A comprehensive test device for anti-clogging performance of drip irrigation emitters

A comprehensive test and sprinkler technology, applied in the direction of measuring devices, machine/structural component testing, mechanical component testing, etc., can solve the problems of different standards, single function, limited intelligence, etc., to achieve high synchronization, Uniform particle concentration in water body, flexible and convenient test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

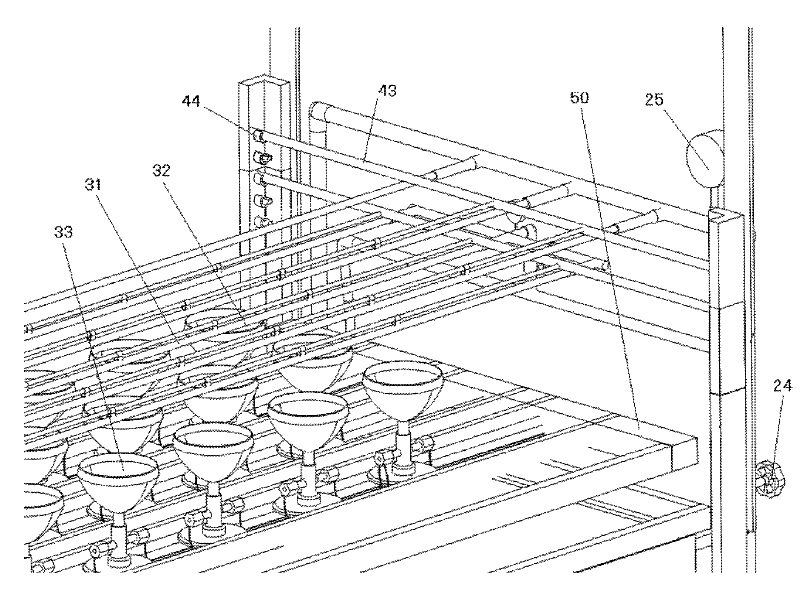

[0024] Such as figure 1 As shown, the present invention includes a frame, a set of water supply system 10 is arranged below the frame, a set of drip irrigation system 30 is arranged above the frame, and a composite mobile device 50 is arranged on the frame below the drip irrigation system 30, the composite mobile device A sump 70 is arranged on the frame below the sump 50, and a water outlet (not shown) is arranged at the bottom of the sump 70 .

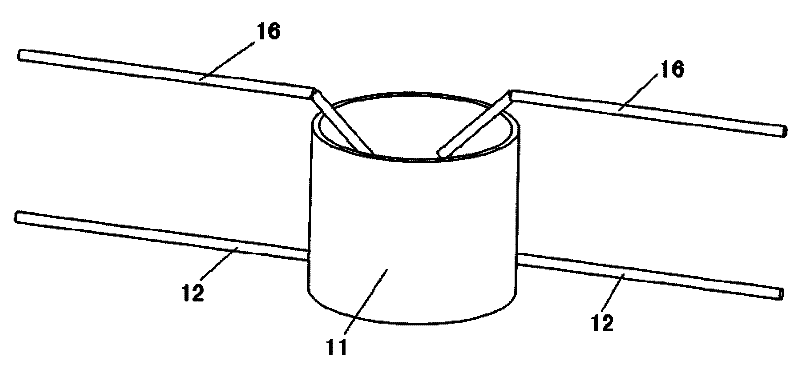

[0025] Such as figure 1 , figure 2 As shown, the water supply system 10 of the present invention includes a regulating water tank 11 located at the top opening below the water outlet of the sump 70. The bottom of the regulating water tank 11 is provided with a drain valve (not shown in the figure), and its side is provided with two valves with height Poor water pump suction pipe 12, the other end of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com