Environment-protecting nickel-iron-chromium electrothermal alloy pickling treatment device

An electrothermal alloy and processing device technology, which is applied in the field of environmentally friendly nickel-iron-chromium electrothermal alloy pickling processing devices, can solve the problems of insufficient pickling effect of alloys, and achieve the effects of improving stability, uniform concentration and ensuring pickling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

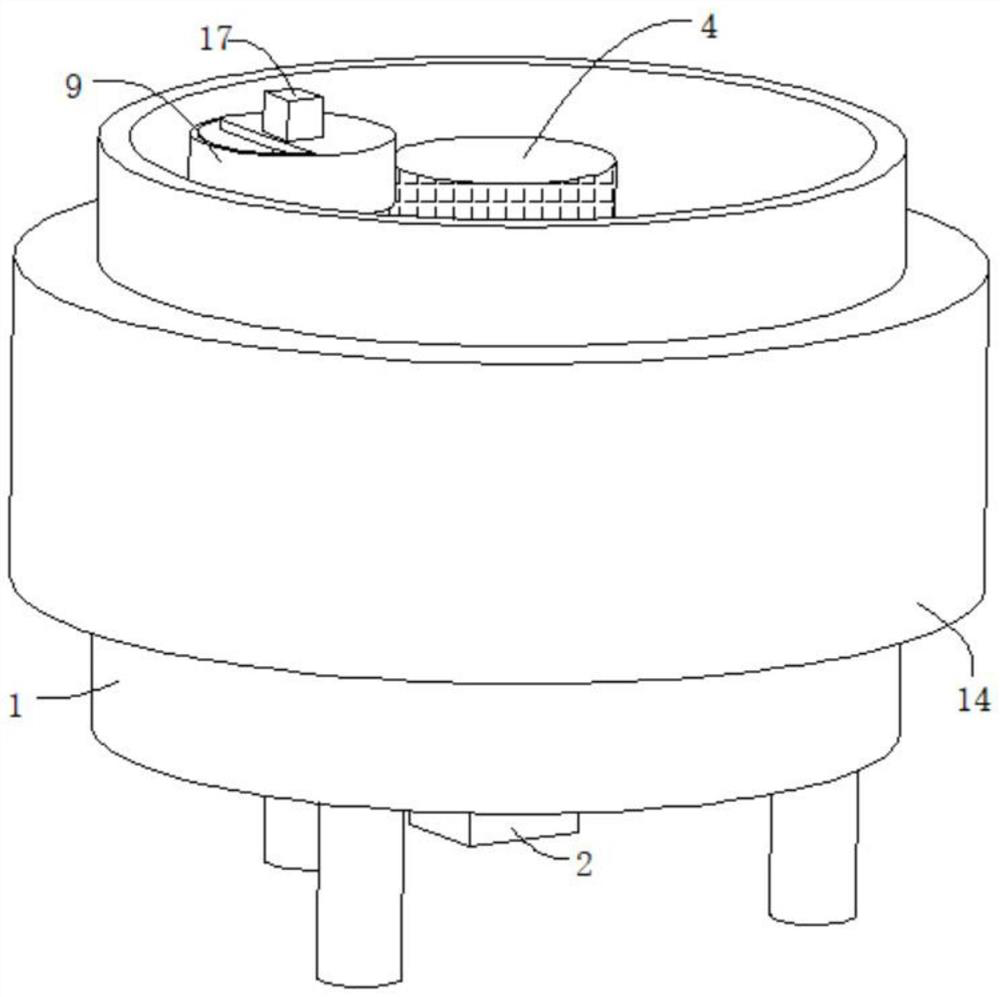

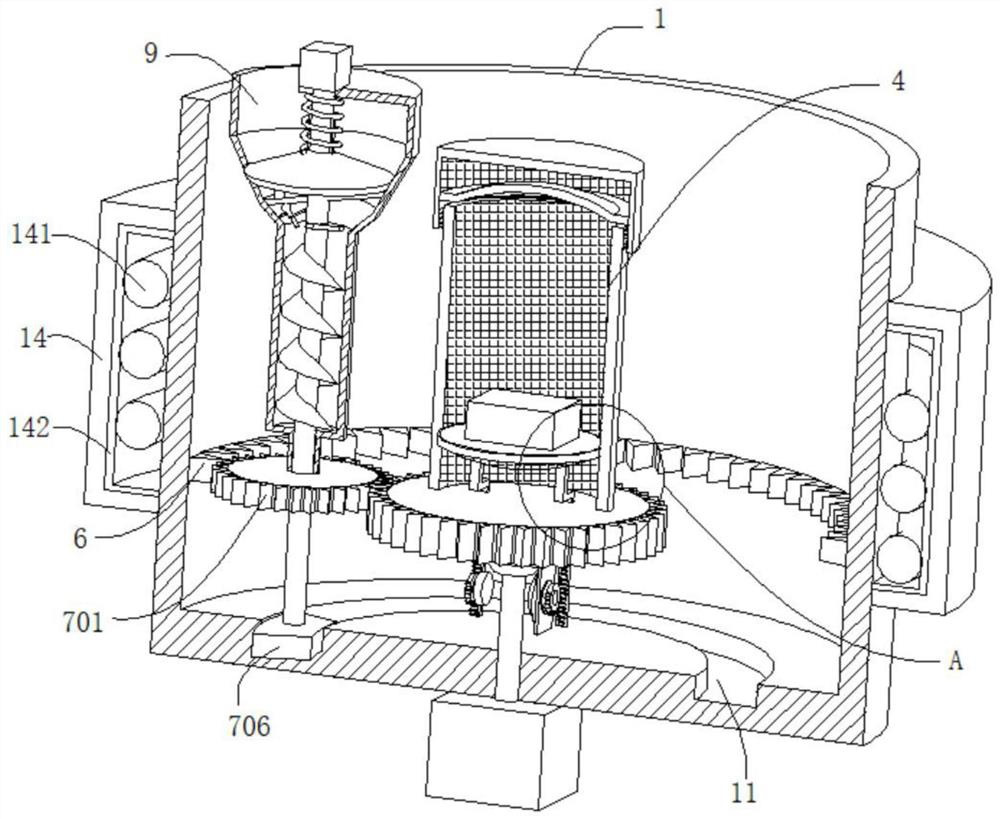

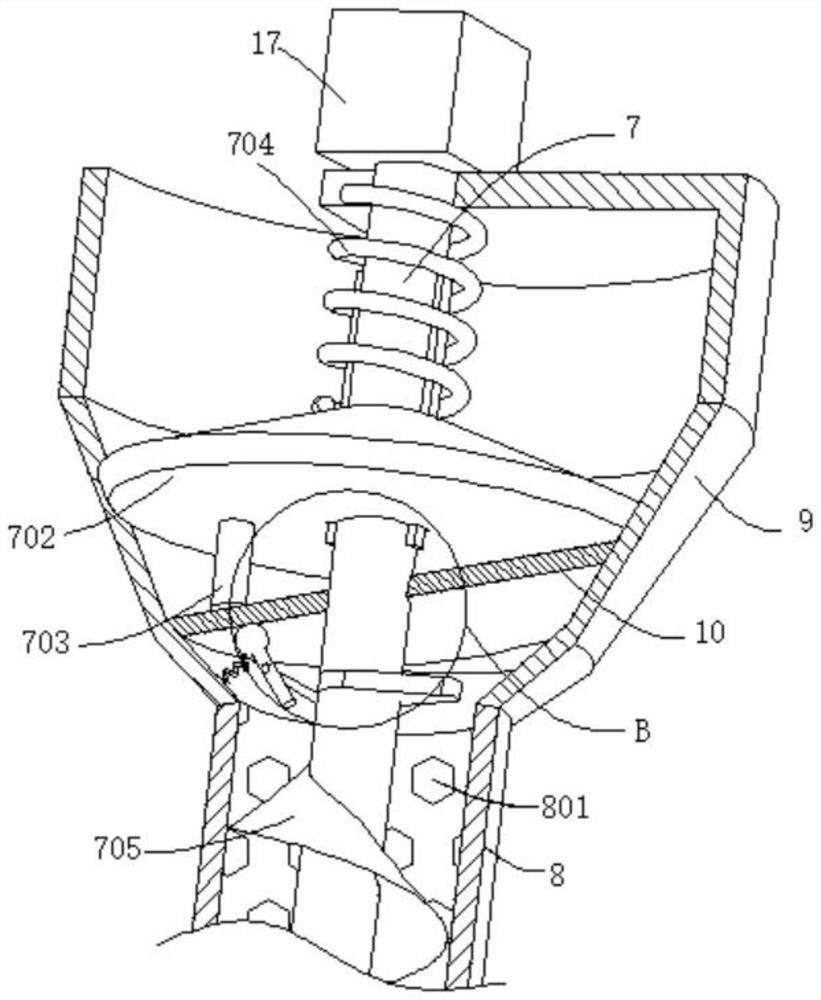

[0036] refer to figure 1 , figure 2 , image 3 and Figure 7, an environment-friendly nickel-iron-chromium electrothermal alloy pickling treatment device, comprising a pickling tank 1, the bottom wall of the pickling tank 1 is connected with a first motor 2, the output end of the first motor 2 is connected with a rotating shaft 201, and the rotating shaft 201 The end away from the first motor 2 passes through the pickling tank 1 and is connected to the first gear 3, the top of the first gear 3 is connected to the filter cylinder 4, and the metal parts 5 are placed in the filter cylinder 4, and the