Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about How to "In line with the design concept" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

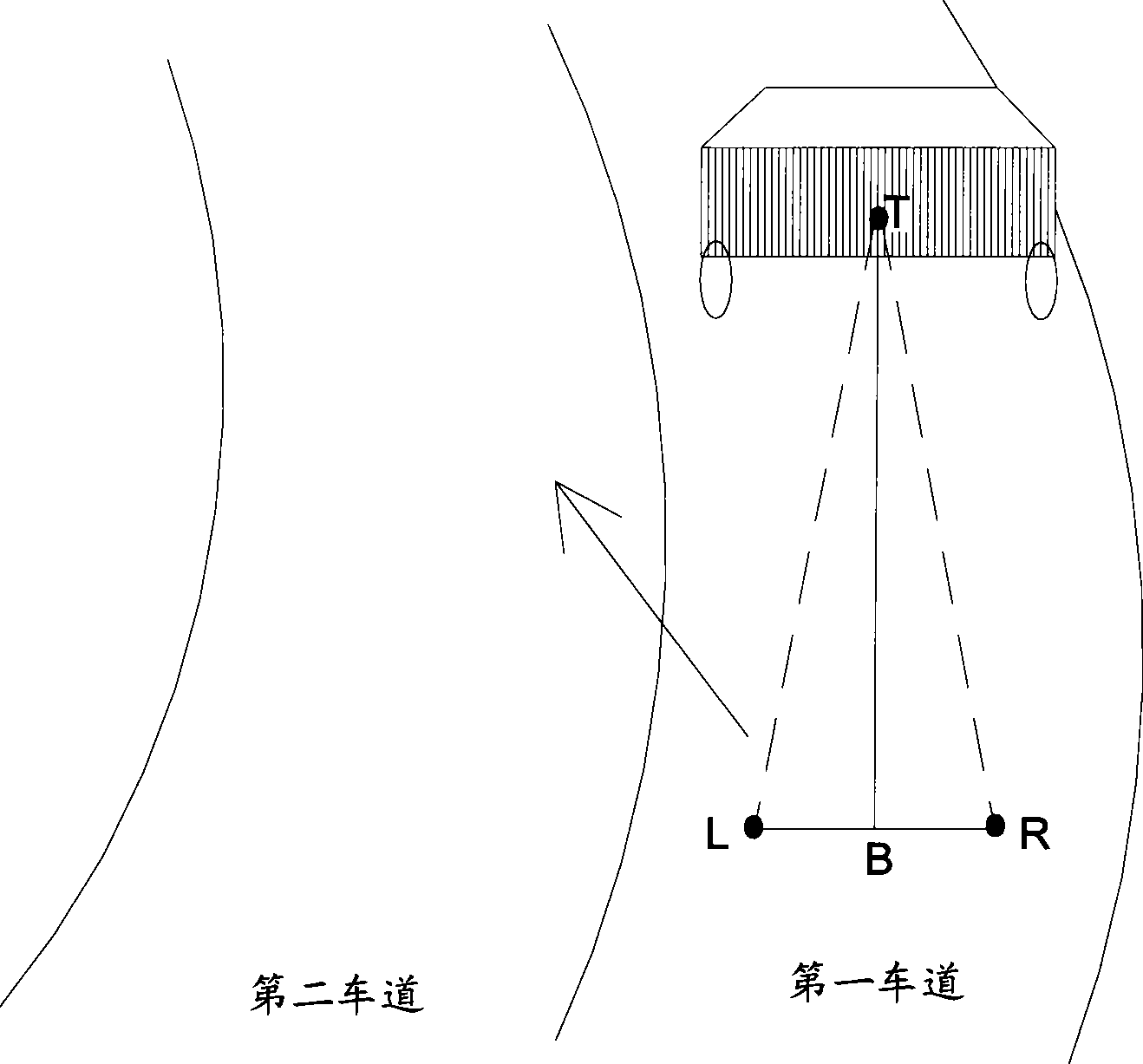

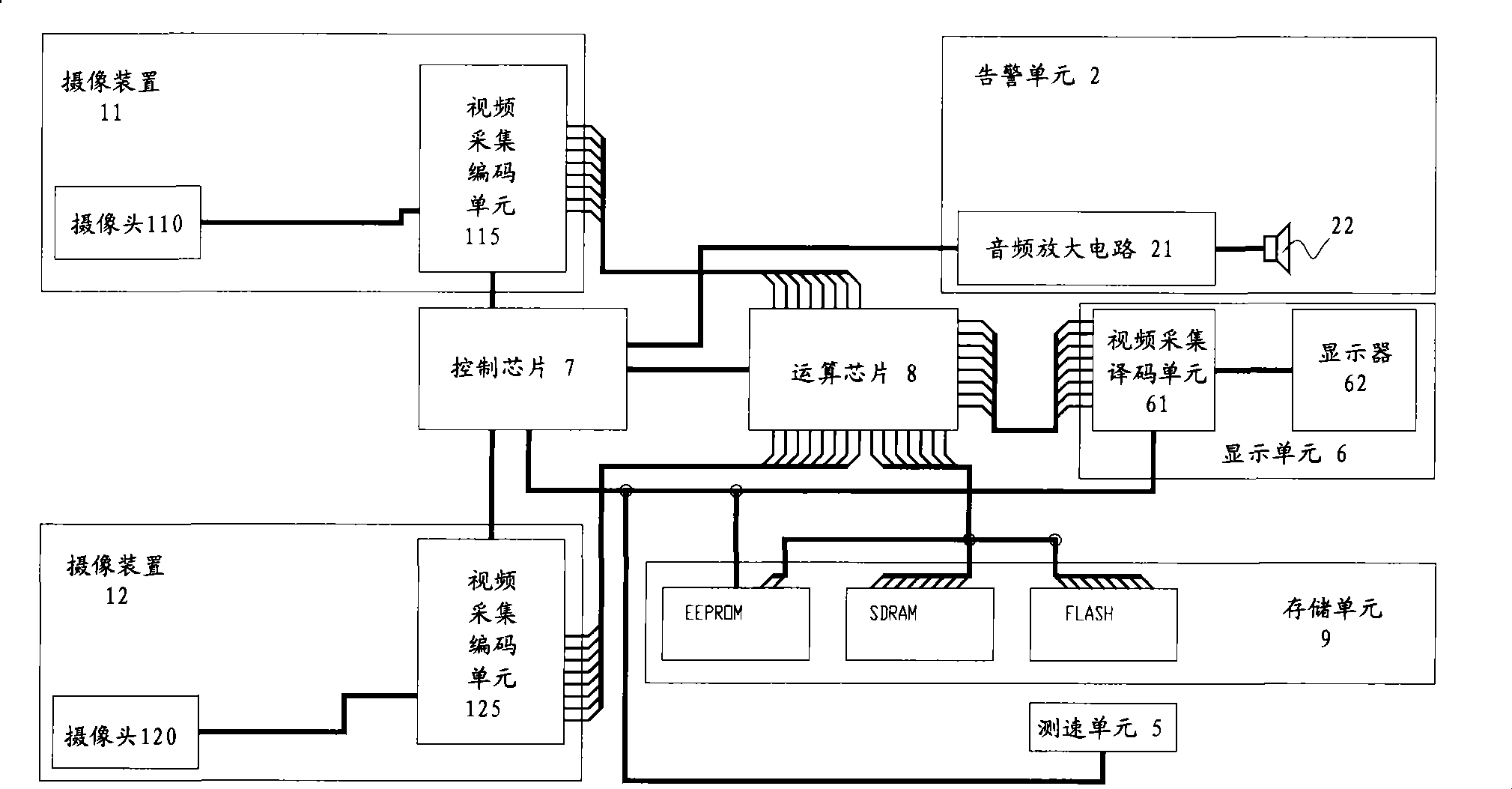

Vehicle obstacle-avoidance warning system and corresponding circuit thereof

InactiveCN101450646AImprove securityEasy to implementOptical rangefindersAcoustic signal devicesObstacle avoidanceVIT signals

The invention discloses an obstacle-avoidance warning system for a vehicle. The system comprises a camera unit, a synthesis module, a distance measuring module, a calculating module and a warning unit, wherein the camera unit placed at the front part of a vehicle body and shooting road condition images in front of the vehicle body from two different visual angles on a same horizontal line; the synthesis module is used for synthesizing the images of the two different visual angles; the distance measuring module is used for measuring distance between the vehicle body and an obstacle by using the synthesized front and back images; the calculating module is used for calculating collision time difference by using the distance, and generating a signal with mark meaning when the calculating collision time difference is equal to or larger than a preset value; and the warning unit is acted by the signal with the mark meaning to warn. Moreover, the invention also discloses a corresponding circuit of the system, and application of the system on an automatic navigation automobile. By integrating multiple advanced techniques of different domains, the automobile has higher safety; and the system improves intelligent degree of the automobile, and is convenient for wide popularization and application based on the advantages of low cost, high performance, strong portability, and the like.

Owner:STEELMATE CO LTD

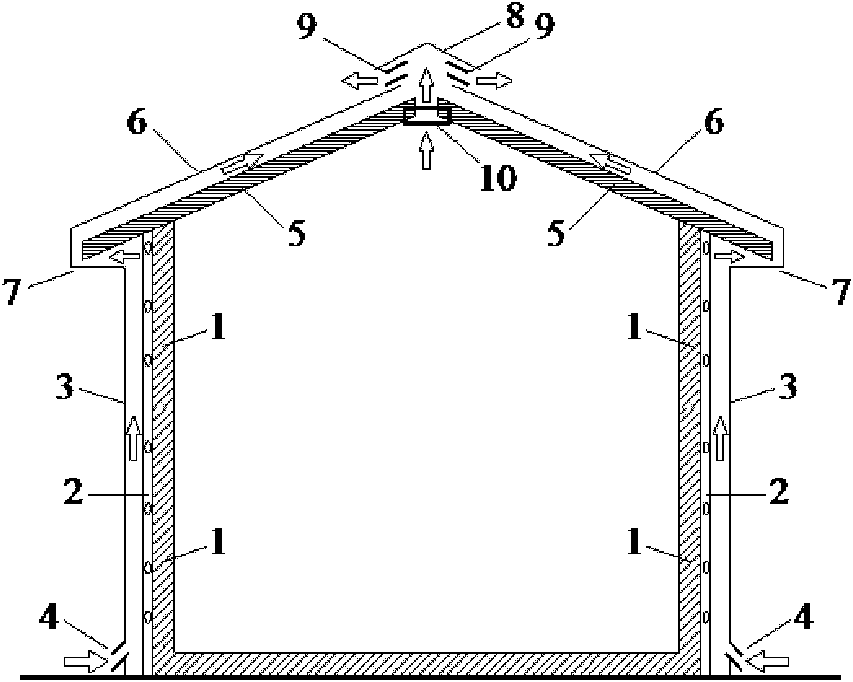

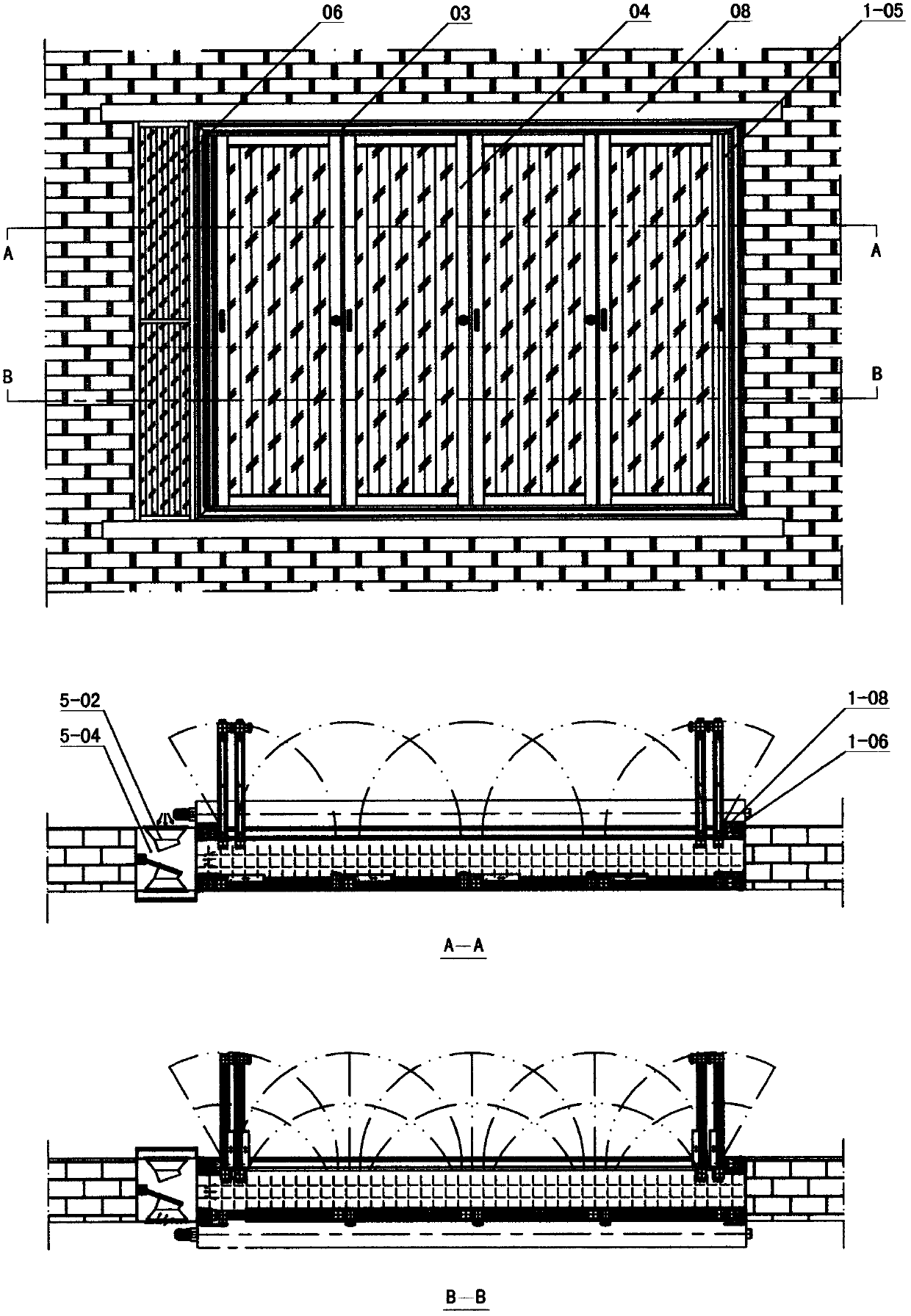

Heat preservation ventilating rebuilding method of low-floor building external wall and roof

InactiveCN102174857AIt has the effect of heat preservation and energy savingIn line with the design conceptRoof covering using slabs/sheetsConstruction materialSheet steelEngineering

The invention provides a heat preservation ventilating rebuilding method of low-floor building external walls and roofs, belonging to the technical field of constructional engineering, wherein the solar energy is absorbed by orderly building an insulation board, a color sheet steel shingle, an outer window-shade, a roof sheathing and a rising ridge; in winter, the hot air can be absorbed; in summer, the hot air can be exhaled; and in spring and autumn, an air insulation layer is formed. According to the method in the invention, the existing building rebuilding can meet the comprehensive demands of heat insulation, heat preservation, energy conservation, ventilating, reasonable cost, and low carbon building.

