Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Increase pickling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid pickling promotor for iron and steel

The acid pickling promoter for iron and steel consists of inorganic salt as reducing agent 10-80 wt%, organic metal ion chelating chelating agent 1-20 wt%, synergist 1-20 wt% and water 10-50 wt%. The acid pickling promoter is suitable for being added into acid pickling liquid to promote the elimination of dense oxide scale on the surface of steel, shapes and other iron and steel product. It can raise the surface quality of silicon steel plate after being acid pickled, shorten acid pickling period, reduce acid consumption and improve acid pickling environment.

Owner:HUAZHONG UNIV OF SCI & TECH +2

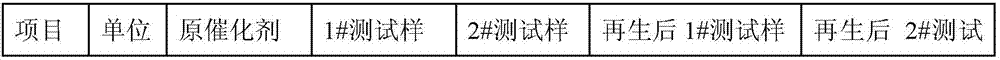

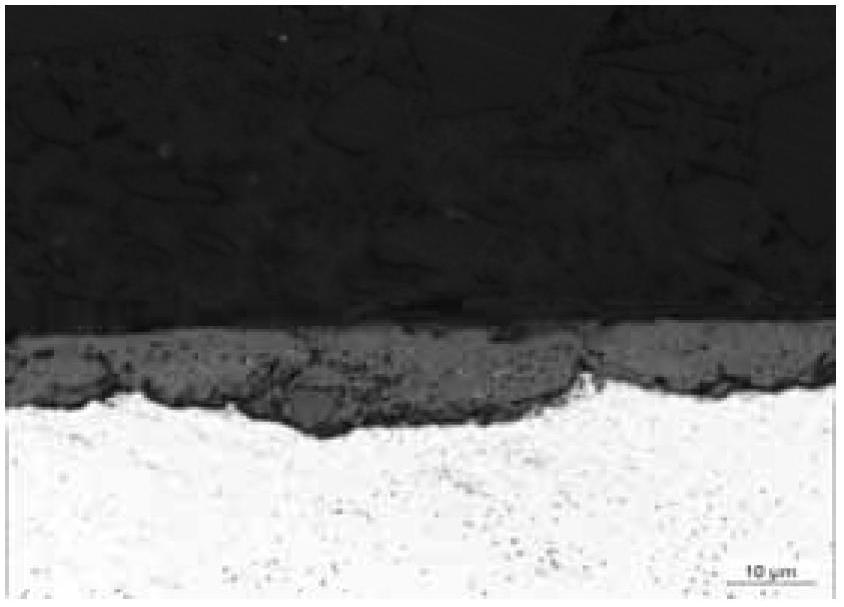

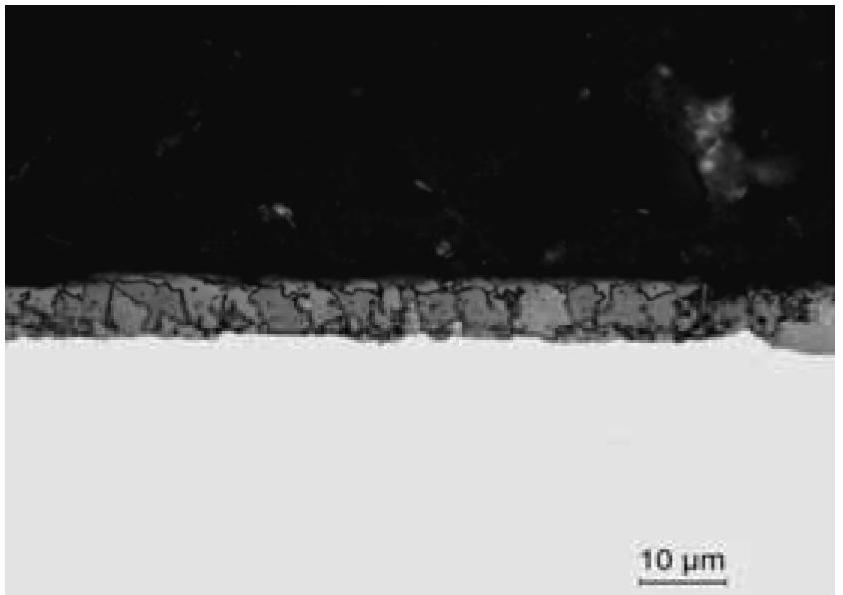

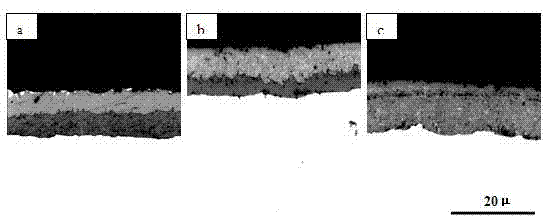

Method for regeneration of spent denitration catalyst

InactiveCN106902895AImprove pickling effectIncrease pickling speedDispersed particle separationCatalyst regeneration/reactivationPotassium hydroxideArsenic

The invention discloses a method for regeneration of a spent denitration catalyst, and relates to a composition for a cleaning solution and an application thereof, and an activity recovering method for a spent SCR catalyst. The invention is used for solving the technical problems in the prior art that a lost catalyst active component in a regeneration process cannot be selectively supplemented and an iron rust defect of a metal module framework cannot be effectively eliminated. The method comprises the following steps: one, dust cleaning; two, spraying; three, cleaning; four, re-cleaning; five, acidification; six, pre-drying; and seven, activity supplementing. Cleaning media of sodium hydroxide and potassium hydroxide can dissolve inactivated V2O5 and toxic element arsenic on the surface of the catalyst. While the method can selectively supplement the catalyst active component (TiO2), the iron rust removal rate of the metal module framework reaches 19% to 24%. The invention belongs to the field of spent denitration catalyst regeneration.

Owner:黑龙江丰迪环保科技有限公司

Method for making easy-to-pickle steel plate

InactiveCN102671992AIncreasing the thicknessImprove lateral uniformityRare end control deviceWork treatment devicesSheet steelStrip steel

The invention provides a method for making an easy-to-pickle steel plate and belongs to the technical field of metallurgy. The method comprises the following steps of: smelting molten steel, and making a plate blank by continuous casting; descaling by using high pressure water, performing rough rolling on the descaled plate blank, performing finish rolling, cooling to the temperature of 500 to 550 DEG C, cooling at the speed of 5 to 10 DEG C per minute to obtain the steel which is easy to pickle and in a hot rolling state and of which the content of FeO is over 25 percent; performing finish rolling, cooling to the temperature of 650 to 700 DEG C at the speed of 1 to 5 DEG C per minute to obtain the steel which is easy to pickle and in a cold rolling state and has a uniform structure and of which the content of iron oxide scale FeO is less than 10 percent. By adopting the method, the thickness of the iron oxide scale is reduced by 20 to 30 percent compared with the conventional process, the pickling speed of the strip steel is increased from 150 to 160 m per minute to 180 to 200 m per minute compared with the conventional process, not only the pickling quality of the steel plate is guaranteed, but also the pickling efficiency is effectively improved.

Owner:NORTHEASTERN UNIV +1

A kind of production method of pickling-reducing steel

InactiveCN102266868AImprove surface quality and labor productivityReduce generationRoll mill control devicesMetal rolling arrangementsMicrostructureReaction curve

The invention relates to a production method for pickling steel with reduced acid and belongs to the technical field of metal rolling. The technical scheme is that: a FeO eutectoid reaction curve in a scale microstructure in the hot rolling process of target steel is formed; a rolling process is controlled, optimized and adjusted according to the FeO eutectoid reaction curve in the scale microstructure in the hot rolling process of the target steel; and the scale microstructure is changed, the generation of Fe2O3 which is difficult to pickle is reduced, the pickling speed is improved in the pickling process, and acid consumption of each ton of steel is reduced to pickle steel with acid. The invention has the advantages that: the scale is well controlled in the hot rolling process, and thesurface quality of a hot rolled strip coil and labor productivity are greatly improved; and the scale microstructure is changed, the generation of Fe2O3 which is difficult to pickle is reduced, the pickling speed is improved by 10 percent in the subsequent pickling process, and the acid consumption of each ton of steel is reduced by 7.5 percent. The pressure of excessive waste acid emission on the environment is greatly lightened, and the method has the advantages of energy conservation, emission reduction and great social benefit.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Production method for continuous pickling of hot rolled duplex stainless strip steel

The invention discloses a production method for continuous pickling of hot rolled duplex stainless strip steel. The production method comprises the following steps: shot blasting and descaling after annealing; electrolytic pickling and pre-pickling with sulfuric acid; grinding and scrubbing; treatment in a sulfuric acid pickling bath; treatment in a mixed acid pickling bath; treatment in another mixed acid pickling bath, wherein the concentration of nitric acid in the bath is 100-150g / l, the concentration of hydrofluoric acid in the bath is 35-55g / l, the concentration of metal ions in the bath is 5-20g / l, the acid liquor temperature is 45-65 DEG C and the pickling speed is 10-25m / min. The production method has the beneficial effects that by adjusting the casting amount and rotating speed of a shot blasting machine, the pickling process, the acid liquor concentration, the acid liquor temperature and the acid liquor components, the strip steel pickling speed can be effectively increased, the yield can be increased and a good NO.1 surface can be obtained.

Owner:WISDRI ENG & RES INC LTD

Production method for continuous pickling of hot rolled superaustenitic stainless strip steel

ActiveCN103820799AIncrease pickling speedIncrease productionGrinding machinesHydrofluoric acidStrip steel

The invention discloses a production method for continuous pickling of hot rolled superaustenitic stainless strip steel. The production method comprises the following steps: strip steel shot blasting and descaling after annealing; electrolytic pickling pretreatment with sulfuric acid; grinding and scrubbing; treatment in a sulfuric acid pickling bath; treatment in a mixed acid pickling bath; treatment in another mixed acid pickling bath, wherein the concentration of nitric acid in the bath is 150-250g / l, the concentration of hydrofluoric acid in the bath is 50-70g / l, the concentration of metal ions in the bath is 5-20g / l, the acid liquor temperature is 50-65 DEG C and the pickling speed is 22-28m / min. The production method has the beneficial effects that by adjusting the casting amount and rotating speed of a shot blasting machine, the pickling process, the acid liquor concentration, the acid liquor temperature and the acid liquor components, the strip steel pickling speed can be effectively increased, the yield can be increased and a good NO.1 surface can be obtained.

Owner:WISDRI ENG & RES INC LTD

Improved hot galvanizing method of iron handicraft or furniture

InactiveCN103668030ANo over-cleaning phenomenonImprove ductilityHot-dipping/immersion processesEthylenediamineThiourea

The invention relates to an improved hot galvanizing method of an iron handicraft or furniture. The method comprises the following steps: (1) uncoiling and degreasing a workpiece; (2) removing dust; (3) washing; (4) assisting plating; (5) baking; (6) galvanizing by dipping; (7) settling; (8) passivating; (9) cooling. In the method, a degreasant is changed into acidity and is composed of a sulfuric acid solution, OP-10 and di-o-tolyl-thiourea. Thus, a washing procedure can be saved; a water resource and the degreasant can be saved; the workpiece does not generate an over-cleaning phenomenon; a pickling solution is composed of a hydrochloric acid solution, phosphoric acid, alkylphenol ethoxylates, lauryl sodium sulfate and ethylenediamine tetraacetic acid, so that the pickling speed is improved, formation of acid mist and use of a complexing agent can be restricted, reduction of cadmia in galvanizing zinc is facilitated, the malleability of a zinc coating on the surface of the work-piece is improved, proper temperature and event are adopted in the subsequent galvanizing by dipping, and the thickness and the stability of the zinc coating at the surface of the workpiece are ensured. Thus, the improved hot galvanizing method is a method which is simple and convenient for operation and good in galvanized effect.

