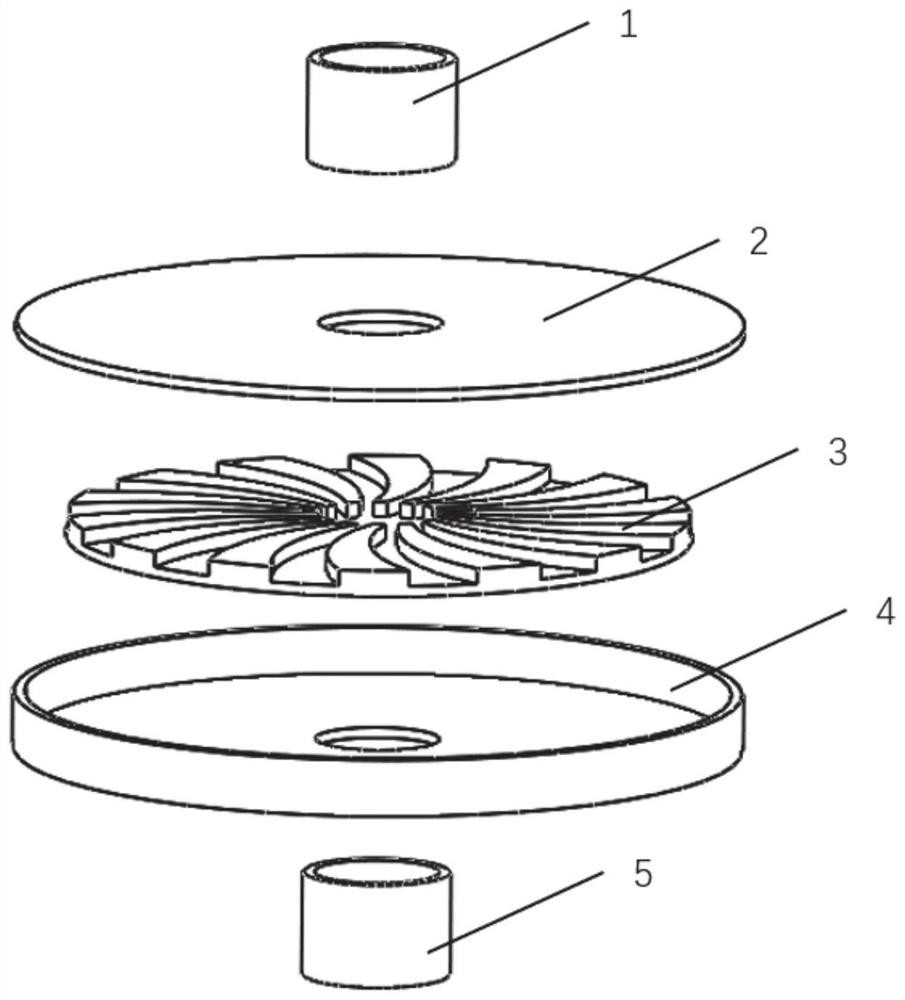

Disc-shaped radial micro-channel radiator

A radial, micro-channel technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problem of poor matching of rotating parts, achieve small inlet and outlet pressure drop, uniform temperature field Good performance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

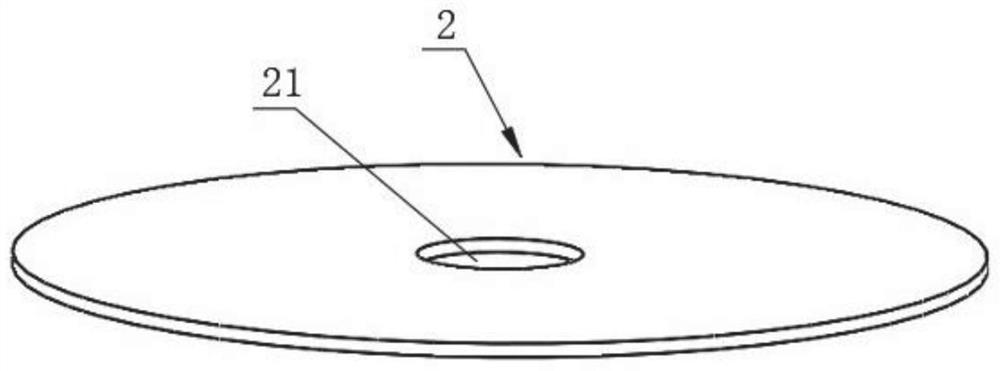

[0036] The working principle of Embodiment 2 is the same as that of Embodiment 1. The upper cover plate 2 is attached to the heat-generating components, and the upper and lower sides of the microchannel module 3 are respectively attached to the upper cover plate 2 and the manifold 4. The heat is obtained by a high heat generation rate. The heat-generating components are generated, and are transmitted to the upper cover plate 2 and the microchannel module 3 through heat conduction. At the same time, the cooling medium enters from the inlet pipe 1 at a certain speed, flows into the through hole 34 of the substrate 31 through the inflow hole 21, and then Flow through the inflow channel formed between the microgroove 33 on the top of the microchannel module 3 and the lower surface of the upper cover plate 2 through the edge of the through hole 34, and flow through the outlet flow formed between the microgroove 33 on the bottom of the microchannel module 3 and the inner bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com