Owner:SHANGHAI JIAO TONG UNIV

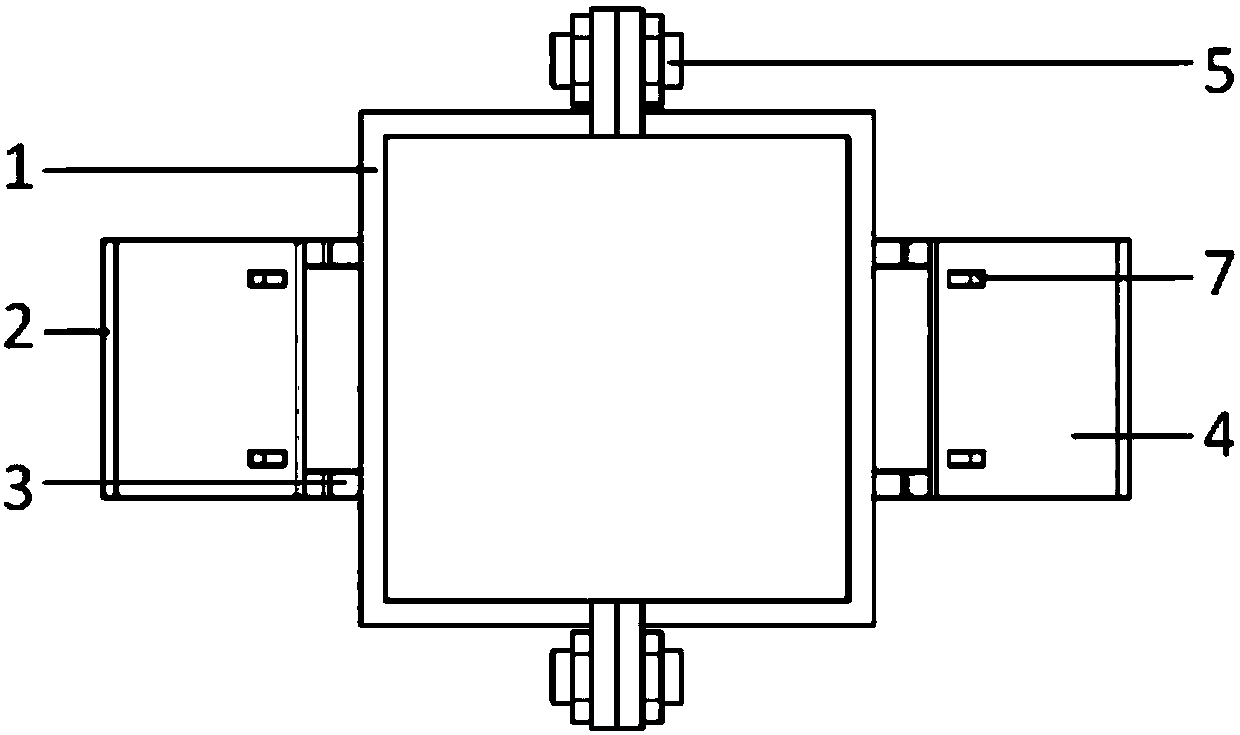

Energy consumption sleeve of prestress assembling node and mounting and working method thereof

ActiveCN107816129AHigh strengthImprove deformation abilityClimate change adaptationProtective buildings/sheltersEnergy consumptionShock absorber

The invention discloses an energy consumption sleeve of prestress assembling nodes and a mounting and working method thereof. The energy consumption sleeve comprises a plurality of split sleeve units,wherein the plurality of the split sleeve units are spliced to form a sleeve for wrapping prestress assembling nodes through high-strength bolts; each split sleeve unit comprises a split column sleeve unit and a beam end sleeve; the split column sleeve units and the beam end sleeves are connected through arc-shaped adhesive elastic dampers at angle parts; the arc-shaped adhesive elastic dampers comprise a plurality of arc-shaped steel plates; and the plurality of the arc-shaped steel plates are overlapped in sequence alternatively through an adhesive elastic material layer. According to the energy consumption sleeve of the prestress assembling nodes, an adhesive elastic material with good energy consumption performance is combined with a node sleeve, so that the energy consumption performance of assembling nodes is greatly improved, meanwhile beam end concrete is saved, the strength and the deformation performance of the nodes are improved, and thus the prestress assembling nodes arerelatively wide in application range.

Owner:SOUTHEAST UNIV

Photovoltaic-powered street lamp type wireless charging pile for electric automobiles

InactiveCN104362713AHigh penetration rateIncrease profitBatteries circuit arrangementsCharging stationsTransformerElectrical battery

The invention discloses a photovoltaic-powered street lamp type wireless charging pile for electric automobiles, which comprises a power supply terminal, a wireless sending terminal and a wireless receiving terminal, wherein the power supply terminal comprises a photovoltaic array and an electric network source which are arranged at the top of a street lamp, and the photovoltaic array is connected with an energy storage battery through a DC (Direct Current) junction station; the wireless sending terminal comprises a main MCU (Microprogrammed Control Unit), a rectifier filter, a DC-DC converter, a high-frequency inverter and a wireless transmitting coil, and the output end of the energy storage battery and the electric network source are connected with the rectifier filter, the DC-DC converter, and the high-frequency inverter through an intelligent selector switch to output high-frequency electromagnetic power and then the high-frequency electromagnetic power is loaded onto the transmitting coil; the intelligent selector switch, the rectifier filter, the DC-DC converter and the control end of the high-frequency inverter are connected with the output end of the main MCU, and the wireless receiving terminal comprises a wireless receiving coil; the wireless receiving coil and the transmitting coil are arranged in a magnetic resonance way, and the received high-frequency electromagnetic signals are stepped down by a high-frequency step-down transformer and rectified by a rectifier and then are output to a working battery of an electric automobile.

Owner:STATE GRID CORP OF CHINA +2

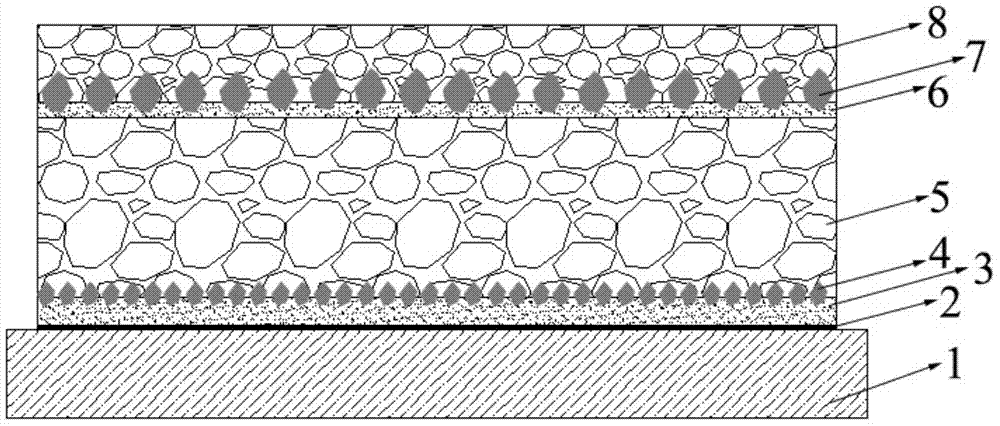

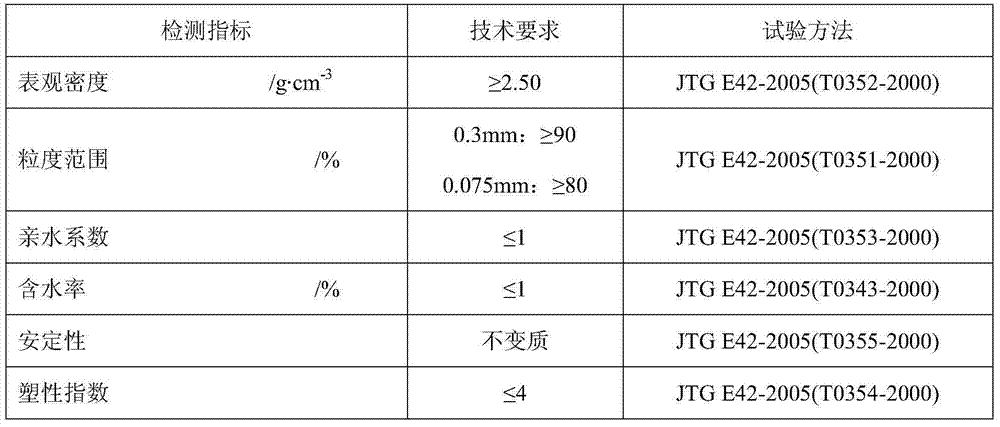

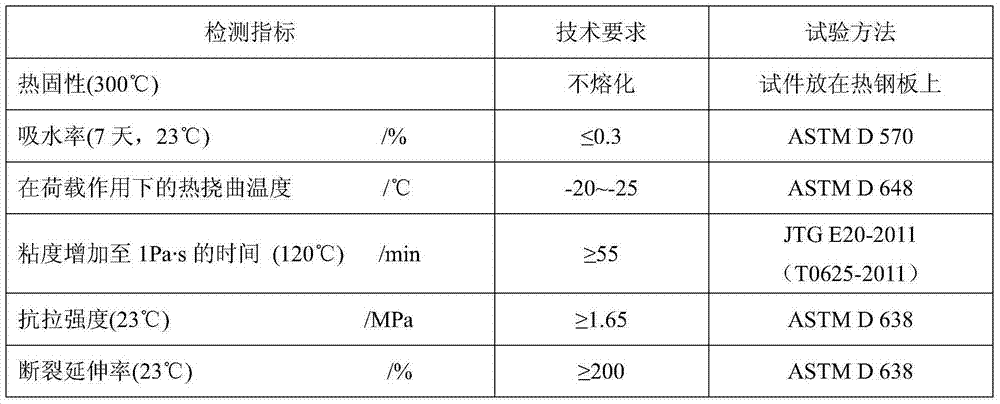

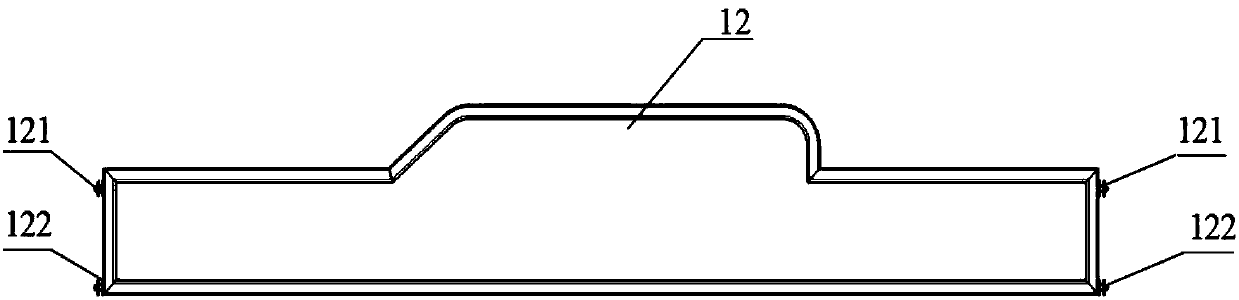

Long-life pavement structure for steel bridge deck and pavement method of pavement structure

ActiveCN104499431AAvoid performance requirementsAdd depthIn situ pavingsBridge structural detailsSteel platesWear resistant

The invention discloses a long-life pavement structure for a steel bridge deck and a pavement method of the pavement structure. The long-life pavement structure comprises an anti-corrosion layer, a lower adhesive layer, a lower gravel layer, a structural layer, an upper adhesive layer, an upper gravel layer and a wearing layer which are sequentially arranged on the steel bridge deck from bottom to top. The pavement structure has excellent antiskid and waterproof performances, low-temperature cracking resistance, high-temperature rutting resistance, fatigue resistance and water stability, is fine in deformation compatibility with a steel plate and wear-resistant, surface aggregates do not easily fall off, the pavement method of the pavement structure is high in mechanization degree and strong in feasibility, the paved steel bridge deck can be put into operation in a short time, only the wearing layer of the pavement structure is damaged, only regular surface milling and top facing repair are needed, the pavement structure does not need to be structurally reconstructed in a long service life period, maintenance is facilitated, maintenance cost is saved, and the pavement method conforms to the design concept of a long-life pavement and also conforms to the energy conservation and environmental protection concept of modern society.

