Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve temperature field uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

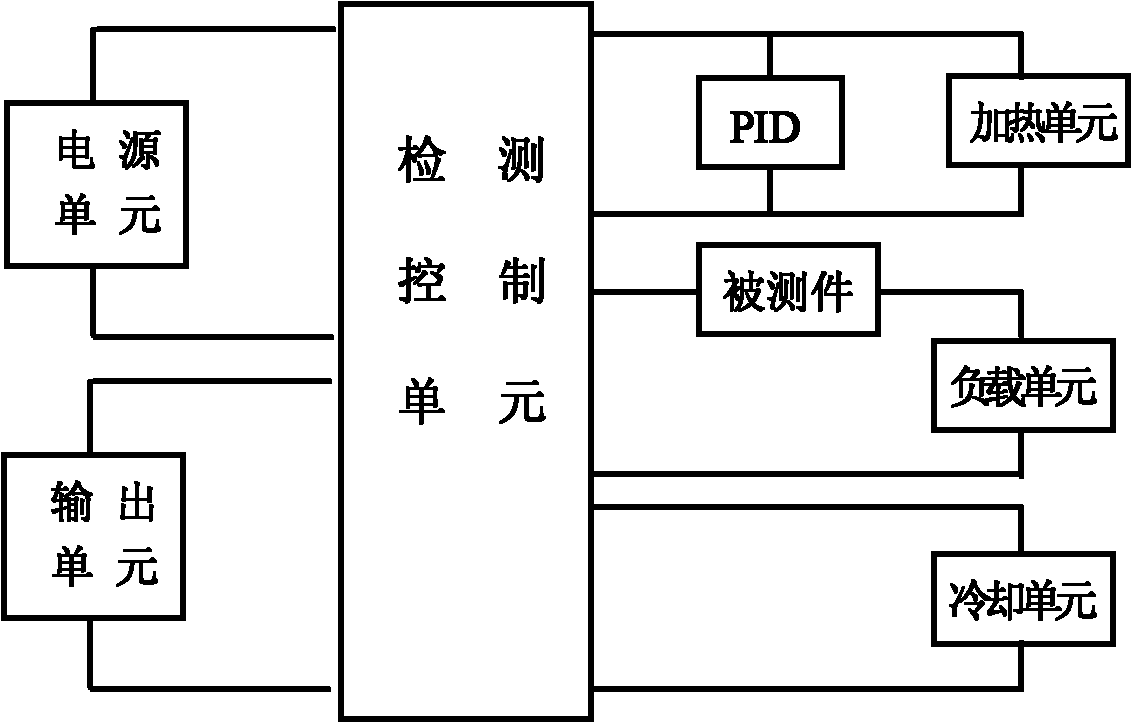

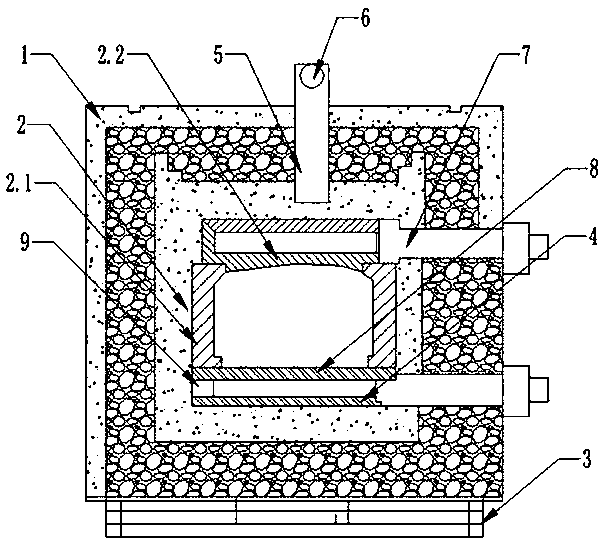

Durability tester for temperature controller

InactiveCN102122169ASmall thermal inertiaPrecise adjustment of heating temperatureTesting/monitoring control systemsAir pumpEngineering

The invention discloses a durability tester for a temperature controller, which comprises a power supply unit, a load unit, a detection control unit, an output unit, a heating unit and a cooling unit. The durability tester is characterized in that the heating unit comprises a copper block in which a heating pipe is arranged, the heating pipe is connected with the power supply unit, an upper surface of the copper block is provided with a thermoelectric couple for acquiring the temperature of the copper block in real time, the thermoelectric couple is connected with the detection control unit, and the upper surface of the copper block is further provided with an insulating heat-resistant pressure plate for fixing a temperature sensitive part of a temperature controller; the cooling unit is a cooling airflow sprayer arranged over the insulating heat-resistant pressure plate and connected with an external air pump of the tester; and the temperature controller is connected with an input end of the load unit through a lead. The durability tester has the advantages that the heating mode of the tester is small in thermal inertia, so that an adjustable range of the conduction and the disconnection of the temperature controller is large, the range of the heating temperature is large, the heating temperature and the cooling speed can be accurately controlled, accuracy of the test result can be improved, and the tester is simple in structure and low in cost.

Owner:宁波市产品质量监督检验研究院

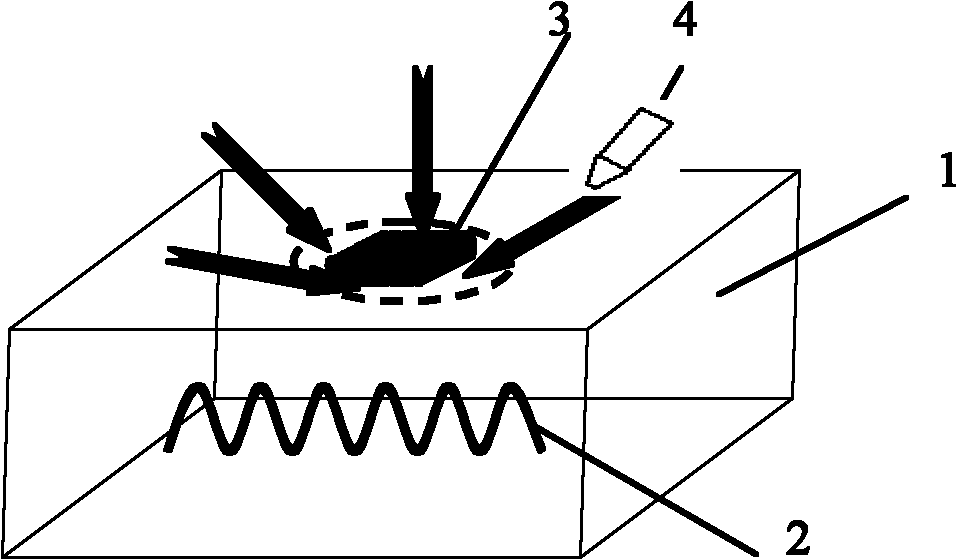

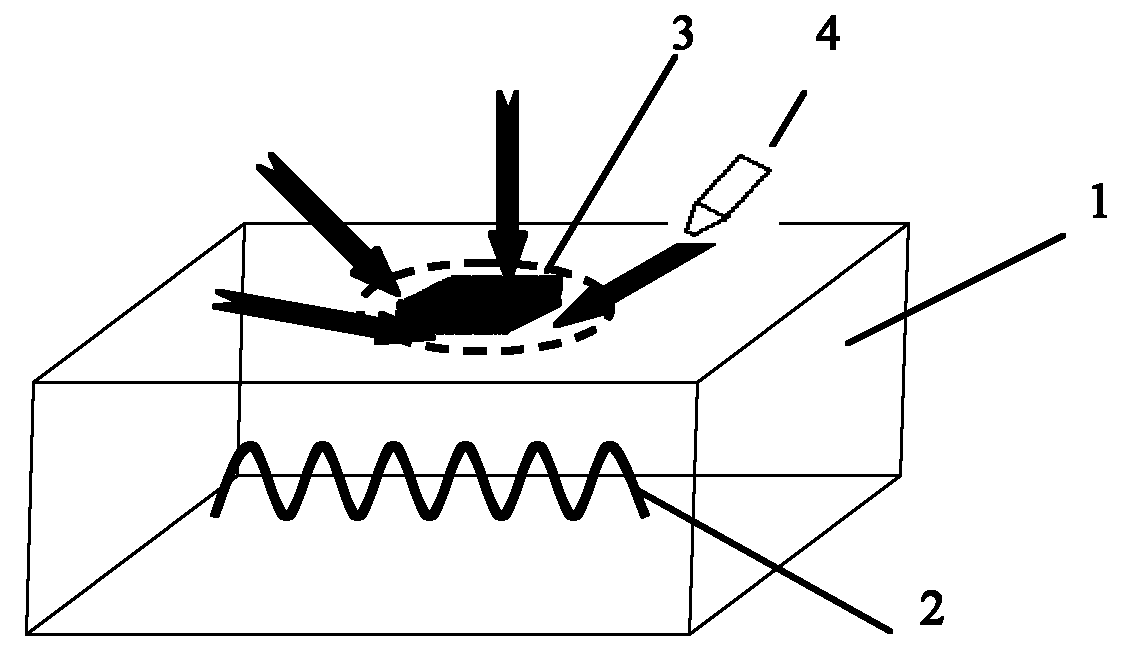

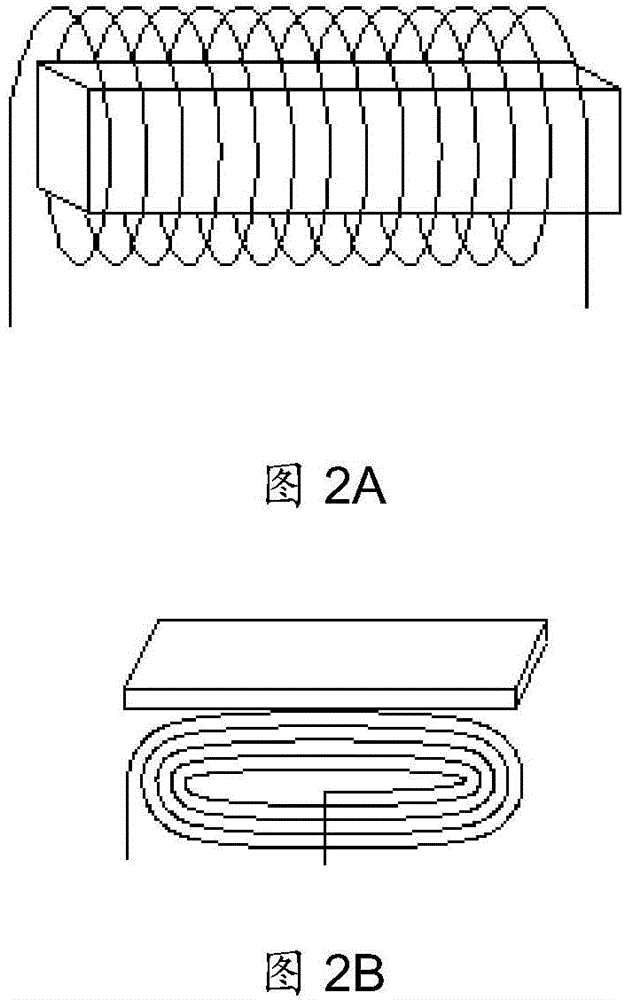

Low-cost quick solidifying method for composite material

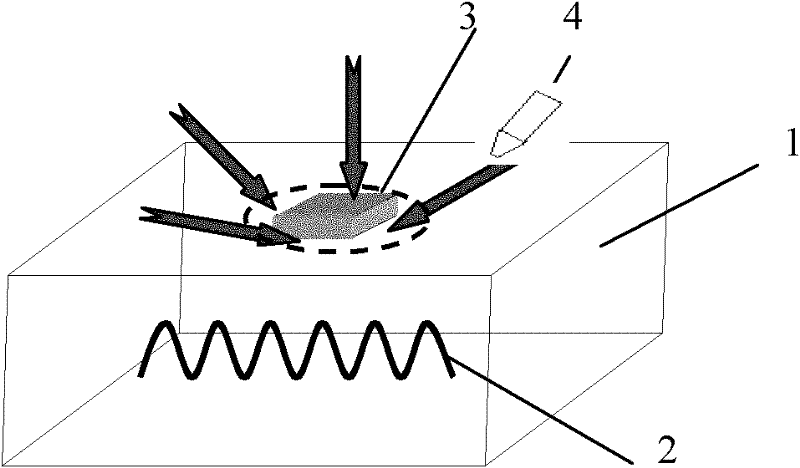

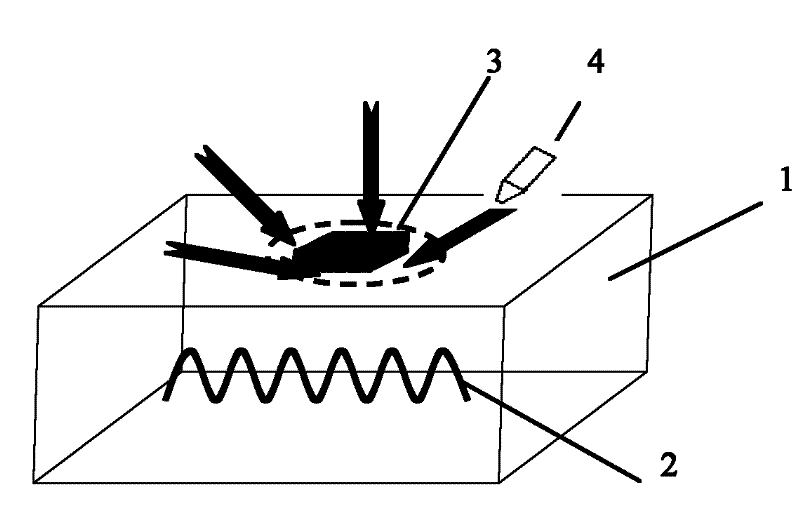

ActiveCN104827613AFast heatingGood uniformity of temperature fieldTemperature resistanceElectromagnetic induction

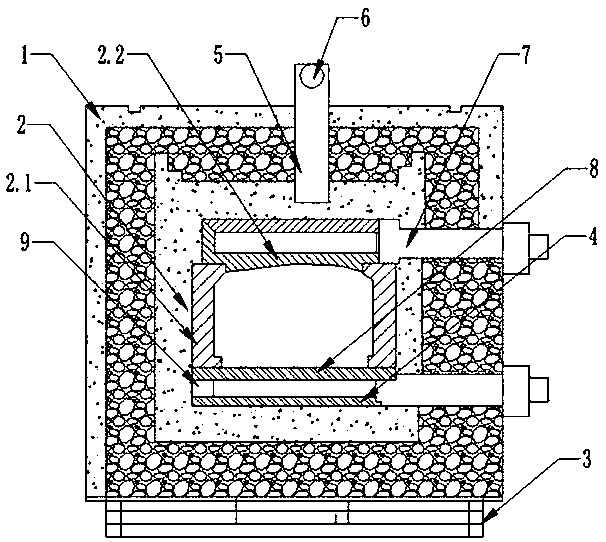

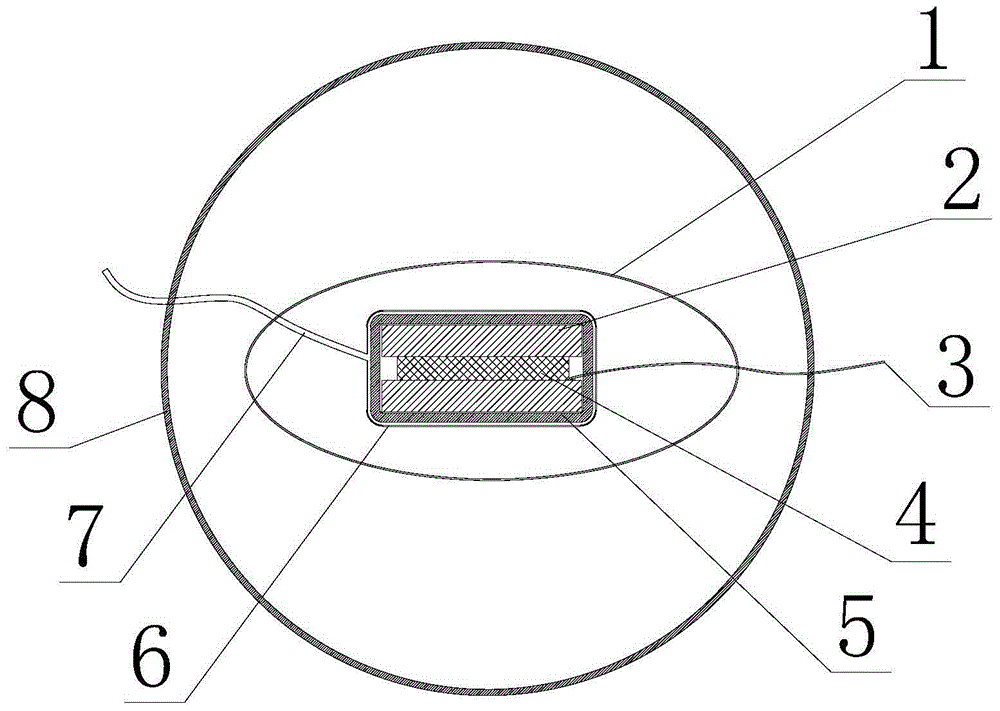

The invention relates to a low-cost quick solidifying method for a composite material. A middle-frequency electromagnetic induction coil directly acts on a metal mould to self heat and solidify to form a composite material, middle frequency heating speed is high, the uniformity of a temperature field is good, the control is exact, the temperature overshoot is small, the production efficiency is greatly improved, and the product quality is ensured; furthermore, by utilizing middle-frequency electromagnetic induction heating, only the self metal mould is heated, a non-metal auxiliary material for forming the composite material is not heated, and the ambient temperature is very low after a special coating is utilized in a forming process, so that a very expensive high-temperature-resistance auxiliary material is not necessary to use when a high-temperature-resistance composite material such as bismaleimide and polyimide is formed; therefore, the manufacturing cost is saved and the energy consumption is low.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

