Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Short flow distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

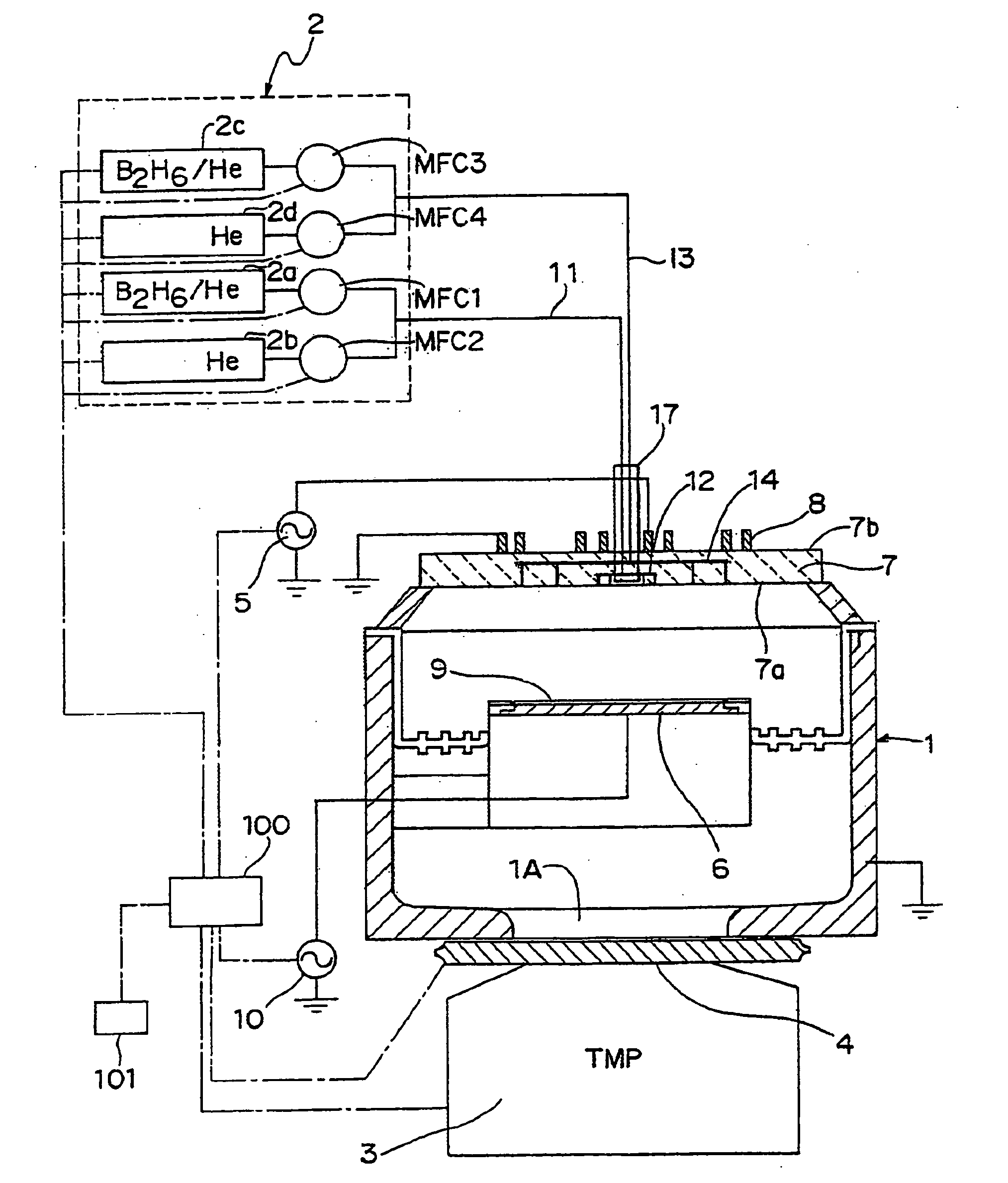

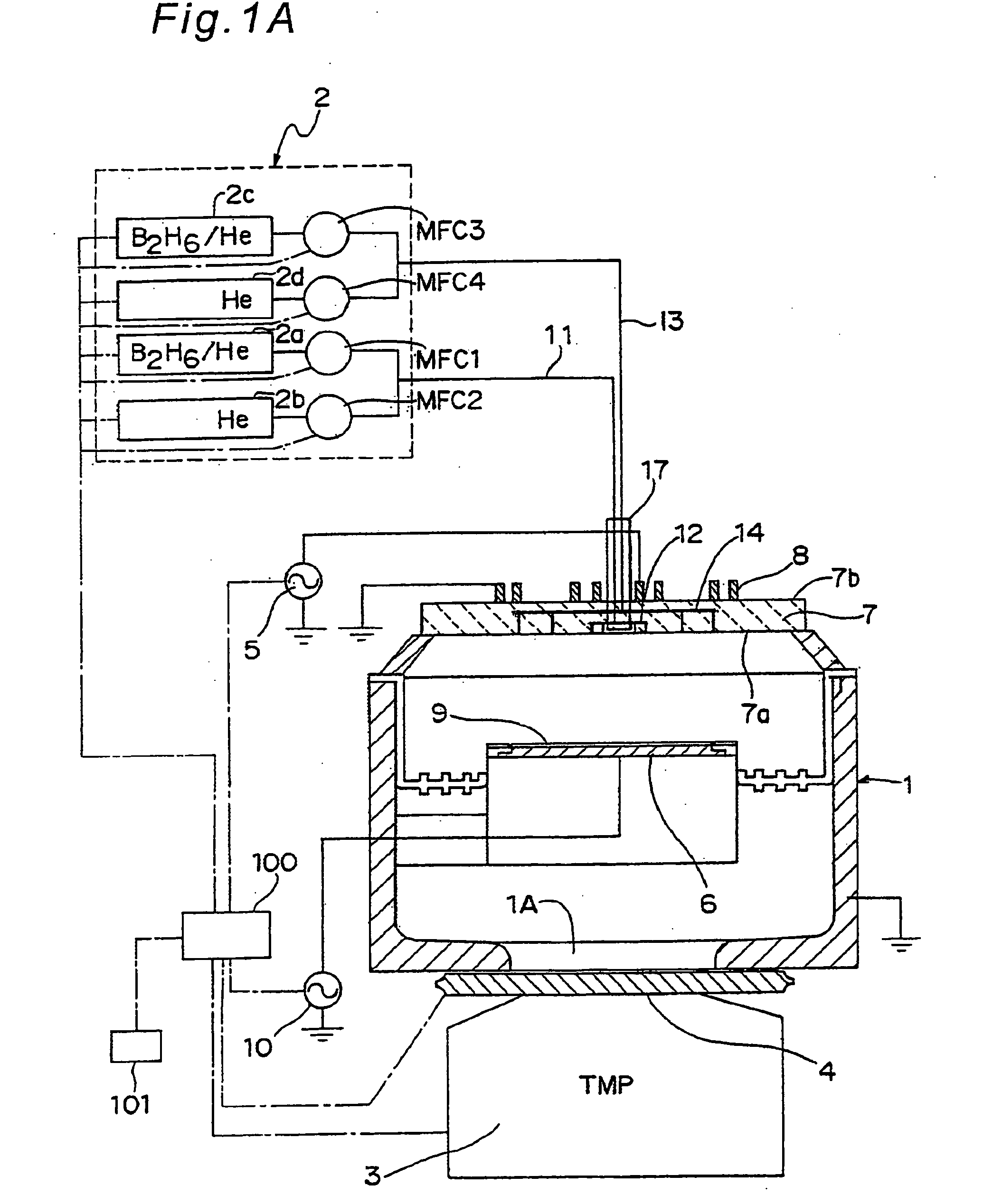

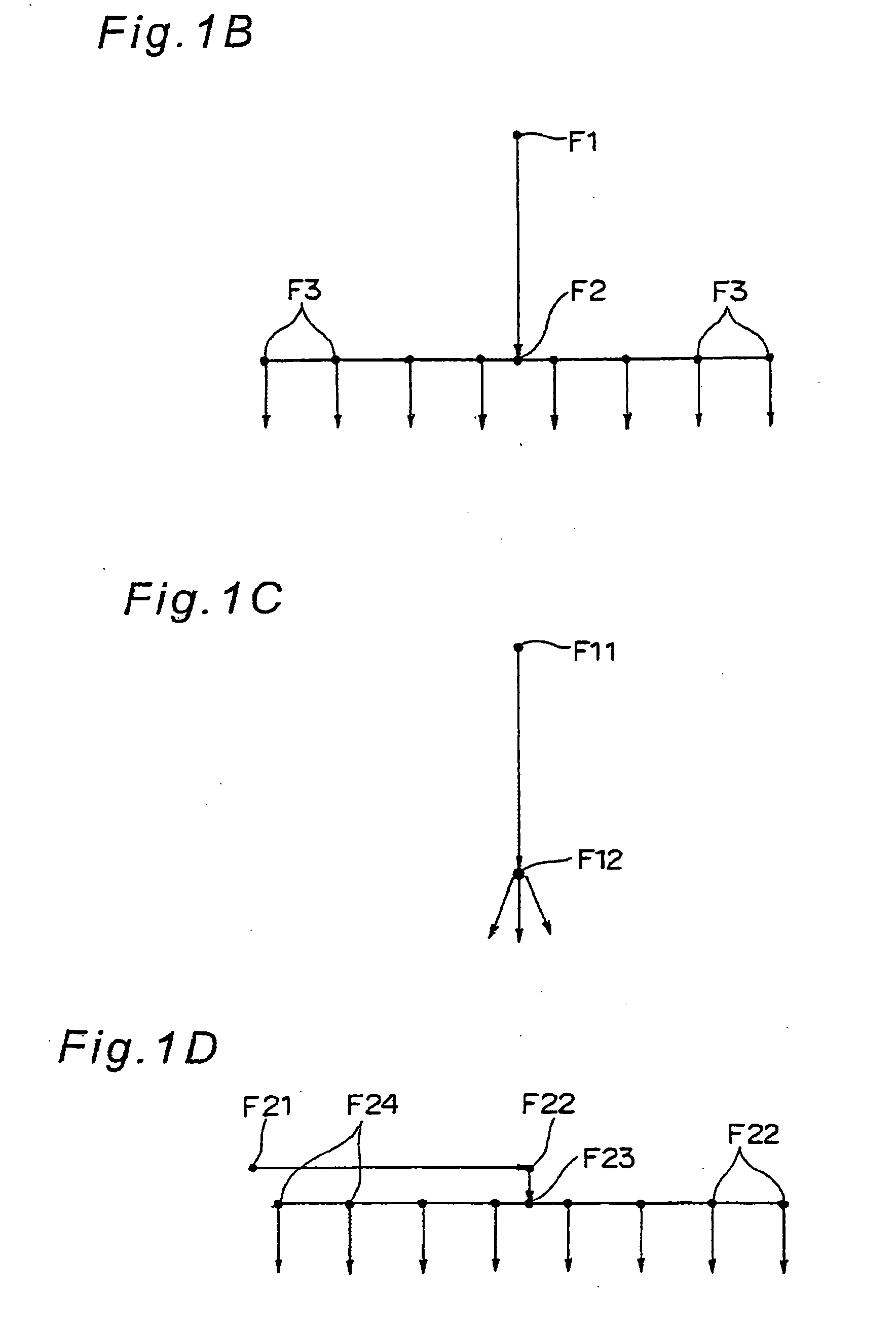

Apparatus and method for plasma doping

InactiveUS20090042321A1High precision uniformityShort flow distanceSemiconductor/solid-state device testing/measurementElectric discharge tubesElectrical resistance and conductanceProduct gas

Gas supplied to gas flow passages of a top plate from a gas supply device by gas supply lines forms flow along a vertical direction along a central axis of a substrate, so that the gas blown from gas blow holes can be made to be uniform, and a sheet resistance distribution is rotationally symmetric around a substrate center.

Owner:PANASONIC CORP

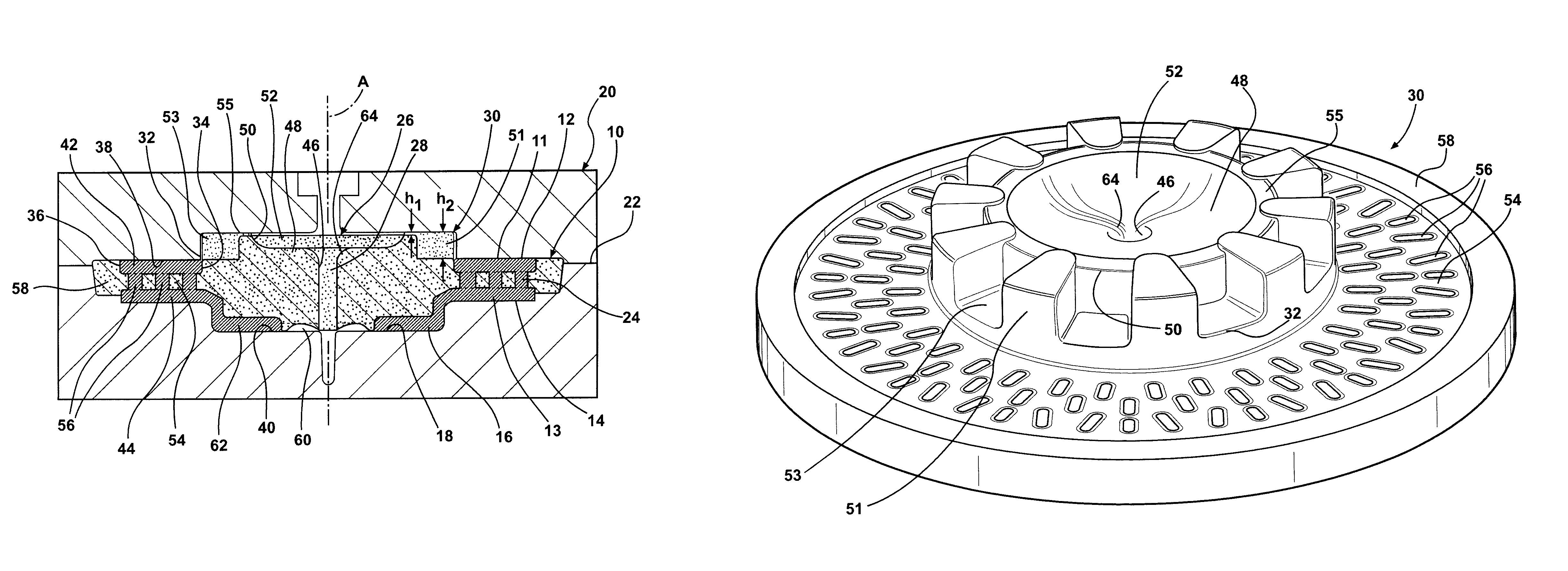

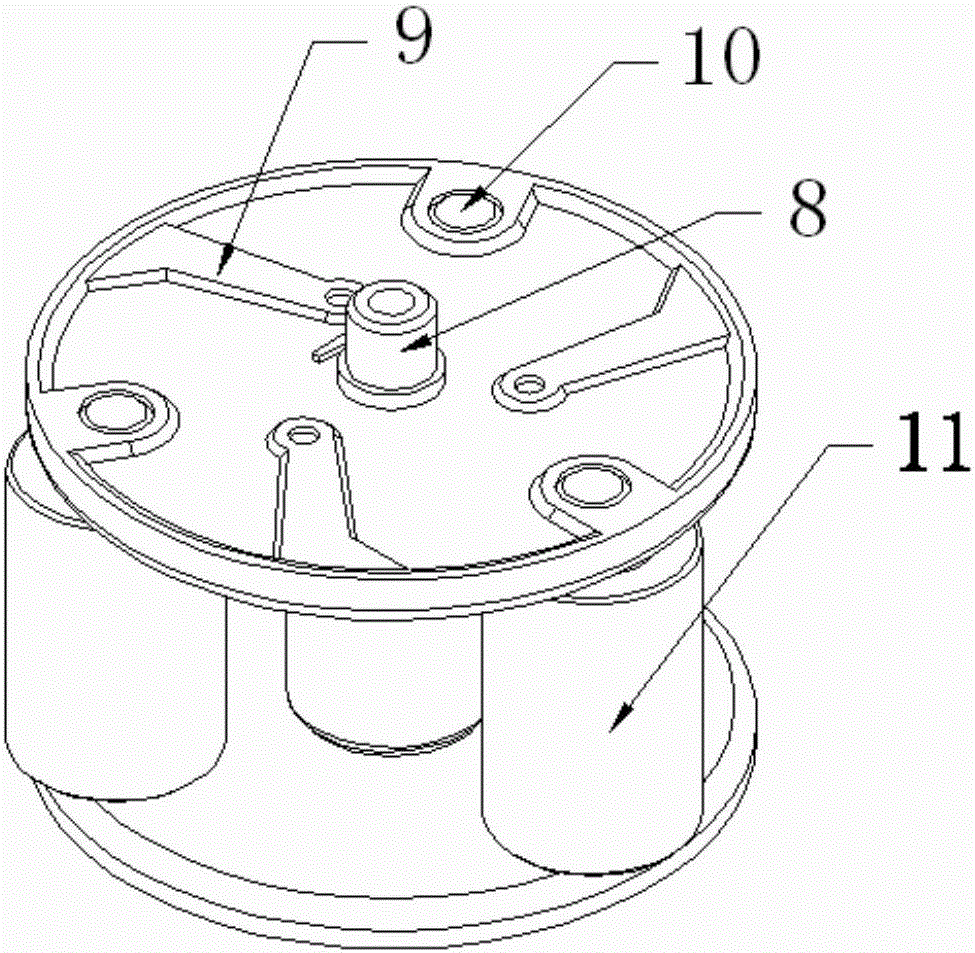

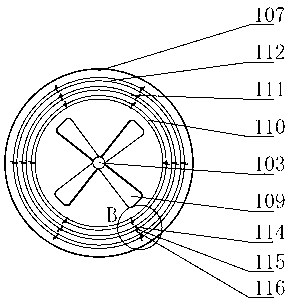

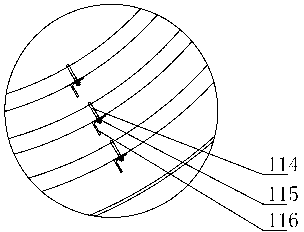

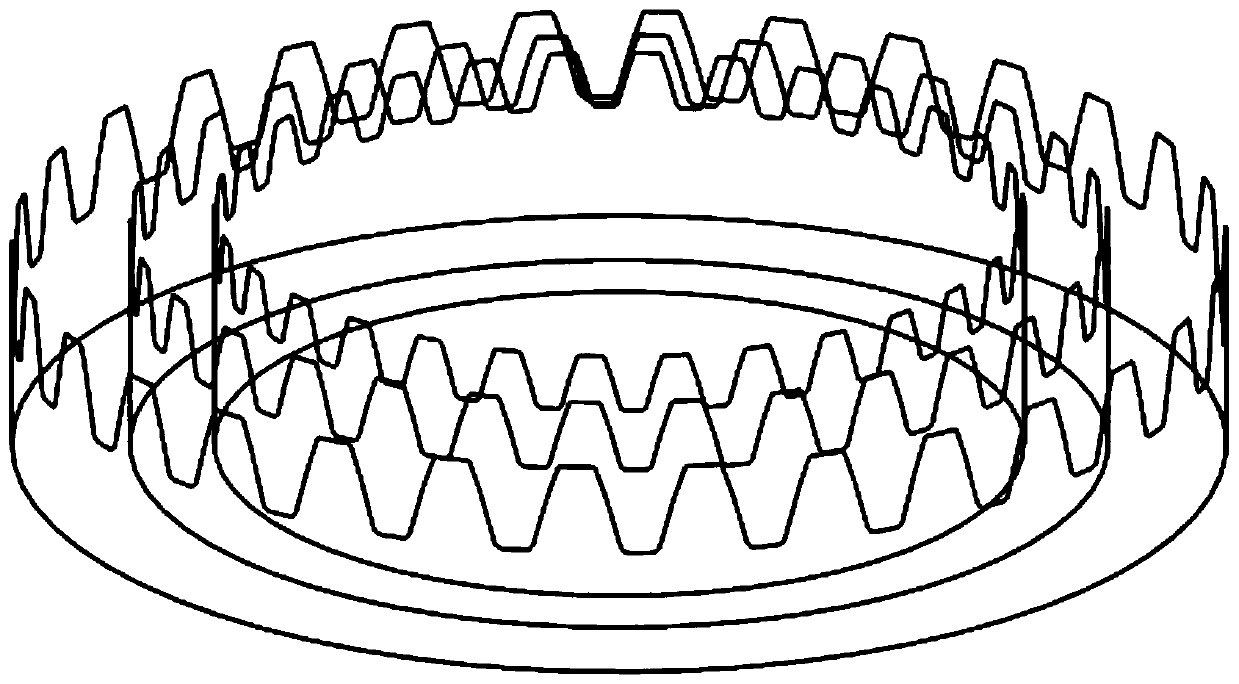

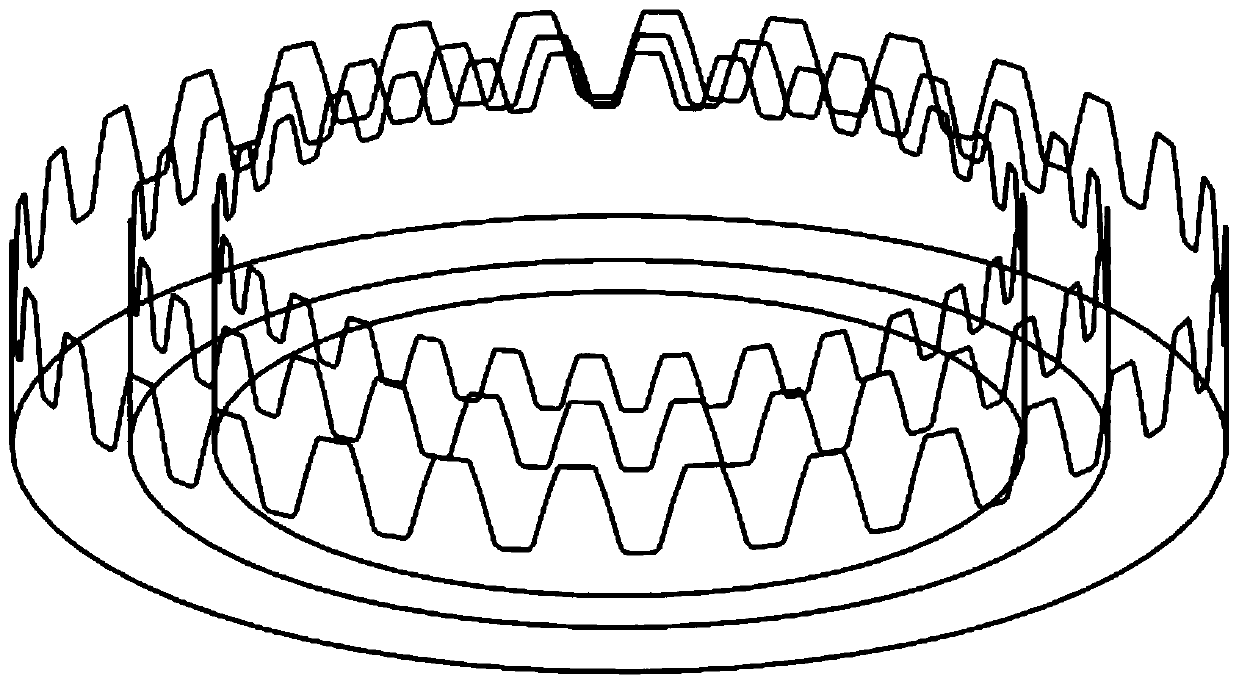

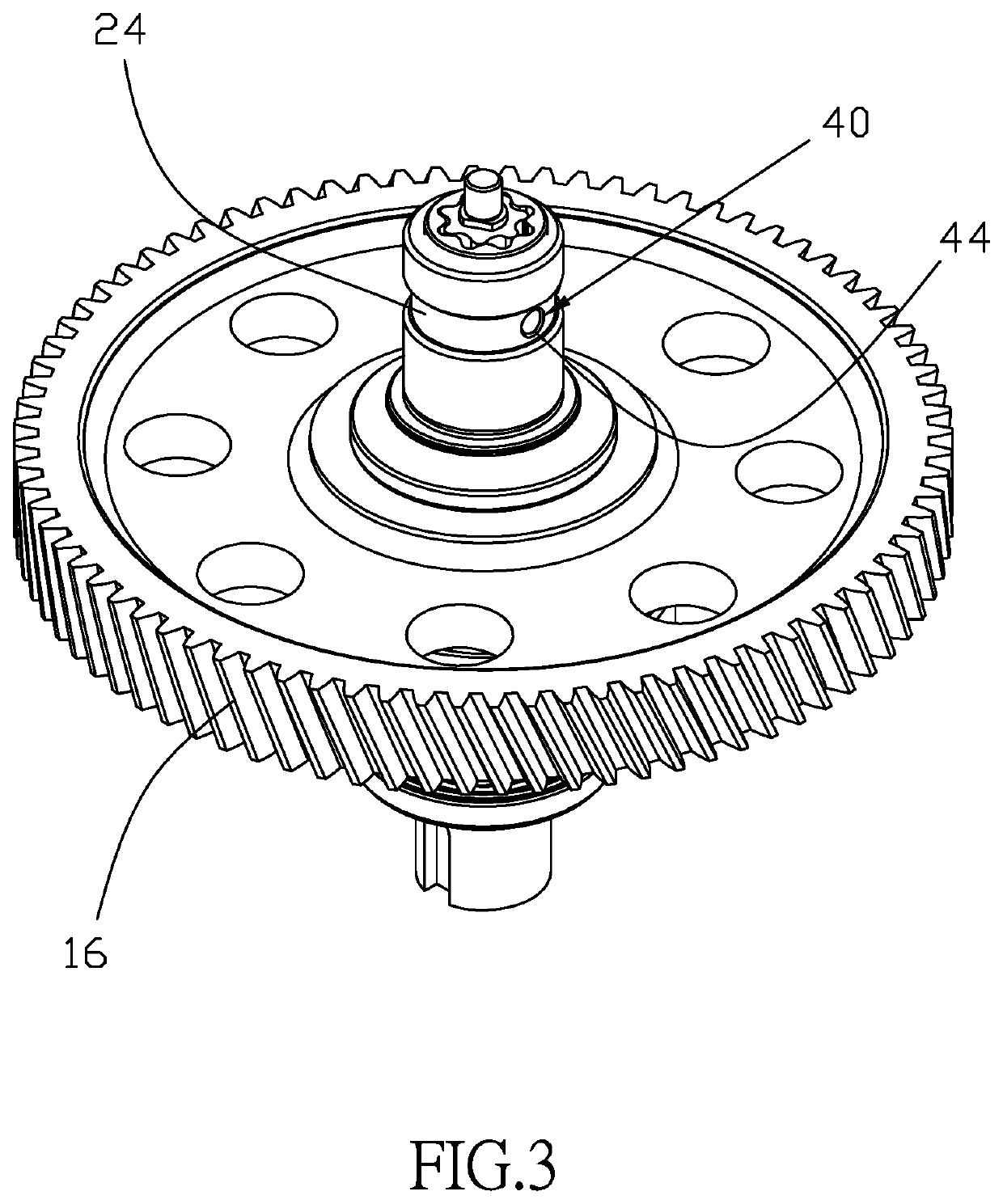

Centrally gated cast metal rotary friction plates and method of manufacture

InactiveUS7753103B1Shorten speedShort flow distanceFoundry mouldsFoundry coresLow frictionMolten metal

A method of casting a rotary friction plate includes preparing a casting mold with a cavity and a core shaped to form the friction plate. Molten metal is poured into the mold through a central sprue where a portion of the metal flows radially outward across the top of the core to fill friction plate forming regions of the cavity from above, while another portion flows through a central opening in the core to fill a hub forming region at the bottom of the cavity as well as additionally supply metal to the lower friction plate forming region from below. The metal is allowed to cool, which begins at the radially outer regions of the at least one friction surface and progresses radially inward to develop a uniform cast structure.

