Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Improve heat balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen recycle for high temperature fuel cells

InactiveUS20040197612A1Improve efficiencyImprove sustainabilityGas treatmentRegenerative fuel cellsOxygenContamination

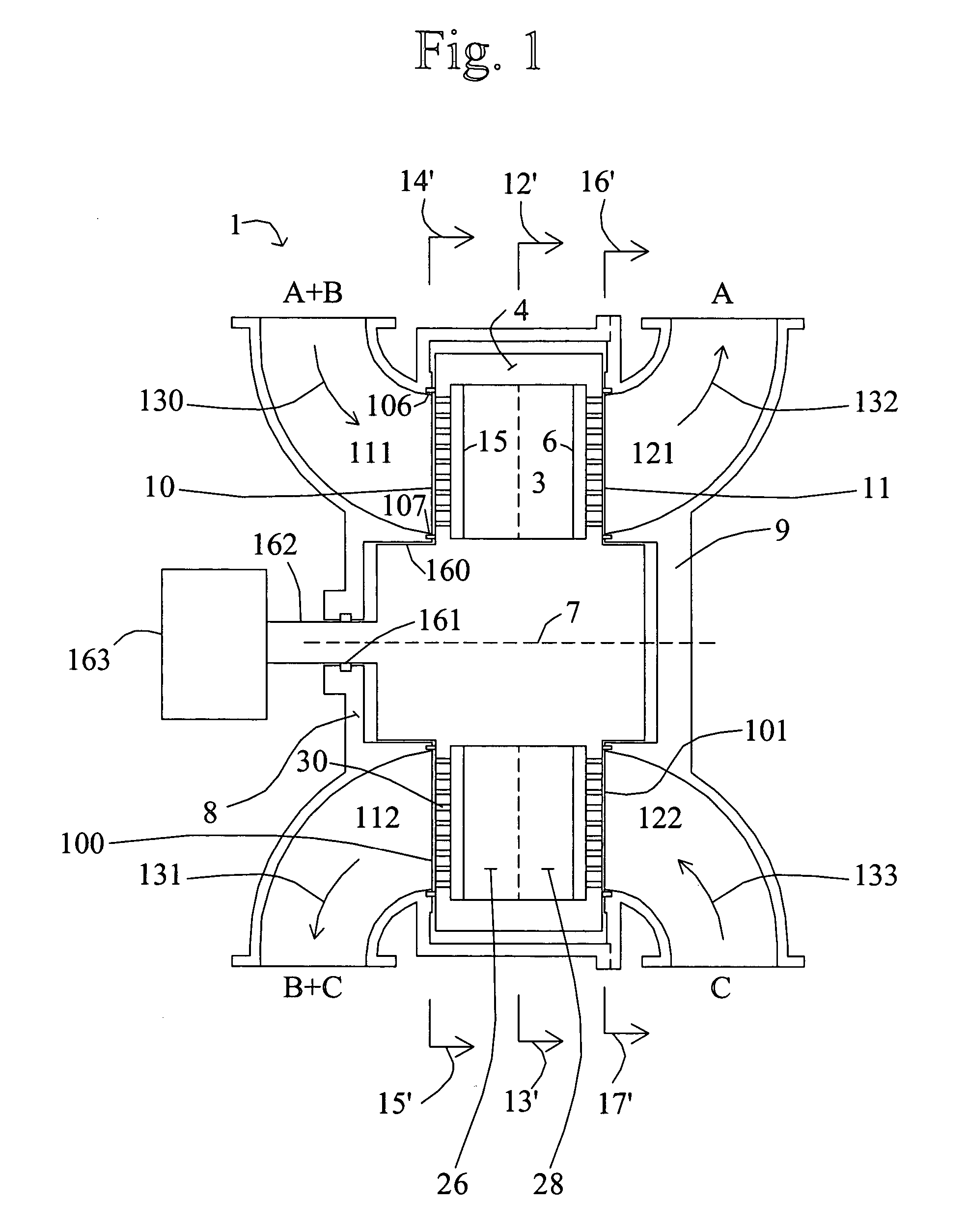

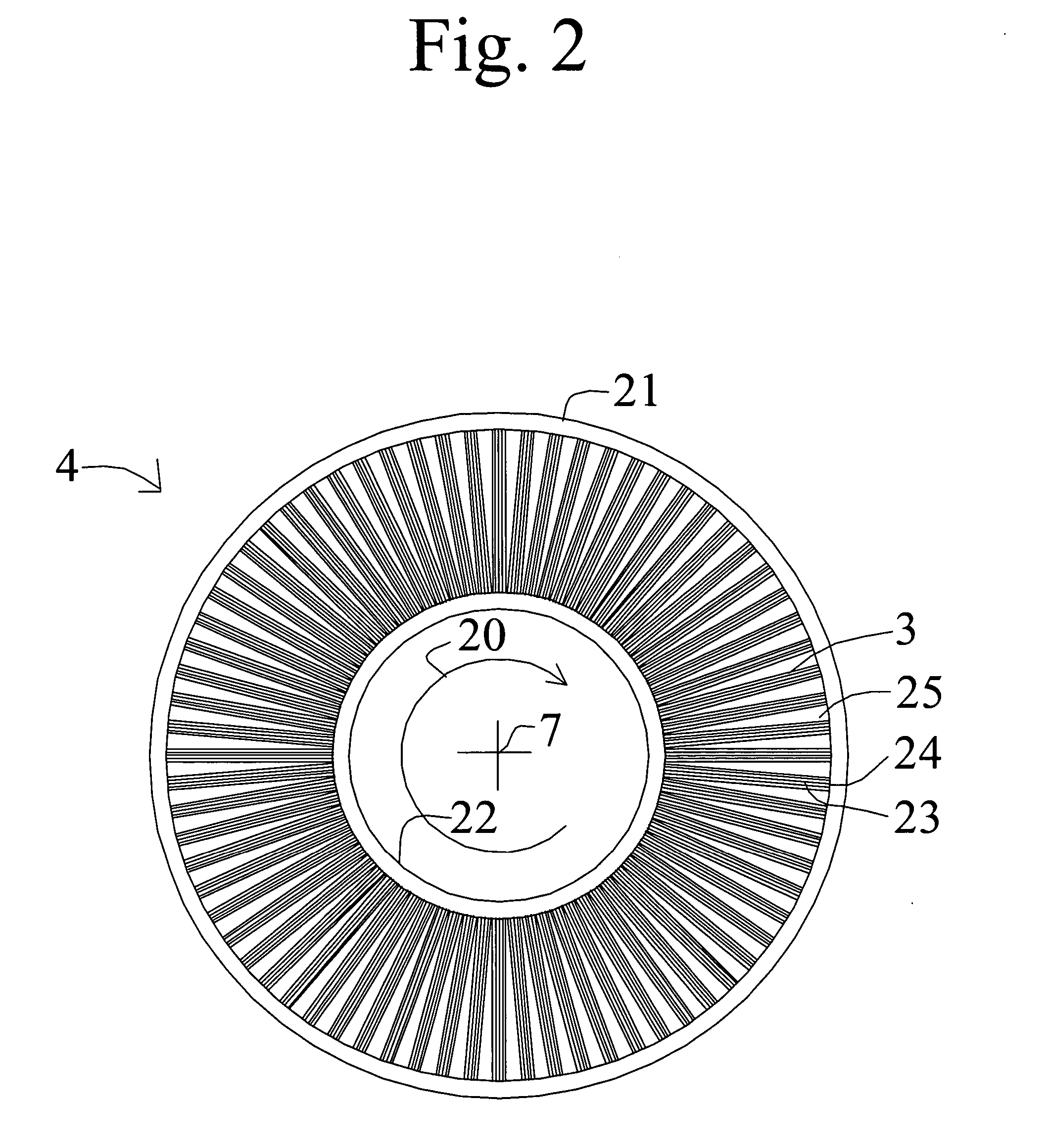

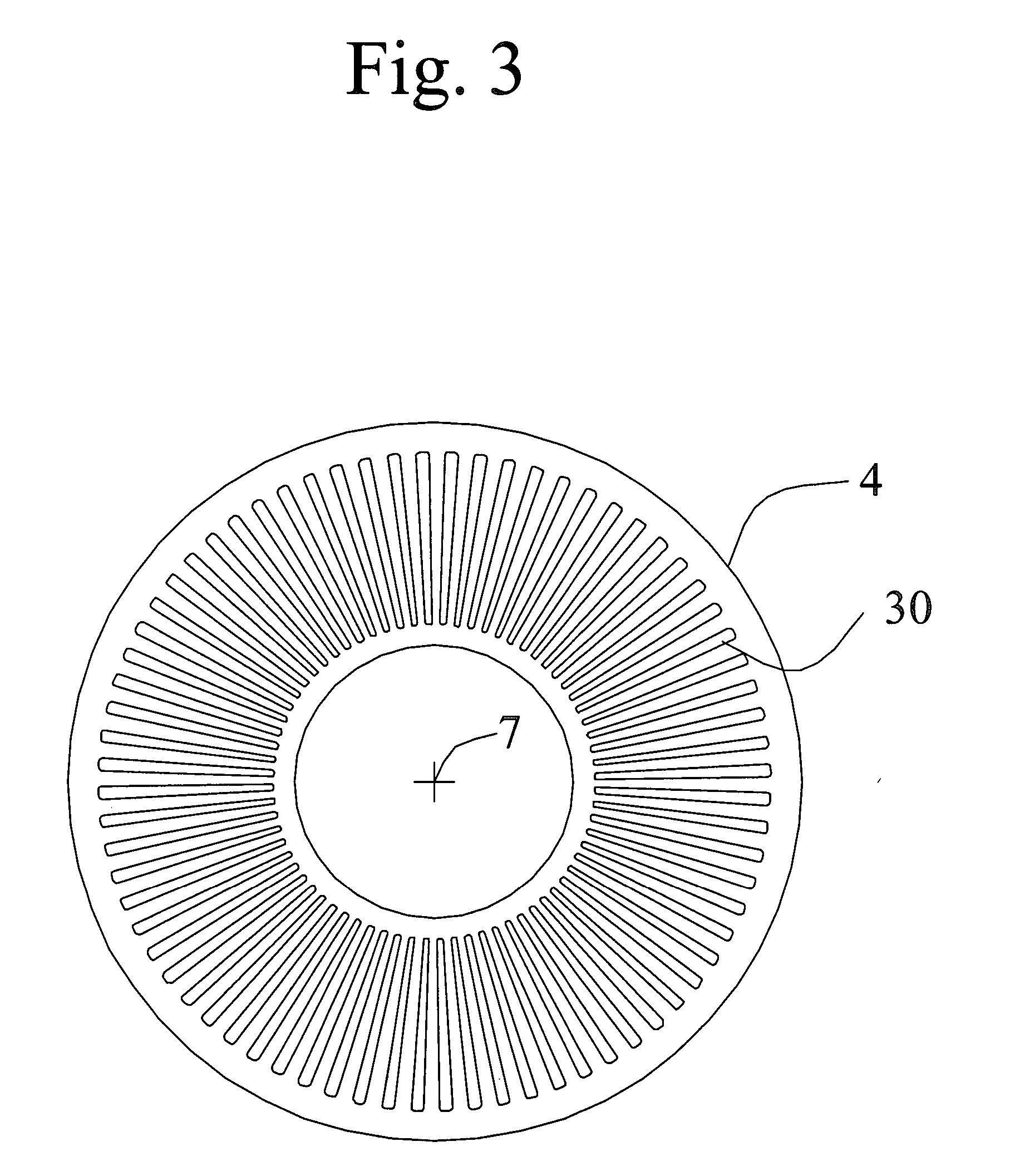

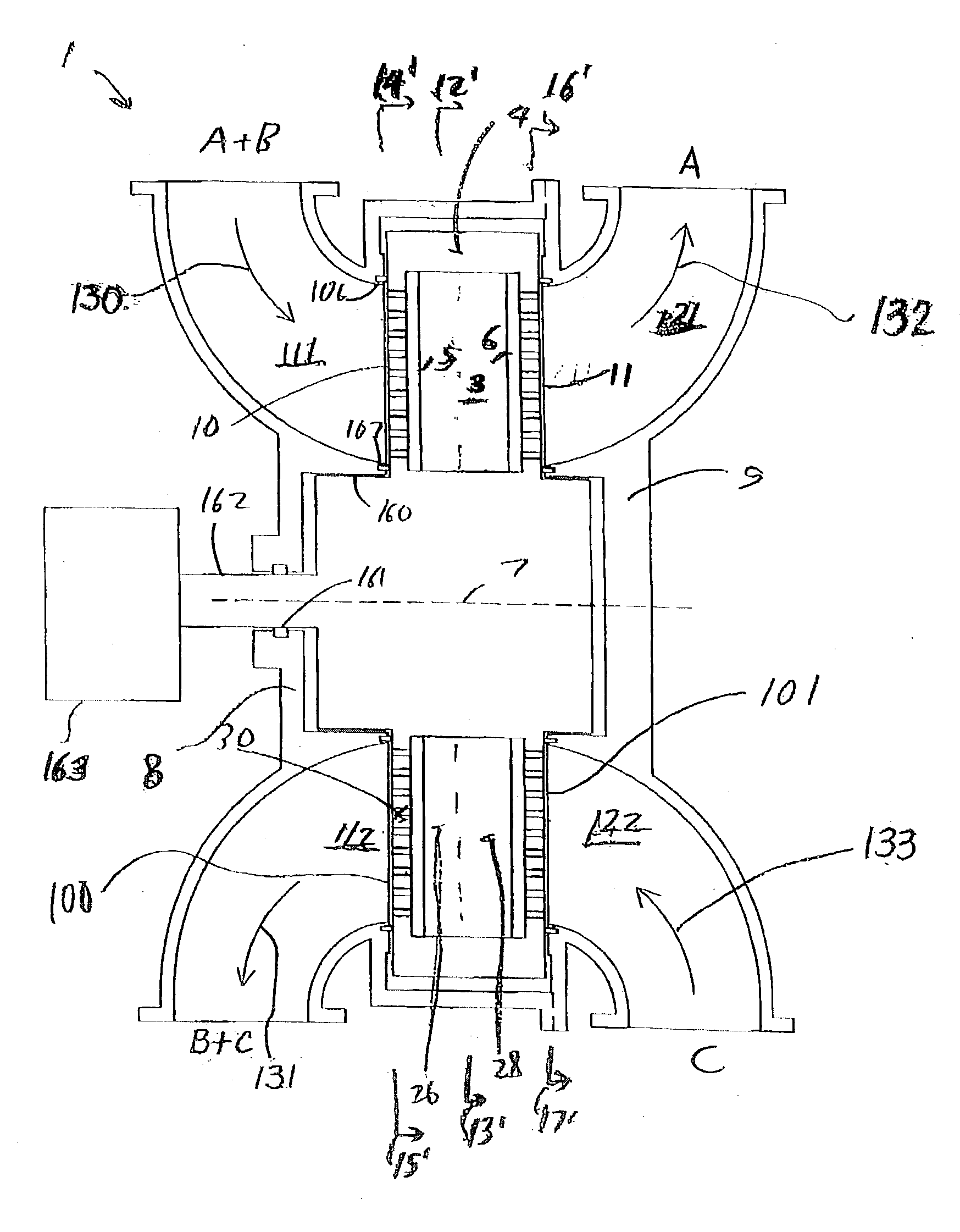

High temperature fuel cell electrical generation systems are provided that are adapted to enable selective generation of electrical power, and / or hydrogen fuel, and / or useable heat, allowing flexible operation of the generation system. In such embodiments, the high temperature fuel cell may be either a MCFC or a SOFC. The disclosed systems relate to high temperature fuel cells exploiting gas separation devices in which a first gas mixture is to be separated so that a first product of the separation is enriched in a first component, while a second component is mixed with a displacement purge stream to form a second gas mixture, with provision to prevent cross contamination of purge gas components into the first product stream. The process may be applied to hydrogen (component A) enrichment from syngas mixtures such as fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere or for recycle to the fuel cell cathode in the case of molten carbonate fuel cells, by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:QUSIR TECH

Hydrogen recycle for solid oxide fuel cell

InactiveUS20040005492A1High outputImprove voltage efficiencyDispersed particle separationFuel cell auxillariesContaminationRadiochemistry

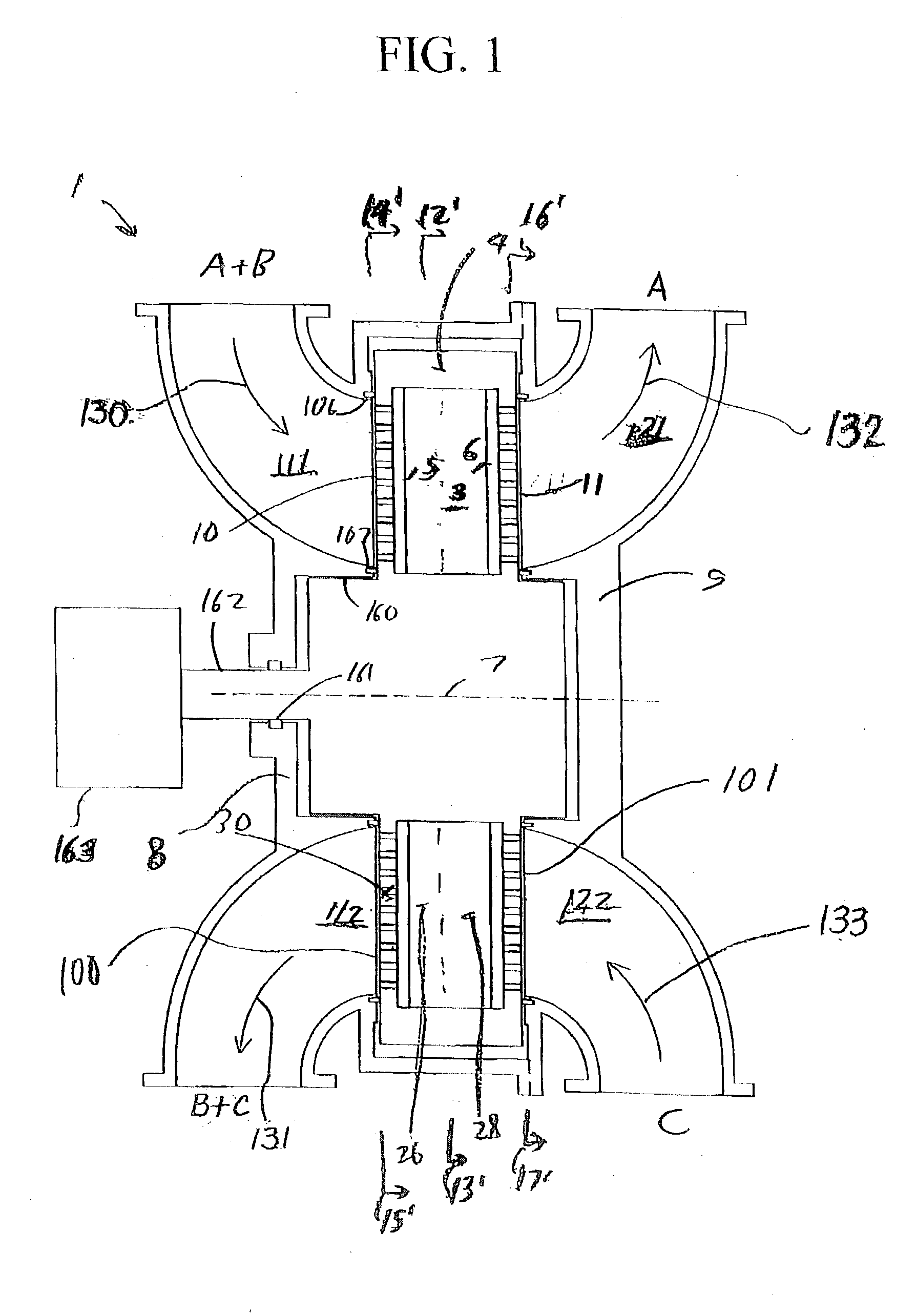

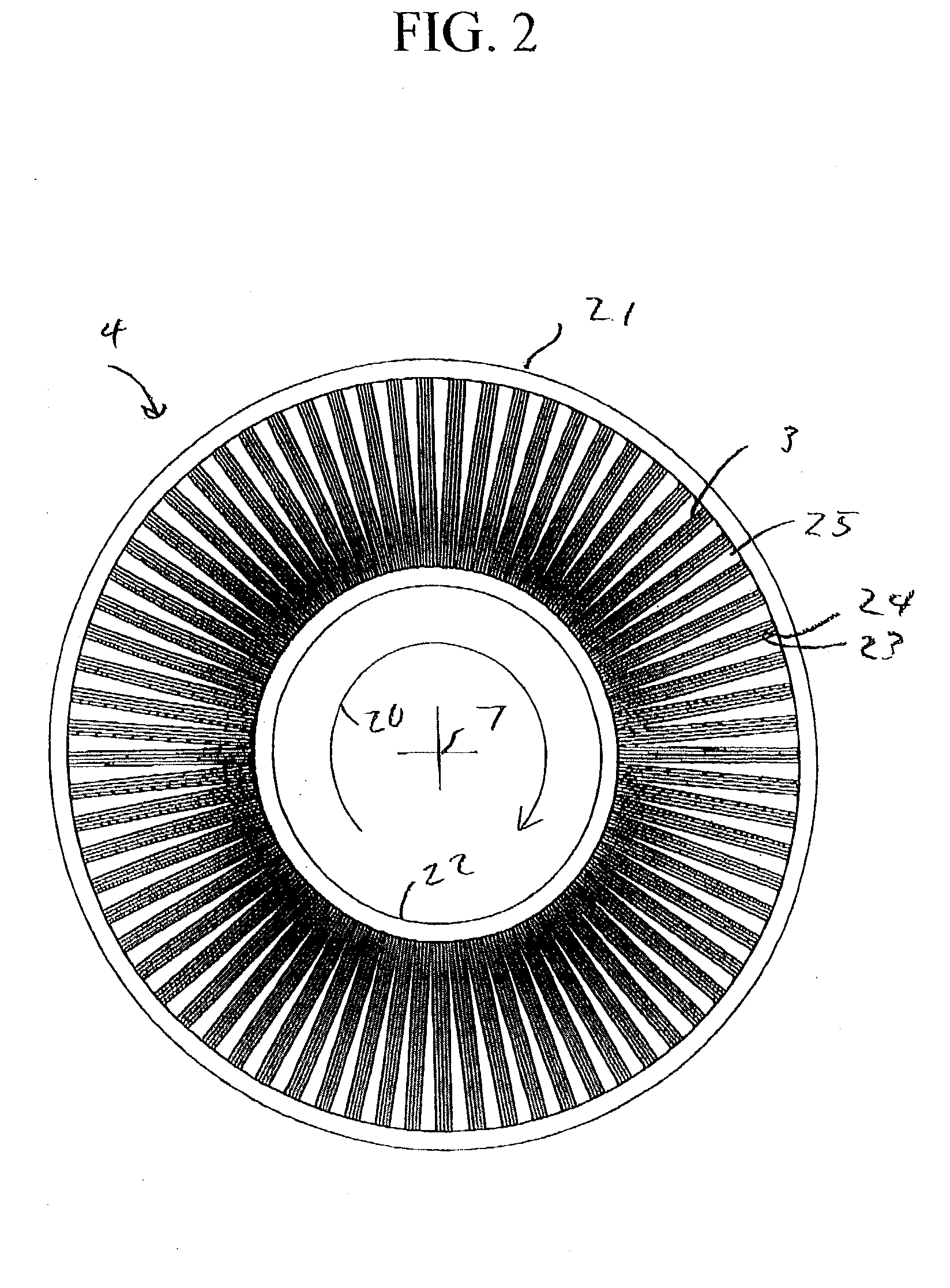

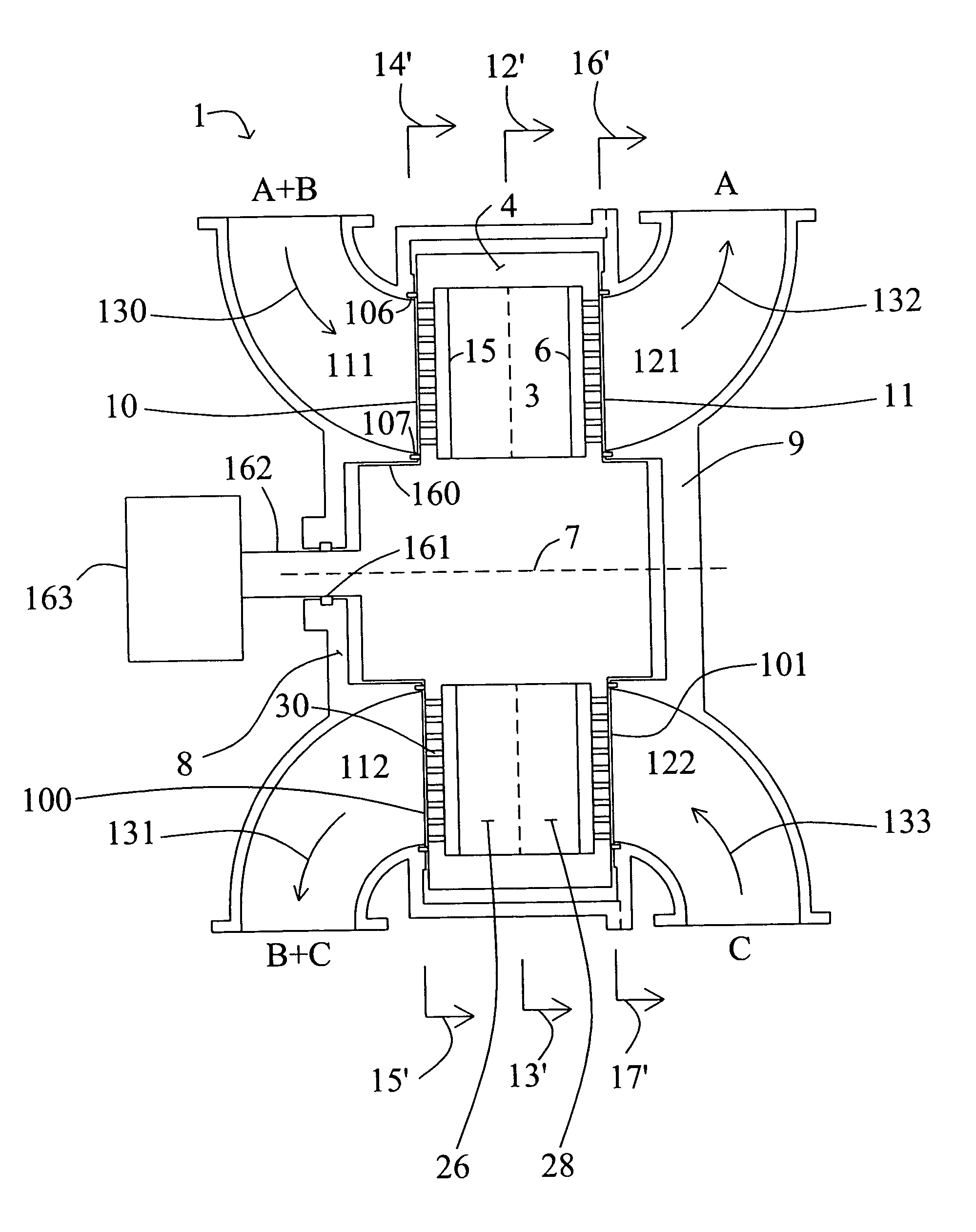

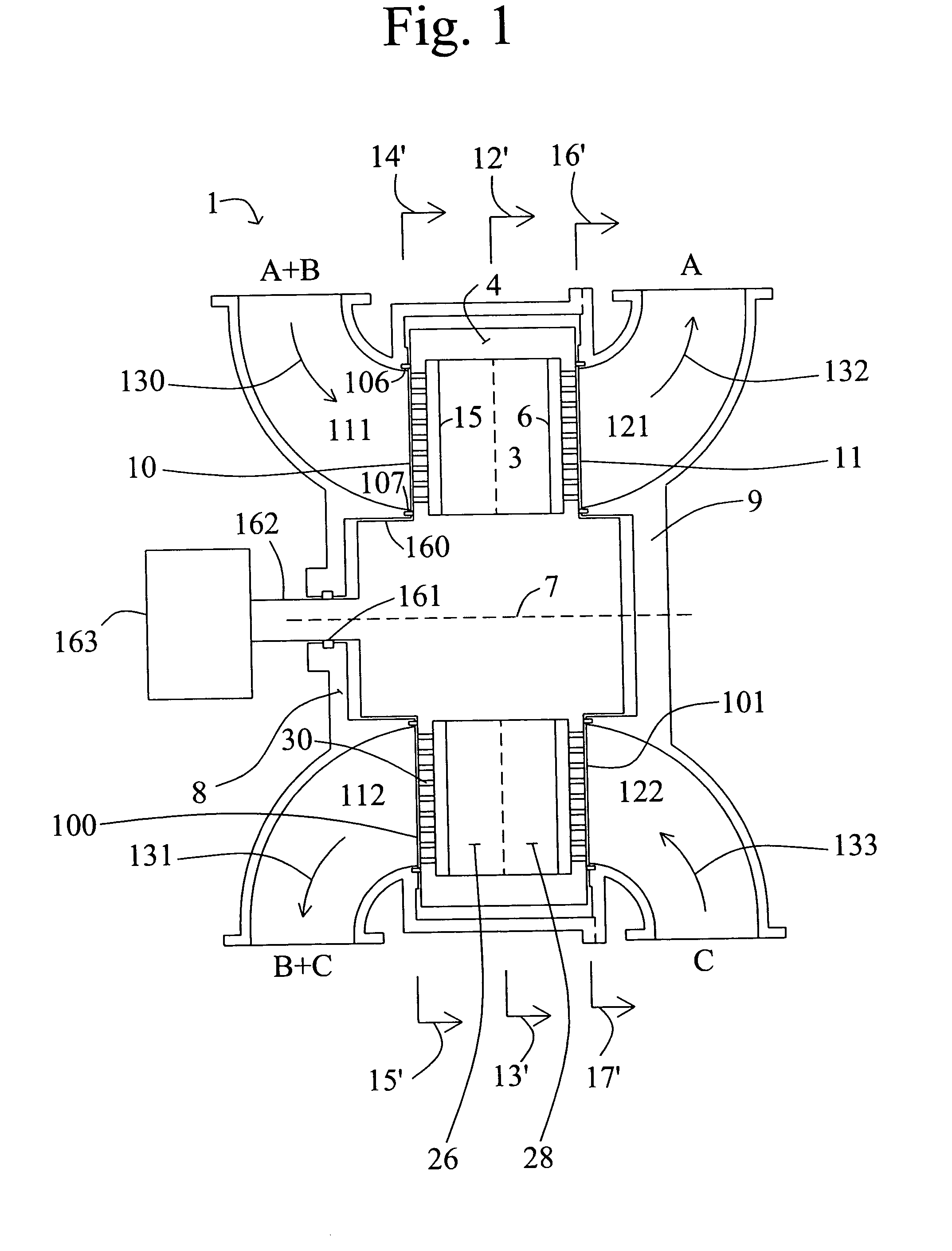

The present disclosure relates to solid oxide fuel cells (SOFCs) exploiting gas separation devices in which a first gas mixture including components A (for example hydrogen) and B (for example carbon dioxide) is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C (for example air, oxygen-enriched air or oxygen-depleted air) contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:AIR PROD & CHEM INC

Hydrogen recycle for solid oxide fuel cell

InactiveUS7387849B2Improve efficiencyImprove sustainabilityDispersed particle separationFuel cell auxillariesContaminationRadiochemistry

The present disclosure relates to solid oxide fuel cells (SOFCs) exploiting gas separation devices in which a first gas mixture including components A (for example hydrogen) and B (for example carbon dioxide) is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C (for example air, oxygen-enriched air or oxygen-depleted air) contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:AIR PROD & CHEM INC