Owner:TIANJIN BIAODIAN METAL HANDICRAFT CO LTD

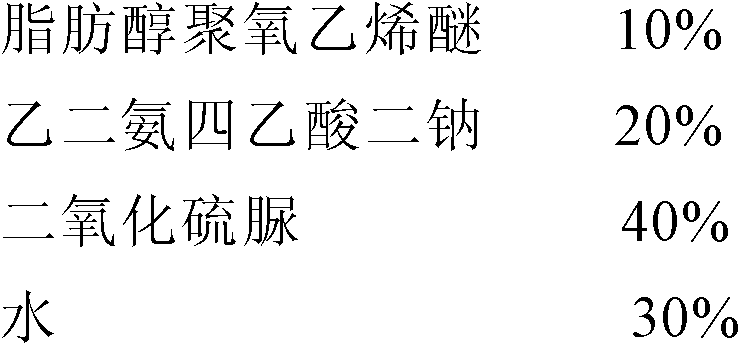

Silicon steel acid cleaning stabilizing material and application method thereof

The invention discloses a silicon steel acid cleaning stabilizing material and an application method thereof. The silicon steel acid cleaning stabilizing material comprises an acid cleaning accelerator and an inhibitor, wherein the acid cleaning accelerator comprises the following components in percentage by weight: 5-20% of surfactant, 5-20% of organic metal chelating agent, 20-40% of reducing agent and 20-40% of water; and the inhibitor comprises the following components in percentage by weight: 10-30% of urotropin, 10-50% of diethylene glycol, 5-15% of o-xylene thiourea, 0-10% of fatty alcohol-polyoxyethylene ether and the balance of water. According to the invention, the silicon steel acid cleaning speed is increased, the speed of hydrogen atom entering strip steel is reduced, the aims of increasing the acid cleaning speed, reducing the acid cleaning temperature, reducing the consumption of hydrochloric acid and reducing brittleness of silicon steel are reached, and stable operation of silicon steel acid cleaning production is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

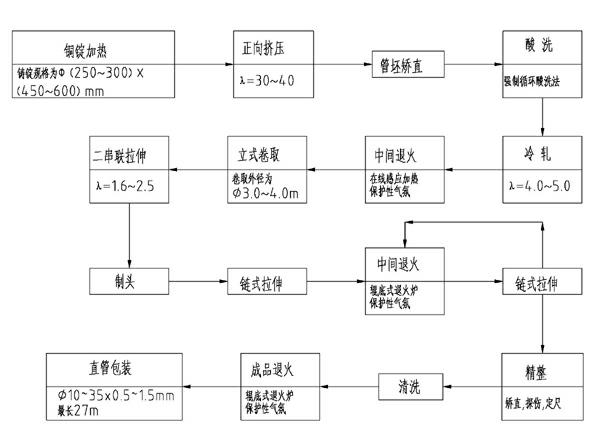

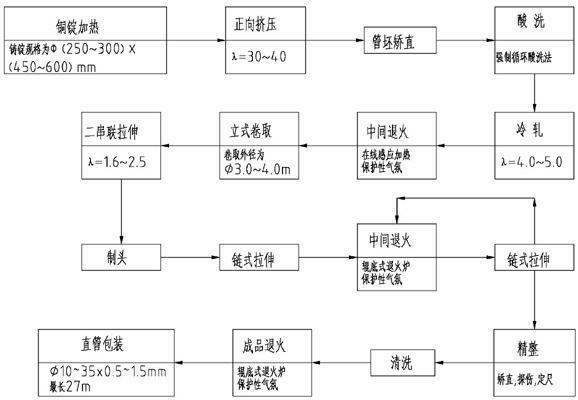

Production process of super long brass condenser pipe

The invention relates to a production process of a super long brass condenser pipe, comprising the following steps of: preheating a cast ingot, peeling and extruding, scale sawing, straightening, forced circulation acid washing, cold rolling, induction continuous annealing, vertical rolling, secondary series stretching, scale sawing, intermediate annealing with protective atmosphere, multi-pass chain type stretching, finishing, cleaning, finished product annealing with protective atmosphere and packaging. According to the production process disclosed by the invention, a large-cast-ingot high-extrusion-ratio is adopted, thus extrusion finished product ratio is improved; a forced circulation acid washing method is adopted, thus environmental protection is enhanced and production operational safety is guaranteed; induction cast ingot heating and online induction intermediate annealing are adopted, thus energy consumption is reduced; a vertical rolling process after online induction is adopted, thus floor area of the process in a workshop is reduced; higher cold rolling elongation is adopted, thus flow of the production process is shortened and production efficiency is improved; longer intermediate product production is adopted, thus number of stretching manufacturing heads is reduced, and finished product ratio is improved; and a super long straight bar condenser pipe is produced, thus application range of the product is expanded.

Owner:CHINA NERIN ENG

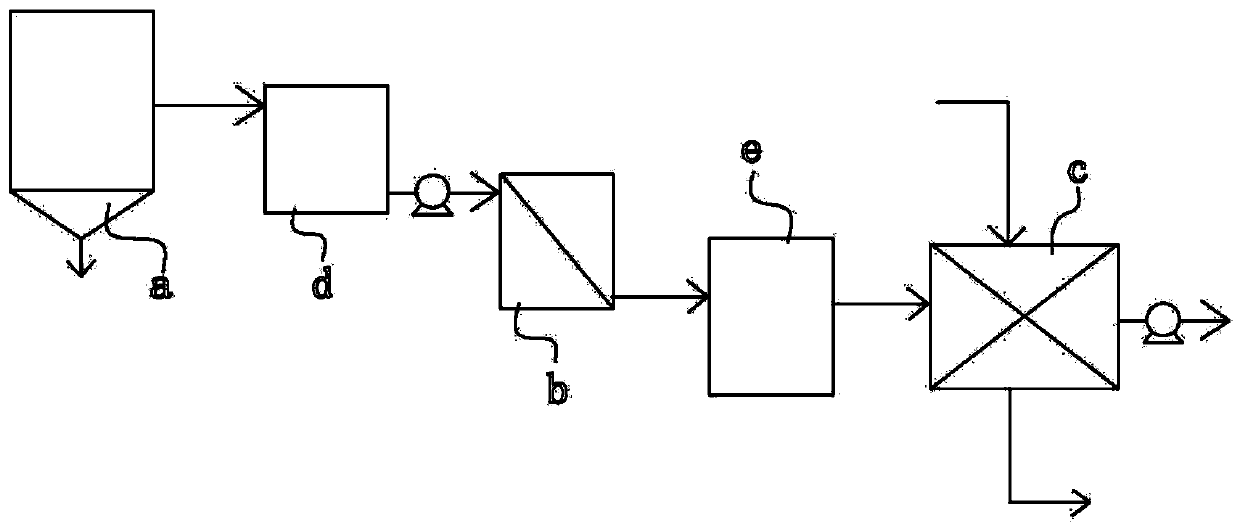

Acid recovery and purification system for pickling waste liquid

ActiveCN110395816AAvoid up and down forceInhibitory concentrationSpecific water treatment objectivesTreatment involving filtrationLiquid wasteFiltration

The invention relates to an acid recovery and purification system for a pickling waste liquid, and belongs to the technical field of wastewater reuse of metal finishing. The system sequentially comprises a waste-acid sedimentation device, a filtration device and an ion exchange resin recovery device; the system further comprises a first storage tank arranged between the waste-acid sedimentation device and the filtration device, and a second storage tank arranged between the filtration device and the ion exchange resin recovery device. The purification system provided by the invention is used for recovery and purification of the pickling waste liquid in the metal finishing industry, and has the advantages of high purity of a cleaning acid, high-efficiency recovery, low energy consumption and less workload.

Owner:ZHEJIANG DONGYANG ENVIRONMENTAL ENG

Preparation method of Chinese smoked sausage

ActiveCN104172220AShorten natural thawing timeAvoid darkeningMeat/fish preservationClimate change adaptationSaline solutionsFood flavor

The invention provides a preparation method of Chinese smoked sausage. The preparation method specially comprises the following steps: 1) selecting and pretreating raw materials of sausage; 2) pickling; 3) cleaning; 4) airing and after-pickling; 5) smoking and roasting; and 6) cleaning, drying, cooling, reshaping and packaging. The preparation method adopts a manure saturated saline solution vacuum thawing, vacuum intermittent pickling, low-temperature roasting and fast drying technology, the sausage can be prevented from deterioration during processing through smoking, and the flavor of the Chinese sausage can be increased.

Owner:HUNAN AGRICULTURAL UNIV

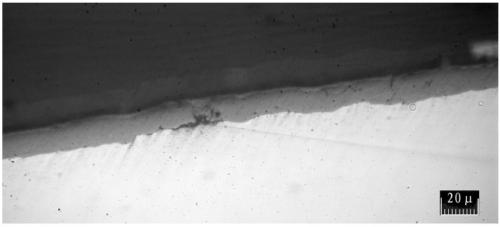

Aluminized steel and preparation method thereof

InactiveCN103320745BReduce concentrationEliminate the effects of hydrogen embrittlementSolid state diffusion coatingThermal fatigueSurface layer

The invention discloses aluminized steel comprising a steel workpiece, wherein a eutectic aluminized alloy layer and an aluminum layer are sequentially arranged on the surface layer of the steel workpiece from inside to outside, and the thickness of the aluminized alloy layer is 14-29 microns. A preparation method of the aluminized steel comprises the following steps: co-firing the steel workpiece to remove oil; pickling to remove rust; washing; carrying out surface activating; carrying out auxiliary infiltrating; drying; carrying out rapid induction aluminizing; immediately immersing the dried steel workpiece in molten aluminum heated to 680-700 DEG C in an induction manner, wherein the infiltration time is 2-3 minutes; and the aluminized steel is obtained by the steps. The aluminized steel disclosed by the invention has superior corrosion resistance, heat resistance, wear resistance and photo-thermal reflectivity, and meanwhile, the bending property of the aluminized steel can be improved, the surface brittleness of diffusion aluminized layers is eliminated and the thermal shock resistance and thermal fatigue resistance can be improved. The preparation method disclosed by the invention can be used for effectively controlling the thickness of the aluminized layer, shortening the technique preparation period, improving the efficiency and increasing the yield.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

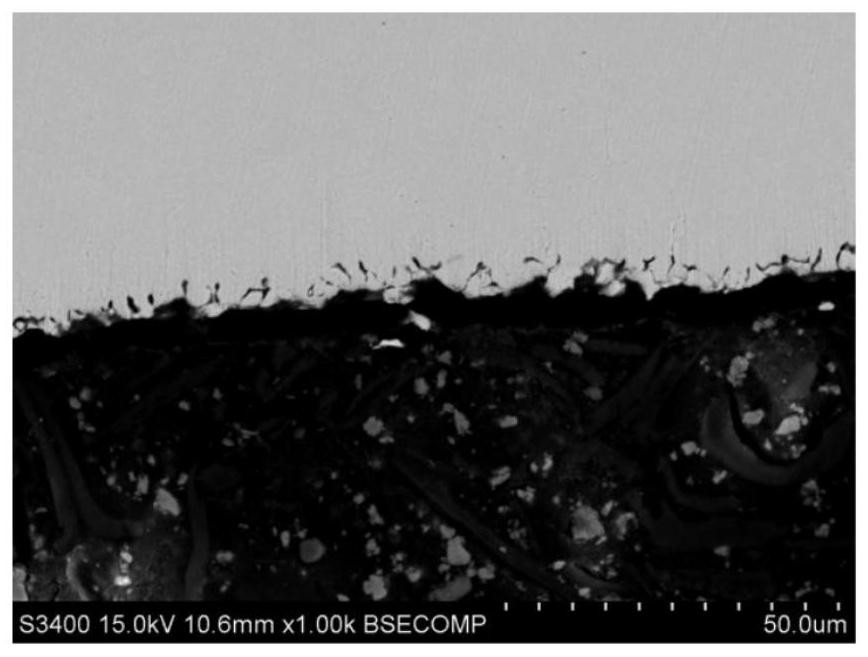

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

Method for accelerating meat curing by alternating vacuum and pressurization

The invention relates to a method for accelerating meat curing by alternating vacuum and pressurization, belonging to the technical field of food processing, and in particular relates to a curing method of meats of livestock and poultry. The method comprises the steps of soaking fresh meat into curing liquid, and curing by alternating vacuum and pressurization, wherein during curing, the vacuum degree is 0.02-0.1MPa, the pressure value is 0.05-0.25MPa, the time ratio of vacuum to pressure is (1-3): 1, and the total time of alternate curing is shorter than 8h. According to the method, curing is carried out by alternating vacuum and pressurization, so that the defects that the meat curing period is long, curing is not even, and the like can be overcome.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Acid pickling promotor for iron and steel