Owner:ROCHESTER WILLIAM R

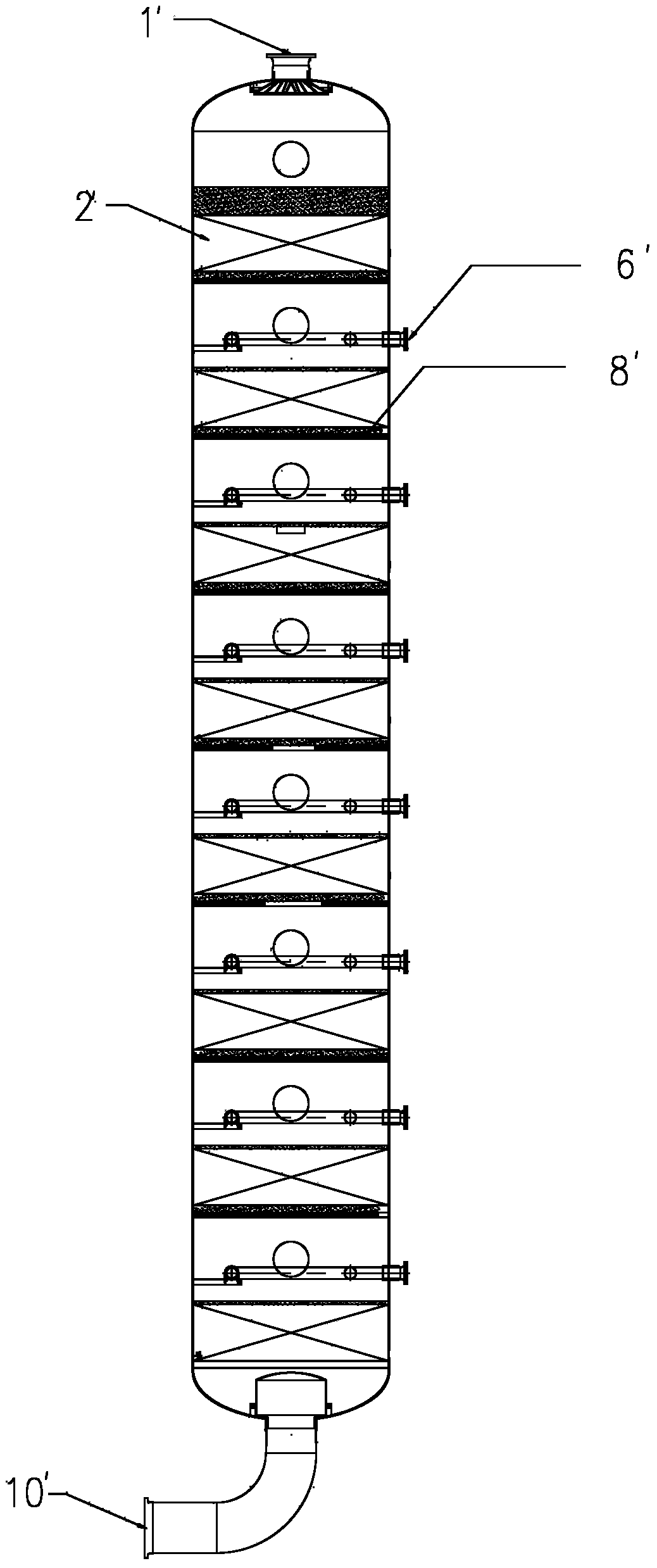

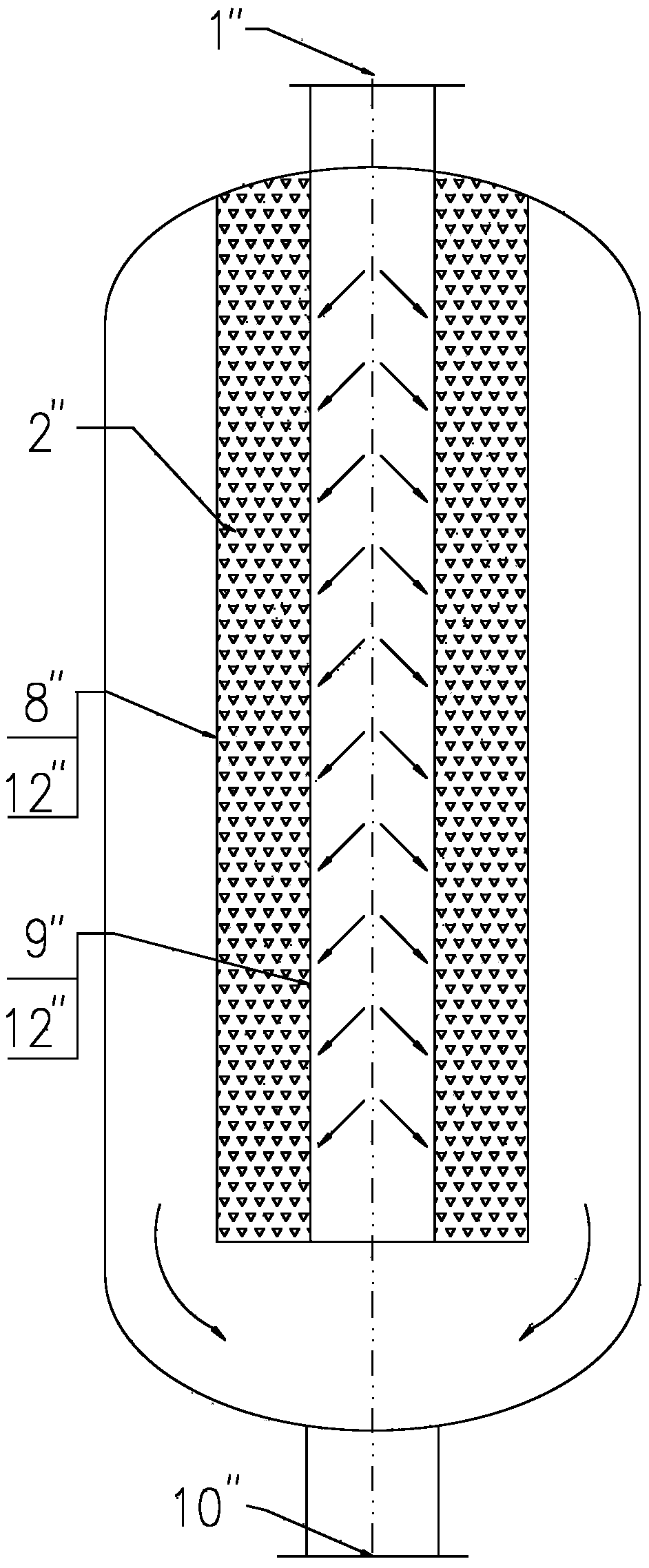

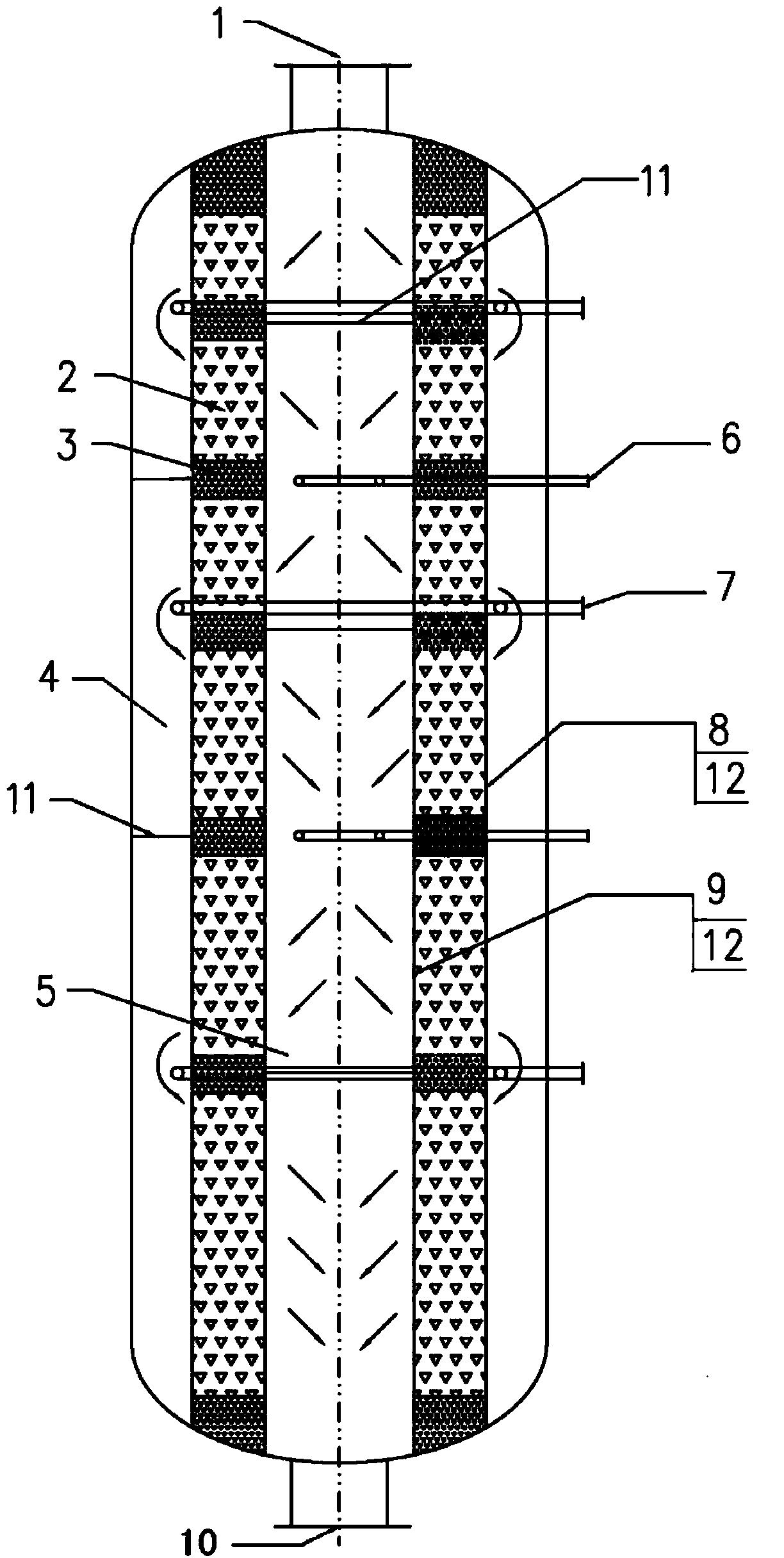

Novel multi-bed radial fixed bed reactor

InactiveCN103846061ASmall pressure dropRealize segmented feedingChemical/physical processesHigh densityFixed bed

The invention relates to a novel multi-bed radial fixed bed reactor which is distributed in a barrel shape. The novel multi-bed radial fixed bed reactor comprises a raw material inlet, catalyst beds, high-density porcelain balls, a ring-shaped channel, a center channel, a center channel distributor, a ring-shaped channel distributor, outer side grids, inner side grids, a reactant outlet and baffles, wherein the raw material inlet is formed in the top of the reactor, and the reactant outlet is formed in the bottom end of the reactor; the catalyst beds are distributed in the reactor along the radial direction in a ring barrel shape; the center channel is arranged in the center of the reactor, and the ring-shaped channel is arranged around the outer ring of the catalyst beds; the center channel and the ring-shaped channel are respectively provided with the baffles; the high-density porcelain balls are arranged on the baffles; the outer side grids are arranged at the outer sides of the catalyst beds, and the inner side grids are arranged at the inner sides of the catalyst beds. The novel multi-bed radial fixed bed reactor has the advantages that the sectional feeding proportion can be flexibly adjusted, and the bed pressure drop is effectively reduced.

Owner:LUOYANG ZHIDA PETROCHEM ENG

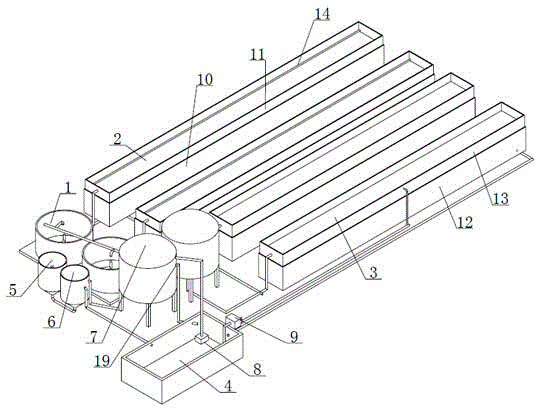

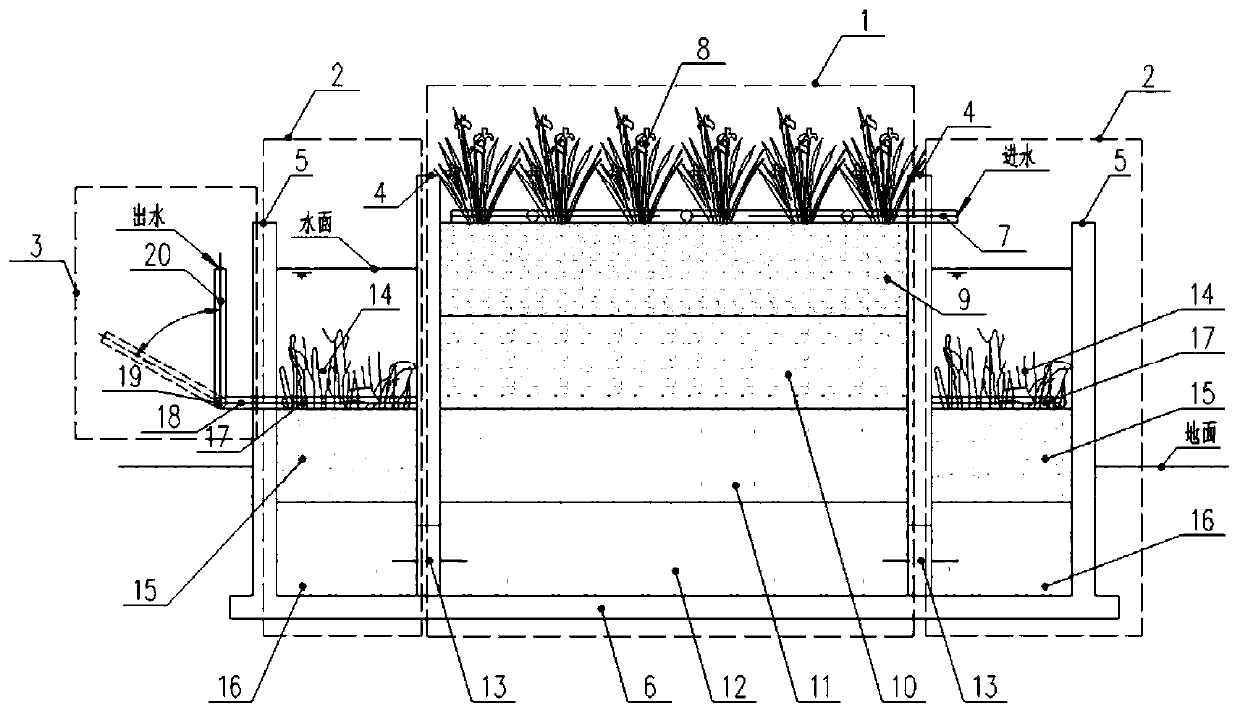

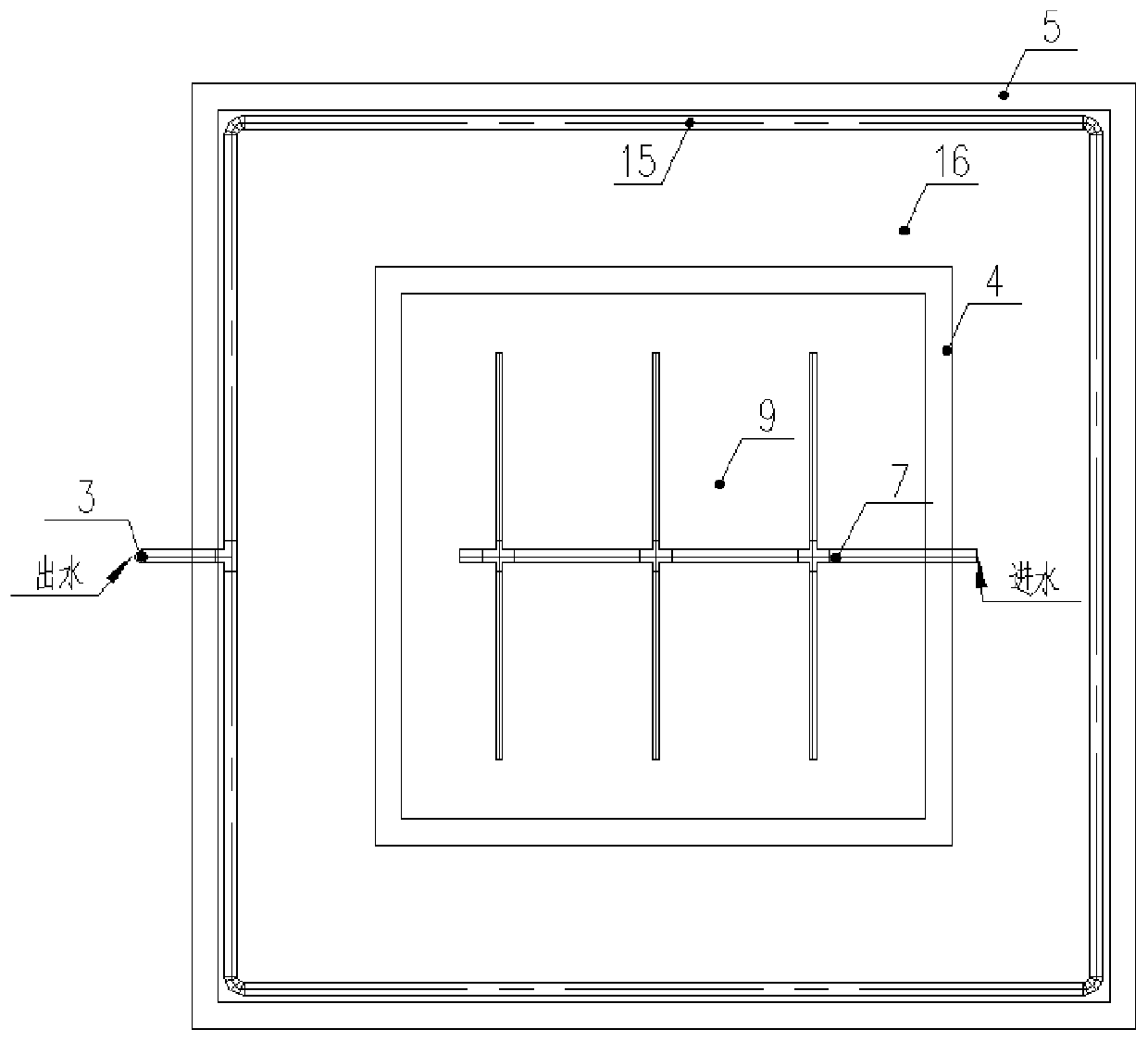

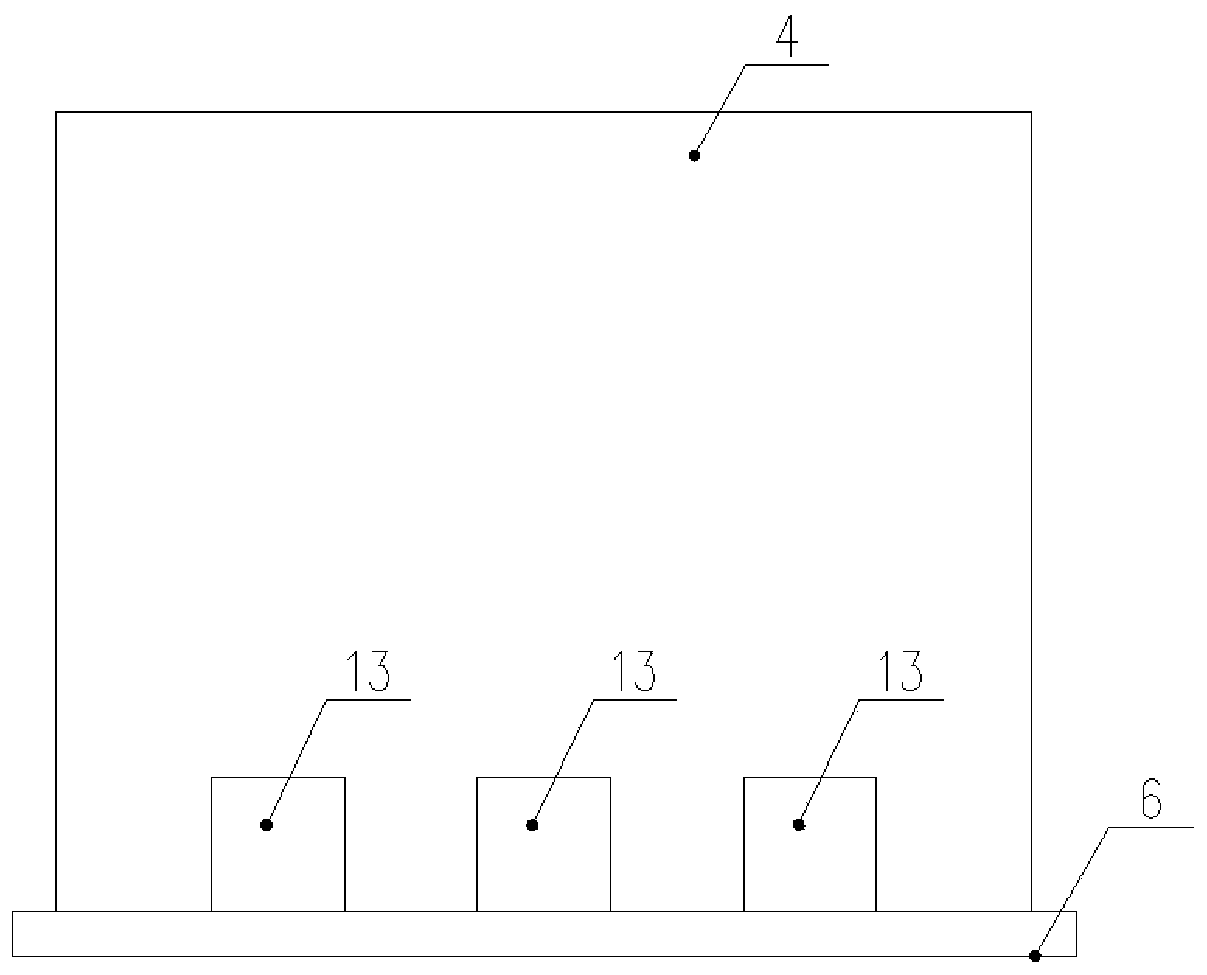

High-density fish and vegetable co-existing system

ActiveCN104585108AEasy to collectSimple structureClimate change adaptationAgricultural fishingOperational costsDecomposition

The invention discloses a high-density fish and vegetable co-existing system which comprises fish tanks, a planting system and a water storage tank, wherein the planting system comprises hydroponic vegetable breeding grooves and river stone breeding beds; the fish tanks are connected with flow diversion tanks and a solid sewage separation tank; the solid sewage separation tank is connected with a bacterial sewage decomposition tank; the bacterial sewage decomposition tank is connected with the water storage tank; the water storage tank is connected with the flow diversion tanks through a water pump; the flow diversion tanks are connected with the planting system; the other end of the planting system is connected with the water storage tank through a pipeline. A fish breeding system is adopted for generating nutritional water, and the nutritional water is diverted into the planting system through the flow diversion tanks and provides normal nutrition for plant growth; large-scale high-density production can be realized and the efficiency is high; water subjected to multiple purification is relatively good in quality; breeding and planting system structures are independent; the co-existing system is simple in structure and convenient to manage and maintain; the breeding system is low in operation cost, low in energy consumption and environment-friendly; the co-existing system has the characteristics of simple structure, stability and convenience for mounting, maintenance and operation; diversity of culture of leaf vegetables and melon and fruit vegetables can be realized.

Owner:姚力元

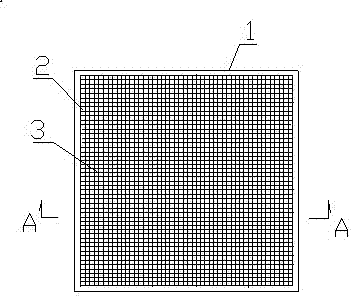

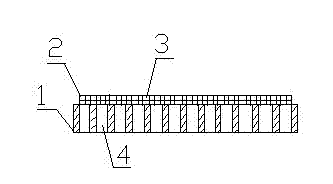

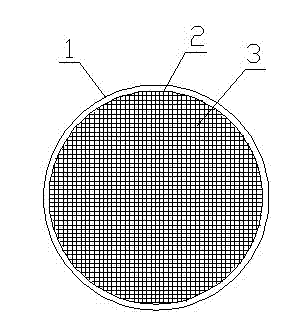

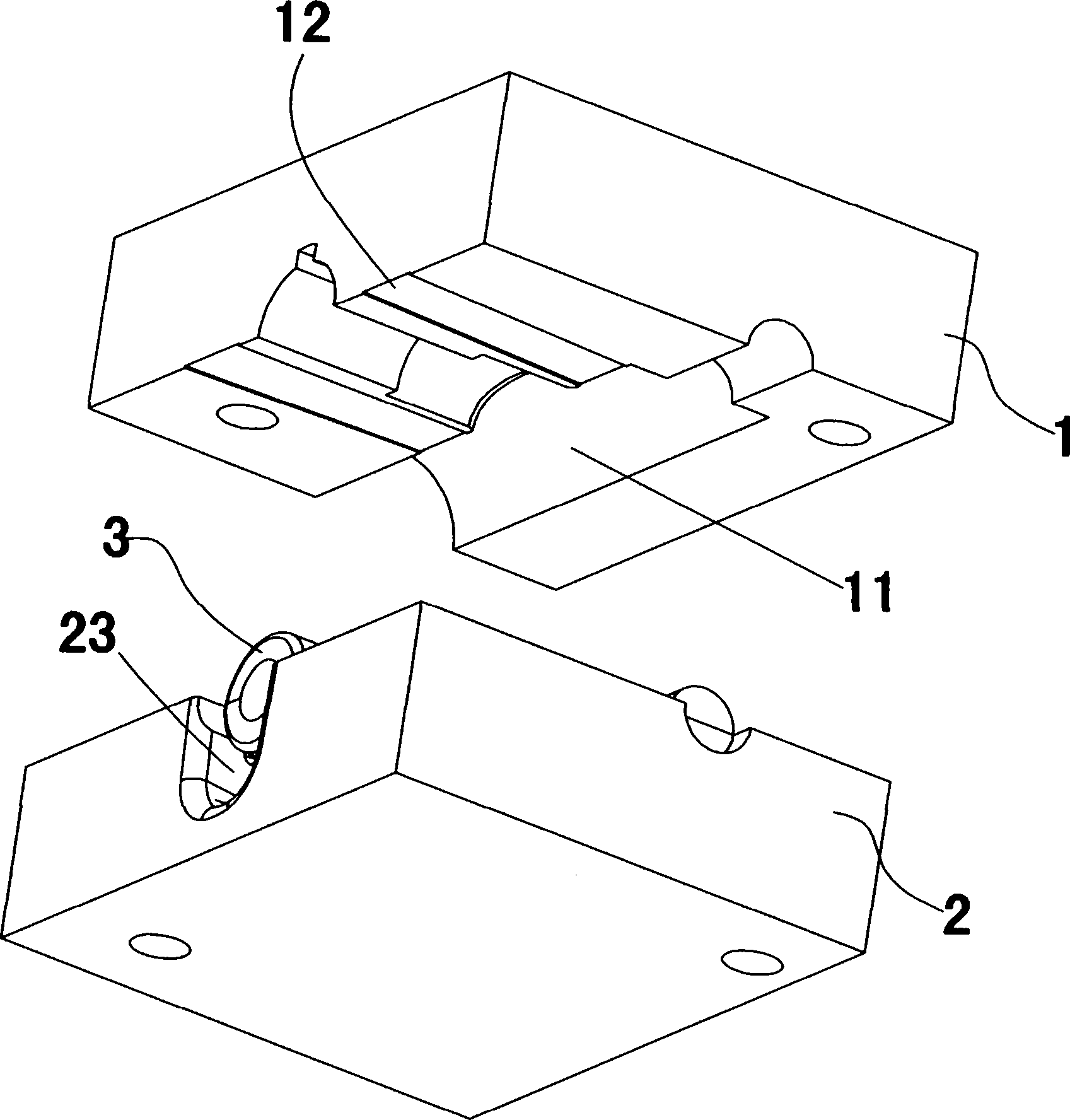

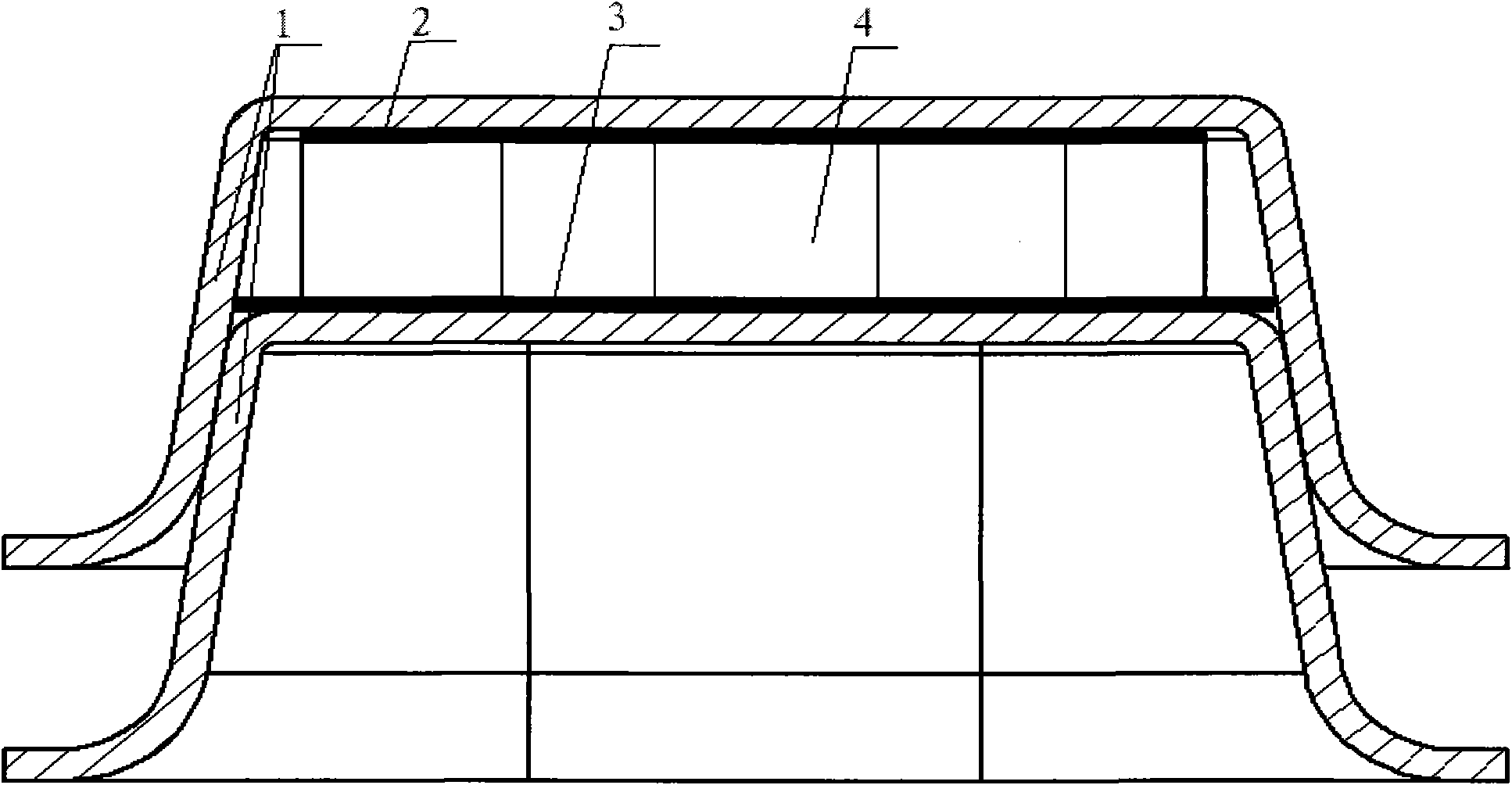

Multilayer casting filter

ActiveCN102350134AShort flow distanceLow flow resistanceFiltration separationPore diameterHoneycomb like

The invention discloses a multilayer casting filter, comprising a support layer (1) made of a ceramic material and a filtering layer (2) made of a ceramic material and arranged on the support layer. The filtering layer contains alveolate filtering holes (3); the support layer contains grid liquid flow holes (4); a hole density of the filtering layer is larger than that of the support layer; an aperture of a filtering hole is smaller than that of a liquid flow hole; a porosity of the support layer is larger than that of the filtering layer (2); and a thickness of the filtering layer is smaller than that of the support layer. The invention can simplify a pouring system, increase produce rate of a cast technology, reduce cast costs, enhance flow velocity and continuity of pouring, facilitate cast mold filling, improve high temperature impact resistance and high temperature bearing capacity of the filter, ensure integrity of the filter in the whole pouring process, facilitate filtering purification of metal liquid and improve inner quality and comprehensive performances of a cast product, and is suitable for pouring of multiple-part mold and large and medium size cast.