pickling tank 1. The inner wall is connected with the rack ring 6, and the second gear 701 is connected between the rack ring 6 and the first gear 3. The outer wall of the second gear 701 is connected with the feeding pipe 8, and the outer wall of the feeding pipe 8 is dug with evenly distributed The discharge hole 801, the second gear 701 is rotatably connected with the rotating...

Embodiment 2

[0039] refer to figure 2 , Figure 4 , Figure 5 and Figure 6 , an environment-friendly nickel-iron-chromium electrothermal alloy pickling treatment device, which is basically the same as that of Embodiment 1, furthermore, the filter cylinder 4 includes a cylinder body 401 and a cylinder cover 402, and the outer wall of the cylinder body 401 is fixed with an external thread 4011 The inner wall of the cylinder cover 402 is fixed with an internal thread 4021 matching the external thread 4011, and the cylinder body 401 and the inner wall of the cylinder cover 402 are respectively connected with a first elastic filter 4012 and a second elastic filter 4022, and the metal parts 5 are placed Between the first elastic filter screen 4012 and the second elastic filter screen 4022, the outer wall of the rotating shaft 201 is connected with the first bevel gear 2011, the outer wall of the rotating shaft 201 is connected with the fixed frame 12, and the first bevel gear 2011 is rotatab...

Embodiment 3

[0042] refer to Figure 1-3 , an environment-friendly nickel-iron-chromium electrothermal alloy pickling treatment device, which is basically the same as that of Embodiment 1, furthermore, the inner wall of the feed tank 9 is connected with a fixed rod 901, and the outer wall of the fixed rod 901 is rotatably connected with a swing rod 902. A second elastic element 903 is connected between the rod 902 and the inner wall of the feed tank 9, a rubber hammer 904 is connected to the outer wall of the swing rod 902, and the rubber hammer 904 is movable against the bottom wall of the filter screen 10, and a cam 707 is connected to the outer wall of the rotating rod 7 , the cam 707 and the swing rod 902 move against each other; the cam 707 squeezes the swing rod 902, so that the swing rod 902 rotates with the fixed rod 901 as the center of a circle, and the second elastic element 903 is compressed, so that the rubber hammer 904 hits the filter screen 10, Make the hydrochloric acid sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com