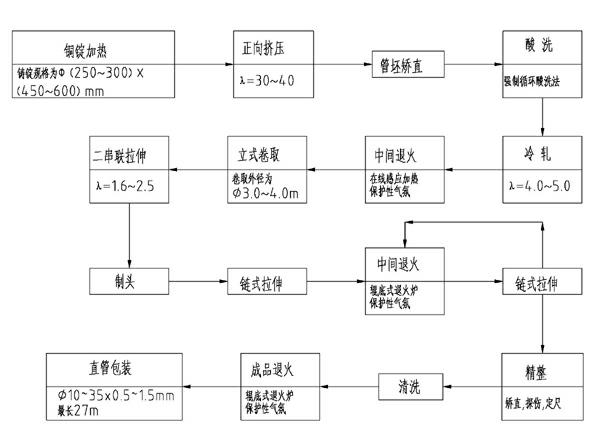

Production process of super long brass condenser pipe

A production process and condenser tube technology, which is applied in the field of ultra-long brass condenser tube production process, can solve the problems of short product length, low yield rate, and high energy consumption, and achieve increased yield rate, high production efficiency, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0010] Firstly, the large-scale ingots from the melting and casting workshop, with a specification of Φ(250-300)×(450-600)mm, are sent to the ingot induction heating furnace for preheating and homogenization treatment, and the temperature is 700-800°C. Then the preheated ingot is sent to the dephosphorization cleaning system to remove the scale produced during the heating process, and then the ingot with good quality is transported into the extrusion cylinder through the pushing device, and the peeling extrusion process is adopted, and the extrusion ratio λ is 30~40, extrude the tube billet with a length of 10~15 m, and then enter the tube billet straightening machine after cutting the head and tail for straightening. The straightened brass condenser pipe billet enters the pickling system and adopts forced circulation The pickling method avoids acid mist corrosion and obtains a bright tube billet with good quality. The pickled tube billet enters a cold rolling mill for cold rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com