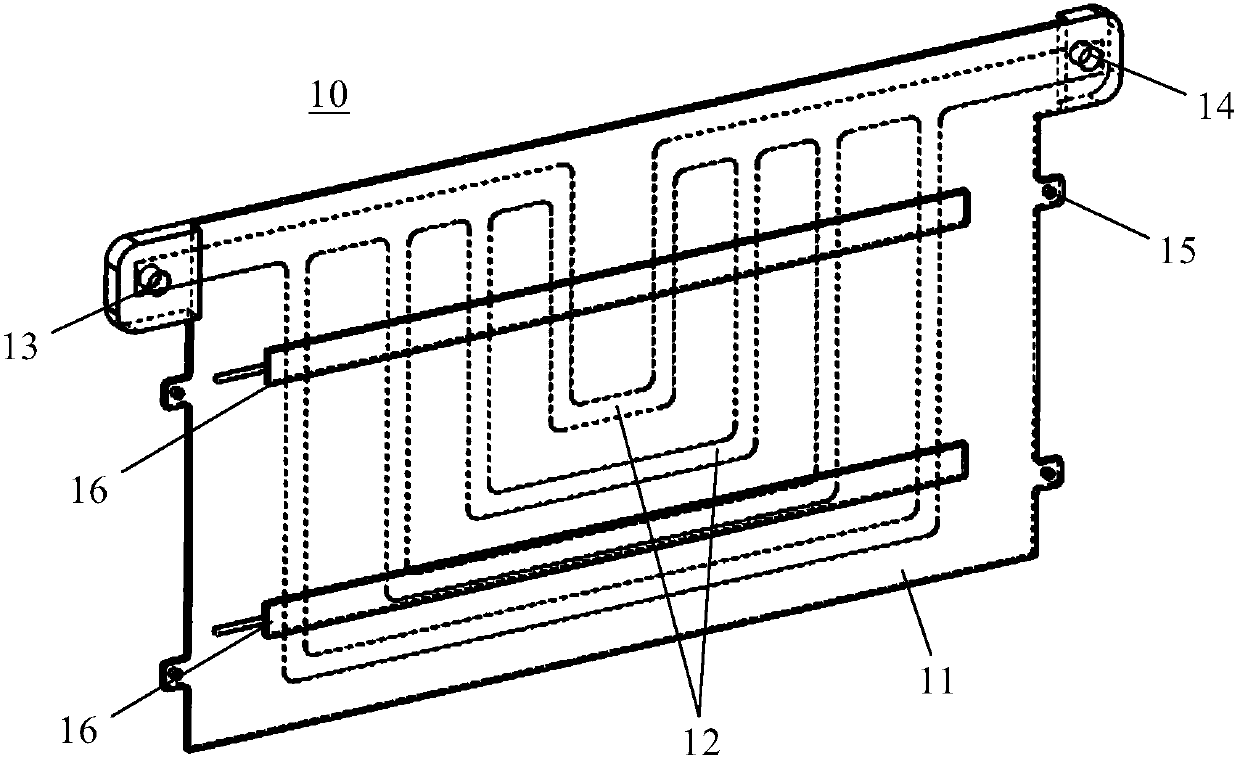

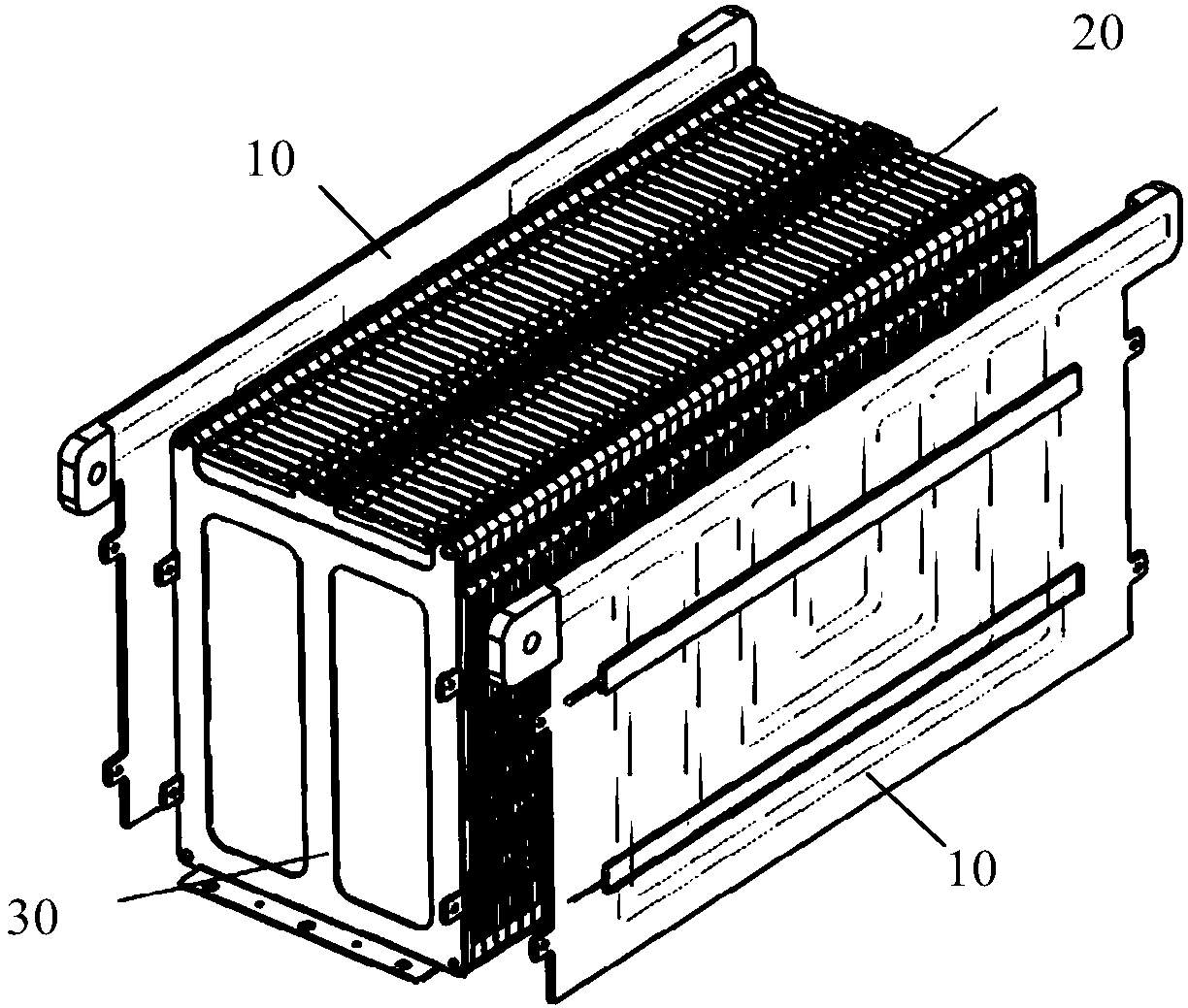

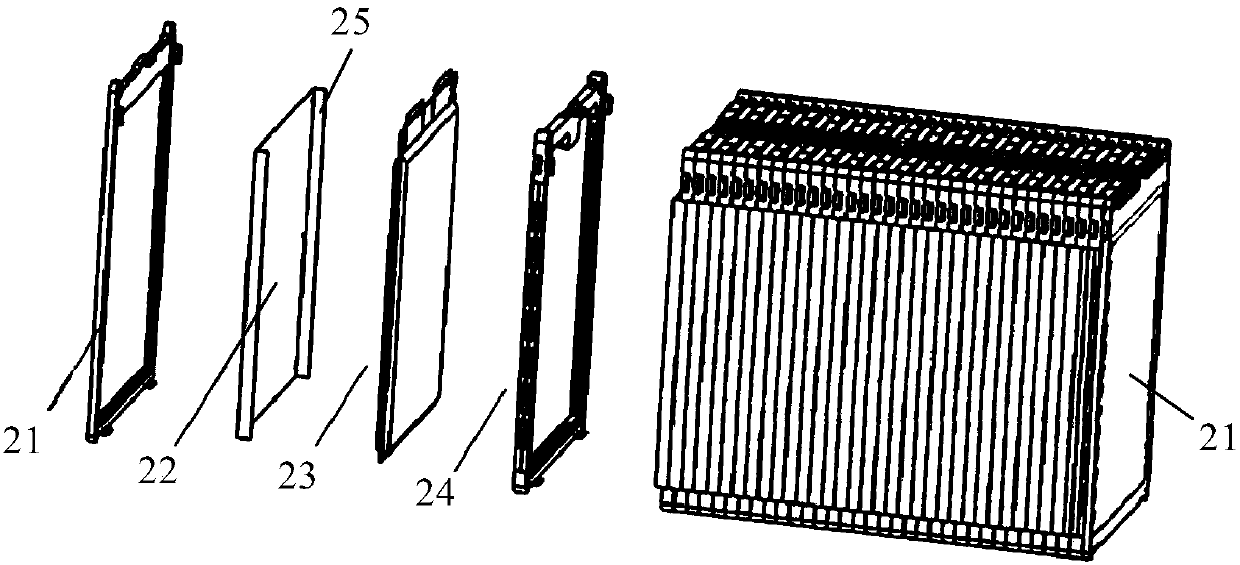

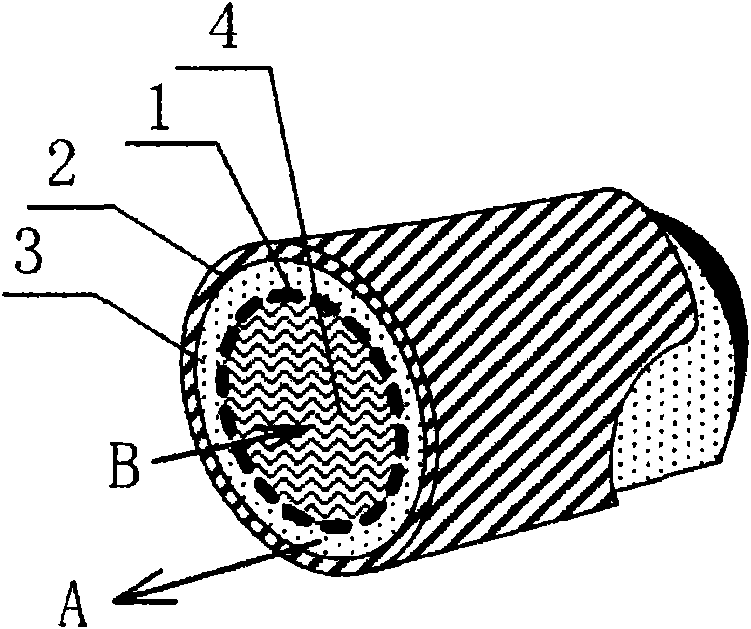

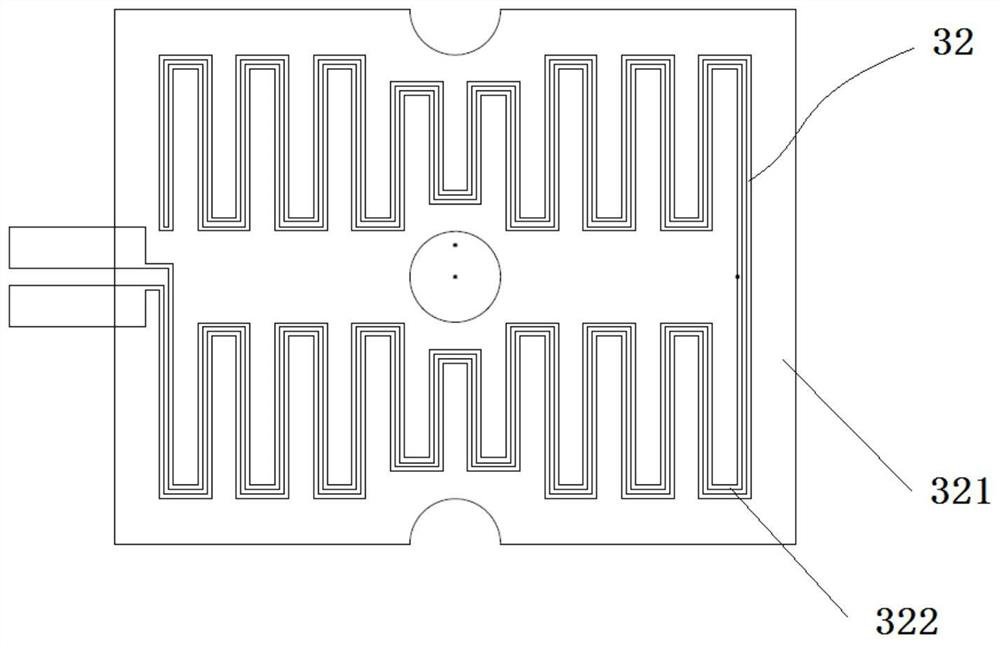

Liquid cooling plate for soft package power battery and battery module

PendingCN108054461AImprove temperature field uniformityExtended service lifeSecondary cellsBatteriesPower batteryElectrical battery

The invention discloses a liquid cooling plate for a soft package power battery and a battery module. The liquid cooling plate comprises a rectangular plate body and at least one PTC electric heatingstrip, wherein a plurality of runners are arranged in the plate body; a water inlet and a water outlet are formed in two ends of the plate body separately; the runners communicate with the water inletand the water outlet; the at least one PTC electric heating strip is fixed on the side wall of the plate body; and each runner is intersected with the at least one PTC electric heating strip. The battery module comprises a building block battery block; support vertical plates are arranged at two ends of the building block battery block and the liquid cooling plates are arranged at two sides; andthe support vertical plates are fixedly connected with the liquid cooling plates to form the battery module. The liquid cooling plate disclosed by the invention is capable of quickly cooling and preheating each single battery at the same time, so that a temperature field of the whole battery module is good in uniformity; the service life of the battery module is prolonged; and the use security ofthe battery module is improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Heat exchanger using microporous hydrophobic membrane for strengthening heat exchange

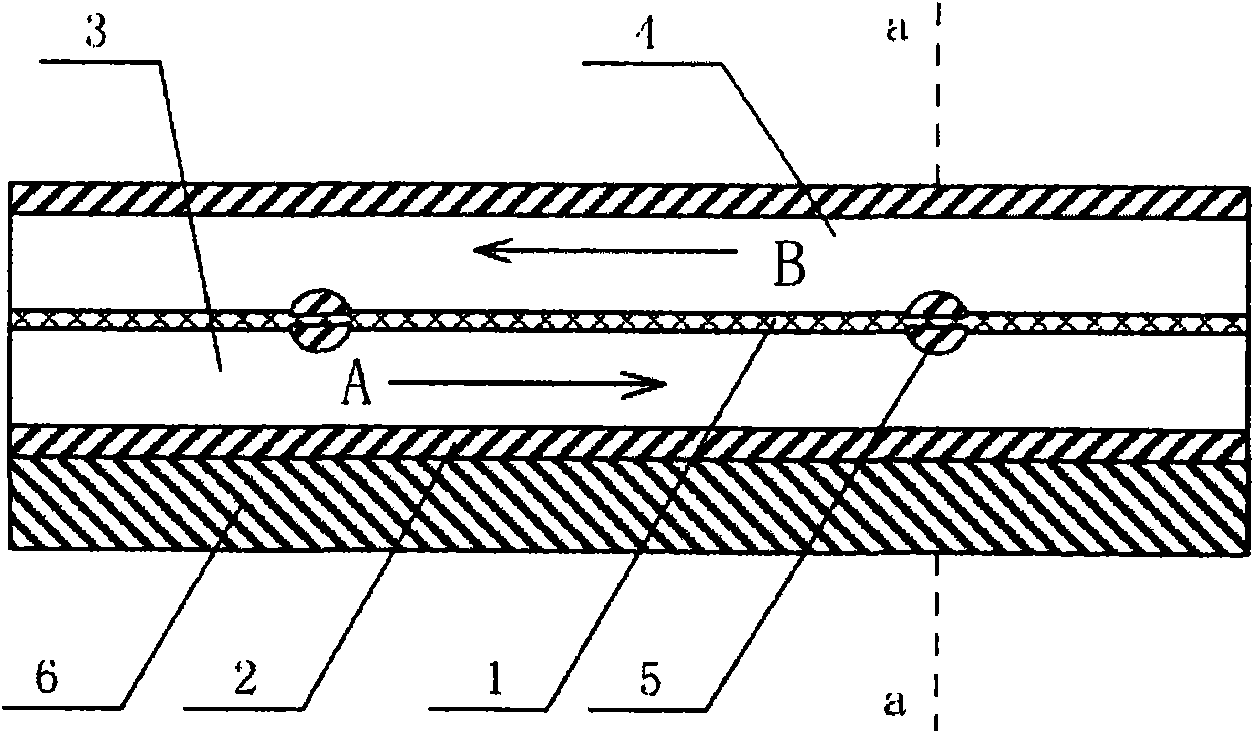

InactiveCN101576356ALower operating temperatureImprove uniformityStationary tubular conduit assembliesDistillationHeat currentEngineering

The invention discloses a heat exchanger using a microporous hydrophobic membrane for strengthening heat exchange. The shell of the heat exchanger is made of metal and fluid in the internal pipeline in the heat exchanger is divided by the microporous hydrophobic membrane into two parts flowing in opposite directions; fluid on a hot side of the heat exchanger contacts a heat exchange surface; the fluid on the hot side is heated by an external heat current, the temperature of the fluid on the hot side rises to generate a vapor pressure difference between two sides of the membrane, a working medium on high vapor pressure side evaporates and penetrates the membrane to flow to a low pressure side to achieve an effect of phase change heat transfer.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

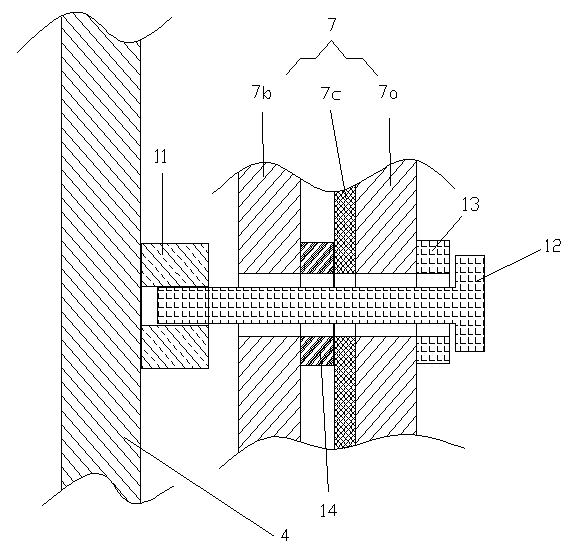

Heat shield of polysilicon CVD (chemical vapor deposition) reactor

InactiveCN103342362AHigh temperature resistantRisk of releaseSilicon compoundsEngineeringHeat losses

The invention relates to the field of an energy-saving device for a polysilicon CVD (chemical vapor deposition) reactor. An integrated quartz heat shield with best performance in the prior art is difficult to enlarge in size, poor in pressure resistance capability and fragile; and the produced heat radiation is high. According to the technical scheme provided by the invention, the heat shield is formed by splicing two or more quartz glass components; the overall heat shield of the reactor is formed by sleeving and superposing one or more layers of the splicing parts, and is fixed on the inner wall of the reactor through a fixing part; and one layer of quartz glass closest to a silicon rod is coated with a back reflection film. The heat shield provided by the invention obviously reduces the heat loss, and has the advantages that the heat stress of the silicon rod is low, the core melting and rod cracking probability of the silicon rod is low, the temperature field is uniform, the large-diameter silicon rod can be beneficially obtained, the yield is high, the equipment is easy to manufacture, convenient to operate and simple to maintain, etc.