Owner:JIANGXI BAOAN NEW MATERIAL TECH

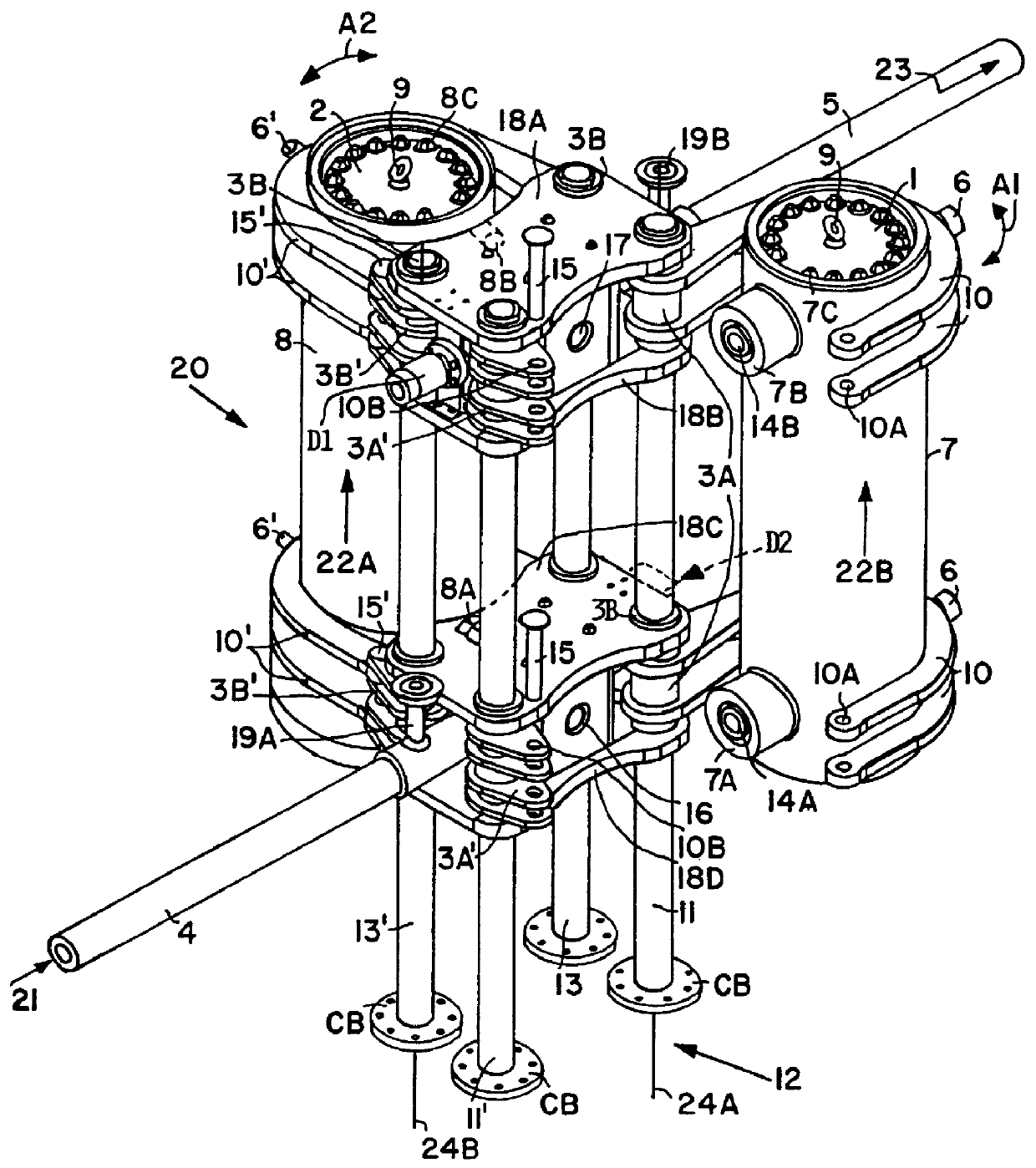

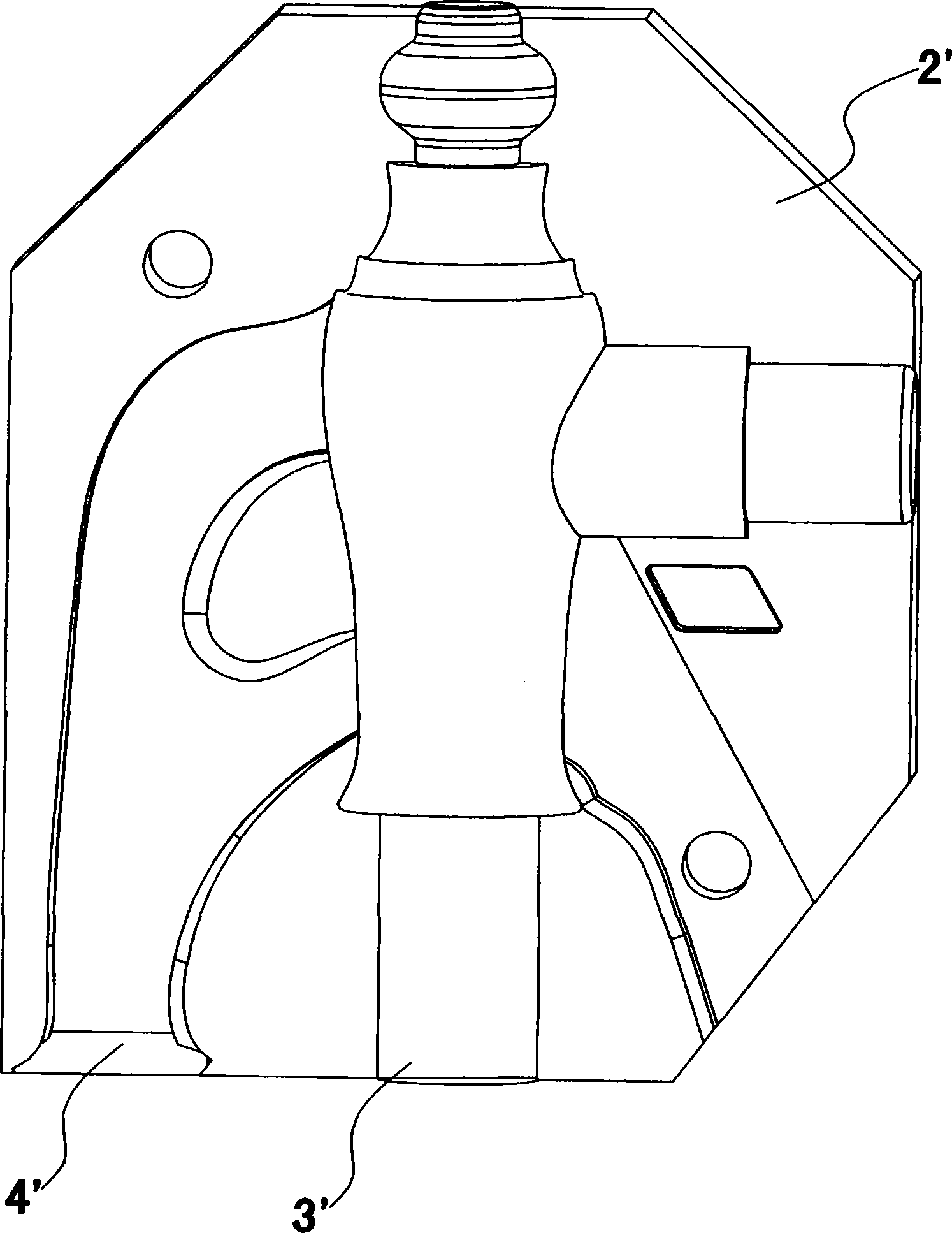

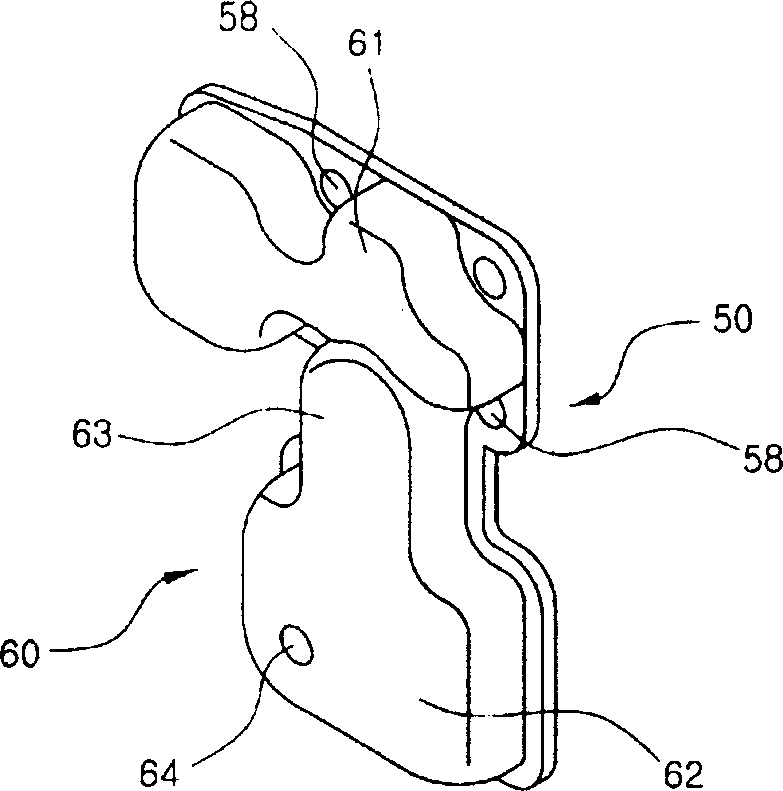

Parallel filters for plastic melts

InactiveUS6117320AEasy accessAvoid insufficient lengthSettling tanks feed/dischargeLoose filtering material filtersWaste managementHinge angle

A filter for filtering plastic melt prior to feeding the melt into an extruder nozzle, for example a thermoplastic film extruder nozzle, has preferably two filter housings for holding respective exchangeable filter cartridges. Both filter housings are articulated by hinges to a column mounting so that one filter housing can be serviced while the other filter housing with its filter cartridge is in a filtering position and vice versa. A single filter may be used alternatively. In both instances the column mounting may include at least one, preferably two, mounting columns.

Owner:LINDAUER DORNIER GMBH

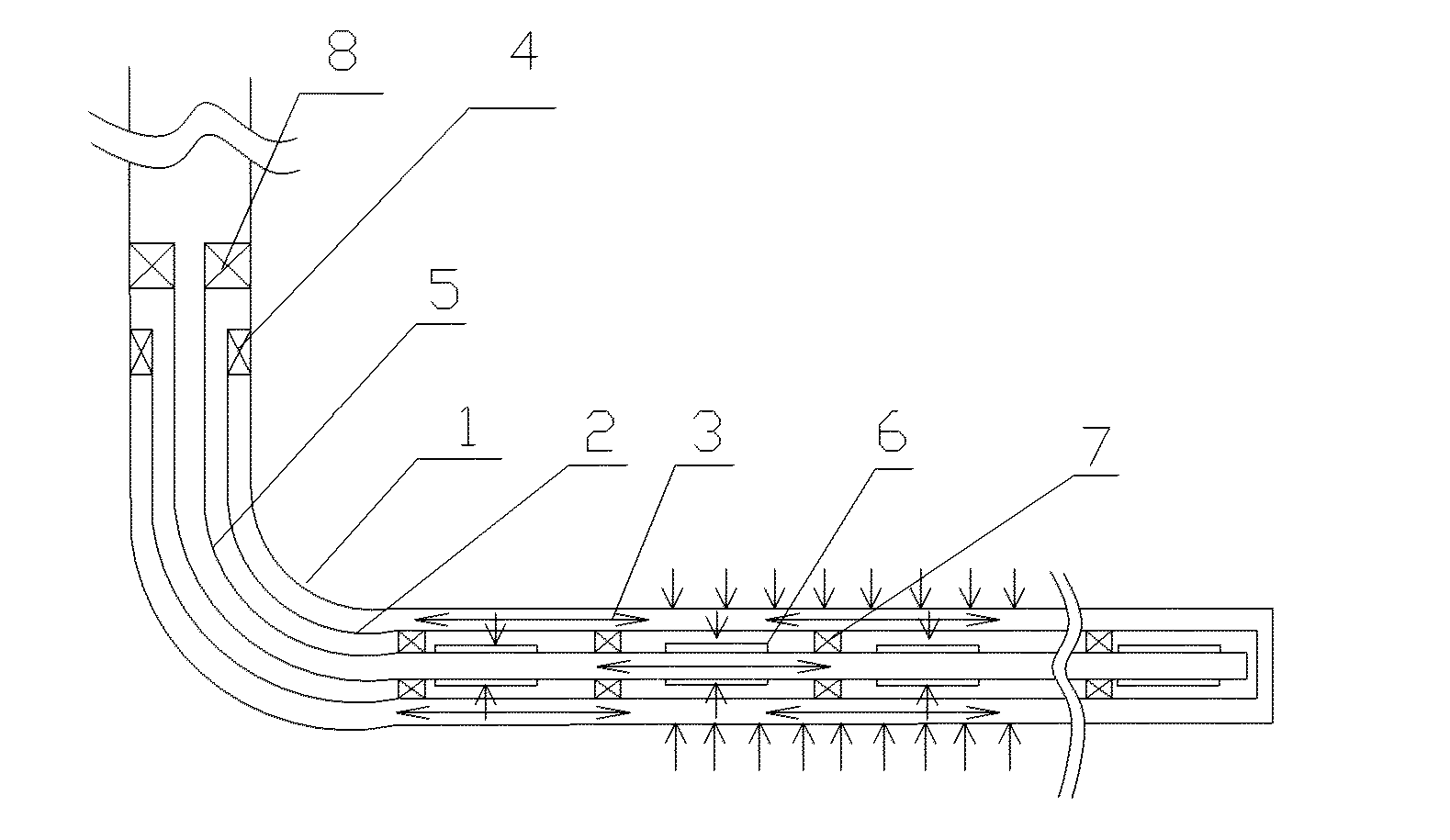

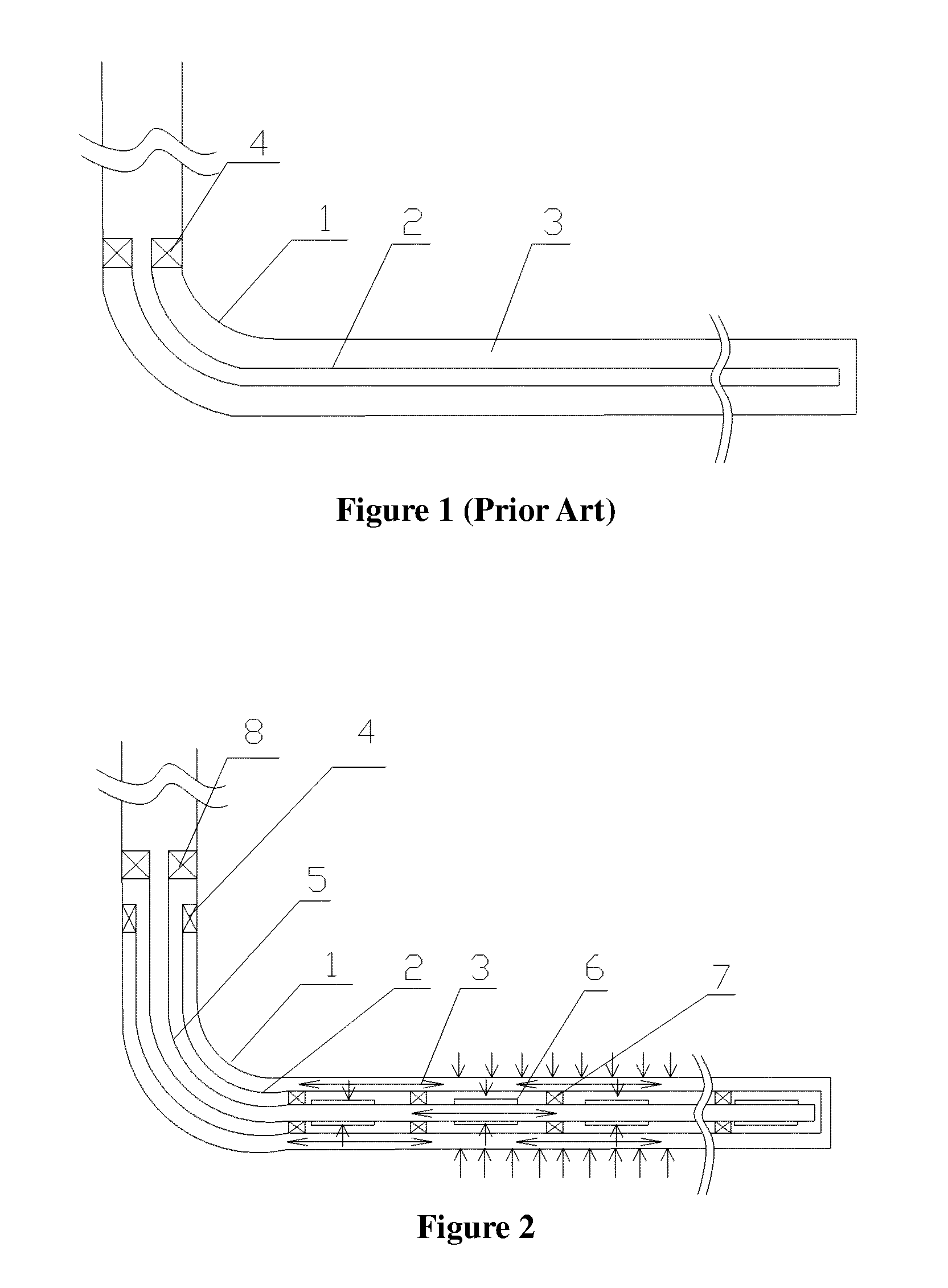

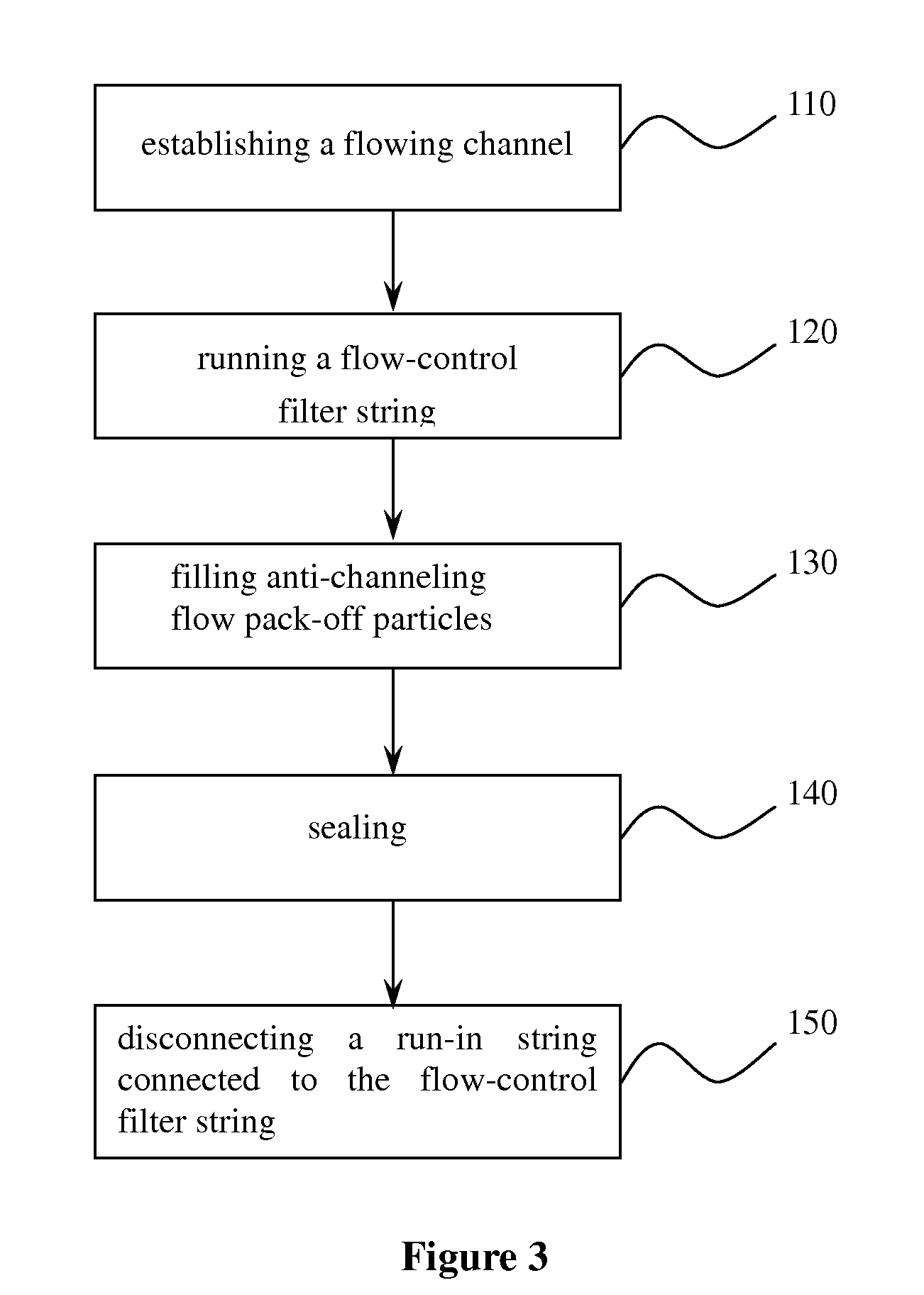

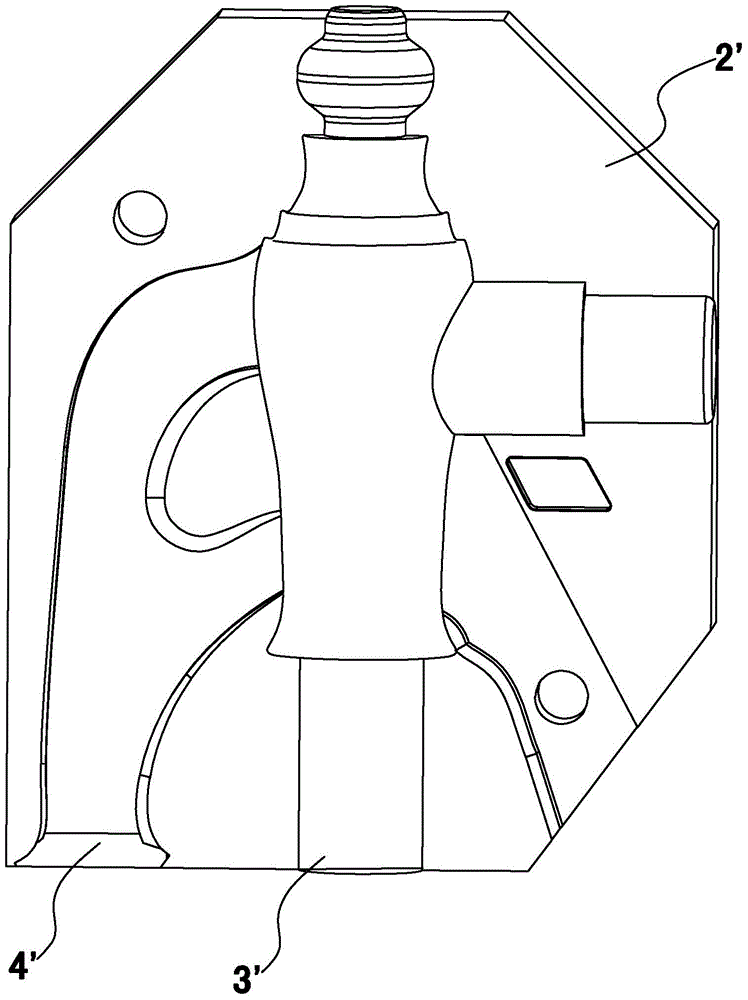

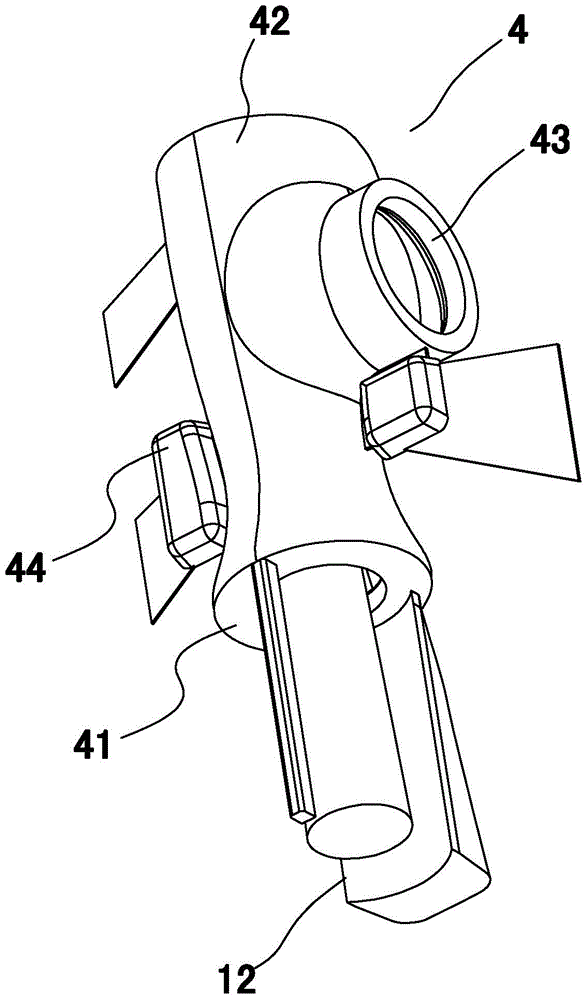

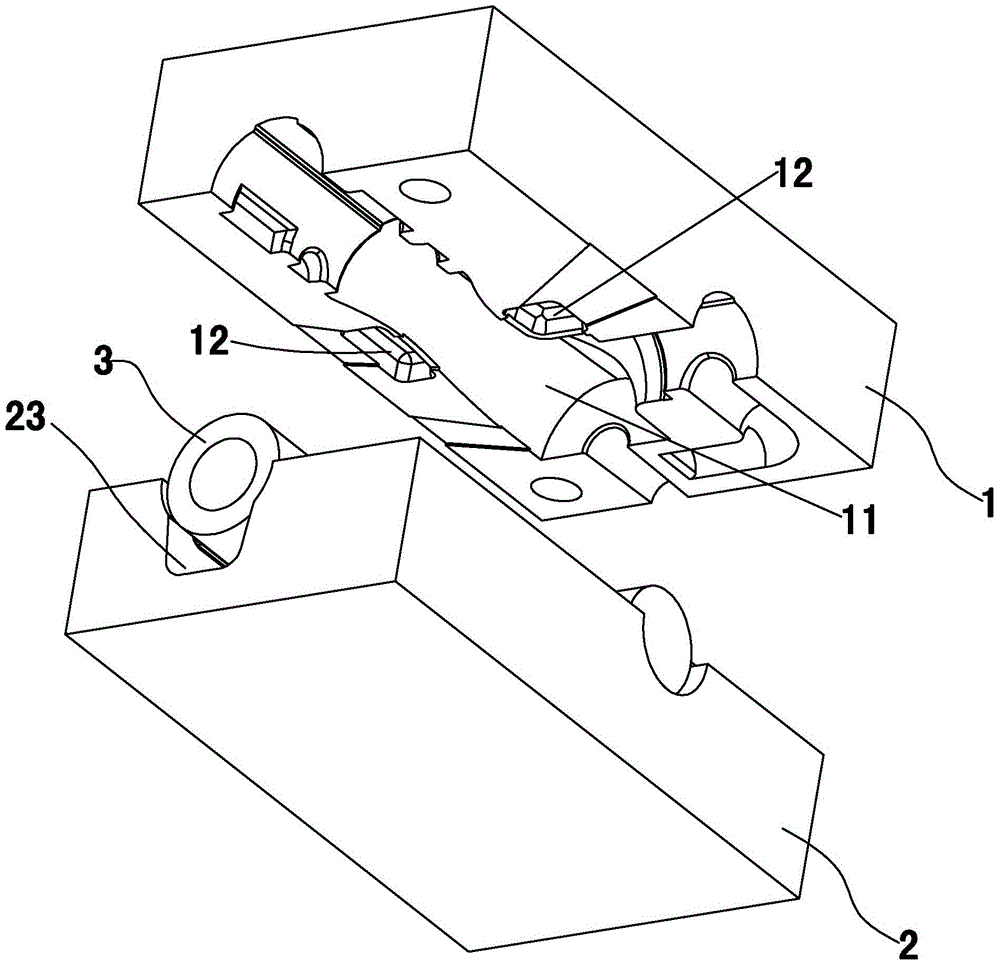

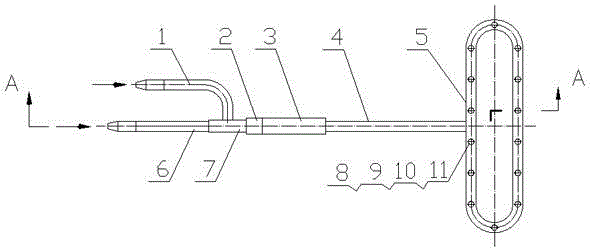

Segmented current controlling method of current controlling filter pipe column for oil-gas well and structure of oil-gas well

ActiveUS20120273196A1Facilitating segmental managementGood effect to productionFluid removalDrinking water installationEngineeringParticulate flow

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Gravity casting process of lead-free brass tap

The invention provides a gravity casting process of a lead-free brass tap, which has the advantages that a flowing distance of a product in a casting process is short, the simultaneous solidification is achieved, hot cracks are reduced; a heat balance effect of a mould is good, so that heat balance of the product is facilitated, and the stress micro-cracks during cooling are reduced. The gravity casting process of the lead-free brass tap comprises the following step of casting and forming lead-free brass liquid through a gravity casting device, wherein the gravity casting device comprises an upper half mould, a lower half mould and a sand core, wherein mould cavities matched with a tap body in shape are respectively and correspondingly arranged between the upper half mould and the lower half mould, the sand core is arranged in the mould cavities between the upper half mould and the lower half mould, the shape of the sand core is matched with the shapes of a water inlet part and a water outlet part of the tap and an inner cavity of an installing part of a valve core, a casting cavity is formed between the sand core and the mould cavity, a sprue in which lead-free molten copper is cast is arranged in the lower half mould, the sprue is connected with the casting cavity, the sprue is provided with an internal sprue and an external sprue, and the internal sprue is correspondingly arranged at the casting cavity for forming the water inlet part of the tap body.