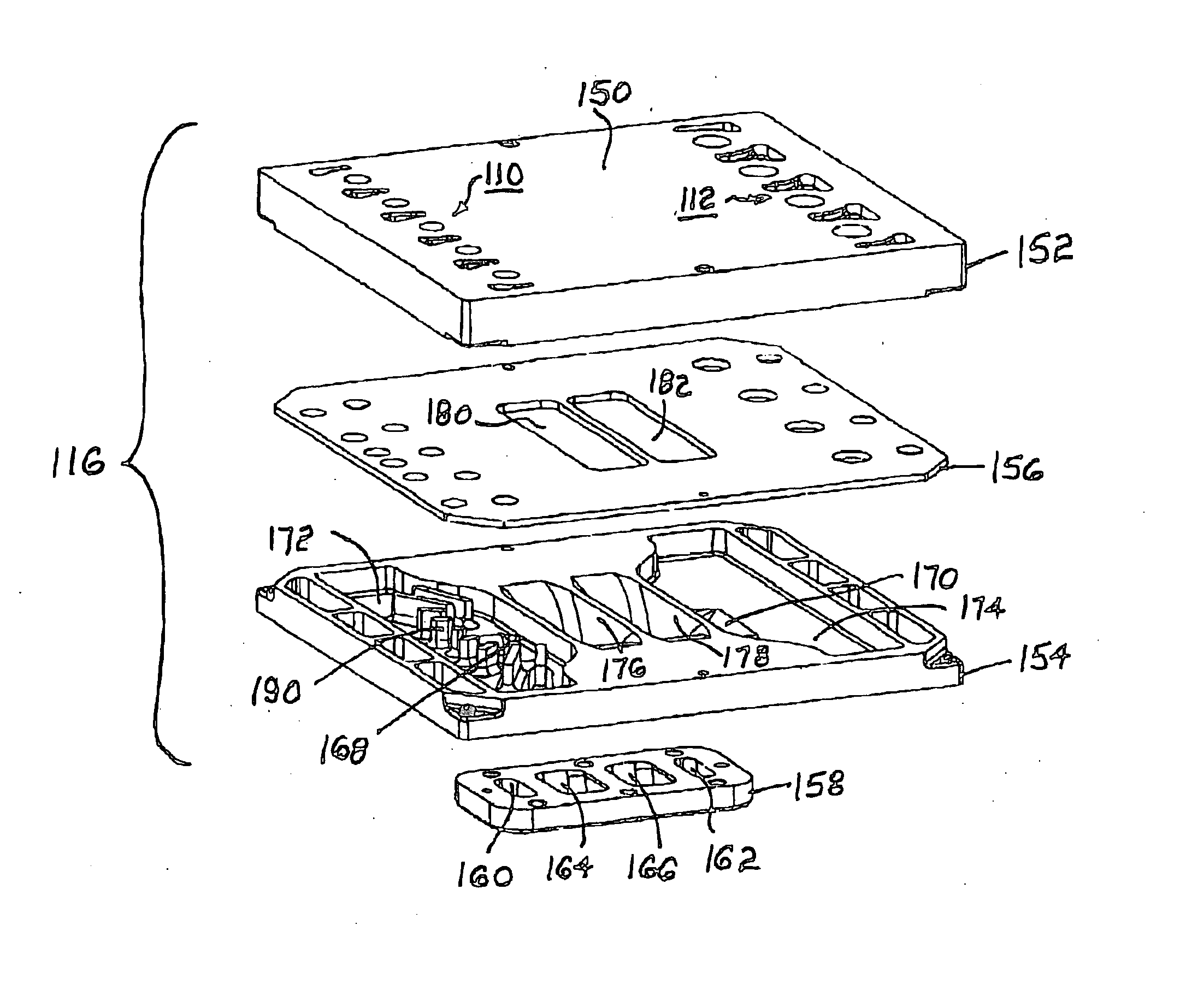

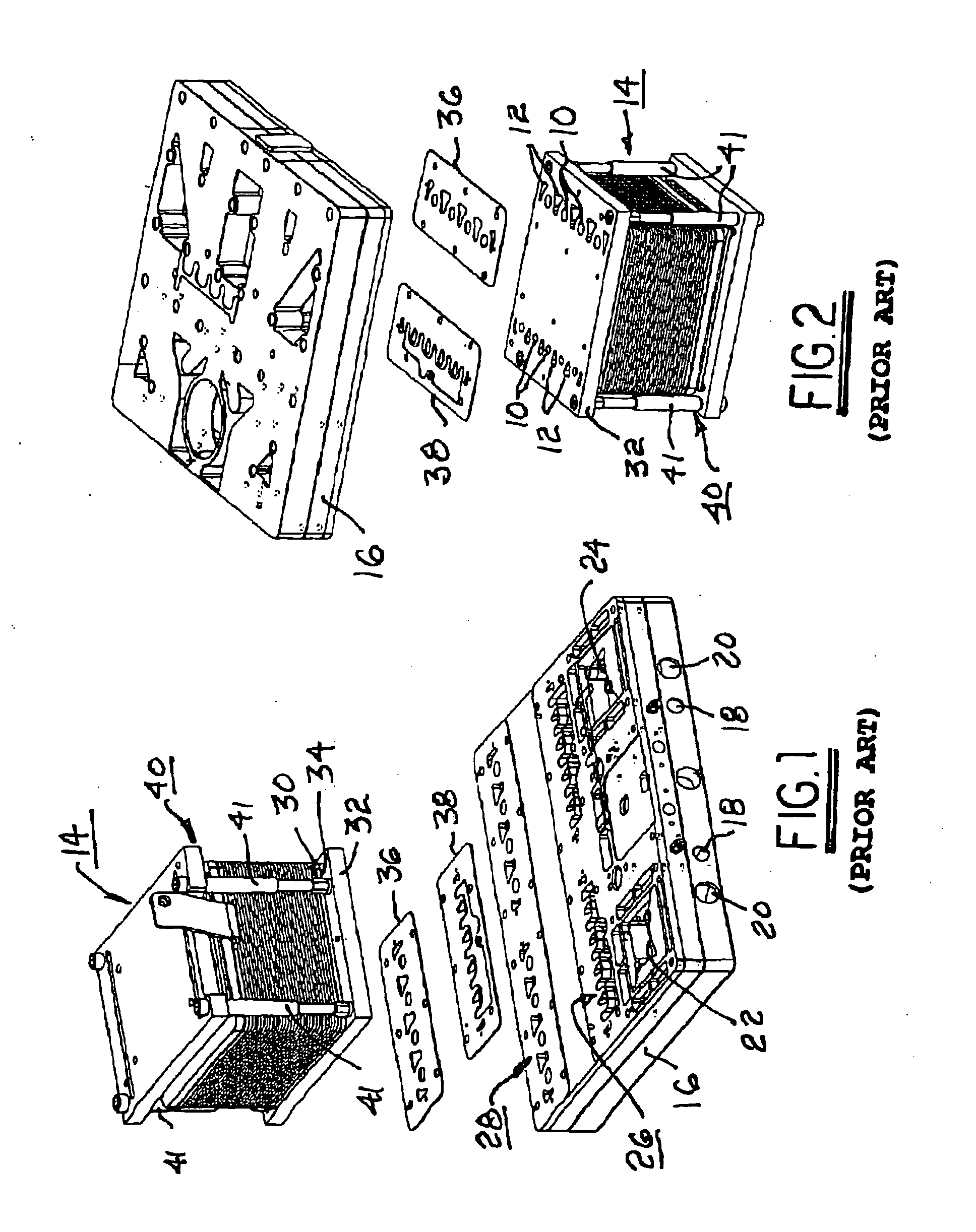

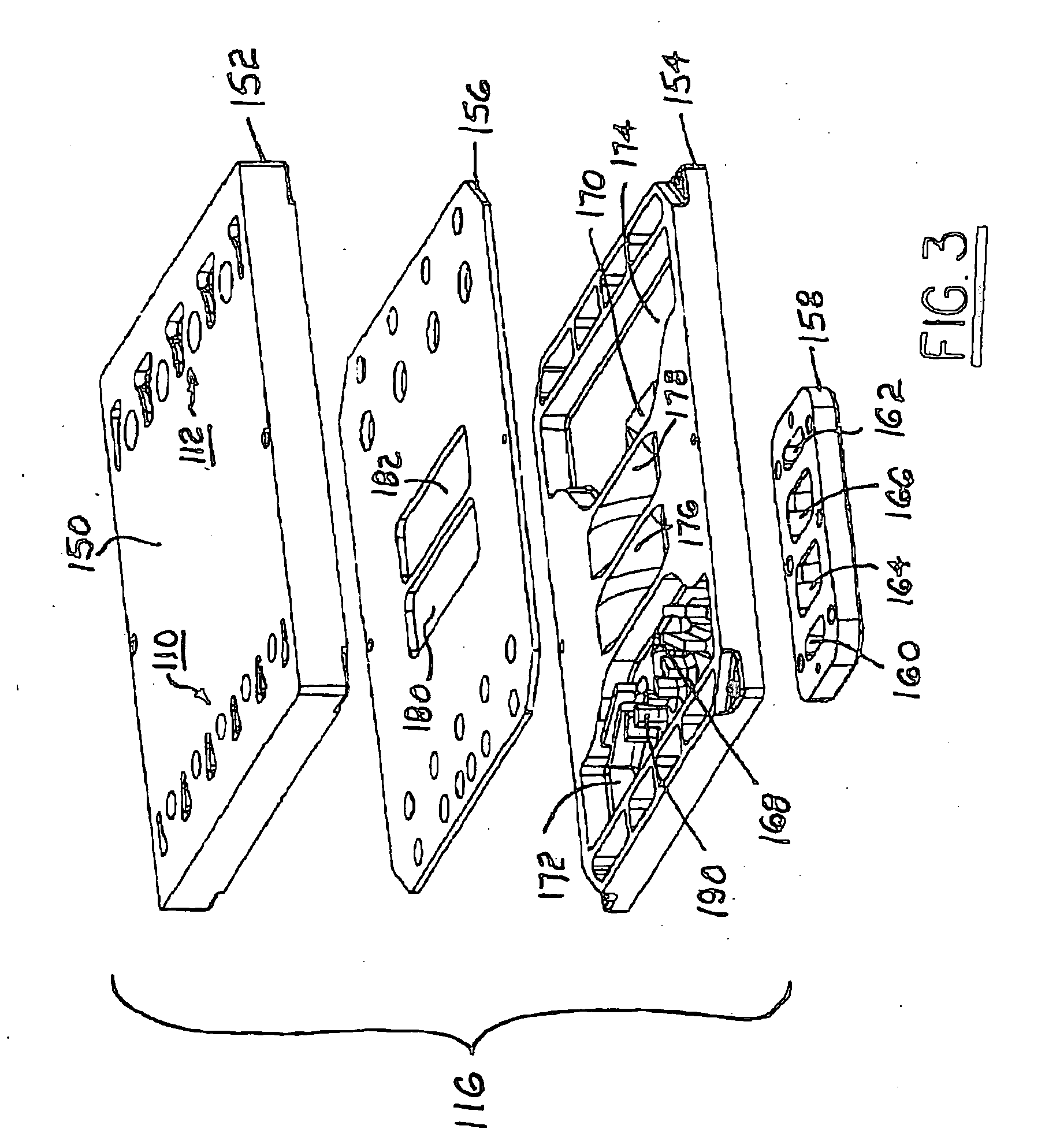

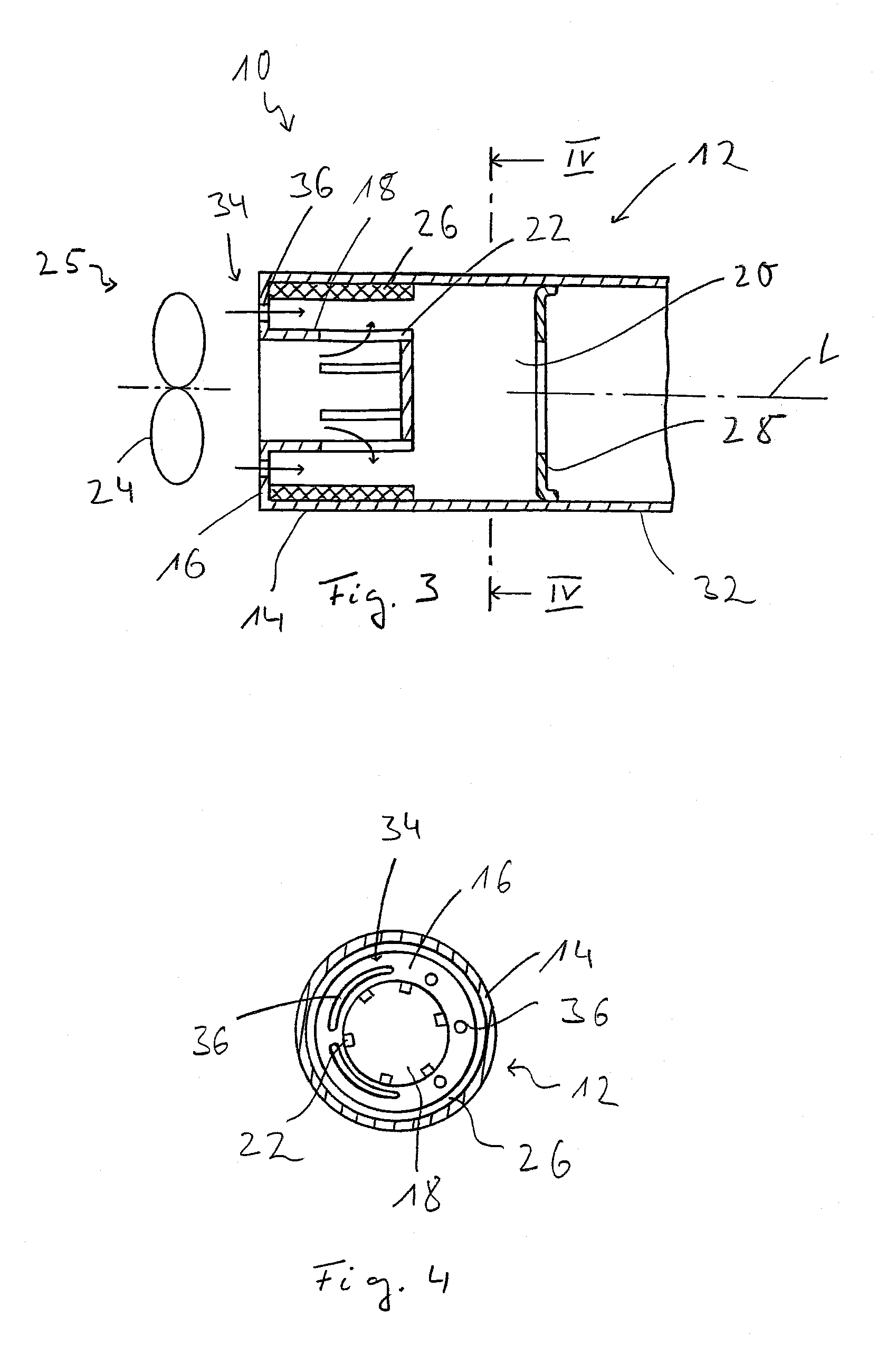

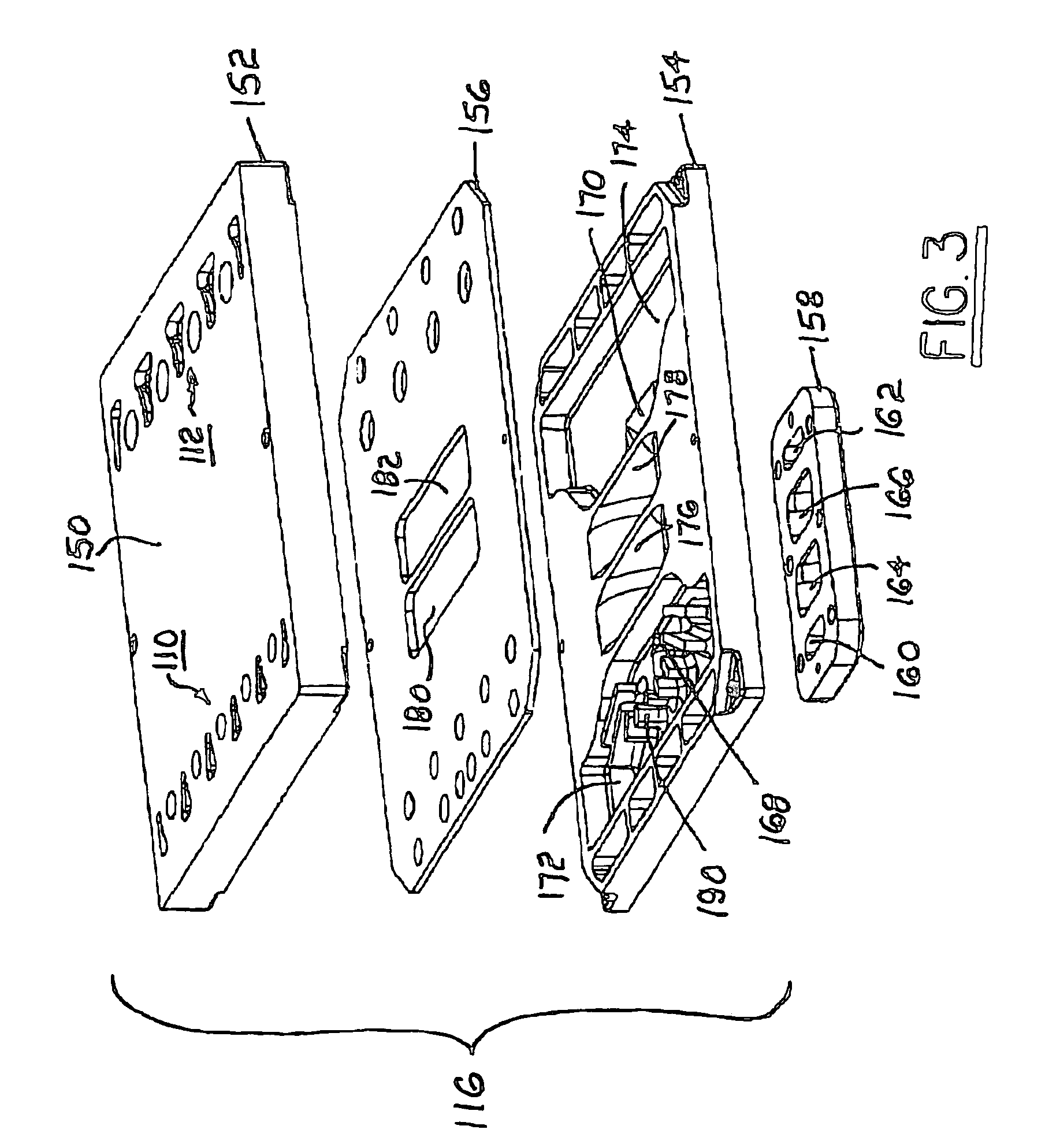

Solid oxide fuel cell stack having an integral gas distribution manifold

ActiveUS20070248868A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

An SOFC stack module including an integral individual stack manifold containing all of the gas pathways necessary for supply and exhaust of fuel gas and cathode air to and from the stack chimneys. The stack is mounted and hermetically joined directly to the manifold without an intermediate base plate. Flanges at the inlet and outlet ports couple to system distributary manifolds via high temperature sealing joints. The manifold preferably is fabricated of a ferritic stainless steel, and may be formed in a one-piece casting, a combination of multiple castings and stamped plates metallurgically joined (brazed or welded together), or stamped from sheet metal stock. Preferably, the manifold includes fin structures extending into adjacent fuel gas and cathode air chambers to enhance balancing of temperatures by heat exchange therebetween. Heat exchange may be further improved by configuring the manifold to have a plurality of interleaved anode and cathode gas supply chambers.

Owner:BATTELLE MEMORIAL INST +1

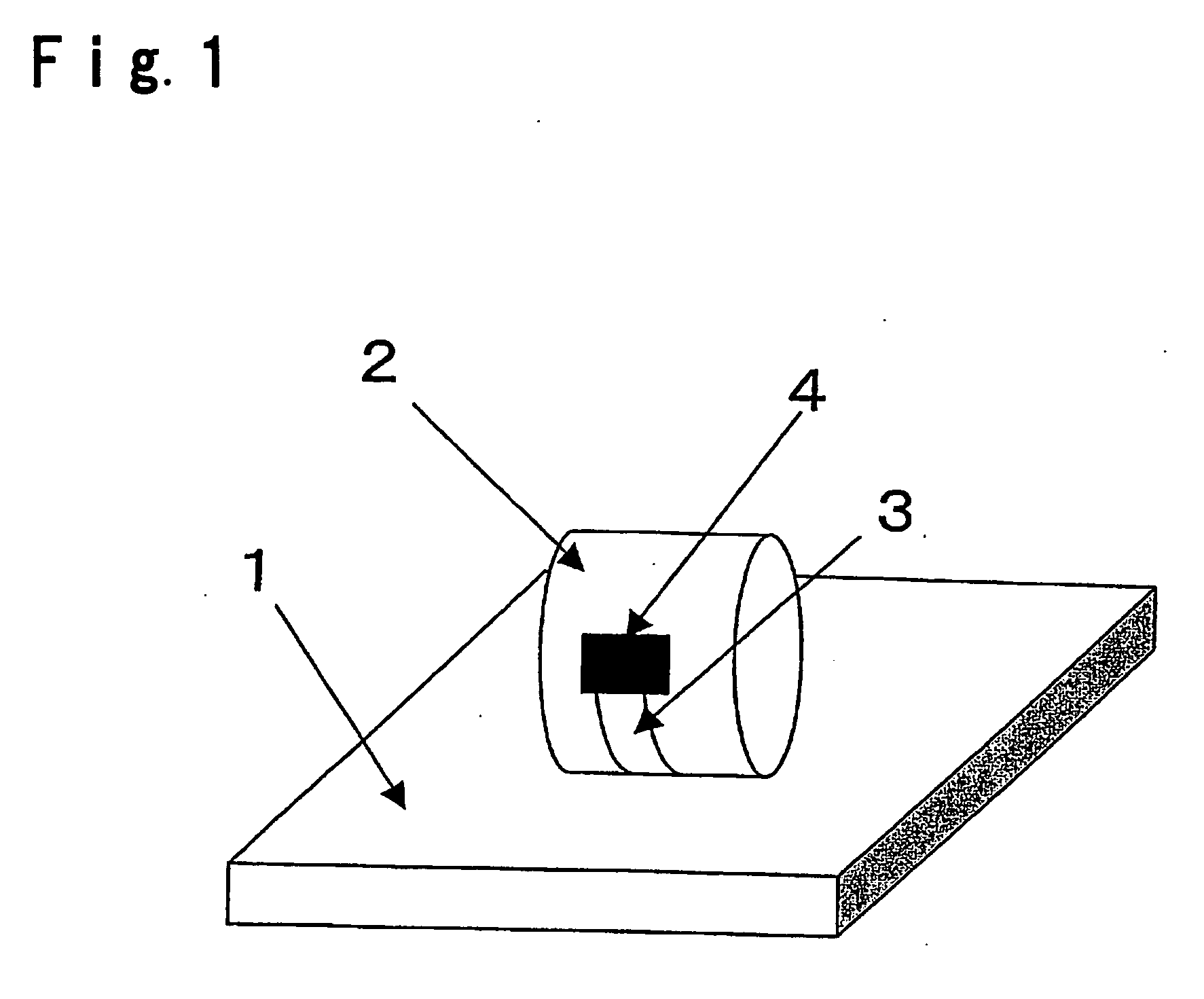

Drying system

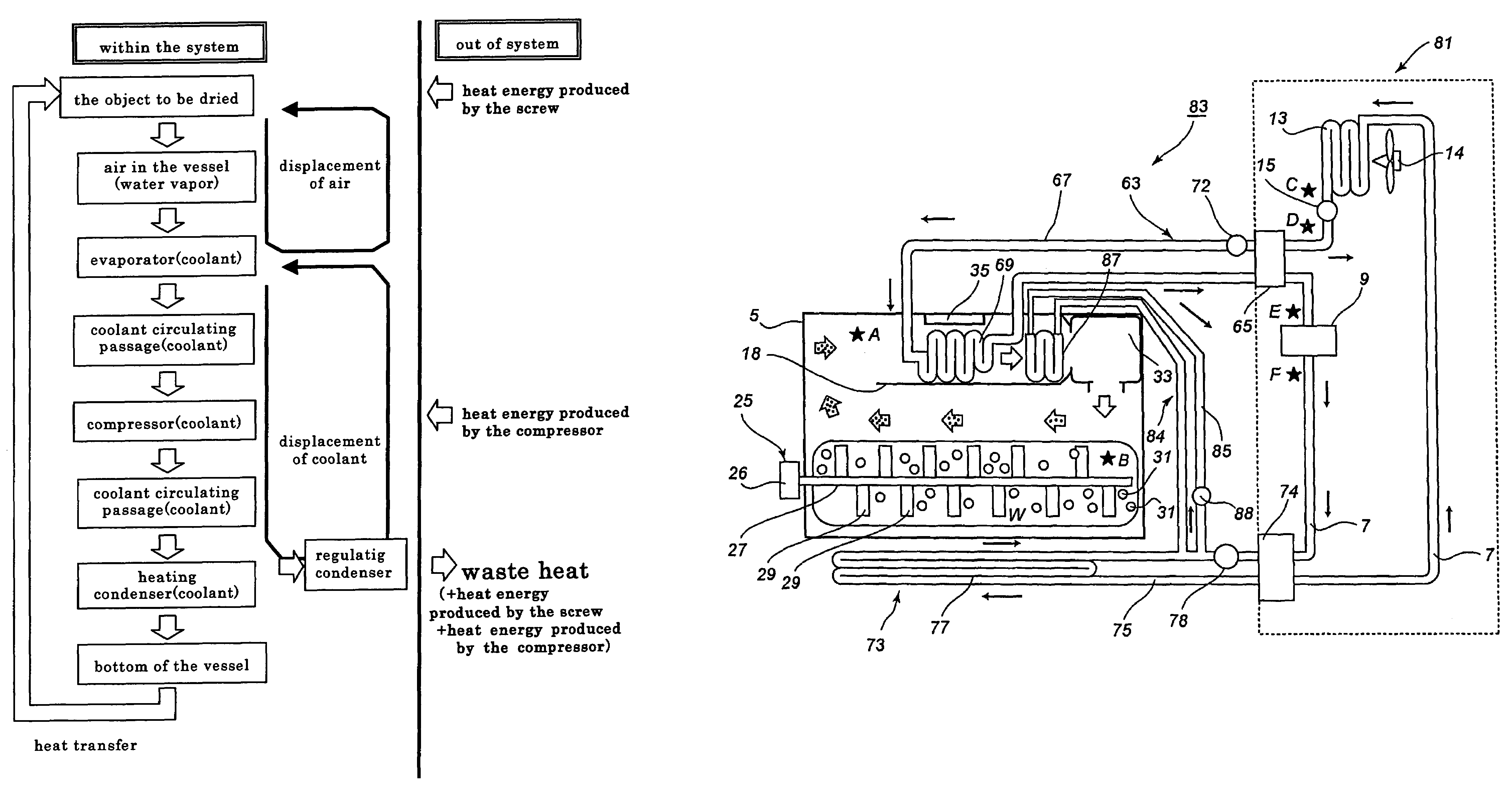

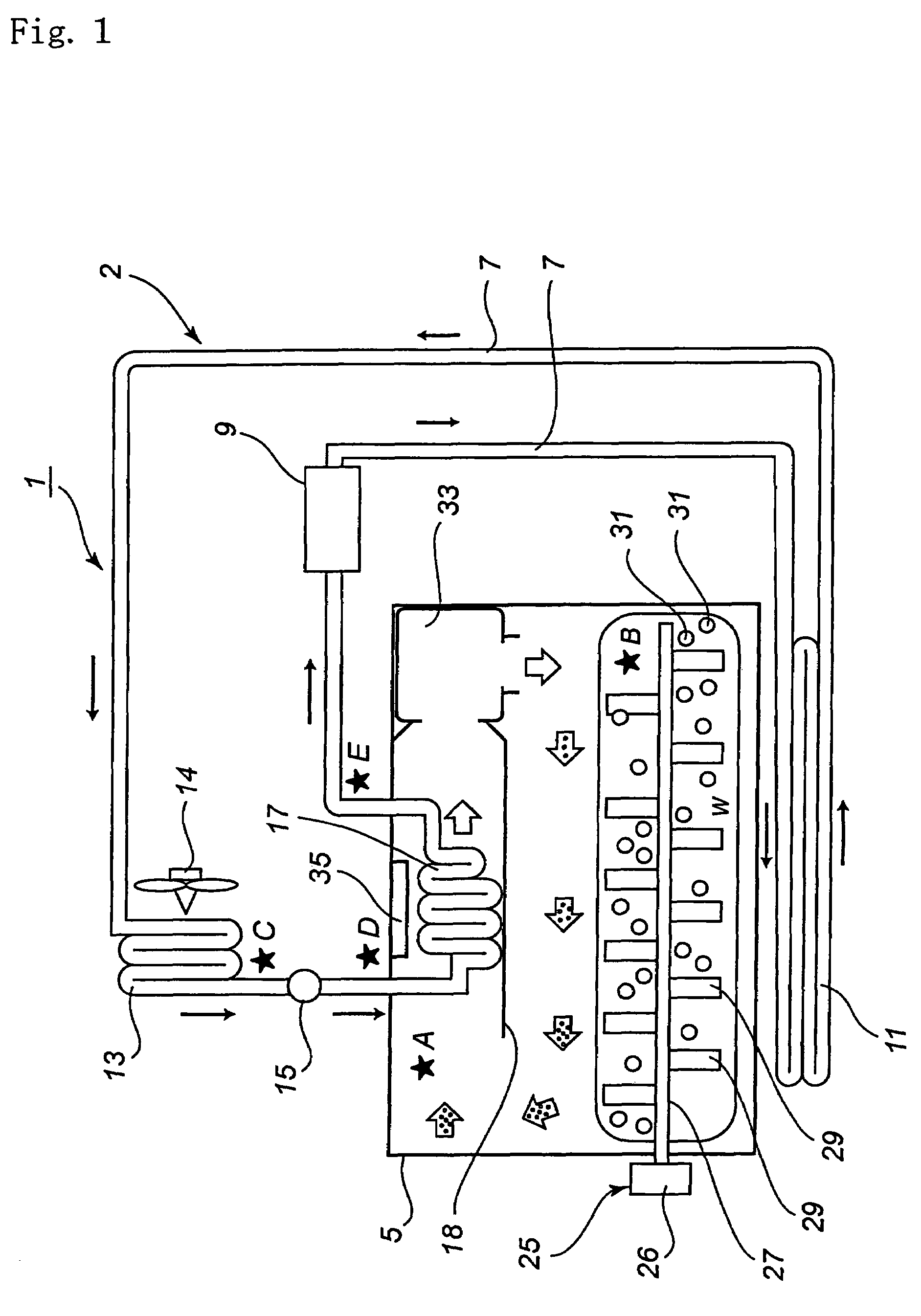

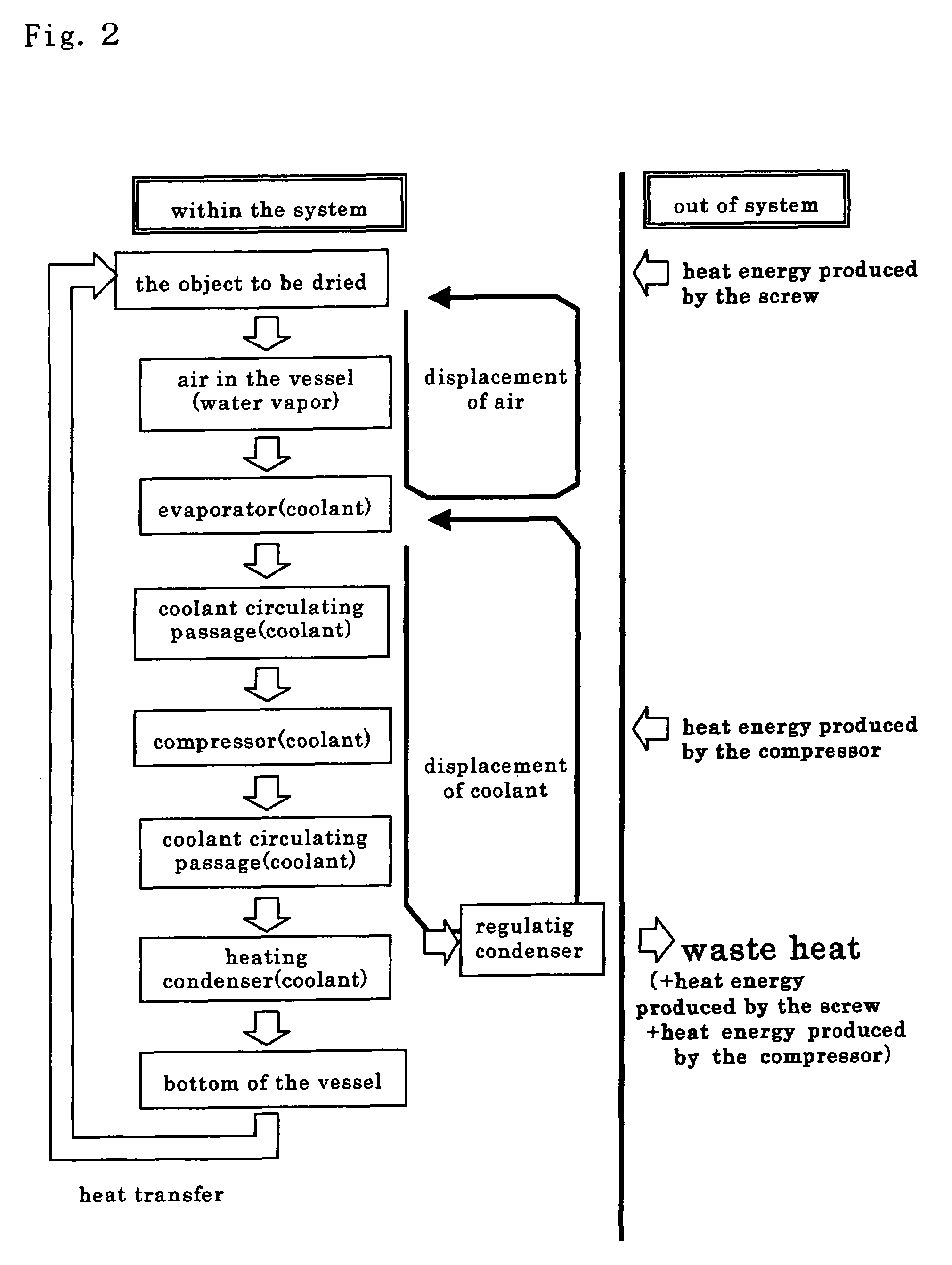

InactiveUS7624514B2Improve drying efficiencyReduce water contentDrying solid materials with heatHeat recovery systemsVaporizationEngineering

In a drying system using a compression refrigeration system, a condenser is divided into a regulating condenser and a heating condenser. The regulating condenser is capable of regulating the amount of exhaust heat discharged to outside the system. The heating condenser produces moist air by feeding heat to an aqueous object to be dried placed in a processing vessel to evaporate the moisture in the object. Heat of condensation of steam is recovered by an evaporator as heat of a refrigerant, and the recovered heat is discharged in the heating condenser to use it for the vaporization of the moisture in the object, and excess heat is discharged by the regulating condenser to outside the system.