Owner:SOUTHEAST UNIV

Resonator nano-beam parallel plate electrostatic control device and control method thereof

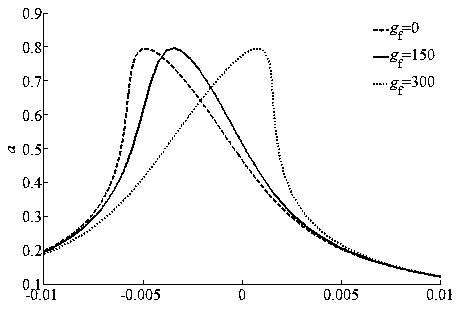

InactiveCN105515547AIn line with the design concept of micro scaleIn line with the design conceptImpedence networksParallel plateEngineering

The invention discloses a resonator nano-beam parallel plate electrostatic control device and a control method thereof. The resonator nano-beam parallel plate electrostatic control device comprises three parts: a driving device, a signal extraction device and a control device. The control method comprises the following steps of: 1, determining a driving clearance condition of nano-beam linear-like stable vibration; and 2, determining a nonlinear feedback control voltage gain gf of a voltage amplifier. The resonator nano-beam parallel plate electrostatic control device utilizes the characteristic that a resistance of a graphene thin film is changed along with deformation of the graphene thin film, is applied to vibration control of a nano-beam and a driving electrode as a displacement sensor, and solves the problem of failure of an existing NEMS (Nano Electro Mechanical System) device, which is caused by harmful nonlinear influence generated due to electrostatic driving.

Owner:SHANDONG UNIV OF TECH

Electrospun fiber-reinforced calcium phosphate bone cement composite material and application thereof

ActiveCN103877621AIn line with the design conceptGuaranteed to be pureProsthesisCalcium biphosphateCement composites

The invention discloses an electrospun fiber-reinforced calcium phosphate bone cement composite material and application thereof. The electrospun fiber-reinforced calcium phosphate bone cement composite material is formed by mixing electrospun fiber, a chitosan solution and a solid phosphate mixture, and is prepared by the following ways: directly spinning the electrospun fiber in the chitosan solution containing chitosan, citric acid and glucose; then, mixing with the solid phosphate mixture to obtain the electrospun fiber-reinforced calcium phosphate bone cement composite material. The electrospun fiber-reinforced calcium phosphate bone cement composite material disclosed by the invention, on the basis of reserving advantages of the calcium phosphate bone cement, is relatively high in compressive strength in an initial stage, and a porous scaffold material is formed with gradual degradation of the electrospun fiber in a later stage, which is favorable for growth of a new bone tissue.

Owner:GUANGDONG PHARMA UNIV

High-strength and wear-resisting liteglow glass product and preparation method thereof

The invention discloses a high-strength and wear-resisting liteglow glass product and a preparation method thereof. The glass product is prepared from the following components: silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide, graphene, titanium dioxide, diboron trioxide, sodium silicate, potassium oxide, antimony oxide, arsenic oxide and noctilucent powder. The preparation method comprises the following steps: firstly, carrying out mixed melting on all the components to obtain a molten mass; secondly, raising the temperature of the molten mass to 1400 to 1500DEG C and performing thermal insulation for 12 to 14 hours; thirdly, feeding a glass molten mass into a forming machine to obtain glass products with different shapes and sizes; fourthly, carrying out annealing treatment on the glass products to obtain a finished product. The glass product prepared by the preparation method disclosed by the invention has better strength and wear resistance; the fragile degree of the product can be greatly reduced, the service life of the product is prolonged, and the use cost of the product is reduced.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Electric automobile wireless charging system based on Internet of Things

ActiveCN104467092AReduce operating costsHigh penetration rateBatteries circuit arrangementsElectromagnetic wave systemElectrical batteryElectric energy

The invention discloses an electric automobile wireless charging system based on the Internet of Things. The electric automobile wireless charging system based on the Internet of Things comprises a power supply end, a power supply controller and a power receiving end, wherein the power supply end comprises a network source, a distributor, a microwave power source, a waveguide tube and a microwave transmitting array antenna, the network source, the distributor, the microwave power source, the waveguide tube and the microwave transmitting array antenna are connected in sequence, the distributor and the microwave power source are arranged in a lamp pole of a street lamp, the distributor is connected with the underground network source through a coaxial cable, an antenna support is arranged on the side, facing a road surface, of the lamp pole of the street lamp, the transmitting array antenna is arranged at the outer end of the antenna support, the waveguide tube is arranged in the antenna support, the power supply controller is connected with the distributor and the microwave power source, the power receiving end comprises a wireless microwave receiving antenna and a rectification electric energy receiver connected with the wireless receiving antenna, power is supplied to a rechargeable battery by the output end of the rectification electric energy receiver, the control end of the rectification electric energy receiver is connected with a vehicle-mounted controller, and power is supplied to the rechargeable battery under the control of the vehicle-mounted controller. According to the electric automobile wireless charging system based on the Internet of Things, a wireless charging pole is combined with the street lamp, and the electric automobile wireless charging system capable of achieving roadside charging conveniently and rapidly is provided.

Owner:山东同其智能科技有限公司

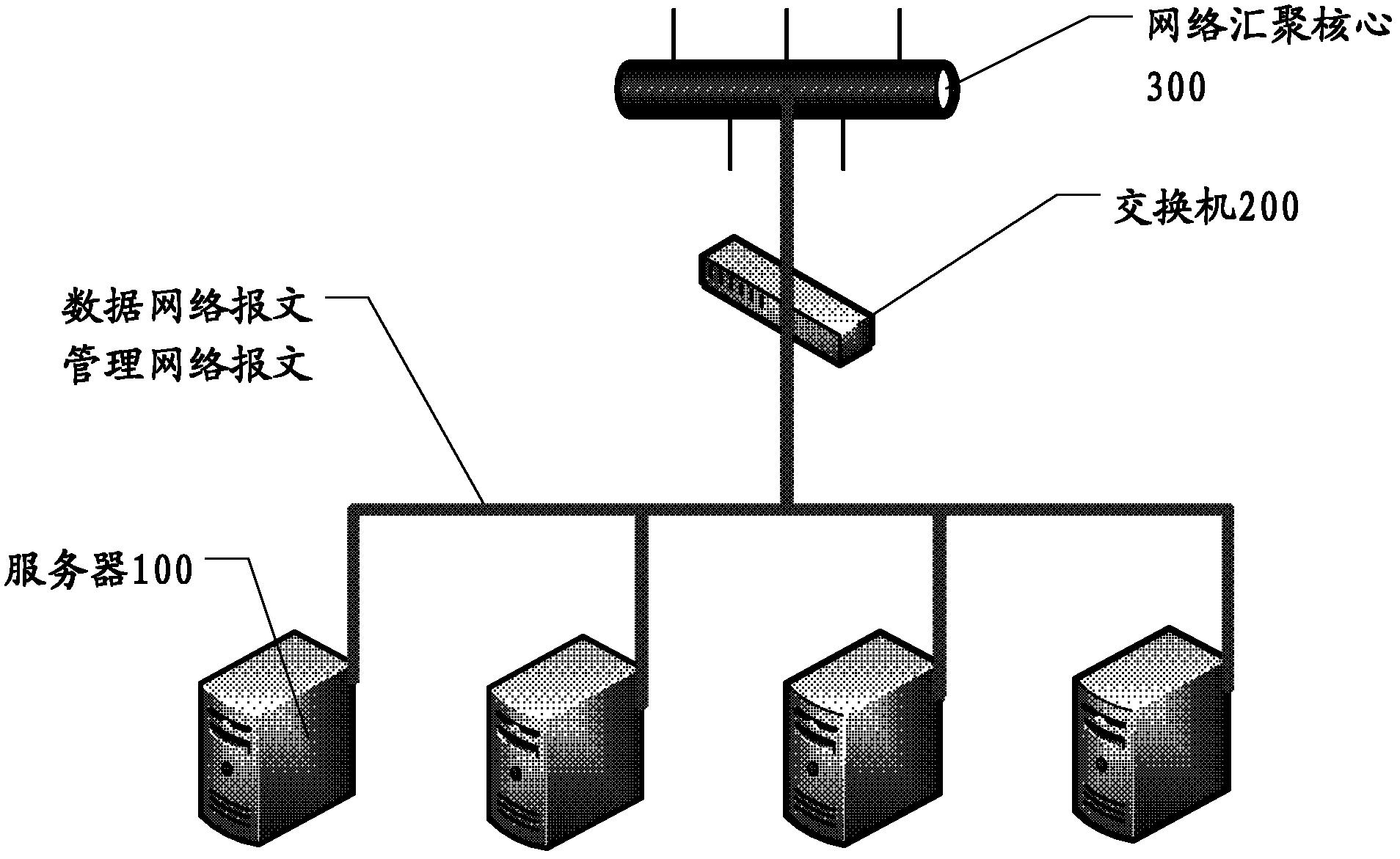

Convergence method, system and device of data network and management network

ActiveCN102281162AAvoid wastingImprove securityData switching networksNetwork managementMedia access control

The invention provides a fusion method and a fusion system of a data network and a management network and devices. The system comprises a switch, the switch comprises a first network segment and a second network segment, the first network segment corresponds to a first media access control (MAC) address, and the second network segment corresponds to a second MAC address. A server is used for receiving network message sent by the switch and judging that the network message is data network message or management network message according to the MAC address in the network message. According to the embodiment, the server is simultaneously accessed to the data network and the management network through a server network card, a switch port and a set of network gathering core, so the access cost of the server can be greatly reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