Owner:XINTE ENERGY

Integral molding method for vertical-rib composite material stiffened wallboard through autoclave

ActiveCN111347694AImprove heating uniformityImprove temperature field uniformityDomestic articlesMold removalAutoclave

The invention relates to an integral molding method for a vertical-rib composite material stiffened wallboard through an autoclave and belongs to the technical filed of composite material molding. Theintegral molding method for the vertical-rib composite material stiffened wallboard through the autoclave includes the steps of soft mold manufacturing, product blanking, and product manufacturing. Askin molding mold is paved with a composite material faceplate, is placed into the autoclave and is taken out of the autoclave after solidified molding. The composite material faceplate is paved witha skin. All webs, middle flange strips and radius fillers are laid on respective tools. The middle flange strips and the radius fillers are demolded after laying is finished. U-shaped groove webs, the middle flange strips, the radius fillers, and bilateral L-shaped webs are placed on a positioning mold and combined and then placed into the autoclave so as to be preformed into a long purlin: the skin with the composite faceplate and the skin molding mold are together placed into the autoclave to be preformed; the long purlin and the skin are taken out of the autoclave; the long purlin is demolded and is positioned with the skin in a combination mode; a stripping cloth, an isolating film, the soft mold, and a ventilated felt are positioned on the long purlin; and the long purlin is encapsulated with a vacuum bag to enter the autoclave to be solidified; and after solidified well, the long purlin is taken out of the autoclave, and is demolded and milled to form a product. The integral molding method is used for manufacturing the vertical-rib composite material stiffened wallboard.

Owner:GUANGLIAN AVIATION IND CO LTD

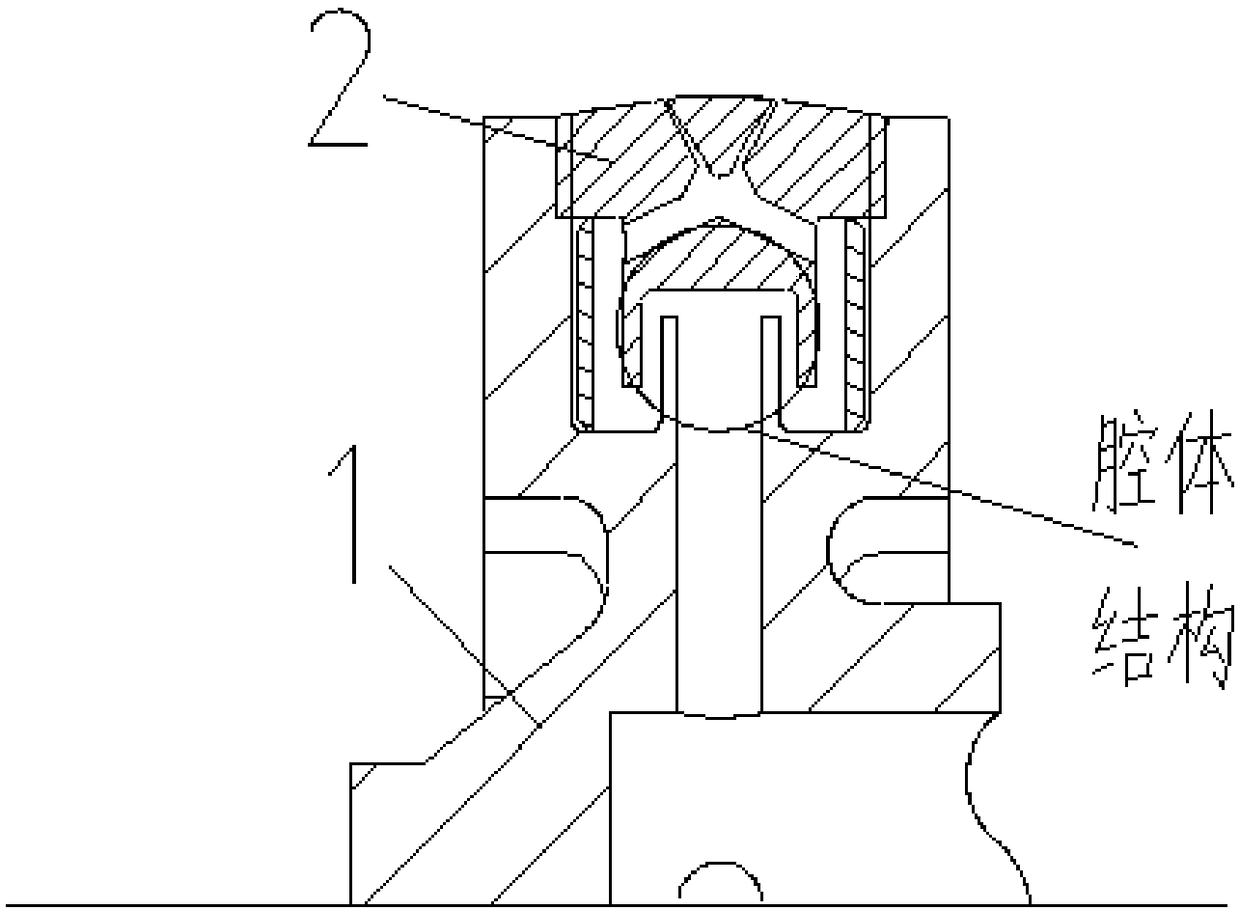

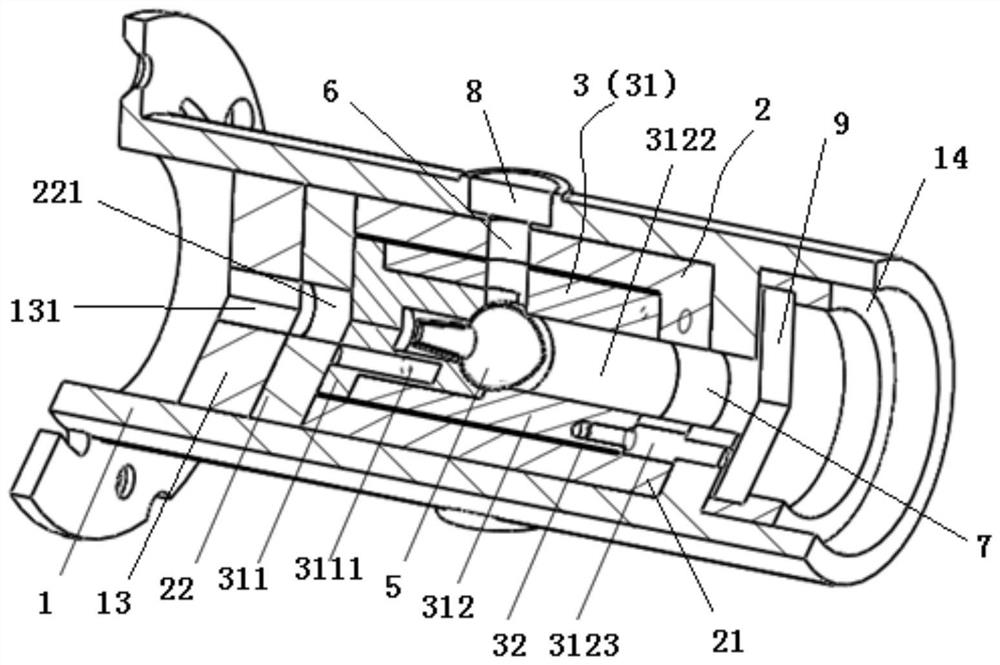

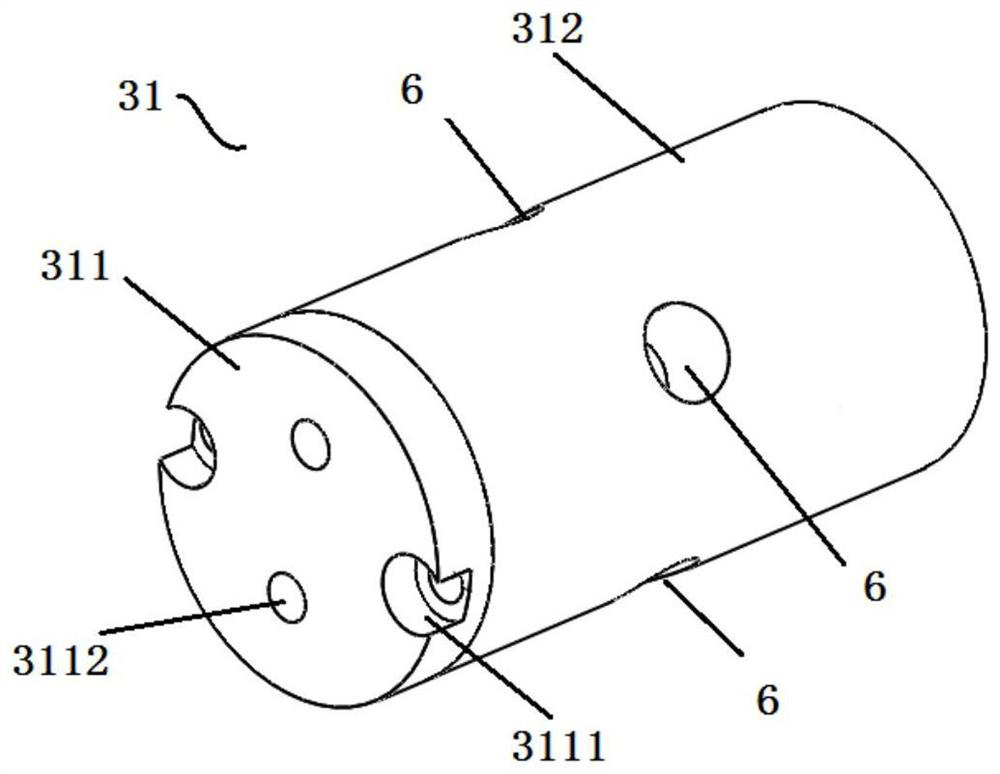

Wide cone angle atomizing oil throwing disc structure

ActiveCN108150292AImprove temperature field uniformityEfficient combustionTurbine/propulsion fuel supply systemsCombustion chamberSpray nozzle

The invention relates to a wide cone angle atomizing oil throwing disc structure, and relates to the technical field of turbine engines. According to the wide cone angle atomizing oil throwing disc structure, the design of spraying holes in the nozzles and the design of a cavity formed between an oil throwing disc body and the nozzles are adopted so that the good atomization effect can be obtainedat the lower rotating speed of the engine while the small turbine engine has the characteristic of being compact in structure, meanwhile, certain taper angle distribution can be guaranteed, the uniformity of the temperature field in a flame tube is improved, and the oil supply pressure is reduced; according to the wide cone angle atomizing oil throwing disc structure, the wide airspace work of the engine can be supported, namely, under different oil supply flows, atomized particle size distribution can be ensured by the oil throwing disc so that efficiently and stably burning in a combustionchamber can be ensured.

Owner:BEIJING POWER MACHINERY INST

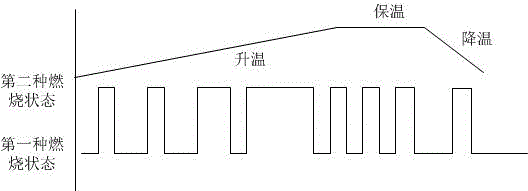

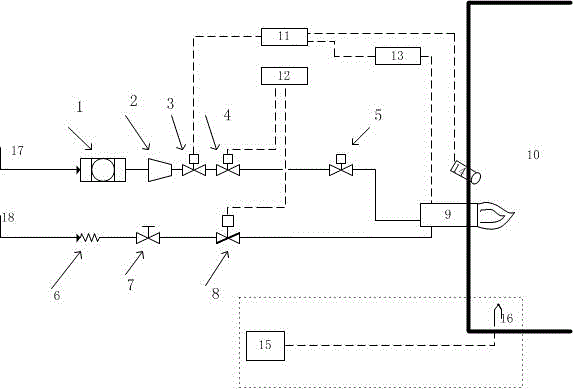

Intelligent pulse combustion system

InactiveCN106196052AImprove combustion efficiencyReduce energy consumptionGaseous fuel burnerHeat transfer efficiencyAutomotive engineering

The invention discloses an intelligent pulse combustion system. The intelligent pulse combustion system comprises a gas pipeline, a combustion assisting air pipeline, a combustor and a control system; the gas pipeline introduces gas into the combustor; the combustion assisting air pipeline introduces air into the combustor; nd the control system controls coordinated work of the gas pipeline, the combustion assisting air pipeline and the combustor to realize intelligent pulse combustion control. The intelligent pulse combustion system realizes intelligent pulse combustion control through controlling the combustion state switching and the combustion lasting time of the combustor by the control system according to a deviated value between a detected industrial furnace actual temperature and a preset temperature. The intelligent pulse combustion system can realize precise control of a combustion atmosphere, improves the heat transfer efficiency, largely reduces the energy consumption, needs no online adjustment, can increase the burner load adjusting ratio, is simple and reliable, is low in manufacturing cost, and can reduce generation of NOx.

Owner:钟海胜

Forming method suitable for T-shaped and L-shaped composite material wall plates

The invention belongs to the technical field of forming of composite materials, and relates to a forming method suitable for T-shaped and L-shaped composite material wall plates. A forming mode combining a soft film positioning plate and a soft film is adopted, a fit clearance does not exist, pressure transmission is uniform, and the internal quality of formed wall plates is good. There are only afew molds in a vacuum bag, heat transferring is uniform, and the uniformity of a temperature field is good. The number of molds entering a tank is small, a soft film forming mold is low in precisionand does not need to enter the tank, and the overall mold cost is low. The assembling clearance is small, the forming quality is good, and the forming method is suitable for wall plates with large skin thickness change or large skin shape change. By means of the forming method suitable for T-shaped and L-shaped composite material wall plates, the internal quality of composite material wall platesformed through the method is high, studs are high in position precision, and the forming method is particularly suitable for forming wall plates with complex surfaces and many variable-thickness areas, and lays a certain technical foundation for development of composite materials.

Owner:AVIC COMPOSITES

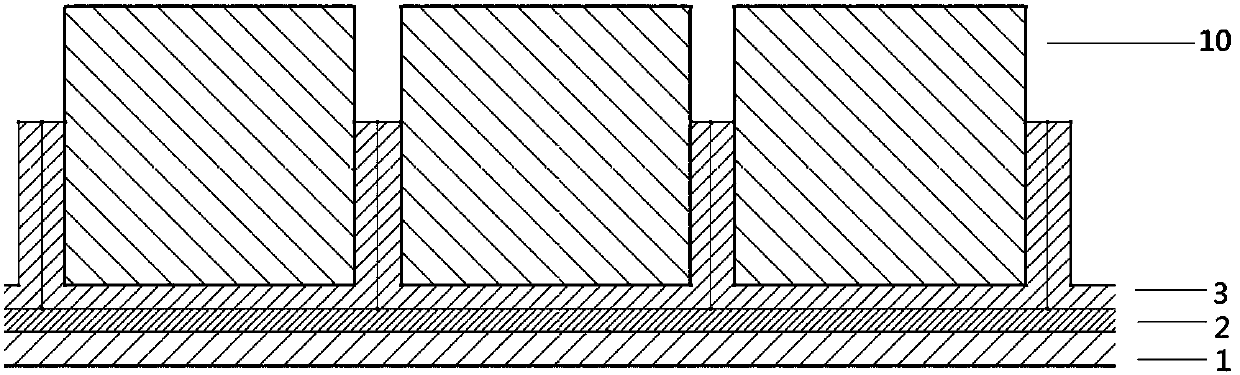

Heat conduction structure and heating and evaporating assembly

PendingCN107829070AReduce distractionsFast conductionVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention discloses a heat conduction structure. The heat conduction structure comprises a plurality of heat conduction pipes. Each heat conduction pipe is of a hollow tubular body with an opening. The outer walls of the multiple heat conduction pipes are mutually attached and fixed, and the shape of the section, in the radial direction, of the multiple attached heat conduction pipes is a gridshape. The invention further provides a heating and evaporating assembly. The heating and evaporating assembly comprises a crucible and the above heat conduction structure, and the shape and the sizeof the heat conduction structure are matched with the shape and the size of the crucible. The heat conduction structure is arranged in the crucible, and the outer walls of the heat conduction pipes on the outermost part of the heat conduction structure make contact with the inner wall of the crucible. According to the provided heat conduction structure and the provided heating and evaporating assembly, the heat conduction structure is formed by the multiple heat conduction pipes, a plurality of auxiliary evaporation bodies are formed, and disturbance among the auxiliary evaporation bodies canbe reduced; and the heat of the crucible wall adjacent to a heating source can be rapidly conducted into the crucible, and uniformity of the temperature field in the non-balance state is promoted.