Owner:GREEN SEIJU CO LTD

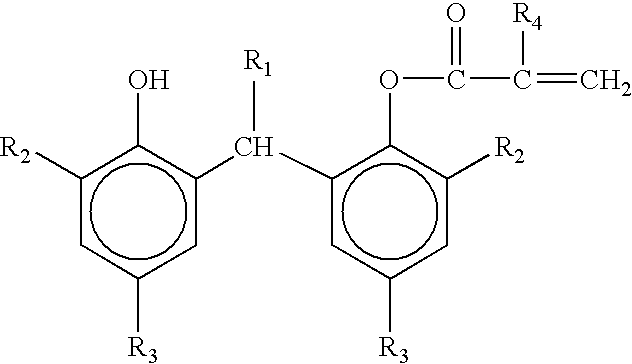

Heat-shrinkable film

InactiveUS20060233984A1Improve heat balanceImprove shrinkageWrappers shrinkageSynthetic resin layered productsPolymer scienceDynamic viscoelasticity

A heat shrinkable film and a heat shrinkable multilayer film excellent in balance of heat resistance, high shrinkability, high shrinkability particularly at a low temperature, resistance to spontaneous shrinkage, chemical resistance and rigidity, are provided. A heat shrinkable film and a heat shrinkable multilayer film obtained from a resin composition comprising an aromatic vinyl compound / conjugated diene block copolymer having a micro phase separation structure comprising a soft phase and a hard phase and further having a specific structure and a specific dynamic viscoelasticity spectrum and a styrene polymer having a syndyotactic structure, in a specific proportion.

Owner:DENKA CO LTD

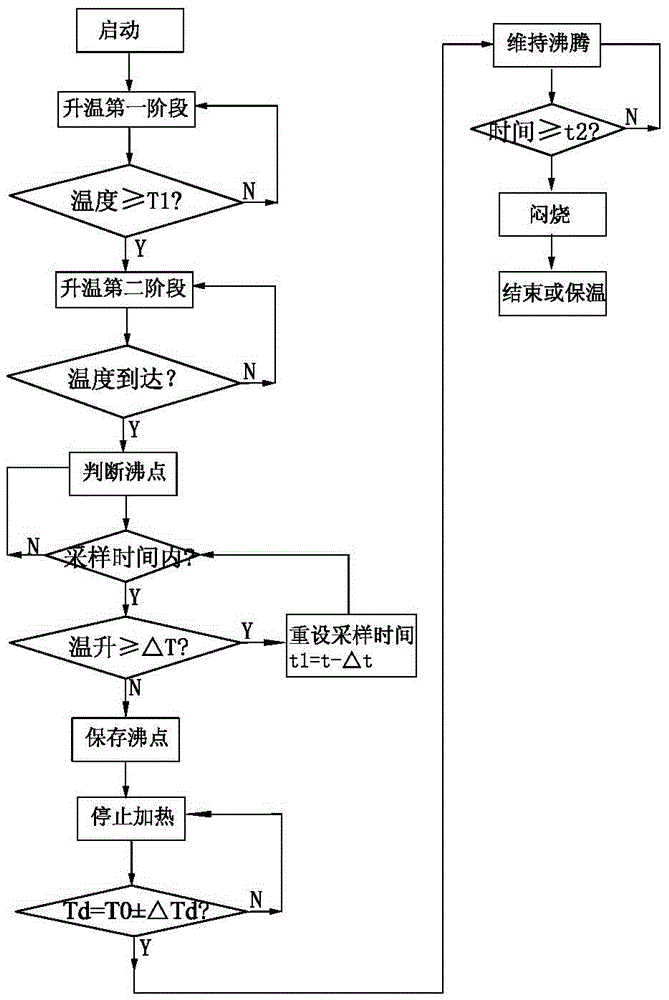

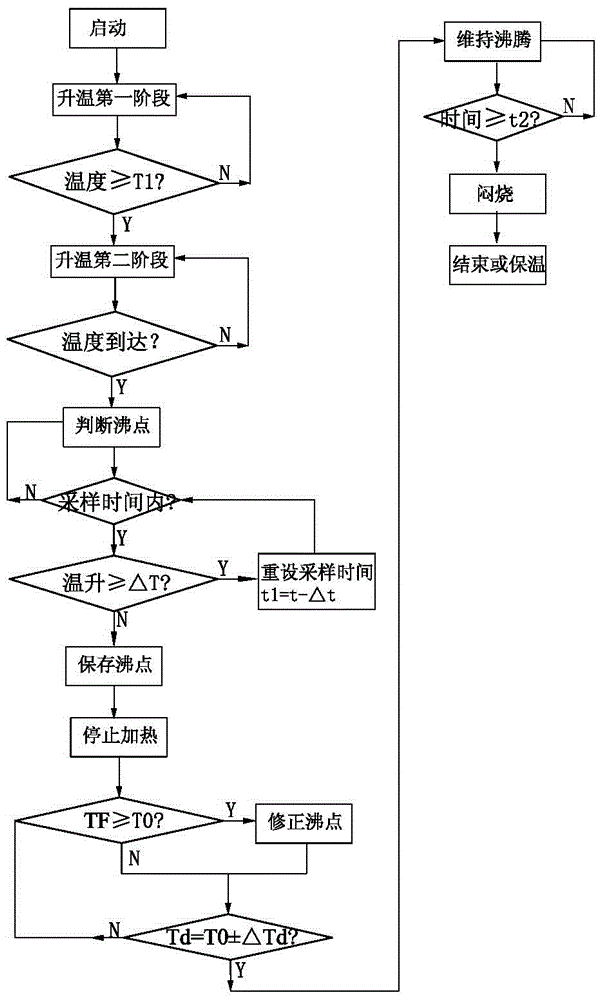

Cooking method for household appliance

ActiveCN105662115AGood cooking consistencyGuaranteed accuracyWarming devicesVessels with intergral heatingBoiling pointEngineering

The invention relates to a cooking method for a household appliance. According to the method, in the boiling point judgment stage, the bottom temperature is kept to be T4 which is 110-120 DEG C; a top temperature sensor is used for detecting the top temperature; a master control chip is used for presetting a sampling time t; the master control chip is used for presetting the sampling time t1 once again if the rising range of the top temperature is more than delta T in the sampling time t, and t1 is the difference between t and delta T; and the master control chip is used for saving the value of the top temperature to be a boiling temperature point T0 if the rising range of the top temperature is less than delta T. Therefore, by adopting the cooking method, the accuracy of the boiling point can be guaranteed in any environment and no matter how much food is cooked in the appliance, and the problem of poor cooking effect due to the fact that a traditional cooking appliance performs insufficient boiling or over boiling in different environments can be solved; and moreover, the cooking effect is little influenced by the cooking amount, the uniformity of cooking effect is improved, and the risk of spilling in the cooking process is avoided.

Owner:JOYOUNG CO LTD

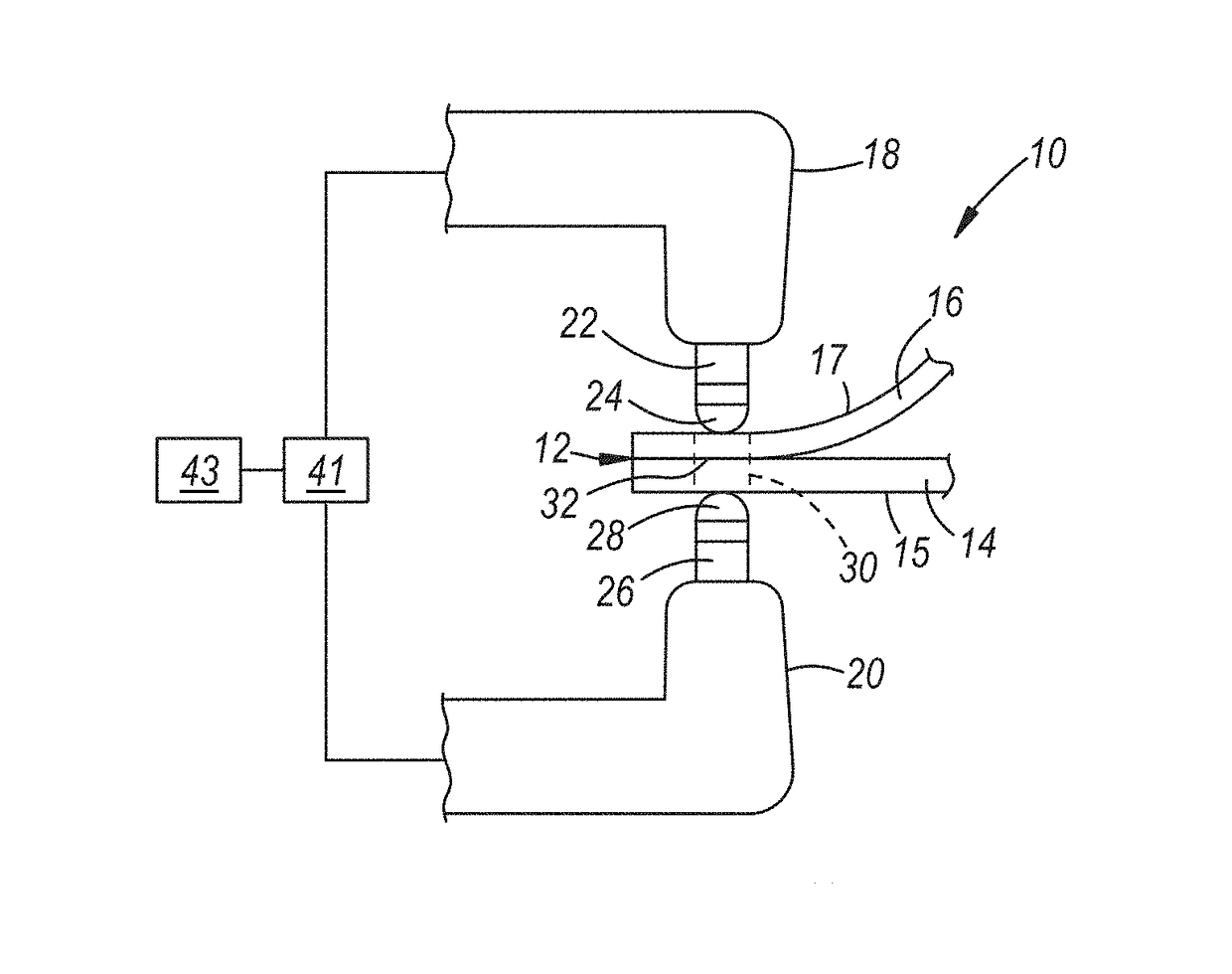

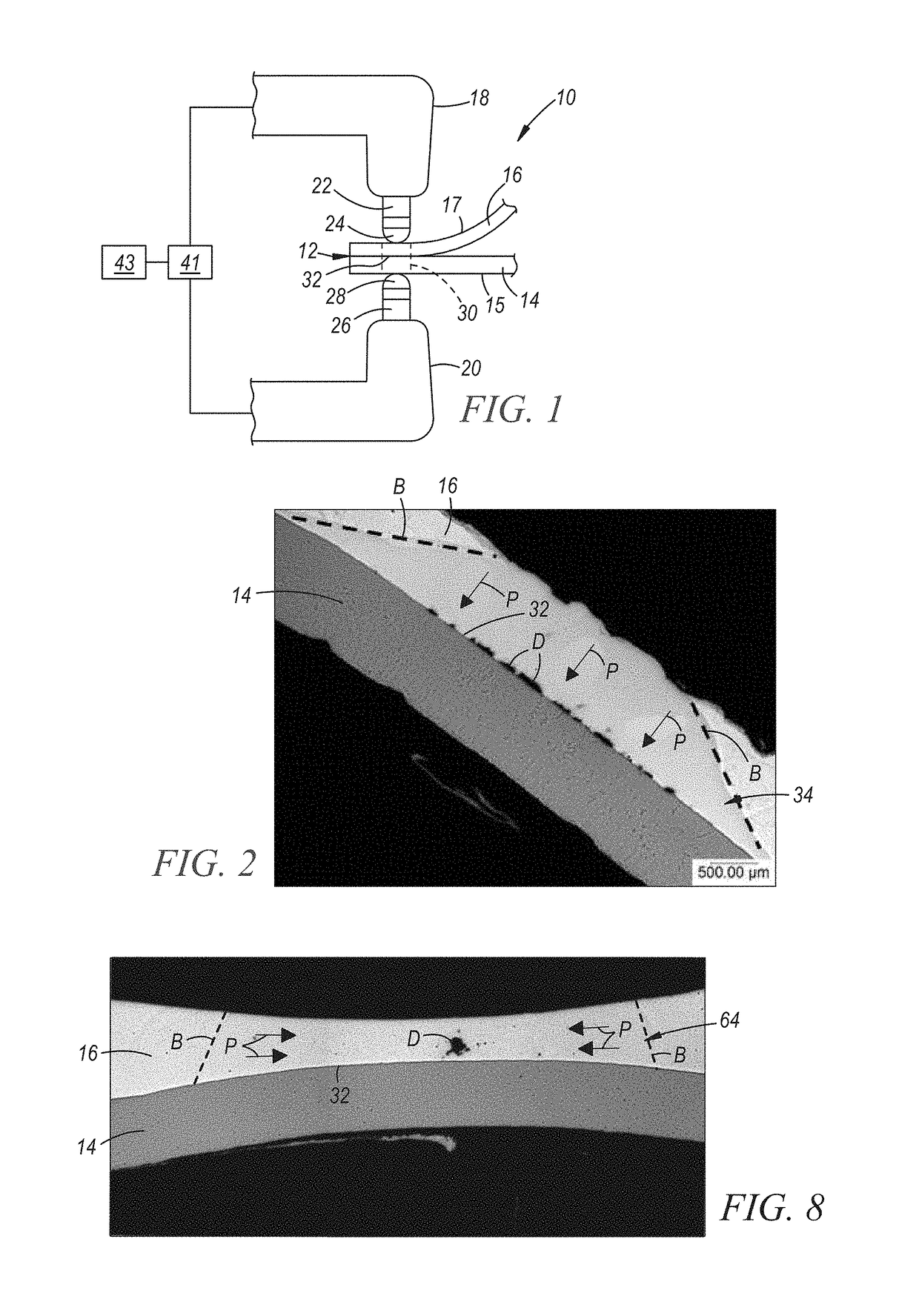

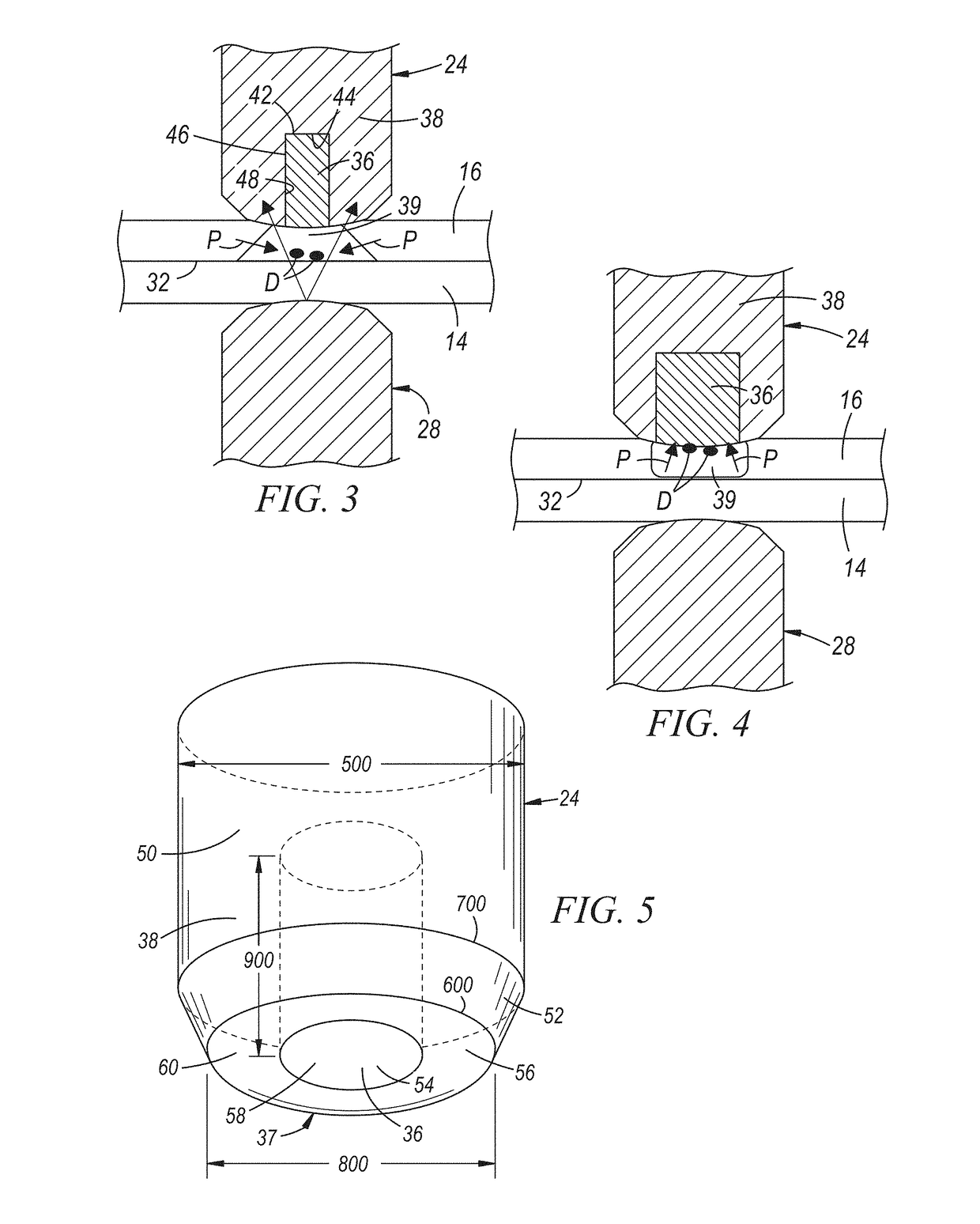

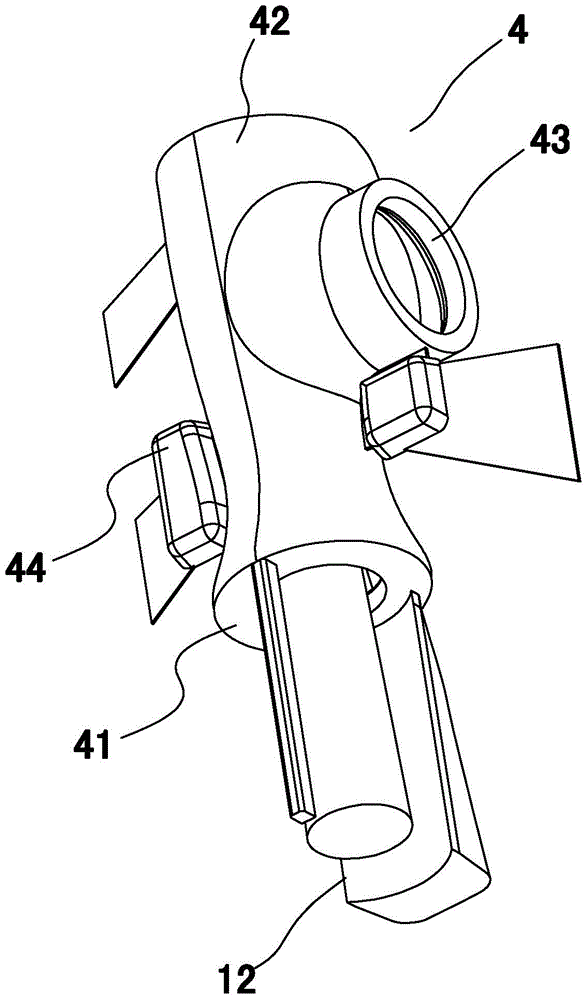

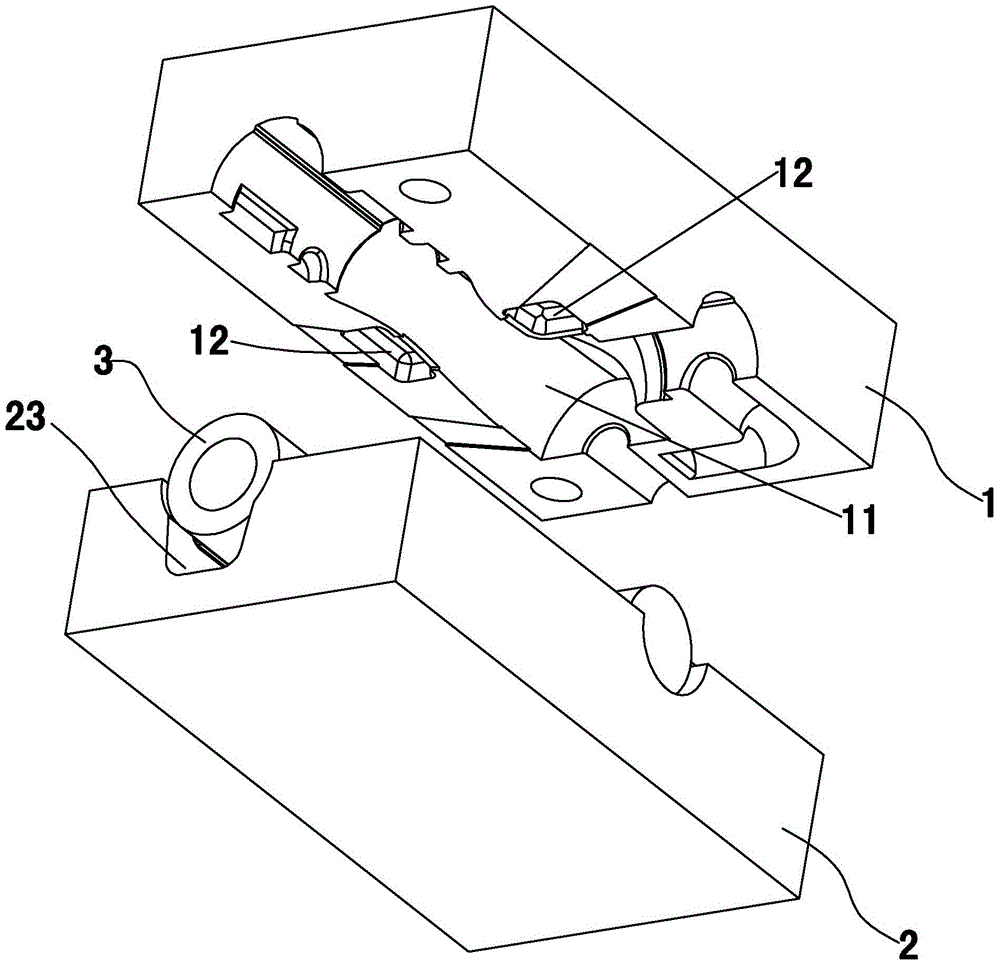

Resistance spot welding steel and aluminum workpieces with electrode having insert

ActiveUS20170297135A1Increased durabilityHigh strengthPressure electrodesWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy workpiece, and a welding electrode used therein. In one step of the method a workpiece stack-up is provided. The workpiece stack-up includes a steel workpiece and an aluminum or aluminum alloy workpiece. Another step of the method involves contacting the aluminum or aluminum alloy workpiece with a weld face of the welding electrode. The welding electrode has a body and an insert. The insert is composed of a material having an electrical resistivity that is greater than an electrical resistivity of the material of the body. The weld face has a first section defined by a surface of the insert and has a second section defined by a surface of the body. Both the first and second sections make surface-to-surface contact with the aluminum or aluminum alloy workpiece amid resistance spot welding.

Owner:GM GLOBAL TECH OPERATIONS LLC

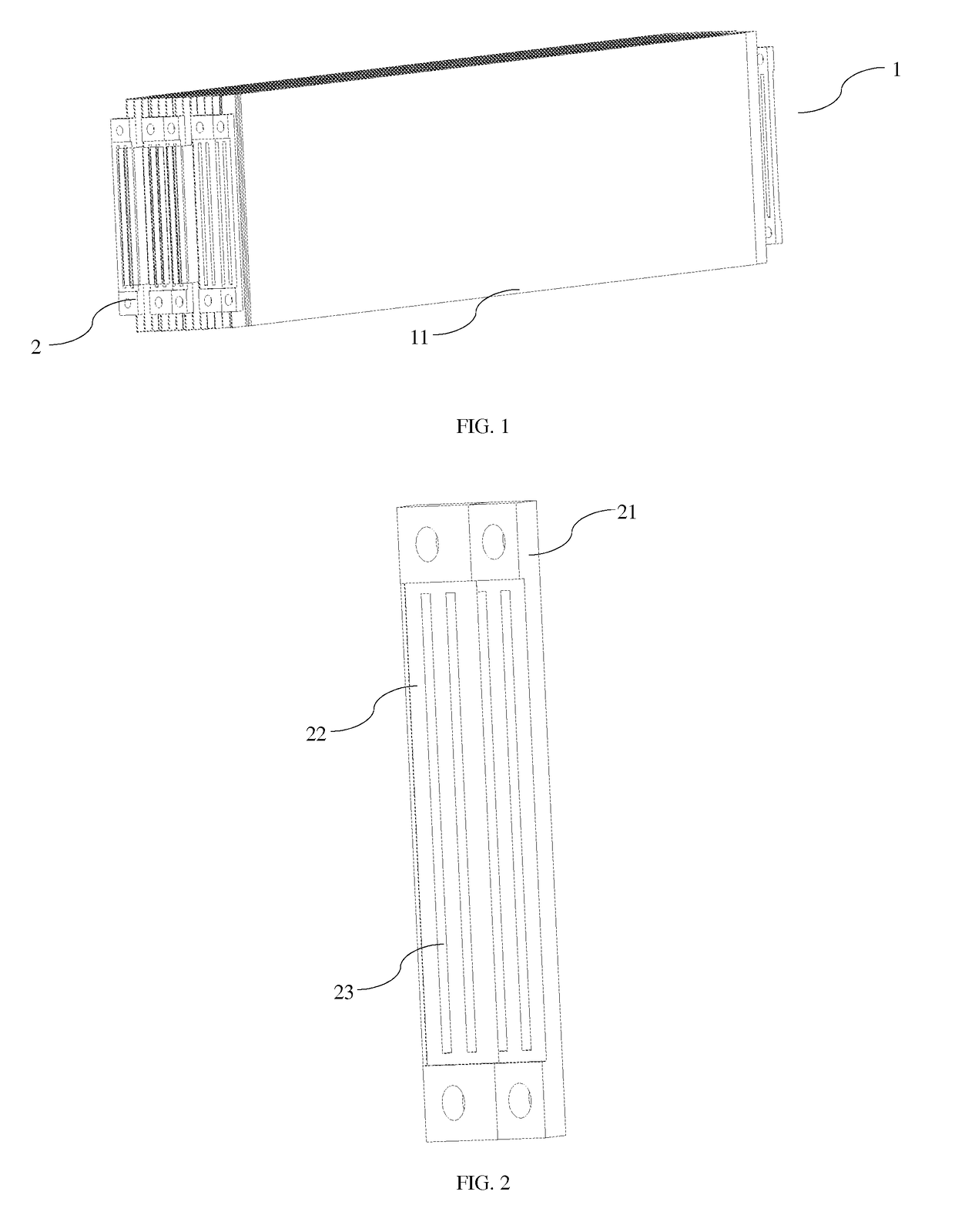

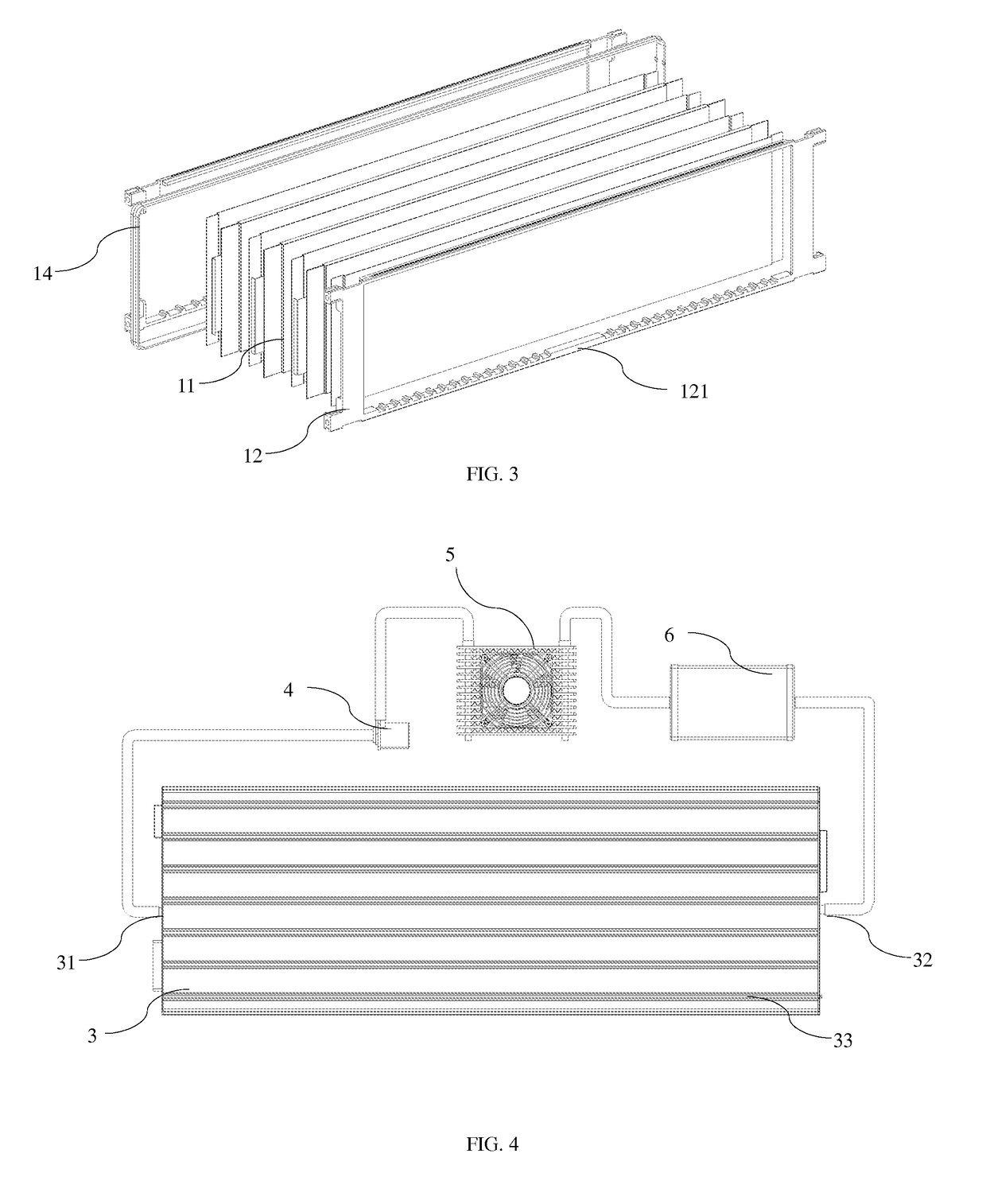

Liquid-cooled battery pack system

ActiveUS20170162923A1Improve securityIncrease energy densitySecondary cellsCell component detailsEngineeringDesoldering

The present invention provides a battery module and a liquid-cooled battery system that uses it, a battery cell and a current collector sheet, on the premise that the materials like the electrode and separator and so on are completely the same, energy density of the battery pack is greatly increased; the cell and the current collector sheet are fully welded connections, the joints are fewer and it is not prone to produce desoldering, also ensuring the stability of the of the cell tab and high current carrying capacity, and when putting the parallel battery module in series, the use of wires are avoided, thus reduces the volume of the battery pack; the innovative design for the liquid-cooled battery pack system, improves the thermal balance between the cells, and the heat-dissipation in battery pack distributes more evenly, the insulation property of the battery package is highly improved, controlling the heat-dissipation capacity of the system by adjusting the flow rate of the circulating pump, not only the unnecessary energy consumption can be avoided, but also have a better impact resistance.