Owner:HUAZHONG UNIV OF SCI & TECH +2

Novel stainless steel pickling-passivating solution and pickling-passivating process thereof

InactiveCN105331989ANo irritating smellImprove protectionMetallic material coating processesGallic acid esterThiourea

The invention discloses novel stainless steel pickling-passivating solution. The novel stainless steel pickling-passivating solution comprises the following components in parts by weight: 30-40 parts of hydrogen peroxide, 20-30 parts of hydrofluoric acid, 5-15 parts of citric acid, 3-7 parts of thiourea derivatives, 2-8 parts of octaphenyl polyoxyethyiene, 50-80 parts of deionized water, 1-5 parts of a silane coupling agent, 5-10 parts of polyaspartic acid, 3-8 parts of polyacrylamide, and 5-12 parts of gallic acid. The invention further discloses a pickling-passivating process thereof. The stainless steel pickling-passivating solution does not contain nitric acid and inorganic strong acid, can achieve integration of a pickling function and a passivating function, and can effectively improve the corrosion resistance of stainless steel surfaces; the process is simple and has no special requirements on operation environment; and the stainless steel pickling-passivating solution is widely applicable to elimination for iron rust, welding spots, oil stain, and black and yellow oxide skins generated during the processes of formation, assembly, welding and the like, and comprehensive passivation for stainless steel workpieces.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

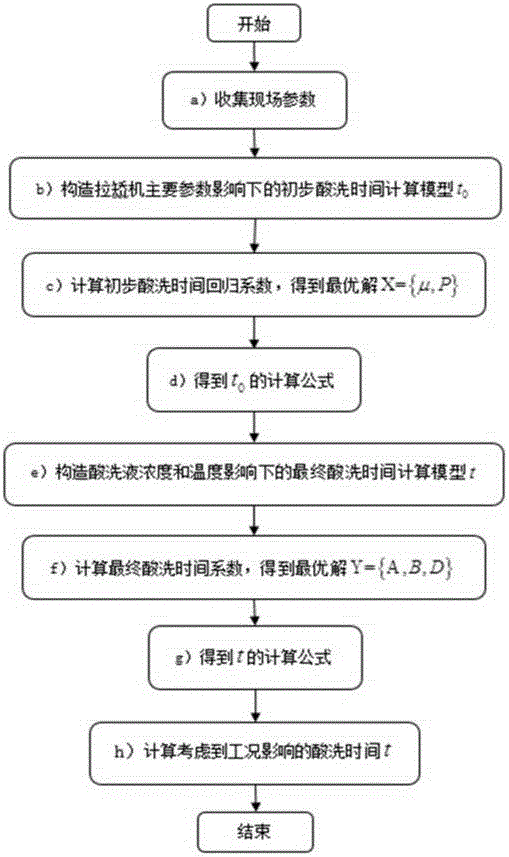

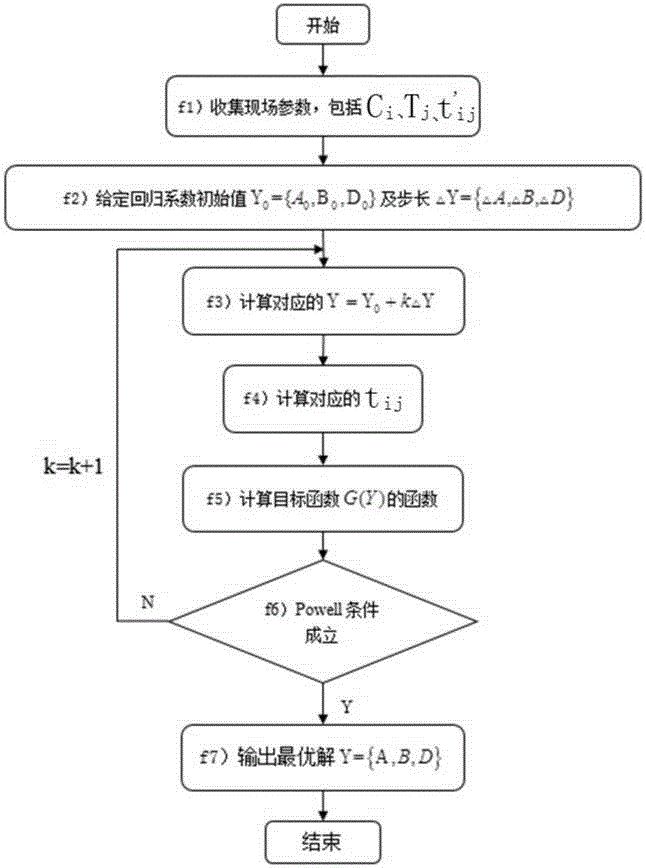

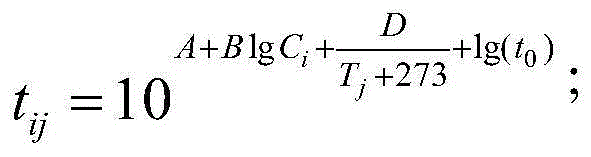

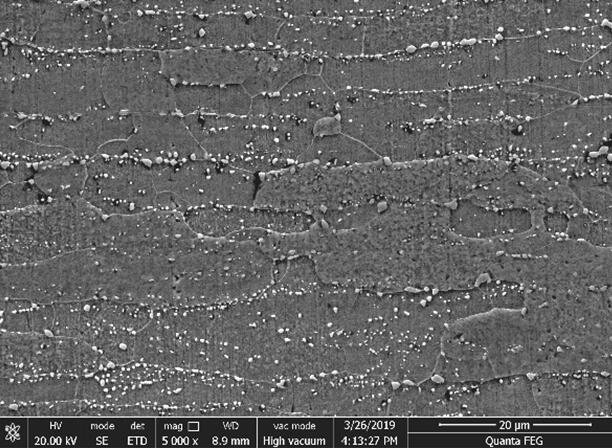

Prediction method of pickling time considering pulling-correcting and scale breaking effect

InactiveCN106238470AIncrease pickling speedThe calculation method is accurateWork treatment devicesMeasuring devicesProduction lineStrip steel

The invention discloses a prediction method of pickling time considering pulling-correcting and scale breaking effect. The method comprises following steps: step a. collecting test parameters; step b. establishing an influence coefficient model of pulling-correcting and scale breaking on pickling time; step c. calculating parameters of the influence coefficient model by means of the regression method; step d. establishing a pickling time calculating model considering the influence of pickling solution concentration, temperature and pulling-correcting and scale breaking; step e. calculating pickling time coefficients by means of the regression method; step f. calculating pickling time according to the pickling time calculating model; step g. obtaining a pickling time calculating model from optimal solutions; step h. calculating pickling time in consideration of condition influence. The method of the invention combines the device and technical characteristics of straightening machines of striped steel pickling production line; the calculation method and results of pickling time are more accurate compared with the prior art, and the method solves the problem of on-site production and improves pickling speed of stripped steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of 1800 MPa-grade cold-rolled steel for hot stamping forming

ActiveCN111876676ASolve the problem of high strength and difficult cold rollingLow costHot stampingButt welding

The invention discloses 1800 MPa-grade cold-rolled steel for hot stamping forming. The 1800 MPa-grade cold-rolled steel is composed of the following chemical components including, by weight, 0.25%-0.35% of C, 0.20%-0.40% of Si, 1.10%-1.45% of Mn, less than or equal to 0.020% of P, less than or equal to 0.012% of S, 0.030%-0.060% of Als, 0.25%-0.60% of Cr, 0.030%-0.060% of Ti, 0.0025%-0.0055% of Band the balance Fe and inevitable impurities. According to the process route, the production method comprises the steps of raw material steel strip hot rolling, primary bell-type furnace annealing, continuous flash butt welding, acid pickling, cold continuous rolling, secondary bell-type furnace annealing, leveling and finished product obtaining. After hot stamping forming, a 1800 MPa-grade cold-rolled steel strip for hot stamping forming has the yield strength of 1359-1369 MPa, the tensile strength of 1821-1846 MPa and the percentage elongation after fracture of 6.5%-6.0% , meets the use requirements of the 1800 MPa-grade steel strip for hot stamping forming, and has the characteristics of low cost and high efficiency.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

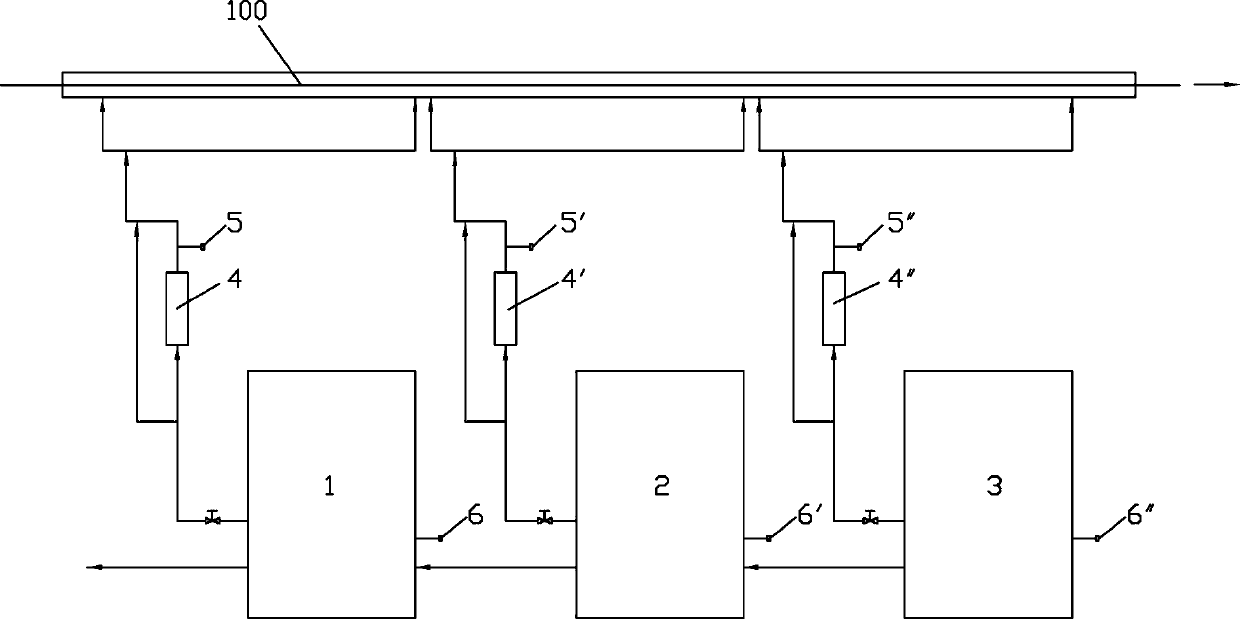

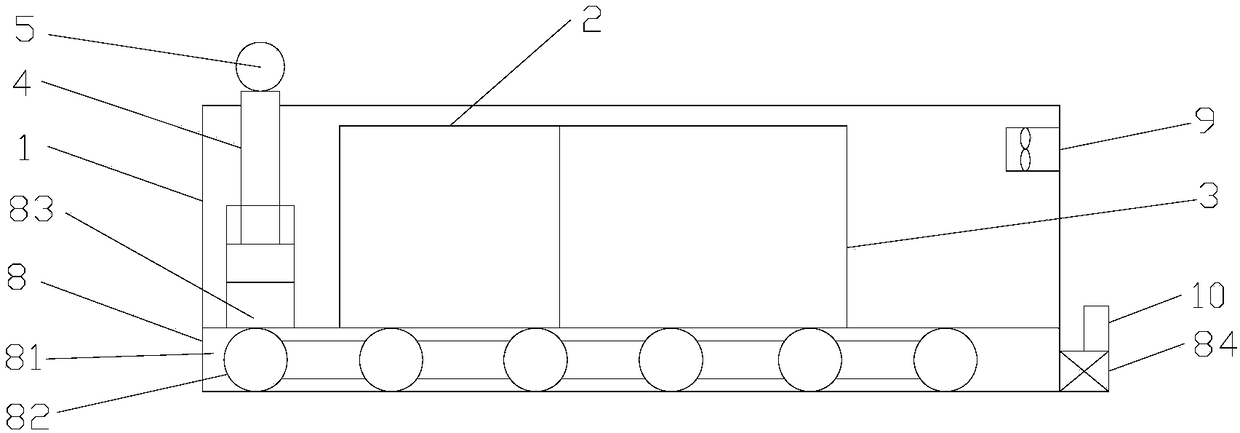

Automatic pickling system

PendingCN108085703AReasonable structureSpeed up dryingHot-dipping/immersion processesPulp and paper industryPiston rod