Owner:SHENZHEN INST OF ADVANCED TECH

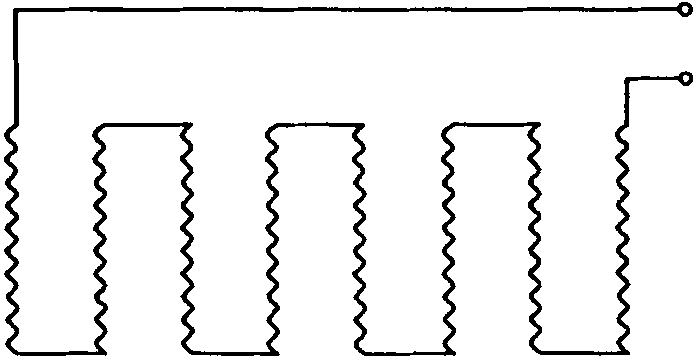

High shimming air chamber heating structure

ActiveCN111854743AIncrease local temperatureImprove temperature field uniformityNavigation by speed/acceleration measurementsOhmic-resistance heatingEngineeringHeat conservation

A high shimming air chamber heating structure is used for an atomic spin inertia measurement system and comprises a supporting base, a heat preservation device and a heating device. The heat preservation device wraps the heating device and then is fixed into the supporting base. The heating device comprises an inner heat conduction device and a high shimming heating film wrapping the whole side surface of the inner heat conduction device; the inner heat conduction device comprises an air chamber seat and an air chamber fixing part which are made of high-thermal-conductivity materials and are in butt joint with each other, the alkali metal air chamber is clamped and coated through mutual opposite pressing of the air chamber seat and the air chamber fixing part, the heat conduction area of the alkali metal air chamber is increased, and the local temperature of the alkali metal air chamber is prevented from being too high. The high shimming heating film directly coats the side surfaces ofthe air chamber seat and the air chamber fixing part which are made of high-thermal-conductivity materials; and the high shimming heating film is a high shimming heating film of which the temperaturefluctuation amplitude is kept between 5mK and 8mK in normal work, so that the temperature fluctuation in the alkali metal gas chamber is kept between 0.5 K and 1.5 K when the atomic spin inertia measurement system works normally.

Owner:BEIHANG UNIV

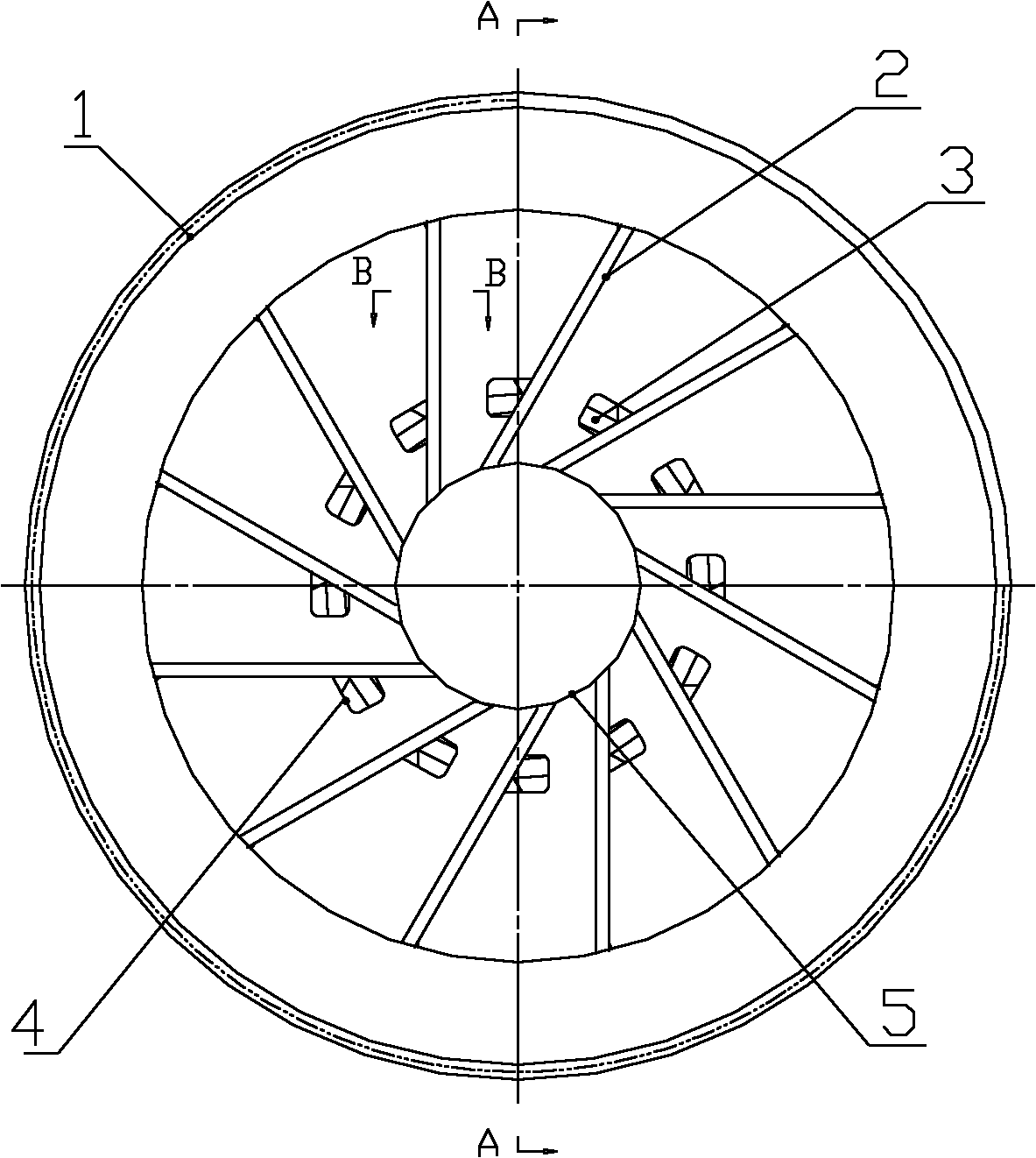

High-reliability multiblade cold/hot air flow mixed spoiler

ActiveCN102042908AImprove temperature field uniformityEfficient blendingGas-turbine engine testingJet-propulsion engine testingAirflowEngineering

The invention provides a high-reliability multiblade cold / hot air flow mixed spoiler which comprises an outer ring and a spoiling component, wherein the outer ring can be connected with the inner wall of the pipeline through screws, and the spoiling component is arranged on the inner wall of the outer ring; the spoiling component comprises a plurality of flat blades and a spacing ring, and the blades are uniformly distributed in the circumferential direction; one end of each blade is welded on the inner wall of the outer ring and forms a certain included angle with the approach flow direction, and the other end of each blade is a free end and extends towards the central axis of the outer ring to form a center hole; the free end of each blade is provided with a spacing hole of which the cross-sectional shape is greater than that of the spacing ring; and the spacing ring orderly penetrates through the spacing hole of each blade. The invention overcomes the defect that the air flow temperature field uniformity of the existing high-flow high-temperature simulated ground equipment can not satisfy the requirements, provides a static mixed mode of multiblade spoiling and variable cross-section pipelines, and has the advantages of high flow, high temperature difference and high reliability.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

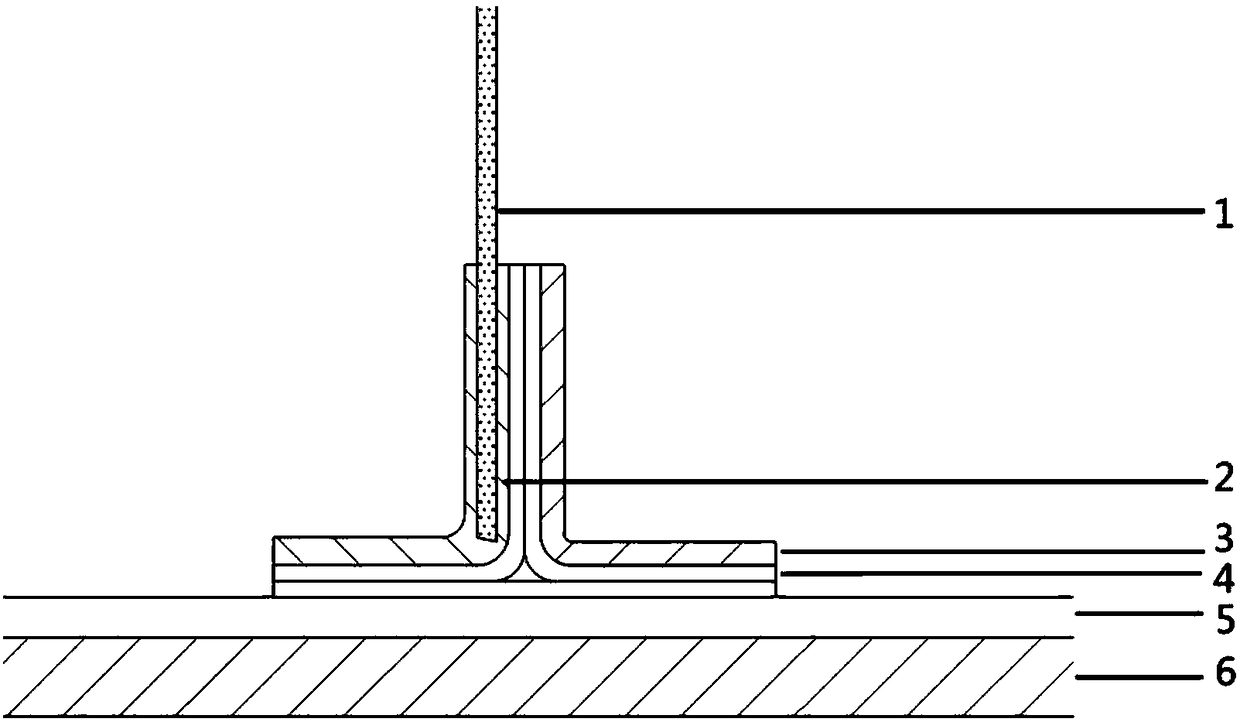

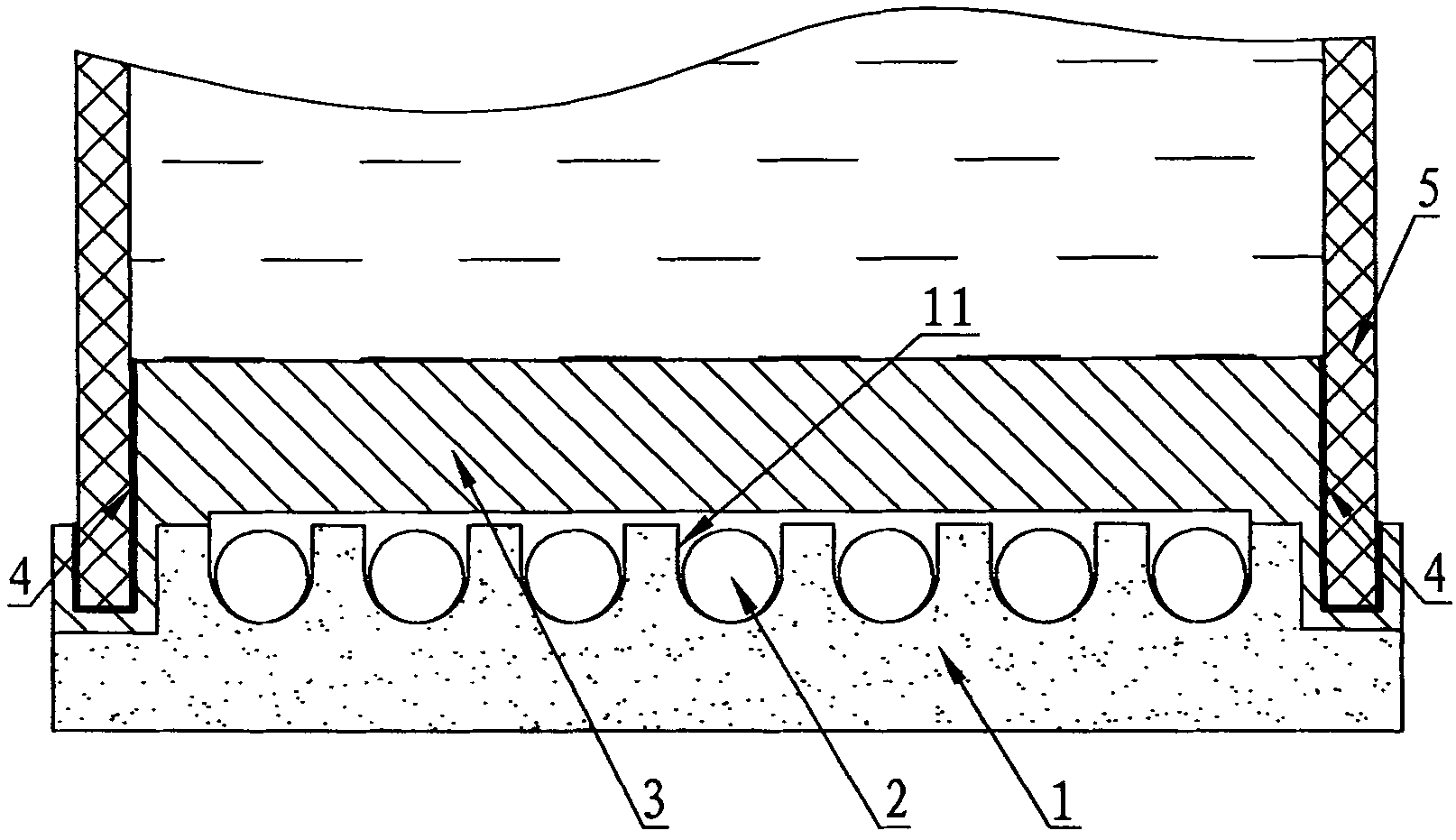

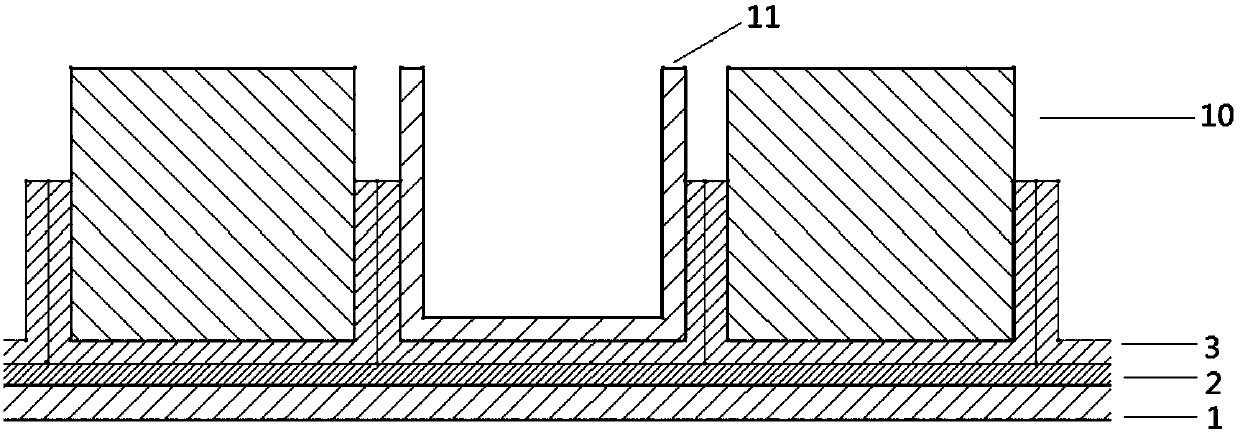

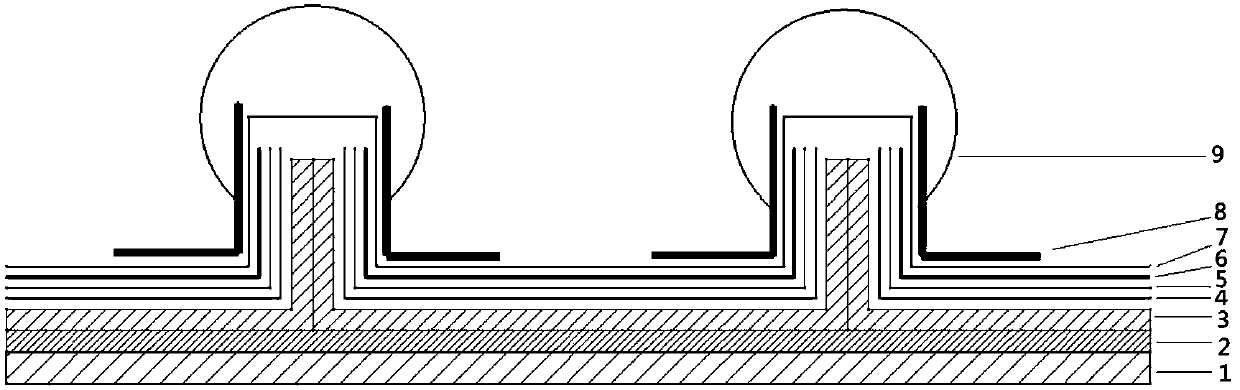

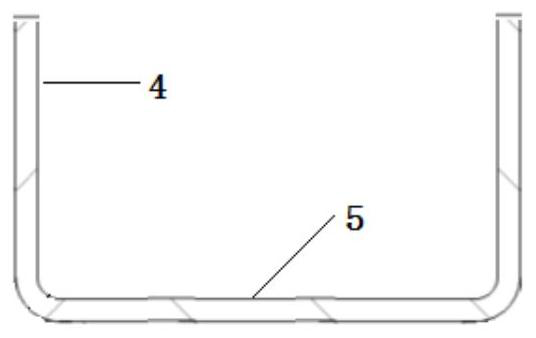

Silicon wafer etching bath liquid isolation type uniform heating device

InactiveCN102157620AUniform heating temperatureThere will be no local high and local lowAfter-treatment detailsFinal product manufactureElectricityLiquid temperature

The invention provides a silicon wafer etching bath liquid isolation type uniform heating device. The device comprises a heat insulation base, electric heating coils, a stainless steel plate, corrosion-resistant adhesive layers and an etching bath body, wherein grooves for the electric heating coils are distributed on the heat insulation base; the depth of the grooves is more than the diameter of the electric heating coils; the electric heating coils are distributed in the grooves; the stainless steel plate is arranged above the heat insulation base; the etching bath body is connected with the stainless steel plate in an adhesive manner by the corrosion-resistant adhesive layers; and the radiating area of the stainless steel plate is equivalent to the bottom of the etching bath. The device has the following beneficial effects: a plane type uniform heating device for the stainless steel plate is arranged at the bottom of the etching bath, the electric heating coils are arranged below the stainless steel plate, the electric heating coils firstly heat the whole stainless steel plate and then the stainless steel plate uniformly transfers the heat to the corrosive liquid in the etching bath, thus not only improving the speed of temperature rise of the liquid in the etching bath but also improving the uniformity of the temperature field.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