Owner:LONGYAN HONGHANG SANITARY WARE CO LTD

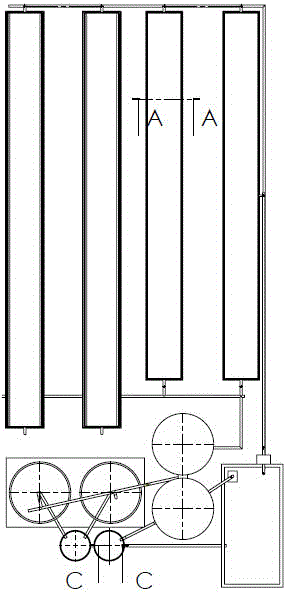

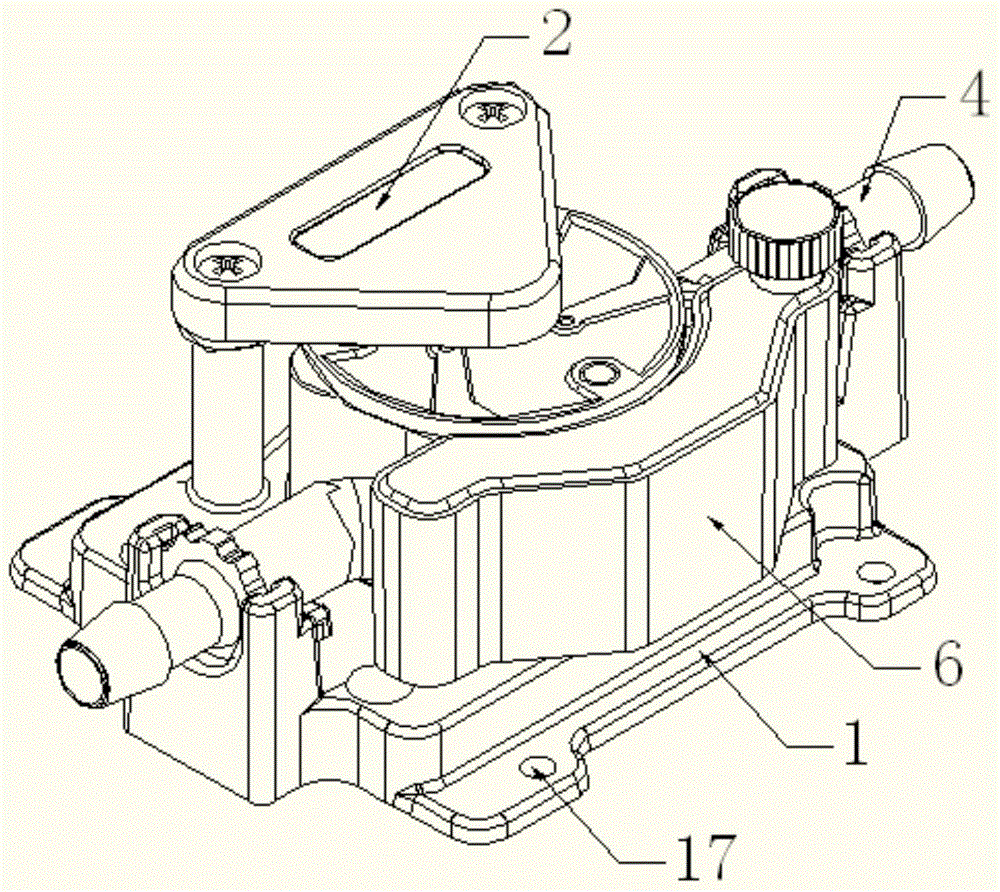

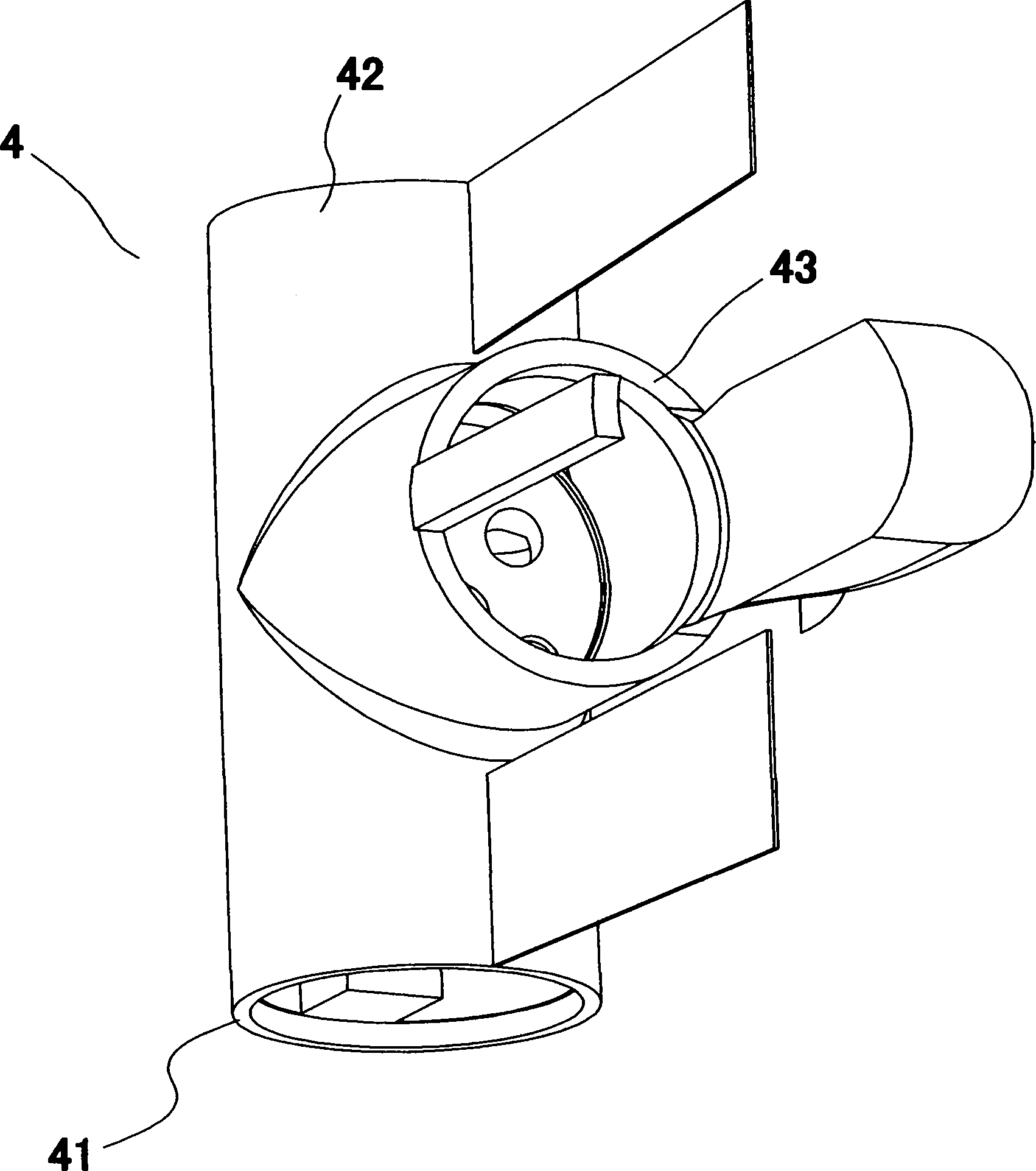

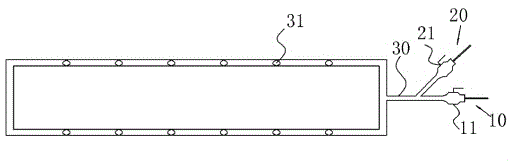

Linear type fast-assembling peristaltic pump assembly

InactiveCN105697343ASave installation spaceShort flow distancePositive displacement pump componentsFlexible member pumpsPeristaltic pumpInterference fit

The invention discloses a linear type fast-assembling peristaltic pump assembly. The linear type fast-assembling peristaltic pump assembly comprises a base, an extrusion roller assembly fixed to the base, and an upper support covering the extrusion roller assembly. Mounting grooves are fixed to the left and right edges of the base correspondingly, hoses with connectors are mounted in the mounting grooves, and the inner side faces of the hoses are in interference fit with the extrusion face of the extrusion roller assembly. The two ends of each hose are located on the same straight line. A locating column is further fixed to the base and rotatably connected to one end of a pressing block, and the other end of the pressing block is fixedly connected with the base through a hand screw. The hoses are covered by the pressing block, and the inner side wall of the pressing block makes contact with the outer walls of the hoses. The linear type fast-assembling peristaltic pump assembly has the remarkable effects that an inlet and an outlet of each hose are located on the same straight line, multiple special requirements can be met, a mounting space of a user is saved, the flowing distance is reduced, and the staying time is shortened; operation is simple, convenient and quick.

Owner:CHONGQING JIEHENG PERISTALTIC PUMP

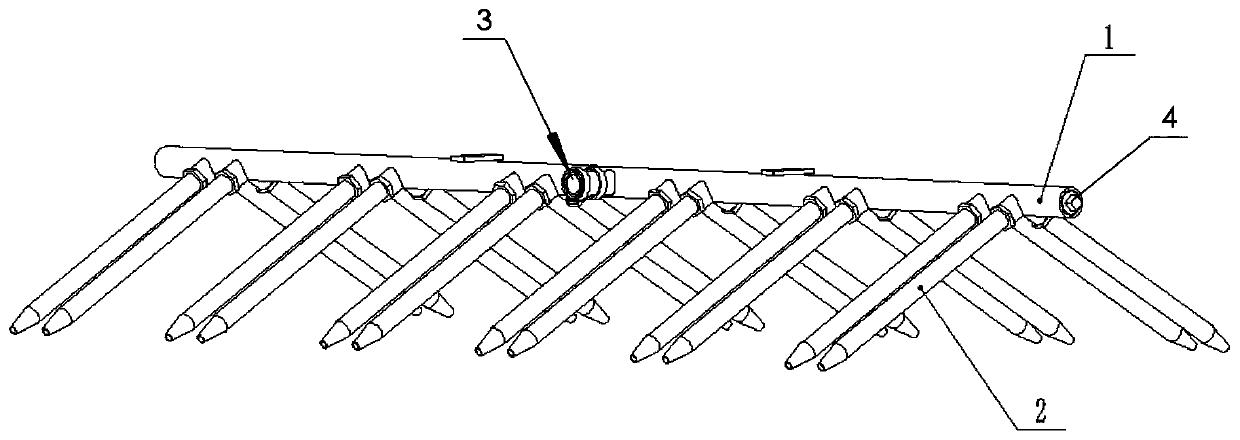

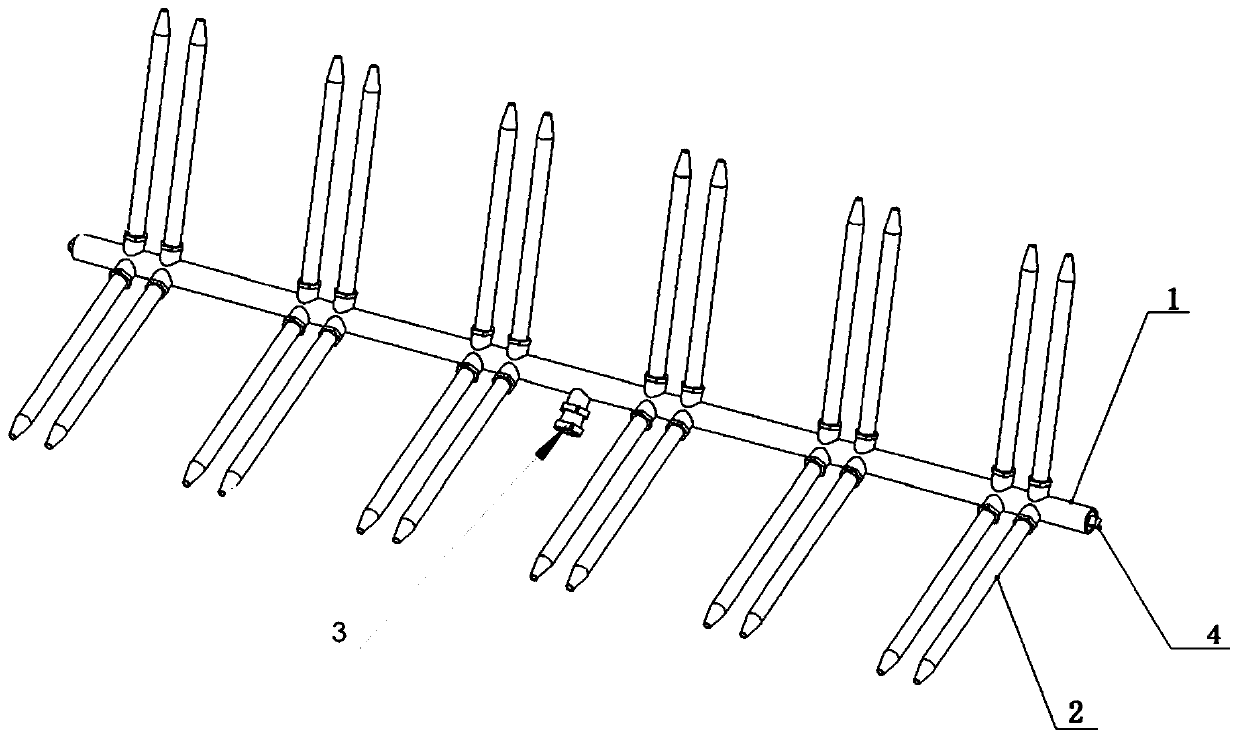

Pouring sand mould of arc needles for pasture collection machinery and pouring method

PendingCN109261896AReduce thicknessReduce sand ratioFoundry mouldsFoundry coresPastureMaterials science

The invention provides a pouring sand mould of arc needles for pasture collection machinery and a pouring method. The pouring sand mould includes an upper shell body, a lower shell body and core assemblies; the upper shell body is of an arc structure, and a first straight pouring gate is formed in the arc structure and is communicated with a pouring cup for storing pouring liquid; the lower shellbody is of an arc structure matched with the upper shell body, and a second main pouring gate penetrating through the upper and lower ends of the lower shell body is formed in the portion, corresponding to the first straight pouring gate, of the lower shell body; after the upper shell body and the lower shell body are buckled, at least one first mould cavity is formed, the mould cavities are in arc shapes, the first straight pouring gate and the second straight pouring gate are both communicated with the mould cavities, and after the mould cavities are subjected to pouring, arc needle castingsare formed; the core assemblies are arranged inside the mould cavities and are used for assisting the mould cavities in forming the arc needle castings. According to the pouring sand mould of the arcneedles for the pasture collection machinery and the pouring method, the sand mould is changed into a shell type from an overlapping type; an allowance gate is additionally formed, during pouring, sand consumption is reduced, and the finished product rate is increased.

Owner:西安合力汽车配件有限公司

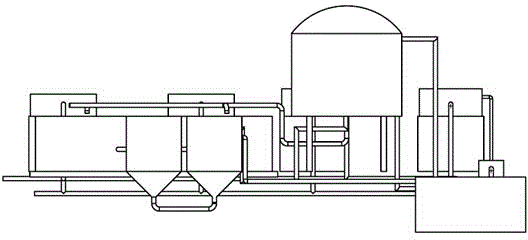

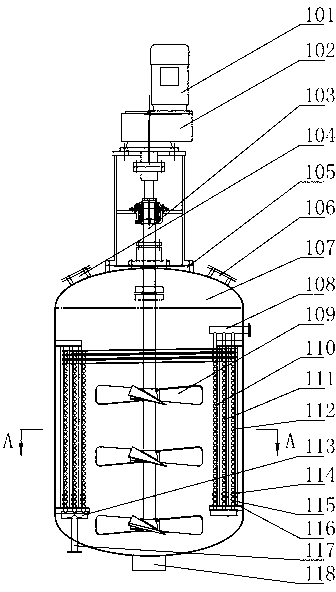

Multifunctional heat exchanging device of crystallizing kettle

The invention relates to a multifunctional heat exchanging device of a crystalizing kettle. The device comprises a container, wherein a transmission device is mounted at the top of the container through a base; the transmission device comprises a motor and a speed reducer; a rotating shaft is mounted at an output end of the speed reducer; the rotating shaft extends into the container; blades are mounted on the rotating shaft located in the container; a feed port and an observation hole are formed at the top of the container, and a material outlet is formed at the bottom of the container; an upper connecting pipe and a lower connecting pipe are arranged at an interval in the vertical direction in the container; a hot water outlet is formed at the top of the upper connecting pipe, and a cooling water inlet is formed at the lower part of the lower connecting pipe; a first oblique base pipe and a second oblique base pipe are uniformly arranged at an interval on the circumferential faces of the bottom of the upper connecting pipe and the upper part of the lower connecting pipe; and a plurality of cooling pipes are mounted in parallel at intervals in the vertical direction between the first oblique base pipe and the second oblique base pipe. The multifunctional heat exchanging device has the advantages of high reaction speed and high production efficiency.

Owner:无锡市华立石化工程有限公司

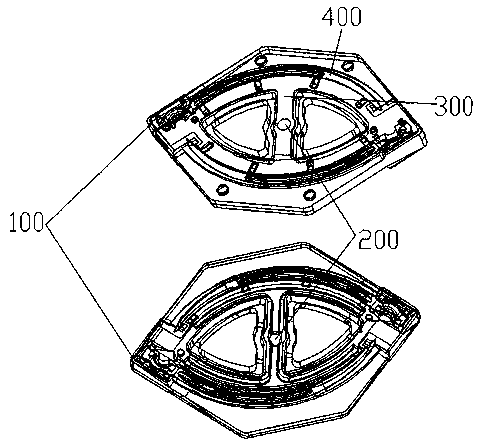

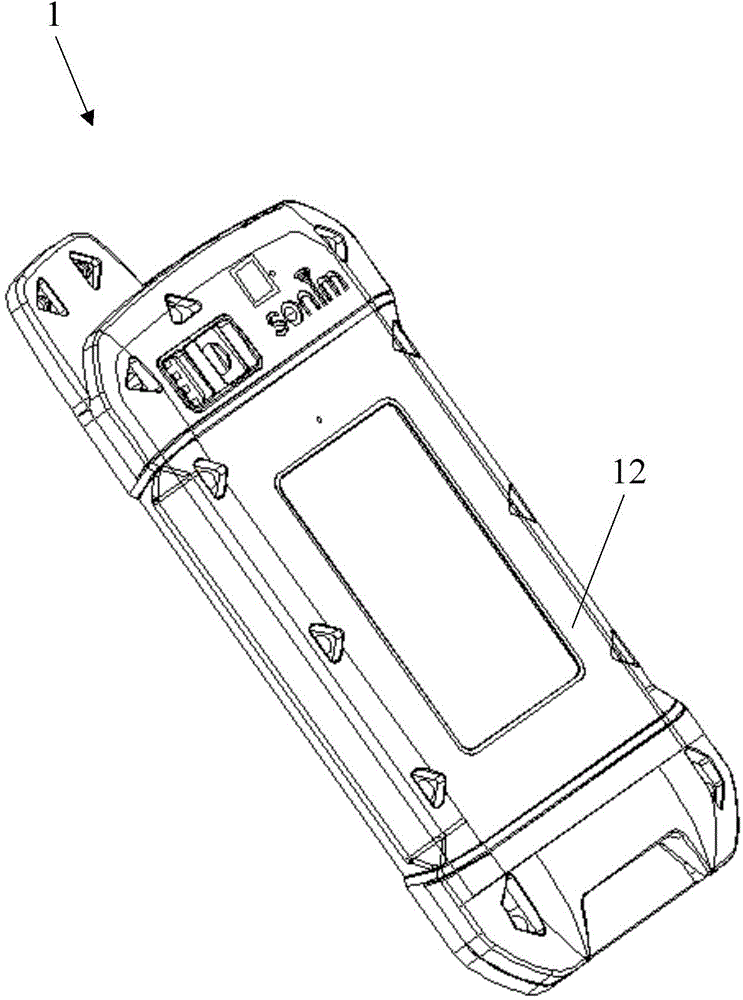

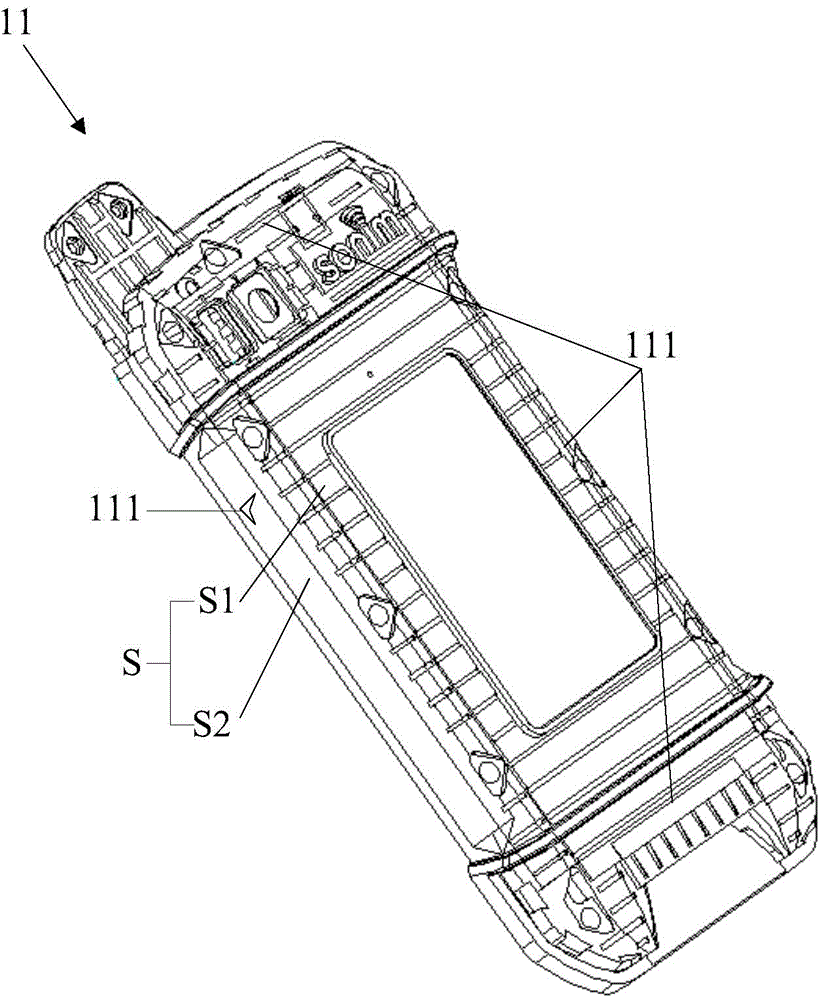

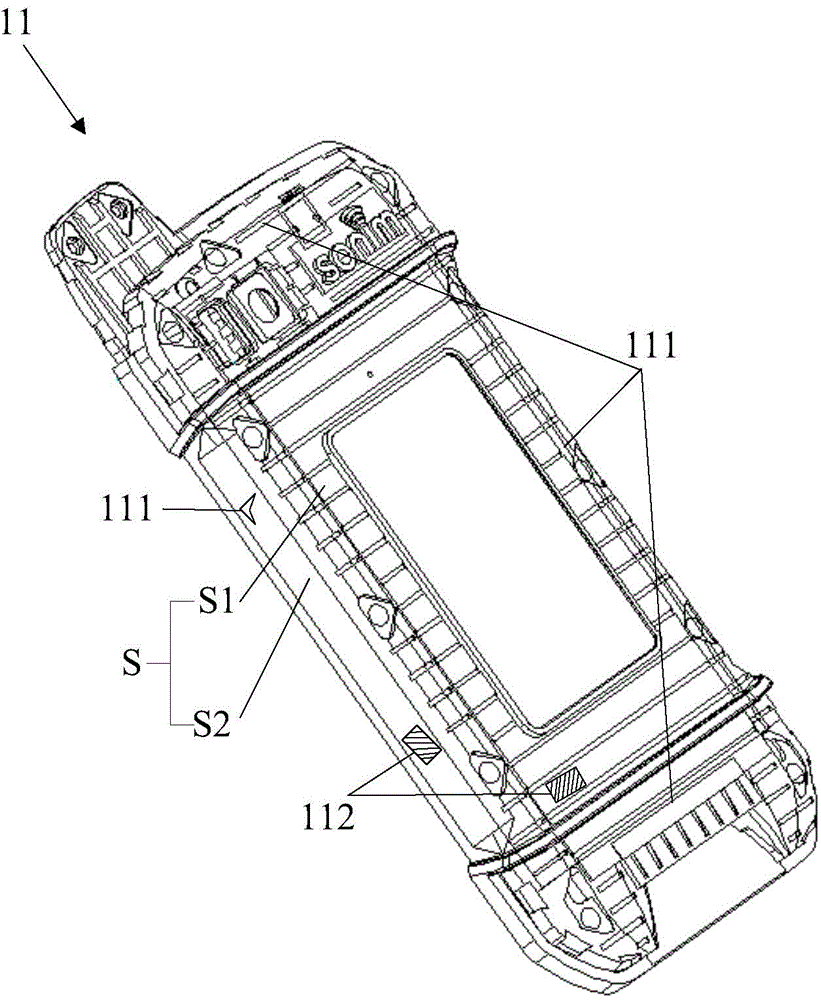

Double-shot injection moulding shell and injection mold

InactiveCN105984076AImprove bindingIncrease binding areaTelephone set constructionsEngineeringInjection moulding

The invention relates to structural design of a shell and discloses a double-shot injection moulding shell and an injection mold. The double-shot injection moulding shell comprises a first plastic layer and a second plastic layer combined with each other, wherein a first combining surface of the first plastic layer is provided with at least one first convex block; a second combining surface of the second plastic layer is provided with a first concave groove corresponding to the first convex block; the first plastic layer and the second plastic layer are combined through the first combining surface and the second combining surface; the first convex block is tightly embedded in the first concave groove. Therefore, the combining area of the two plastic layers of the double-shot injection moulding shell is increased to enable the combination of the two plastic layers to be firmer and prevent the two plastic layers from stripping.

Owner:SHANGHAI SIMCOM LTD

Casting technology for lead-free brass tap

ActiveCN104259393AGuaranteed thermal balanceSimple structureFoundry mouldsFoundry coresHeat balanceMaterials science

The invention provides a casting technology for a lead-free brass tap, which the advantages that the flowing distance of products in the pouring process is short, simultaneous solidification is realized, and hot cracks are reduced; the die has excellent heat balance effect, is favorable to the heat balance of the products and reduces stress micro-cracks during cooling. The casting technology comprises the step of casting-molding lead-free brass fluid through a gravity casting device, wherein the gravity casting device comprises an upper half die, a lower half die and a sand core, die cavities fitted with the shape of a tap body are respectively correspondingly arranged between the upper half die and the lower half die, the sand core is arranged in the die cavities between the upper half die and the lower half die, the shape of the sand core is matched with the shape of a water-in part, a water-out part and an inner cavity of a valve core mounting part of the tap body, pouring cavities are formed between the sand core and the die cavities, a gate for allowing lead-free melt copper to be poured is further formed in the upper half die or the lower half die, the gate is connected with the pouring cavities, the gate is provided with an inner gate and an outer gate, and the inner gate is correspondingly arranged at the pouring cavity part for molding the valve core mounting part of the tap body.