The invention relates to an automatic pickling system, which comprises a heating water tank, a pickling tank, a washing tank, two pneumatic cylinders, a fixed shaft, a supporting shaft, a cleaning tank, two sets of transporters and a fan, wherein a pickling tank and a washing tank are arranged inside the heating water tank, the pickling tank is on the left of the washing tank, the fixed shaft is connected to piston rods of the two pneumatic cylinders, the pneumatic cylinders are at both ends of the fixed shaft, the supporting shaft is fixed on the bottom of the fixed shaft, the fixed shaft isperpendicularly connected to the supporting shaft, the cleaning tank is connected to the bottom of the supporting shaft, the two sets of transporters are fixed on the external sidewalls of the heatingwater tank, and the fan is mounted on the side part of the heating water tank. Not only is pickling speed increased, but also a pickled material can be washed with water and air-dried before being galvanized.

Owner:JIAXING HENGRUI METAL SURFACE TREATMENT CO LTD

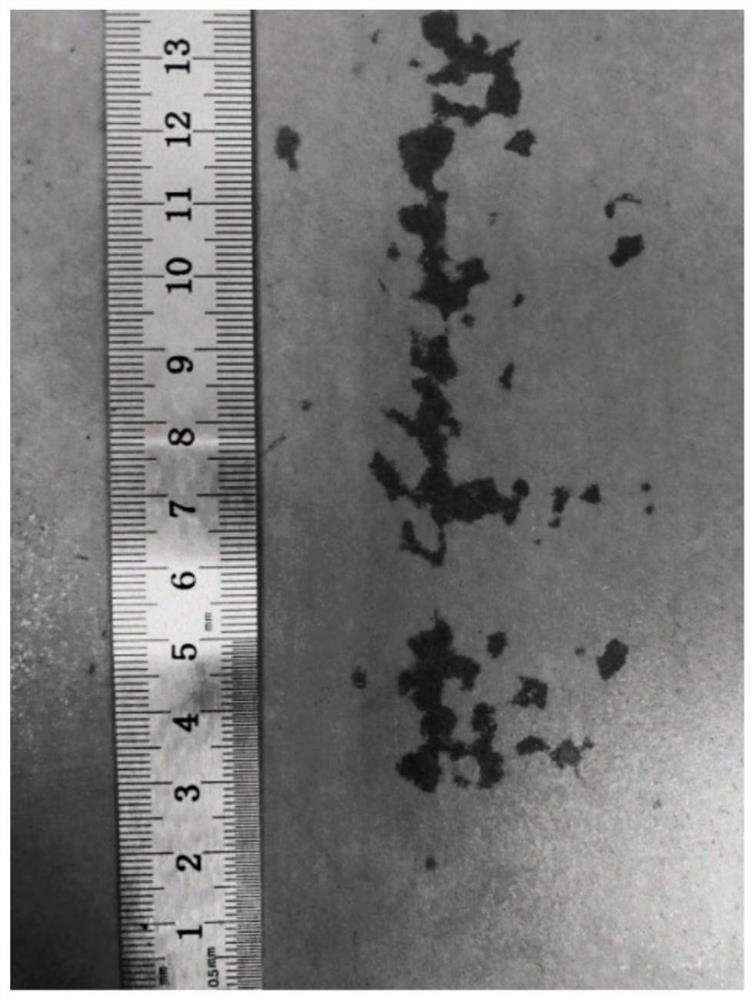

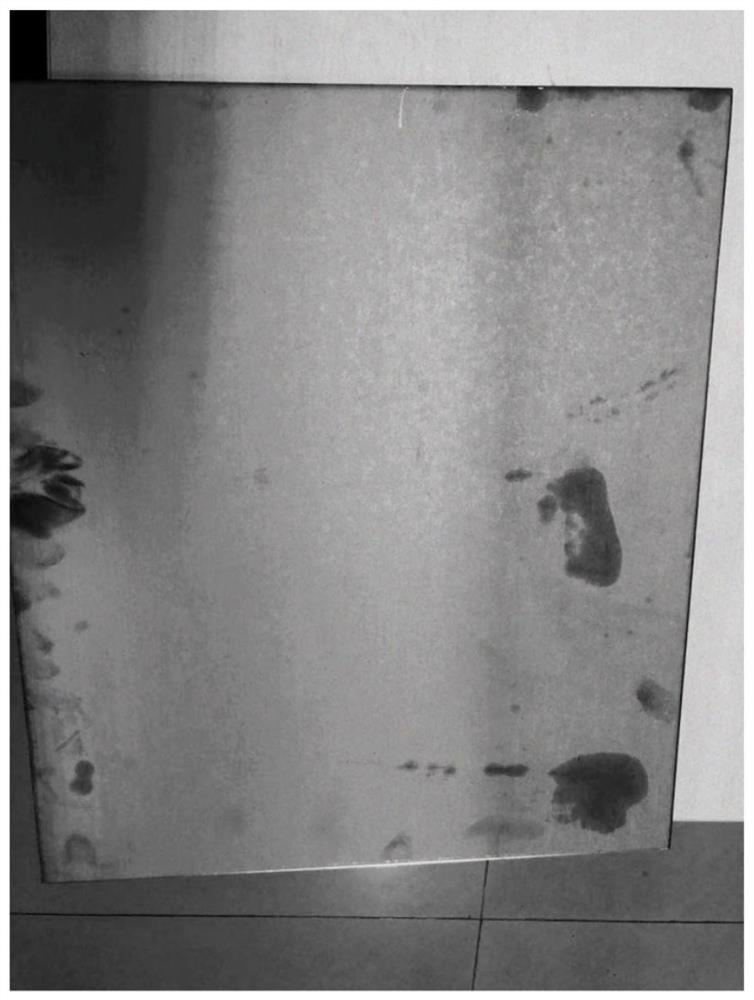

Method for preventing corrosion of high-manganese hot-formed steel after acid pickling

ActiveCN111659732AIncreased efficiency of iron or matrix iron actionReduce dosageMetal rolling arrangementsManganeseMetallic materials

The invention relates to the technical field of metal material processing, in particular to a method for preventing corrosion of high-manganese hot-formed steel after acid pickling. The method comprises the following steps that a plate blank of the high-manganese hot-formed steel is placed in a heating furnace and is heated to 1180-1210 DEG C, and heat preservation at the temperature is carried out for 25-40 minutes; rough rolling is conducted on the heated plate blank, the plate blank enters a finishing mill, the inlet temperature of the finishing mill is 1000-1010 DEG C, and coiling and uncoiling are conducted after finish rolling; the uncoiled plate blank enters a withdrawal and straightening machine, the insertion depth of a bending roller of the withdrawal and straightening machine iscontrolled to be 5-15 mm, and a hot-rolled coil obtained after withdrawal and straightening and descaling enters an acid pickling stage; and the hot-rolled coil is rinsed after taken out, wherein thechloride ion content of rinsing water is less than or equal to 10 mg / L, drying is carried out after rinsing, oiling is carried out, and then coiling is carried out to complete the method for preventing corrosion. According to the method for preventing corrosion of the high-manganese hot-formed steel after acid pickling, by controlling the components of the high-manganese hot-formed steel, the keytemperatures and processes of rough rolling and finish rolling, controlling the rolling rhythm, controlling the withdrawal and straightening parameter and operation in other aspects, occurrence of corrosion of the high-manganese hot-formed steel after acid pickling can be effectively prevented, and the method is simple, high in applicability and remarkable in effect.

Owner:SHOUGANG CORPORATION +1

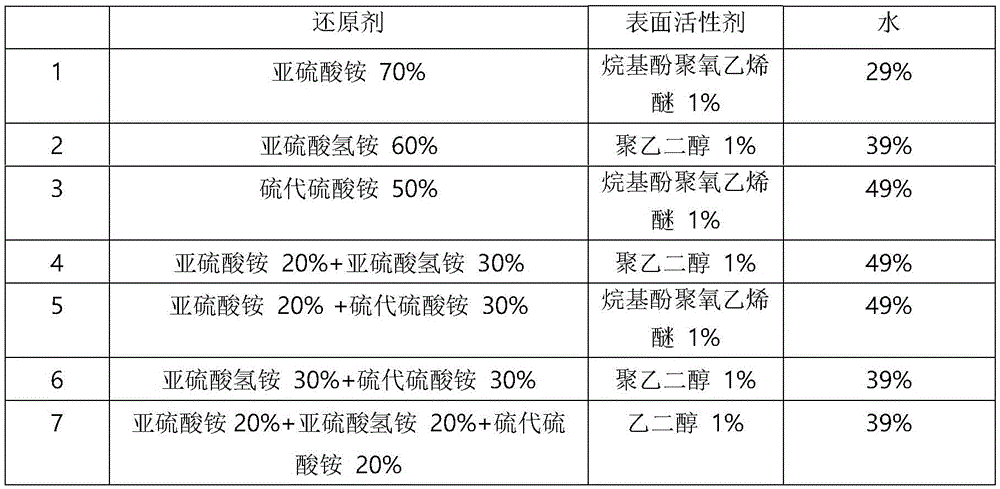

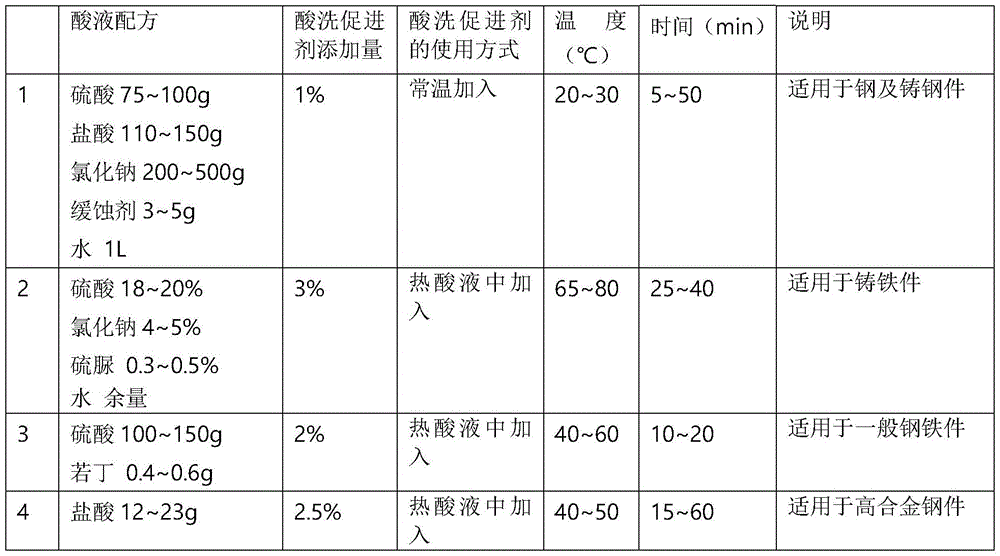

Steel acid pickling accelerant not containing metal elements and application method of steel acid pickling accelerant

ActiveCN105568301AIncrease pickling speedIncrease production capacitySurface-active agentsMetallurgy

The invention provides an efficient steel acid pickling accelerant not containing metal elements. The steel acid pickling accelerant is composed of a reducing agent and a surface active agent. The steel acid pickling speed can be greatly increased or the acid pickling temperature can be reduced as long as a small number of accelerants are added, and therefore the purposes of improving productivity, reducing acid mist, saving energy and reducing emission are achieved.