Owner:MICROVAST

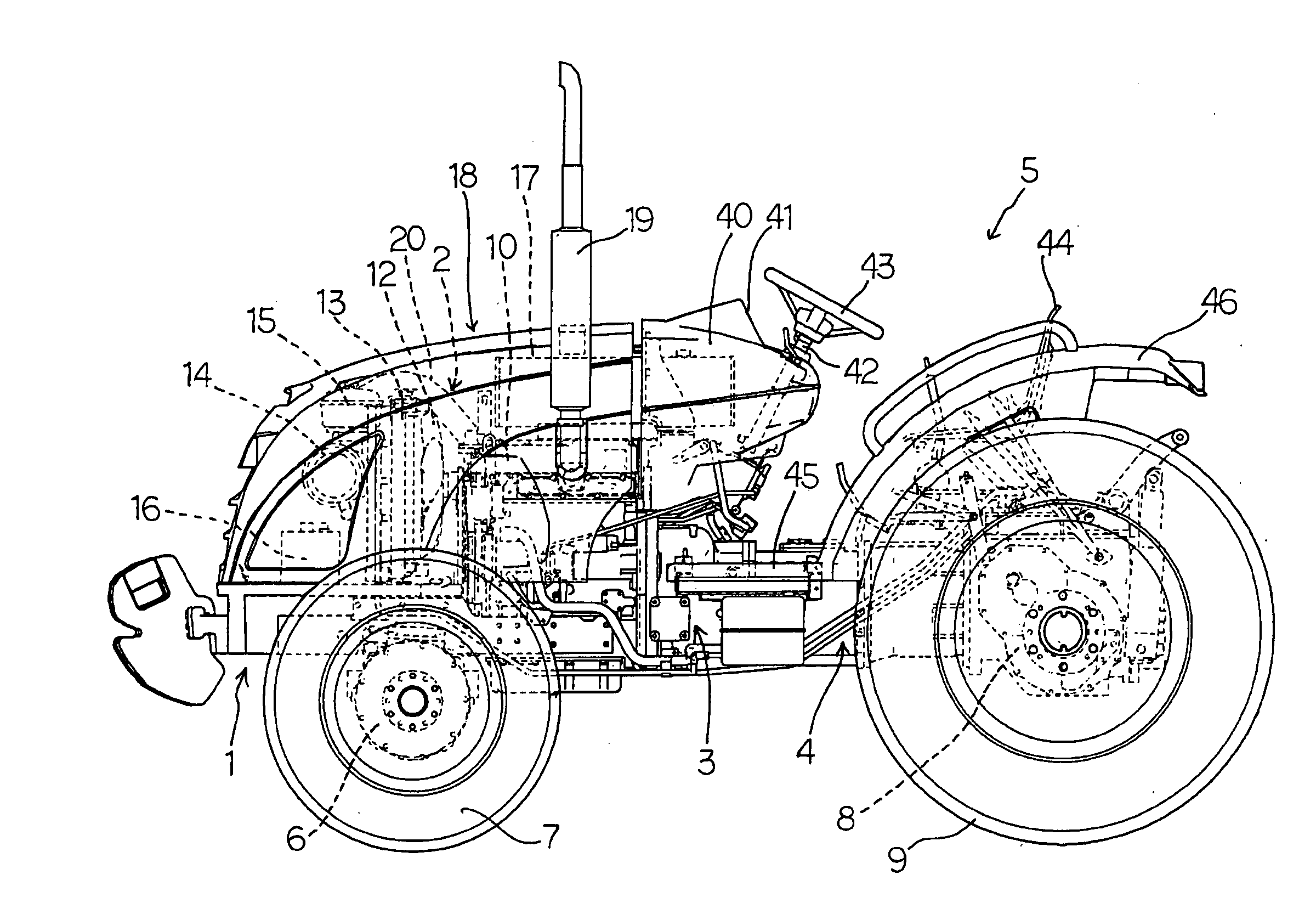

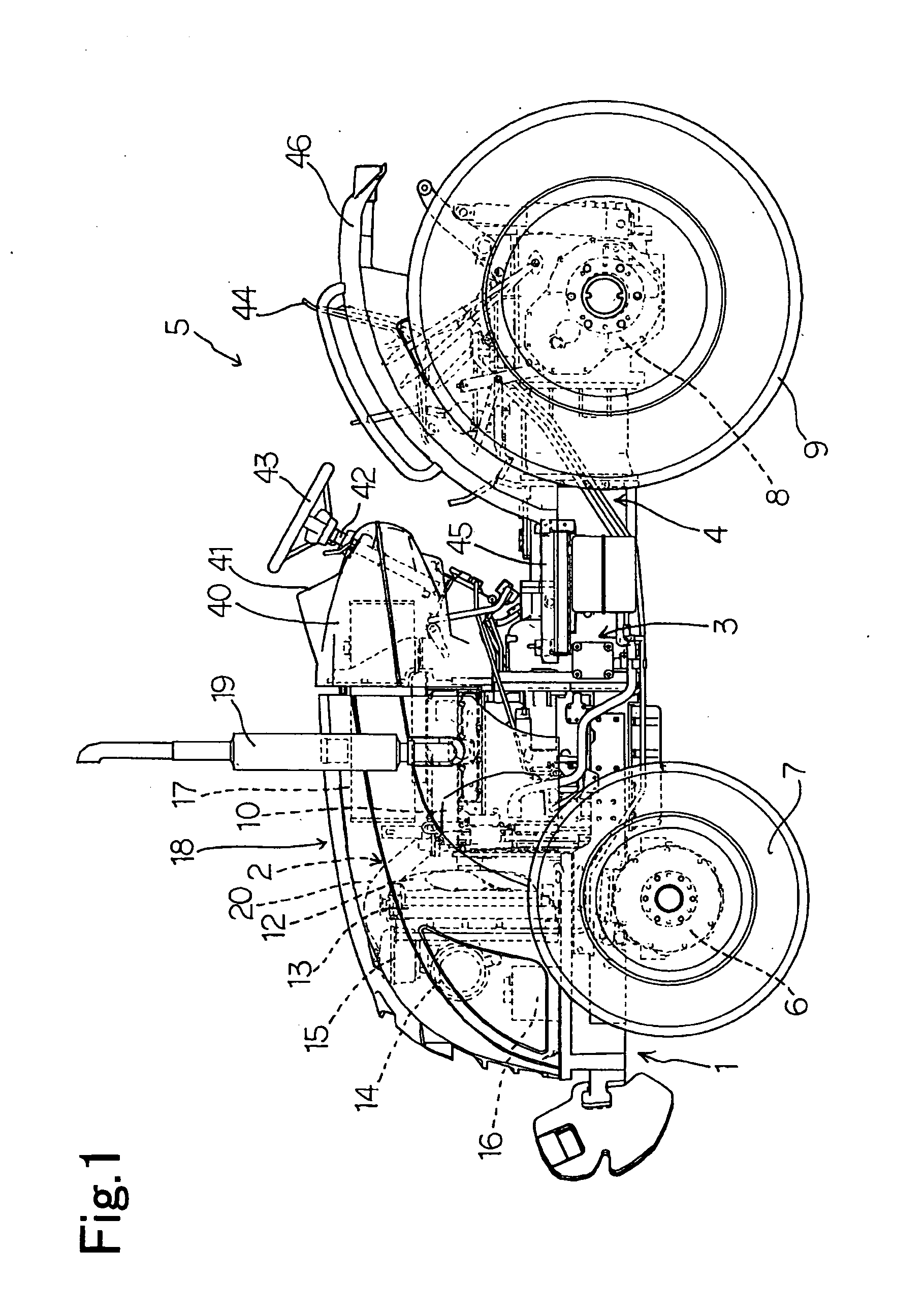

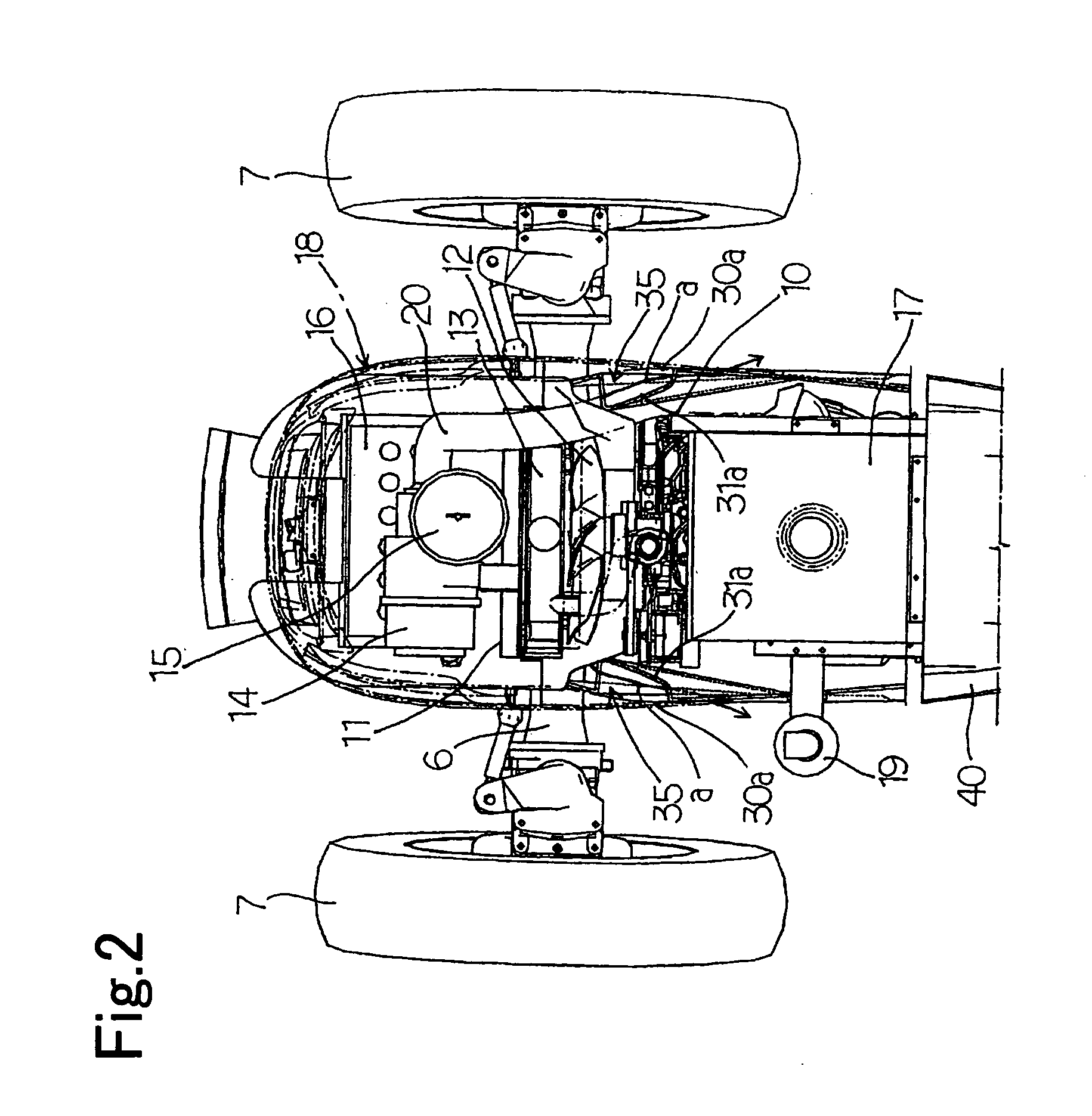

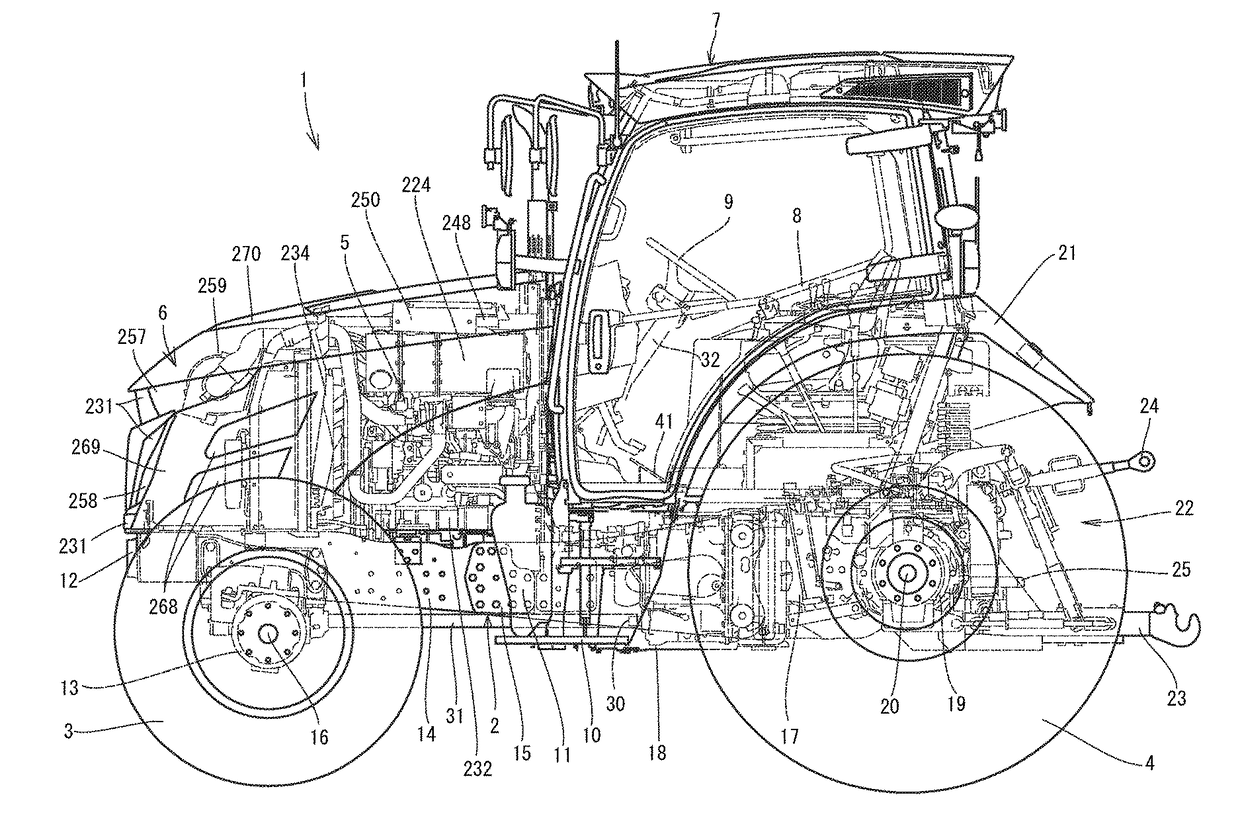

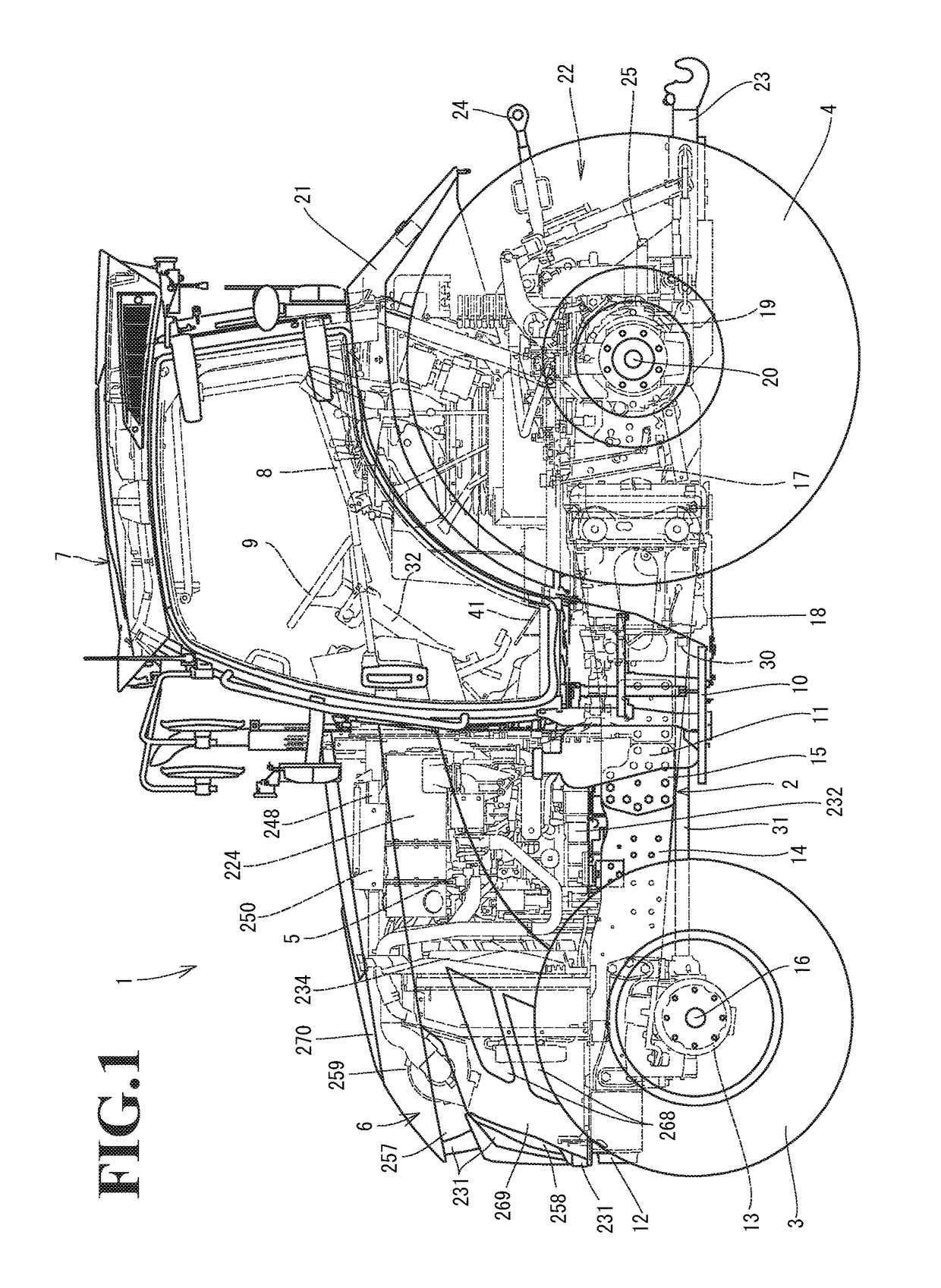

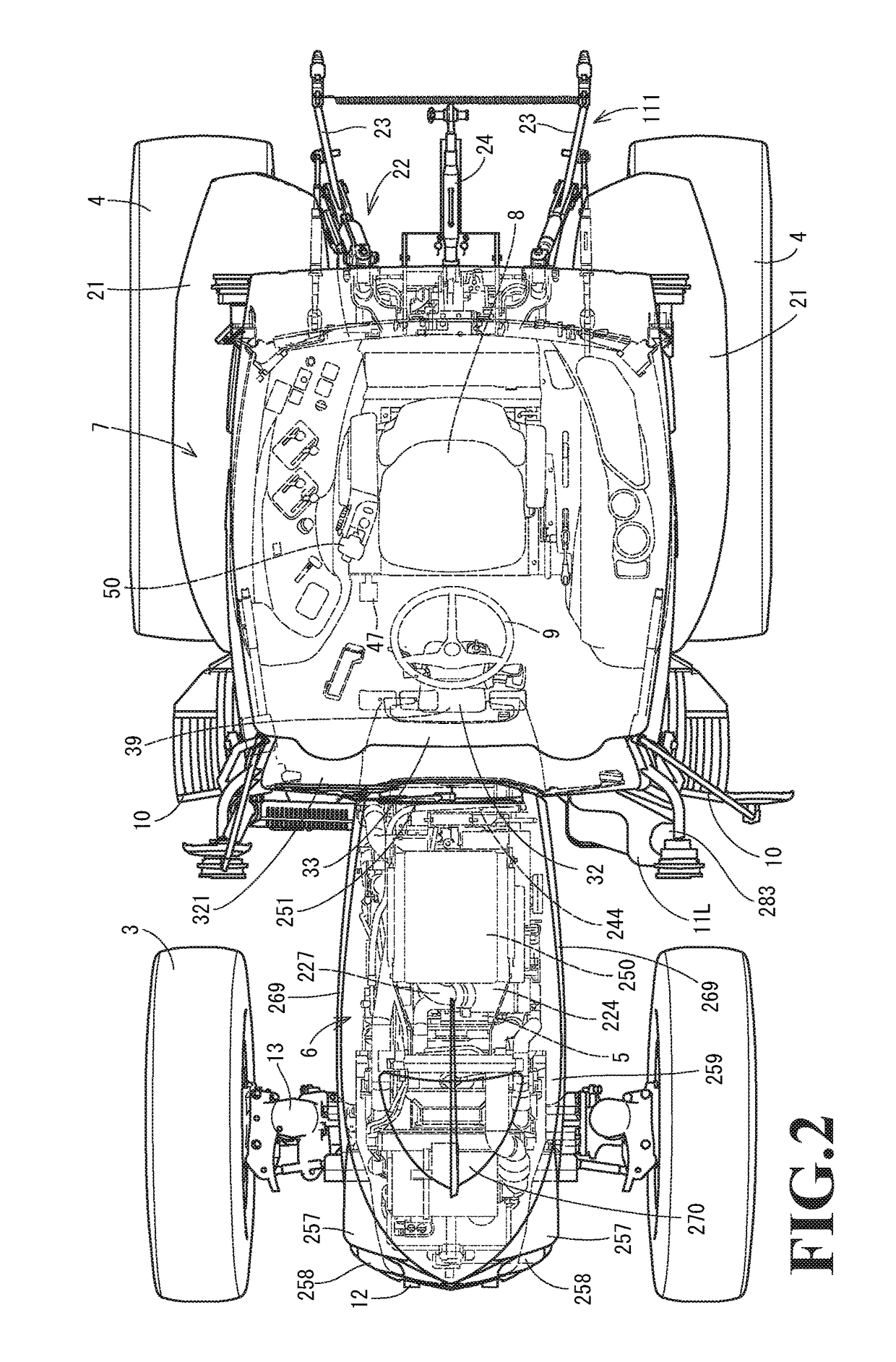

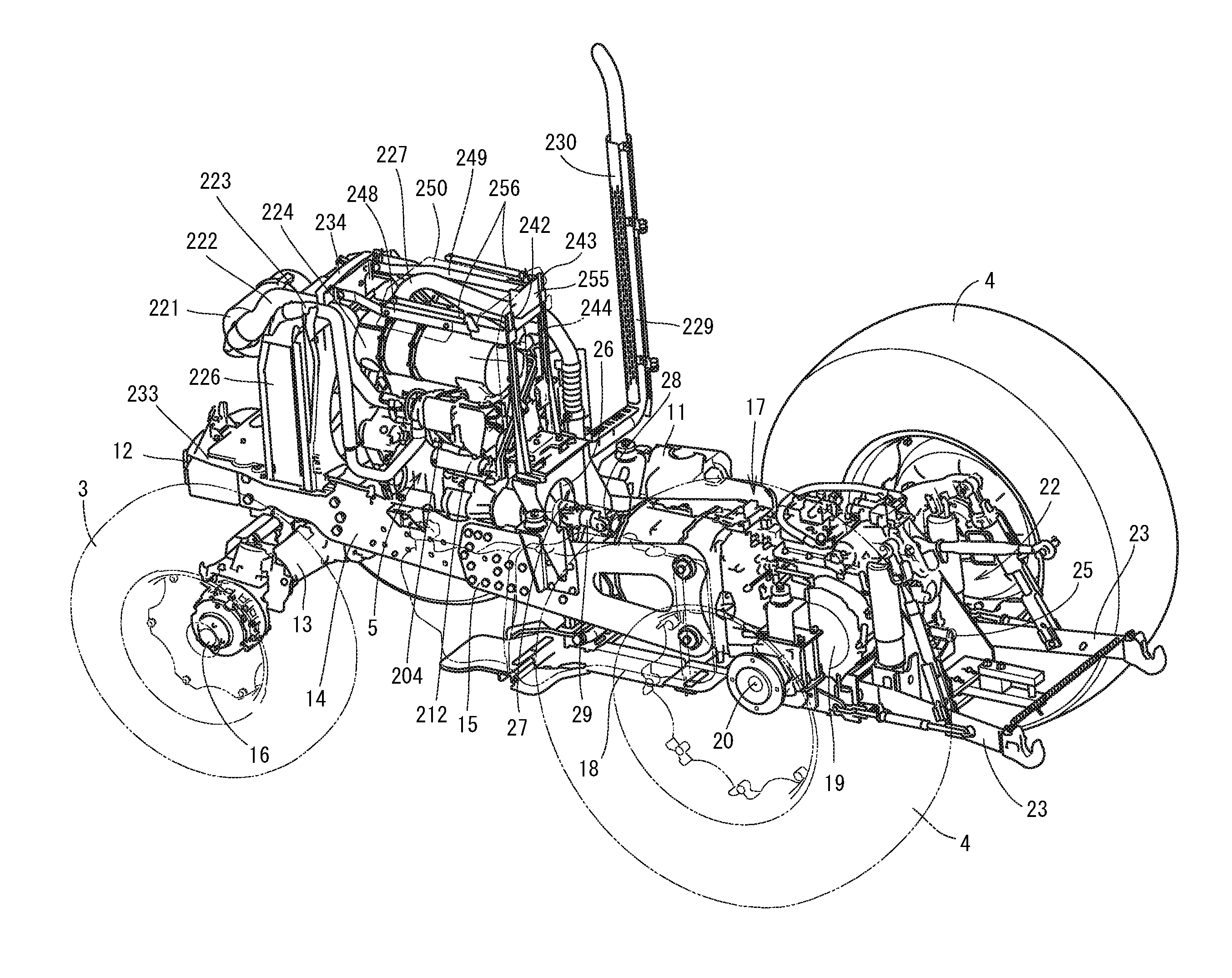

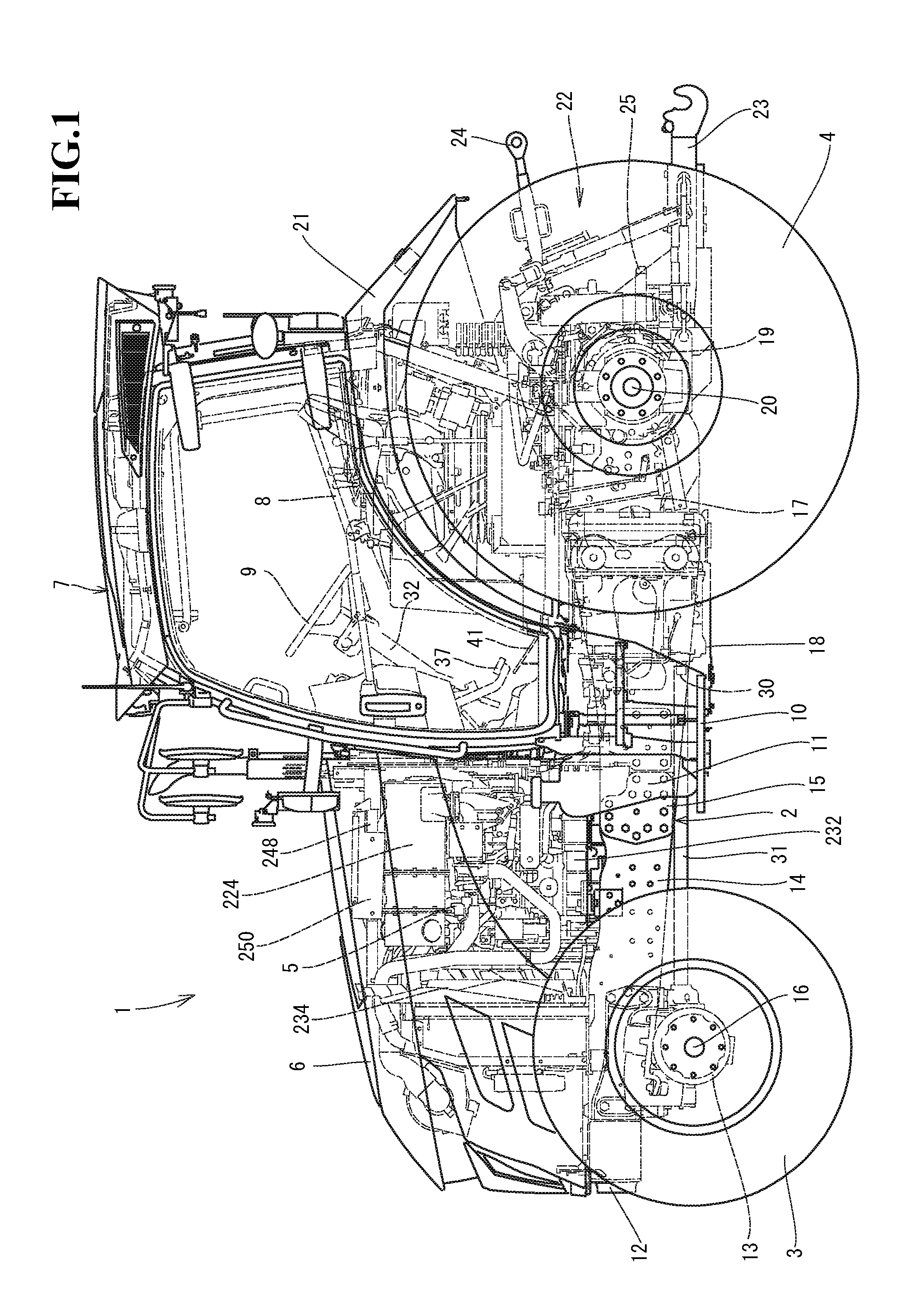

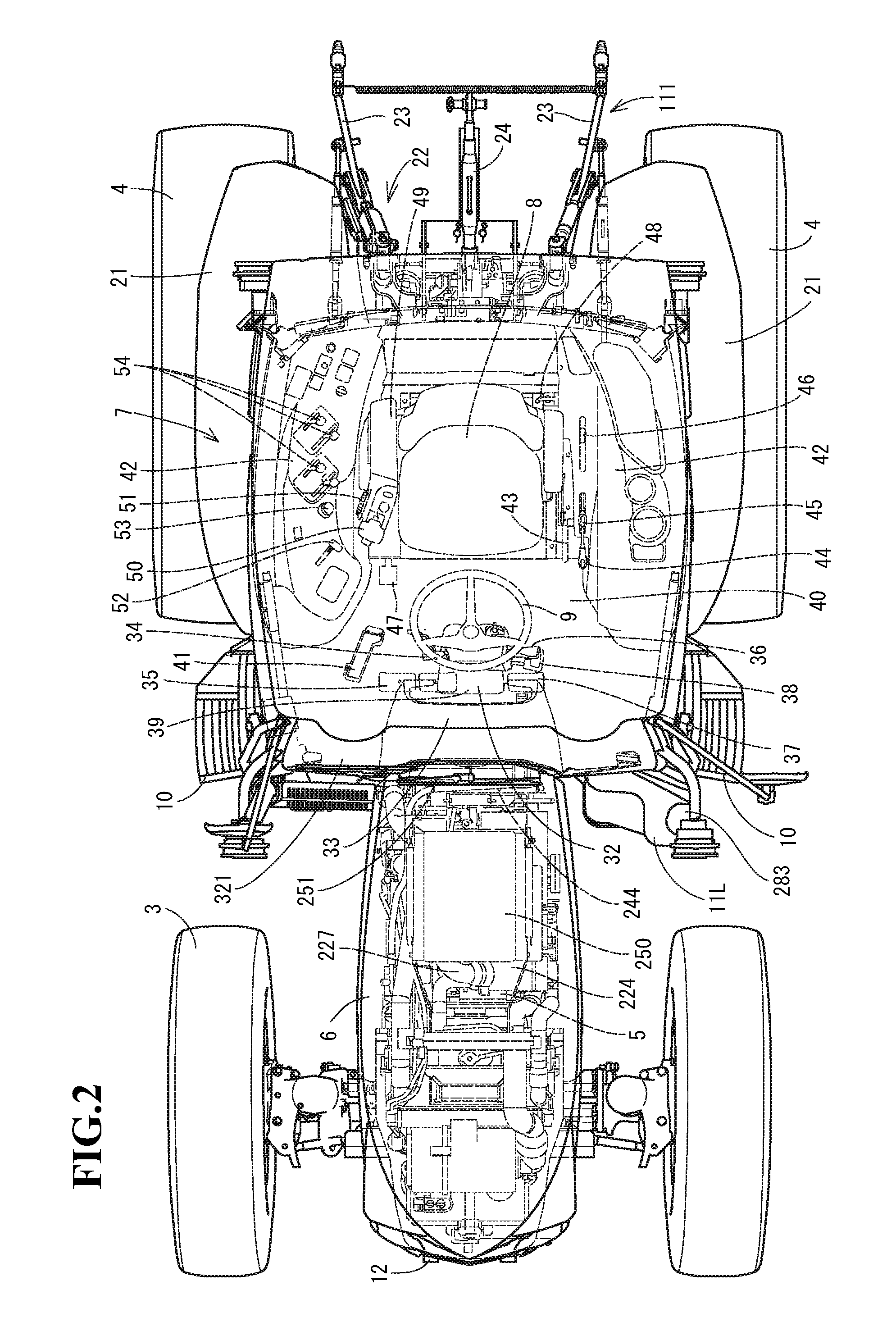

Tractor

InactiveUS20100089674A1Increase widthImprove cooling effectSuperstructure subunitsPropulsion coolingHeat balanceTractor

The present invention is provided for sufficiently ensuring a heat balance in the inside of a bonnet. In a tractor in which a radiator including an outside-air suction fan is arranged frontward of an engine, the radiator and the outside-air suction fan are covered with a bonnet, and the outside air is sucked by the outside-air suction fan through a front grille portion formed in the bonnet thus cooling the radiator, a radiator cooling air discharge opening portion is formed in a side wall portion of the bonnet, and the radiator cooling air discharge opening portion opens in the rearward direction.