Owner:GUANGDONG WEIXIANG SANITARY WARE

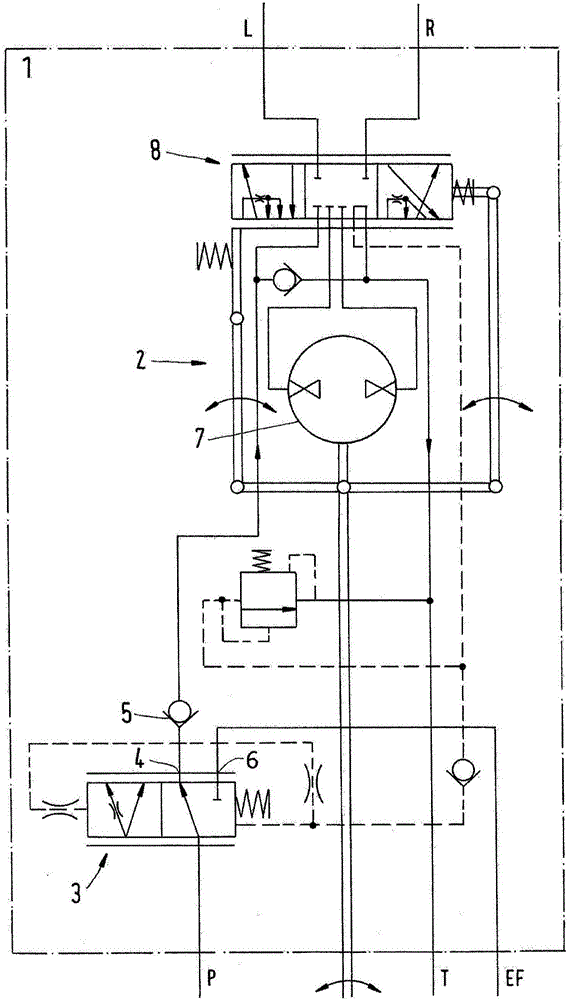

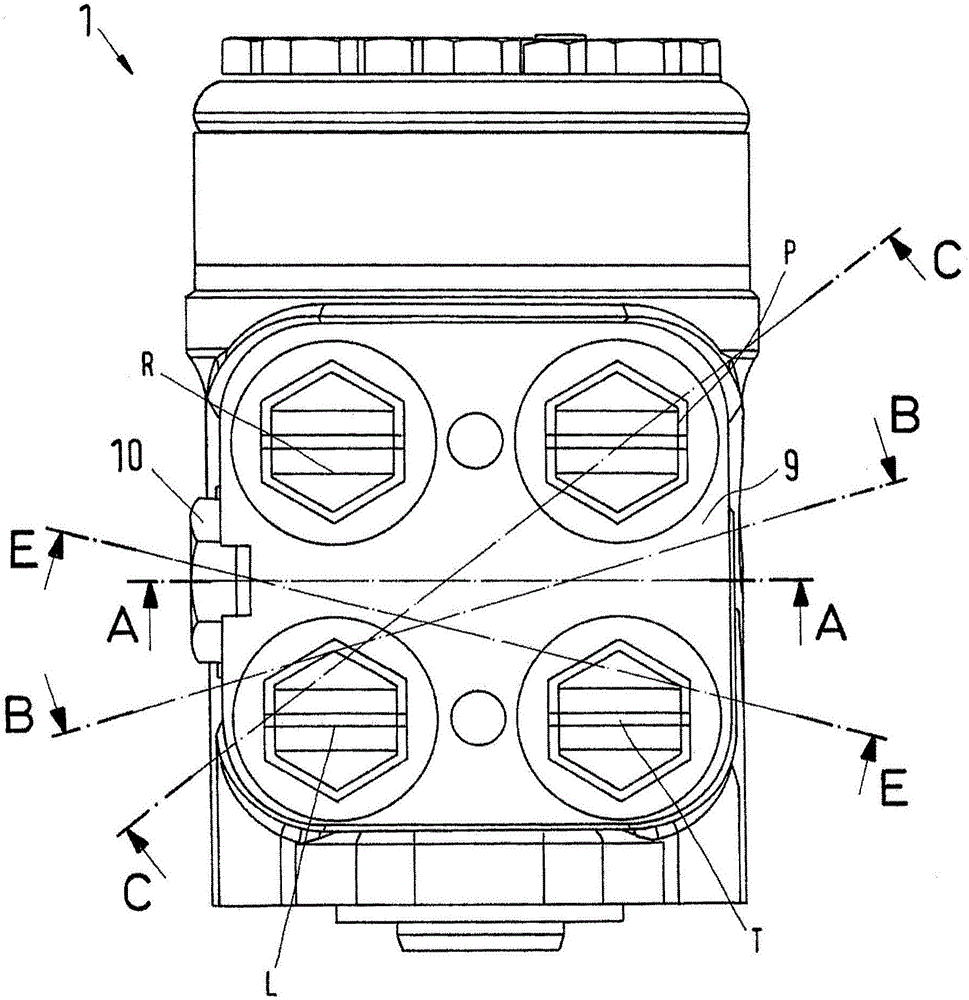

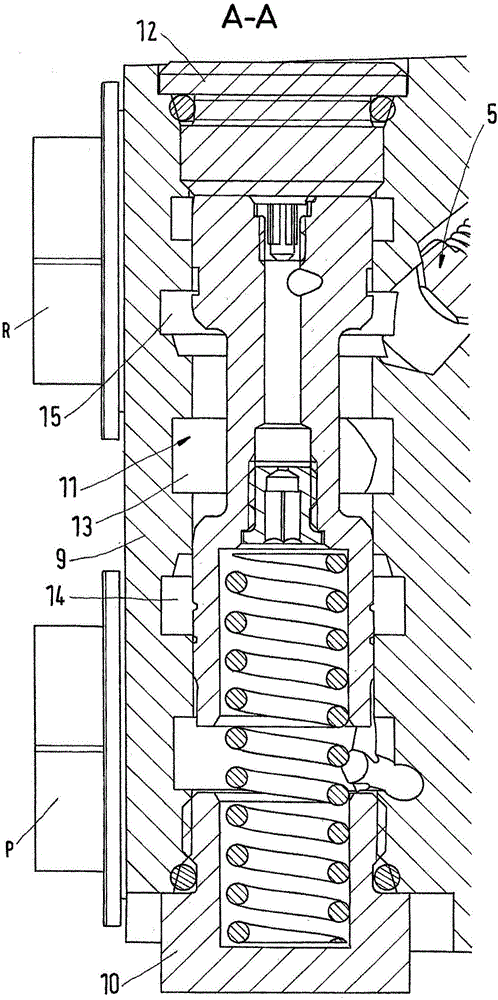

Hydraulic steering

The invention relates to a hydraulic steering (1) comprising a hydraulic steering unit (2) and a priority valve (3). The hydraulic steering unit (2) and the priority valve (3) are arranged in a common housing (9). The hydraulic steering (1) comprises a hydraulic pressure supply port (P), a low pressure port (T), two steering connection ports (L, R) and an excess flow port (EF) to supply an external implement. The priority valve (3) distributes hydraulic fluid from the hydraulic pressure supply port (P) between the hydraulic steering unit (2) and the excess flow port (EF). The task of the invention is to provide a more compact hydraulic steering. To this end the hydraulic pressure supply port (P), the low pressure port (T) and the two steering connection ports (L, R) all enter on the same side of the housing (9), and the priority valve (3) is arranged adjacent to the four ports hydraulic pressure supply port (P), the low pressure port (T) and the two steering connection ports (L, R) with two of the four ports (P, T, L, R) on either side of the priority valve (3).

Owner:丹佛斯动力系统有限公司

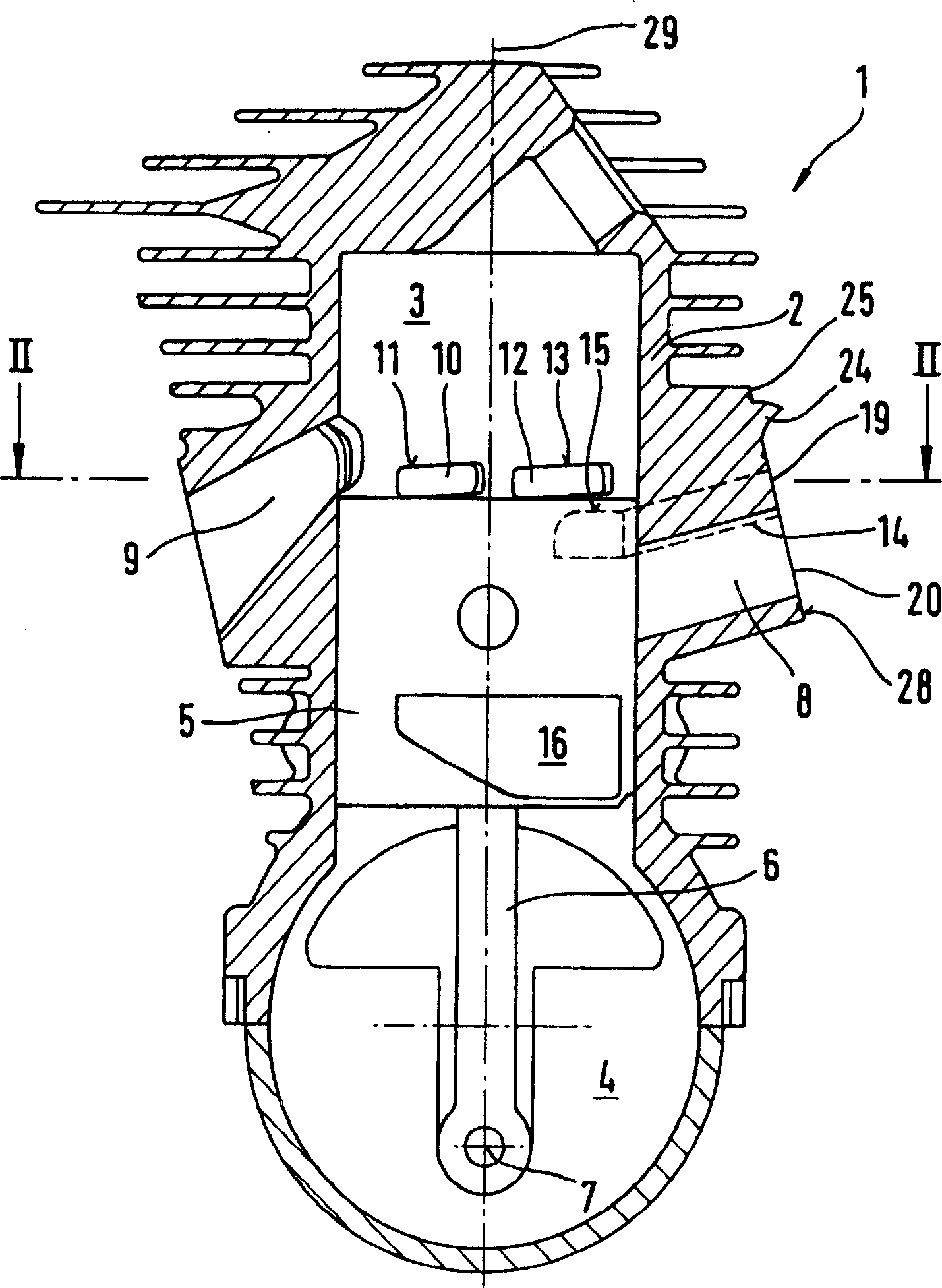

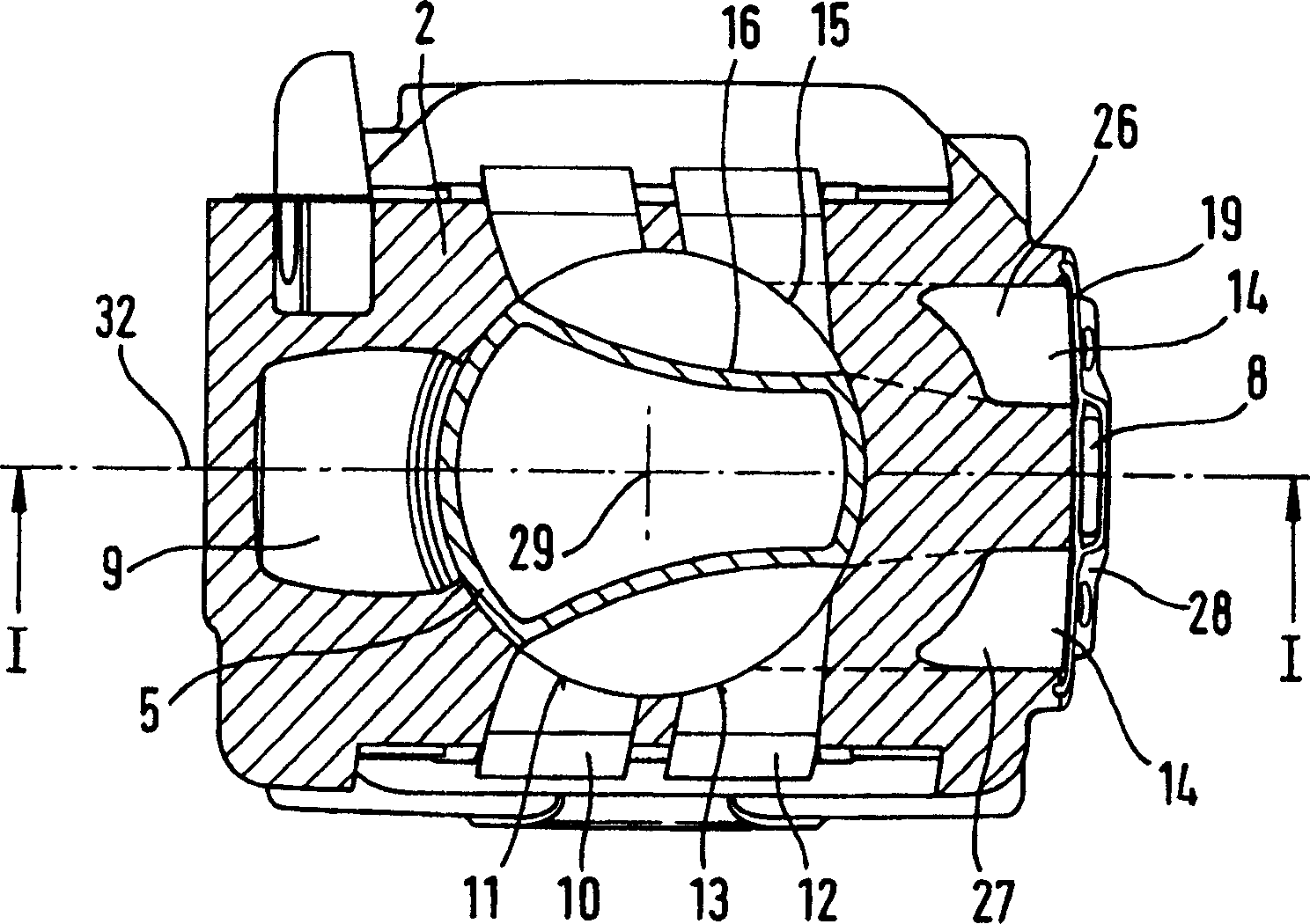

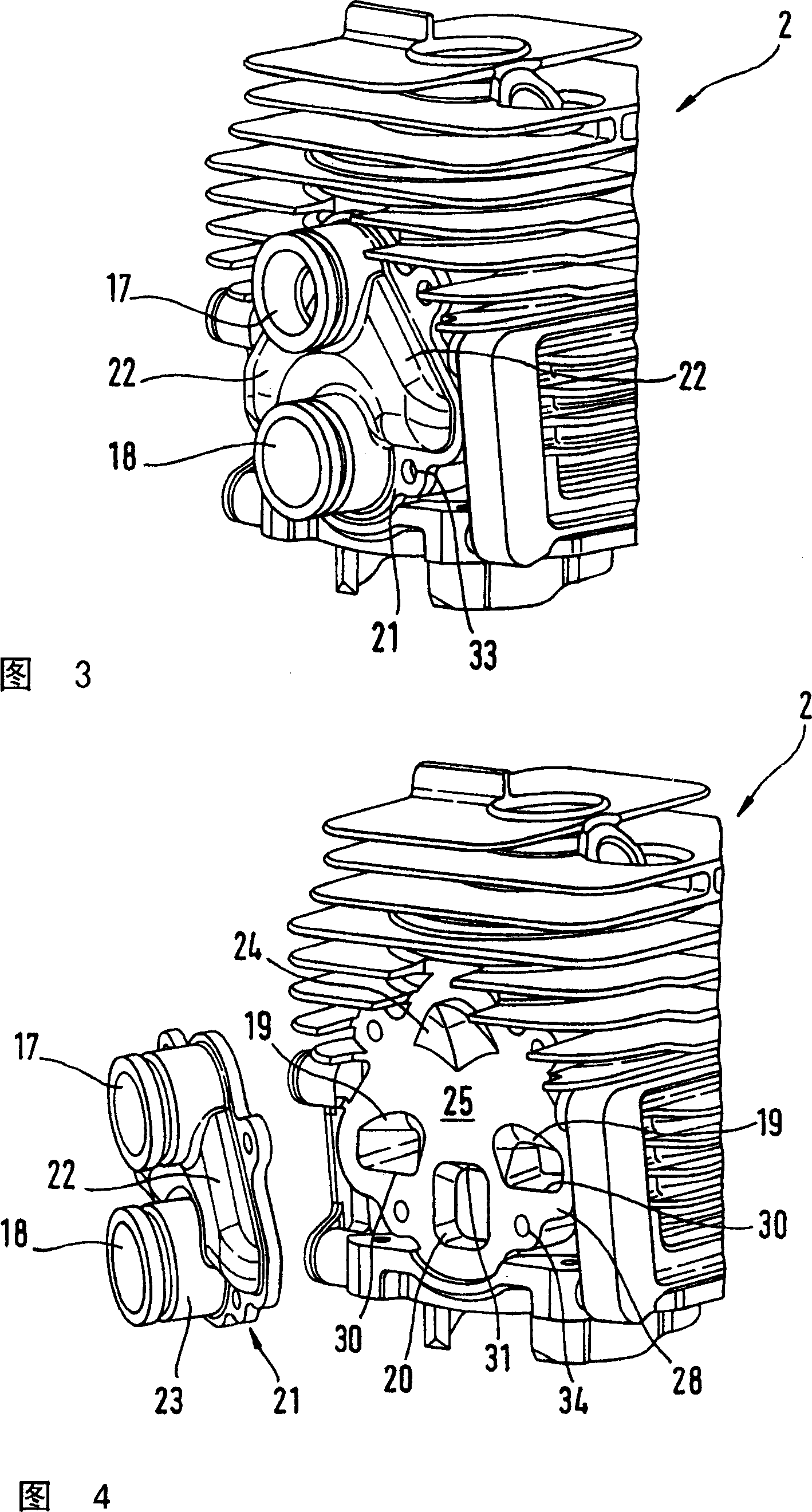

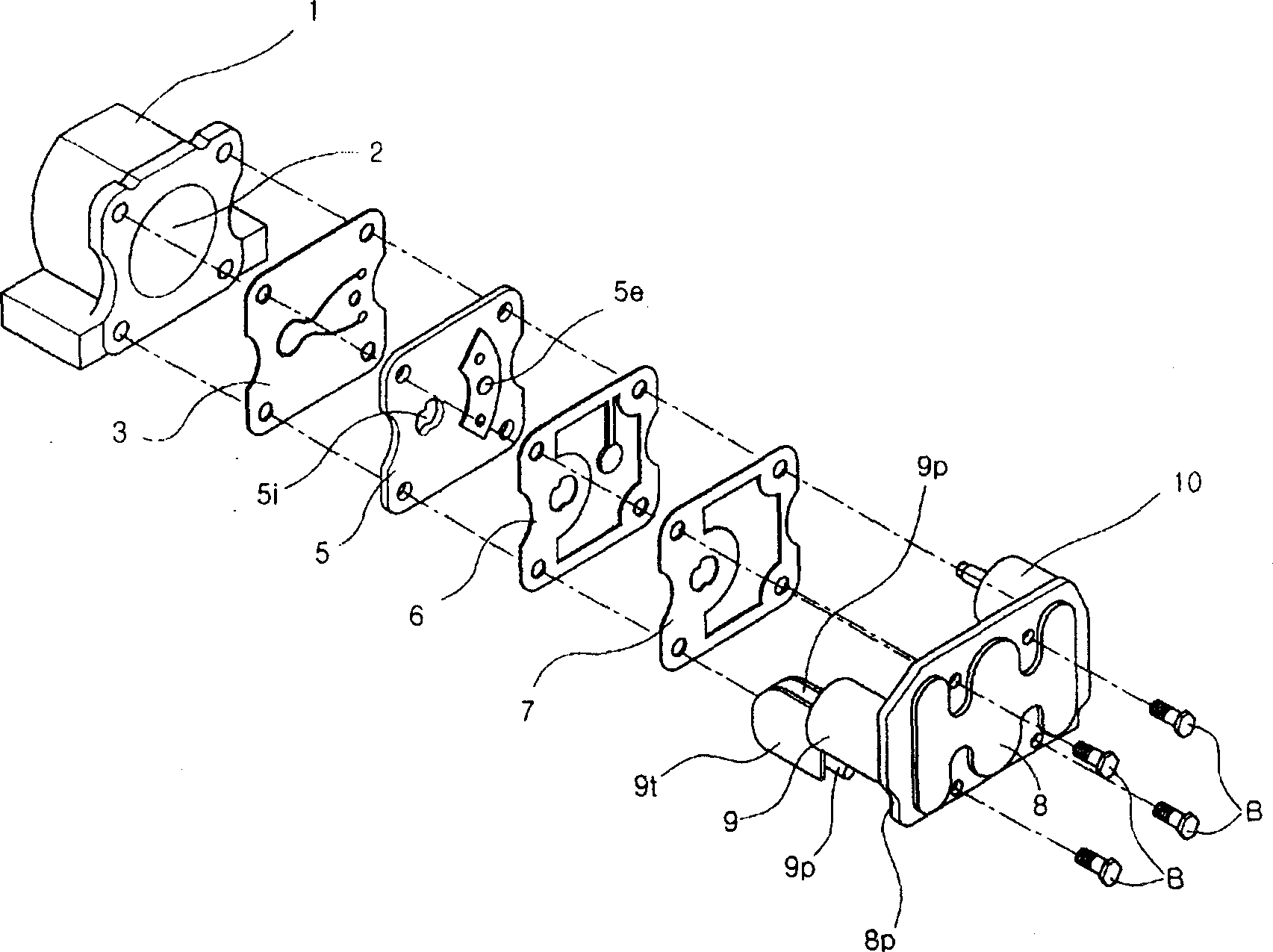

Two stroke engine

ActiveCN1534174ASmall structure sizeLow flow resistanceCylinder headsCombustion enginesFour-stroke engineEngineering

A two-cycle engine is provided and includes a cylinder in which is formed a combustion chamber delimited by a reciprocating piston that via a connecting rod drives a crankshaft rotatably mounted in a crankcase that, in predetermined positions of the piston, communicates with the combustion chamber via transfer channels. The cylinder has an outlet from the combustion chamber. An intake duct leads into the crankcase for a supply of fuel, and an air duct supplies substantially fuel-free air. In the vicinity of the piston the air duct is divided into two branches that open out at air openings of a connecting flange formed on the cylinder. A cover is disposed on the connecting flange and extends over the air openings. A flow divider on the connecting flange projects beyond a plane thereof and into the cover. The flow divider divides an air flow in the air duct to the two branches.

