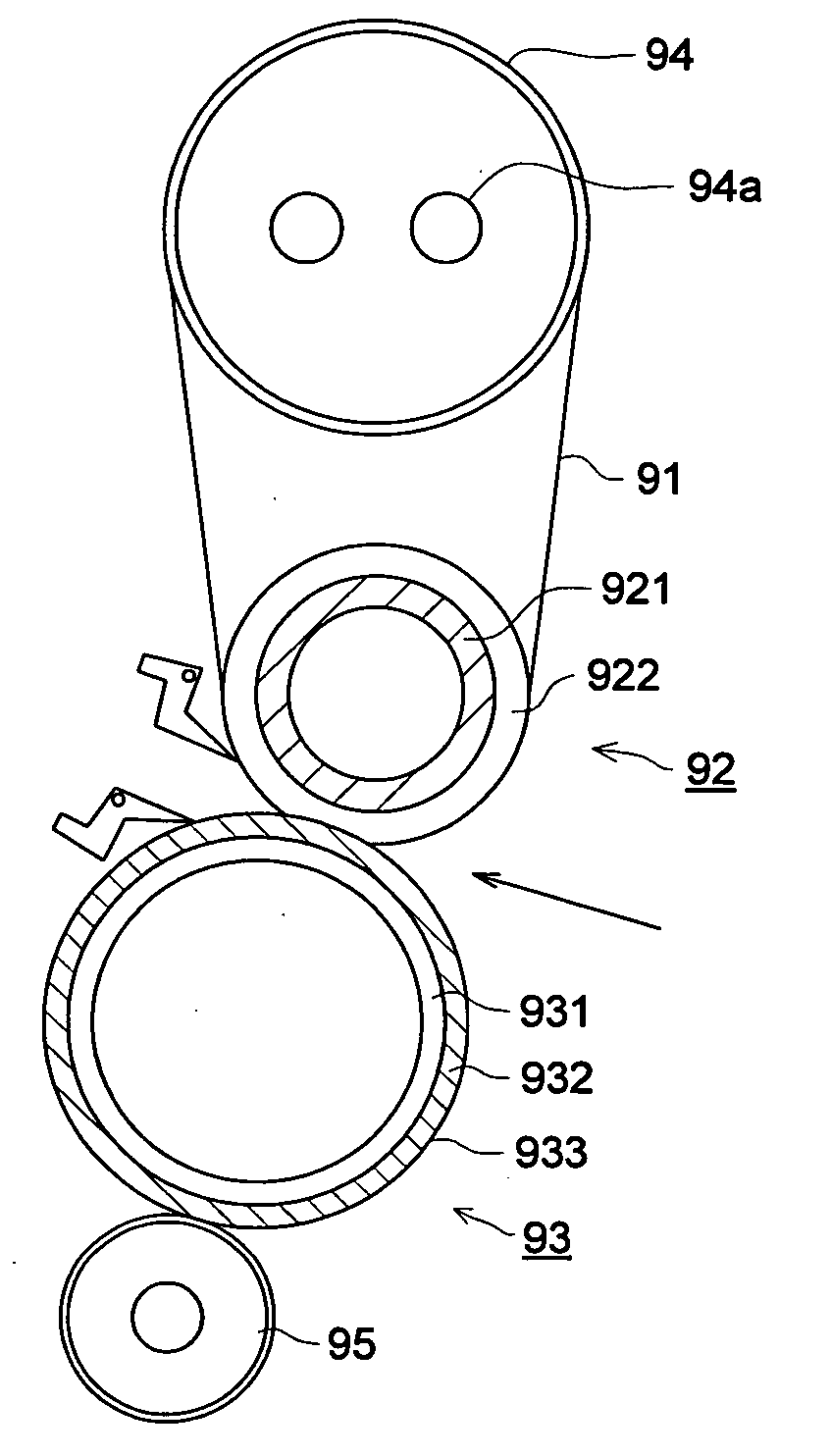

Image forming apparatus

ActiveUS20060072946A1Extension of lifetime of productLow hardnessElectrographic process apparatusEngineeringImaging equipment

There is described a fixing device equipped in an image forming apparatus, which employs an electro-photographic method for forming an image on a transfer material, and having a lifetime longer than conventional one. The fixing device includes a first roller having a first elastic layer formed in a cylindrical shape on an outer surface of the first roller; and a second roller having a second elastic layer formed in a cylindrical shape on an outer surface of the second roller. A hardness of the second elastic layer is higher than that of the first elastic layer, and a nip section is formed between the first elastic layer and the second elastic layer. A longitudinal length of the first elastic layer in an axial direction of the first roller is greater than that of the second elastic layer in an axial direction of the second roller.