Owner:SUZHOU CANASTAR NEW MATERIALS TECH CORP

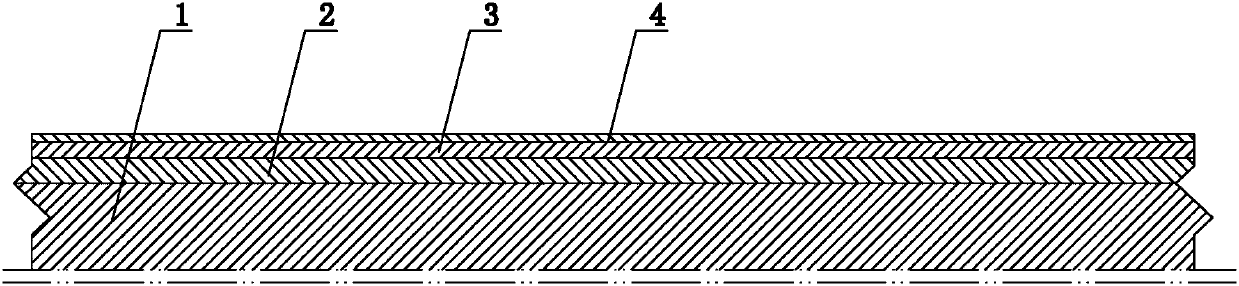

Pickling device for stones

ActiveCN107512720ASolve the problem of insufficient removal of impuritiesTake advantage ofSilicaAcid concentrationEngineering

The invention belongs to the technical field of stone impurity removal, and specifically discloses a pickling device for stones. The pickling device comprises a sand washing cylinder, an acid collecting tank and a motor; the acid collecting tank is communicated with the lower surface of the sand washing cylinder, and a valve is arranged at a connection part of the acid collecting tank and the sand washing cylinder; the sand washing cylinder is internally provided with an annular grid, and a sieving unit which comprises a filter layer, a separation layer and a support layer from top to bottom in sequence; a part, in the annular grid, of the filter layer is provided with mesh openings, a part, in the annular grid, of the support layer is provided with an opening; the separation layer is connected between the filter layer and the support layer in a sliding way, one end of the separation layer is connected with a spring which is fixed on the inner wall of the sand washing cylinder, and the other end of the separation layer is provided with a weighting block which is located on the outer wall of the sand washing cylinder; one side, near the spring, of the separation layer is provided with a through hole. After the pickling device is adopted, impurity removal and purification on the stones such as quartz sand can be realized, the quartz sand can be pickled with acids with different acid concentrations according to the quartz sand with different volumes, so that the degree of pickling can be effectively controlled and the pickling quality is ensured.

Owner:中石合创北京科技有限公司

Acid pickling process method for high-temperature coiled material and application

The invention discloses an acid pickling process for a high-temperature coiled material. The contents of the acid pickling process for the high-temperature coiled material comprises the following steps that 1) withdrawal and straightening scale breaking is conducted on strip steel in a withdrawal and straightening machine, and the withdrawal and tension is controlled to be that the tensile stressin the strip steel is controlled to be exceeded 0-20% of the yield limit of a material; the insertion depth of the withdrawal and straightening machine is 0.4 D + (3-10) mm, and D is the diameter of ascale breaking roller; and 2) the strip steel subjected to the scale breaking enters acid tanks to be subjected to acid pickling, and the strip steel sequentially enters three acid tanks, the mass concentrations of hydrochloric acid in the acid tanks are 4 + / -1%, 10 + / -2% and 12 + / -2% correspondingly, and the corresponding acid tank temperatures are set to be 85 + / -2 DEG C, 80 + / -3 DEG C and 75 + / -3 DEG C correspondingly, and the circulation amount of pickling solution in the acid tanks is not less than 230 m<3> / hour. According to the acid pickling process for the high-temperature coiled material, by controlling the withdrawal and straightening scale breaking parameters and the pickling process parameters, the pickling speed of the high-temperature coiled material can be greatly increased, the phenomenon of insufficient pickling of the strip steel is prevented, and meanwhile, the consumption of the hydrochloric acid in the pickling process can be greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

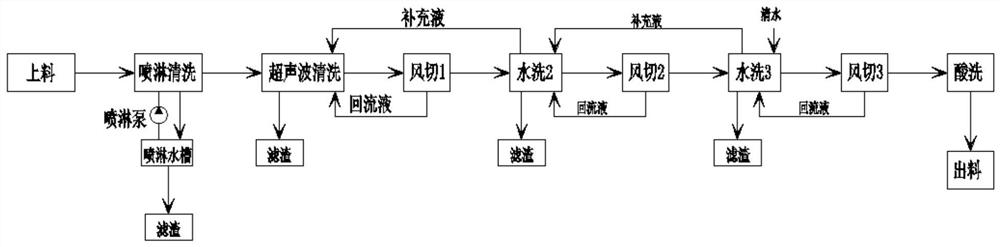

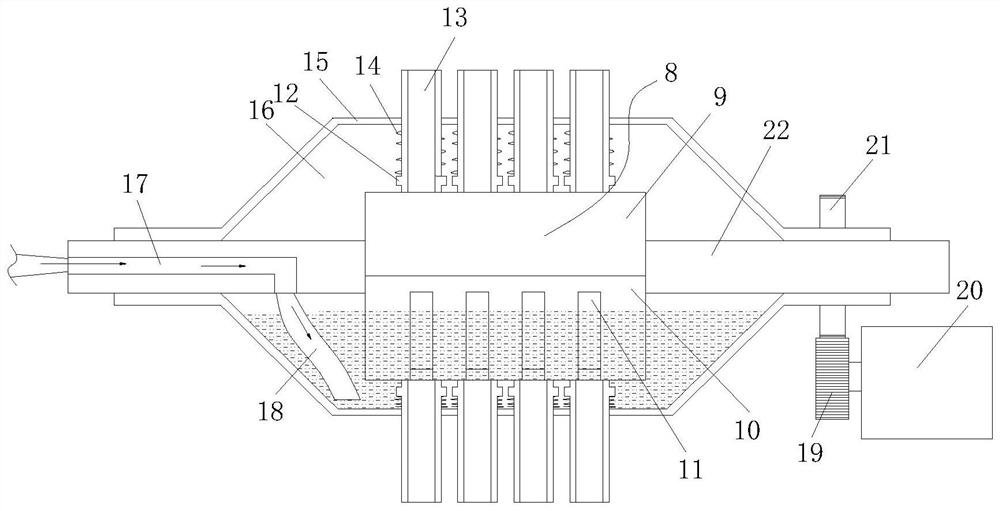

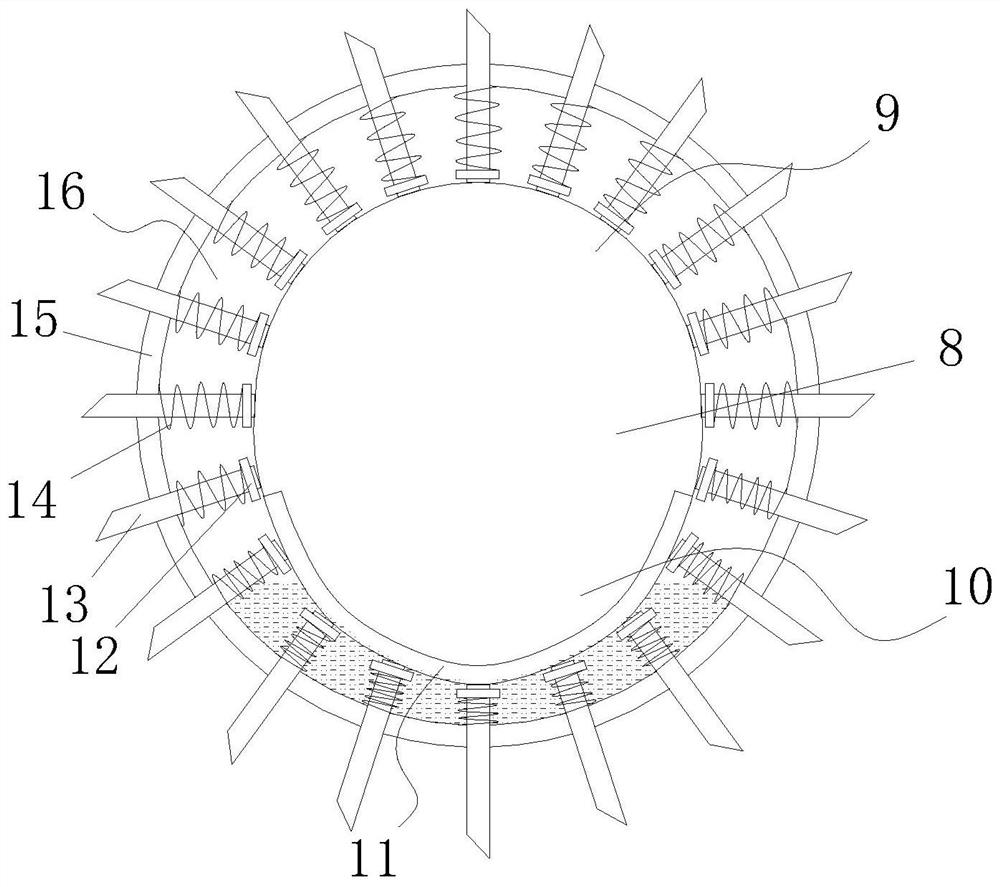

Application of ultrasonic cleaning machine in fastener hot galvanizing intelligent production line system

InactiveCN112222090AGood degreasing effectFast degreasingDrying gas arrangementsCleaning using liquidsUltrasonic cavitationCleansing Agents

The invention discloses an application process in the technical field of fastener hot galvanizing intelligent production. The application process comprises the following steps that spraying cleaning is conducted, specifically, a high-pressure pump is used for circularly spraying cleaning liquid to the surface of a fastener, and dust and the like on the surface of the fastener are flushed off; ultrasonic cleaning is conducted, specifically, the fastener reaches an ultrasonic cleaning station along with a crawler belt and is immersed in cleaning liquid, and an ultrasonic generator impacts the surface of the fastener through mechanical vibration with high ultrasonic cavitation seepage force and is combined with the decontamination effect of a cleaning agent to clean away oil stains on the surface of the fastener; slitting 1, high-pressure air is used for purging the surface of the fastener, so that liquid on the surface falls back into a groove, and the situation that the liquid is brought into the next procedure to pollute working liquid is avoided; and water washing 1, wind shearing 2, water washing 2, wind shearing 3 and acid pickling are conducted, and finally discharging is conducted. According to the application process, the oil removal effect is good, the oil removal speed is high, the subsequent acid time and the acid consumption are reduced, the subsequent waste acid cleanliness is high, resource utilization is facilitated, the subsequent acid pickling speed is increased, equipment integration is achieved, the occupied area is small, and the automation degree is high.