Owner:YANMAR CO LTD

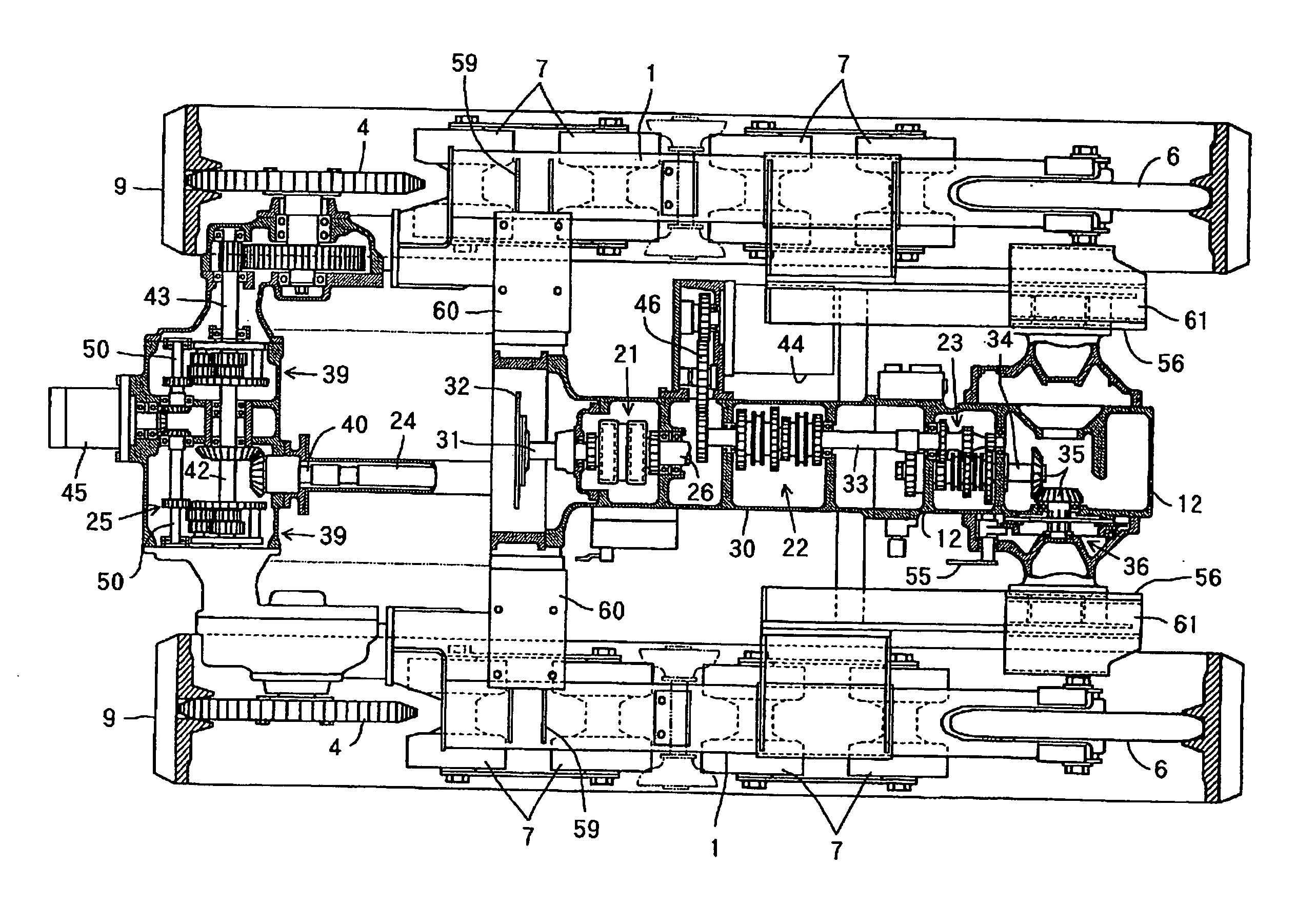

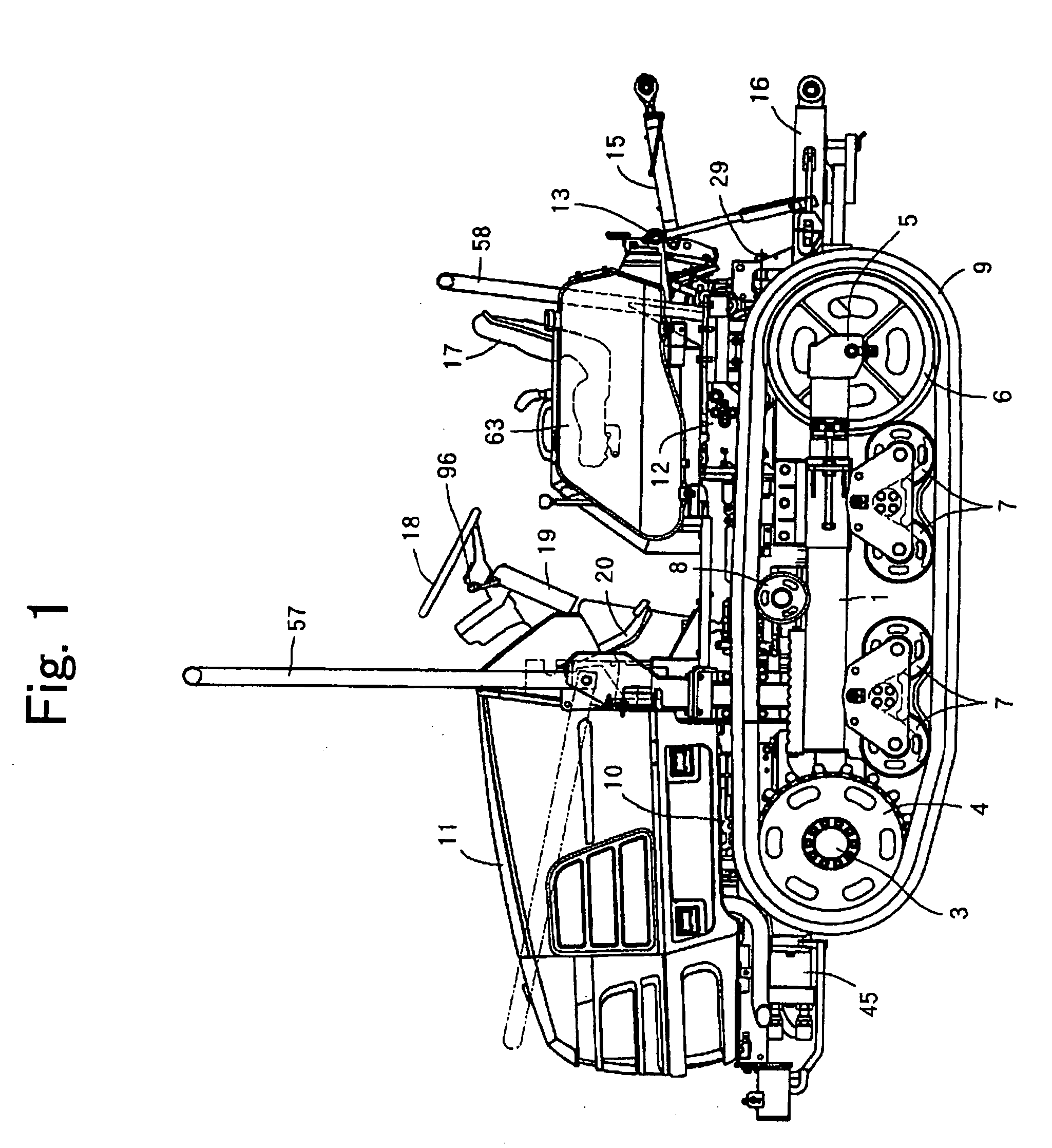

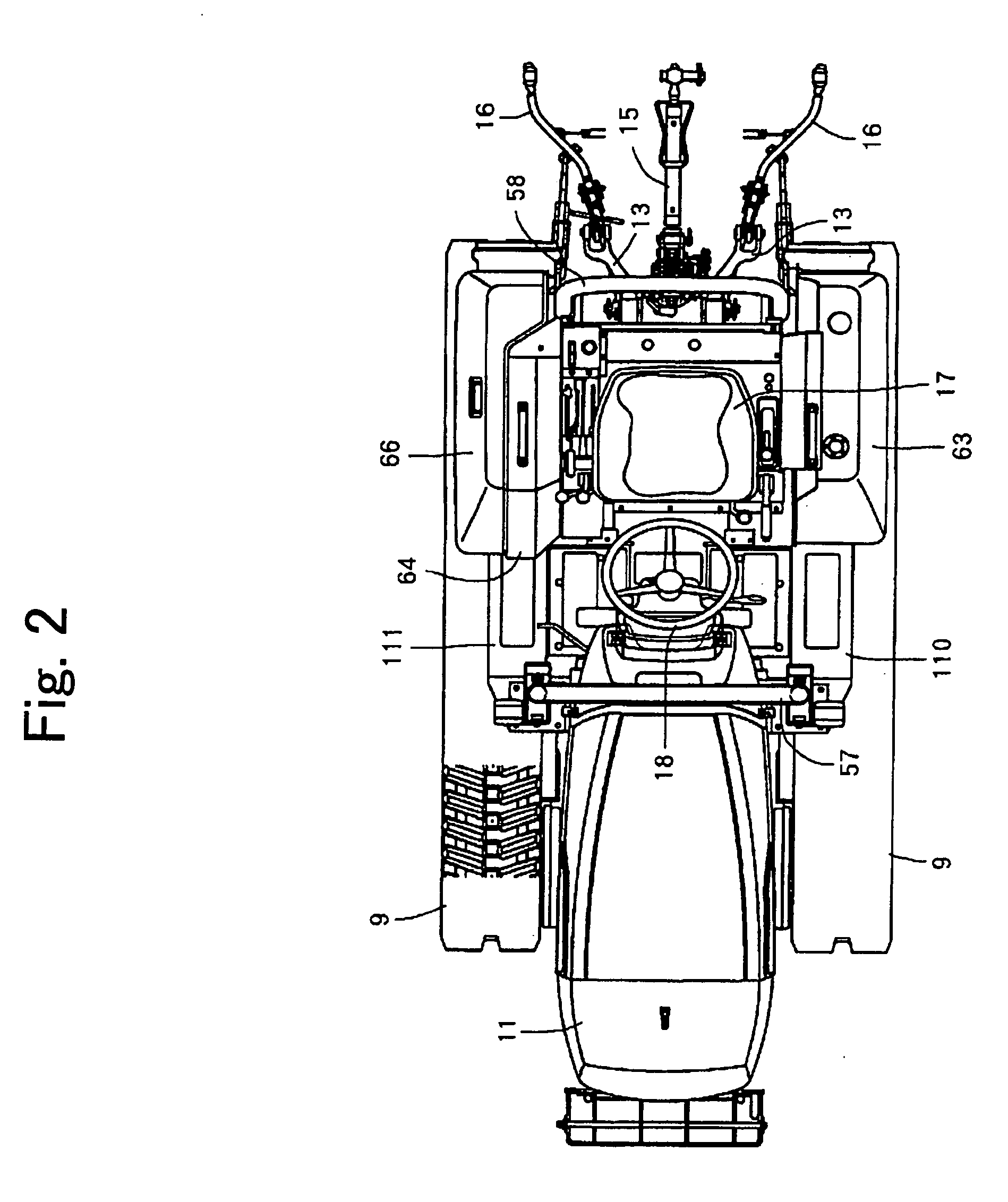

Crawler tractor

InactiveUS20060048977A1Improve maintainabilityGood adhesionSuperstructure subunitsTractorsSteering wheelEngineering

A crawler tractor comprises steering mechanisms (44) (45) for rotating a machine body by causing right and left crawler belts (9) to move differentially. The tractor is characterized in that the steering mechanism (44) is connected to a drive system located behind a reverser mechanism (21) that moves the machine body forward and back. Even when the machine body movement direction is changed from forward to back, the direction of the steering wheel (18) and the direction of the rotation of the machine body are kept the same, so that a reversed steering phenomenon is prevented from occurring, and an appropriate operation in forward or back movement is enabled with a simple structure that does not require an additional mechanism such as a reverse-steering preventions mechanism.

Owner:YANMAR CO LTD

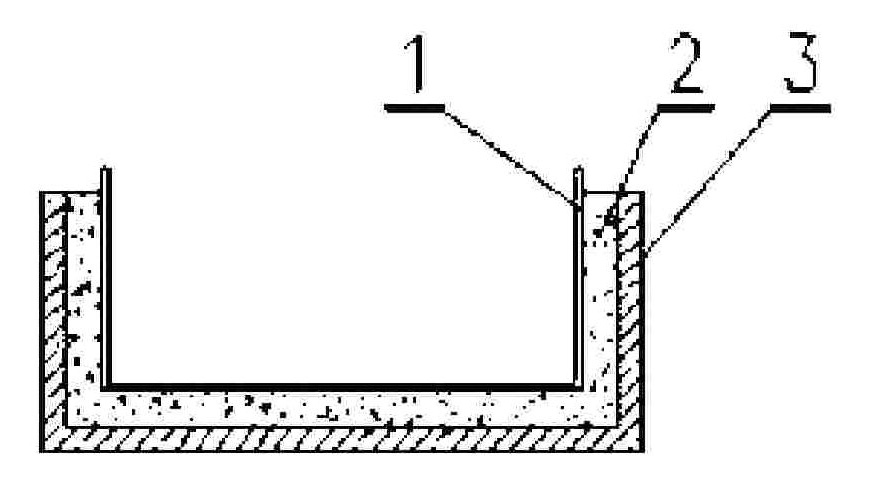

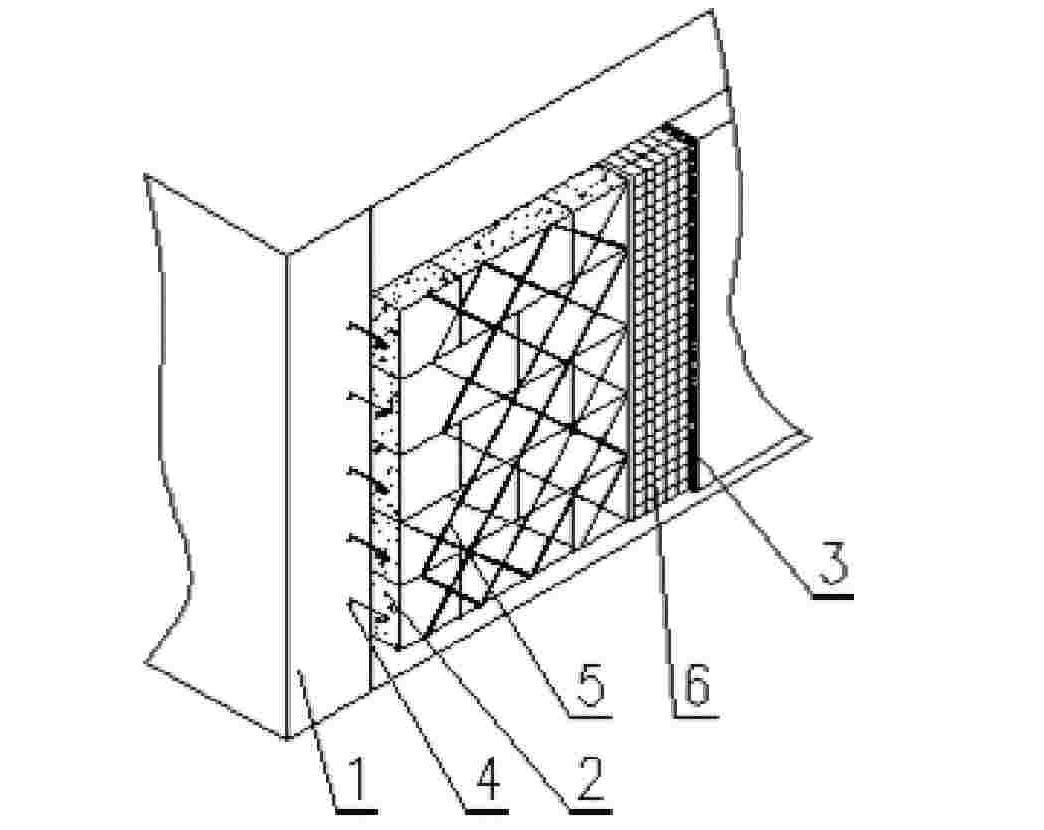

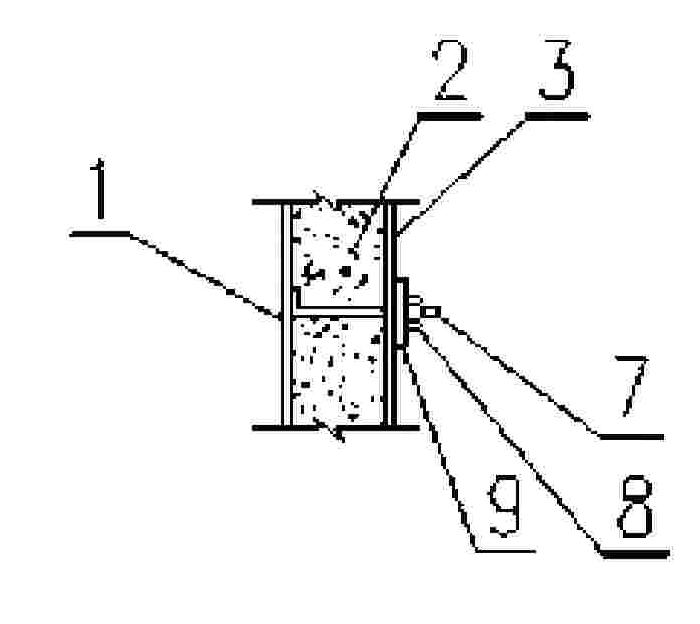

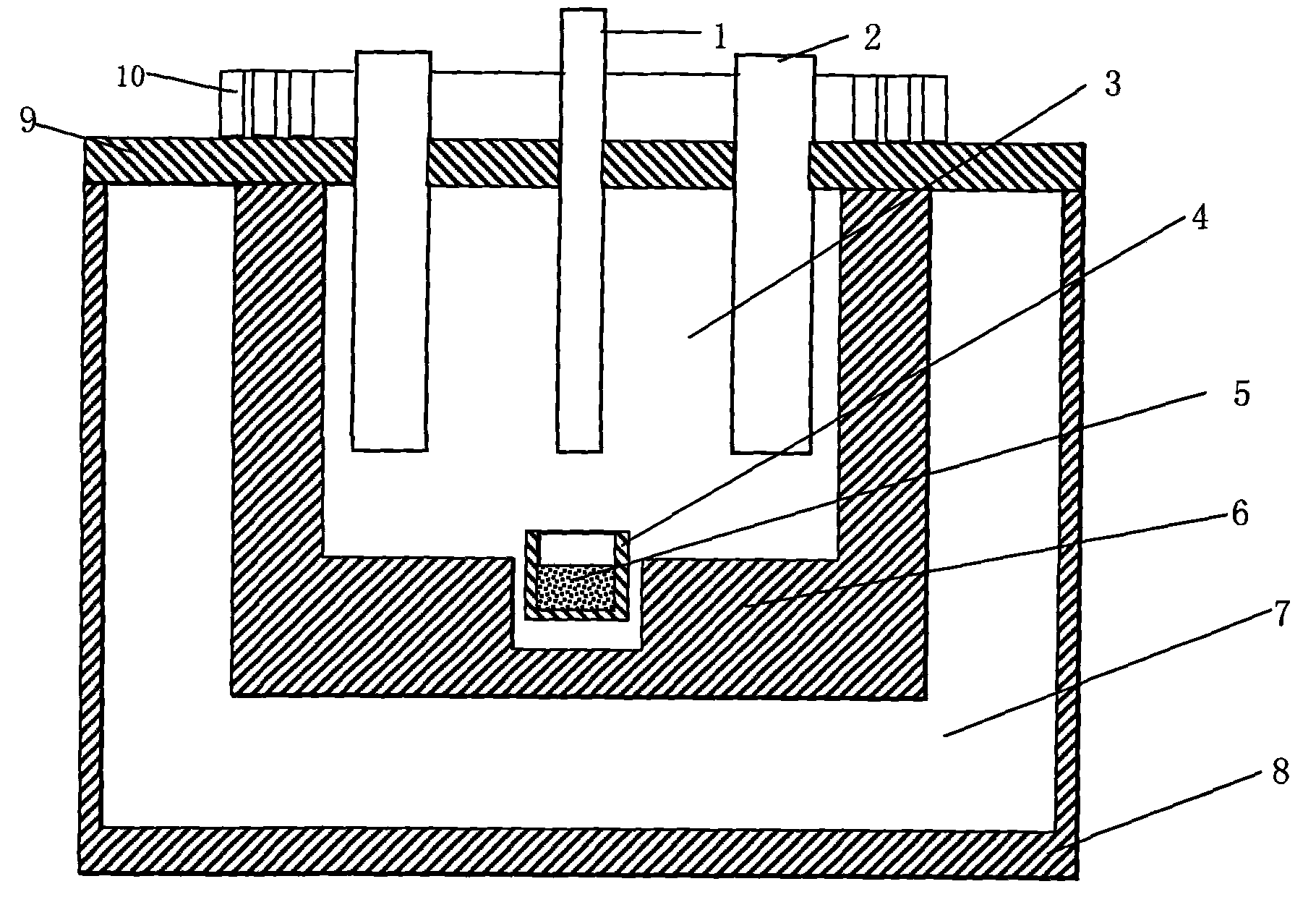

External thermal insulation structure of electrolytic cell

The invention discloses an external thermal insulation structure of an electrolytic cell, comprising the shell of the electrolytic cell, a thermal insulating layer and a protective layer, wherein the thermal insulating layer is arranged outside the shell of the aluminium electrolytic cell; and the protective layer can be arranged outside the thermal insulating layer optionally. A thermal insulation structure outside the aluminium electrolytic cell can be a full-thermal insulation structure outside the shell of the aluminium electrolytic cell and also can be a thermal insulation structure in a local range. The thermal insulation structure outside the aluminium electrolytic cell can be a fixed thermal insulation structure or a detachable thermal insulation structure, thus the problem of heat balance of the electrolytic cell can be solved under the condition that the stability of the electrolytic cell is strengthened, the electrode distance is reduced and the voltage is lowered; the normal working requirements of the electrolytic cell are met; and in particular, the cost and time can be greatly saved when the heat balance of the existing electrolytic cell is maintained.

Owner:ZUNYI ALUMINUM

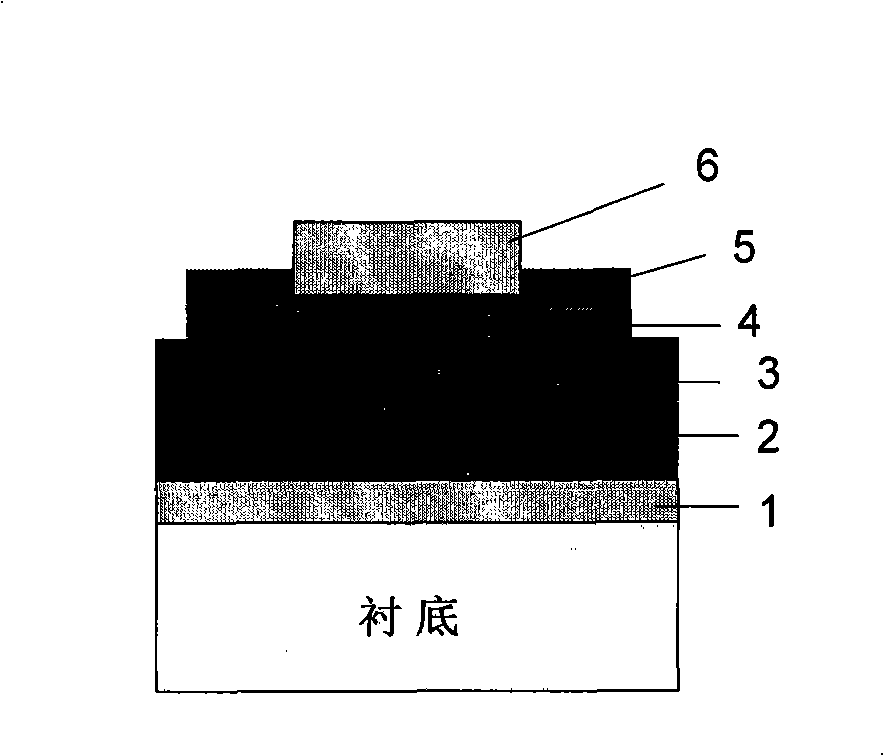

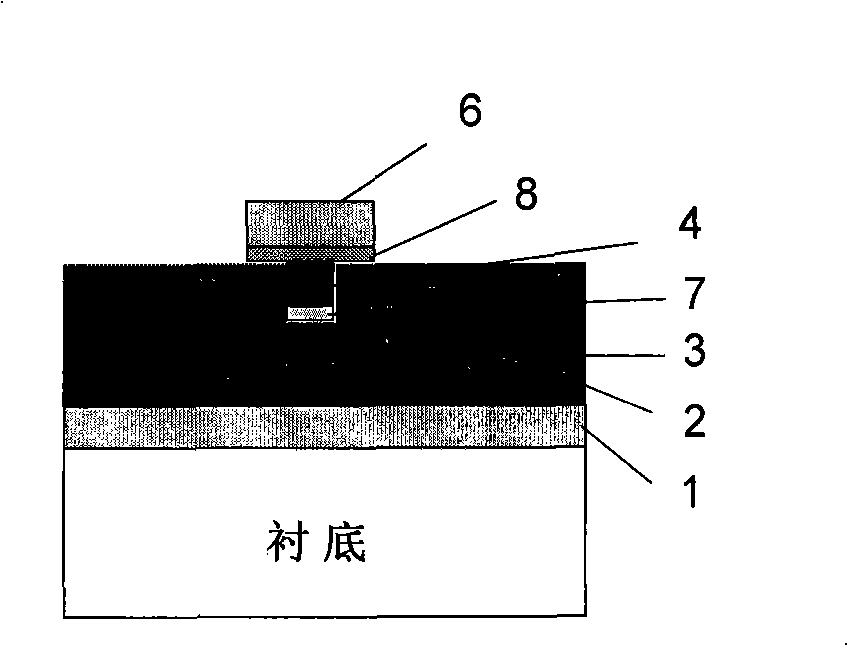

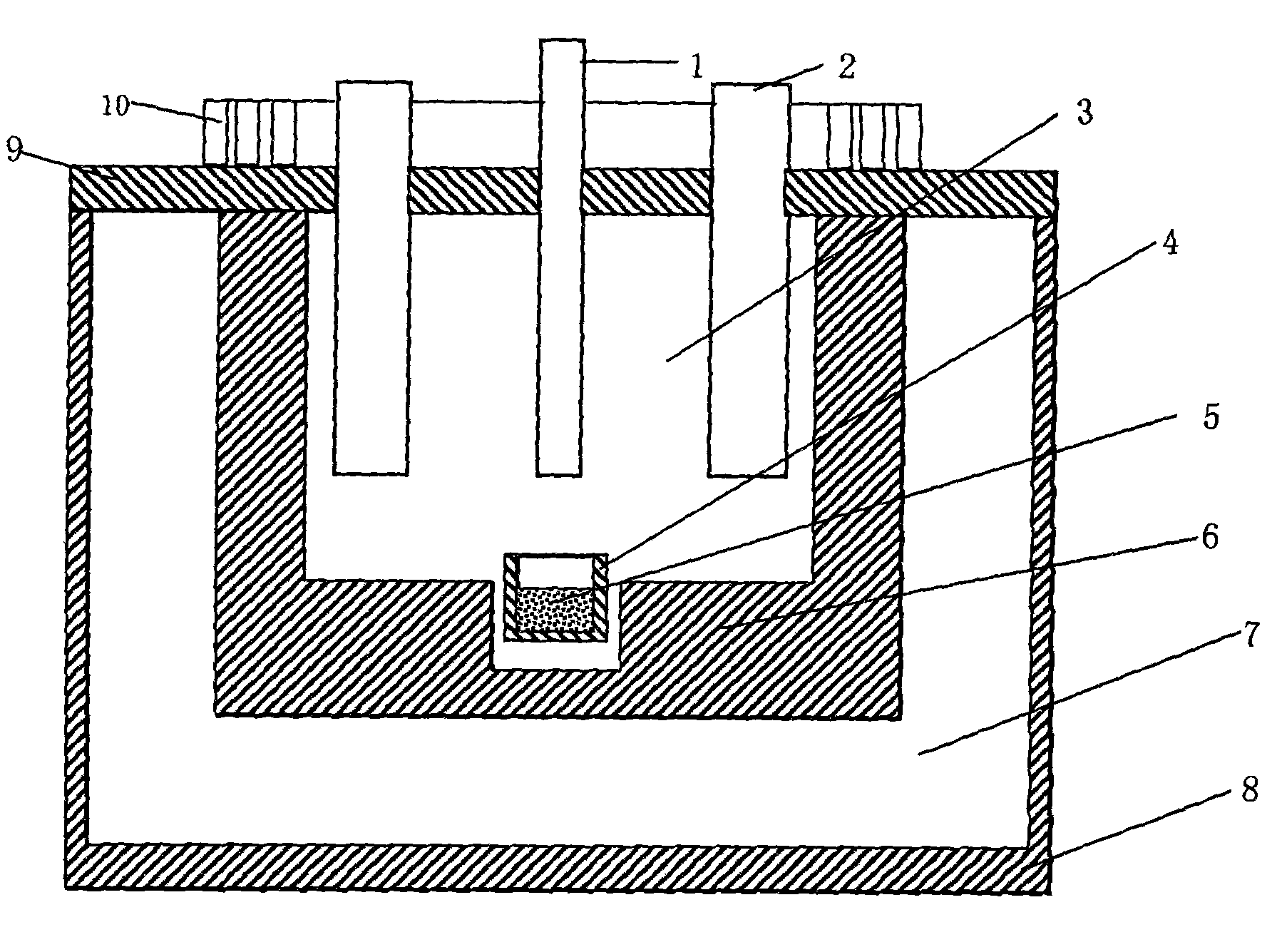

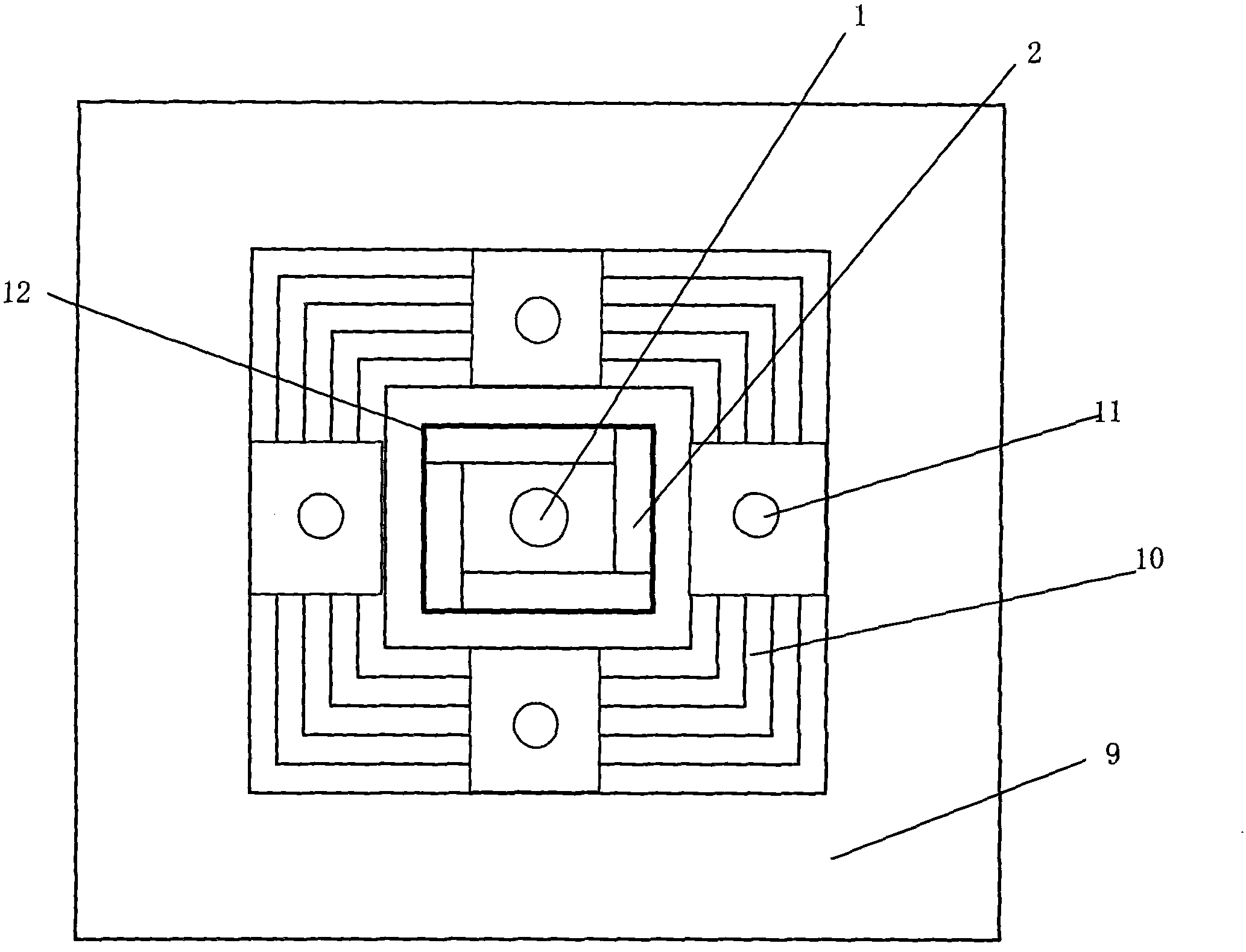

Construction for enhancing reliability of phase-change memory storage unit and manufacturing method thereof