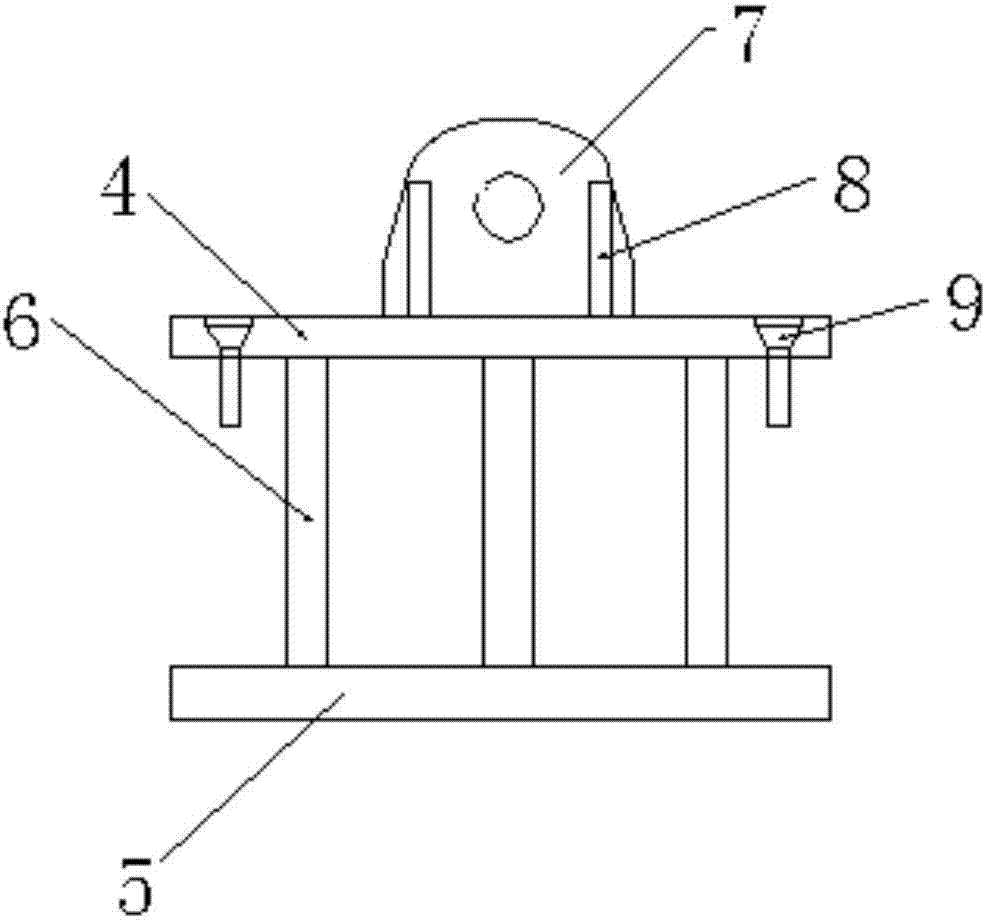

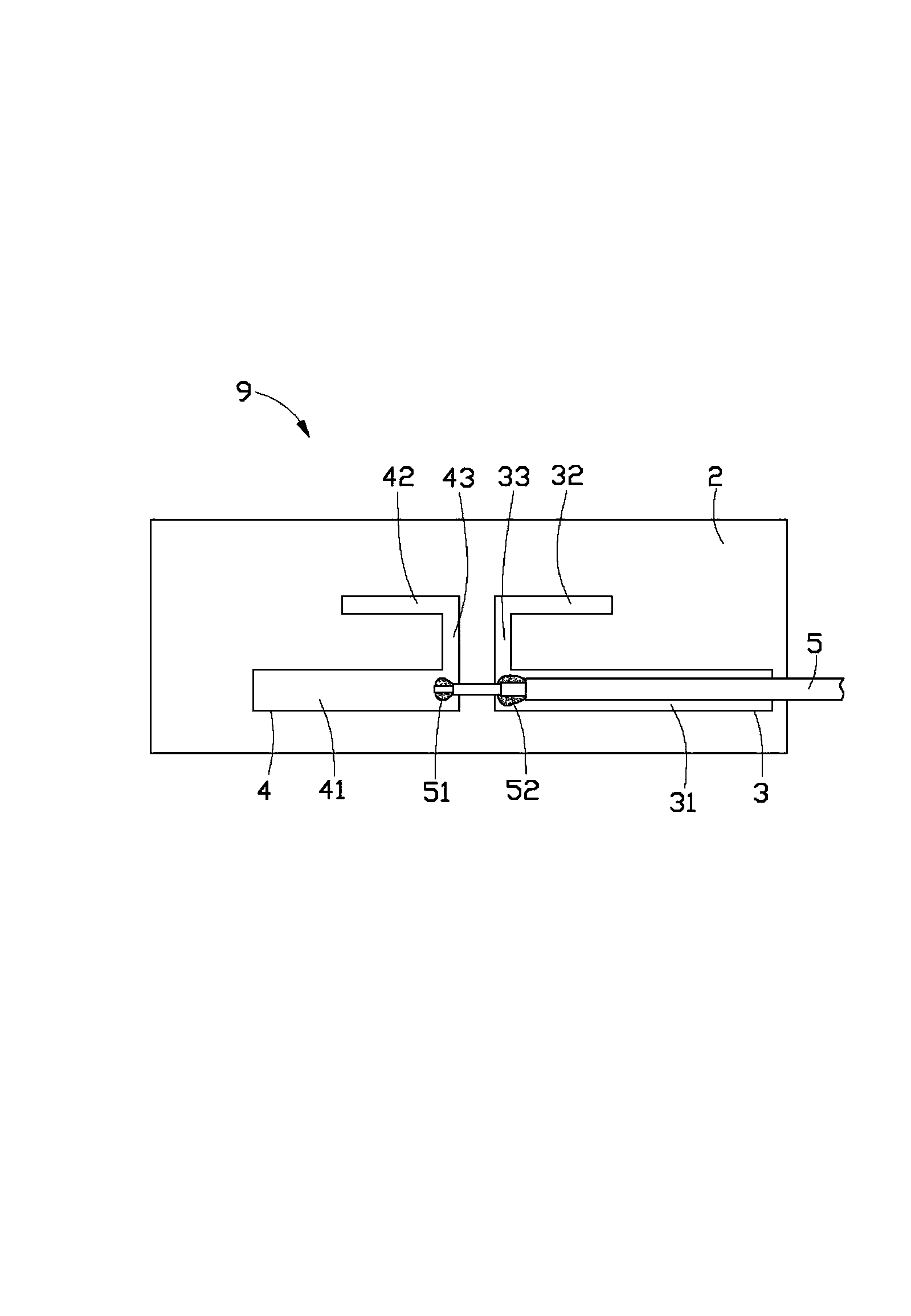

Plug-and-play anti-seismic energy dissipation device suitable for fabricated frame structure

InactiveCN107447885AImprove lateral stiffnessStrong energy consumptionProtective buildings/sheltersShock proofingPlug and playHysteresis

The invention relates to the field of building components, and discloses a plug-and-play anti-seismic energy dissipation device suitable for an assembled frame structure, which includes a support seat I pre-buried in a concrete foundation and a support seat II pre-buried in a concrete column And the energy dissipation damping device connecting the support base I and the support base II. The invention can provide greater lateral stiffness under earthquake action, and when the energy-dissipating damping device yields under tension or compression, it uses hysteretic characteristics to dissipate earthquake energy, and has a strong energy-dissipating capacity; all components are prefabricated in the factory, and the construction site Only simple assembly is required, the construction speed is fast, the industrialization level is high, and it is easy to replace after the earthquake, which conforms to the "plug and play" design concept.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

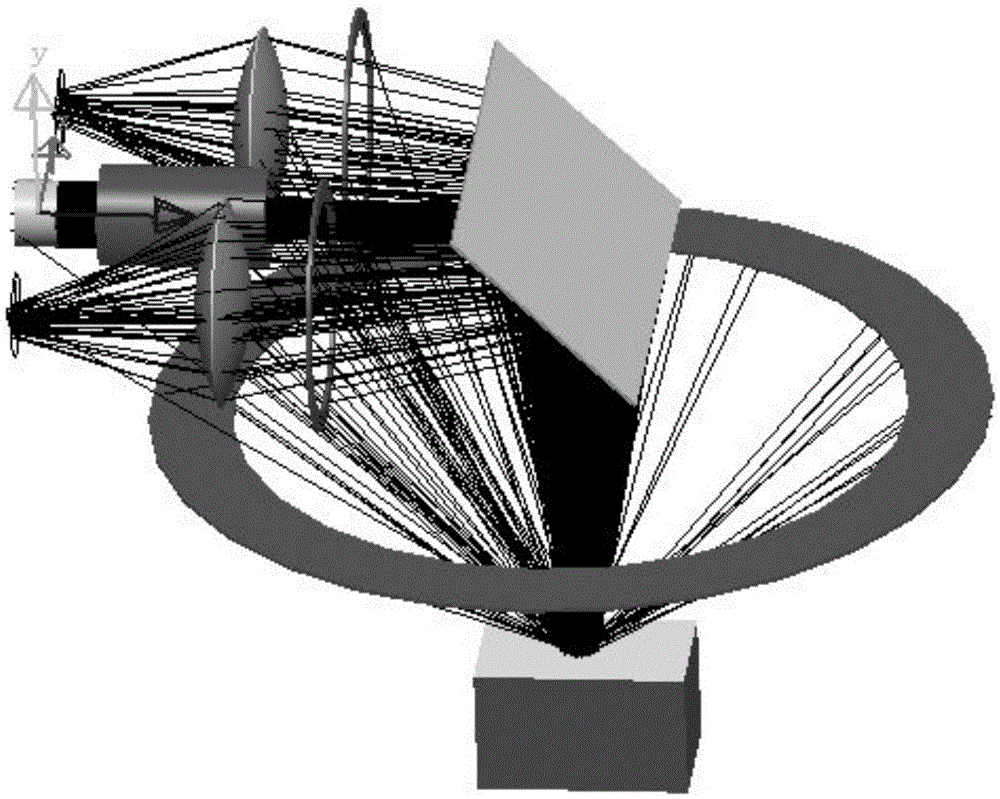

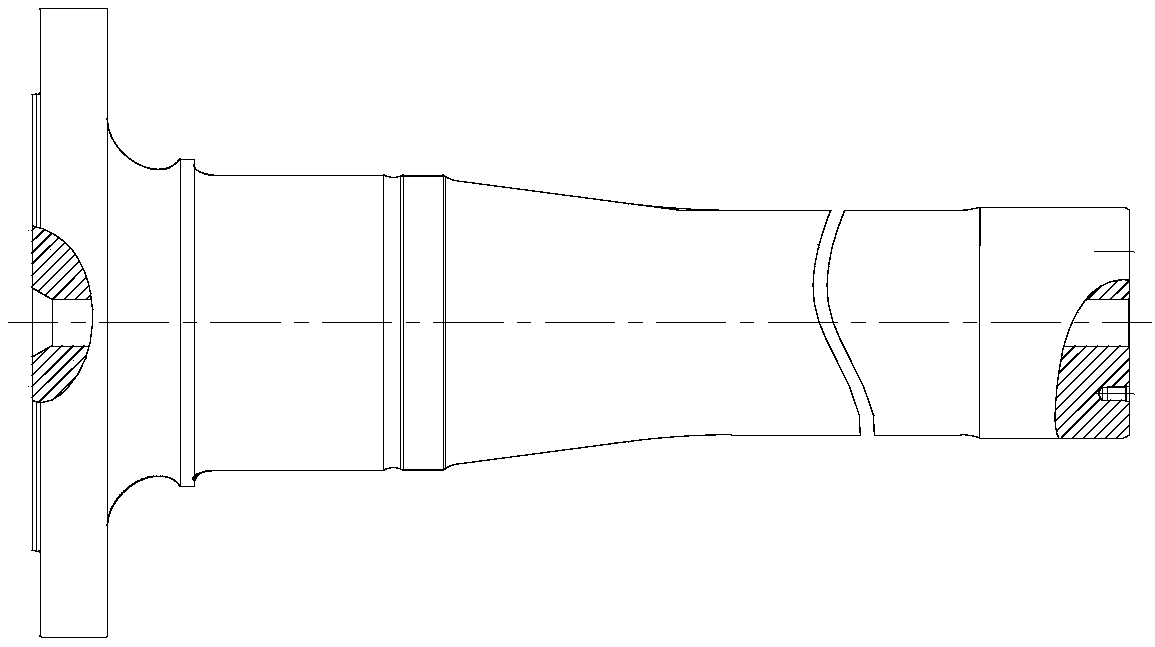

Vehicle-mounted laser radar optical system based on Light Tools and working method for same

ActiveCN105467399AIncrease light energySimple structureElectromagnetic wave reradiationRadar systemsPhotovoltaic detectors

The invention provides a vehicle-mounted laser radar optical system based on Light Tools and a working method for the same. The system comprises a pulse laser, a beam expansion lens, a sway lens, variable lens diaphragms, focusing lenses and a photoelectric detector, wherein the pulse laser gives out laser beams; the beam expansion lens is placed in front of the pulse laser, the laser beams pass through the beam expansion lens to be collimated and compressed, decreased in laser divergence angle, and irradiated to the surface of the sway lens; the sway lens is disposed in an inclined manner relative to the beam expansion lens, and the laser beams are irradiated to the surface of a target by an emission window after being reflected by the sway lens; the variable lens diaphragms are disposed on two sides of the beam expansion lens, and parts of the laser beams are reflected by the sway lens and then enter the variable lens diaphragms; the focusing lenses are disposed on two sides of the beam expansion lens, and parts of the laser beams pass through the focusing lenses and are then focused and irradiated to the photoelectric detector; and the photoelectric detector is disposed behind the focusing lenses, and parts of the laser beams are irradiated to a photosurface center of the photoelectrical detector. The system and the working method provided by the invention increase optical energy which can be received by the photoelectric detector, increase a detection distance of a laser radar system, simplify an optical system of a traditional laser radar and reduce research and development cost.

Owner:DALIAN ROILAND SCI & TECH CO LTD

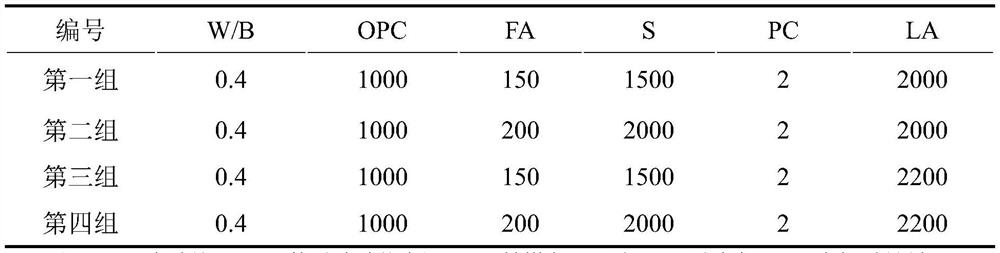

Lightweight aggregate based on surface modification, preparation method of lightweight aggregate and lightweight concrete

The invention discloses a lightweight aggregate based on surface modification, a preparation method of the lightweight aggregate and lightweight concrete. The lightweight aggregate based on surface modification comprises EPS foam particles and a coating layer covering the surfaces of the EPS foam particles, wherein the coating layer is prepared from the following raw materials in parts by mass: 1000 parts of ordinary Portland cement, 15-30 parts of nano silicon dioxide and 3-5 parts of a polycarboxylate water reducing agent, wherein the water-binder ratio is 0.35-0.4. The preparation comprises the steps: mixing the raw materials of the coating layer, spraying the mixture on the EPS foam particles subjected to water soaking treatment, granulating, removing moisture in the granulating process, and finally curing to obtain the lightweight aggregate with porous surface and uniform particles. The preparation is simple, and the operation is convenient; and the obtained lightweight aggregate increases the hydrophilic performance of the EPS foam particles, avoids layering of EPS, is high in strength and low in stacking density, has the characteristics of light weight, energy conservation, heat preservation, sound insulation, economy, environmental protection and the like when being used in the lightweight concrete, and is easy to popularize and apply.

Owner:WUHAN UNIV OF TECH

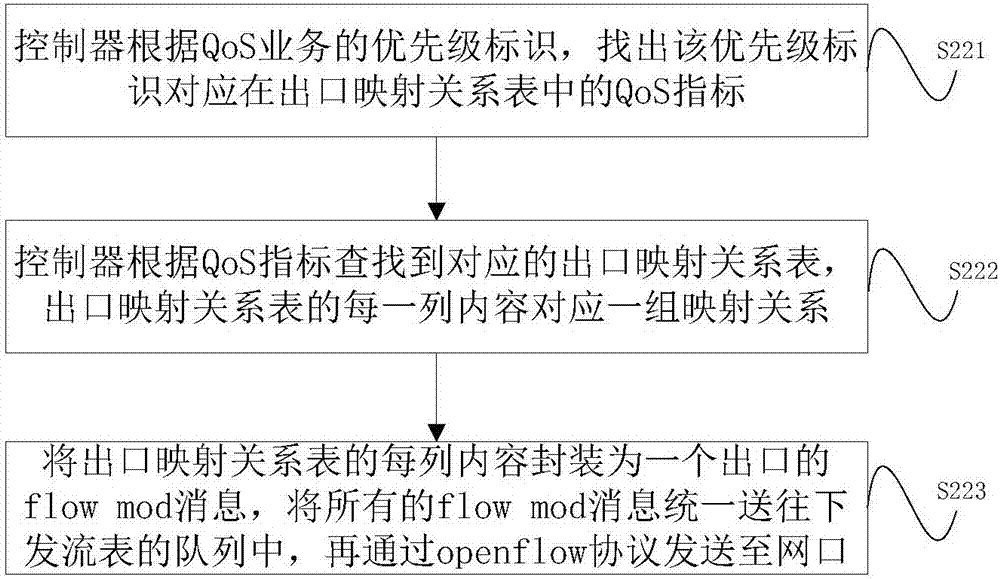

Method and system for realizing QoS function on SPTN device

ActiveCN107332686AIn line with the design conceptImprove configuration diversityData switching networksPass rateABLE protocol

The invention discloses a method and system for realizing QoS function on SPTN device. The method comprises the following steps: S1, a user configures configuration data of QoS service in a northern interface, wherein the configuration data comprise a priority identifier, a guaranteed pass rate and a maximum allowable rate of the QoS service, and a queue scheduling and congestion strategy; S2, a controller generates a flowmod message of an inlet and an outlet and issues the flowmod message through an openflow protocol, the controller generates a metermod message and issues the metermod message through the openflow protocol, and the controller generates an of-config message and issues the of-config message through an netconf protocol; and S3, a driving module of an SPTN devices receives the flowmod message of the inlet and the outlet, the metermod message and the of-config message, and performs corresponding configuration according to the flowmod message, the flowmod message of the outlet, the metermod message and the of-config message so as to issue the service.