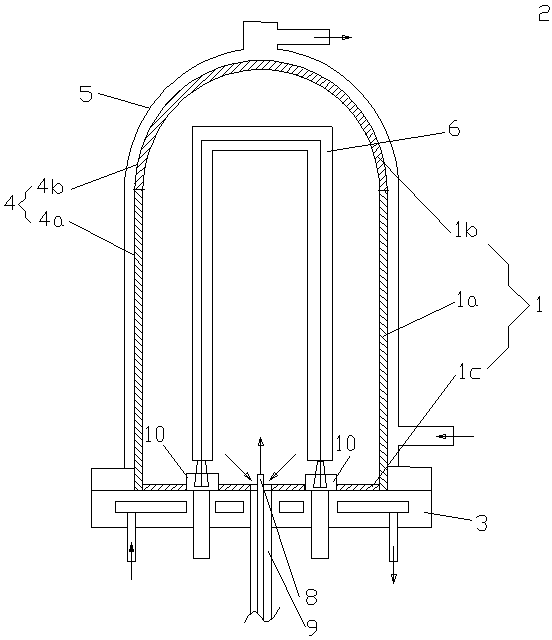

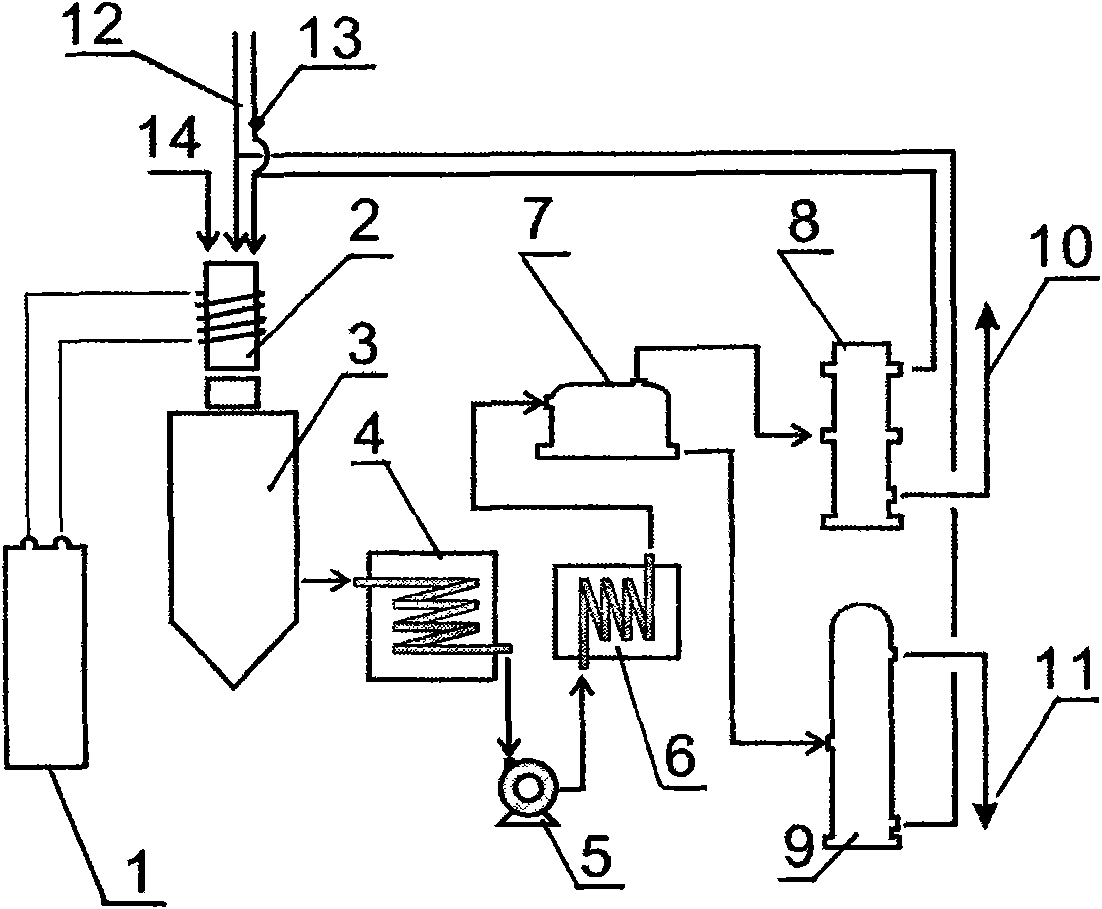

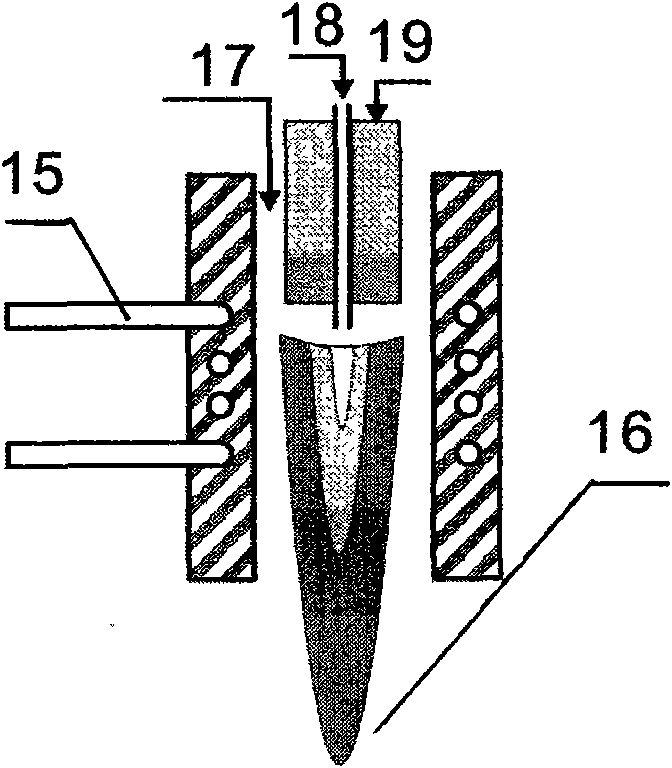

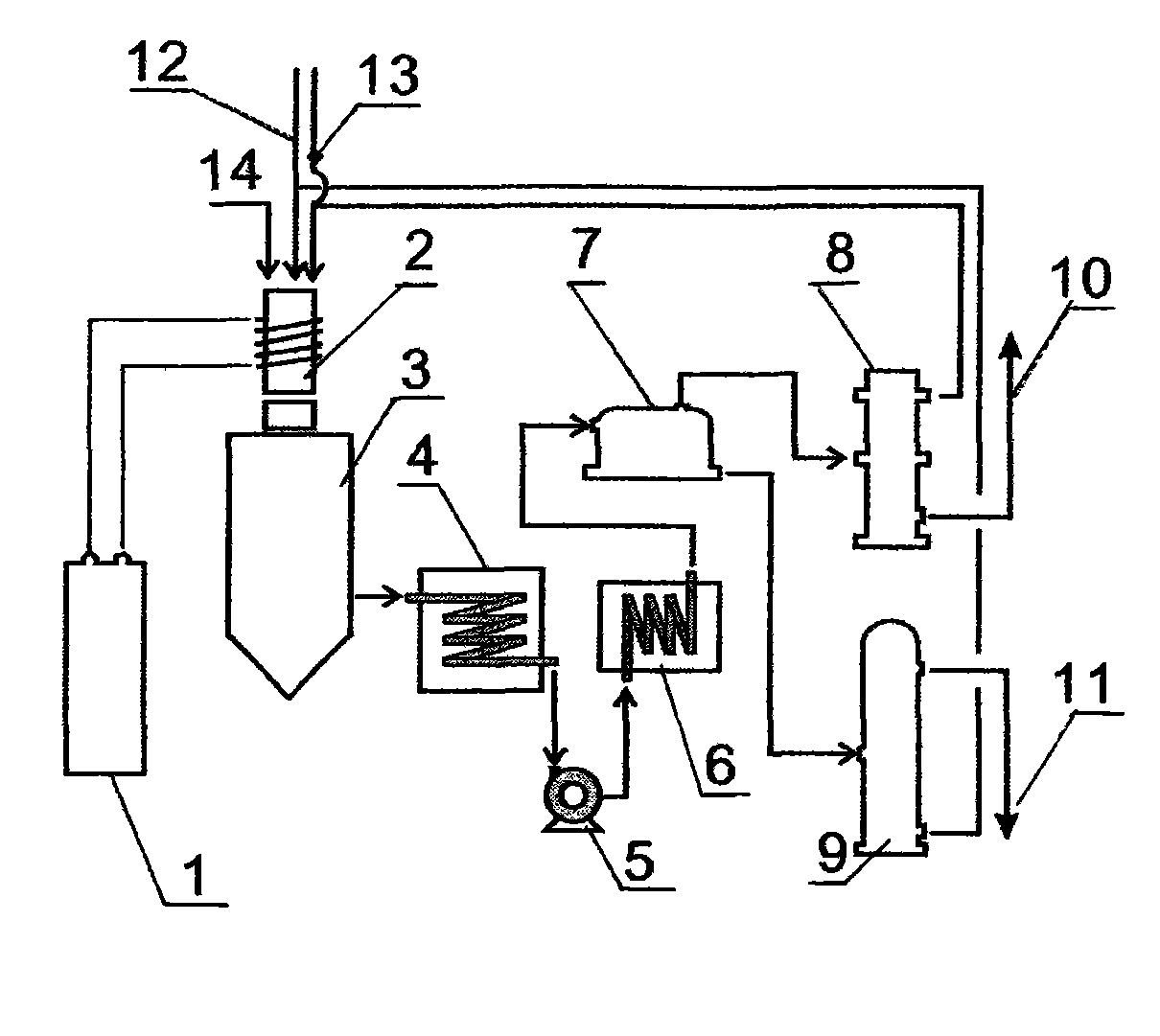

Method for preparing trichlorosilane by plasma hydrogenization of silicon tetrachloride

ActiveCN101475175BReduce manufacturing costIncrease productionHalogenated silanesDistillationPlasma flame

The invention discloses a method for producing trichlorosilane from silicon tetrachloride through plasma hydrogenation. The method is characterized in that through induction of a high-frequency coil, hydrogenous plasma is produced to treat a gaseous silicon tetrachloride raw material added to a plasma region; two raw materials participate in reaction in a plasma state; and the silicon tetrachloride is hydrogenated into the trichlorosilane. In a high-frequency coil inducted plasma rector, a gas circuit is divided into three circuits of axis central gas, central main gas and protective gas; hydrogenous gas is subjected to plasma arc starting to form a hydrogenous plasma flame region; the gasified silicon tetrachloride is added through an axis center, reacts in the hydrogenous plasma flame region, and is converted into the trichlorosilane; after the reaction, mixed gas is subjected to heat exchange, condensation, cooling and distillation procedures to obtain a trichlorosilane liquid, a silicon tetrachloride liquid, chlorine hydride, hydrogen gas and argon gas respectively, wherein the silicon tetrachloride, circulating hydrogen gas and the argon gas are in the reactor; and the trichlorosilane and the chlorine hydride enter the polysilicon production procedure. The method can concisely treat the silicon tetrachloride as a byproduct of polysilicon with high efficiency and environmental protection, simultaneously obtains raw materials needed by the polysilicon, and greatly reduces the output of waste and production cost for the polysilicon.

Owner:DONGFANG TURBINE CO LTD

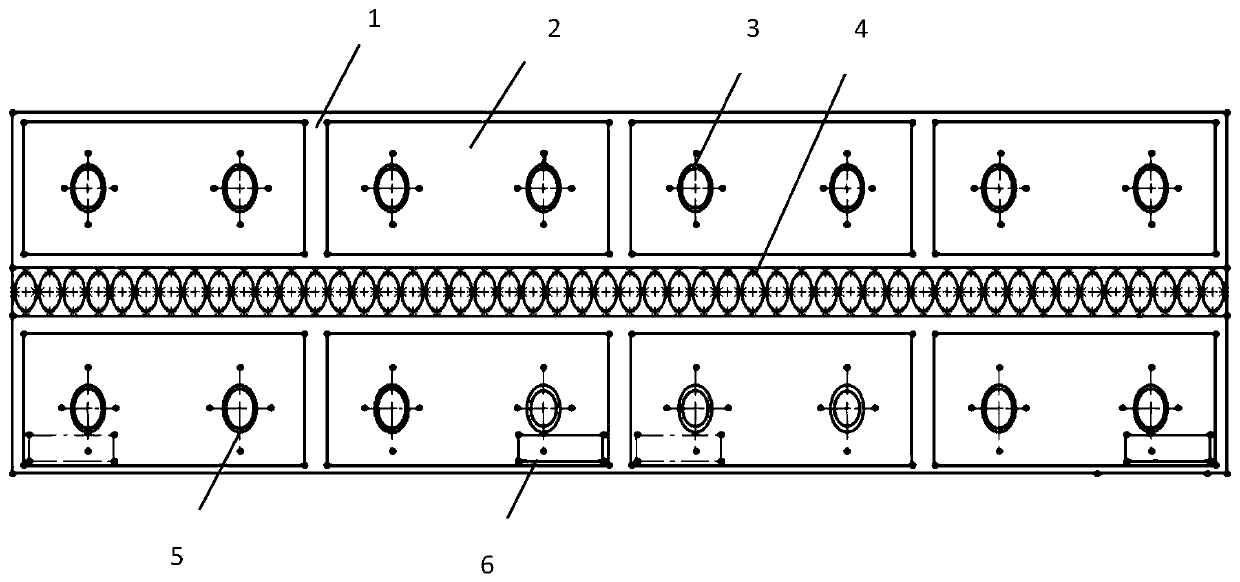

Adjustable ceramic roller kiln nozzle layout structure

InactiveCN111412746AChange the layoutSpeed up the flowFurnace typesStructural engineeringBody burning

The embodiment of the invention discloses an adjustable ceramic roller kiln nozzle layout structure. The adjustable ceramic roller kiln nozzle layout structure comprises a kiln body, a roller way arranged in the kiln body, upper nozzles and lower nozzles, wherein the upper nozzles and the lower nozzles are arranged in the kiln body and symmetrically arranged on the left side and the right side ofa kiln body burning zone; the upper nozzles are positioned above the roller way; the lower nozzles are positioned below the roller way; and the upper nozzles and the lower nozzles are in one-to-one correspondence and are arranged symmetrically up and down. According to the adjustable ceramic roller kiln nozzle layout structure, the layout mode of original nozzles is changed, so that gas turbulenceinside a kiln is enhanced, gas flowing is accelerated, the temperature difference is reduced, and therefore the uniformity of a temperature field is improved, the heat transfer rate is increased, andthe quality of a ceramic product is improved.

Owner:GUANGDONG UNIV OF TECH

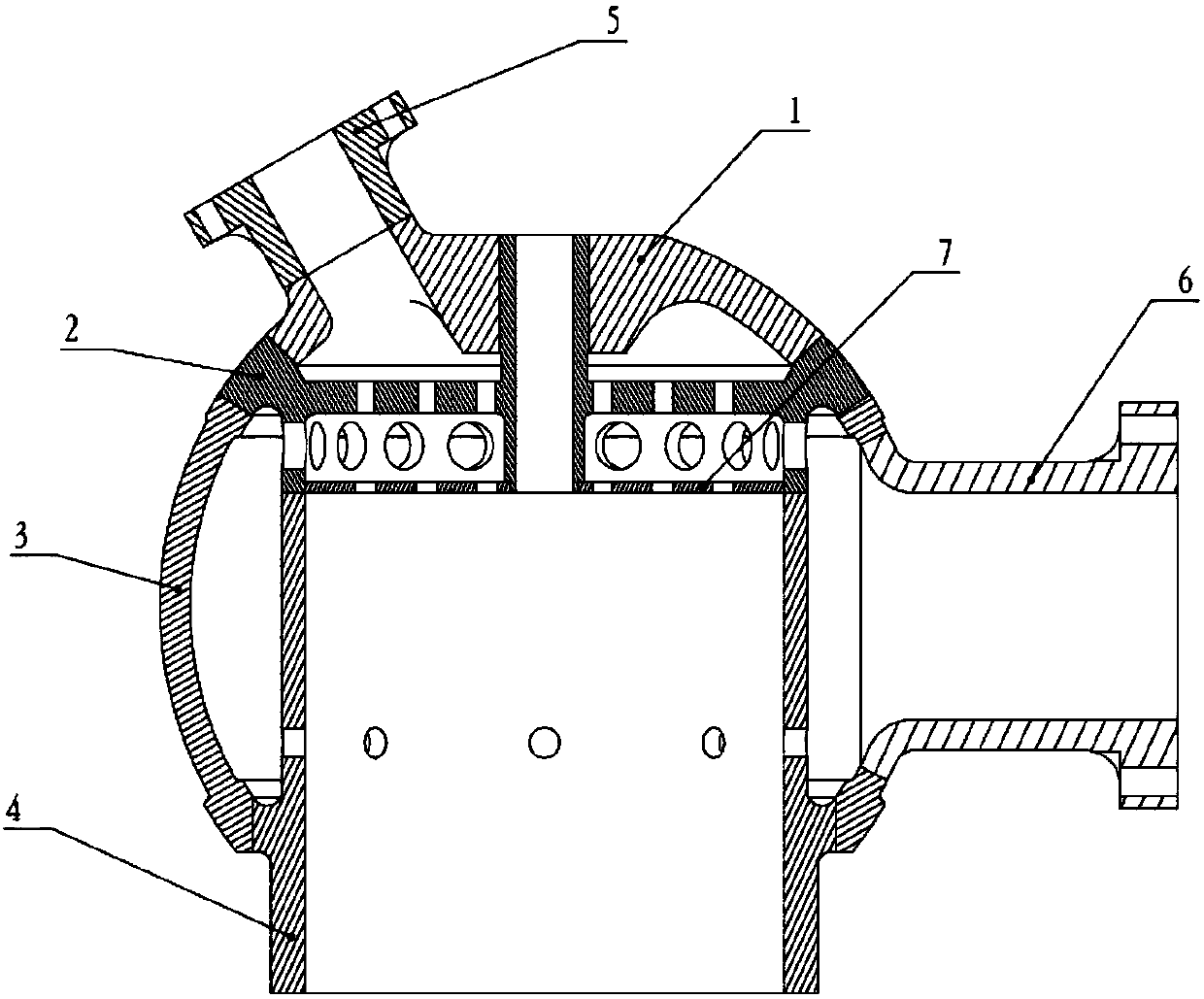

High-pressure-bearing pre-combustion chamber head shell structure

PendingCN107917016AReduce weightImprove pressure bearing capacityRocket engine plantsVariable thicknessStructural reliability

The invention discloses a high-pressure-bearing pre-combustion chamber head shell structure. The structure comprises a top cover, a second bottom, a fuel collector, a body part and a first bottom, a pre-combustion chamber head shell adopts a spherical structure, so that the partial working environment of the body part is improved, the overall pressure bearing capacity and structural reliability ofa head of a pre-combustion chamber are improved, and structure arrangement of the fuel collector is facilitated; and the body part adopts a variable wall thickness design, and radial through-holes are uniformly formed in the portion, wrapped in the fuel collector, of the body part, so that part of fuel can directly enter the combustion chamber through the radial through-holes to be mixed with thehigh-temperature fuel gas so as to improve the uniformity of the temperature field at the outlet of the combustion chamber, meanwhile, structures such as a flow disturbing ring, a grid and an elbow of the body part are eliminated, and the weight of the pre-combustion chamber is effectively reduced.