ActiveCN101335329AImprove adhesionFast heat balanceSolid-state devicesRead-only memoriesCushionPhase-change material

The invention relates to a structure which can improve the reliability of a memory cell of a phase change memory and a preparation method thereof. The structure and the method are characterized in that a thin layer of cushion material is added between a nanometer heating electrode and a pillar-shaped phase change material of the same diameter to improve adhesiveness and interface match between the phase change material and the heating electrode, simultaneously, electrical match between the phase change material and the heating electrode can be improved, and an ohmic contact can be formed. In addition, a thin layer of thermal resistance material is added between the phase change material and the top electrode so as to improve thermal balance in the process of device erasing and writing, and reduce heat dissipation of the top electrode and energy consumption of the device. The structure of the memory cell prevents diffusion between the phase change material and the heating electrode and the interfacial failure in the process of repeated erasing and writing, and improves the reliability of the device. The heating electrode, the cushion material and a phase change region are limited to the same dielectric hole to form a self-aligned pillar-shaped structure, and an insulating layer does not need to be prepared around the phase change material, thereby reducing the technology process.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

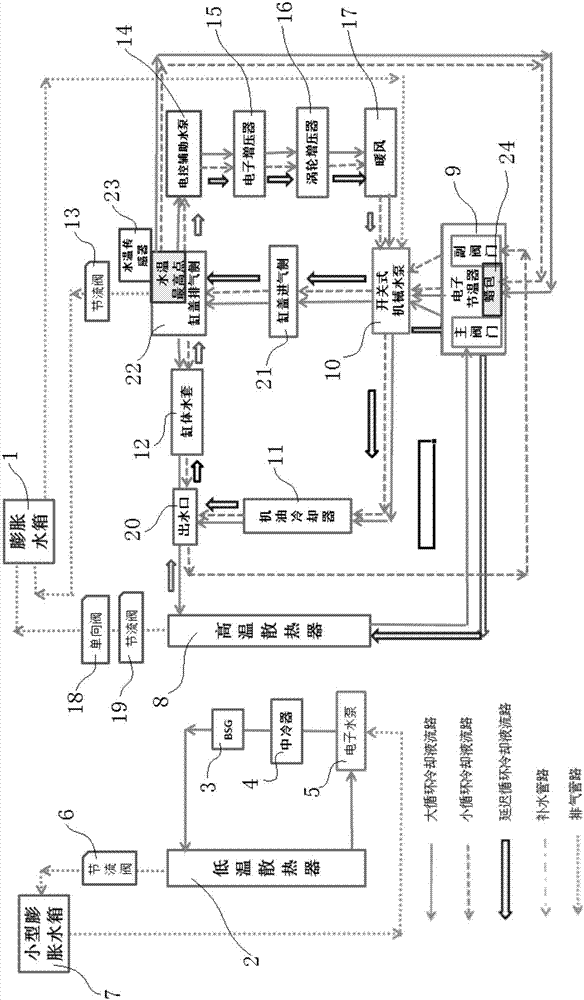

Engine cooling system

ActiveCN106948915AReduce fuel consumptionIncrease temperatureLiquid coolingCoolant flow controlExpansion tankThermodynamics

The invention relates to an engine cooling system. The engine cooling system comprises a high-temperature circulation cooling system and a low-temperature circulation cooling system. The high-temperature circulation cooling system is provided with a large cycle cooling liquid flow path, a small cycle cooling liquid flow path and a delay cycle cooling liquid flow path. In the large cycle and the small cycle, cooling liquid passes through a cylinder cover water jacket and then is diverted, one part of cooling liquid enters a cylinder water jacket, and the other part of cooling liquid enters warm air. Independent expansion water tanks are adopted in the high-temperature circulation cooling system and the low-temperature circulation cooling system. An electric control auxiliary water pump is additionally arranged for the high-temperature circulation cooling system, the delayed cycle is achieved, the cooling liquid is diverted into the cylinder water jacket and the warm air after passing through the cylinder cover water jacket, and the engine cooling system can better meet the heat supply requirement of various components after engine shutdown. The problem about the flowing direction of cooling circulation between different components is solved, and the engine knock probability can be reduced by arranging the independent expansion water tanks.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

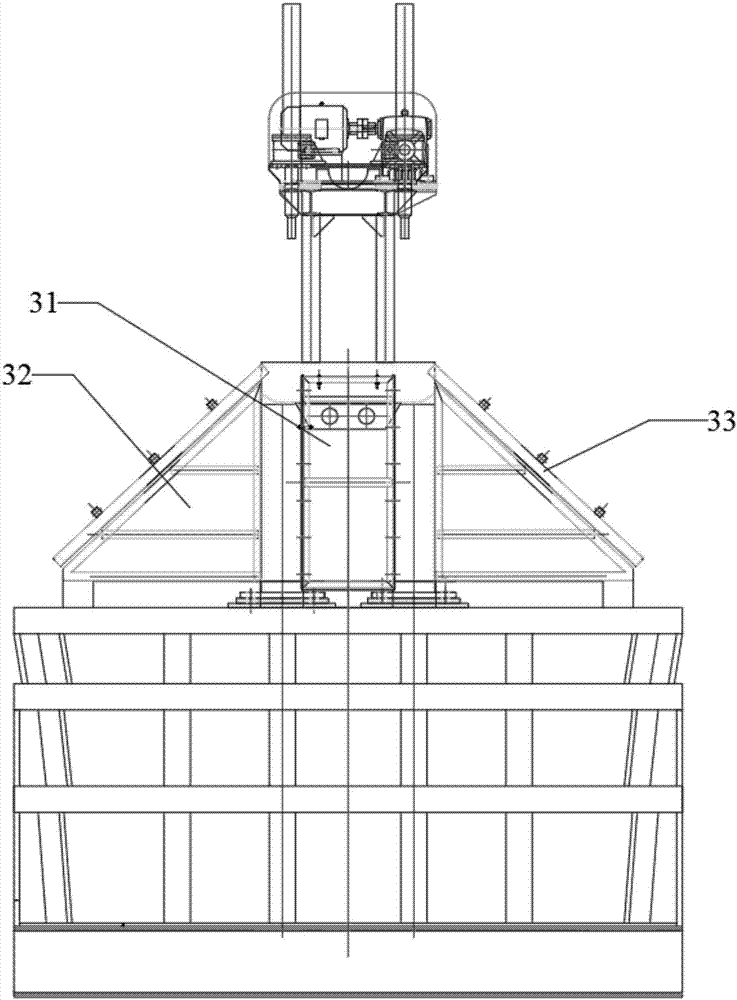

Lining structure of rare earth electrolysis cell, and rare earth electrolysis cell

The invention relates to a lining structure of a rare earth electrolysis cell, and the electrolysis cell. The lining structure comprises a bottom lining and a side lining, wherein the bottom lining comprises a ceramic fiber layer, a bottom refractory layer, an impermeable layer and a graphite layer which are sequentially stacked from bottom to top; the side lining is arranged in a manner of surrounding the bottom lining; the side lining extends upwards to achieve the space above the top surface of the graphite layer; and the bottom lining and the side lining are combined and encircled to forma cavity allowing an electrolysis reaction to be carried out. The lining structure of the rare earth electrolysis cell is reasonable in structural material selection and layout, and the electrolysis cell is high in heat balance performance, and capable of effectively reducing heat loss; a hearth of the electrolysis cell is easier to form due to the use of a silicon carbide protection layer with high heat conductivity, so that a side heat-insulation material of the electrolysis cell is much effectively protected; and in addition, a cylindrical cathode is adopted, so that the phenomenon that a current density is high at the cathode and low at an anode is more obvious, and an electrolysis reaction area is effectively enlarged.

Owner:CENT SOUTH UNIV

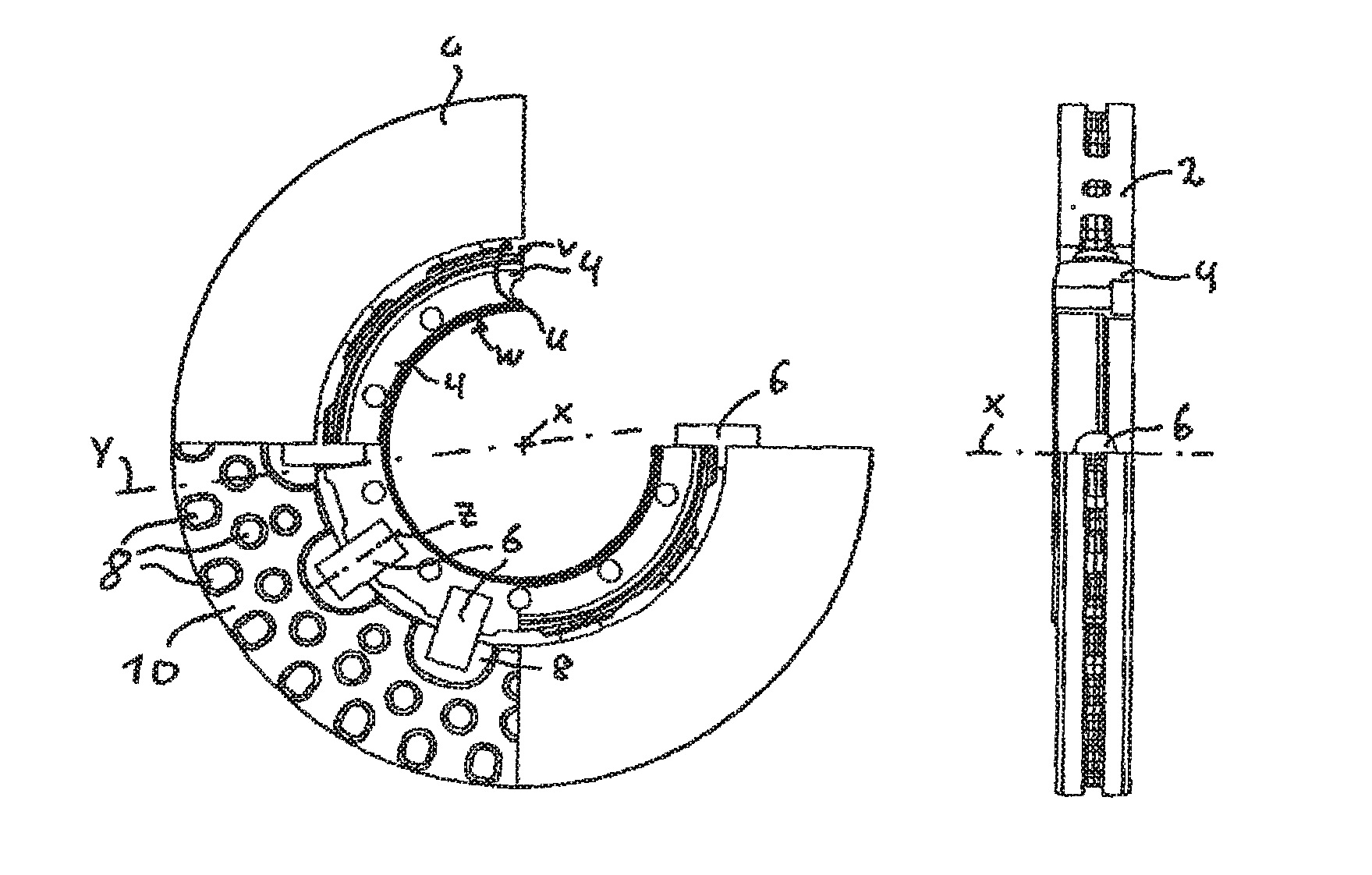

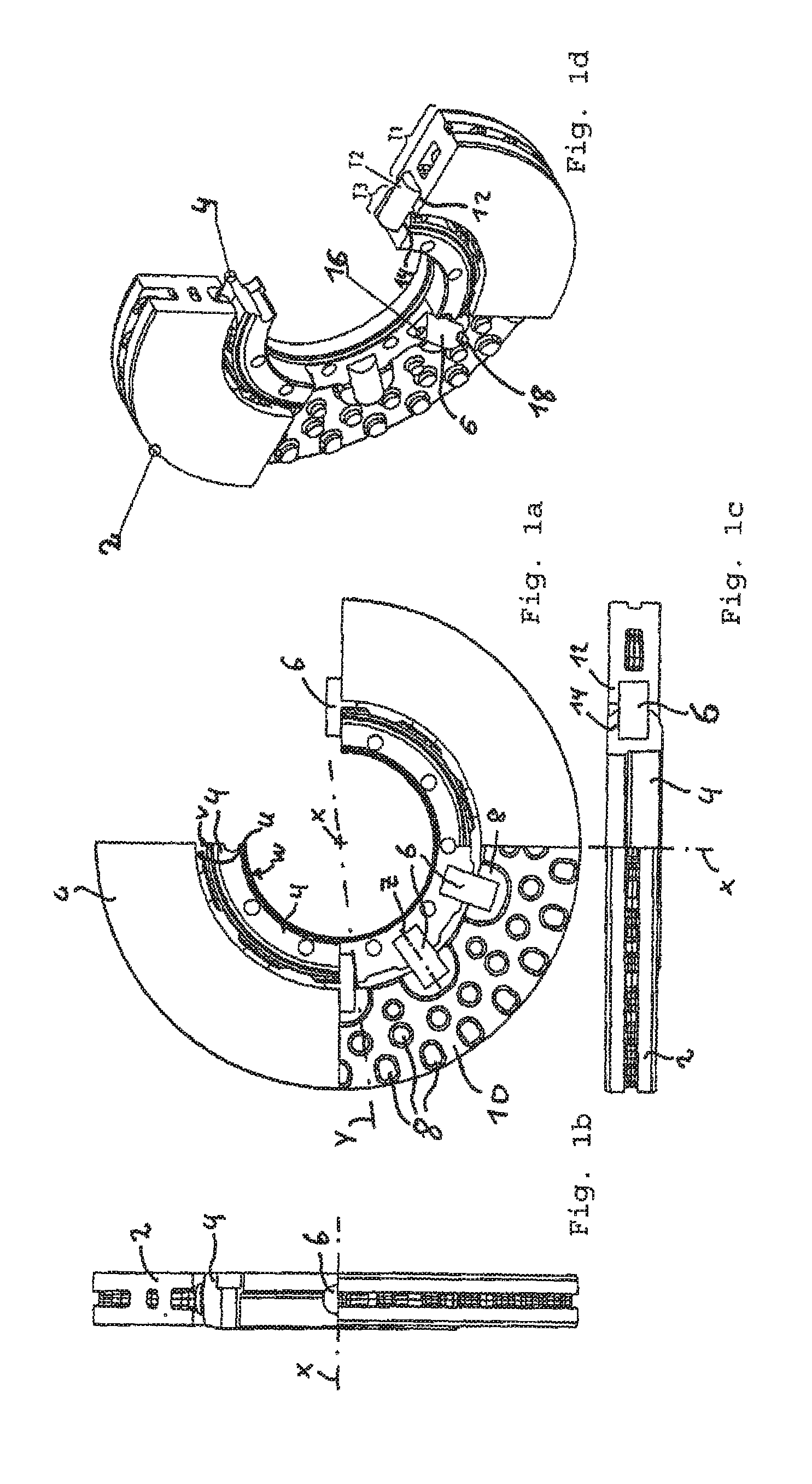

Brake disc arrangement for disc brakes

InactiveUS8967339B2Improve heat balanceLower temperature levelBraking element arrangementsBraking discsEngineeringMechanical engineering

A brake disc arrangement for disc brakes, in particular for land vehicles, including a friction ring, an attachment adapter for attaching the brake disc arrangement to a wheel hub, and at least one connection element for connecting the friction ring and the attachment adapter, wherein the attachment adapter comprises a fastening area in which the connection element is stationarily fixed, and wherein the friction ring comprises a receptacle area in which the connection element is accommodated such that the friction ring can move radially relative to the connection element.