Owner:武汉光网信息技术有限公司

Collagen aggregate based flocculent antibacterial hemostatic material and preparation method thereof

ActiveCN105327389AIn line with the design conceptGood hemostatic effectBandagesPyrrolidinonesCompatibilization

The invention discloses a collagen aggregate based flocculent antibacterial hemostatic material and a preparation method thereof. The preparation method is characterized by comprising steps as follows: DCMC (dialdehyde carboxymethyl cellulose) and silver nitrate are blended, a mixed solution containing nano-silver is prepared through redox reaction, then certain amount of collagen aggregate and certain amount of polyvinylpyrrolidone are dissolved in the mixed solution sequentially, the mixture is subjected to processes including gradient dilution, dealcoholization, vacuum drying, impregnation, freeze-drying, moderate grinding, sterilization and the like, and the collagen aggregate based flocculent antibacterial hemostatic material is obtained finally. The material adopts the collagen aggregate more similar to a natural tissue collagen structure, and compared with common collagen materials, the prepared flocculent hemostatic material has excellent physical and chemical properties and biological properties such as structural stability, mechanical property, biological degradability, biocompatibility and the like, can promote wound healing and repair, has broad-spectrum antibacterial / antimicrobial activity of the nano-silver, has large contact surface with the wound surface, is high in hydrophilia and stickiness and can be used for hemostasis repair of body surface wound and general civil hemostasis emergency.

Owner:SICHUAN UNIV

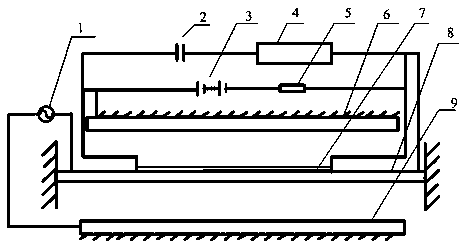

Heat exchange amount measurement device used in pool boiling experiment research and measurement method thereof

ActiveCN106595907AEnsure personal safetyAvoid wasting resourcesCalorimeterMeasurement deviceHeat measurement

The invention discloses a heat exchange amount measurement device used in pool boiling experiment research and a measurement method thereof, is suitable for a heat exchange measurement technology of pool boiling outside a pipe and especially relates to a heat exchange amount measurement technology of a physical process in which condensation is generated in the pipe and pool boiling is generated outside the pipe, and two sides have phase changes. The measurement device can automatically supplement water for an experiment water tank so as to maintain a stable liquid level. Through measuring a water supplementing flow, pressure, a temperature and other signals, an enthalpy difference of steam generated through pool boiling and water supplementing is used to multiply by the water supplementing flow so as to calculate and acquire a pool boiling heat exchange amount. Four modules of an experiment module, an automatic water supplementing module, a measurement module and a steam recovery module are included. A technology problem of measuring the heat exchange amount in the pool boiling experiment research is solved, especially for the heat exchange amount measurement of the physical process in which condensation is generated in the pipe and pool boiling is generated outside the pipe, and two sides have phase changes. The device and the method can be effectively applied to correlation industrial fields of chemical engineering, pharmacy and the like and can be also applied to a heat exchange amount measurement process in which a heat working medium of an inner side of the pipe is high-temperature and high-pressure working medium condensation.

Owner:XI AN JIAOTONG UNIV

Broadband antenna

InactiveCN103427156AIn line with the design conceptTo achieve broadband effectRadiating elements structural formsAntenna earthingsBroadbandPrinted circuit board

The invention provides a broadband antenna which is installed in a wireless electronic device. The broadband antenna comprises a printed circuit board, a feeding device, a first antenna radiating body and a second antenna radiating body, wherein the first antenna radiating body and the second antenna radiating body are arranged on the surface of the printed circuit board. A gap is formed between the first antenna radiating body and the second antenna radiating body. The first antenna radiating body is of an n-shaped structure having the broadband function and comprises a first middle section, a first subsection and a second subsection, wherein the first subsection and the second subsection are connected with the first middle section, and the length of the first subsection is not equal to that of the second subsection. One end, close to the gap, of the first subsection and one end, close to the gap, of the second antenna radiating body are provided with a first feeding point and a second feeding point respectively. The feeding device is electrically connected with the first feeding point and the second feeding point and conducts feeding on the first antenna radiating body and the second antenna radiating body through the first feeding point and the second feeding point. One end, not electrically connected with the second feeding point, of the feeding device makes contact with a metal structure of the wireless electronic device so as to be grounded.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

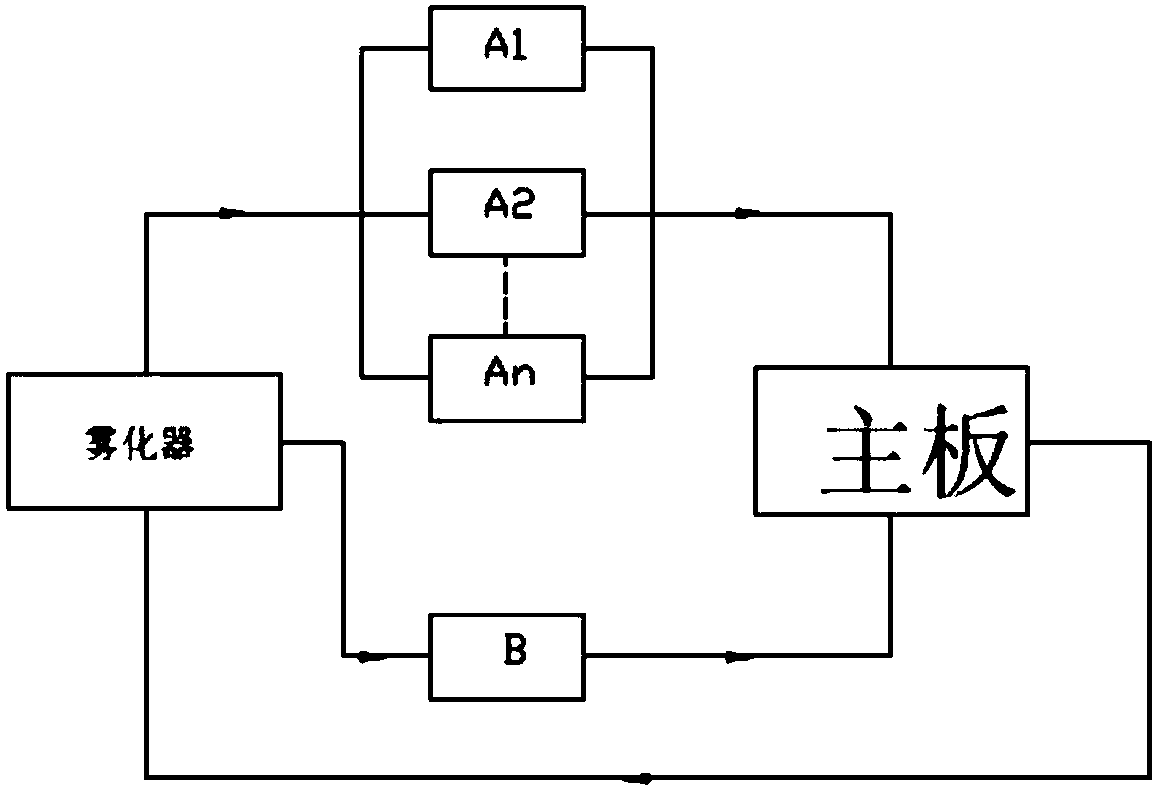

Control method of atomization device control system

The invention provides a control method of an atomization device control system. The control method of the atomization device control system comprises the following steps: recognizing whether an atomizer is matched with a mainboard or not, if the atomizer is not matched with the mainboard, determining that the atomizer is not matched with the mainboard, and then completing recognition; if the atomizer is matched with the mainboard, entering next step; step two, if the atomizer is matched with the mainboard, sending out a command by the mainboard to detect the type of electronic tobacco tar ina tobacco tar bin and the shelf life of the electronic tobacco tar, if the shelf life of the electronic tobacco tar exceeds expiration date, reporting that the electronic tobacco tar has expired, andforbidding the atomizer to atomize the tobacco tar; if the shelf life of the electronic tobacco tar is in the expiration date, entering next step; and step three, adjusting the working mode of the atomizer by the mainboard according to the detected type of the electronic tobacco tar and the storage time T of the electronic tobacco tar so that the atomizer is matched with the current electronic tobacco tar during working. The system can be adjusted automatically, the electronic tobacco tar tastes good, health of human bodies is ensured effectively, invasion of external risks is avoided, and theatomization device control system conforms to human design concepts.

Owner:INNOKIN TECH

Method for designing excavation surface of foundation pit of tunnel open excavation section on basis of BIM

ActiveCN108920870AHigh degree of automationPracticalGeometric CADData processing applicationsTerrainEnvironmental geology

The invention discloses a method for designing an excavation surface of a foundation pit of a tunnel open excavation section on the basis of BIM. The method comprises the following steps: S1, settinga three-dimensional space line position of the tunnel open excavation section; S2, setting a digital three-dimensional terrain of the tunnel open excavation section; S3, building a tunnel main body structural model of the open excavation section; S4, generating a control line for the excavation surface of the foundation pit of the tunnel open excavation section; S5, generating a sloping line of the excavation surface of the foundation pit of the tunnel open excavation section; S6, controlling height of the excavation surface of each level by virtue of height and generating the excavation surface; S7, controlling the height of the excavation surface of each level by virtue of elevation and generating the excavation surface; S8, generating a final slope cutting model; and S9, reading maximumexcavation depth of the excavation surface. The method disclosed by the invention realizes design of the excavation surface of the foundation pit of the tunnel open excavation section in a three-dimensional scene, is an indispensable link in tunnel BIM design and has obvious popularization and application values.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Rapid forming process of large flange of high-power wind power main shaft

InactiveCN109226617AHigh densityImprove longitudinal mechanical propertiesForging/hammering/pressing machinesElectricityIngot

The invention discloses a rapid forming process of a large flange of a high-power wind power main shaft. The process comprises the steps of (1) casting of a steel ingot blank material, wherein the steel ingot blank material includes a main body and a riser, then a water opening is cut off, and the trim part of the riser is cut off; (2) preliminary forging on fire, wherein a blank material feedingfurnace is heated to 1170-1230 DEG C, the temperature is kept for 7-12 hours, upsetting is conducted until the height is H, pulling is conducted until the blank material is 1.7-2.3H long, then upsetting is conducted again until the height is H, and branch materials in eight directions are pulled; (3) secondary forging on fire, wherein the blank material is sent back to the furnace for being heatedto 1170-1230 DEG C, the temperature is kept for 5-10 hours, then steps are pulled out, the riser is thermally cut, and the blank material is placed in a padding mold and a flange mold and forged andformed to obtain the large flange by adopting a partial upsetting mode. The process can effectively solve problems in free forging methods of conventional shafts, rapid forming of the large flange endof the high-power wind power main shaft is achieved, the machining allowance is small, there is no need to consider the problem of drawing out a concave core, and the tangential performance of the large flange of the wind power main shaft can be effectively improved.