Owner:ANDREAS STIHL AG & CO KG

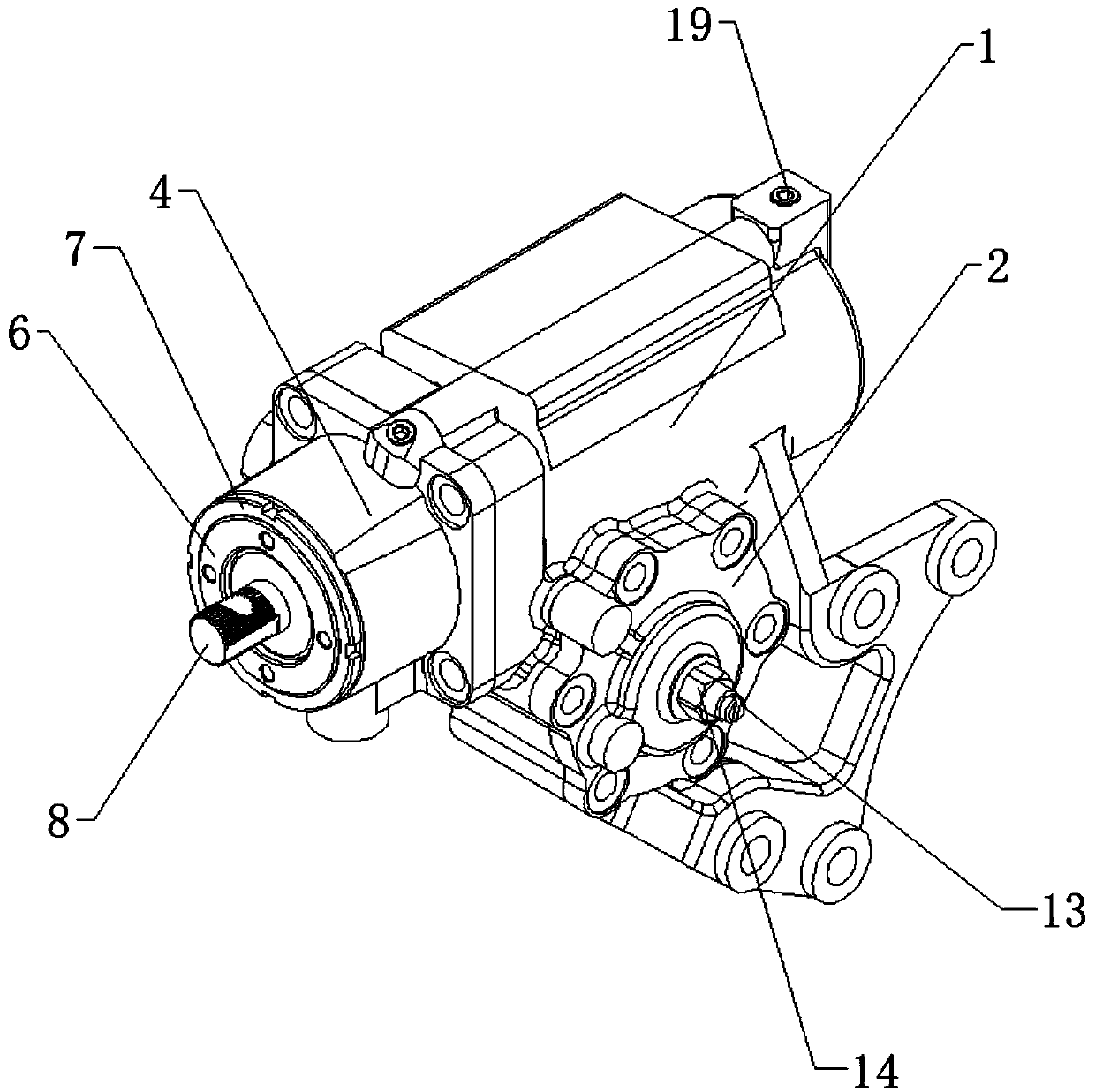

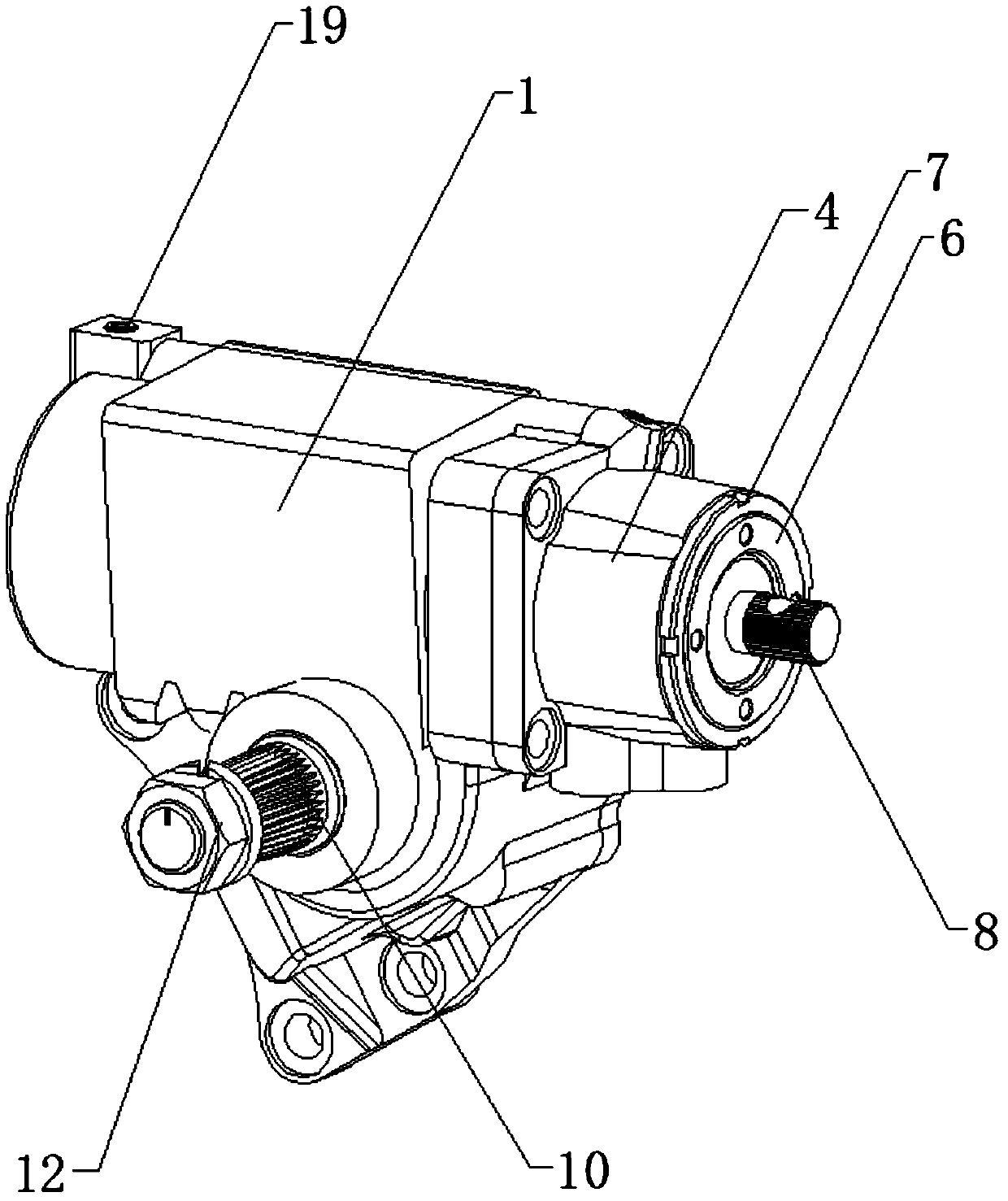

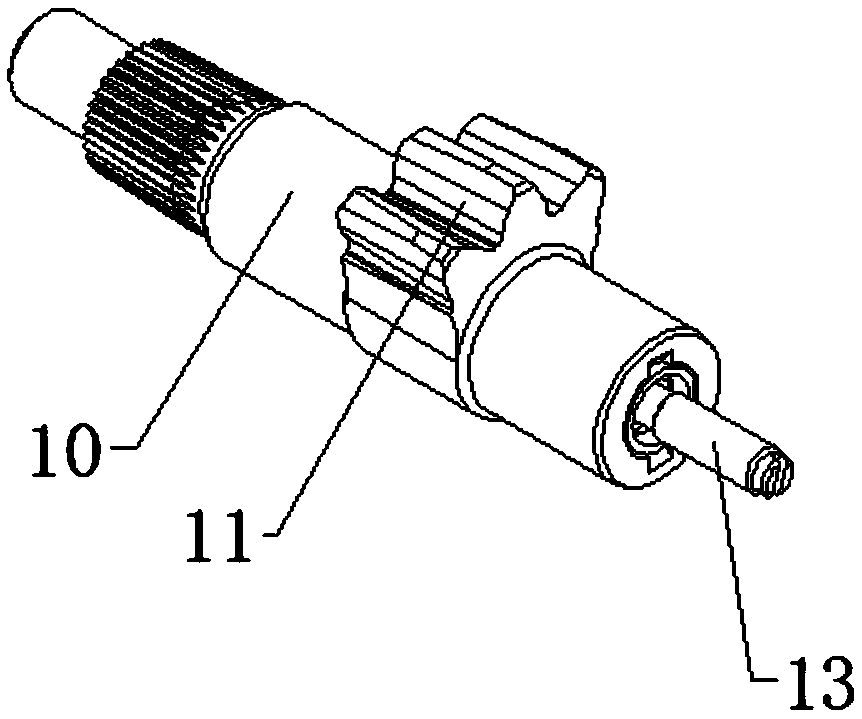

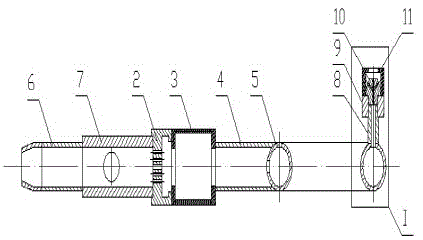

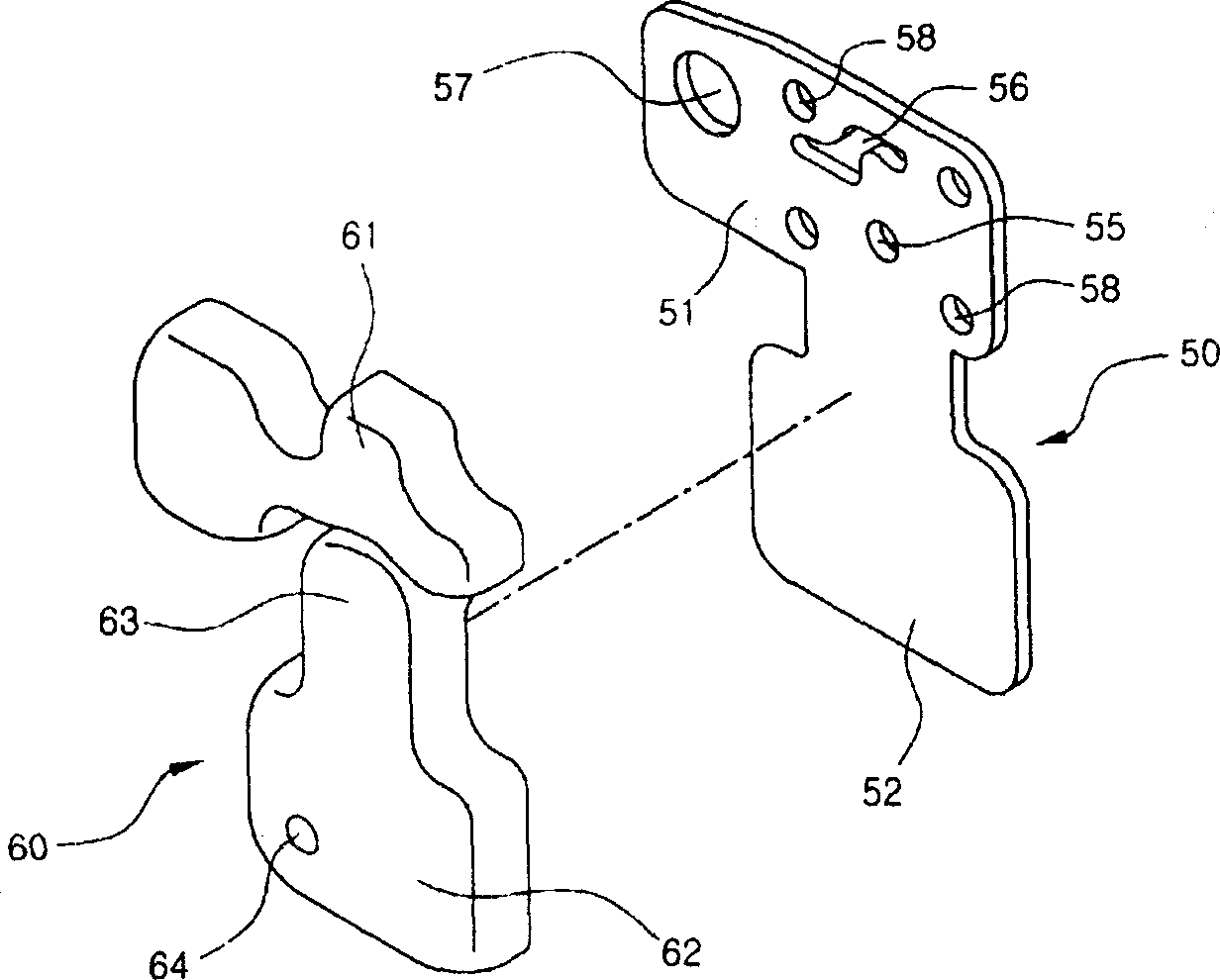

Internal circulation structure of screw and nut assembly for commercial vehicle

InactiveCN111169530AReduce the form of failureHigh strengthMechanical steering gearsSteel ballEngine valve

The invention relates to the technical field of commercial vehicles, in particular to an internal circulation structure of a screw-nut assembly for a commercial vehicle. The structure comprises a steering engine shell assembly and a steering engine side cover, the steering engine side cover is connected to the outer wall of one end of the steering engine shell assembly through screws. The inner wall of the end, close to the steering engine shell assembly, of the steering engine side cover is sleeved with a rocker arm shaft bearing. The outer wall of the end, perpendicular to the steering engine side cover, of the steering engine shell assembly is connected with a steering engine valve body through screws. The inner wall of the steering engine valve body is sleeved with a screw bearing; a steering screw is connected to the inner wall of the screw bearing through a bearing; the outer wall of the steering screw is in threaded connection with a steering nut, a reverser is in clamp connection onto the inner wall of the steering nut, a steel ball is in rolling connection to the internal of the reverser, and the steel ball is tangent with the outer wall of the steering screw. According tothe invention, the problem that an outer circulation structure guide pipe fails is solved, noise is reduced, transmission efficiency is improved, and the outer circulation structure guide pipe has acertain popularization value.

Owner:ZHEJIANG SHIBAO CO LTD

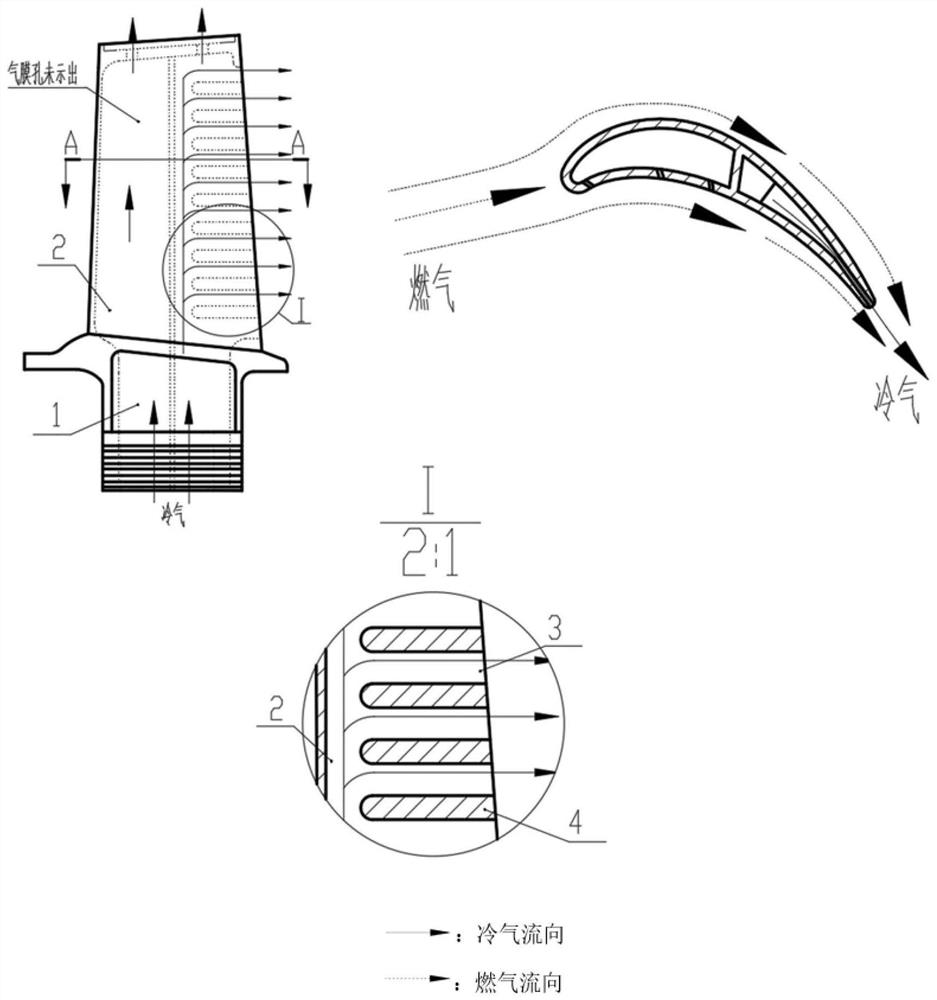

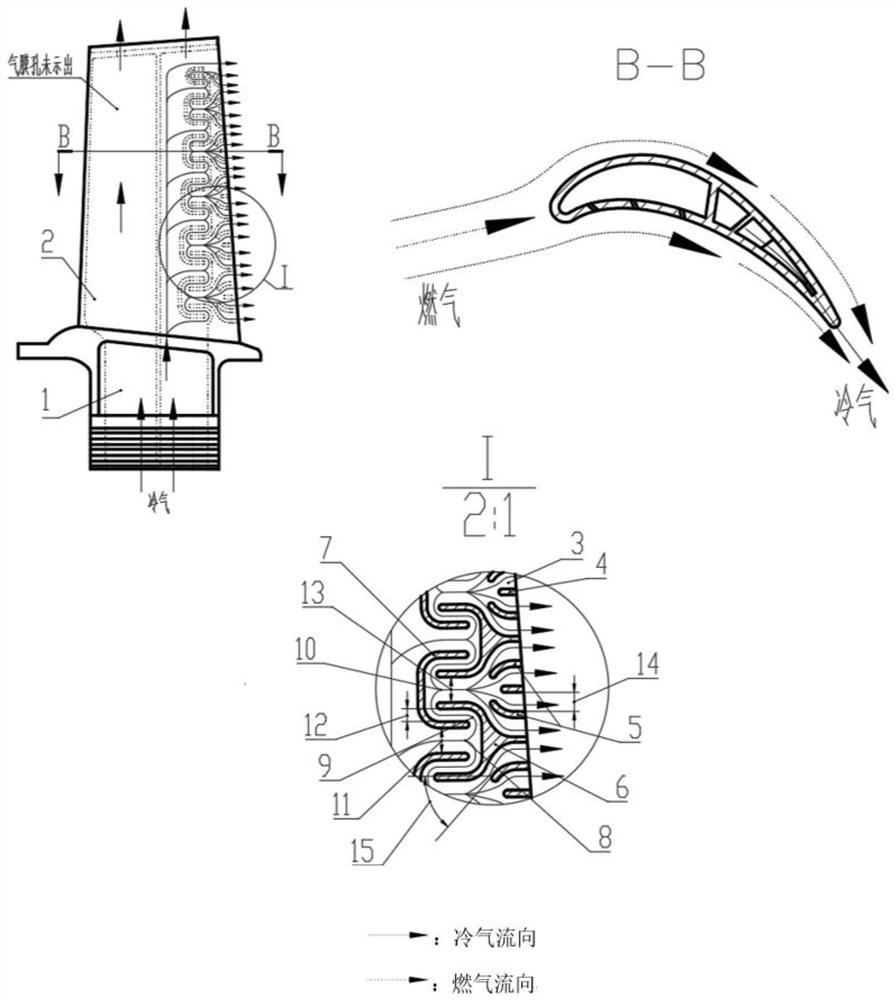

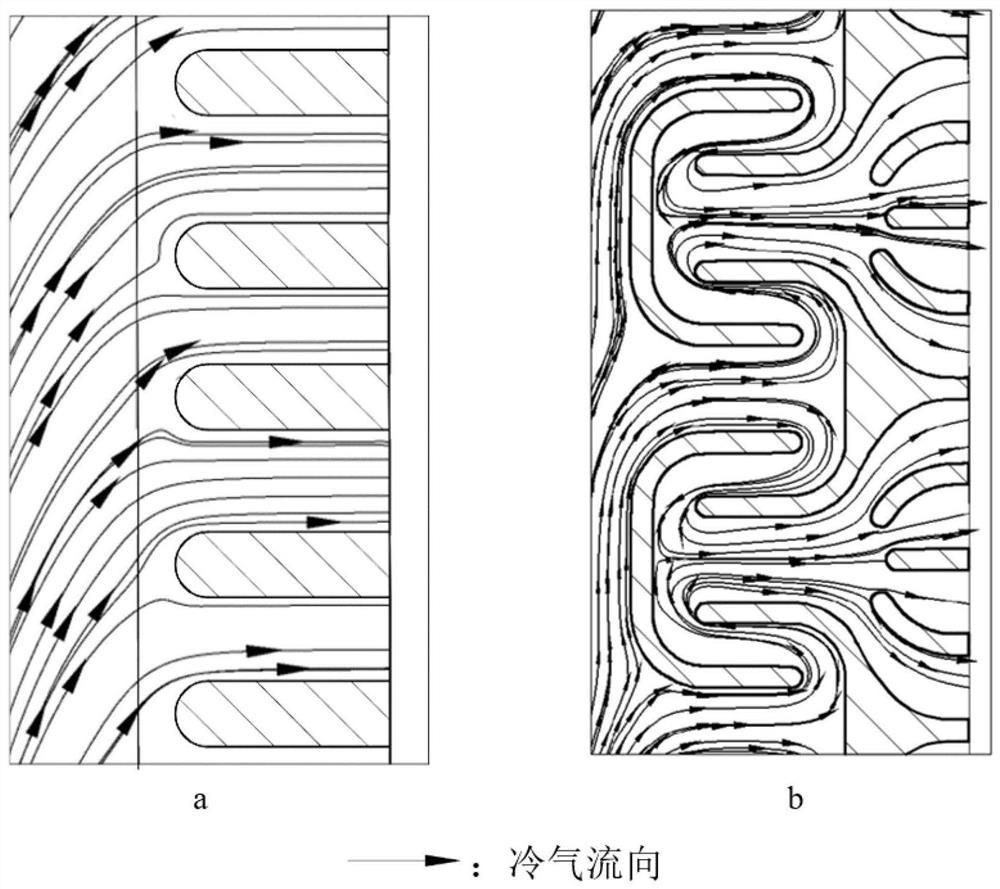

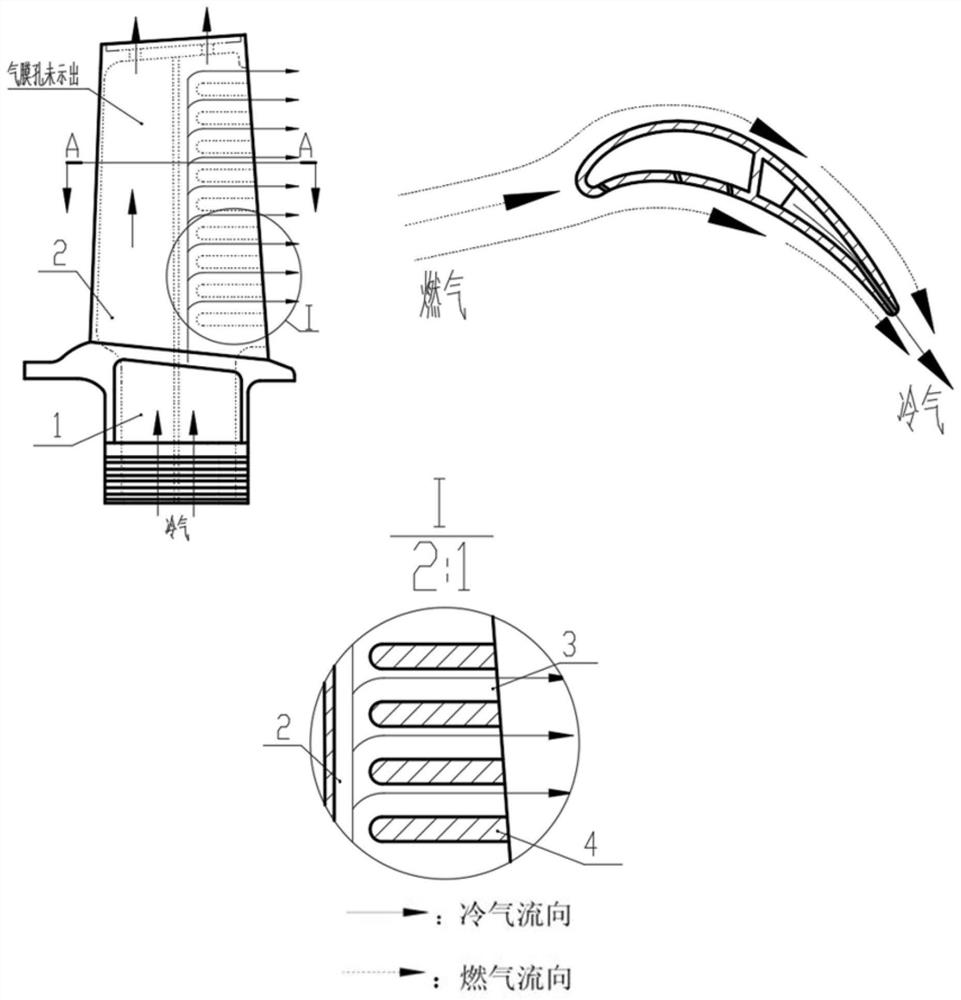

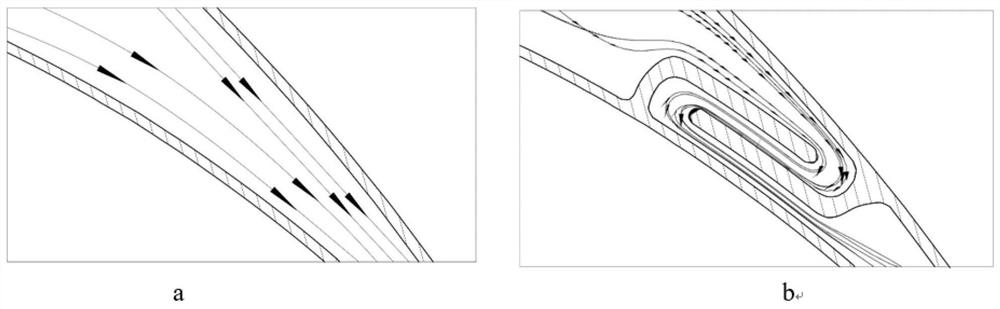

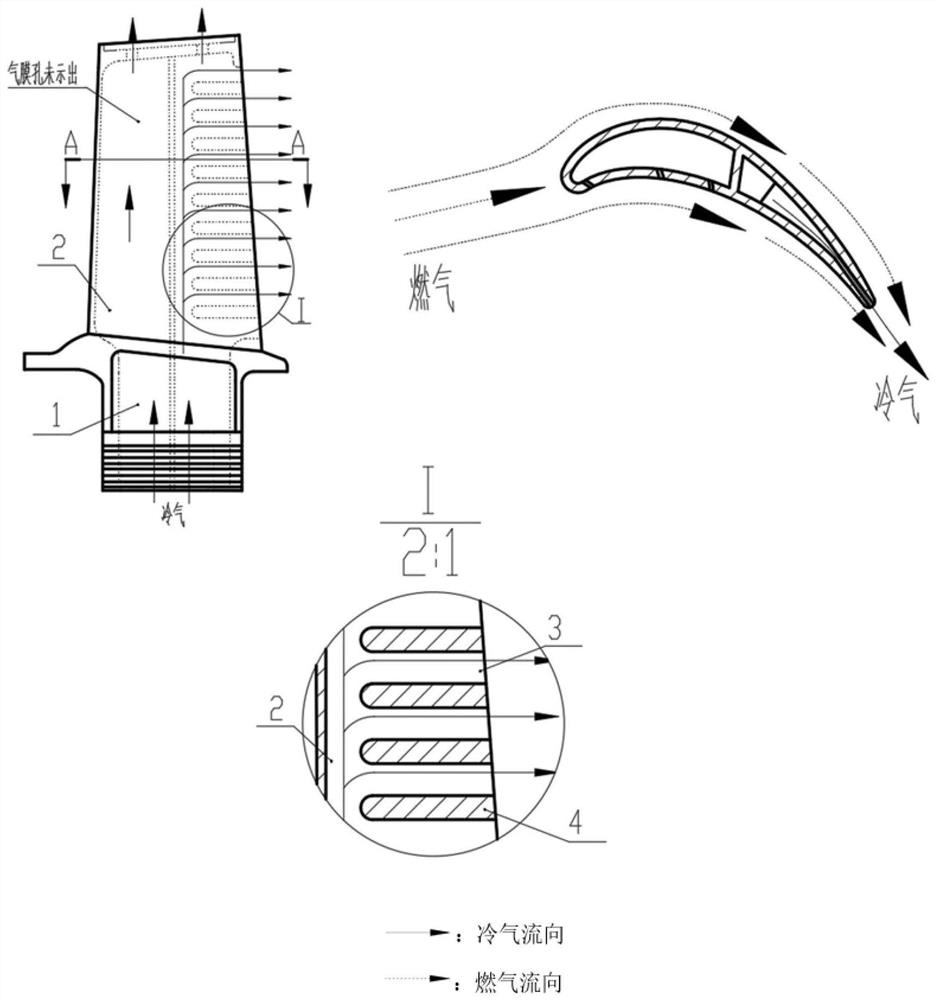

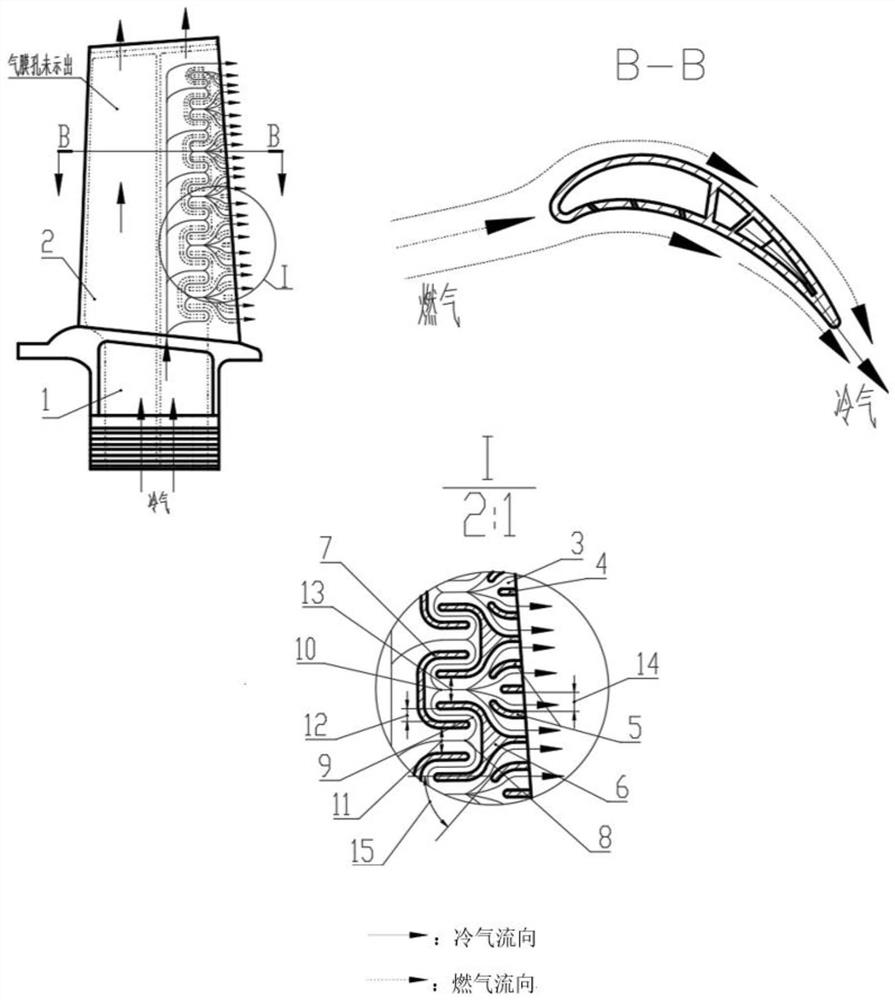

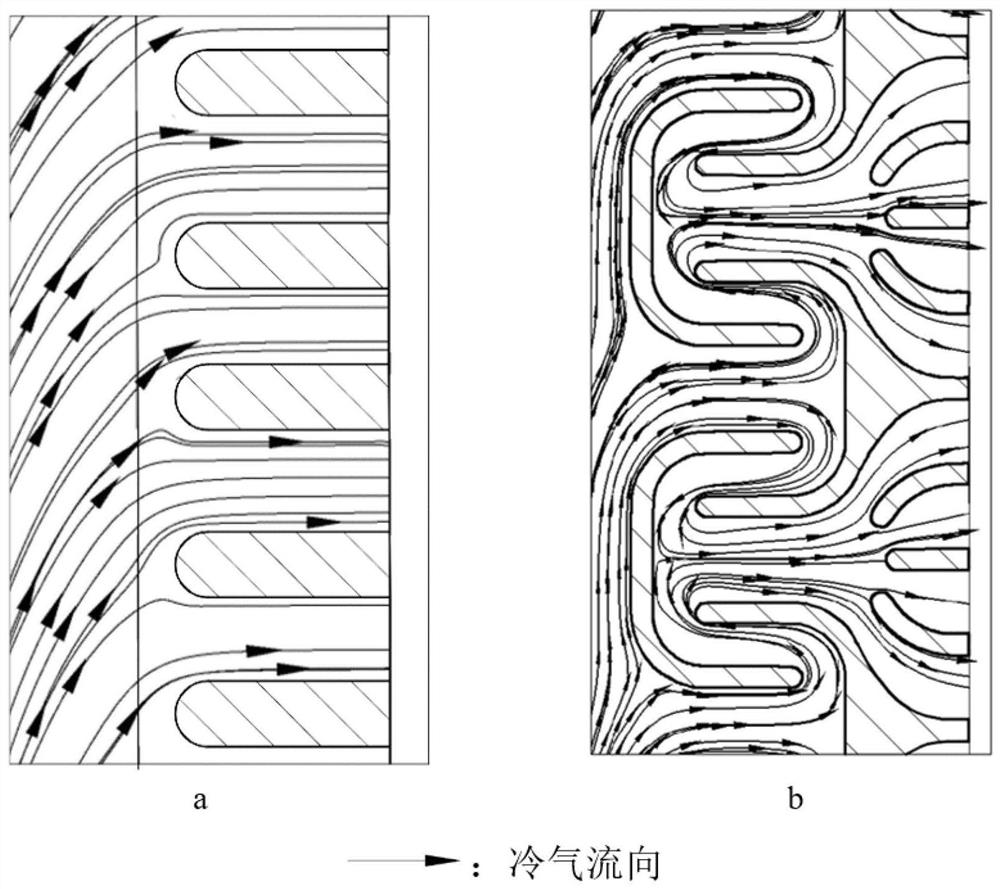

Turbine blade separation transverse rotation re-intersection type cooling structure

ActiveCN112943379AIncrease the heat exchange areaImprove cooling effectBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade separation transverse rotation re-intersection type cooling structure. An inner cavity cold air channel is arranged in a hollow turbine blade of the cooling structure, and low-temperature cooling gas flows in the blade to cool the blade. Herringbone partition ribs and C-shaped partition ribs are evenly distributed on the tail edge of the blade in the radial direction and are combined in a staggered mode to guide airflow to be separated, transversely rotate and then intersect. A cold air separation channel is formed between every two adjacent C-shaped ribs, the width of the cold air separation channel is D1, cold air flows downstream in the channel and then is separated into two air flows flowing towards the blade root and the blade tip correspondingly, and the two air flows rotate by 180 degrees for the first time in two cold air rotation channels correspondingly and flow reversely in the incoming flow direction. Each strand of cold air can flow out after passing through a trailing edge crack after being turned for multiple times, and the flowing distance is increased by about 40% compared with a conventional structure, so that the utilization rate of the cold air is increased, and the temperature of the blade is reduced.