Owner:SAF HOLLAND GMBH

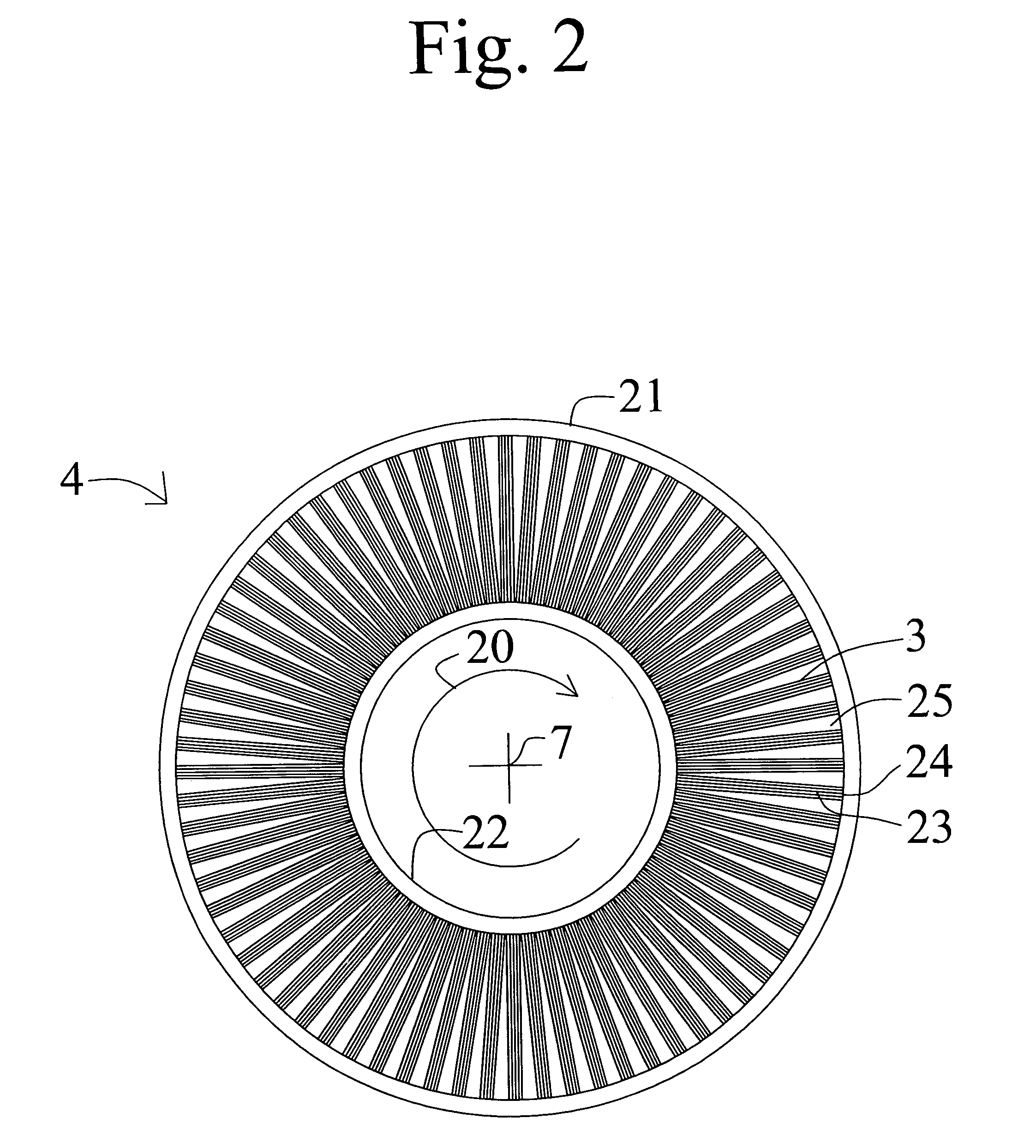

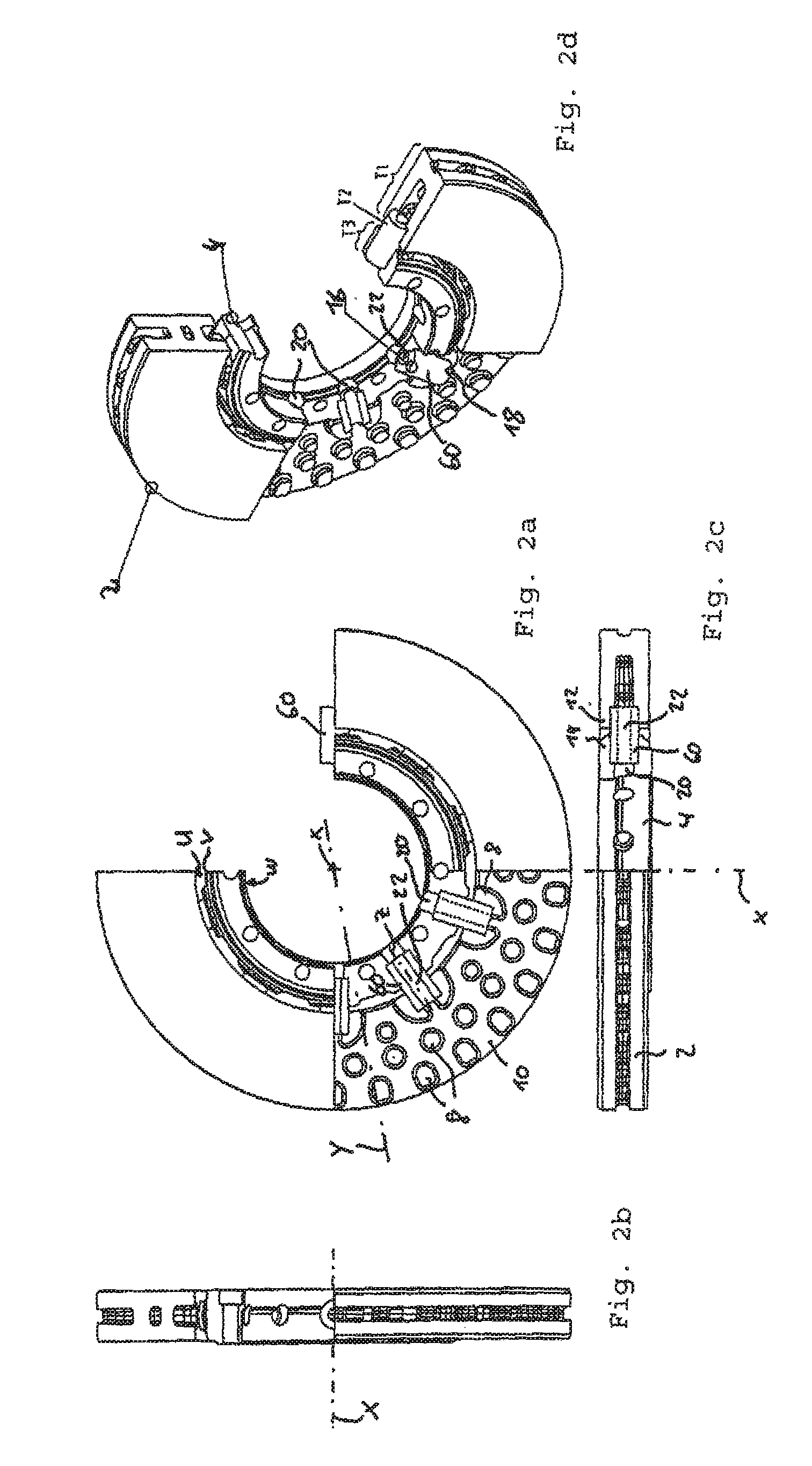

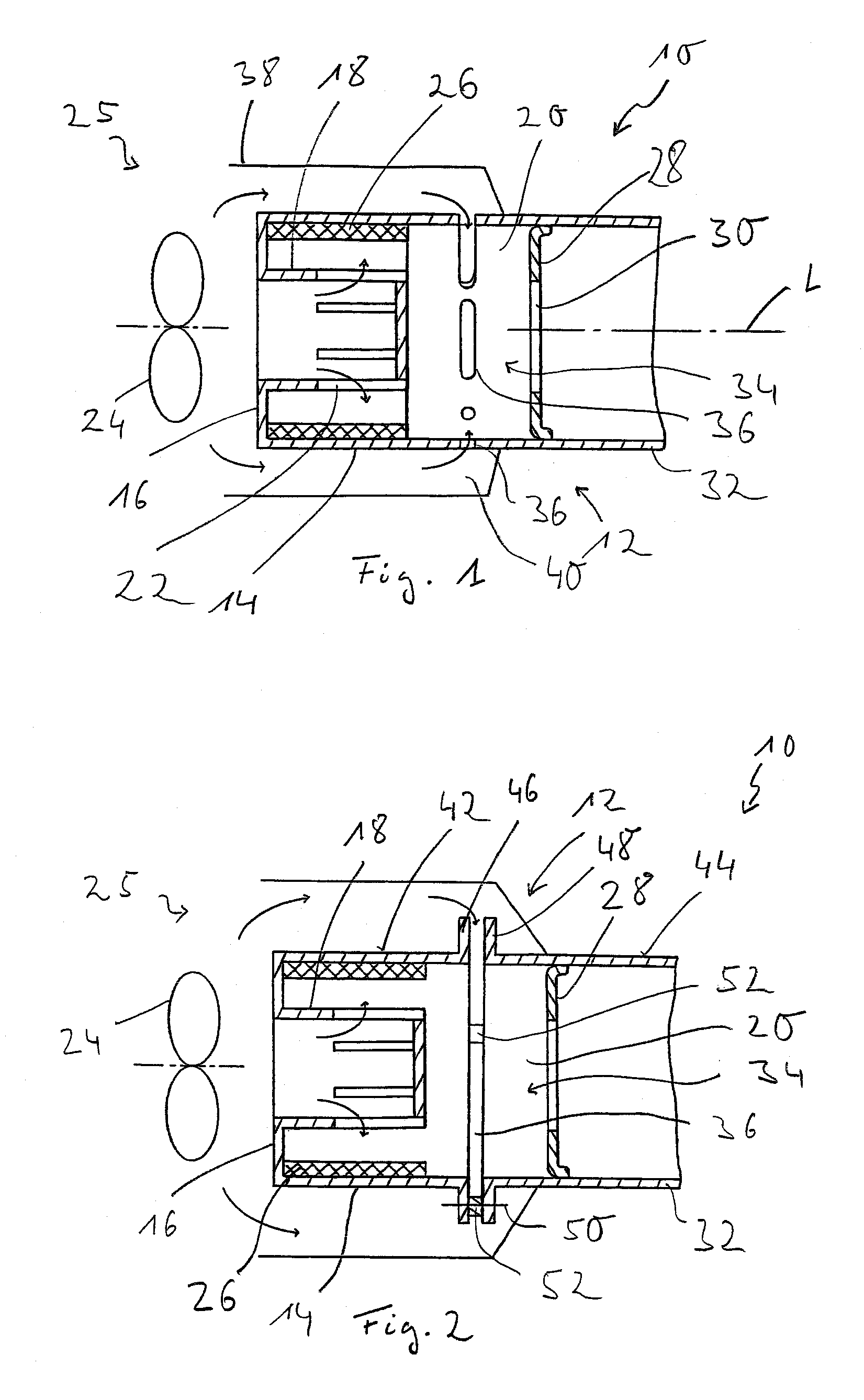

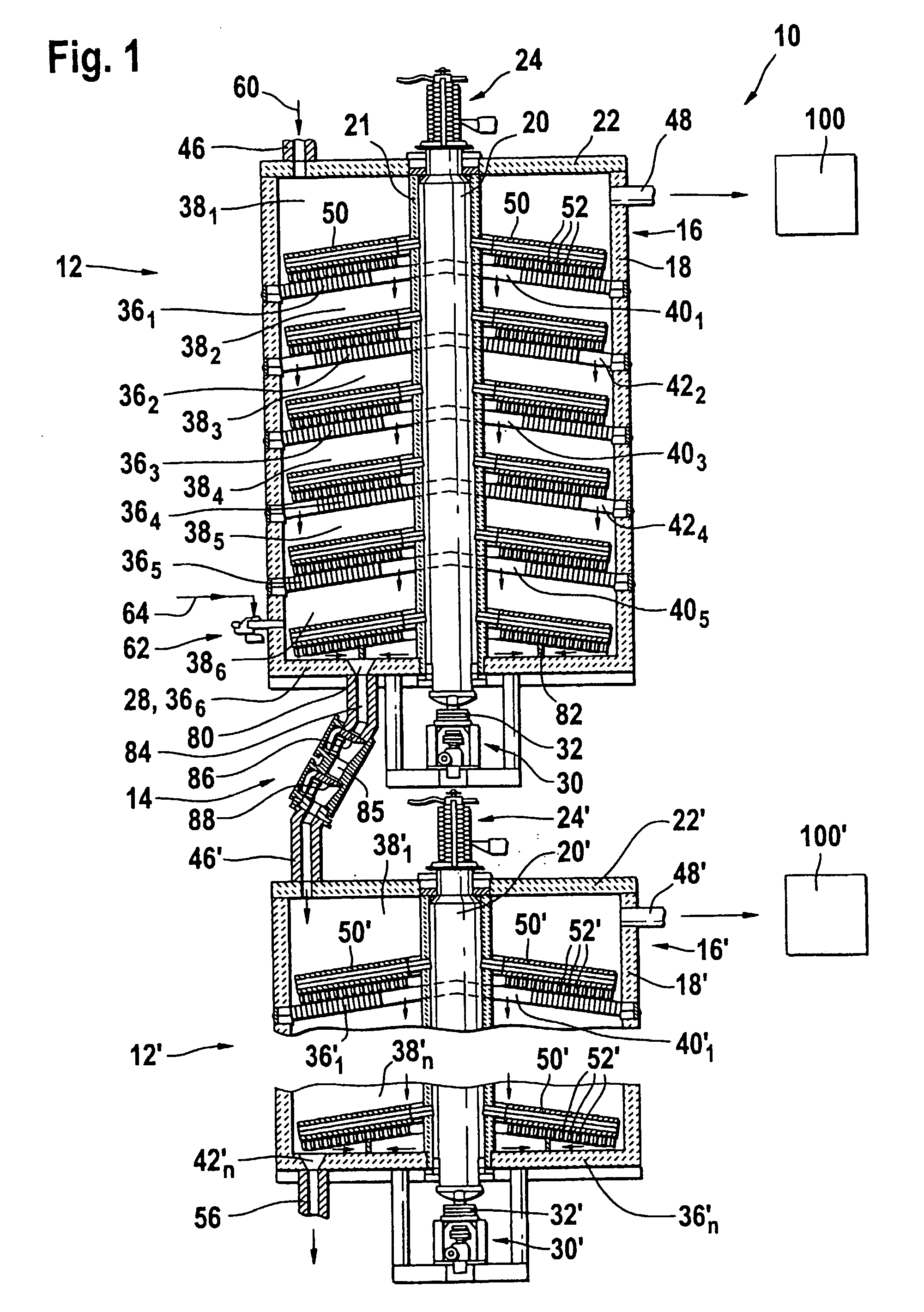

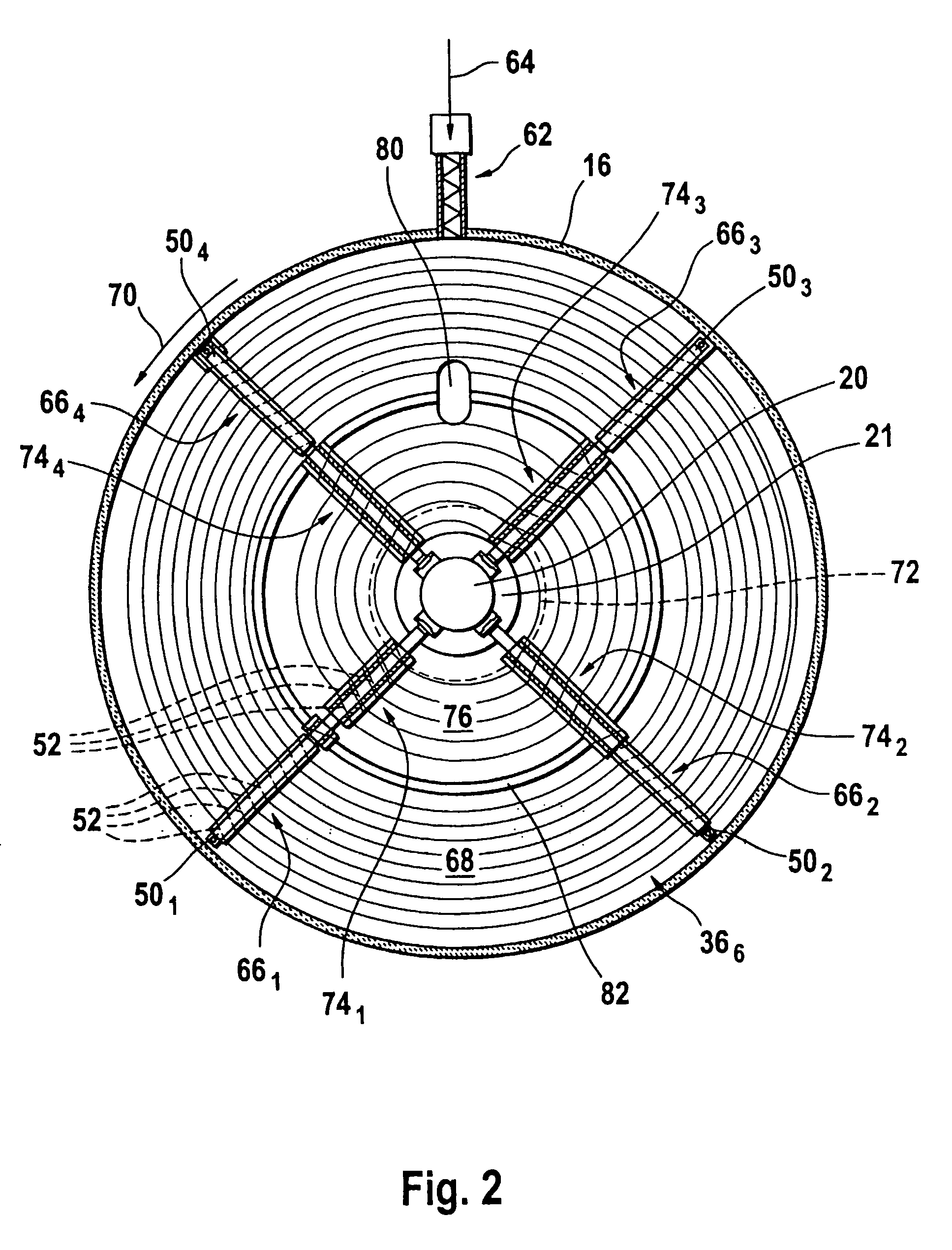

Evaporator assembly unit, especially for a vehicle heater or a reformer arrangement of a fuel cell system

InactiveUS20070273052A1Improve heat balanceGood and uniform mixingElectric spark ignitersUsing liquid separation agentFuel cellsEngineering

An evaporator assembly unit, especially for a vehicle heater or a reformer arrangement of a fuel cell system, includes a wall arrangement (12) enclosing an evaporation chamber (20) with a circumferential wall (14) and with a bottom wall (16). An air introduction shoulder (18) extending in the direction of a wall longitudinal axis (L) is provided with a plurality of first air introduction openings (22). Evaporator medium (26), that is porous at least in some areas, is provided on the side of the wall arrangement (12) facing the evaporation chamber (20). An auxiliary air opening arrangement (34) with at least one second air introduction opening (36) is provided in the wall arrangement (12).

Owner:EBERSPAECHER CLIMATE CONTROL SYST GMBH & CO KG

Solid oxide fuel cell stack having an integral gas distribution manifold

ActiveUS7771884B2Prevent leakageHigh strengthFuel cells groupingFuel cell auxillariesFuel cellsEngineering

An SOFC stack module including an integral individual stack manifold containing all of the gas pathways necessary for supply and exhaust of fuel gas and cathode air to and from the stack chimneys. The stack is mounted and hermetically joined directly to the manifold without an intermediate base plate. Flanges at the inlet and outlet ports couple to system distributary manifolds via high temperature sealing joints. The manifold preferably is fabricated of a ferritic stainless steel, and may be formed in a one-piece casting, a combination of multiple castings and stamped plates metallurgically joined (brazed or welded together), or stamped from sheet metal stock. Preferably, the manifold includes fin structures extending into adjacent fuel gas and cathode air chambers to enhance balancing of temperatures by heat exchange therebetween. Heat exchange may be further improved by configuring the manifold to have a plurality of interleaved anode and cathode gas supply chambers.

Owner:BATTELLE MEMORIAL INST +1

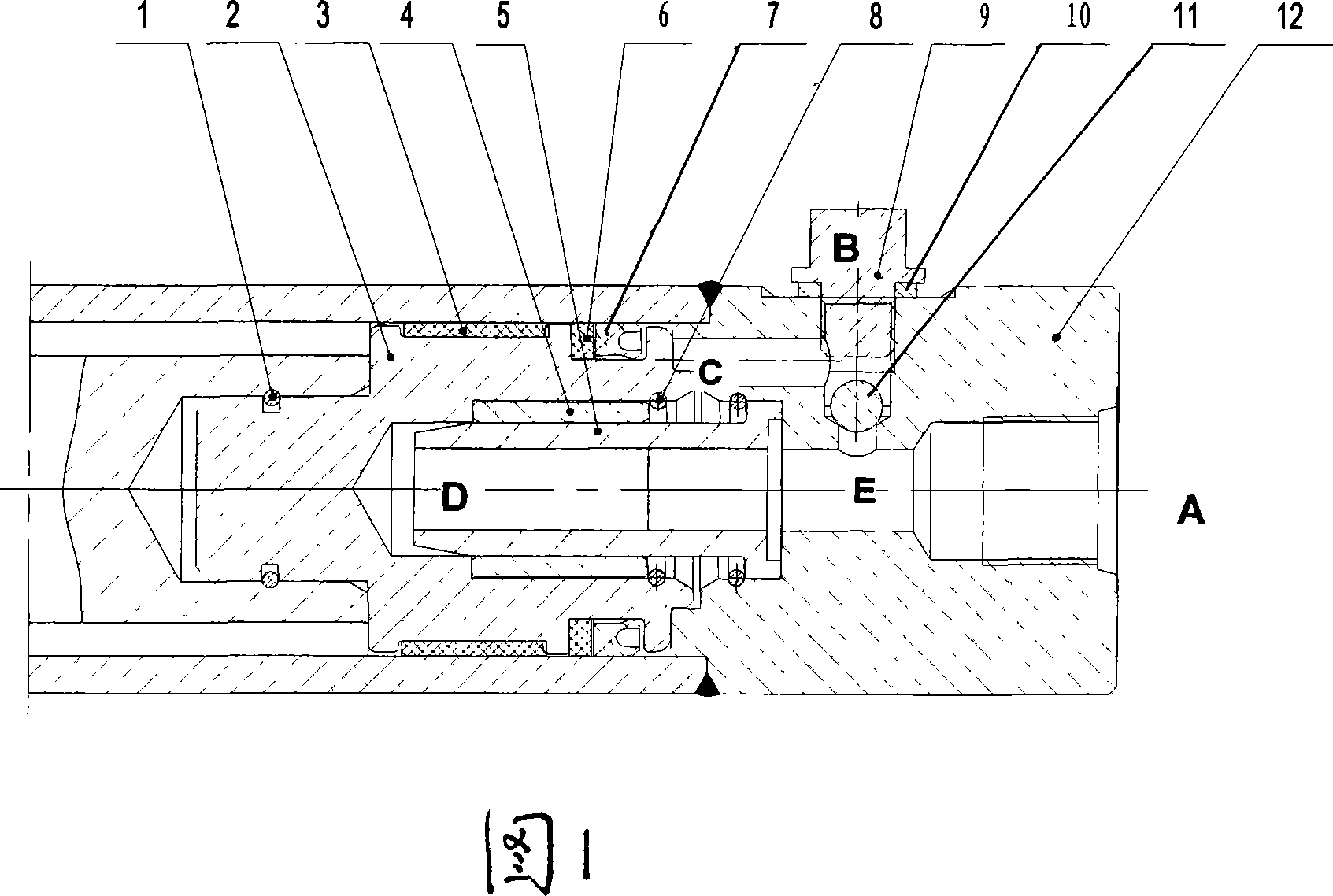

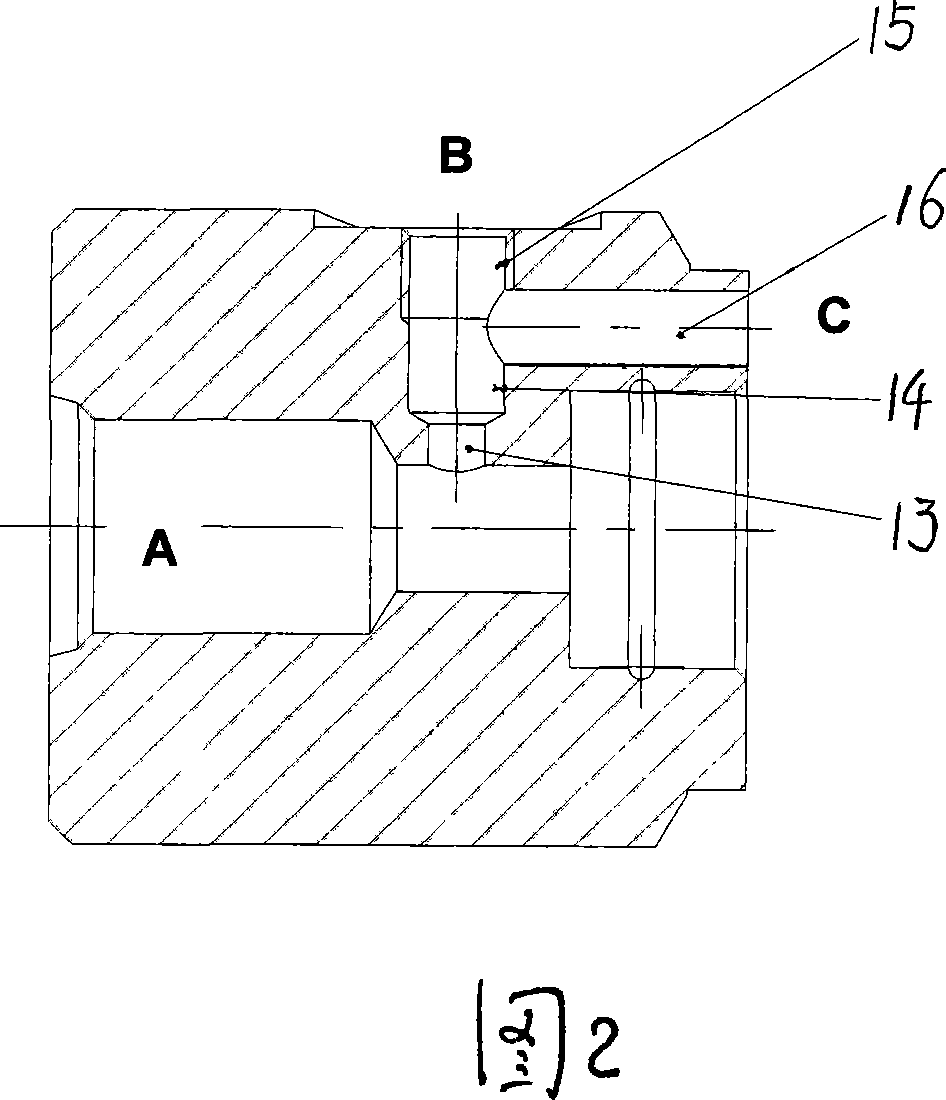

1-3.5T gap buffer lift oil cylinder with one-way valve at cylinder bottom

ActiveCN101050782ASmooth liftNo lifting slownessLifting devicesFluid-pressure actuatorsHydraulic cylinderSteel ball

The present invention relates to a 1-3.5T intermittent buffered lifting hydraulic cylinder with cylinder bottom non-return valve. It is an improvement on existent lifting hydraulic cylinder structure, and its improvement lies in that on the radial direction of oil groove side of cylinder bottom a small through hole is cut, said small through hole and shaft are connected with steel bal hole and threaded hole, and on the cylinder bottom a by-pass oil groove is set, and said by-pass oil groove is correspondent to the piston bottom portion, and in the steel ball hole a steel ball is mounted.

Owner:ANHUI HELI CO LTD

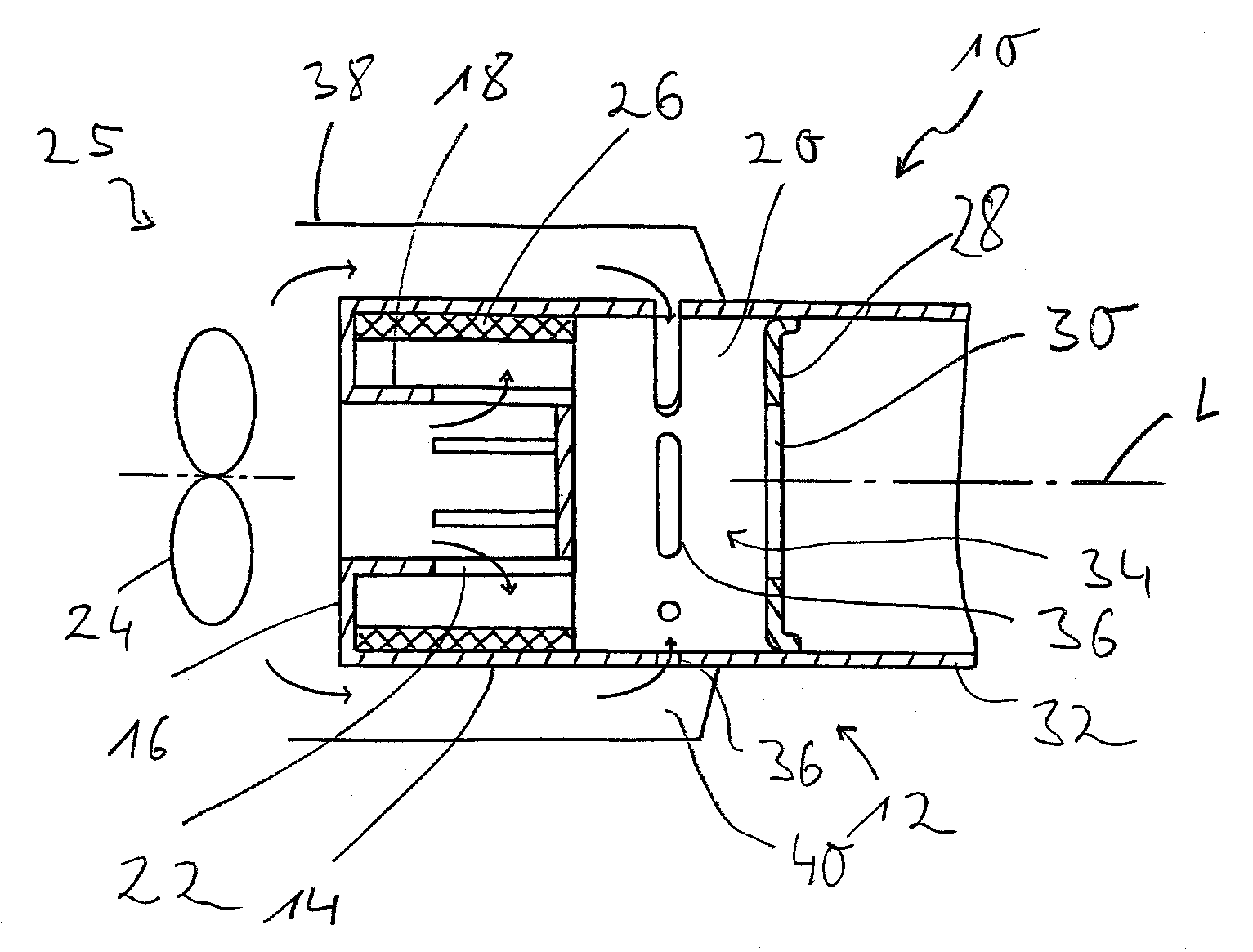

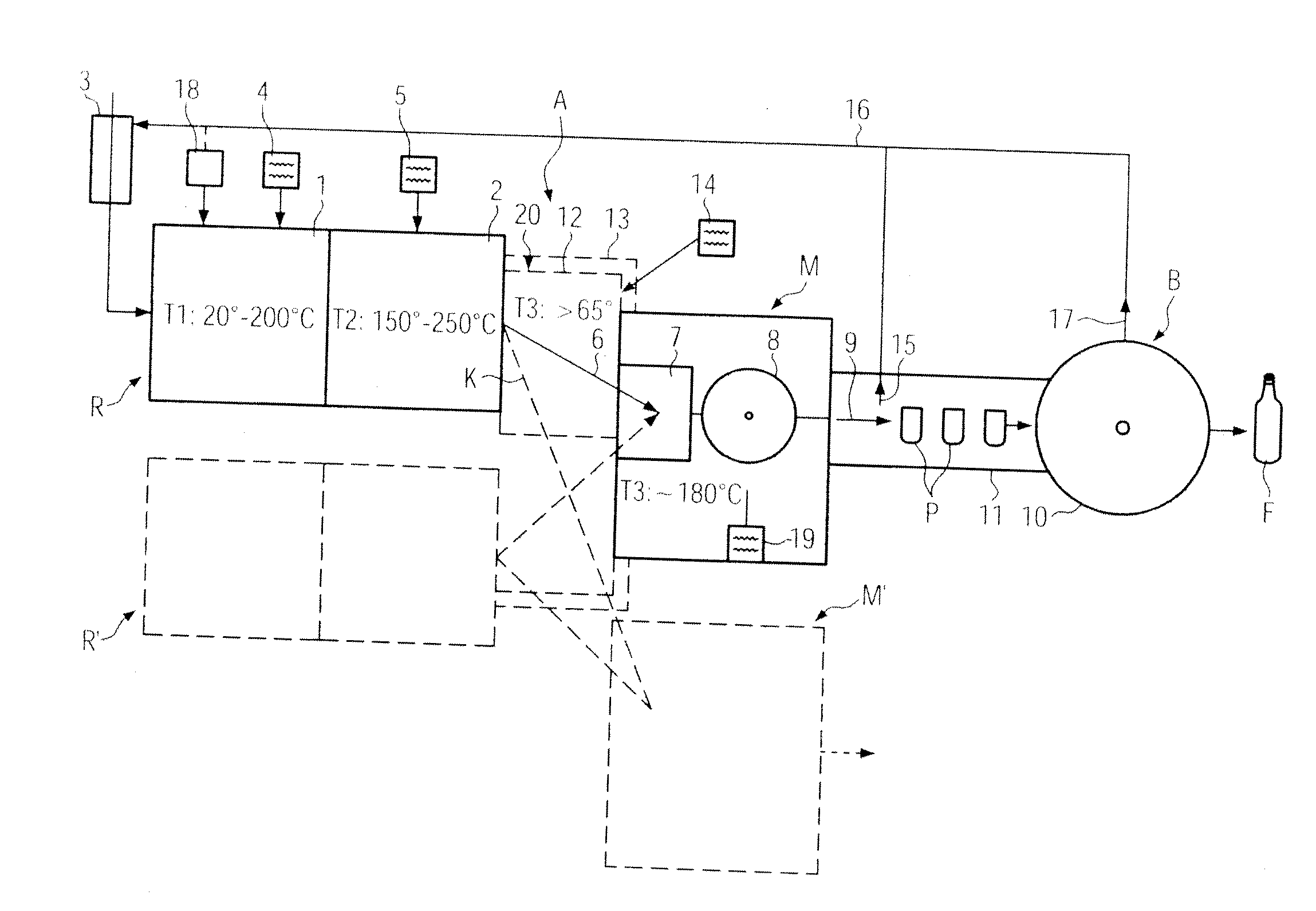

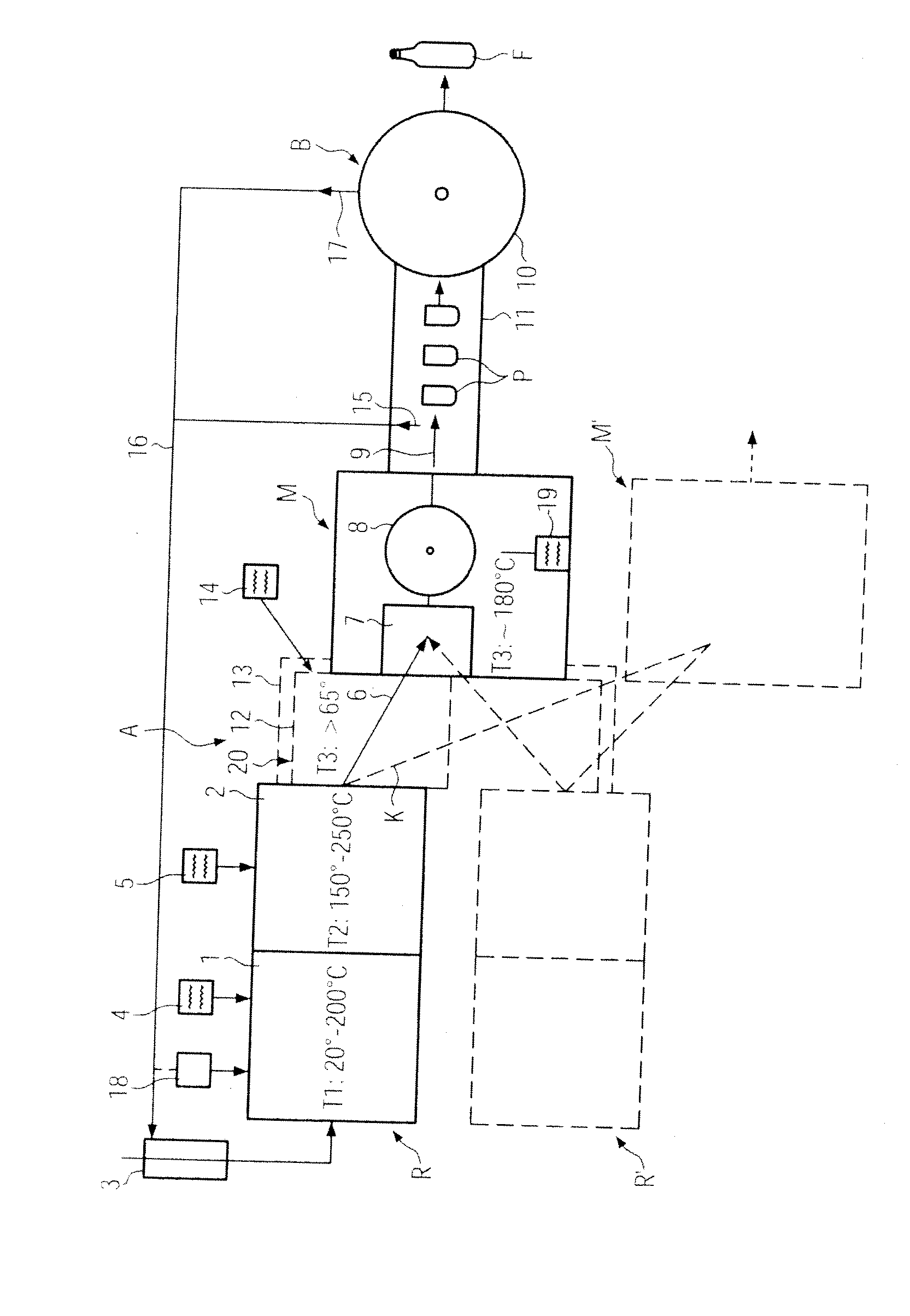

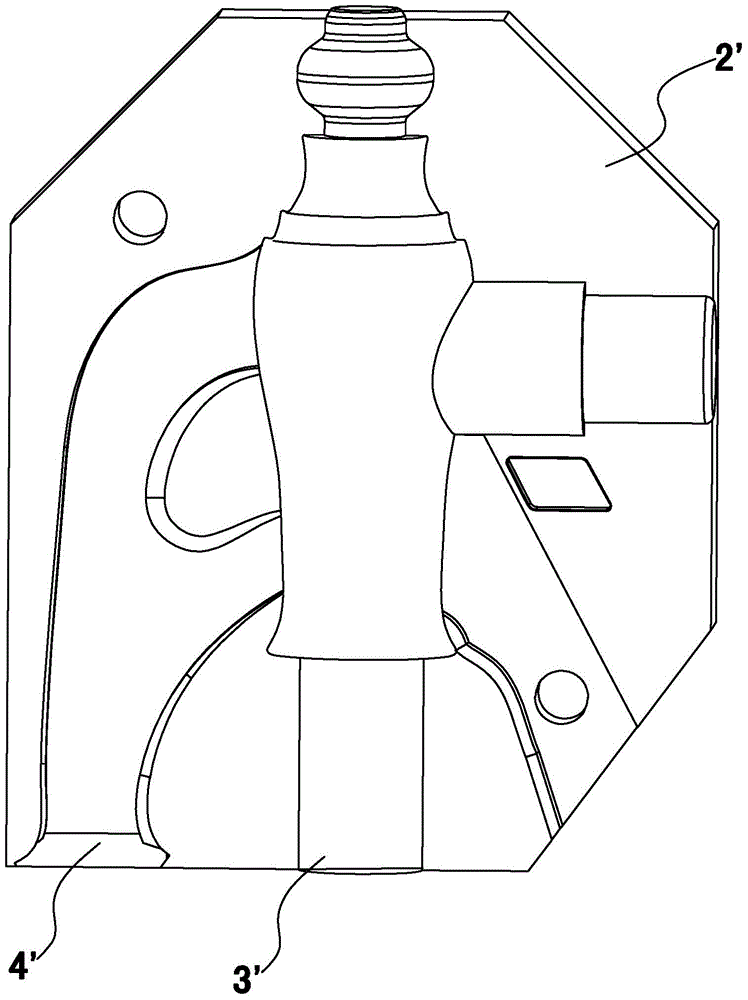

Method and plant for the manufacture of container preforms

InactiveUS20110198768A1Prevent waste of plasticImprove heat balanceArtificial filament recoveryConfectioneryPlastic materialsMaterial transfer

A method for the manufacture of container preforms in which recycled plastic material is subjected to at least one heat treatment in a recycling machine before it is transferred to a preform machine, where at least a major portion of heat introduced into the plastic material during its heat treatment and storage is transferred from the recycling machine with the plastic material into the preform machine. In a plant embodied for carrying out the method, the recycling machine is coupled with the preform machine either directly or via at least one intermediate storage such that at least a major portion of heat introduced in the recycling machine during a heat treatment of the plastic material can be transferred with the plastic material into the preform machine.

Owner:KRONES AG

Gravity casting process of lead-free brass tap

The invention provides a gravity casting process of a lead-free brass tap, which has the advantages that a flowing distance of a product in a casting process is short, the simultaneous solidification is achieved, hot cracks are reduced; a heat balance effect of a mould is good, so that heat balance of the product is facilitated, and the stress micro-cracks during cooling are reduced. The gravity casting process of the lead-free brass tap comprises the following step of casting and forming lead-free brass liquid through a gravity casting device, wherein the gravity casting device comprises an upper half mould, a lower half mould and a sand core, wherein mould cavities matched with a tap body in shape are respectively and correspondingly arranged between the upper half mould and the lower half mould, the sand core is arranged in the mould cavities between the upper half mould and the lower half mould, the shape of the sand core is matched with the shapes of a water inlet part and a water outlet part of the tap and an inner cavity of an installing part of a valve core, a casting cavity is formed between the sand core and the mould cavity, a sprue in which lead-free molten copper is cast is arranged in the lower half mould, the sprue is connected with the casting cavity, the sprue is provided with an internal sprue and an external sprue, and the internal sprue is correspondingly arranged at the casting cavity for forming the water inlet part of the tap body.