Owner:BEIJING AEROSPACE PROPULSION INST

Biomass gas steam generator

ActiveCN110043883AReduce NOx contentSmall temperature changeSteam boilersGaseous fuel burnerCombustion chamberLithium bromide

The invention discloses a biomass gas steam generator. The generator comprises a pre-combustion chamber, a mixing chamber, a lean combustion chamber, a smoke tube, a smoke returning chamber, an axialblade combustor and an ejector; lithium bromide dilute solution or water is introduced through an introduction opening, the lithium bromide dilute solution or water is heated through the lean combustion chamber, a second return smoke pipe, a third return smoke pipe, a lower middle smoke returning chamber, an upper middle smoke returning chamber and a pipe plate to form saturated steam; lithium bromide concentrated solution is introduced into a low-pressure generator from a outlet opening through a liquid bag; the saturated steam is led out from the outlet opening, secondary air is introduced from a secondary air inlet opening, hot air formed by heating is mixed with the weak reducing flue gas at an outlet of the pre-combustion chamber in the mixing chamber through the ejector to form high-temperature high-speed lean air, then the high-temperature high-speed lean air is sprayed into the lean combustion chamber, and is mixed with secondary biomass gas to realize lean combustion. The biomass gas steam generator has the advantages of rich combustion and lean combustion, the energy consumption of a fan is low, the radiant heat flux is high, the temperature field uniformity is good, thecombustion is stable, the Nox generation amount is low, the greenhouse gas emission is low, and the structure is compact.

Owner:ZHONGYUAN ENGINEERING COLLEGE

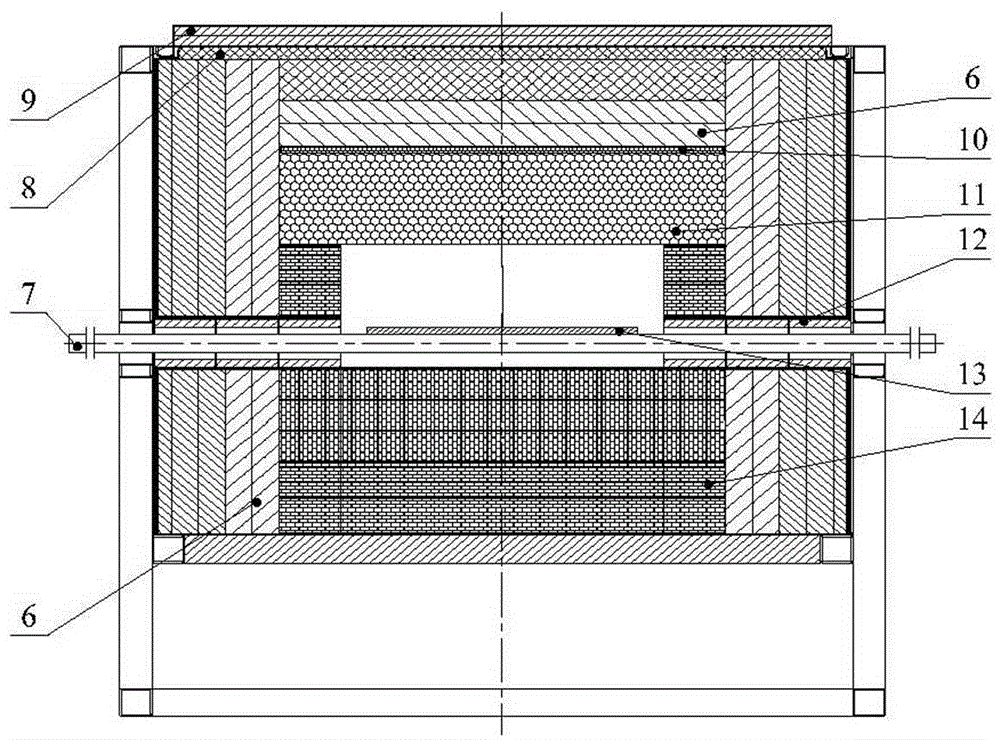

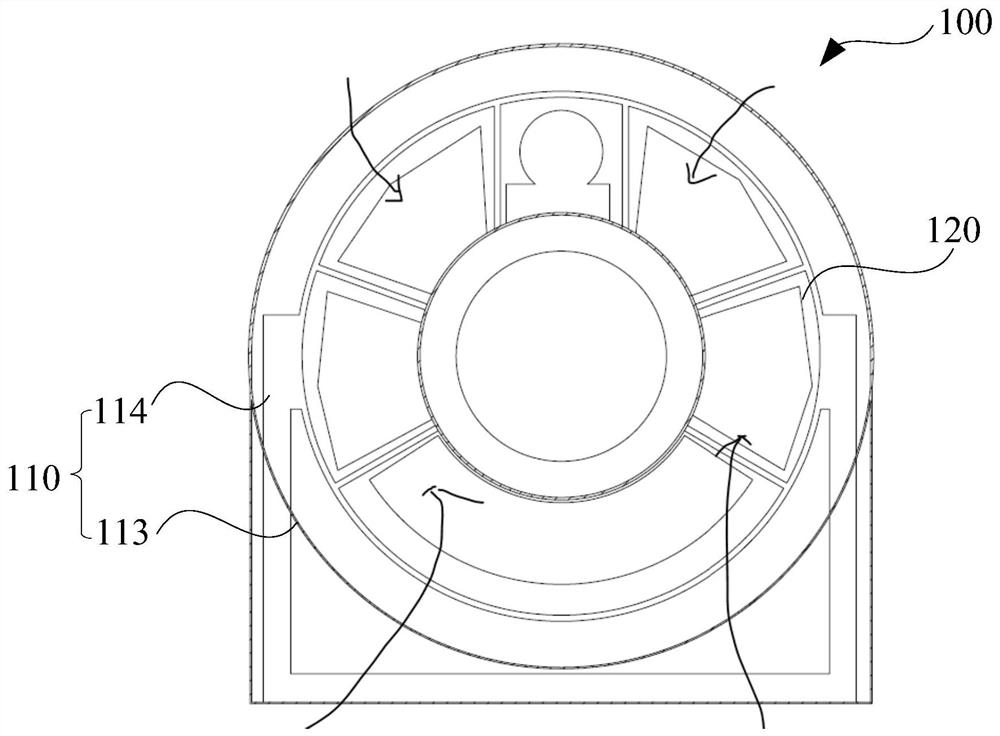

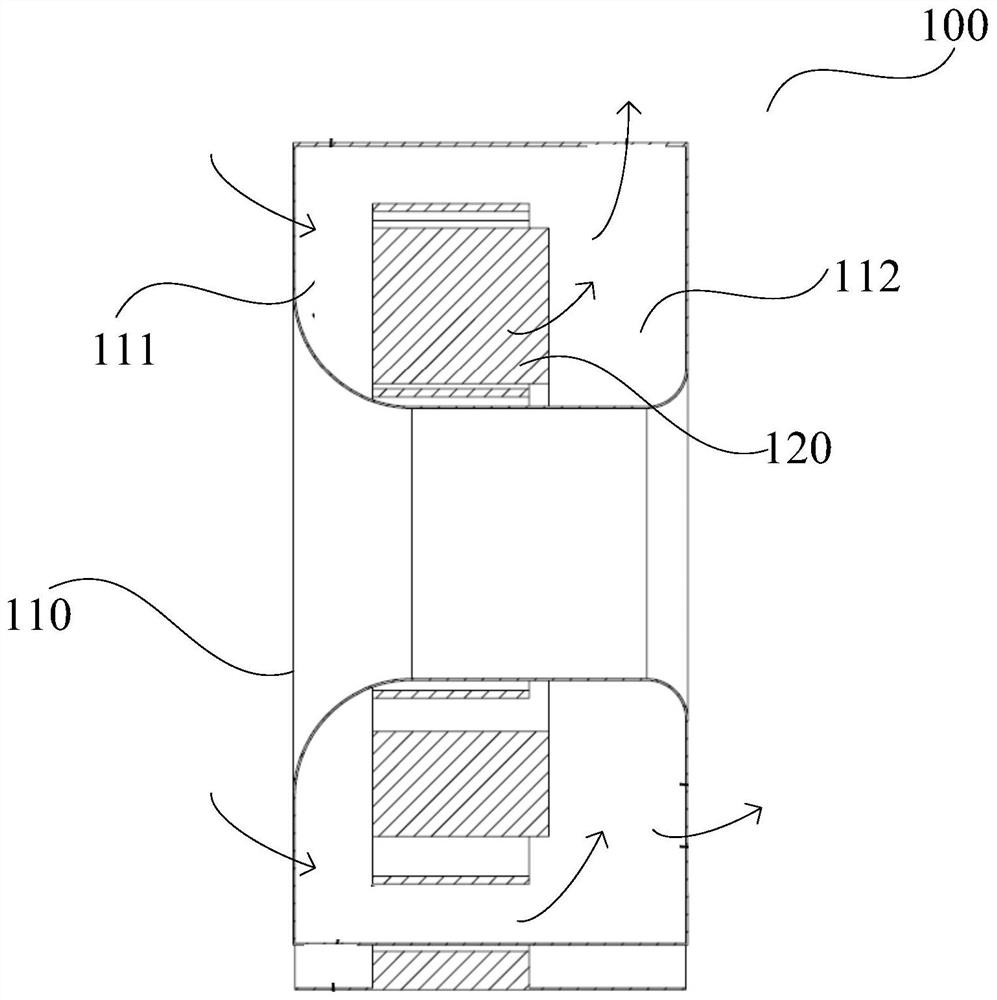

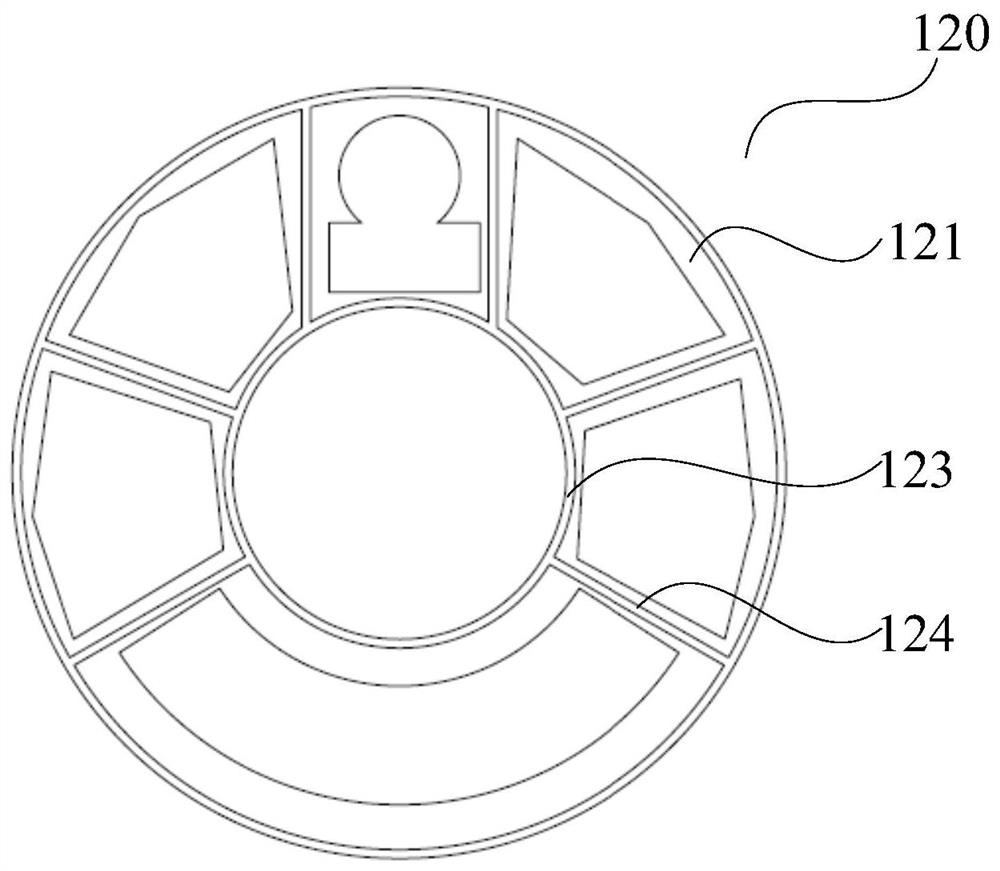

Liquid-helium-free animal imaging superconducting magnet

PendingCN113871132AImprove temperature field uniformityUniform temperature fieldSuperconducting magnets/coilsNuclear physicsSuperconducting Coils

The invention provides a liquid-helium-free animal imaging superconducting magnet. The liquid-helium-free animal imaging superconducting magnet comprises a superconducting magnet, a liquid-helium-free low-temperature system and a pull rod. The superconducting magnet comprises a main magnet, a shielding magnet and a 4K container, the main coil is wound in an external wire slot of the main framework to form the main magnet, the shielding coil is wound in an external wire slot of the shielding framework to form the shielding magnet, and the 4K container contains the superconducting magnet; the liquid-helium-free low-temperature system comprises a refrigerating machine, a refrigerating machine primary cold head, a cold shield, a refrigerating machine secondary cold head, a cold conduction ring, a cold conduction belt and a Dewar container, the refrigerating machine primary cold head is directly connected with the cold shield to achieve primary refrigeration, the refrigerating machine secondary cold head is directly connected with the cold conduction ring, and the cold conduction ring is connected with the shielding coil and the main coil through the cold conduction belt. Secondary refrigeration of the superconducting magnet is achieved, and the Dewar container is used for forming a low-temperature system vacuum environment; the superconducting magnet and the cold shield are suspended and fixed in the Dewar container through a pull rod to reduce system contact heat leakage; the diameter of the inner hole of the superconducting magnet is suitable for small animal imaging.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

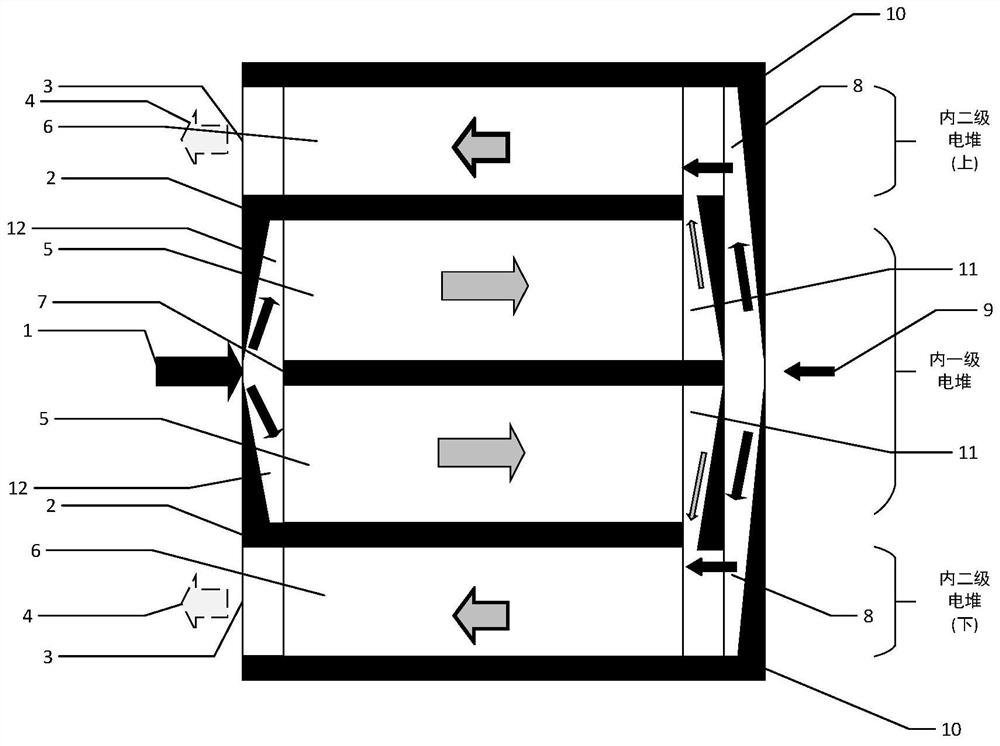

Internal cascade solid oxide fuel cell stack with high fuel utilization rate

ActiveCN111952632AImprove net power generation efficiencyReduce the temperatureFuel cell heat exchangeReactant parameters controlFuel cellsMechanical engineering

The invention relates to an internal cascade solid oxide fuel cell stack with a high fuel utilization rate. Fuel is input into an internal primary stack through a main fuel supply pipeline; air is input into the inner primary galvanic pile and the inner secondary galvanic pile through the air inlet; tail gas of the inner primary galvanic pile enters the inner secondary galvanic pile through a cascade circulation loop; fuel is supplemented to the inner secondary electric pile through an auxiliary fuel supply pipeline; and the inner secondary galvanic pile exhausts tail gas through a tail gas exhaust pipeline. The cascade loop is additionally arranged, so that the fuel utilization rate is increased; the inner primary galvanic pile in the middle position is additionally arranged, it is ensured that partial reforming reaction occurs in the inner primary galvanic pile by managing fuel gas components in the main fuel supply pipeline, the uniformity of the internal temperature field of the galvanic pile is improved, the internal temperature of the galvanic pile is reduced, and the parasitic power of a draught fan is reduced; and an auxiliary fuel supply pipeline is additionally arranged,so that the temperature of mixed fuel entering the internal secondary electric pile and the controllability of gas components are improved.

