Lightweight aggregate based on surface modification, preparation method of lightweight aggregate and lightweight concrete

A technology of surface modification and lightweight aggregate, which is applied in the field of lightweight concrete, can solve the problems of EPS concrete deficiency, retention of EPS concrete mix ratio design, etc., to increase hydrophilic performance, improve living comfort, and reduce building energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

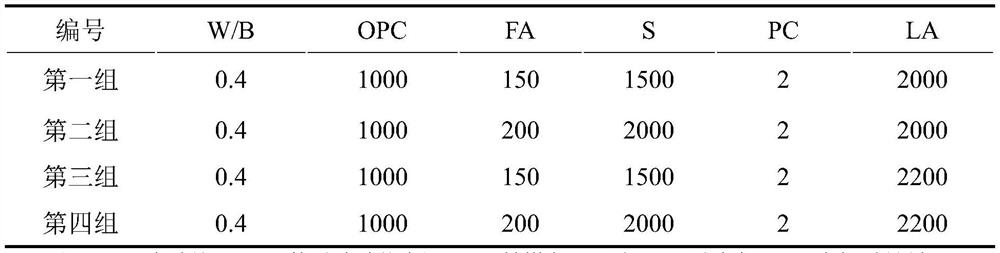

Examples

Embodiment 1

[0038] Providing a lightweight assembly based on surface-modified, including the following steps:

[0039] 1) 15 parts of nano silica, 1000 parts of ordinary silicate cement and 3 parts of the water reducer, and stirred well in the mixer, and then add a standard consistency amount under room temperature under room temperature conditions, and continued to stir Evenly obtained modified light collector shell slurry material;

[0040] 2) Soak the EPS foam particles in tap water, and the wetting treatment 1 h reaches the saturated water-absorbent state, then placed in a sugar coating, then the modified light collector shell slurry material obtained in the EPS foam particles is discharged until the surface of the EPS foam particles The thickness is 2 mm, then the spherical blank is obtained by the causal process, and in the process of the cooker in the cooker, the surface of the blank is removed by hot air, resulting in a spherical blank of the surface, and the particles, and then at th...

Embodiment 2

[0043] Providing a lightweight assembly based on surface-modified, including the following steps:

[0044] 1) 30 parts of the nanosilica, 1000 parts of ordinary portland cement and 5 parts of water reducer, placed stir mixer, and then follow the normal consistency aqueous gel was added at room temperature over 0.4, stirring was continued until to obtain a uniform paste-modified shell lightweight aggregate material;

[0045] 2) The EPS foam particles immersed in tap water, wetting treatment After 1h saturated water absorption state is placed dragee pan, and then Step 1) of the modified housing of lightweight aggregate slurry material is sprayed until the surface of the particles in the EPS foam wrapping layer a thickness of 2mm, then through the process to obtain a spherical ball into a blank, and the balling process to a kettle of hot air on to remove surface moisture blank to give the surface a porous, spherical particles of uniform billet, and then at a temperature of 20 ± 3 ℃, ...

Embodiment 3

[0048] Providing a lightweight assembly based on surface-modified, including the following steps:

[0049] 1) The nano silica 15 parts, 1000 parts of ordinary portland cement and 5 parts of water reducer, placed stir mixer, and then follow the water-cement ratio was added 0.4 normal consistency at room temperature, stirring was continued until to obtain a uniform paste-modified shell lightweight aggregate material;

[0050] 2) The EPS foam particles immersed in tap water, wetting treatment After 1h saturated water absorption state is placed dragee pan, and then Step 1) of the modified housing of lightweight aggregate slurry material is sprayed until the surface of the particles in the EPS foam wrapping layer a thickness of 2mm, then through the process to obtain a spherical ball into a blank, and the balling process to a kettle of hot air on to remove surface moisture blank to give the surface a porous, spherical particles of uniform billet, and then at a temperature of 20 ± 3 ℃, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com