Production method of 1800 MPa-grade cold-rolled steel for hot stamping forming

A technology of hot stamping forming and production method, which is applied in the production field of cold-rolled steel for 1800MPa-level hot stamping forming, can solve the problems of undisclosed key process and equipment of cold rolling welding, achieve reduction of energy consumption of production line, low alloy cost, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

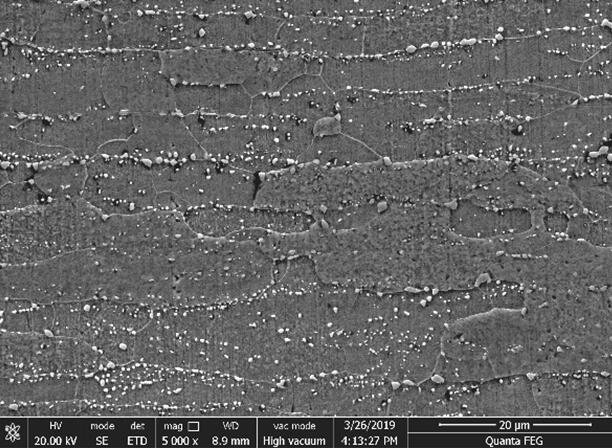

Image

Examples

Embodiment 1

[0033] Hot-rolled raw steel strip: thickness 3.2mm, yield strength 603MPa, tensile strength 740MPa, elongation after fracture A 50mm was 25.0%.

[0034] Primary Bell Furnace Annealing:

[0035] The annealing hot spot is 726°C / 733°C, the holding time is 18h, and the annealing process adopts a hydrogen atmosphere. The heating rate from room temperature to 650°C is 79.9°C / h, and the average hydrogen flow rate is 39.8m 3 / h; 650℃~700℃ heating rate is 33.9℃ / h, 700~740℃ heating rate is 24.8℃ / h, when the hot spot in the heating section is ≥650℃, the average hydrogen flow rate is 25.0m 3 / h. The average flow rate of hydrogen is 17.8m at 6 hours before heat preservation 3 / h. When cooling to 580°C, switch to air-cooling mode and cool at full speed, air-cool to 380°C, switch to water-cooling mode and cool at full speed, and the temperature of the oven is 98°C.

[0036] Continuous flash butt welding:

[0037] The welding mode is dripping oil + annealing mode, the flash voltage ...

Embodiment 2

[0047] Hot-rolled raw steel strip: thickness 3.0mm, yield strength 611MPa, tensile strength 752MPa, elongation after fracture A 50mm was 24.5%.

[0048] Primary Bell Furnace Annealing:

[0049] The annealing hot spot is 727°C / 731°C, the holding time is 18h, and the annealing process uses a hydrogen atmosphere. The heating rate from room temperature to 650°C is 80.0°C / h, and the average hydrogen flow rate is 39.9m 3 / h; 650℃~700℃ heating rate is 33.6℃ / h, 700~740℃ heating rate is 24.9℃ / h, when the hot spot in the heating section is ≥650℃, the average flow rate of hydrogen is 24.8m 3 / h. The average flow rate of hydrogen is 17.9m at 6h before heat preservation 3 / h. When cooling to 580°C, switch to air-cooling mode and cool at full speed, air-cool to 380°C, switch to water-cooling mode and cool at full speed, and the temperature out of the furnace is 95°C.

[0050] Continuous flash butt welding:

[0051] The welding mode is dripping oil + annealing mode, the flash volt...

Embodiment 3

[0061] Hot-rolled raw steel strip: thickness 2.4mm, yield strength 650MPa, tensile strength 765MPa, elongation after fracture A 50mm was 23.0%.

[0062] Primary Bell Furnace Annealing:

[0063] The annealing hot spot is 728°C / 734°C, the holding time is 18h, and the annealing process adopts a hydrogen atmosphere. The heating rate from room temperature to 650°C is 79.7°C / h, and the average hydrogen flow rate is 39.8m 3 / h; 650℃~700℃ heating rate is 33.8℃ / h, 700~740℃ heating rate is 25.0℃ / h, when the hot spot in the heating section is ≥650℃, the average flow rate of hydrogen is 24.9m 3 / h. The average flow rate of hydrogen is 18.0m at 6 hours before heat preservation 3 / h. When cooling to 580°C, switch to air-cooling mode and cool at full speed; when air-cooling to 380°C, switch to water-cooling mode and cool at full speed, and the temperature out of the oven is 97°C.

[0064] Continuous flash butt welding:

[0065] The welding mode is dripping oil + annealing mode, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com