Owner:LONGYAN HONGHANG SANITARY WARE CO LTD

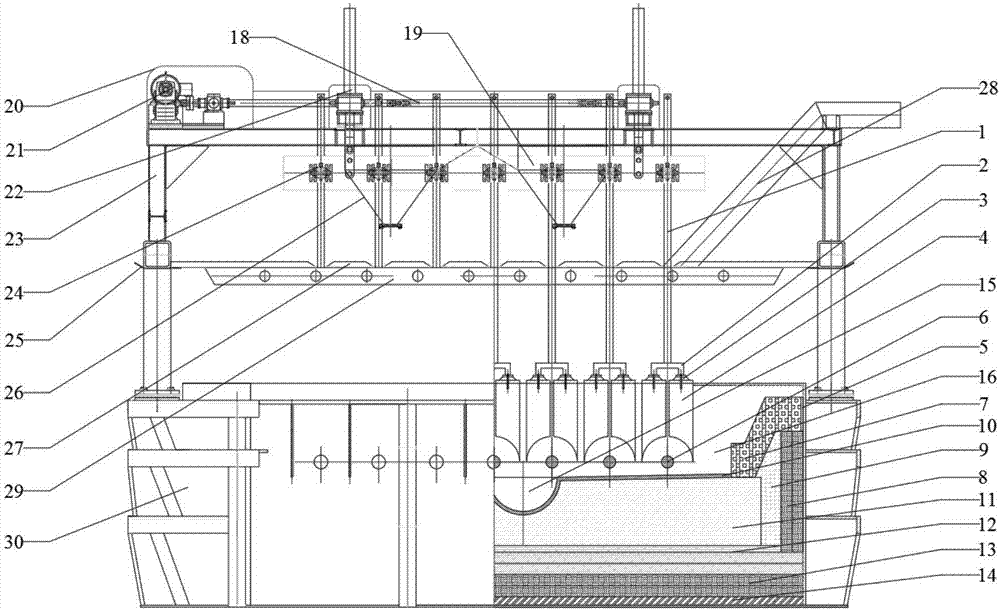

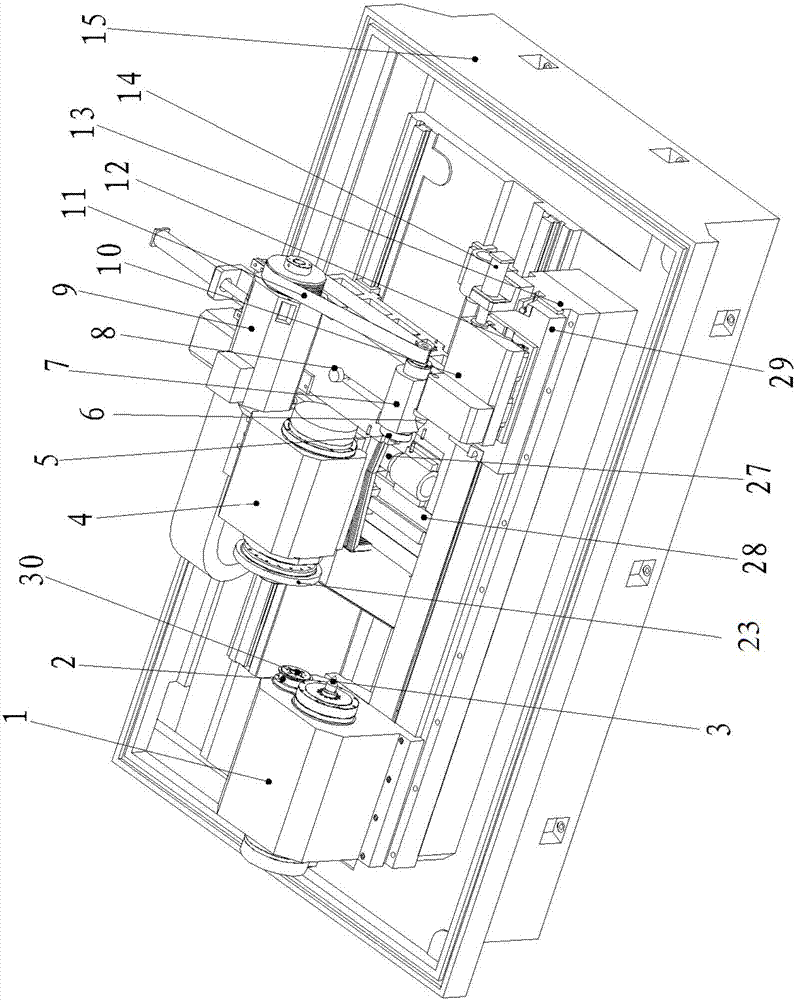

Dual grinding head servo numerical control camshaft grinding machine

PendingCN107186579AObvious cost advantageExpand the scope of processingGrinding carriagesGrinding drivesRotational axisEngineering

The invention provides a dual grinding head servo numerical control camshaft grinding machine, and belongs to the field of camshaft numerical control machining. According to the dual grinding head servo numerical control camshaft grinding machine, two grinding heads are horizontally arranged in parallel, the large grinding head is mainly used for machining workpieces of large specifications, the small grinding head is mainly used for machining workpieces with concave faces, and therefore the machining range of the machine is widened. The large grinding head and the small grinding head use a feed drive system in common, the small grinding head is driven by an oil cylinder to switch a machining station and a non-machining station, a grinding head feed shaft and a headstock rotary shaft are in two-shaft linkage, a servo shaft driven by a numerical control system is not added relative to a single grinding head, and therefore the dual grinding head servo numerical control camshaft grinding machine has prominent cost advantages relative to dual grinding head machines of other types.

Owner:湖南铱索数控装备股份有限公司 +1

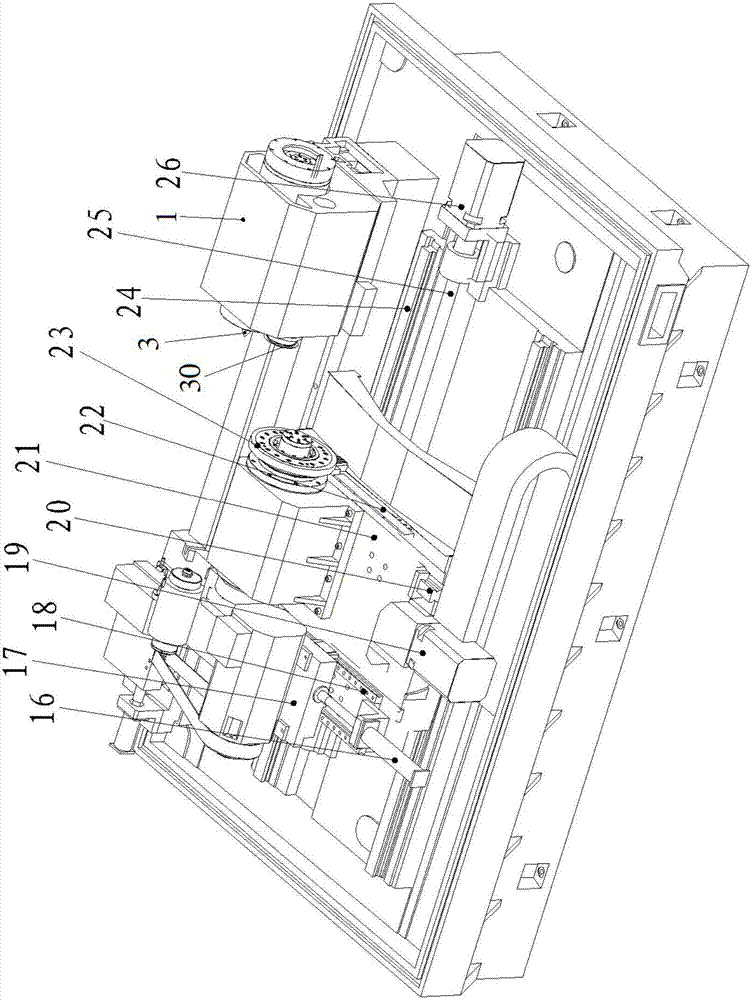

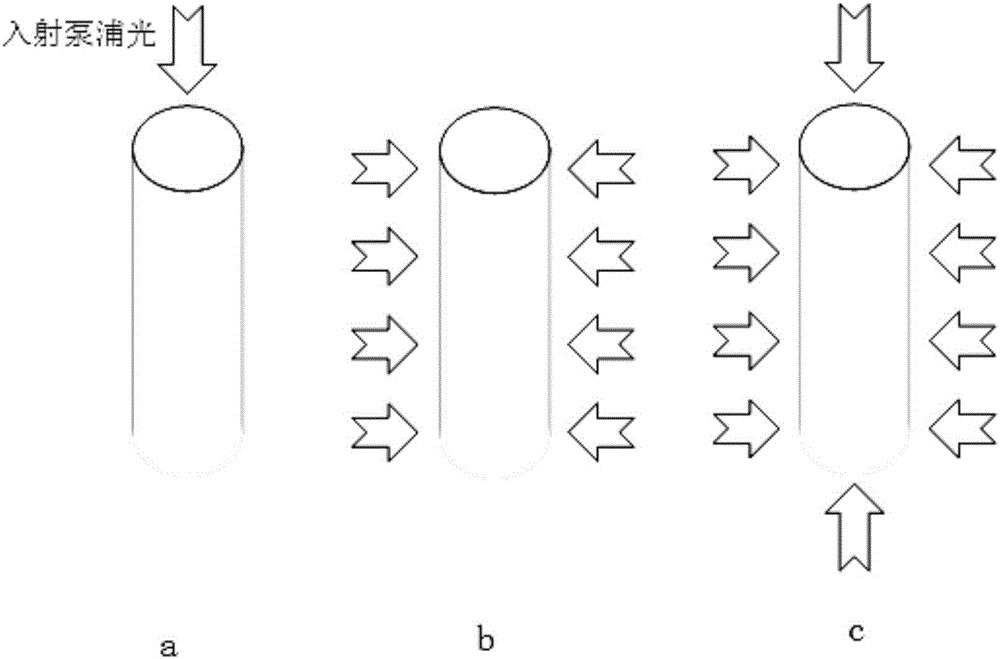

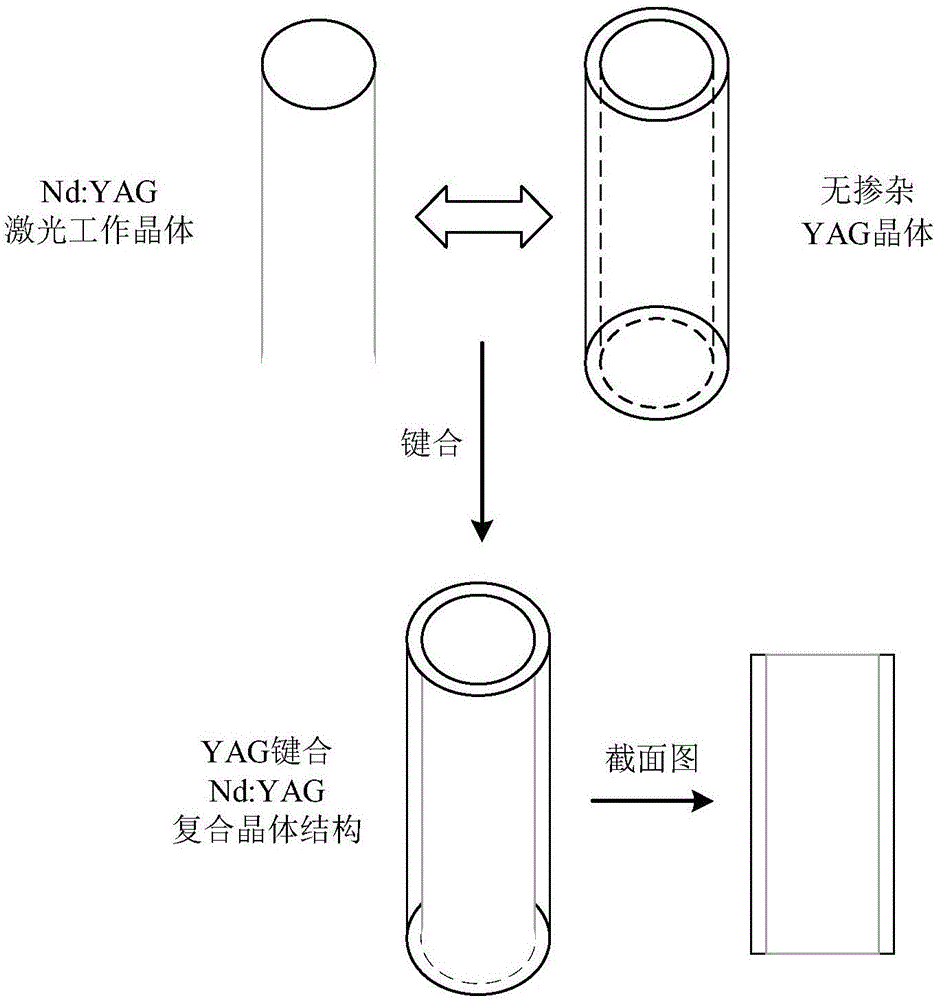

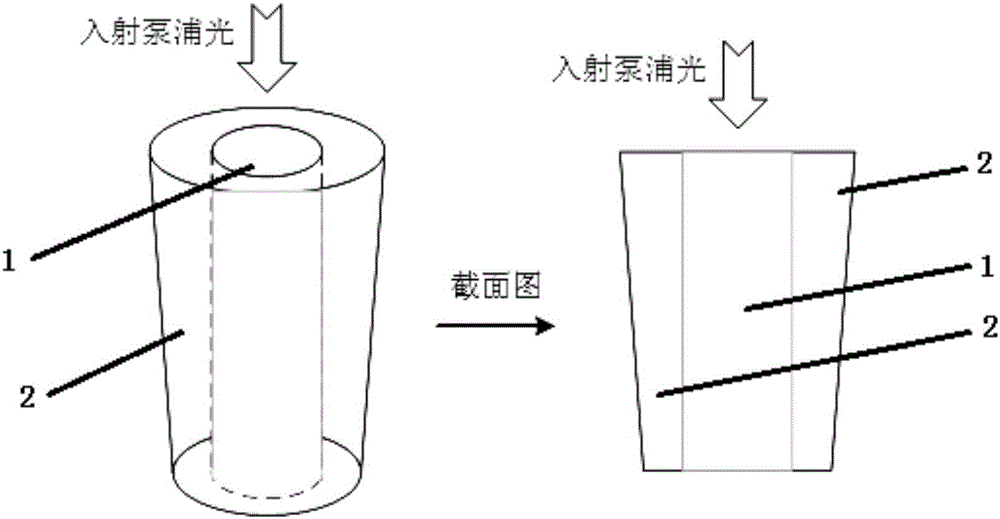

Solar-pumped composite crystal with high absorption efficiency and radiating performance and preparation thereof

InactiveCN106451040AImprove cooling effectIncrease cooling areaActive medium materialActive medium shape and constructionHigh absorptionSystems design

The invention provides a solar-pumped composite crystal with high absorption efficiency and radiating performance and preparation thereof; the composite crystal includes a neodymiumx yttrium aluminum garnet doped crystal layer and a neodymiumx yttrium aluminum garnet crystal layer; the neodymiumx yttrium aluminum garnet crystal layer is located at the outside of the neodymiumx yttrium aluminum garnet doped crystal layer. The preparation method is to bond the neodymiumx yttrium aluminum garnet crystal layer with the neodymiumx yttrium aluminum garnet doped crystal layer. By using the high heat conductivity of non-doped YAG crystal, the radiating performance of a laser crystal is promoted; the radiating area of the laser working crystal is enlarged by a composite structure; the surface radiating balance degree of the Nd: YAG crystal is improved by bonding the solid material; meanwhile, the utilization efficiency of the pumped light is effectively improved. The composite crystal can be applied to the solar pump, in particular to the laser system design of the solar pump; the radiating ability of the solar pump system and the pump light utilization efficiency are improved; the temperature balance function can further improve the light beam quality of the output laser, and expand the using scale of the light pump laser.

Owner:SHANGHAI SATELLITE ENG INST

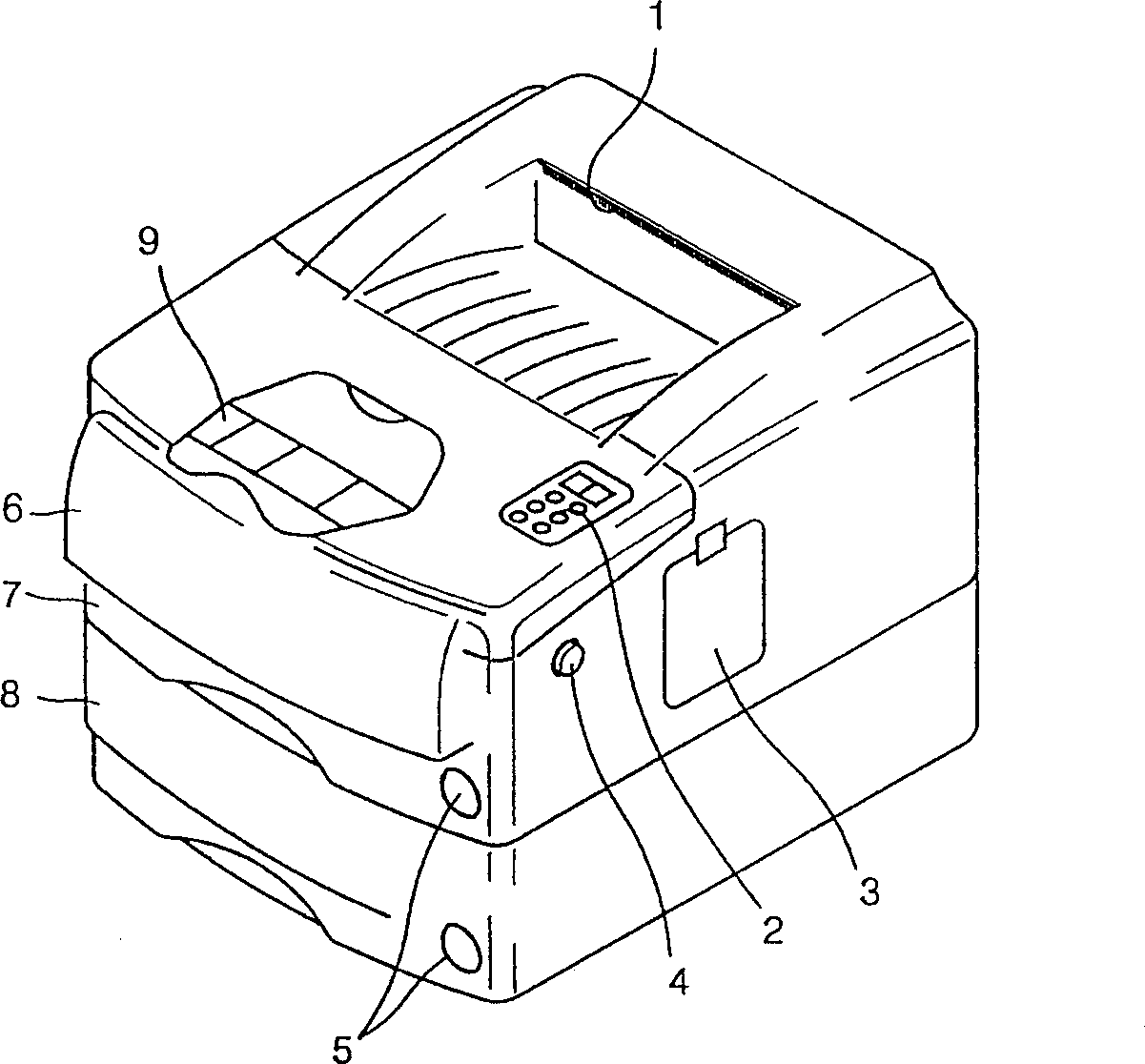

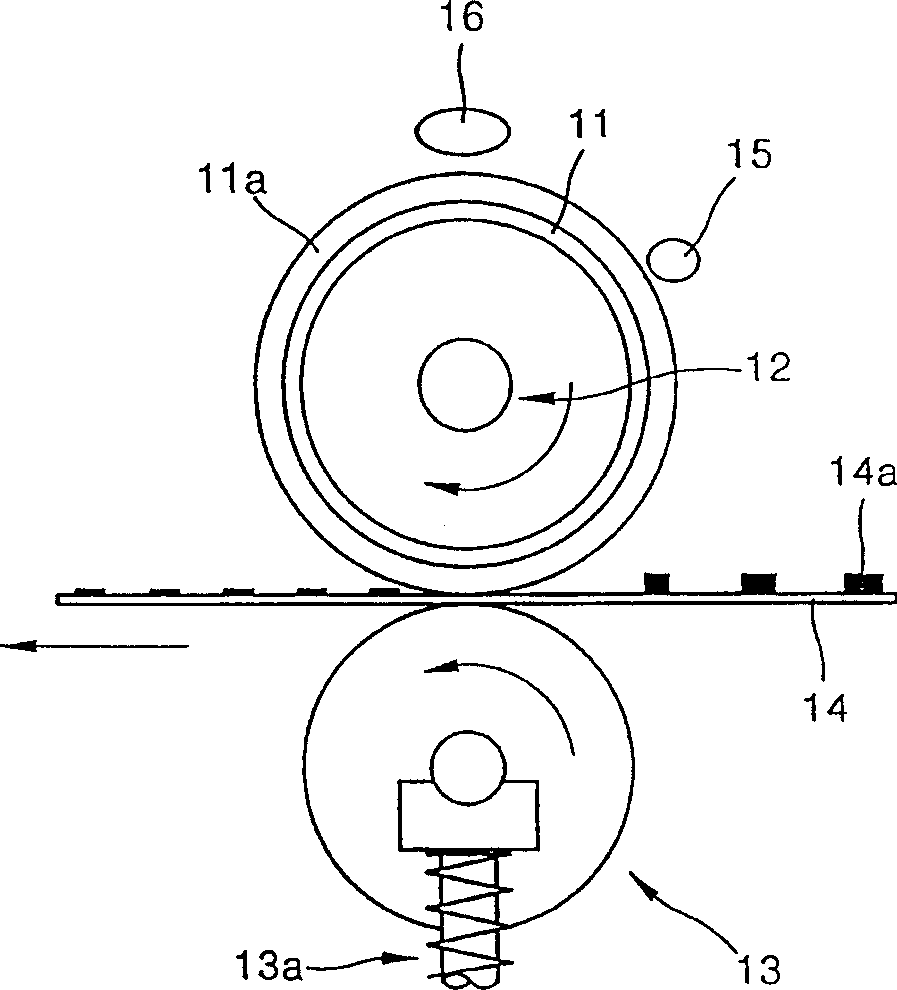

Fixing roll assembly of electronic photography image-forming device

InactiveCN1360232AReduced local temperature deviationImproved heat distribution characteristicsElectrographic process apparatusRoller heating devicesWorking fluidHermetic seal

A structurally improved fusing roller assembly based on the heat pipe principle is provided. The fusing roller assembly includes a fusing roller and a heat pipe coaxially mounted inside the fusing roller. A resistance heater is helically wound around the exterior cylindrical surface of the heat pipe, and rests between the inner cylindrical surface of the fusing roller and the exterior cylindrical surface of the heat pipe. The heat pipe is hermetically sealed. The sealed inner space is partially filled with a working fluid. The surface of fusing roller can be instantaneously heated up to a target fusing temperature. The fusing roller assembly can be heated up to a target fusing temperature within a shorter period of time without need for warm-up and stand-by period, so that power consumption decreases.

Owner:SAMSUNG ELECTRONICS CO LTD

Working vehicle

ActiveUS20170072786A1Improve heat balanceEfficient processVehicle sub-unit featuresSuperstructure subunitsExhaust gasAutomotive engineering

The working vehicle includes an engine installed in a front portion of a traveling machine body, and a post-processing device configured to purify exhaust gas from the engine. The post-processing device is mounted on an upper side of the engine. The engine and the post-processing device are covered with a hood. A hood shield plate is disposed on a rear surface side of the hood and covers at least the post-processing device from a rear surface. A heat insulating layer is formed between an operating seat 8 disposed on a rear side of the hood and the hood shield plate.

Owner:YANMAR POWER TECHNOLOGY CO LTD

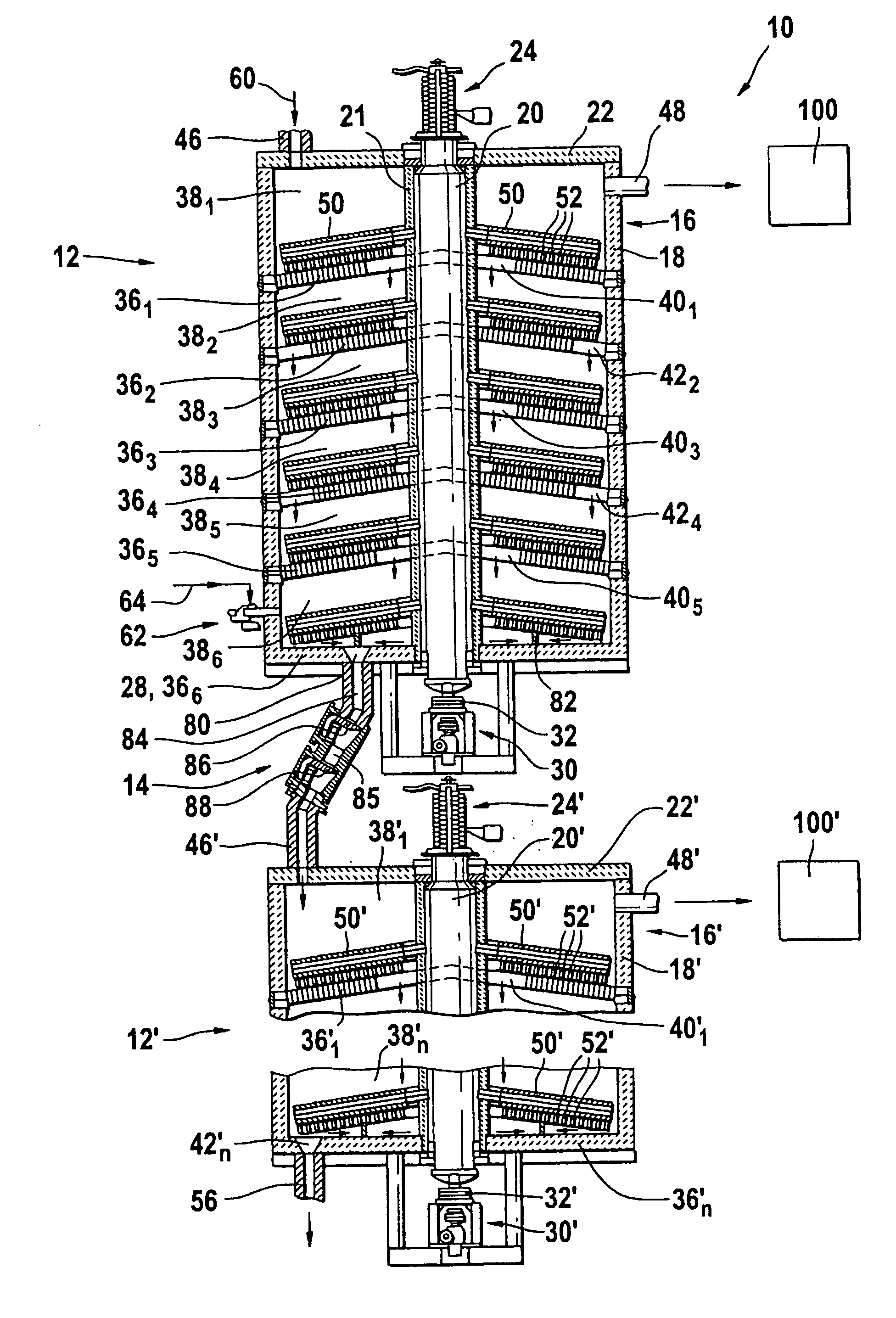

Method of operating a multiple hearth furnace

InactiveUS20040123785A1Easy feedingImprove heat balanceHand ironCharge manipulationEngineeringMechanical engineering

A method of operating multiple hearth furnace (10) with a plurality of vertically aligned hearth floors (361, 362, 363, 364, 365), comprises in particular following steps. A first material is fed onto the uppermost hearth floor and moved over this uppermost hearth floor (361) before it falls through a drop hole (40) onto the next lower hearth floor. This first material is processed in this way from hearth floor to hearth floor down to the lowermost hearth floor (366). A second material is fed onto one of the hearth floors to be mixed into the first material. This second material (64) is moved separately from the first material in a separate annular zone (68) of the hearth floor onto which it is fed before it is mixed into the first material. The method allows to provide an efficient thermal preconditioning of the second material prior to mixing it into the first material without requiring any supplementary equipment therefore.

Owner:PAUL WURTH SA

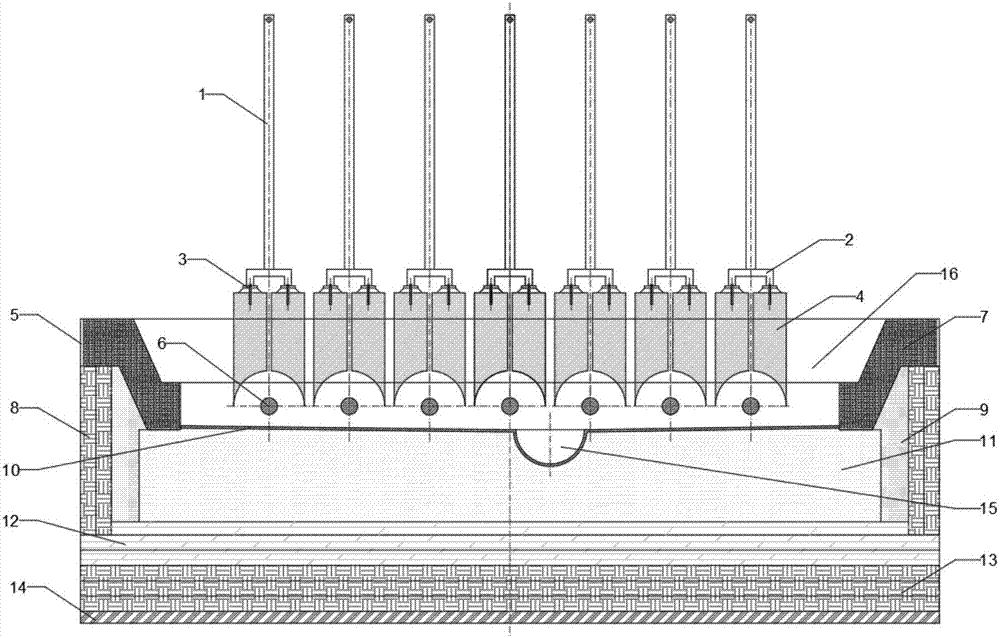

4000A-electrolytic furnace for producing oxide molten salt through electrolysis

The invention relates to a 4000A-electrolytic furnace for producing an oxide molten salt through electrolysis, which comprises a negative electrode, a positive electrode, a molten salt, a crucible, a graphite cuvette, a steel jacket and the like. A packing layer is filled between the graphite cuvette and the steel jacket, a throat opening on a furnace panel is quadrate, and a heat radiator is arranged above the furnace panel to play a role in balancing and stabilizing the furnace temperature. The electrolytic furnace has simple and convenient furnace building process steps and a simple furnace building method, the furnace building materials are few in variety, and part of the materials is low in price and is practical. When the furnace life becomes due, only an inner liner of the graphitecuvette is required to be replaced, and the other parts of the furnace body can be used in a long term. The electrolysis temperature is easy to control, the product quality is high, the electrolysis current can reach 4000A, the product yield is high, and the production operations are easy. The product carbon contents are very easy to control, and produced rare earth products have different electrolysis temperatures due to different varieties so that the carbon contents can be different, but the same point is that all the carbon contents can reach less than 0.03, and the carbon contents of theproducts of most varieties can reach about 0.01.

Owner:カン州晨光希土新材料有限公司

Novel aluminum cell furnace building process

InactiveCN101302629AMeet the requirements of high temperature productionImprove insulation effectElectrolysisMetallurgy

The invention provides a novel process for furnace building of an aluminum electrolyte bath. The process method is as follows: all rubbishes in the furnace building area are cleared away, and cathode steel bars are pasted by normal mounting window steel plates and tightly pressed so as to make dry type antiseepage materials unable to flow out; and steel plates are used as baffle plates for both ends of carbon clearances between cathode carbon blocks; the dry type antiseepage materials are arranged in the bath around the cathode carbon blocks, and are vibrated and flattened by a vibrator. The process method has the advantages of effectively solving the problem that the dry type antiseepage materials flow out due to the unsealing of the cathode window, simplifying the process of building the furnace, shortening the construction time and reducing the labor input, strengthening the heat retaining capacity of the bath bottom, lowering the heat loss and the stressing damage of the bath bottom and reducing the environmental pollution of solid wastes generated due to the major repair of the bath; moreover, the dry type antiseepage materials can be cyclically utilized, and the heat retaining performance and the reasonable heat balance of the electrolyte bath are better than that of the originally designed electrolyte bath, and the dry type antiseepage materials can react with seepage electrolytes in the electrolyte bath to generate a compact viterous body-formed nepheline layer, which can prevent the electrolytes from continuous seepage and prolong the service life of the electrolyte bath.

Owner:河南神火铝业股份有限公司

Working vehicle

ActiveUS20170015191A1High temperature environmentAvoid negative effectsVehicle sub-unit featuresSuperstructure subunitsEngine mountExhaust gas

A working vehicle includes an engine mounted in a front portion of a travelling vehicle, and a post-processing device configured to purify exhaust gas from the engine. The engine and the post-processing device are covered with a hood. An upper surface side of the hood is inclined to extend diagonally upward from a front side to a rear side. The post-processing device is mounted on an upper side of the engine, and is positioned on a rear and inner side of the inclined upper surface side of the hood.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Aluminum electrolysis cell forced ventilation afterheat utilization device and utilization method

The invention relates to an aluminum electrolysis cell forced ventilation afterheat utilization device, in particular to the aluminum electrolysis cell forced ventilation afterheat utilization device and a utilization method. A cell shell of an electrolysis cell, a cradle frame and a cell edge plate form a forced ventilation sealing box; the cell shell of the sealing box is welded with a cooling plate; a wind inlet pipe is arranged on the sealing box, and is connected with a wind blower; an exhaust hole is formed in the cell edge plate, and is communicated with a horizontal collection exhaust pipe; and the horizontal collection exhaust pipe is arranged at the outer side of the cell shell, collects forced ventilation tail gas exhausted from the sealing box, and exhausts the tail gas into a cell hearth. The utilization device is simple in structure and convenient for manufacturing and installation, can transfer heat, absorbed from the lower part of the cell, in forced ventilation to the upper part of the electrolysis cell for heating the cell hearth so as to help the electrolysis cell to build excellent heat balance under the low voltage cell condition.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com