Owner:TSINGHUA UNIV

High sintering roller way kiln

ActiveCN103453764BAchieving temperature field uniformityImprove temperature field uniformityMaterial analysis using microwave meansElectricityWater discharge

The invention discloses a high sintering roller way kiln which comprises a kiln body, a heating system, a measurement and control system, an exhaust system and a transmission system, wherein a furnace chamber of the kiln body is divided into a water discharge area, a pre-heating area, a sintering area and a cooling area, the heating system comprises a magnetron microwave heating system and an electric heating system which are arranged in the furnace chamber, a microwave head of the microwave heating system is installed in a microwave source energy feedback port of the kiln body and faces the furnace chamber, the electric heating system is installed on the pre-heating area and on the upper side and lower side of the sintering area, and the transmission system penetrates through the furnace chamber of the kiln body to form closed-loop transmission. The high sintering roller way kiln is easy to operate and maintain, the quality of sintered materials is high, efficient and energy-saving microwave heating and electric heating can be carried out at the same time for high sintering, and microwave heating and electric heating can exist in the same heating area.

Owner:湖南航天有限责任公司

A method for integral forming of U-shaped unit reinforced wall plate autoclave without core mold

ActiveCN105729830BImprove temperature field uniformityRealize entering the tankFlat articlesMechanical engineeringAutoclave

The invention belongs to the technical field of composite molding and relates to a mandrel-free autoclave integral molding method for U-shaped unit stiffened wallboards. According to the mandrel-free autoclave integral molding method for U-shaped unit stiffened wallboards, designed by the invention, a mandrel-free molding method is adopted to meet the requirements of part inner molding quality and vertical rib perpendicularity; and at the same time, the temperature field evenness of dies is improved, multi-die autoclave feeding is realized, and production cost is reduced. A molding device in a molding technology is on the outer side of a vacuum bag, so that the profile precision requirement is not high. U-shaped unit laying dies are only used as laying dies and are not fed into the autoclave with parts, so that the precision requirement is relatively lower. Besides, a pressurization heating process is not carried out, dies are not placed on the parts, fit clearances are not available, pressure is directly applied on the parts, and the inner quality of the parts is great. Compared with a traditional method, the method has the advantages that the molding technology is simple, the manufacture cycle is short, the heat conductivity is great, the temperature rise evenness of the parts is great, and the solidifying of a plurality of components in the large autoclave at a time can be ensured.

Owner:AVIC COMPOSITES

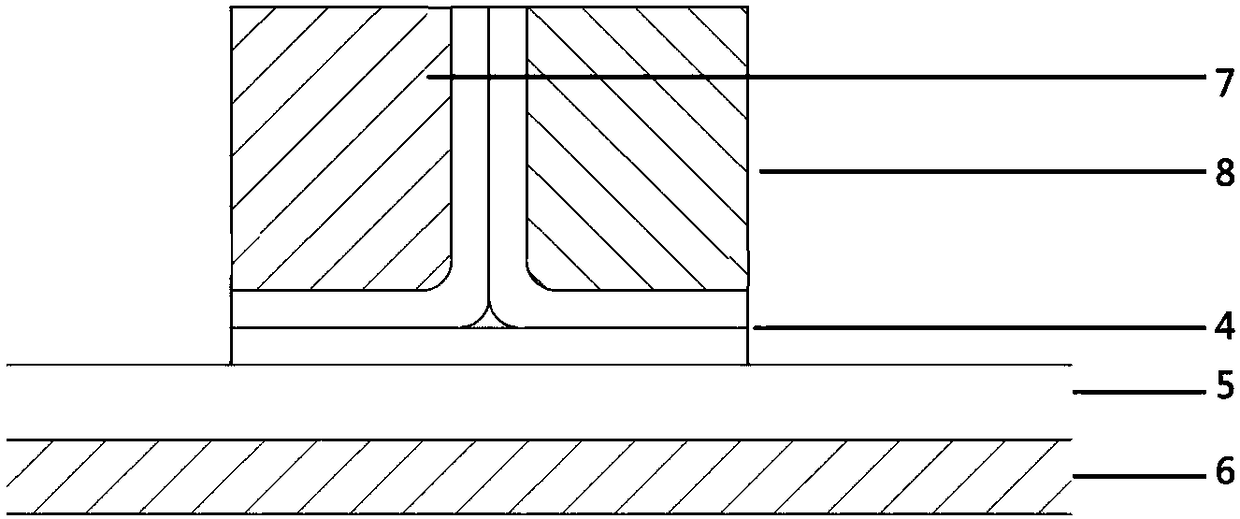

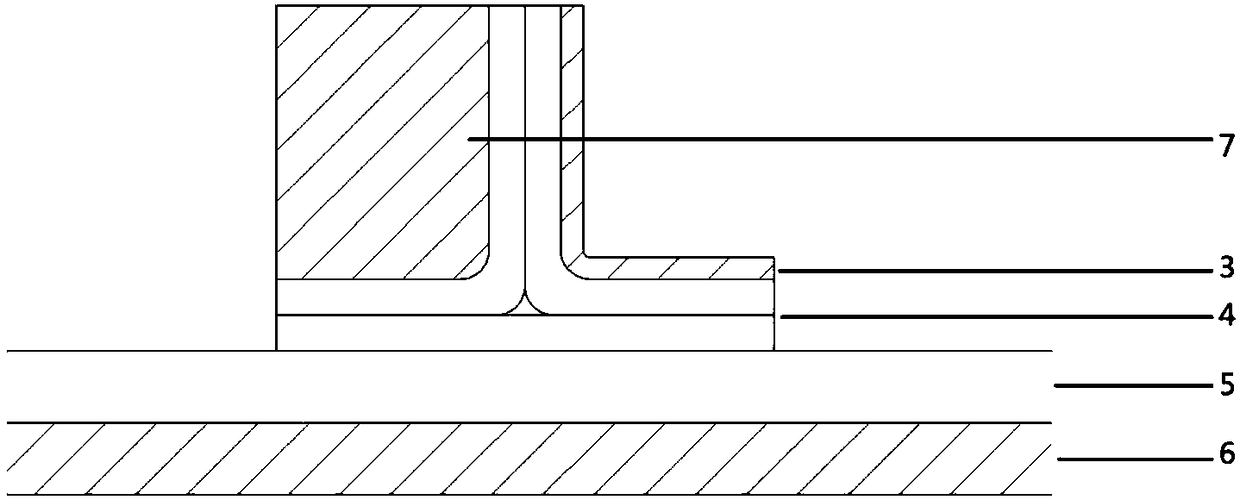

A kind of integral forming method of U-shaped unit reinforced wall panel

ActiveCN110978564BPrecise positioningImprove temperature field uniformityDomestic articlesMechanical engineeringMaterials science

The present invention is an integral molding method of a U-shaped unit reinforced wall panel. This method lays up prepregs on the skin molding die 6 and the unit molding die 7, then assembles them together, and takes out the unit molding before curing. The mold 7 is only retained, and only the skin forming mold 6 is retained. This method can meet the requirements of the internal molding quality and verticality of the vertical ribs, and at the same time improve the uniformity of the mold temperature field, ensure the quality of the product, shorten the manufacturing cycle, and reduce the production cost. The U-shaped unit reinforced wall plate prepared by the method has a high degree of integration, good weight reduction effect and high safety, and provides an important key technology for the application of composite materials in large aircraft.

Owner:AVIC BASIC TECH RES INST

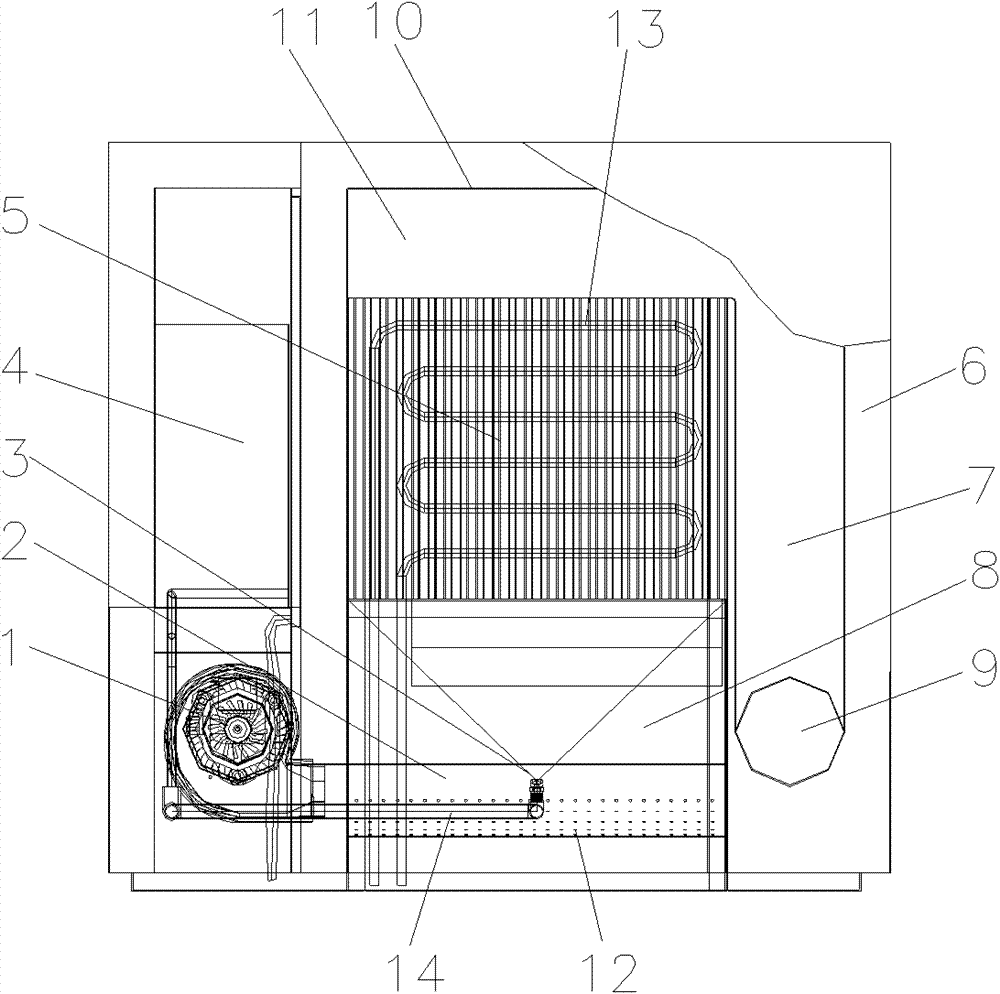

Indoor high enthalpy heater

ActiveCN101943437BPower optimizationImprove operating economyHeat storage plantsElectric heating systemPower gridEngineering

The invention discloses an indoor high enthalpy heater, which comprises a sealed shell, a thermal accumulator and a fan, the side of an upper air bag is connected with a descending air duct, the bottom of a lower air bag is fixed with a horizontal flow-equilibrating tube, the fan is fixed on the side of the shell, and an air outlet of the fan is connected with the other end of the flow-equilibrating tube; and the thermal accumulator is a metallic body, an electric heating tube is embedded in the thermal accumulator, the lower air bag is internally provided a water pipe, the front of which is provided with a nozzle, and the opening of the nozzle points to the thermal accumulator. The indoor high enthalpy heater guarantees high-power thermal load requirements of tens of millions of scattering users at a demand side of a power grid. When the heater is in service, the uniformity of a space temperature field, the use safety, the use economy and the application scope are greatly improved compared with the traditional sauna device.