Owner:KONICA MINOLTA BUSINESS TECH INC

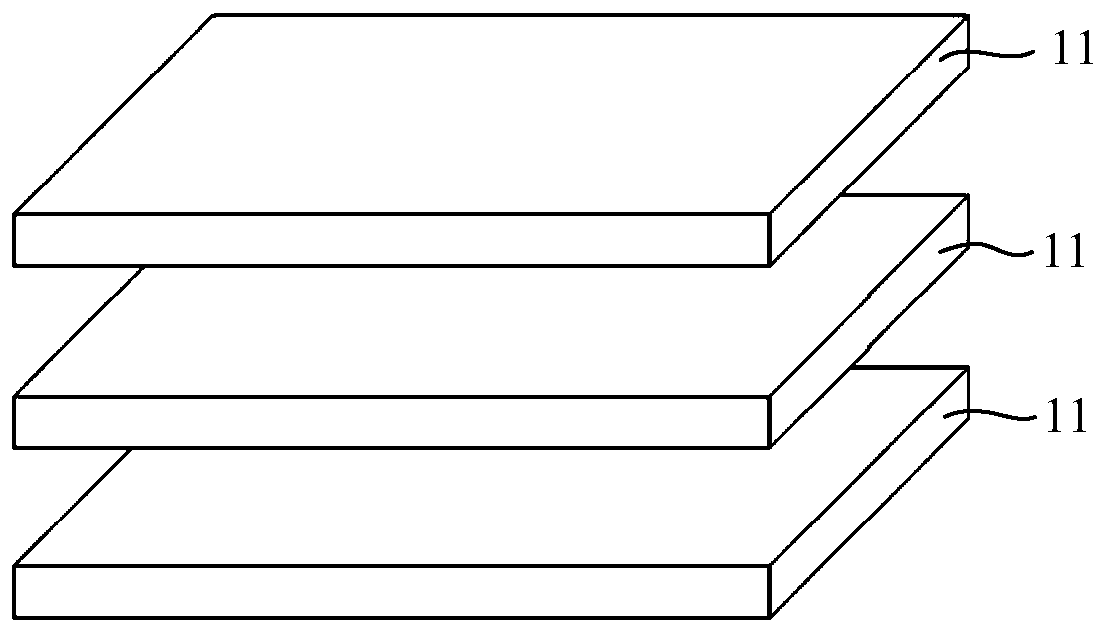

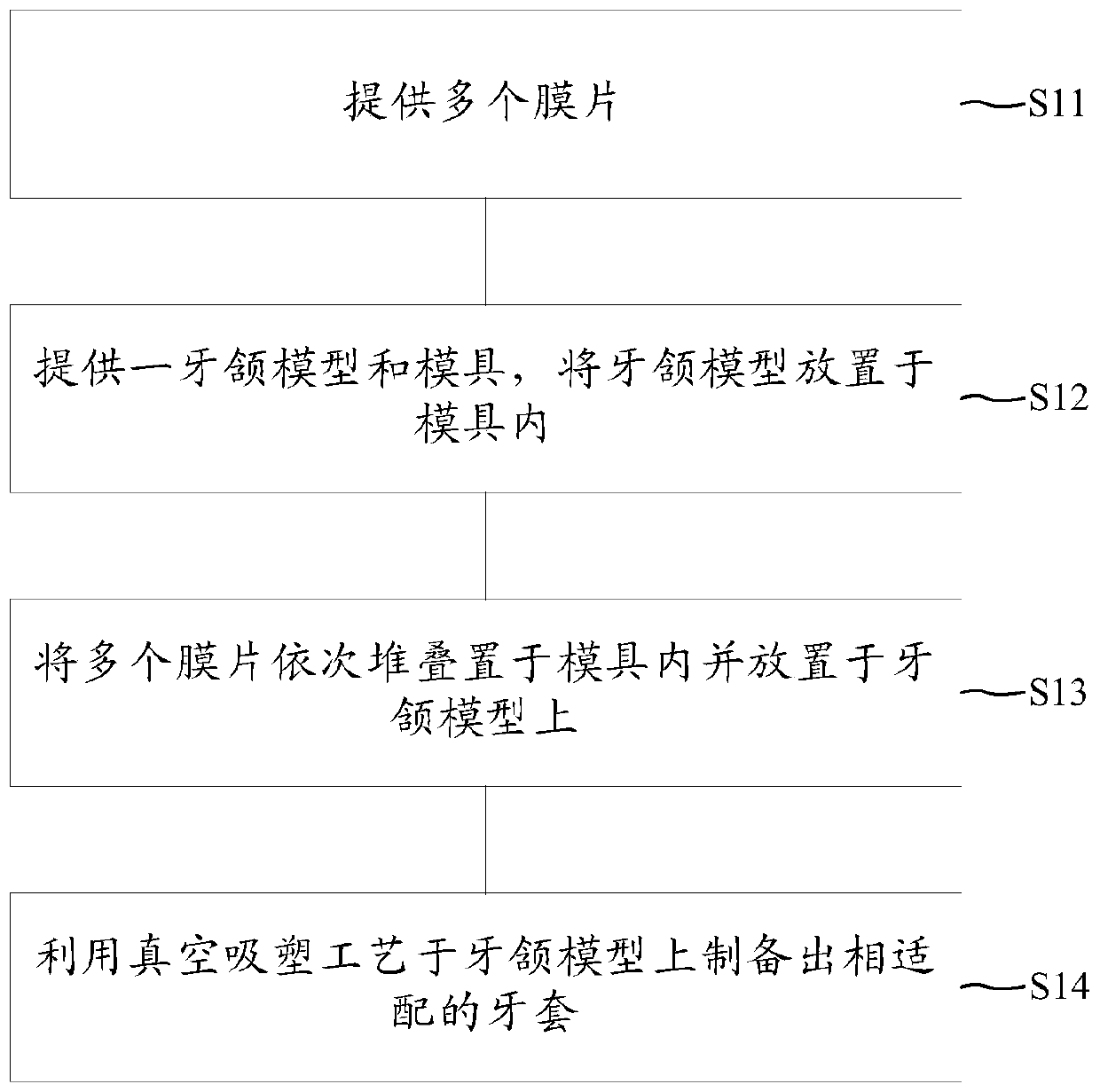

Tooth socket and preparation method thereof

InactiveCN110920031ALow hardnessVariety of hardnessOthrodonticsFlat articlesEconomic benefitsDentistry

The invention relates to a tooth socket and a preparation method thereof. The tooth socket comprises a plurality of prefabricated diaphragms, and the diaphragms are ordered in sequence to be subjectedto vacuum forming. According to the tooth socket, the problems of single tooth sleeve hardness and small application range are effectively solved, through combination of the plurality of diaphragms and vacuum forming, the hardness of the tooth socket is more diversified, the wearing comfort degree can be improved, more correction requirements can be met, and the economic benefit is good.

Owner:上海马可菲斯医疗技术有限公司

Addition-curable silicone composition, cured silicone and optical semiconductor device

InactiveCN110294936AHigh transparencyImprove heat resistanceAdhesivesSemiconductor devicesDevice materialDouble bond

The present invention provides an addition-curable silicone composition generating a cured product. The cured product has a small change in hardness and a small decrease in weight under high temperature conditions, and does not leak oil even when exposed to near ultraviolet to violet light in a high temperature and high humidity environment. The composition contains the following components and iscured by heating: (A) a straight-chain organopolysiloxane having at least 2 alkenyl groups in each molecule and represented by the following average composition formula (1) that is (R<3><1>SiO<1 / 2>)a(R<2><1>R2SiO<1 / 2)b(R<2><1>SiO)c(R1R2SiO)d; (B) organohydrogenpolysiloxane which has, in each molecule, at least two hydrogen atoms bonds with silicon atoms, and which does not have a carbon-carbon double bond capable of addition reactions; (C) a hydrosilylation catalyst containing a platinum group metal; and (D) polyorganometallosiloxane having a Si-O-Ce bond and a Si-O-Ti bond.