Owner:JIANGYIN NANGONG FORGING

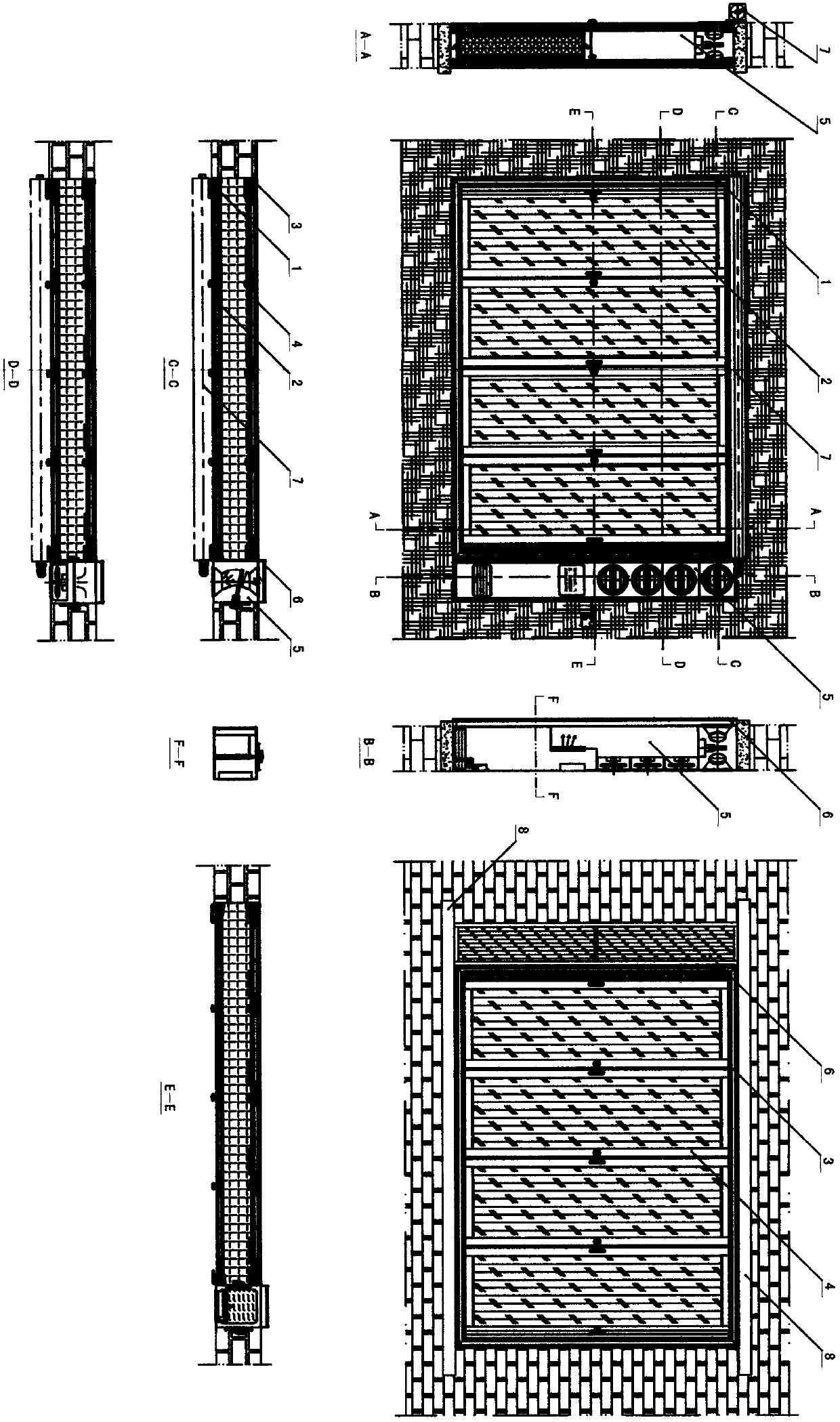

Anti-haze solar purification window

ActiveCN104265134AImprove performancePromote innovationLight protection screensWing arrangementsAutomatic controlFiltration

The invention discloses an anti-haze solar purification window being an innovated product integrating multiple technologies of mechanical structures, solar application, environmental protecting purification and automatic control as a whole in the building field. The anti-haze solar purification window forms one set of intelligent circulating system integrating such functions as electricity generation, energy storage, air pumping, purification, sun shading and air exhausting by such parts as a double-row rotary sealing window inlaid with an amorphous silicon solar panel, a purification box and an electric roller blind. The anti-haze solar purification window has all functions of a traditional window, accords with traditional building codes, uses home-grown electric energy for pumping outdoor air with haze and dust in the purification box for multi-stage filtration to become new clean air to be continuously blown indoors, and exhausts indoor dust and waste gas outdoors in mixture with the air to always keep the indoor air clean so as to benefit the human health. Each of window leaves can be dragged for rotating to be randomly positioned; and six surfaces of the window leaves all can be cleaned and maintained indoors; an electric curtain of the window not only can achieve the effects of sunshading and beautifying, but also can serve as a curtain for family televisions and meeting teaching; and the window has no frame center post, and double rows of windows all can be opened, so that the visual effect and the ventilation effect are both optimal.

Owner:邓庚厚

Foldable turnover sleeping berth

ActiveCN107839567ADoes not take up spaceEasy to installVehicle arrangementsFloor slabMarine engineering

The invention discloses a foldable turnover sleeping berth, and belongs to the technical field of heavy trucks. The foldable turnover sleeping berth comprises a sleeping berth box main body, a floor slab, a turnover sleeping berth body, a turnover guide track and a supporting body, wherein the floor slab is mounted on one side of the sleeping berth box main body; the turnover guide track is fixedon the sleeping berth box main body; the turnover sleeping berth body is unfolded and folded through the turnover guide track; the supporting body is mounted on the turnover sleeping berth body; and when the turnover sleeping berth body is unfolded, the supporting body is positioned on the floor slab, so that the upper surface of the sleeping berth box main body and the upper surface of the turnover sleeping berth body are parallel and level to each other. By the aid of the turnover sleeping berth body, the sleeping berth is widened; by the aid of the turnover guide track, manual adjusting canbe implemented; when the foldable turnover sleeping berth is unfolded, the greatest width of the sleeping berth can reach 1,100 mm, the foldable turnover sleeping berth completely conforms to the design philosophy of 'a bed for couples', and when a truck runs normally, the sleeping berth can be folded and does not occupy the space of a driving cab. The foldable turnover sleeping berth is convenient to broaden, is simple in folding and turnover structure, is firm and durable, and can meet daily rest of three members of family.

Owner:XUZHOU XUGONG AUTOMOBILE MFG CO LTD

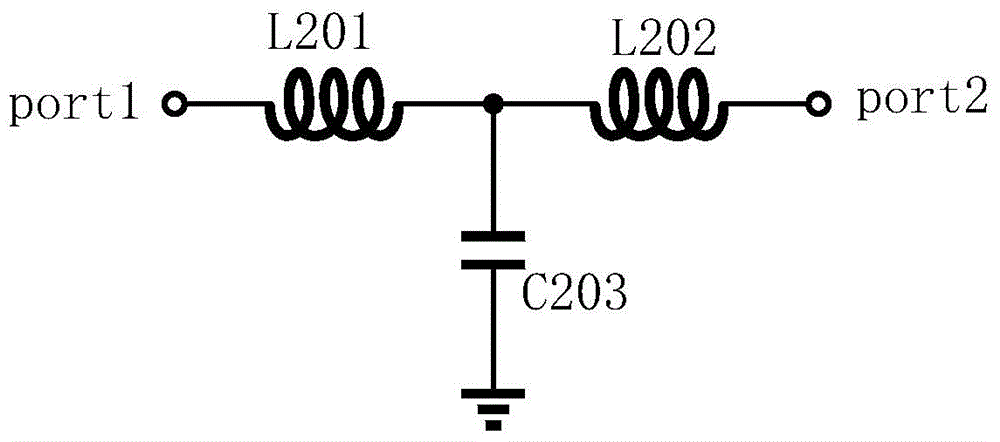

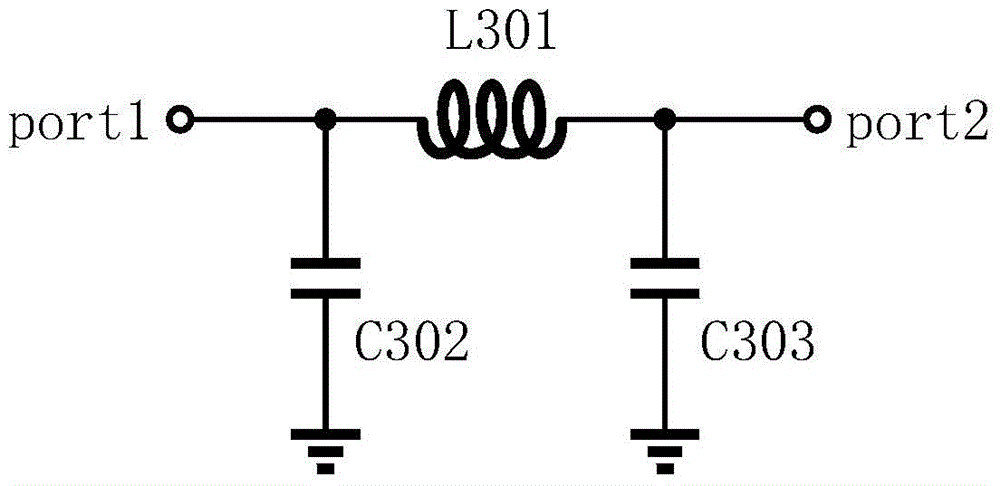

Single-chip radio frequency antenna switch module and radio frequency front end

The invention discloses a single-chip radio frequency antenna switch module. The single-chip radio frequency antenna switch module comprises a substrate, a die, a first low pass filter and a second low pass filter. The inductance of the first low pass filter and the inductance of the second low pass filter are achieved through a metal wire and / or a bonding wire on the substrate. The die is installed on the substrate, and a radio frequency antenna switch, a logic controller, a capacitor of the first low pass filter and a capacitor of the second low pass filter are integrated into the die, and the logic controller is used for turning on or turning off the radio frequency antenna switch according to logic signals. The implementation way is easy to implement, the area of the substrate of the radio frequency antenna switch module can be fully utilized, and therefore the size of the radio frequency antenna switch module can be reduced, and the cost of the radio frequency antenna switch module can be lowered.

Owner:RDA MICROELECTRONICS BEIJING

Environmental protection preparation method of (R)-(-)-4-cyano-3-hydroxy ethyl butyrate

PendingCN109628511AReduce manufacturing costAtom economy is highFermentationChemical industryEthyl butyrate

The invention discloses an environmental protection preparation method of (R)-(-)-4-cyano-3-hydroxy ethyl butyrate and belongs to the technical field of medicine and chemical industry. The method comprises the following steps of: using (S)- epichlorohydrin as a start material, carrying out nucleophilic addition reaction on the epichlorohydrin and liquid hydrocyanic acid under the catalysis of alkali to obtain (S)-(-)-4-chlorine-3-hydroxybutyronitrile; carrying out Pinner reaction on the (S)-(-)-4-chlorine-3-hydroxybutyronitrile and hydrogen chloride-ethanol to obtain a hydrochloride intermediate of urethane, and then hydrolyzing the intermediate to obtain (S)-(-)-4-chlorine-3-ethyl hydroxybutyrate; finally, reacting (S)-(-)-4-chlorine-3-ethyl hydroxybutyrate and hydrocyanic acid and ammonia water under the analysis of biological enzyme to prepare the (R)-(-)-4-cyano-3-hydroxy ethyl butyrate. In the whole synthesis process of the method, other organic solvents other than water are not used, the reaction condition is mild, the process is simple, the chemical purity and optical purity of the product are higher, no waste water, waste salt or waste gas is generated in the whole process,the method achieves win-win of economic benefit and environmental benefit and is favorable for achieving large-scale industrial production.

Owner:抚顺顺能化工有限公司

Sponge city road drainage system

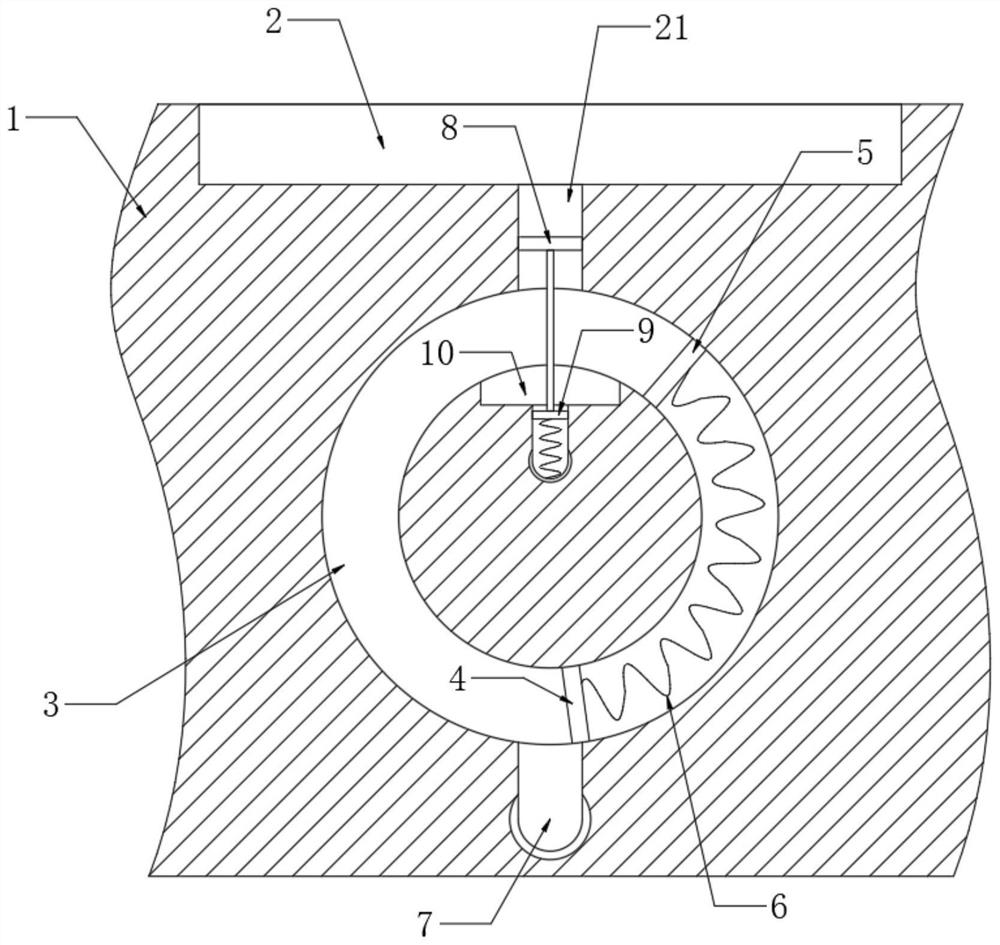

InactiveCN112095746AGuaranteed Absorption EfficiencyIn line with the design conceptFatty/oily/floating substances removal devicesSewerage structuresWater sourceRoad surface

The invention discloses a sponge city road drainage system. The system comprises a drainage channel dug in a roadbed, an annular groove is dug in the roadbed, the annular groove is communicated with the drainage channel through a flow guide groove, a first baffle is slidably connected in the annular groove, and a second baffle is fixedly connected in the annular groove. The first baffle and the second baffle are elastically connected through a first spring, a filter screen is embedded in the flow guide groove, an arc-shaped groove is formed in the inner wall of the annular groove, and a watersupply pipe communicating with the annular groove is embedded in the roadbed. Rainwater containing a large amount of pollutants in the initial stage is guided into a sewage treatment system through ablow-off pipe, the road is gradually flushed cleanly by the rainwater as time goes by, and cleaner rainwater in the later stage can be directly guided into a designated place through the water supplypipe to be collected, so that the rainwater on the road surface is treated by stages, the rainwater absorption efficiency of a sponge city is guaranteed, and meanwhile, a polluted water source can betreated.

