Lightweight high-hardness flexible ceramic decorative material and preparation method thereof

A decorative material with high hardness technology, applied in the field of architectural decorative materials, can solve the problems of bulky decorative materials, reduce quality, and have potential safety hazards, and achieve the effects of high bonding performance, long service life, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

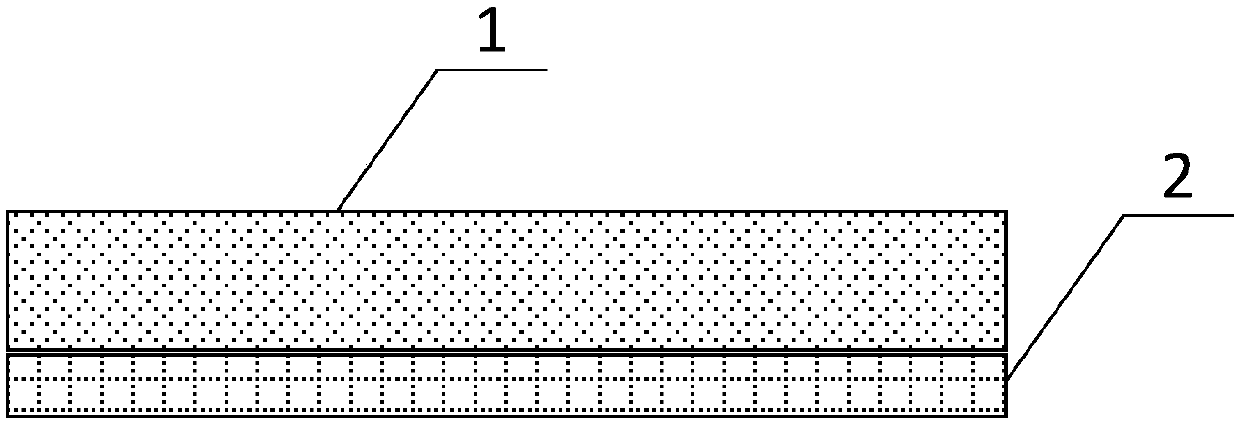

Image

Examples

Embodiment 1

[0024] A method for preparing a lightweight high-hardness soft porcelain decorative material, characterized in that it comprises the following steps:

[0025] Step (1) Preparation of surface layer powder: Take 20 parts of floating beads, 10 parts of cement, 8 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix evenly to obtain a surface layer powder. The density of floating beads is 450kg / m 3 .

[0026] Step (2) Preparation of bottom layer powder: Take 10 parts of cement, 10 parts of quartz sand, 20 parts of fly ash, and 2 parts of coupling agent into a kneader and mix evenly to obtain the bottom layer powder.

[0027] Step (3) Prepare the mixed material: add the surface layer powder obtained in step (1) to 20 parts of silicon acrylic emulsion, add 10 parts of water, and stir to obtain the surface layer mixed material; the second mixed powder obtained in step (2) Add the material to 20 parts of silicon-acrylic emulsion, add 10 parts of w...

Embodiment 2

[0031] A method for preparing a lightweight high-hardness soft porcelain decorative material, characterized in that it comprises the following steps:

[0032] Step (1) Preparation of surface layer powder: Take 20 parts of floating beads, 10 parts of cement, 8 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix evenly to obtain a surface layer powder.

[0033] Step (2) Preparation of bottom layer powder: Take 10 parts of cement, 10 parts of quartz sand, 20 parts of fly ash, and 2 parts of coupling agent into a kneader and mix evenly to obtain the bottom layer powder.

[0034] Step (3) Prepare the mixed material: add the surface layer powder obtained in step (1) to 20 parts of silicon acrylic emulsion, add 10 parts of water, and stir to obtain the surface layer mixed material; the second mixed powder obtained in step (2) Add the material to 20 parts of silicon-acrylic emulsion, add 10 parts of water, and stir to obtain the second bottom laye...

Embodiment 3

[0038] A method for preparing a lightweight high-hardness soft porcelain decorative material, characterized in that it comprises the following steps:

[0039] Step (1) Preparation of surface layer powder: Take 20 parts of floating beads, 5 parts of cement, 8 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix them evenly to obtain a surface layer powder. The density of floating beads is 450kg / m 3 .

[0040] Step (2) Prepare bottom layer powder: Take 10 parts of cement, 10 parts of quartz sand, 10 parts of fly ash, and 2 parts of coupling agent into a kneader and mix evenly to obtain the bottom layer powder.

[0041] Step (3) Prepare the mixed material: add the surface layer powder obtained in step (1) to 20 parts of silicon acrylic emulsion, add 10 parts of water, and stir to obtain the surface layer mixed material; the second mixed powder obtained in step (2) Add the material to 20 parts of silicone acrylic emulsion, add 10 parts of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com