Owner:徐州瑞马智能技术有限公司

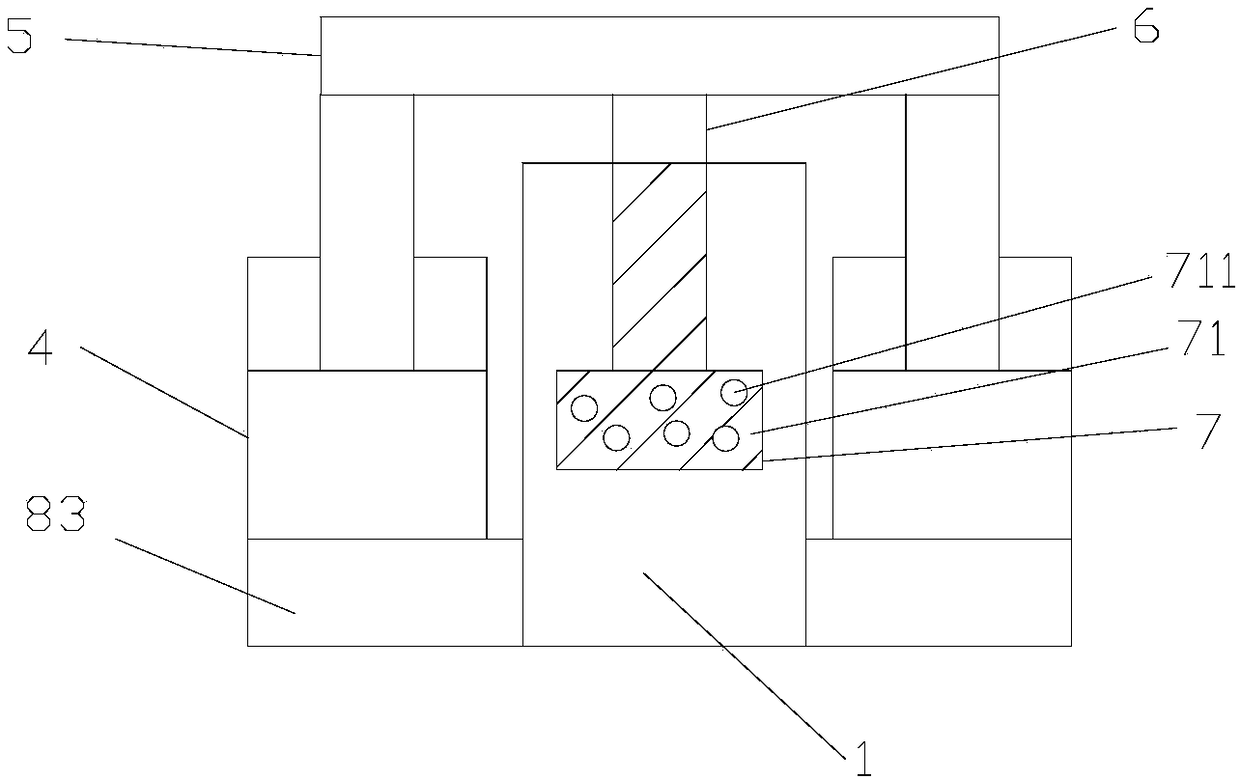

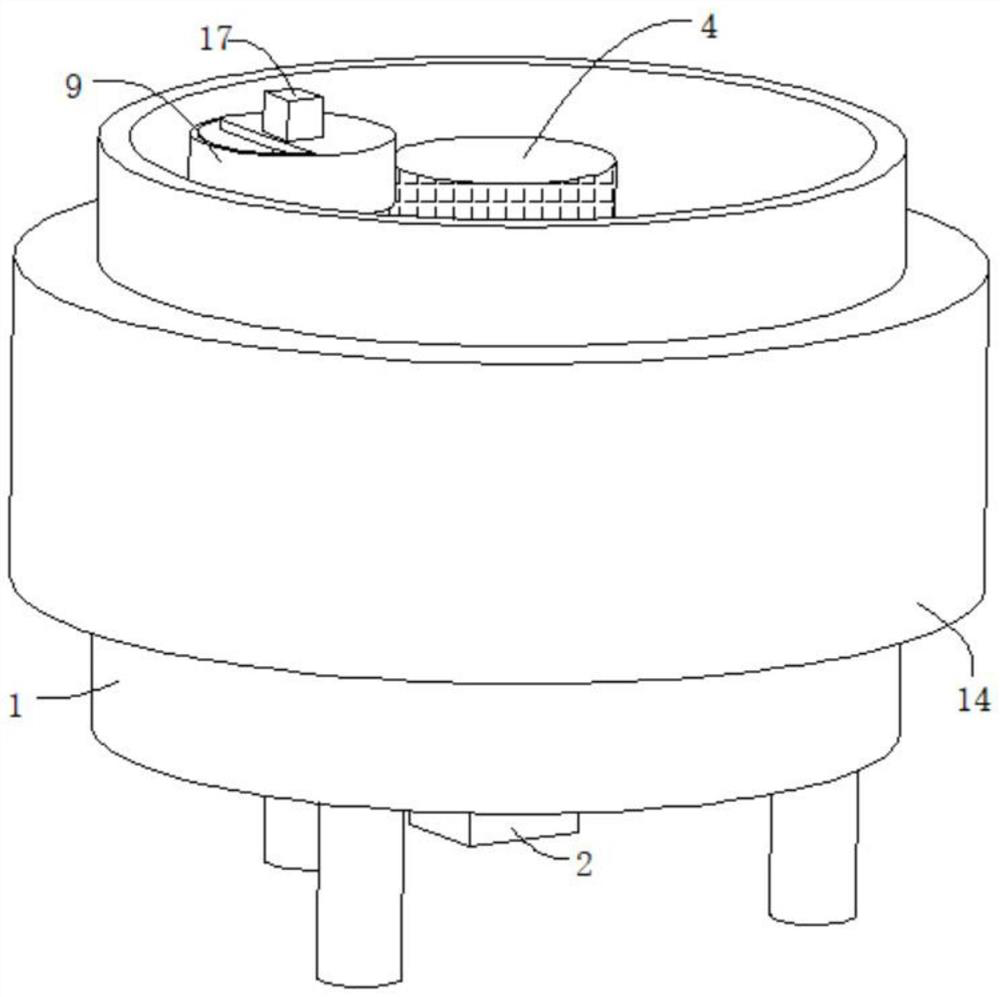

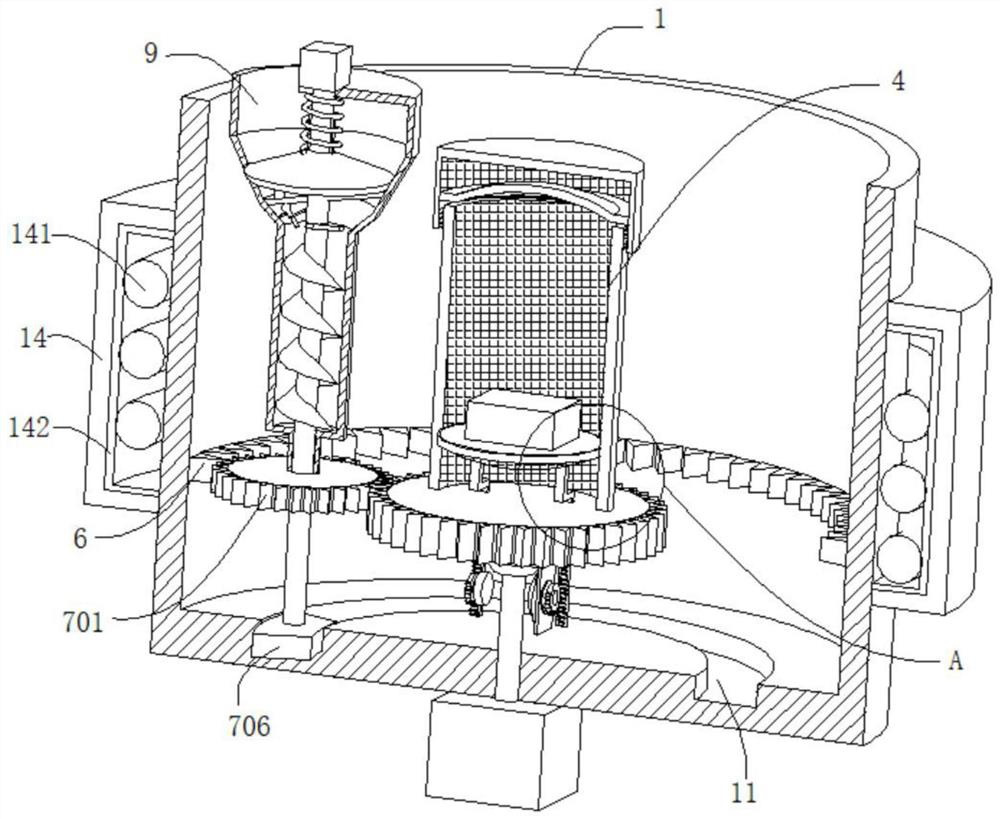

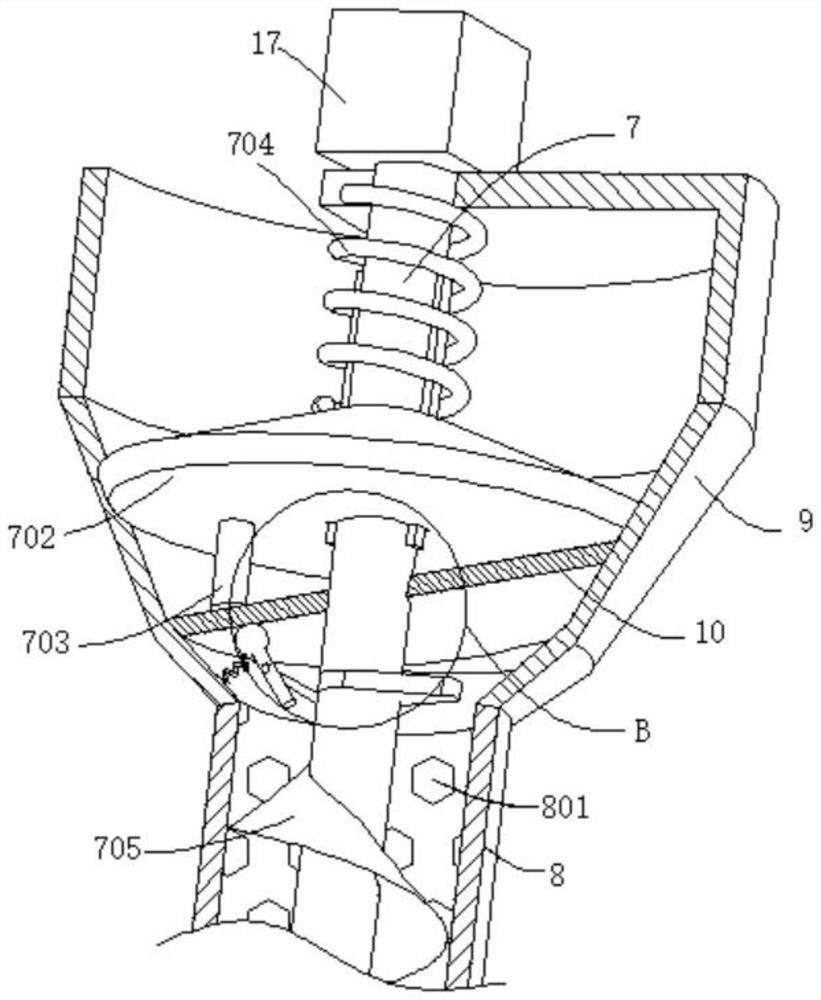

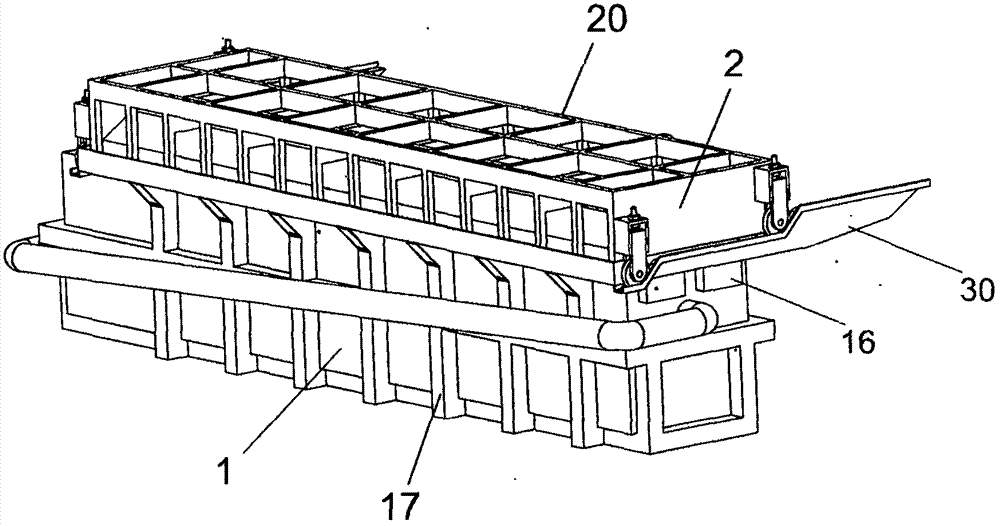

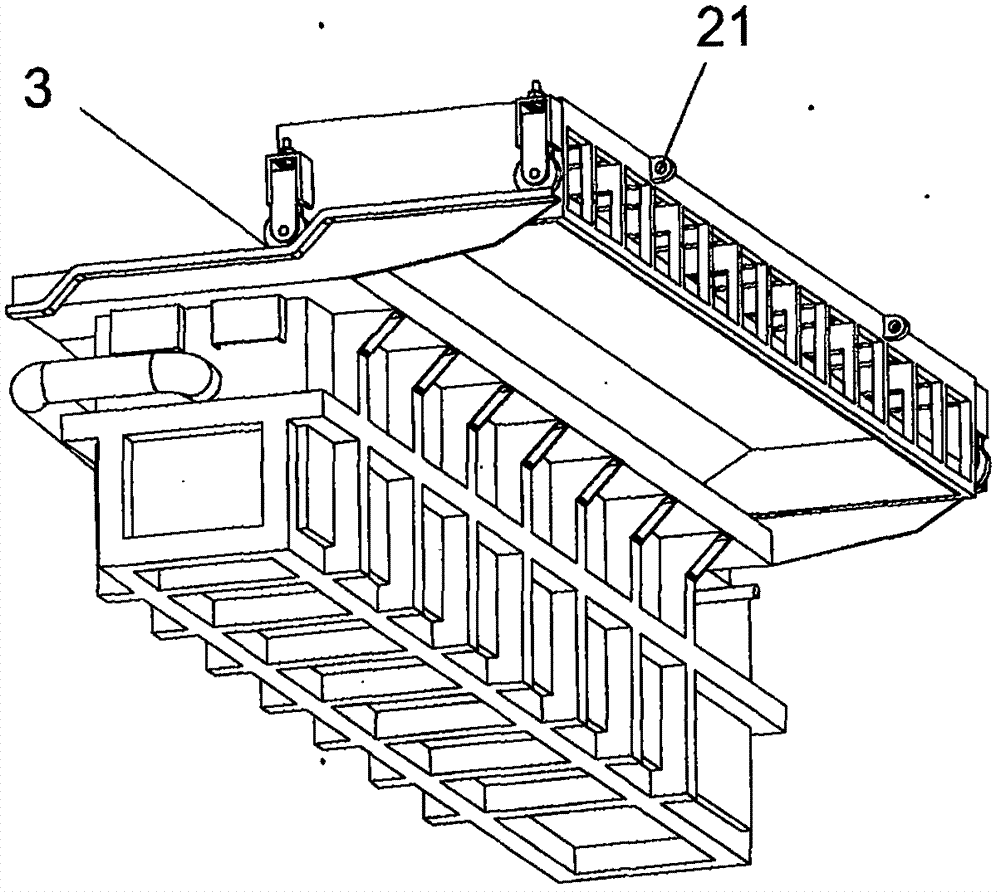

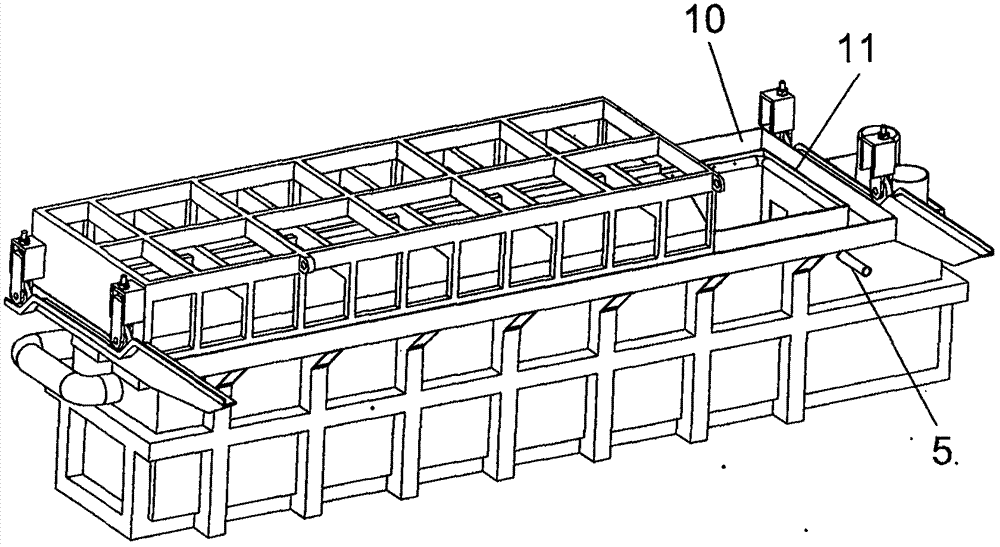

Chicken breast pickling device

PendingCN113491321AIncrease the speed of diffusionImprove processing efficiencyFood shapingBiotechnologyChicken breast

The invention relates to the technical field of meat pickling equipment, in particular to a chicken breast pickling device. The device comprises a rack and a conveying belt used for conveying meat pieces, a supporting plate is arranged at the bottom of the conveying belt, and a plurality of positive pressure liquid filling mechanisms used for injecting marinade liquid into the meat pieces are arranged above the conveying belt. A plurality of negative pressure suction mechanisms used for outwards sucking the marinade liquid in the meat pieces are arranged above the conveying belt, and injection ports of the positive pressure liquid filling mechanisms to the meat pieces and suction ports of the negative pressure suction mechanisms to the meat pieces are distributed in a staggered manner. The device is reasonable in design in the working process, the diffusion speed of the marinade liquid in the meat pieces can be increased, the marinade speed of the meat pieces is increased, and the meat production and processing efficiency can be improved.

Owner:安徽徽之润食品股份有限公司

Nano additive used for steel pipe pickling solution and preparation method for nano additive