Owner:DALIAN UNIV OF TECH

Double sealing face fin plate-type heat exchanger

InactiveCN102338577AGuaranteed gap-free stackingShort flow distanceLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention discloses a double sealing face fin plate-type heat exchanger which comprises a double seal plate-type chip, a double seal soldering flake, a lower soldering flake, fins and an upper soldering flake. The upper soldering flake is arranged on the upper surface of the double seal soldering flake. The lower soldering flake is arranged on the lower surface of the double seal soldering flake. The fins are arranged between the upper soldering flake and the lower soldering flake. The double seal soldering flake is arranged on the double seal plate-type chip. In the invention, after chips are laminated, two sealing faces are formed around; and due to the addition of the double seal soldering flake, after soldering, two soldering sealing faces are formed around, so that even though the inner sealing face is failed, the second layer of sealing face on the outside can still take a sealing effect, and thus, the reliability of a product is greatly promoted.

Owner:高邮市荣清机械电子有限公司

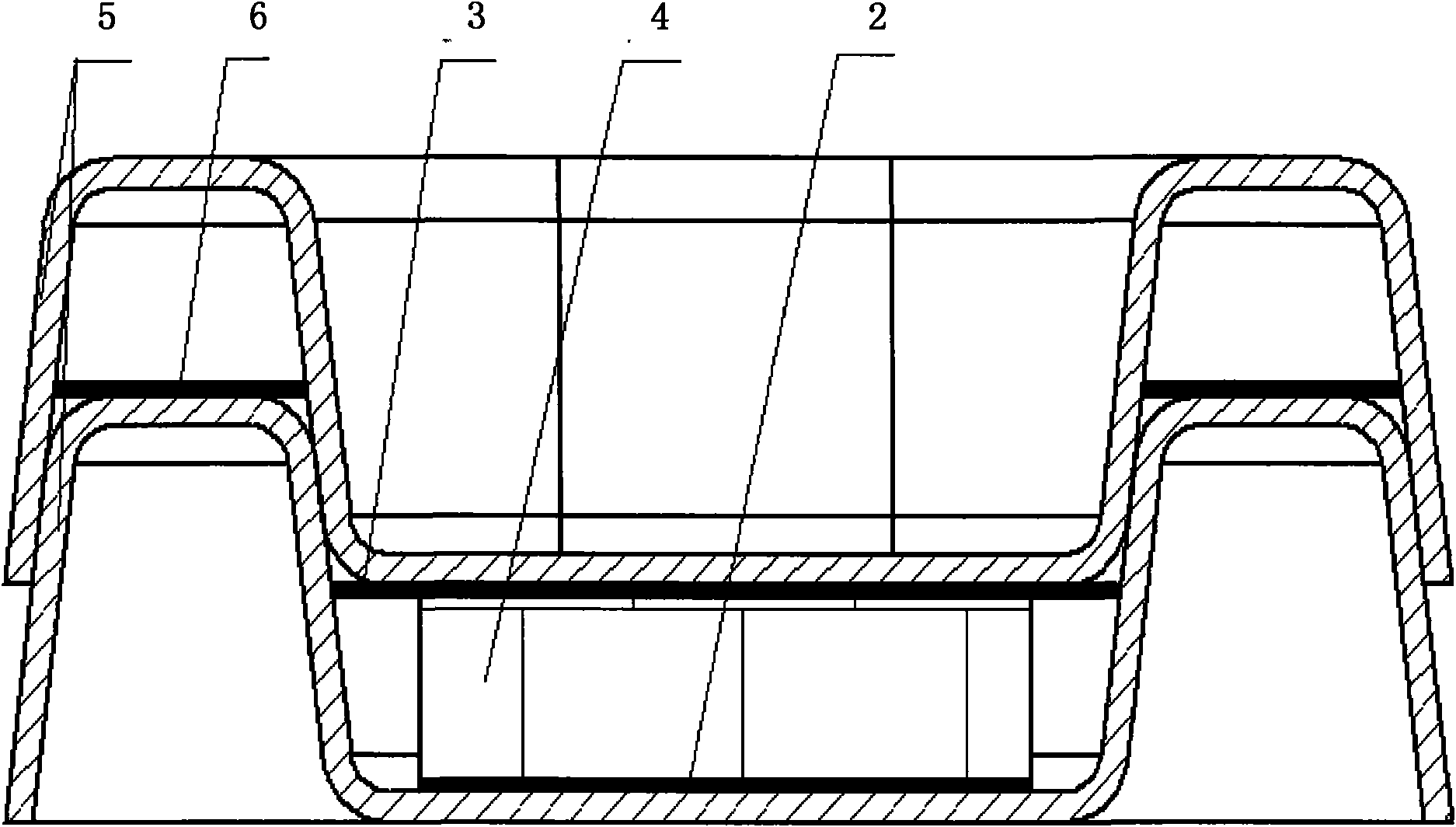

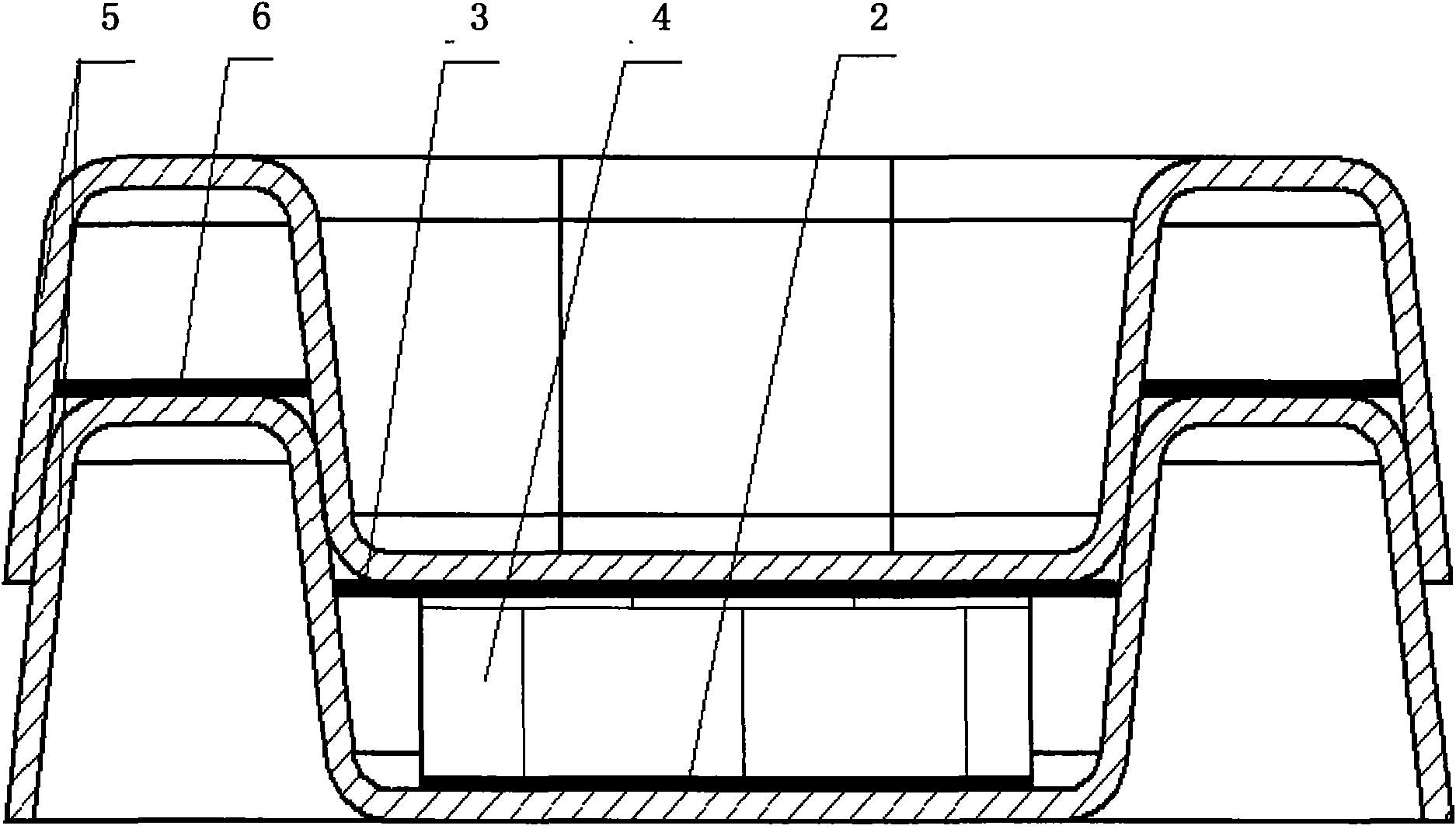

Compound subsurface flow constructed wetland with high drop difference and adjustable water outflow

PendingCN109851053ASmall water resistanceOverall good anti-clogging performanceBiological water/sewage treatmentPipingSubsurface flow

The invention discloses a compound subsurface flow constructed wetland with the high drop difference and the adjustable water outflow. The constructed wetland comprises a downward wetland area, wherein an upward wetland area is circularly arranged around the downward wetland area, the bottom circumference of the downward wetland area is evenly provided with water passing holes communicating with the bottom of the upward wetland area, the top of the downward wetland area is provided with a water distribution pipe, the interior of the upward wetland area is successively provided with an upward pool vegetation layer, a first upward pool filler layer and a second upward pool filler layer from top to bottom, the top of the first upward pool filler layer is provided with a water collection pipe,the water collection pipe communicates with one end of each water outlet transverse pipe, and the other end of each water outlet transverse pipe, after passing through the upward wetland area, communicates with the bottom end of each water outlet vertical pipe through each movable elbow. The water outlet height can be freely adjusted by the movable elbows, so that no-void of the filler layer of the downward wetland area top layer can be ensured during the normal operation of the wetland, and the void can be controlled when the filler layer of the top of the downward wetland area is blocked.

Owner:WUHAN ZHONGKE HYDROBOLOGY ENVIRONMENTAL ENG

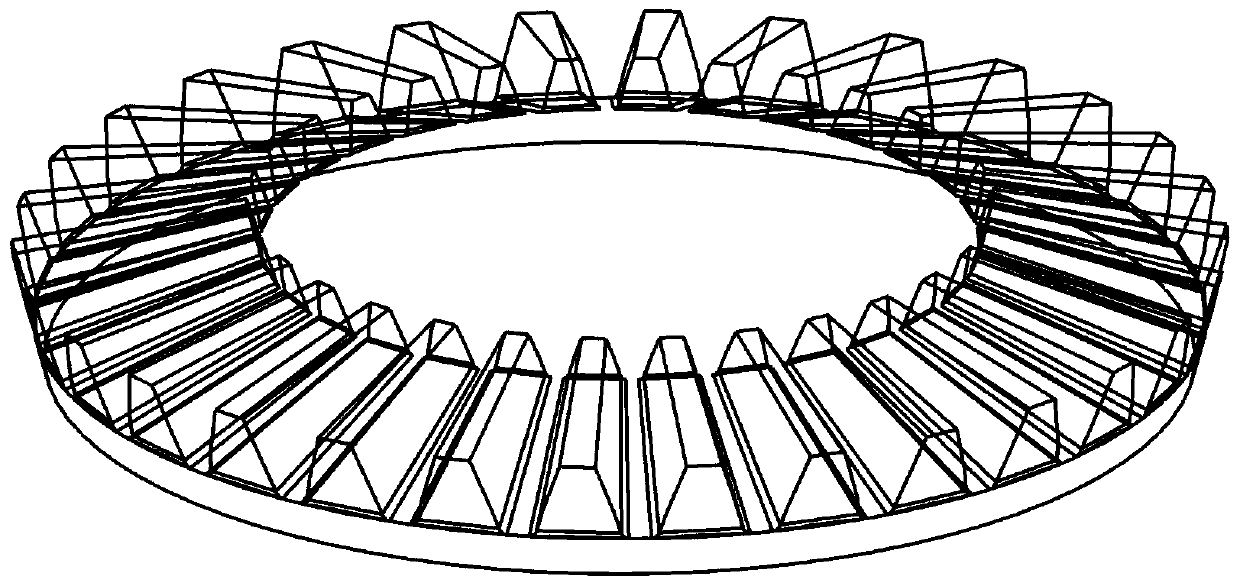

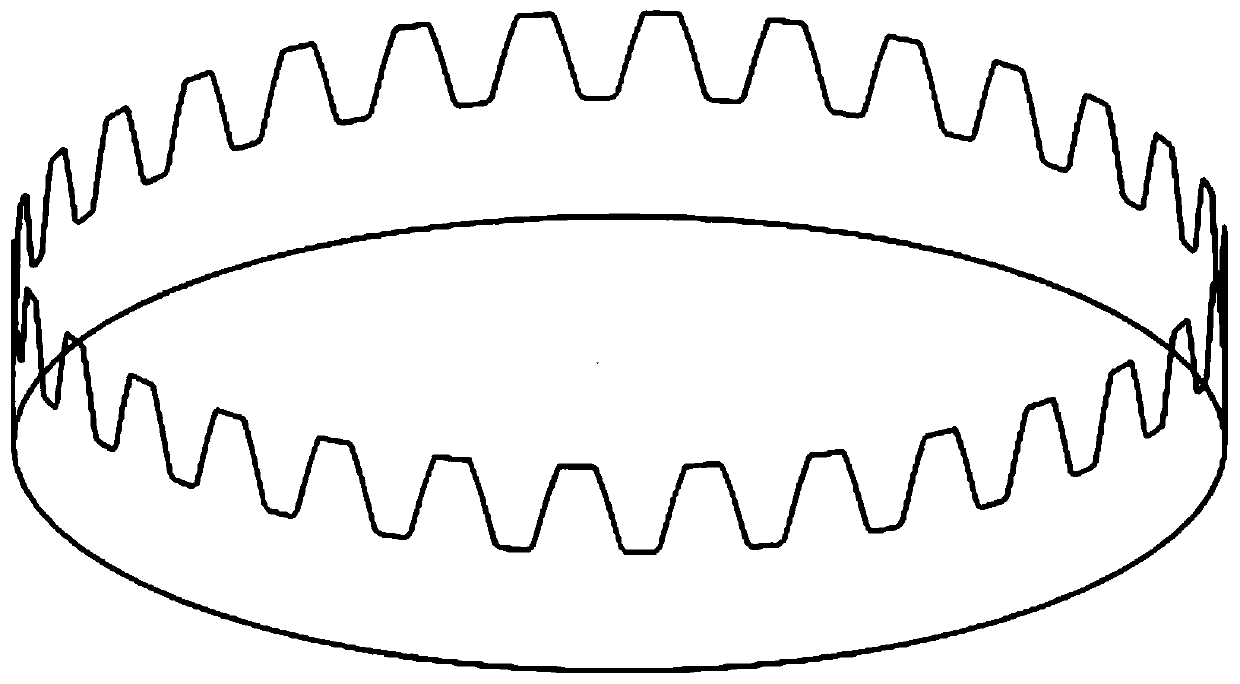

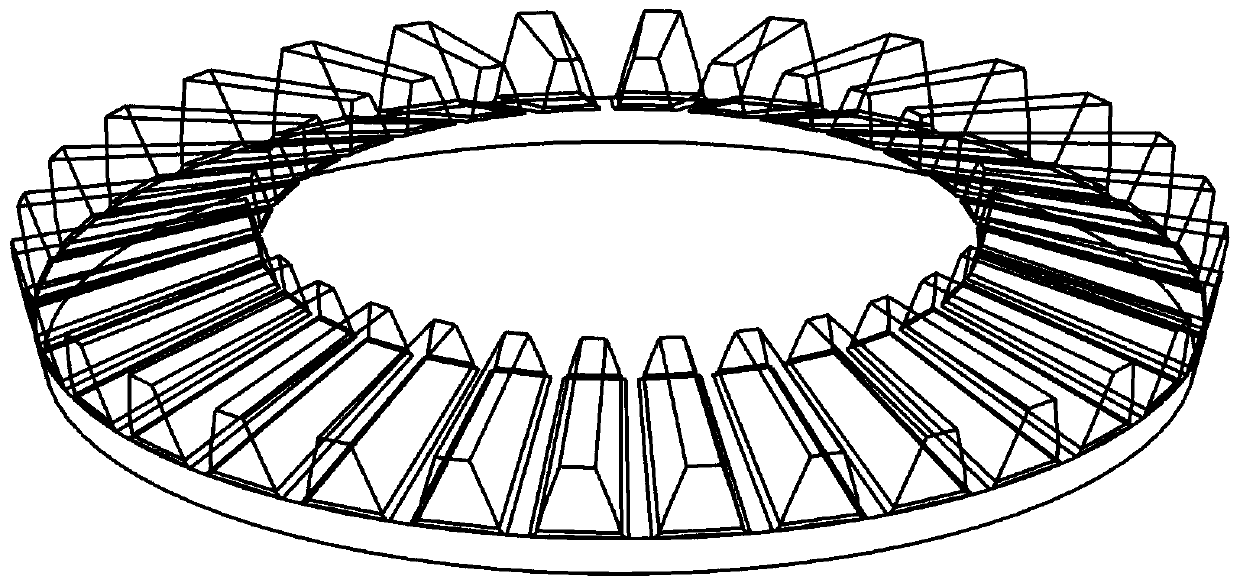

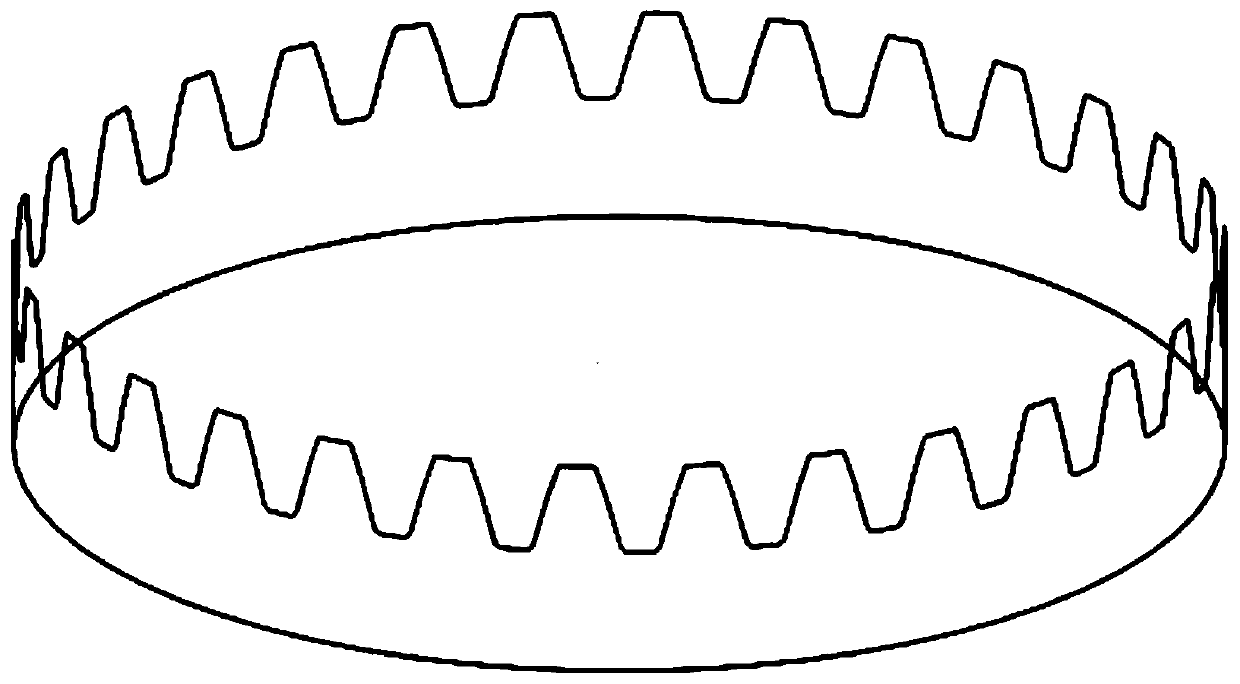

Precision plastic forming method for bevel gear

The invention discloses a precision plastic forming method for a bevel gear, and belongs to the technical field of metal plastic forming. The method comprises the following steps that characterizationparameters of a bevel gear fine forging piece are obtained; wavy line parameters of the big end and the small end of the bevel gear fine forging piece are obtained according to the characterization parameters; pre-forging die manufacturing is conducted according to the wavy line parameters; a cylinder blank is placed in a pre-forging die, closed die forging is conducted, and a pre-formed piece isobtained; and the pre-formed piece is placed in a finish forging die, blocking upset-extruding forming of a tooth profile part is conducted, and a bevel gear fine forging piece with the integral tooth profile is obtained. By means of the precision plastic forming method, the metal filling capability is improved, the metal filling load requirement is reduced, the die stress is reduced, and the service life of the die is prolonged.

Owner:NANJING INST OF TECH

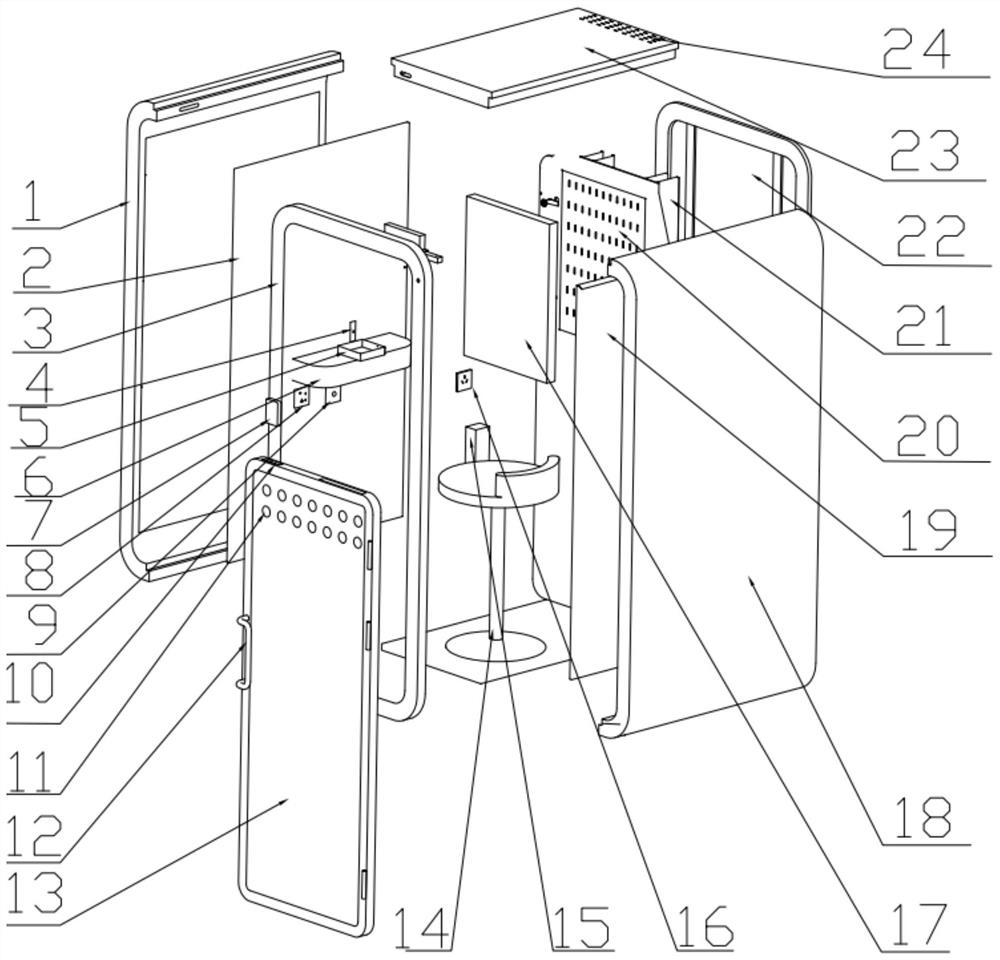

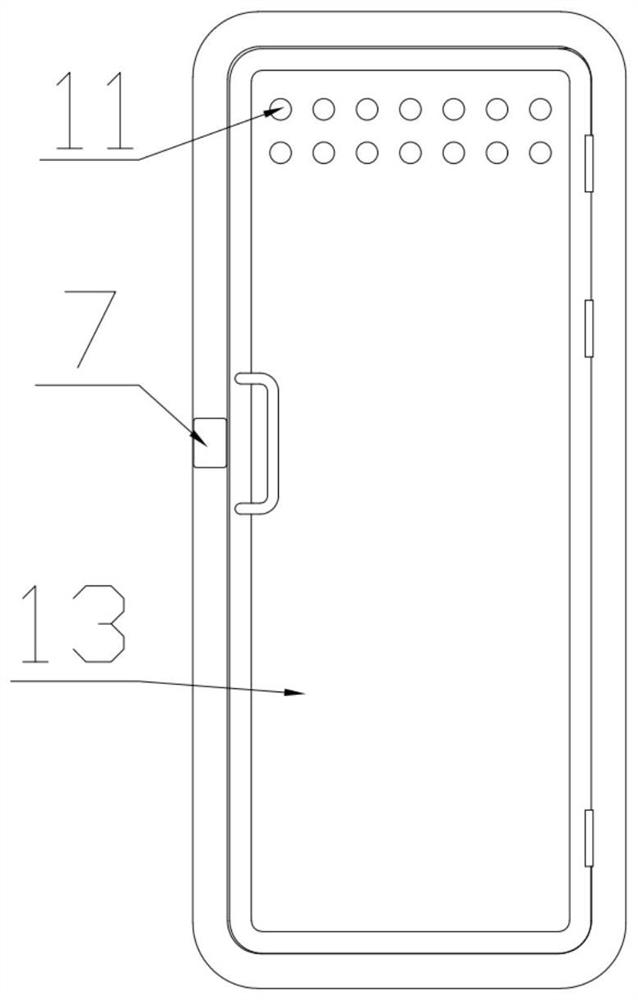

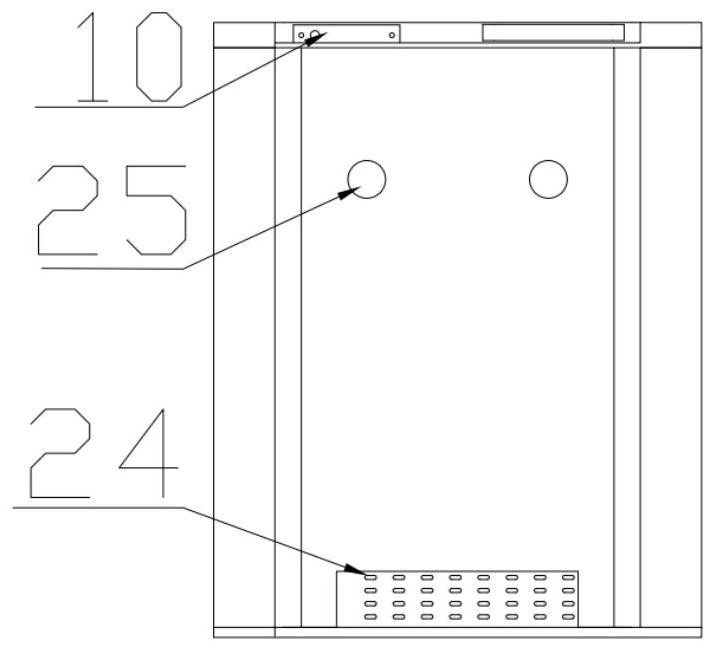

Smoking bin device and using method thereof

PendingCN112112449ASpeed up the flowIncrease profitDispersed particle filtrationLighting and heating apparatusActivated carbonHEPA

The invention discloses a smoking bin device and a using method thereof. The smoking bin device comprises a left side plate assembly, a right side plate assembly, a rear plate, a top plate, a bottom plate and a door assembly, the left side plate assembly, the rear plate, the right side plate assembly, the top plate, the bottom plate and the door assembly are mutually connected to form a square space, an external air inlet is formed in the upper portion of the door assembly, a purification assembly is arranged on the middle upper portion of the rear plate, the purification assembly comprises afirst filter screen, an internal air inlet, a second composite filter screen and at least one set of draught fans which are sequentially arranged from front to back, the second composite filter screencomprises an activated carbon layer, a sterilization layer and an HEPA layer, and an air outlet is formed in the position, corresponding to the rear portion of an outlet of the draught fan, of the top plate. The smoking bin device is short in air flowing distance, uniform in air inlet of the purification assembly, high in utilization rate, high in air circulation speed, capable of reducing indoorsmoke accumulation and sedimentation, good in air exchange effect, thorough in sterilization and air purification and capable of improving the use comfort of a user.

Owner:SHANGHAI FULIANG ENVIRONMENTAL TECH CO LTD

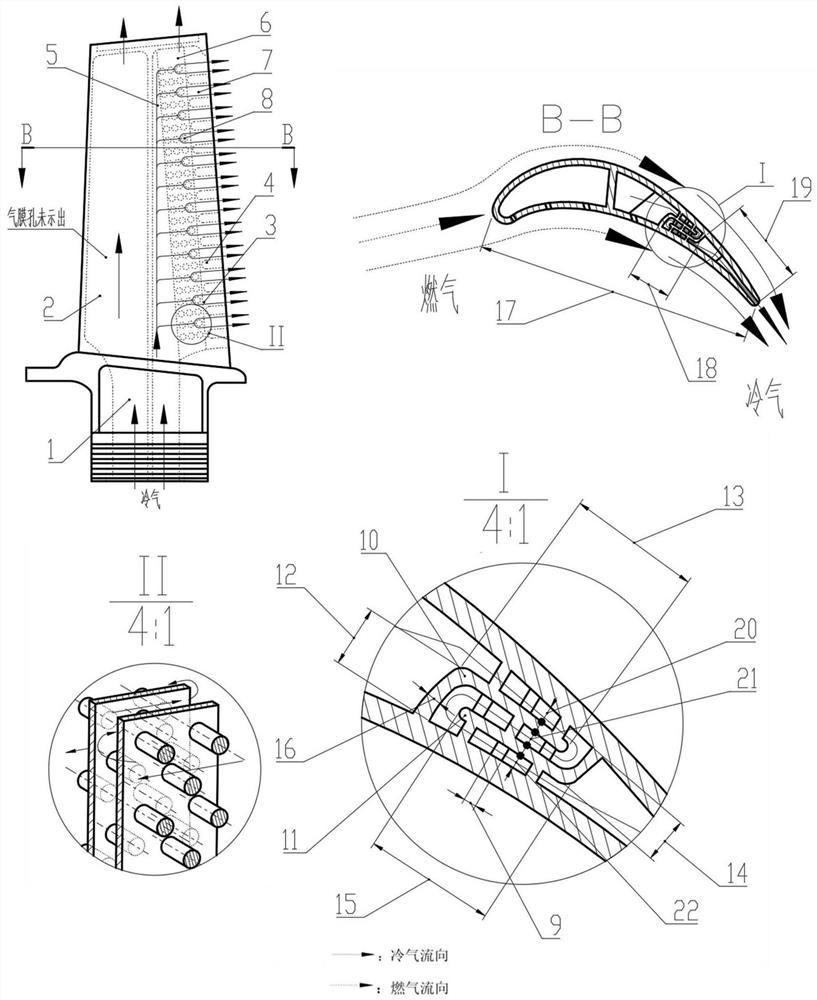

Turbine blade adopting chordwise rotary cooling channel

ActiveCN112901282AIncrease the heat exchange areaImprove cooling effectBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade adopting a chordwise rotary cooling channel. In a conventional tail edge crack structure, cold air flows into the blade from the blade root and is directly exhausted after flowing through a tail edge partition rib. Heat exchange between cold air and the blade mainly occurs on a blade basin, a blade back and the tail edge partition rib, and the heat exchange area is limited. In the blade, the cold air flows through the chordwise rotary cooling channel, heat exchange between the cold air and two L-shaped partition walls and a circular turbulent flow column is increased, and compared with a conventional structure, the heat exchange area is increased by about 20%. More heat exchange areas increase the capacity of taking away heat of the blade, and the cooling effect of the blade is improved.