Owner:浙江鼎美智装股份有限公司

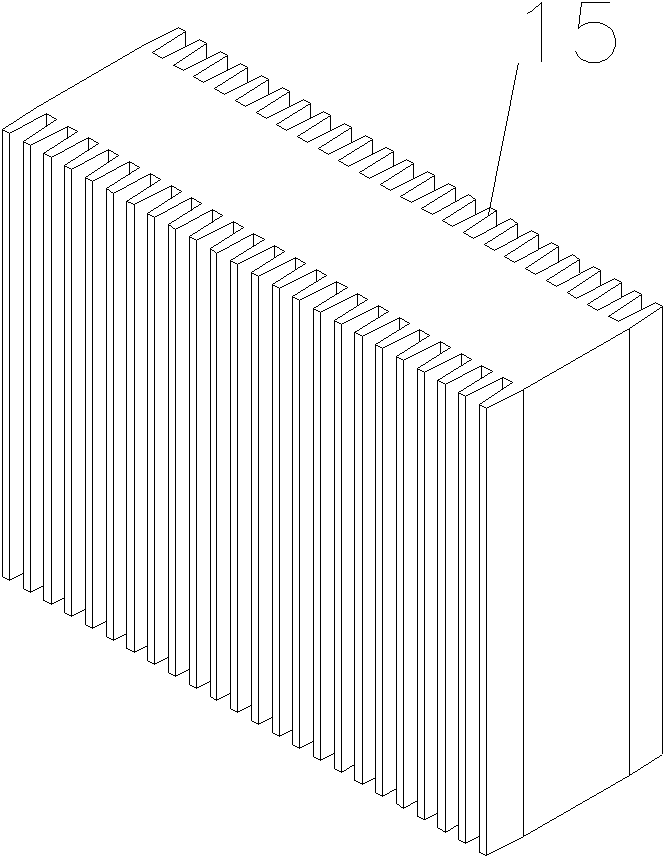

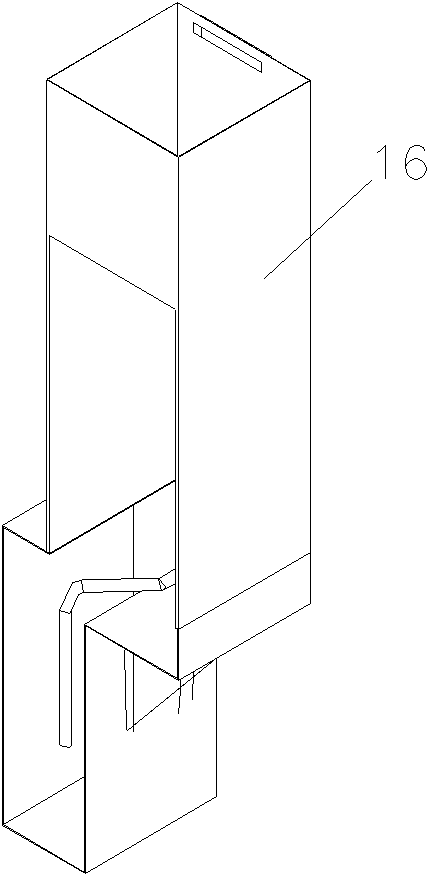

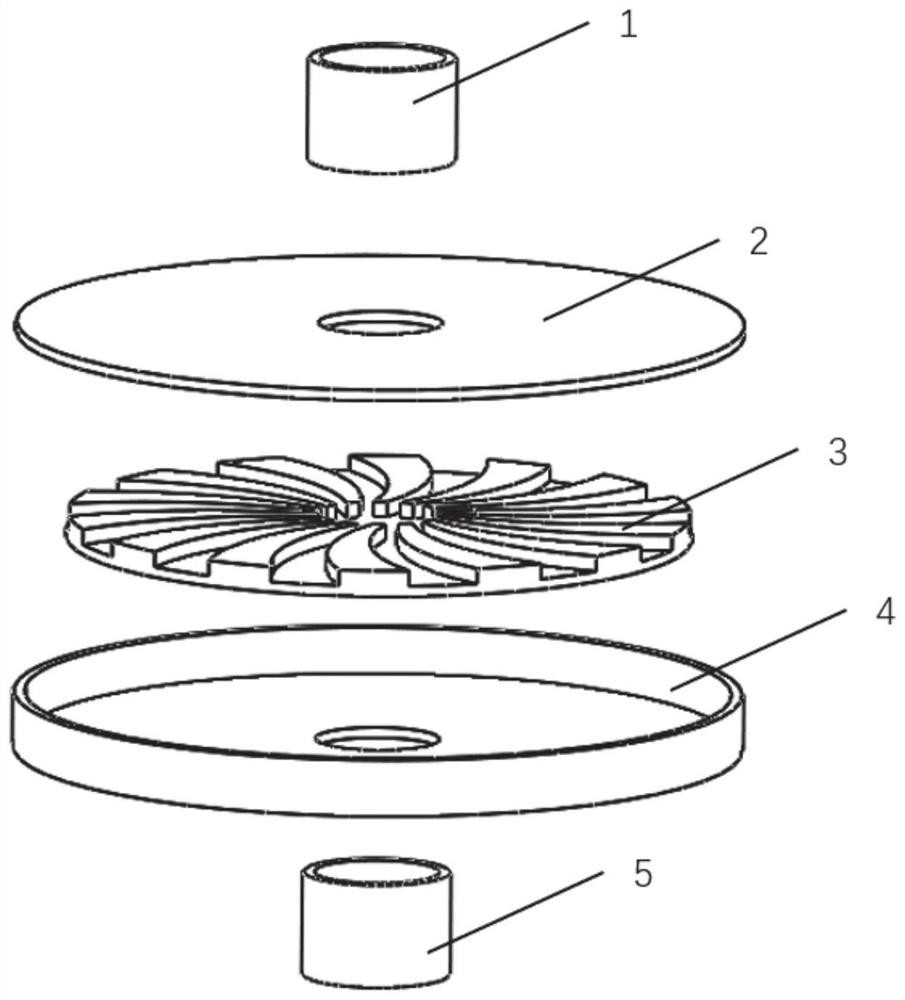

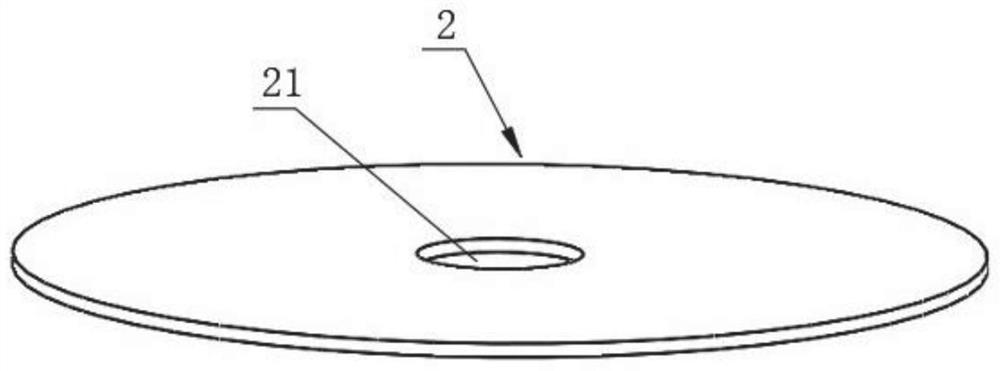

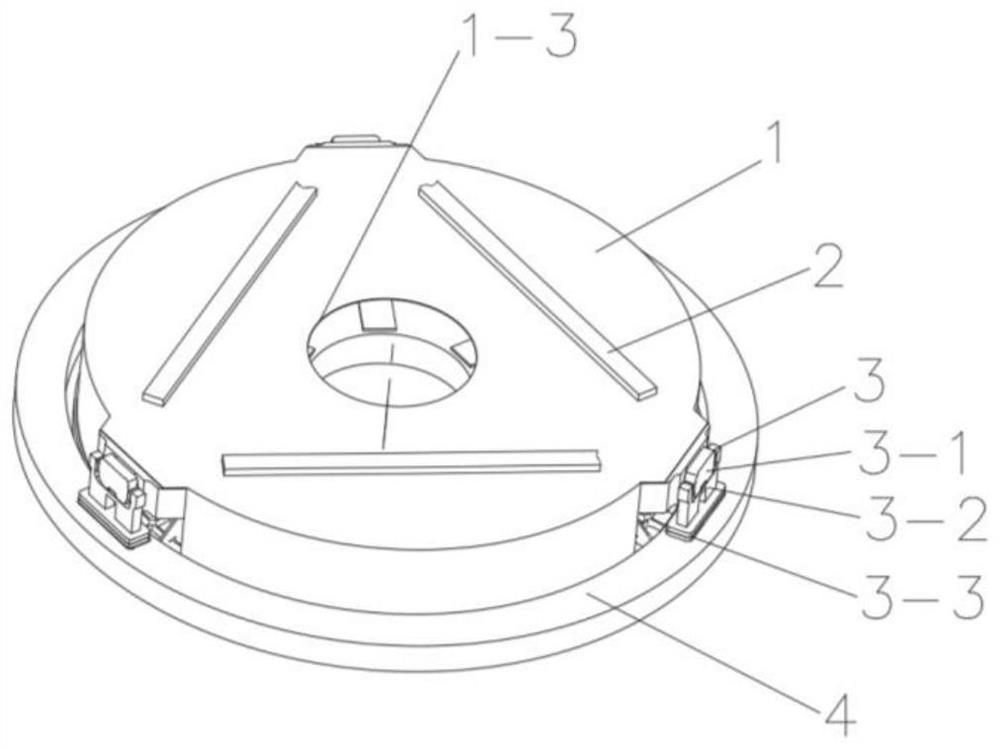

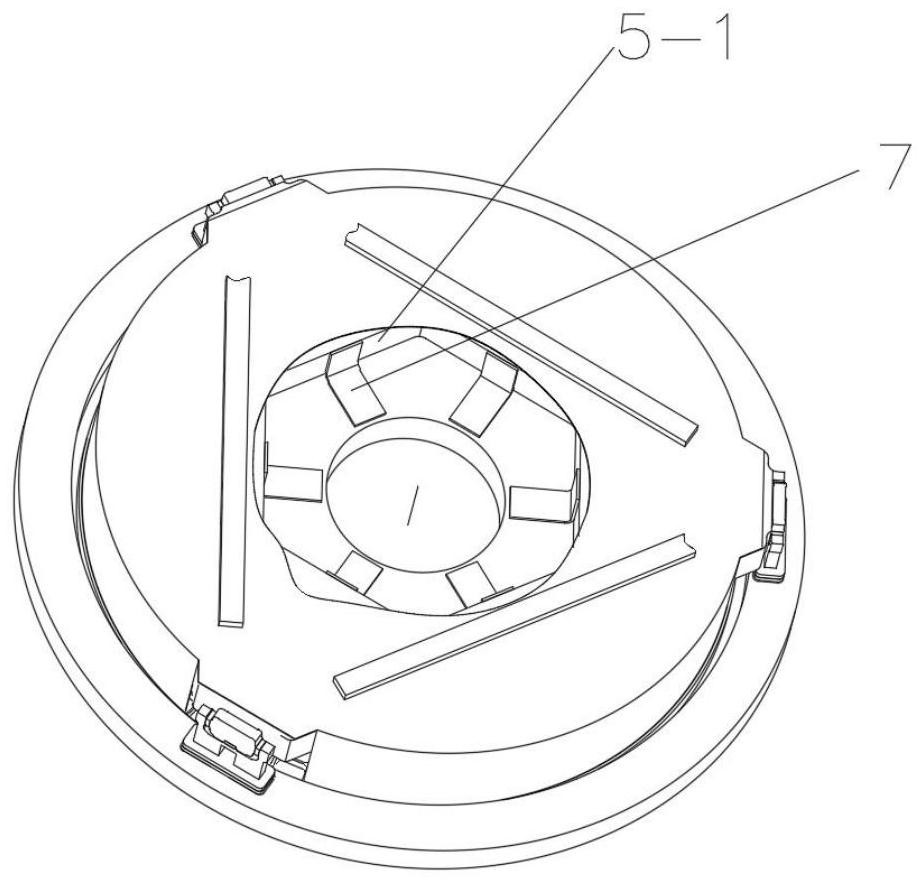

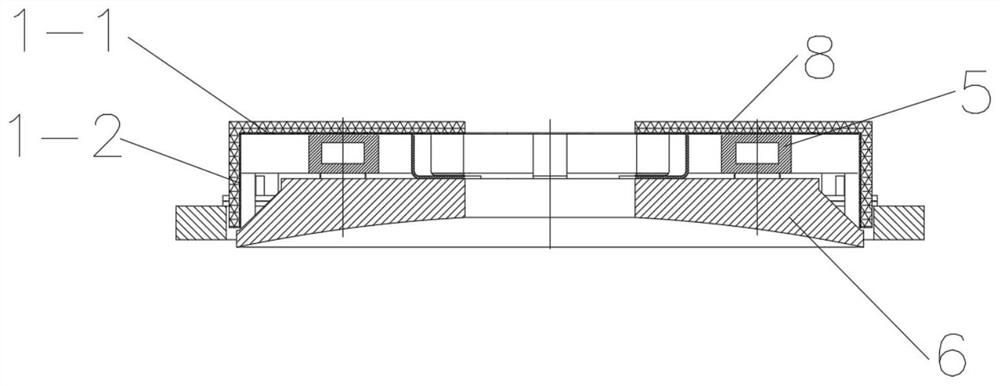

Disc-shaped radial micro-channel radiator

PendingCN113423240ACompact structureEasy to installCooling/ventilation/heating modificationsPhysicsEngineering

Owner:SOUTHEAST UNIV

Durability tester for temperature controller

InactiveCN102122169BSmall thermal inertiaPrecise adjustment of heating temperatureTesting/monitoring control systemsAir pumpEngineering

The invention discloses a durability tester for a temperature controller, which comprises a power supply unit, a load unit, a detection control unit, an output unit, a heating unit and a cooling unit. The durability tester is characterized in that the heating unit comprises a copper block in which a heating pipe is arranged, the heating pipe is connected with the power supply unit, an upper surface of the copper block is provided with a thermoelectric couple for acquiring the temperature of the copper block in real time, the thermoelectric couple is connected with the detection control unit, and the upper surface of the copper block is further provided with an insulating heat-resistant pressure plate for fixing a temperature sensitive part of a temperature controller; the cooling unit is a cooling airflow sprayer arranged over the insulating heat-resistant pressure plate and connected with an external air pump of the tester; and the temperature controller is connected with an input end of the load unit through a lead. The durability tester has the advantages that the heating mode of the tester is small in thermal inertia, so that an adjustable range of the conduction and the disconnection of the temperature controller is large, the range of the heating temperature is large, the heating temperature and the cooling speed can be accurately controlled, accuracy of the test result can be improved, and the tester is simple in structure and low in cost.

Owner:宁波市产品质量监督检验研究院

Rack structure and CT equipment

PendingCN112057100AReduce the overall heightImprove temperature field uniformityComputerised tomographsTomographyEngineeringAir cavity

The invention provides a rack structure and CT equipment. The rack structure comprises a shell and a rack assembly. The rack assembly is arranged in the shell. The rack assembly comprises a fixed rackand a rotary rack. The fixed rack is provided with a first air cavity and a second air cavity which are formed by separating the shell in the axial direction. The rotating rack is rotatably mounted on the fixed rack and provided with a vent hole, and the vent hole communicates with the first air cavity and the second air cavity in the two sides of the rotating rack. The first air cavity, the venthole and the second air cavity are arranged in the axial direction, so that airflow enters the rotating rack in the axial direction and cools the electrical apparatus elements on the rotating rack, the airflow can effectively cool the electrical apparatus elements, it is guaranteed that the temperature field in the fixed rack is high in uniformity, the performance of the detector is prevented from being affected, and the imaging effect of images is guaranteed; and meanwhile, the overall height of the CT equipment can be reduced.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Optical lens body temperature equalization structure based on cold shield radiation cover and flexible cold chain

The invention discloses an optical lens temperature equalization structure based on a cold shield radiation cover and a flexible cold chain. Through the uniform heat radiation of the low-temperature cold shield radiation cover and the heat conduction effect of the flexible cold chain, the cooling of the large-aperture optical lens body and the homogenization of the temperature field are realized. The method has the advantages of uniform radiation heat transfer heat flux density and high heat conduction and heat transfer efficiency. The structrue is suitable for refrigeration and temperature field homogenization of a space remote sensing load large-aperture mirror body and a large-size component arranged in a ground vacuum container.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

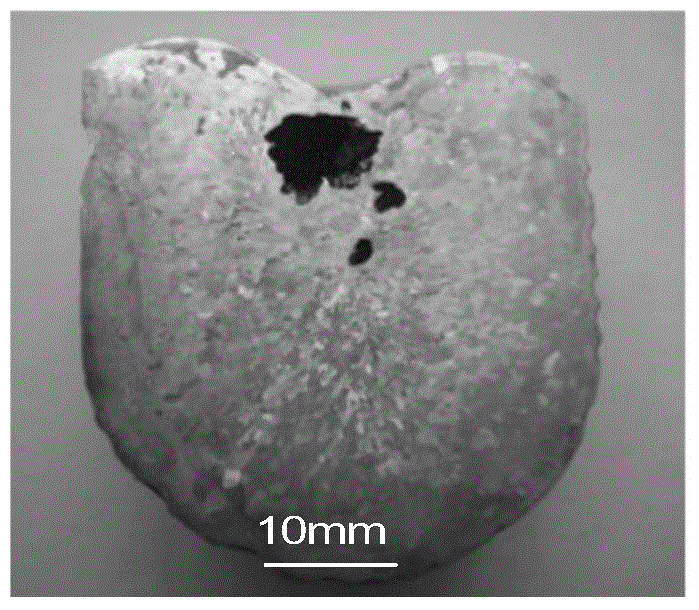

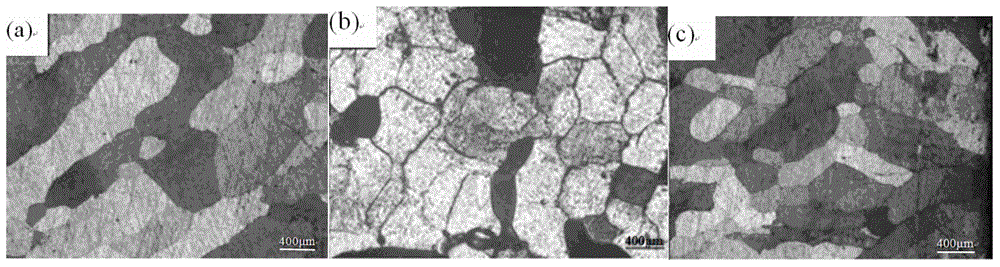

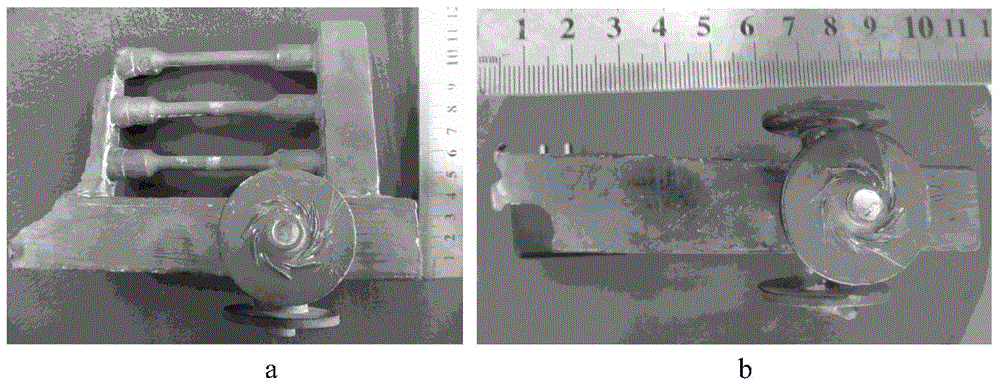

Preparation method for obtaining kilogram-grade high temperature alloy undercooled melt

ActiveCN103484802BImprove liquidityLow solid phase rateIncreasing energy efficiencySolid fractionCleansing Agents

Disclosed is a preparation method for obtaining a kilogram-grade high temperature alloy undercooled melt. According to the preparation method, a medium-frequency induction power source is adopted as a heating power source, a convection current is generated through medium-frequency induction heating, and a macroscopic temperature field of the melt is more even so as to ensure that the melt is evenly cooled at the same time. A high-purity quartz crucible is used as a heating crucible, a B2O3 glass fusion covering agent is used as a cleaning agent or argon is inflated for protection, repeated circulated overheating treatment is adopted to conduct purification treatment on the melt, and the best purification effect is achieved by controlling the overheating temperature, the heat preservation temperature and the cycle index. The cooling rate is reasonably controlled, the temperature difference between the interior and the exterior of the melt is limited within 3 DEG C, and the whole melt is evenly cooled at the same time. The temperature field obtained by the preparation method and the structure of the melt are better in evenness, the whole kilogram-grade undercooled melt is in the undercooled state, the undercooled melt is better in flowability, and the solid fraction is lower than 0.2%. The preparation method is applicable to the field of micro-casting, and whole fine-grain ingot castings can be obtained by controlling the follow-up cooling speed of the kilogram-grade undercooled melt.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

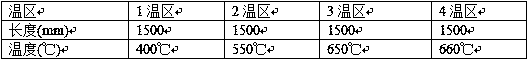

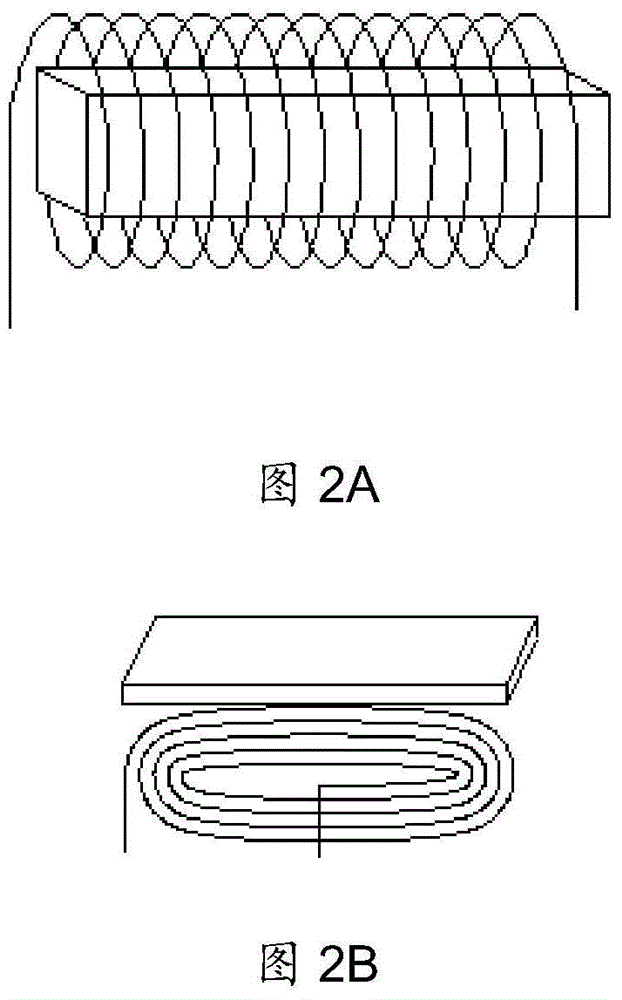

A double pusher kiln for producing ferrovanadium nitride

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

A low-cost and fast curing method for composite materials

ActiveCN104827613BFast heatingImprove temperature field uniformityMiddle frequencyTemperature resistance

The invention relates to a low-cost quick solidifying method for a composite material. A middle-frequency electromagnetic induction coil directly acts on a metal mould to self heat and solidify to form a composite material, middle frequency heating speed is high, the uniformity of a temperature field is good, the control is exact, the temperature overshoot is small, the production efficiency is greatly improved, and the product quality is ensured; furthermore, by utilizing middle-frequency electromagnetic induction heating, only the self metal mould is heated, a non-metal auxiliary material for forming the composite material is not heated, and the ambient temperature is very low after a special coating is utilized in a forming process, so that a very expensive high-temperature-resistance auxiliary material is not necessary to use when a high-temperature-resistance composite material such as bismaleimide and polyimide is formed; therefore, the manufacturing cost is saved and the energy consumption is low.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com