The invention discloses a nano additive used for a steel pipe pickling solution and a preparation method for the nano additive. The nano additive is chemically modified nano lanthanum borate emulsion or / and nano cerium borate emulsion. A chemical modification agent adopts oleic acid and a surfactant. The surfactant is selected from any one or more of alkylbenzene sulfonate, fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylates. The pickling solution is prepared by the nano additive and hydrochloric acid. The nano additive accounts for 0.01-2.0 wt% of the pickling solution. Compared with a hydrochloric acid pickling solution which does not contain a nano additive, the hydrochloric acid pickling added with the chemically modified nano lanthanum borate emulsion or / and the nano cerium borate emulsion can significantly reduce acid mist, improve the pickling efficiency and save the pickling time. An oxide skin on the surface of a pickled steel pipe is thoroughly removed, and the surface is uniform.

Owner:SHANGHAI INST OF TECH

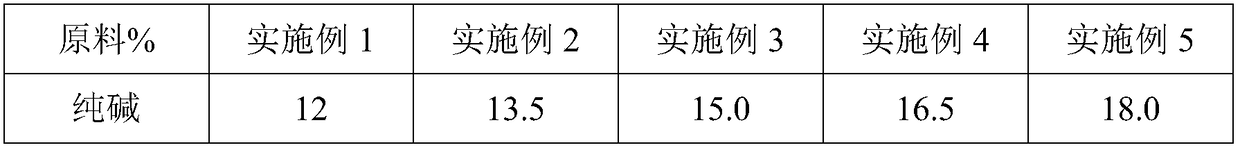

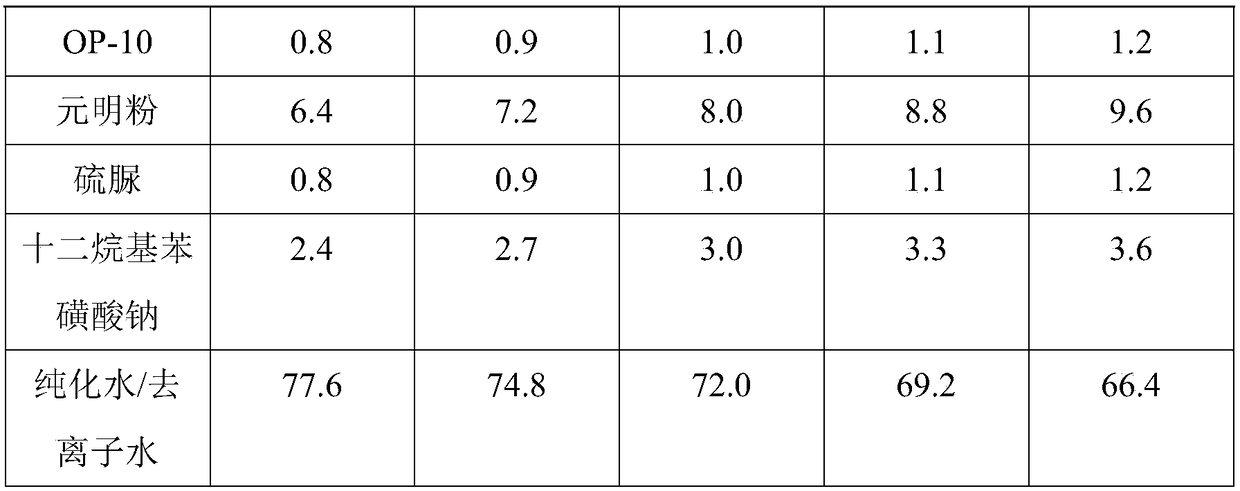

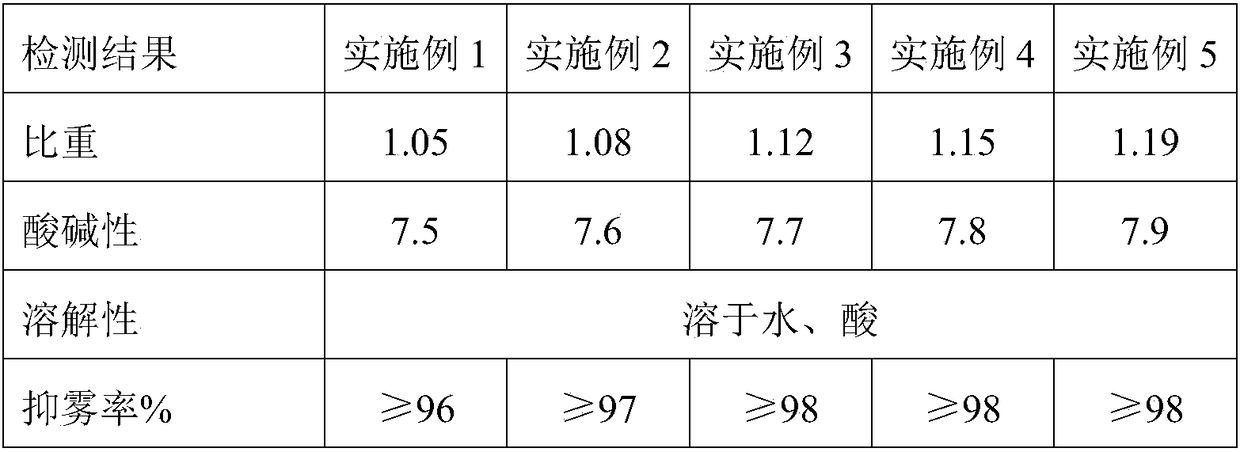

A nitric acid fog inhibitor and a preparing method thereof

The invention belongs to the technical field of metal material surface treatment and particularly relates to a nitric acid fog inhibitor and a preparing method thereof. The fog inhibitor includes, bymass, 12.0-18.0% of sodium carbonate, 0.8-1.2% of an emulsifier, 6.4-9.6% of sodium sulphate, 0.8-1.2% of thiourea and 2.4-3.6% of a surfactant, with the balance being water. The method includes adding the sodium carbonate, the emulsifier, the sodium sulphate, the thiourea and the surfactant into a reactor in order, then slowly adding water, and stirring the materials until all the materials are dissolved. The fog inhibitor prepared from the raw materials and by the method can meet demands on nitric acid fog inhibition in the steel acid pickling industry, and effectively avoid steel loss and waste of acid pickling liquid which are caused by overpickling.