Owner:SHIN ETSU CHEM IND CO LTD

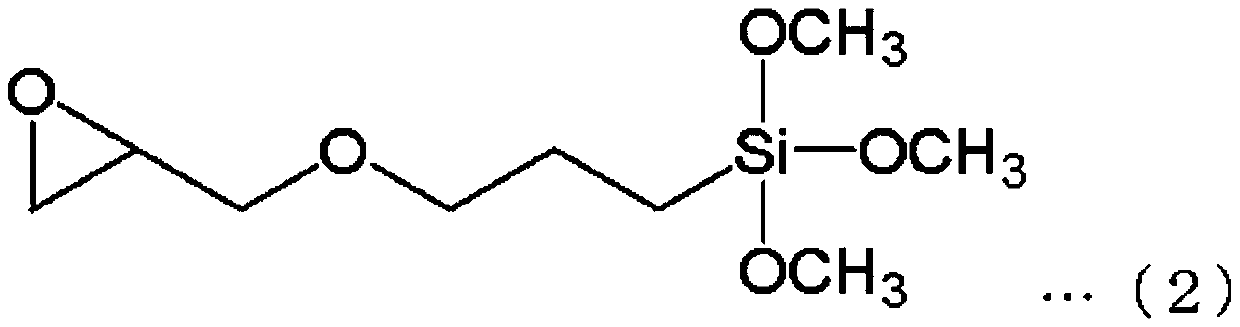

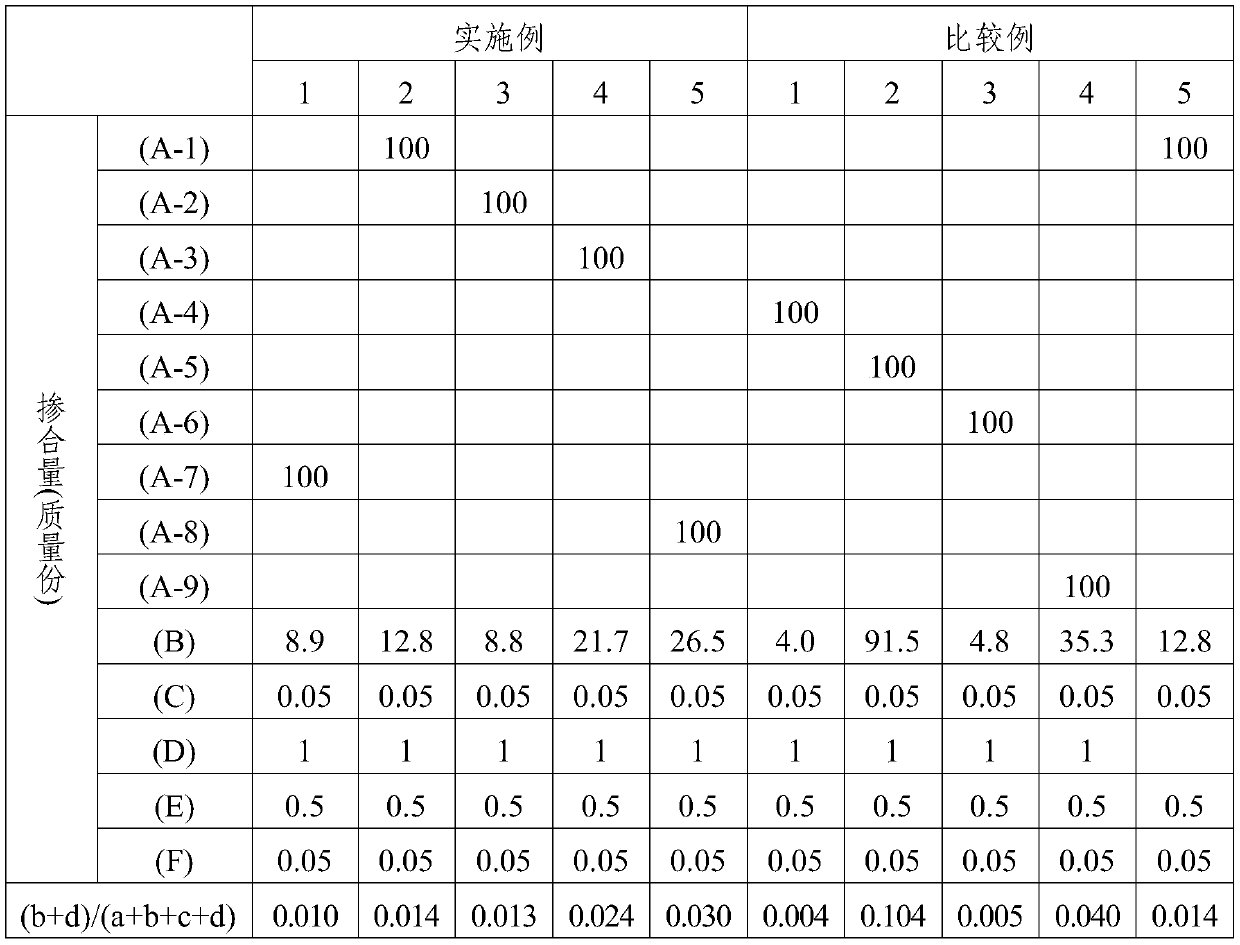

Blend of fluorine-containing elastomers

Provided is a fluorine-containing elastomer blend comprising 5 to 60 wt.% of a high-molecular-weight, fluorine-containing elastomer having a number average molecular weight of 3,000,000 or more, 20 to 80 wt.% of a medium-molecular-weight, fluorine-containing elastomer having a number average molecular weight of 100,000 to 1,000,000, and 10 to 50 wt.% of a low-molecular-weight, fluorine-containing elastomer having a number average molecular weight of 7,000 to 13,000; the number average molecular weight Mn of each tluorine-containing elastomer being measured by liquid chromatography using tetrahydrofuran as a developing solvent at a polymer concentration of 0.5 wt.% at a measurement temperature of 35 DEG C. The fluorine-containing elastomer blend can achieve low hardness and low modulus while improving roll processability.

Owner:UNIMATEC CO LTD

Lightweight high-hardness flexible ceramic decorative material and preparation method thereof

The invention discloses a lightweight high-hardness flexible ceramic decorative material. The lightweight high-hardness flexible ceramic decorative material is composed of two layers, namely a surfacelayer and a bottom layer, wherein the surface layer is composed of floating beads, a coupling agent, silicone acrylic emulsion, cement and inorganic pigments; the bottom layer is composed of cement,quartz sand, silicone acrylic emulsion and fly ash. Compared with an ordinary flexible ceramic material, the flexible ceramic material prepared by the invention has the performances of lightweight andhigh hardness, wherein the mass can be reduced by about 20%, and the hardness is improved by a grade. In addition, the wear resistance and breaking strength of the flexible ceramic material preparedin the invention are similar to those of flexible ceramic materials in the prior art, so that good using time can be ensured.

Owner:万卓(江苏)新材料有限公司

Optical semiconductor apparatus

ActiveUS20190103529A1Decrease internal stressLow hardnessSemiconductor devicesSilicone resinHardness

Provided is an optical semiconductor apparatus having an optical semiconductor device, a light-permeable buffer layer containing a cured high-hardness silicone resin having a thickness of 1-300 μm, which covers at least part of a light-emitting surface of the optical semiconductor device, and a flexible sealing layer containing a cured flexible silicone resin having a lower hardness than the light-permeable buffer layer, which covers the optical semiconductor device and the light-permeable buffer layer.

Owner:HOYA CANDEO OPTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com