Owner:临沂人民公园

Cigarette heating device

ActiveCN110063528ASolve the problem that the temperature cannot be effectively controlledExtended service lifeTobacco devicesEngineeringRefrigeration

The invention discloses a cigarette heating device, and belongs to the technical field of cigarette smoking sets. A smoke cooling segment of a hollow structure is arranged at an opening end of a cigarette insertion hole, and a refrigeration device is arranged at the outer side of the smoke cooling segment; by designing heat dissipation parts of the refrigeration device to make the heat dissipationspeeds of the heat dissipation parts in the axial direction of the cigarette heating device different, heat dissipation is conducted to different degrees at different positions of the smoke cooling segment; specifically, the heat dissipation speeds of the heat dissipation parts close to a cigarette tobacco segment is greater than those of the heat dissipation parts close to a cigarette filter tipsegment, and therefore the purposes are achieved that high-temperature smoke entering the smoke cooling segment is cooled rapidly, and smoke about to enter the cigarette filter tip segment is cooledslowly; the problem is solved that when a smoker uses the cigarette heating device to smoke, the temperature of smoke entering the mouth cannot be effectively controlled; the high-temperature smoke which just enters the smoke cooling segment is cooled rapidly, and the service life of the refrigeration device is prolonged to a certain degree.

Owner:JIANGNAN UNIV

Intelligent attendance checking and punching-in system

InactiveCN107103651AEfficiently provideEasy to checkRegistering/indicating time of eventsIndividual entry/exit registersPunchingComputer module

The invention discloses an intelligent attendance checking and punching-in system. The intelligent attendance checking and punching-in system comprises an attendance checking terminal, a central processing unit and a control terminal, wherein the attendance checking terminal comprises an information acquisition module, an information storage module, a signal output module and a communication module and is used for acquiring attendance checking information and transmitting the information to the central processing unit; the information acquisition module comprises a sound wave acquisition module and a fingerprint acquisition module; the sound wave acquisition module is used for acquiring sound wave signals; the fingerprint acquisition module is used for acquiring attendance checking fingerprint information; the central processing unit is used for carrying out transformation processing on the information obtained by the attendance checking terminal, identifying user information and recording identification information and punching-in information of a user. The intelligent attendance checking and punching-in system disclosed by the invention can be used for effectively providing attendance checking and punching-in information of workers and preventing salary loss caused by the fact that the punching-in of the workers is invalid; the intelligent attendance checking and punching-in system can also be used for preventing phenomena that the punching-in of the workers is missed and the workers forget punching in and has relatively good application value and prospect.

Owner:合肥酷睿网络科技有限公司

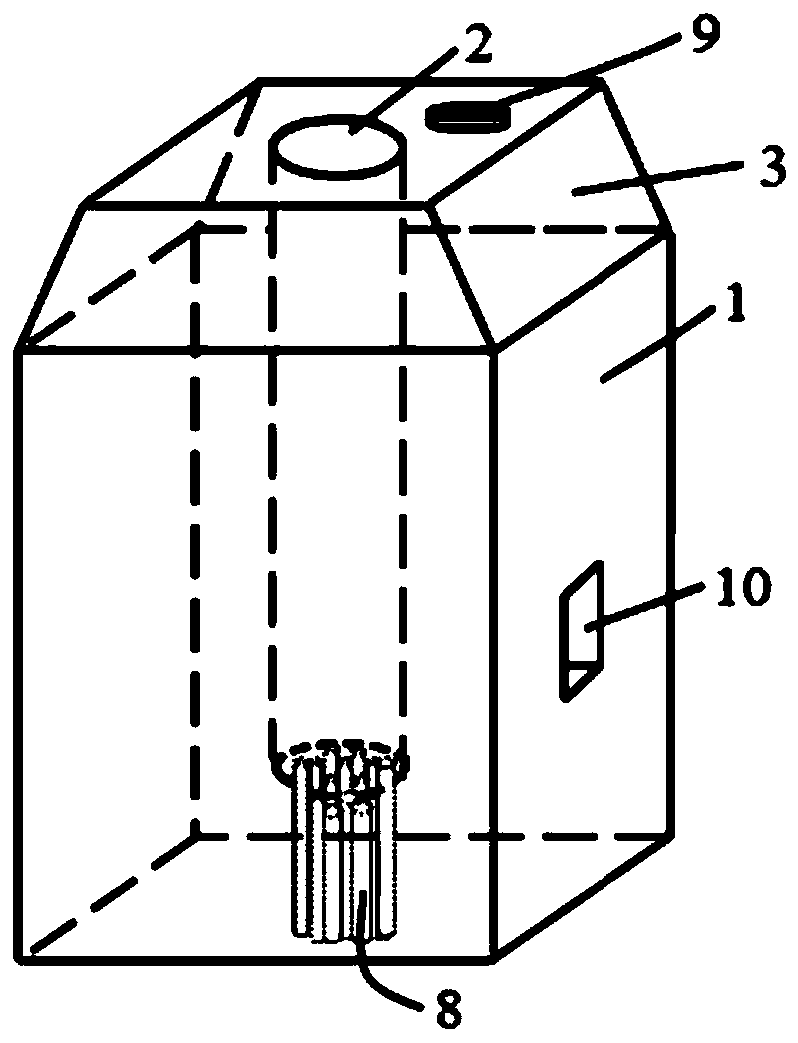

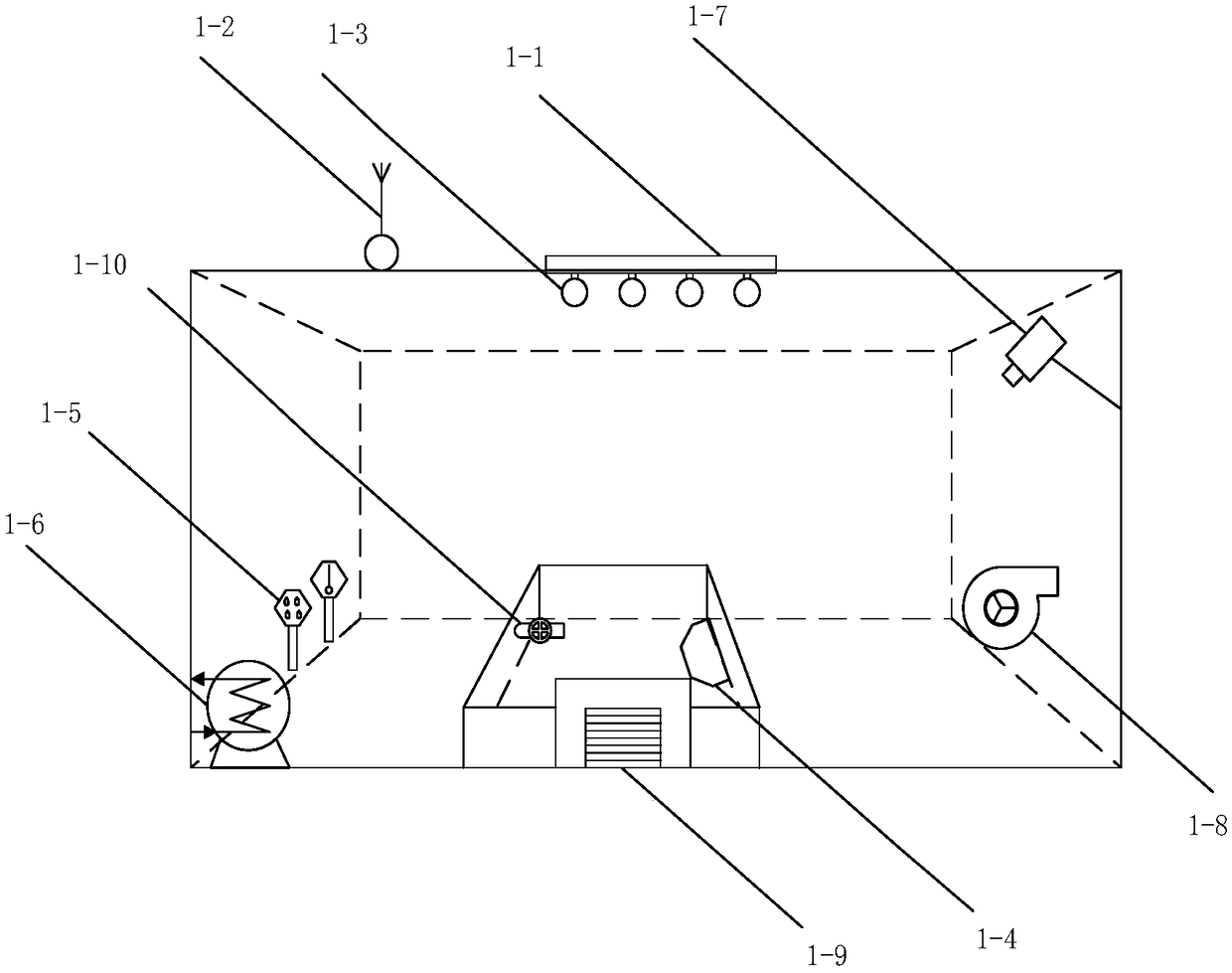

Environmental information collection and automatic processing pig house based on LORA remote communication

PendingCN109329080ATake advantage ofReduce labor costsTransmission systemsComputer controlVideo monitoringSolar power

The invention relates to an environmental information collection and automatic processing pig house based on LORA remote communication, and belongs to the field of physical fusion of information. Thepig house comprises a house body, an LoRa communication module, a control circuit board, a video monitoring module, an internal air quality improvement module, an internal temperature maintenance module and a camera; the control circuit board comprises an STM32 single-chip microcomputer module and an automatic cleaning circuit, a solar energy utilization module and an LoRa communication antenna are installed on a top cover of the house body, the STM32 single-chip microcomputer module is connected with the automatic cleaning circuit, the LoRa communication module and the video monitoring moduleseparately, the communication module is in wireless communication with a terminal monitoring system through the LoRa communication antenna, the video monitoring module is connected with the camera, and the camera and an exhaust fan are installed at the two sides of the house body. The pig house can meet corresponding power supply requirements through solar power generation and monitor the state of pigs in real time; meanwhile, reasonable water supply and feeding in pigsties can be automatically achieved, and the living environment of the pigs is improved.