Owner:泉州罕韩环保科技有限公司

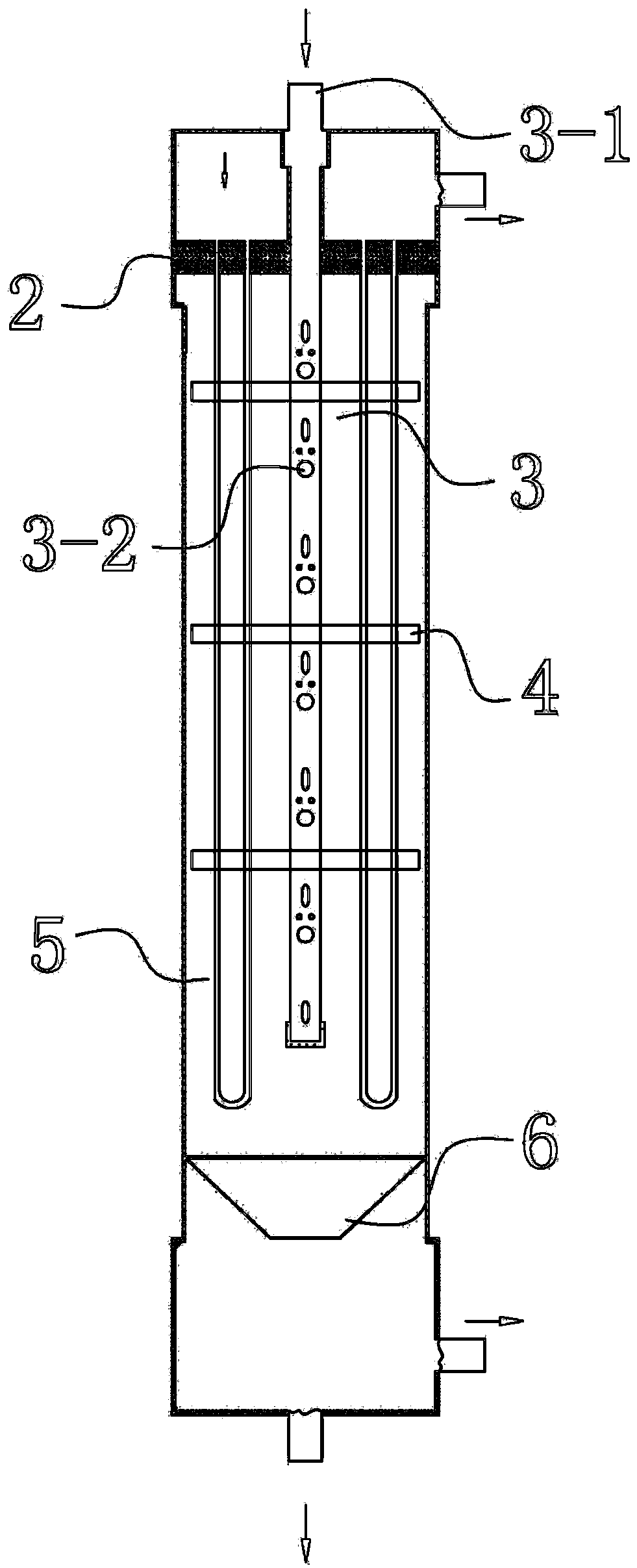

Environment-protecting nickel-iron-chromium electrothermal alloy pickling treatment device

The invention provides an environment-protecting nickel-iron-chromium electrothermal alloy pickling treatment device. The environment-protecting nickel-iron-chromium electrothermal alloy pickling treatment device comprises a pickling tank, wherein the bottom wall of the pickling tank is connected with a first motor, and the output end of the first motor is connected with a rotating shaft; the end,far away from the first motor, of the rotating shaft penetrates through the pickling tank and is connected with a first gear, the top of the first gear is connected with a filter screen cylinder, anda metal workpiece is placed in the filter screen cylinder; a rack ring is connected to the inner wall of the pickling tank, and a second gear is connected between the rack ring and the first gear ina meshed mode; and a conveying pipe is connected to the outer wall of the second gear, discharging holes which are evenly distributed are dug in the outer wall of the conveying pipe, and a rotating rod is rotationally connected into the second gear through a bearing. According to the environment-protecting nickel-iron-chromium electrothermal alloy pickling treatment device, hydrochloric acid is added into the pickling tank, so that the concentration of a pickling solution in the pickling tank is ensured to be sufficient, then the pickling effect and the pickling efficiency of the alloy workpiece are ensured, and the percent of pass of a finished product is ensured.

Owner:杭州海科杭环科技有限公司

Stainless steel acid pickling accelerant and application thereof

The invention discloses a stainless steel acid pickling accelerant. The stainless steel acid pickling accelerant comprises, by weight, 20-30 parts of peel extract, 10-20 parts of sodium citrate, 5-9 parts of polyacrylamide, 5-10 parts of thiourea, 4-10 parts of polylactic acid, 2-5 parts of eugenol, 3-7 parts of linalool, 2-5 parts of polyoxyethylene octylphenol ether, 2-5 parts of fatty alcohol-polyoxyethylene ether, 1-2 parts of surfactants and 30-60 parts of deionized water. The invention further discloses application of the stainless steel acid pickling accelerant. The stainless steel acid pickling accelerant is stable in performance, good in dispersibility, nontoxic, odorless, few in use amount, free of environment pollution, capable of effectively increasing the stainless steel acid pickling speed and capable of being widely applied to removing surface scales of silicon steel.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

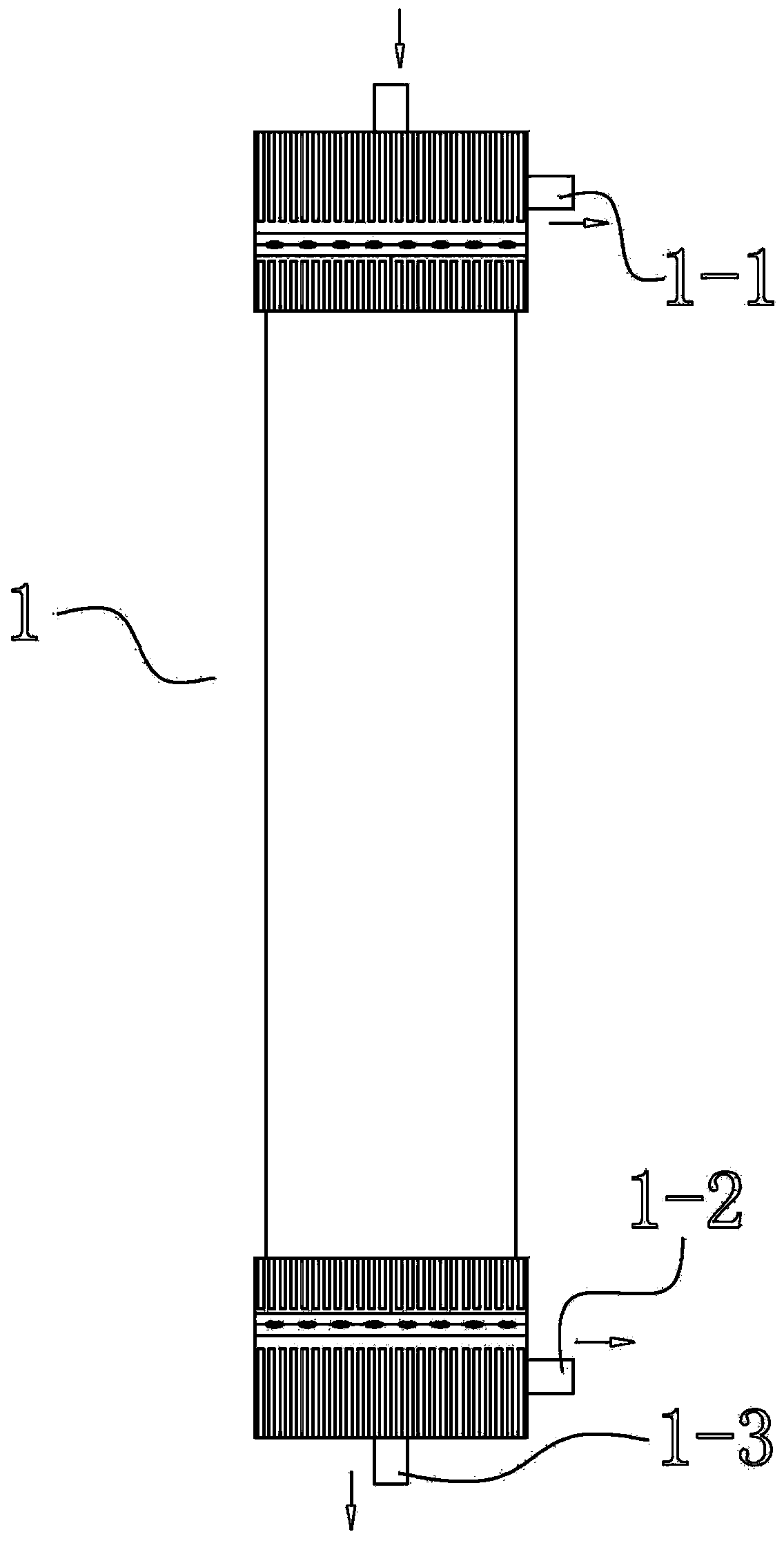

A stainless steel pipe pickling tank

The invention provides a stainless steel pipe pickling tank which comprises a tank body and a tank cover. An opening is formed in the upper portion of the tank body. A water storage tank surrounding the opening is arranged on the opening. The tank cover is buckled in the water storage tank. The tank cover can be opened along one side of the tank body in a sliding mode. The pickling tank further comprises a tank cover lateral sliding mechanism. The tank cover lateral sliding mechanism comprises a lifting guide rail, rollers arranged on the two sides of the tank cover and matched with the guide rail, an acid fluid circulating device and a spraying system, wherein the acid fluid circulating device comprises a suction pump, a fluid pumping pipe and a fluid discharge pipe, and the fluid pumping pipe and the fluid discharge pipe are arranged on the suction pump; the spraying system is arranged in the tank body. A gas pumping cavity is formed in one end of the tank body, and a gas inlet channel is formed in the other end of the tank body. The tank cover and the water storage tank are sealed in a water injection mode. The lateral sliding type tank cover is compact in equipment structure. The acid fluid circulating device can improve the pickling effect and shorten pickling time. The spraying system can wash acid fluid on the inner cavity of the tank body and on steel pipes. Acid mist in the tank body is pumped away through a gas pumping box, and zero leakage of the acid mist is achieved.

Owner:温州宪江防腐设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com