Owner:张晶 +2

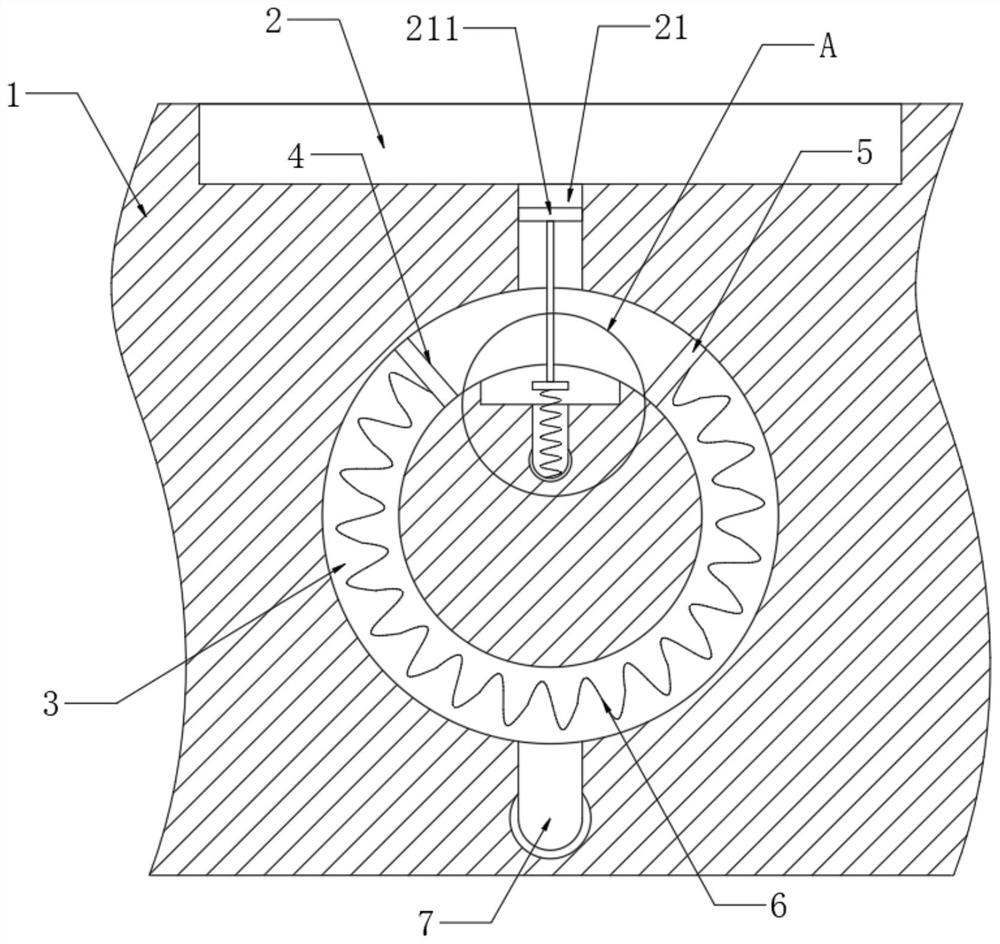

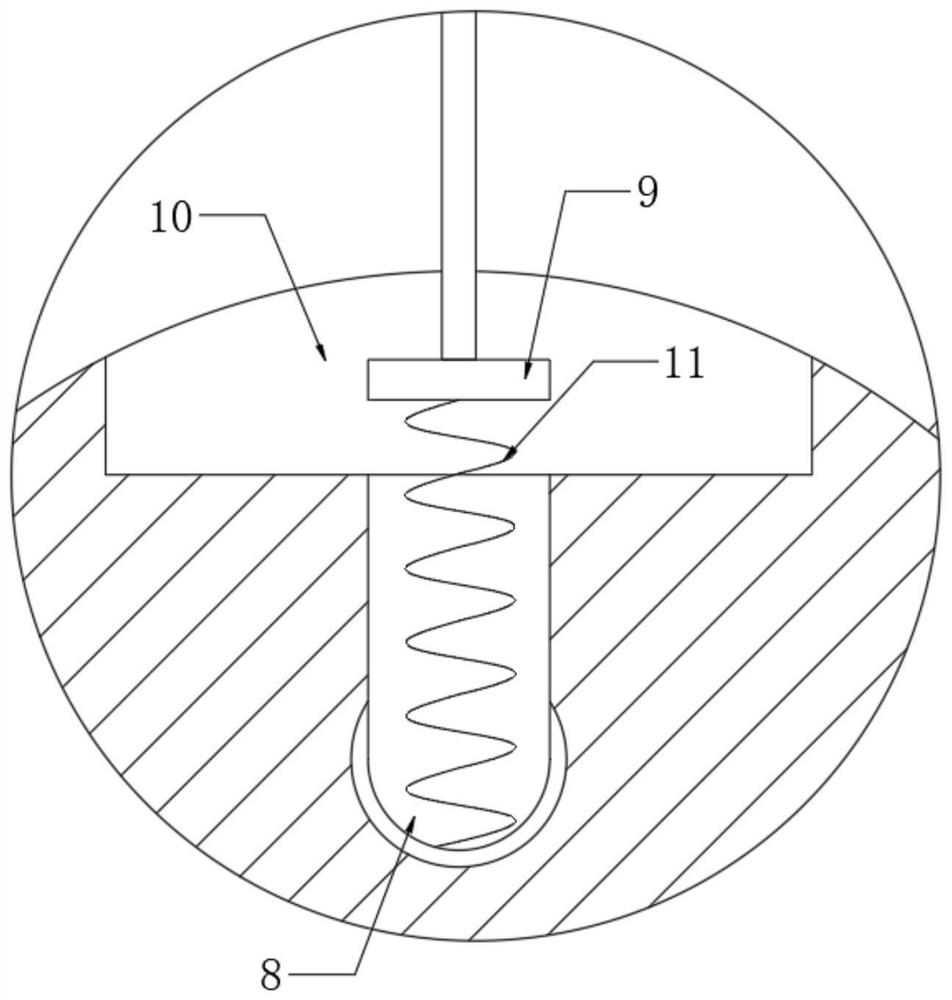

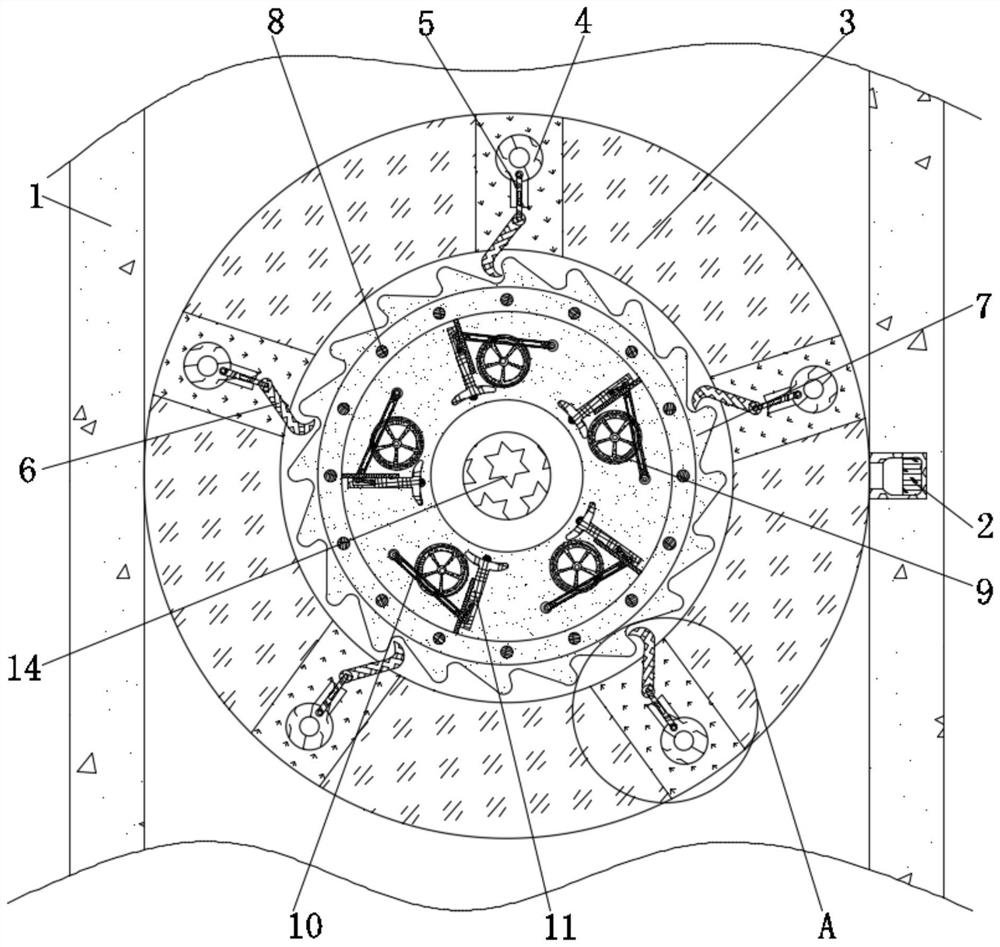

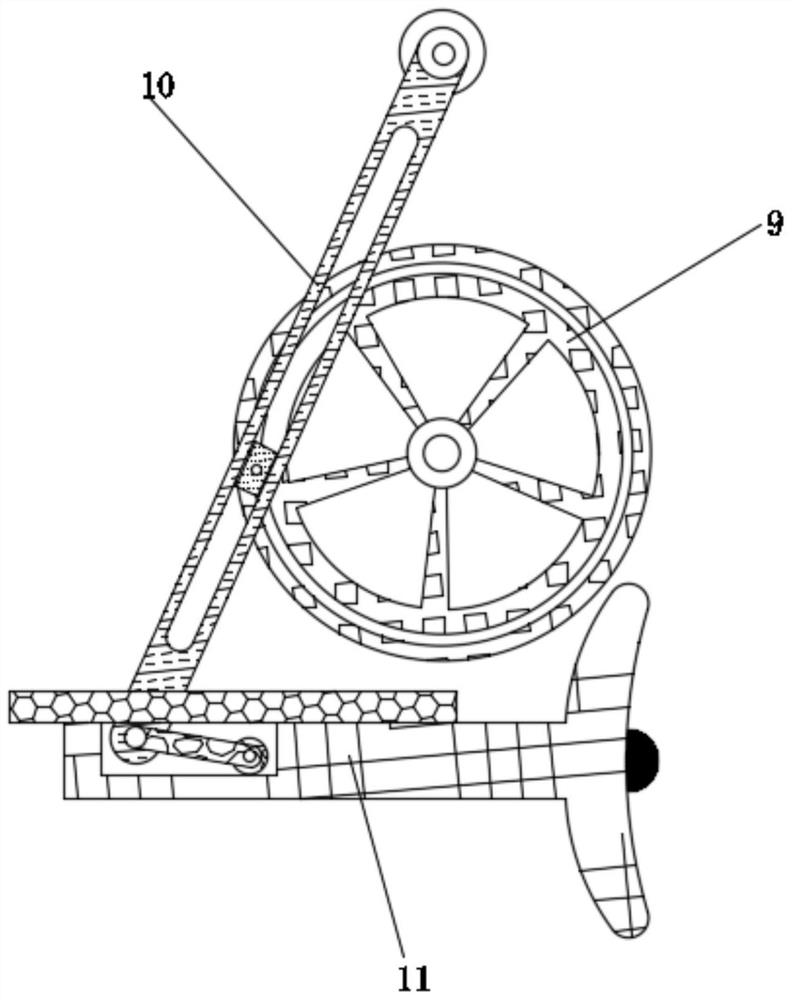

Positioning and punching protection device for automobile hub punching machine tool

InactiveCN112296199AProtect the effect of auto-fixTo achieve the effect of automatic fixationPerforating toolsMetal-working feeding devicesRatchetMotor vehicle part

The invention relates to the technical field of automobile part machining machine tools, and discloses a positioning and punching protection device for an automobile hub punching machine tool. The positioning and punching protection device comprises a shell, wherein a photosensitive component is fixedly connected to the interior of the shell, a supporting plate is fixedly connected to the interiorof the shell, a turntable is movably connected to the exterior of the supporting plate, and a connecting rod is movably connected to the exterior of the turntable. Under the interaction of all the structures of the device, when a wheel hub is machined, the circle center of the wheel hub can be the dead center, in this way, the situation that when an operator fixes the wheel hub, the center of thewheel hub deviates, and consequently the machined wheel hub is unqualified is avoided, machining precision is improved, and the percent of pass of products is guaranteed. A ratchet wheel disc can bedecelerated in time when the rotating speed of the ratchet wheel disc is too high, so that the effect of decelerating the ratchet wheel disc in time when the ratchet wheel disc stalls is achieved, thepersonal safety of an operator is protected, the machining efficiency is improved, and the device conforms to the design concept of intelligent manufacturing.

Owner:温州纽柏贸易有限公司

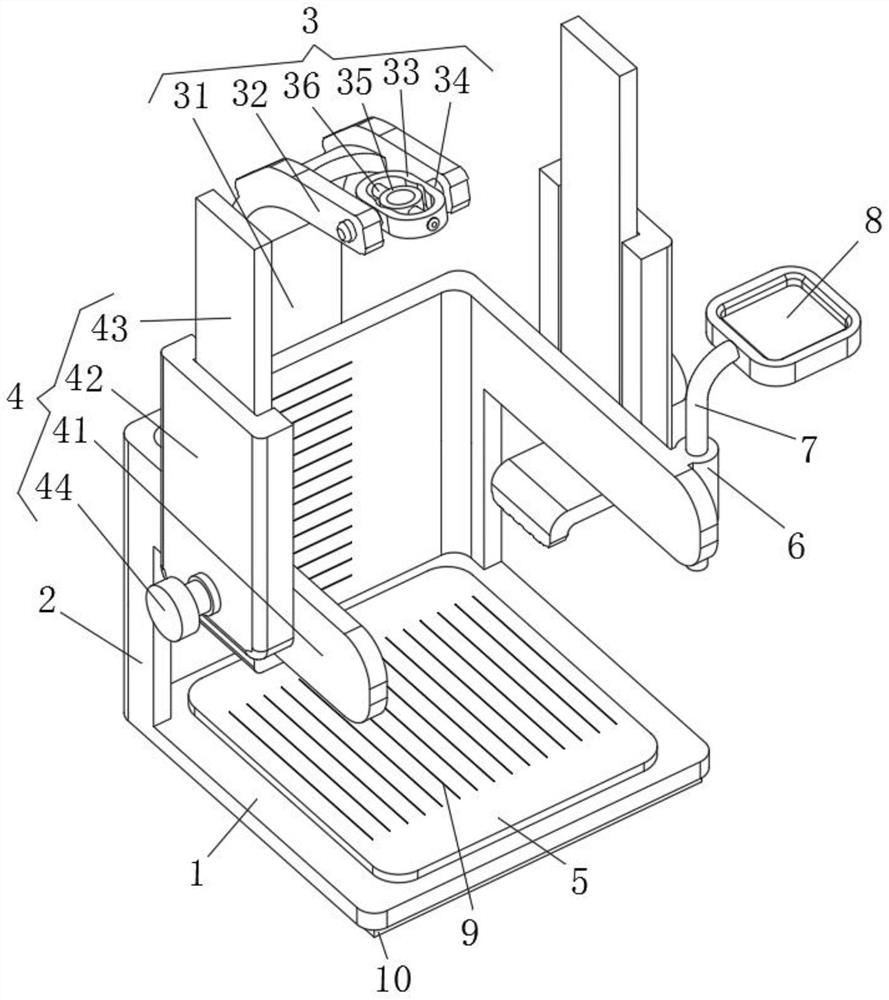

Tumor sampling device facilitating tumor separation

ActiveCN113063620AEasy to separateReduce scratchesWithdrawing sample devicesMechanical measuring arrangementsTumor SampleStructural engineering

A tumor sampling device facilitating tumor separation, disclosed in the invention, comprises a mounting plate, a vertical plate, a limiting mechanism and a positioning mechanism, the vertical plate is fixedly connected to the surface of the edge of the rear side of the mounting plate, and the positioning mechanism is connected to the front side of the vertical plate; the limiting mechanism comprises a supporting plate, a connector, a first connecting ring, a first connecting shaft, a second connecting ring and a second connecting shaft, the supporting plate is fixedly connected to the surface of the middle position of the rear side of the vertical plate, the connector bent forwards is fixedly connected to the upper end of the vertical plate, and the front end of the connector is in a U shape; and the first connecting ring is oval, first connecting shafts are fixedly connected to the surfaces of the two sides of the first connecting ring, and the first connecting shafts are rotationally connected with the two sides of the U-shaped end of the connector. The tumor sampling device facilitating tumor separation can support a surgical knife, is good in stability, reduces the cutting risk and is good in safety.

Owner:陕西省肿瘤医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com