Owner:DALIAN UNIV OF TECH

Welding heater

The invention discloses a welding heater. The welding heater structurally comprises a mixed gas intake pipeline, an annular fire ring and a plurality of spark plug assemblies, the annular fire ring is connected with the mixed gas intake pipeline and communicated with the mixed gas intake pipeline, the centerline in the length direction of the annular fire ring is perpendicular to the gas intake direction of the mixed gas intake pipeline, the annular fire ring is provided with mixed gas ventilation holes along the annular fire ring, the mixed gas ventilation holes correspond to the spark plug assemblies, and the spark plug assemblies are arranged in the mixed gas ventilation holes. By means of the welding heater, during welding preheating or heat preservation or heating, the centerline in the length direction of the annular fire ring is perpendicular to the gas intake direction of the mixed gas intake pipeline, so that mixed gas starts to be distributed to the adjacent spark plug assemblies once the mixed gas enters the annular fire ring through the mixed gas intake pipeline, the flow distance of the mixed gas is short, the fire ignition speed of the mixed gas is high, the burning efficiency of the mixed gas is high, the burning process is stable, uniform and sufficient, efficiency is improved, and cost is saved.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

A kind of precision plastic forming method of bevel gear

ActiveCN109926533BSimple methodExtend your lifeMetal-working apparatusWheelsBevel gearMaterials science

The invention discloses a precision plastic forming method for a bevel gear, and belongs to the technical field of metal plastic forming. The method comprises the following steps that characterizationparameters of a bevel gear fine forging piece are obtained; wavy line parameters of the big end and the small end of the bevel gear fine forging piece are obtained according to the characterization parameters; pre-forging die manufacturing is conducted according to the wavy line parameters; a cylinder blank is placed in a pre-forging die, closed die forging is conducted, and a pre-formed piece isobtained; and the pre-formed piece is placed in a finish forging die, blocking upset-extruding forming of a tooth profile part is conducted, and a bevel gear fine forging piece with the integral tooth profile is obtained. By means of the precision plastic forming method, the metal filling capability is improved, the metal filling load requirement is reduced, the die stress is reduced, and the service life of the die is prolonged.

Owner:NANJING INST OF TECH

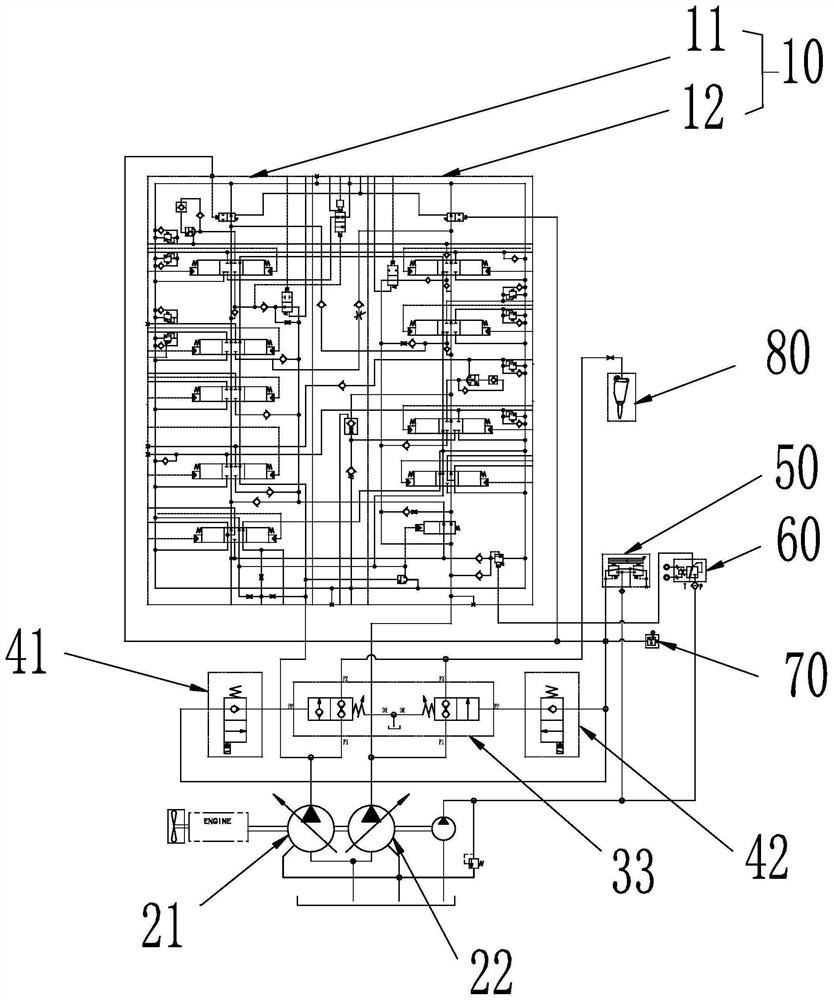

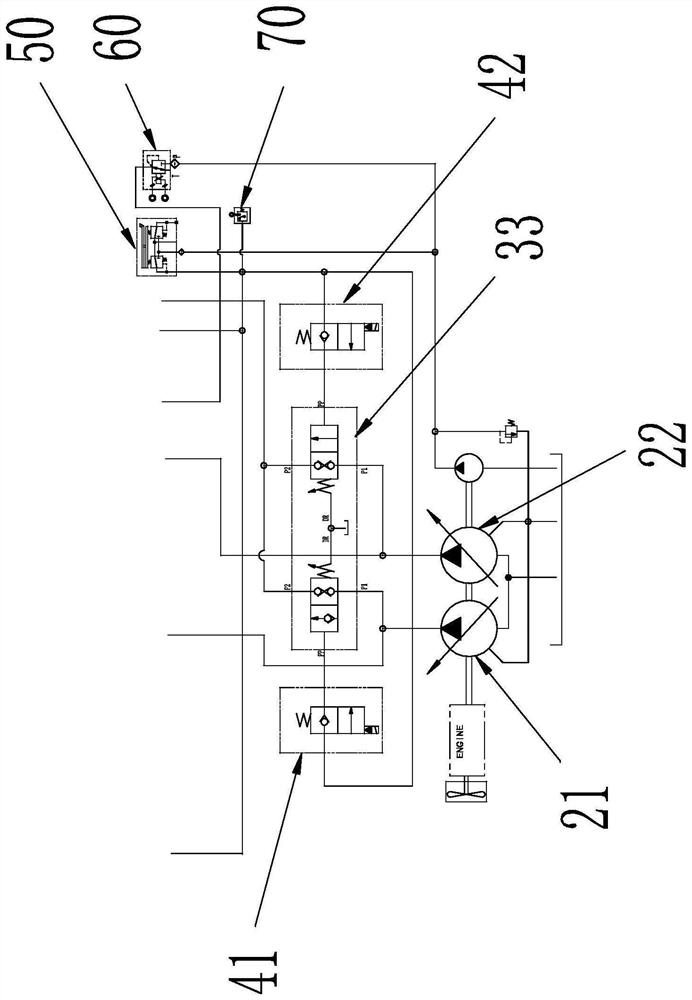

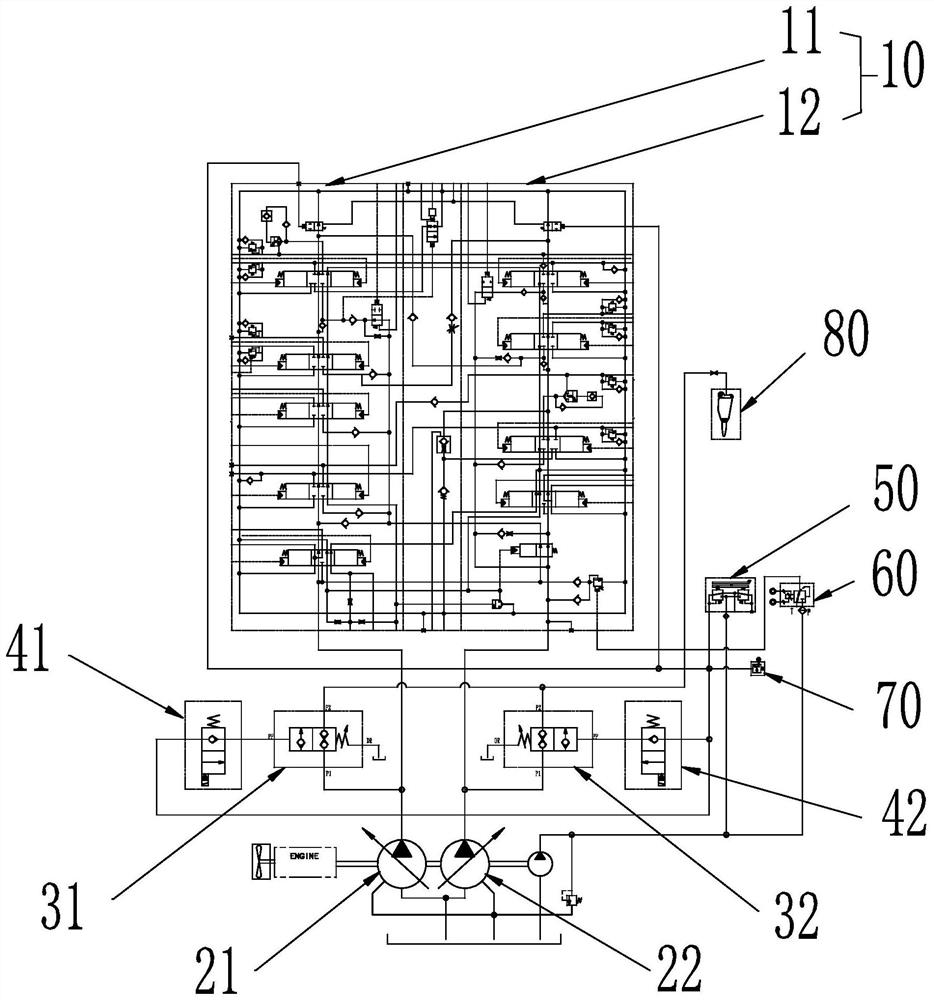

Valve outer confluence hydraulic system and excavator

PendingCN112211250AMeet needsShort flow distanceMechanical machines/dredgersHydraulic pumpEngineering

The invention relates to the technical field of excavator hydraulic control, in particular to a valve outer confluence hydraulic system and an excavator. The valve outer confluence hydraulic system comprises a hydraulic energy supply module, a starting module, a confluence module, a control module, a main valve and a breaking hammer, wherein the hydraulic energy supply module comprises at least two hydraulic pumps, and each hydraulic pump can supply oil to the main valve; the confluence module is communicated with the main valve in parallel, the confluence module is connected between the starting module and the breaking hammer, and all the hydraulic pumps are communicated with the confluence module; the starting module is connected with the confluence module through the control module; andafter the starting module is started, the control module controls the confluence module so that the n hydraulic pumps can supply oil to the breaking hammer through the confluence module, n is a natural number, and n is larger than or equal to zero and smaller than or equal to the number of the hydraulic pumps. When the valve outer confluence hydraulic system provided by the invention is used forsupplying oil to the breaking hammer, the oil supply requirements of breaking hammers with drill rods of different sizes can be met, the pressure loss is small, and the energy utilization rate is high.

Owner:SHANDONG LINGONG CONSTR MACHINERY

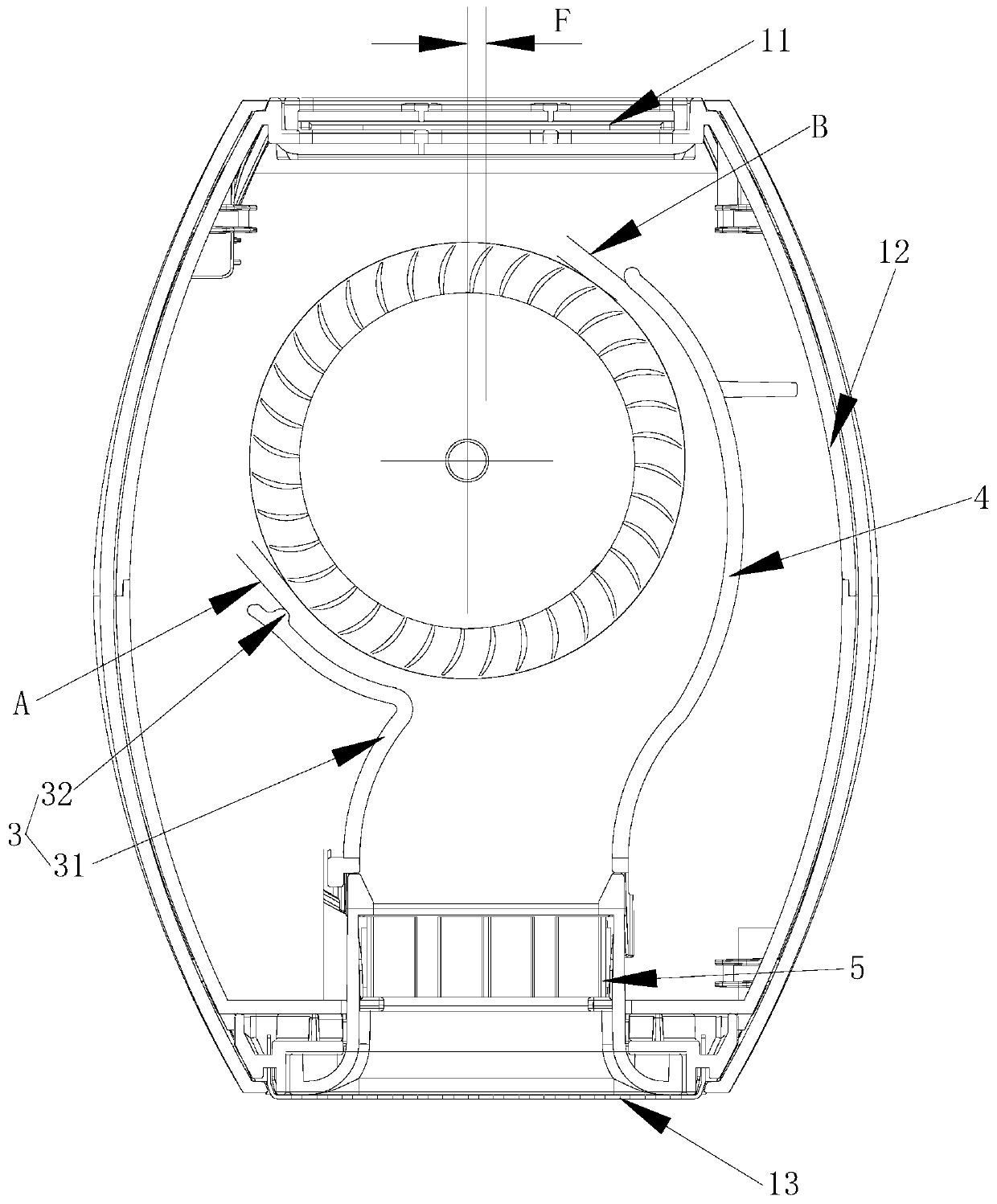

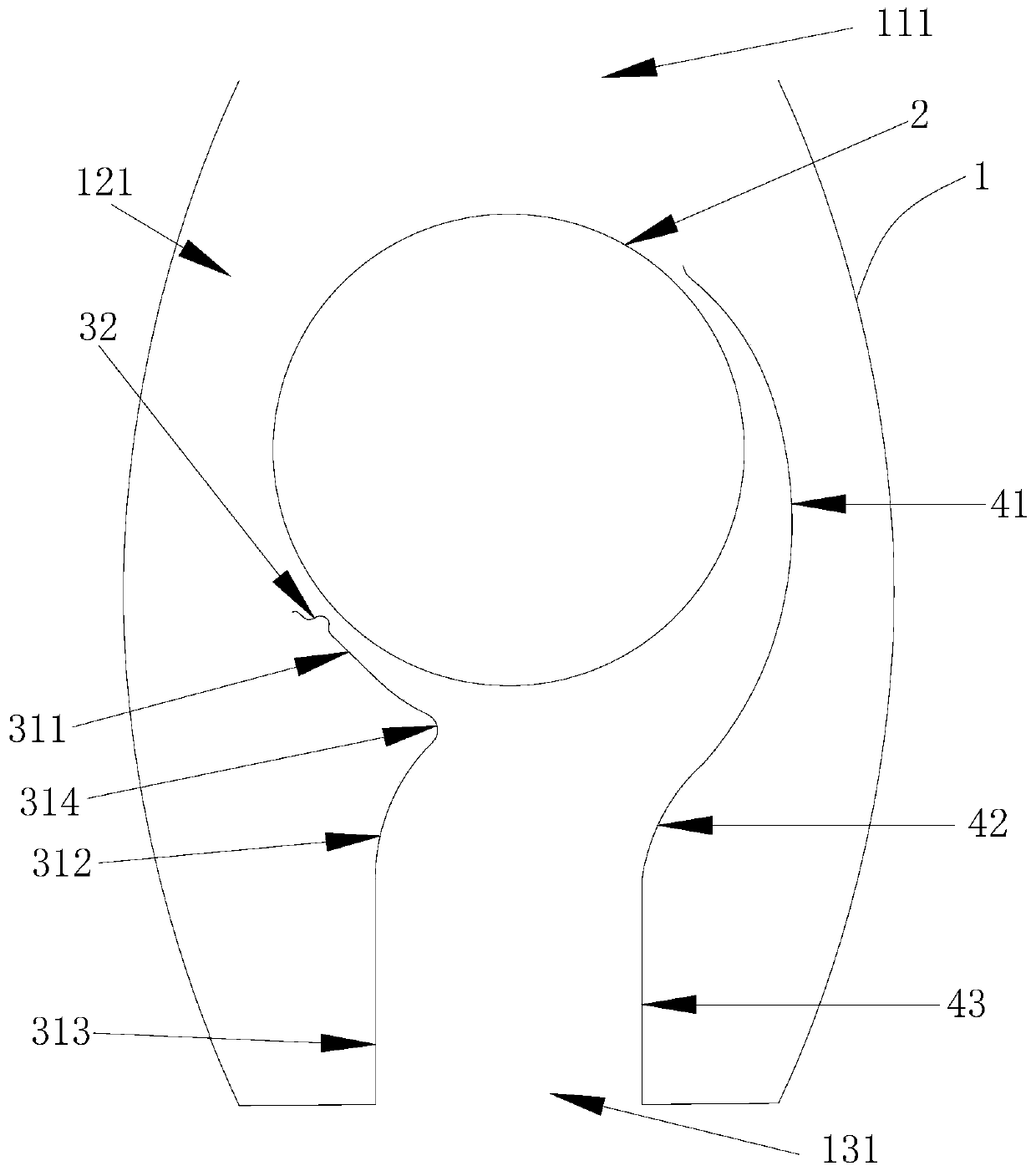

Cross-flow air way module and air warmer

The invention relates to the technical field of household electrical appliances, in particular to a cross-flow air way module and an air warmer. The cross-flow air way module comprises an outer shell,an impeller, an air guide volute tongue and an air guide volute; the outer shell is provided with an air inlet, an air way and an air outlet; the air inlet and the air outlet are formed in two opposite sides of the air way, and communicate with the air way; the axis of the air inlet is parallel to the axis of the air outlet; the air guide volute and the air guide volute tongue are arranged on twoopposite sides of the air outlet; and set gaps are formed between the air guide volute tongue and the impeller and between the air guide volute and the impeller separately. The cross-flow air way module is higher in air outlet quantity and relatively higher in air speed.

Owner:GREE ELECTRIC APPLIANCES INC

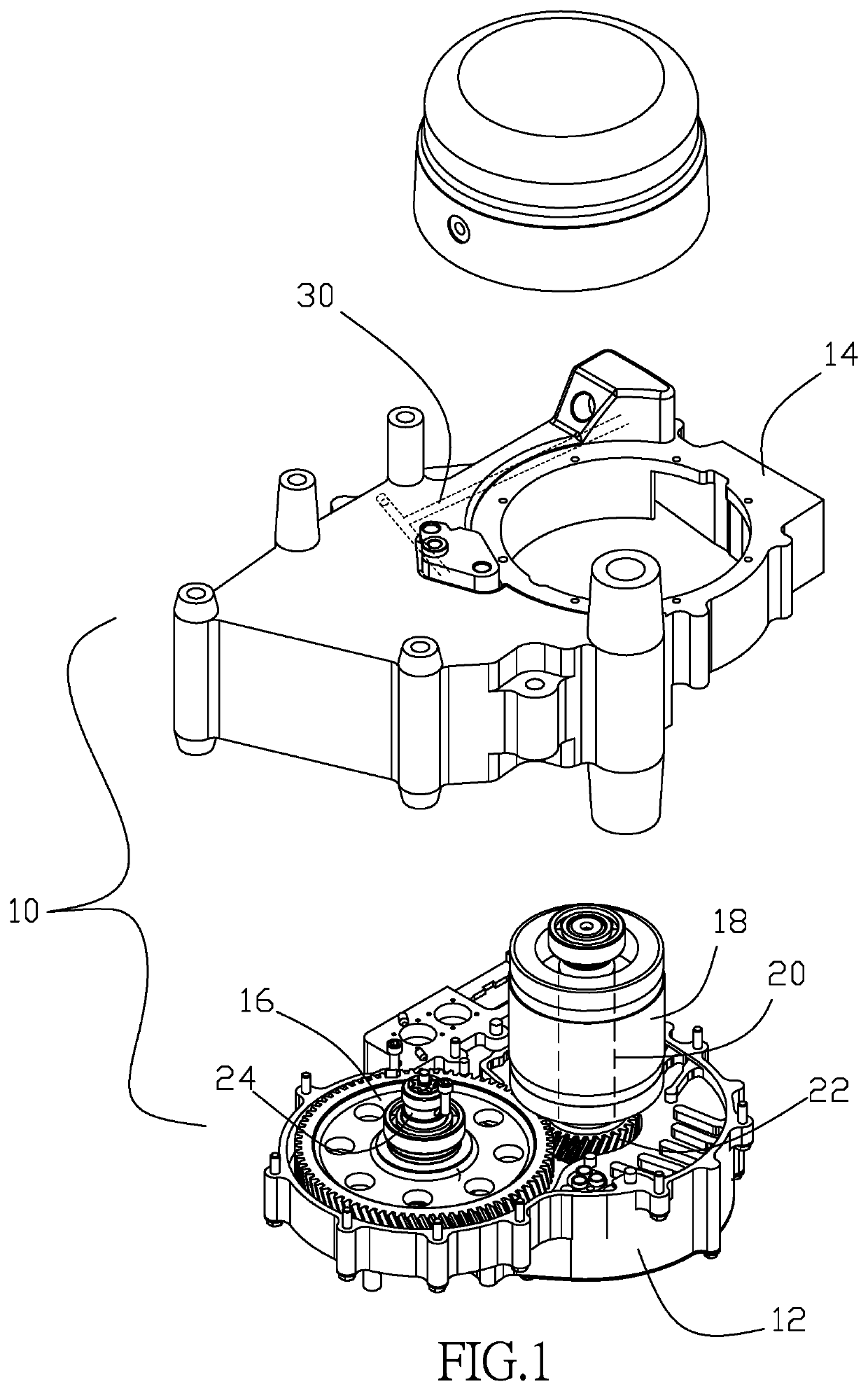

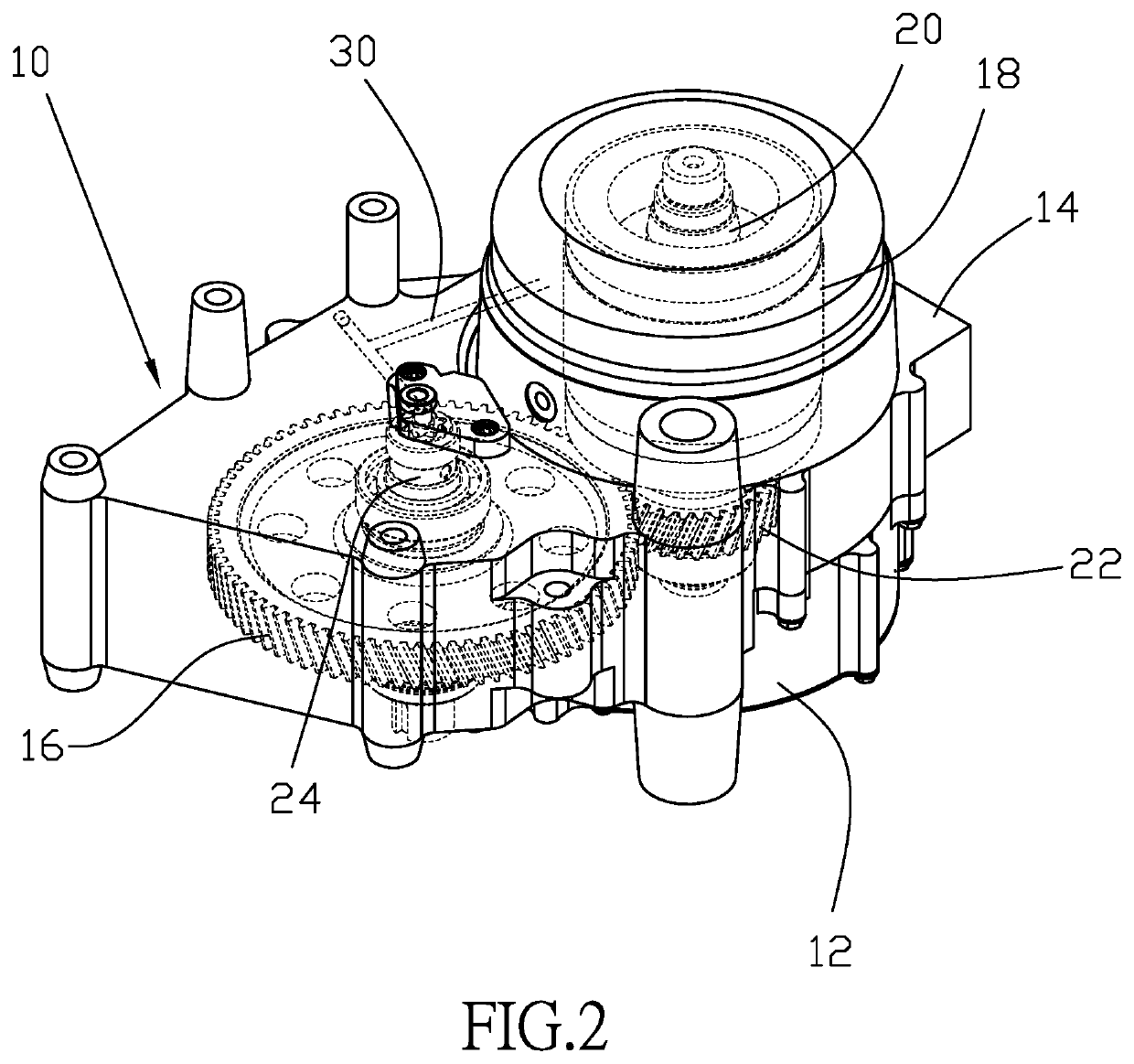

Lubrication system of power assembly of electric scooter

ActiveUS10816083B2Short flow distanceImprove the lubrication effectGearboxesMotorised scootersGear wheelControl theory

A lubrication system of a power assembly of an electric scooter includes a case duct and a bearing seat duct formed in a case of the power assembly, and a driven gear shaft duct formed in a driven gear shaft of a driven gear. Lubricant flows to the case duct, the driven gear shaft duct, a driven gear bearing seat in the case, the bearing seat duct, a driving bearing seat in the case in sequence. The lubrication system has a short flowing distance of the lubricant to enhance the effects of lubrication and reducing temperature.

Owner:FUKUTA ELECTRIC & MACHINERY

Multi-way anti-blocking grinding solution pipeline

PendingCN111531469AShort flow distanceReduced dust depositsPipeline systemsGrinding/polishing apparatusAbrasive blastingMining engineering

The invention provides a multi-way anti-blocking grinding solution pipeline. The multi-way anti-blocking grinding solution pipeline comprises a main pipeline, wherein a plurality of sand blasting pipes communicate with the main pipeline and are inclined downwards, the plurality of sand blasting pipes are divided into multiple groups, each group comprises two sand blasting pipes, the two sand blasting pipes in any group are symmetrically arranged on a main shaft, and a water inlet is formed in the middle position of the main pipeline. Compared with the prior art, a grinding polishing solution enters the main pipeline through the water inlet, the flowing distance of the grinding polishing solution is short, and abrasive powder deposition in the grinding polishing solution can be effectivelyreduced, so that the pipeline blockage is prevented. The plurality of sand blasting pipes communicate with the main pipeline, so that the pipeline adopting design is simple in structure and convenientto maintain and check, the grinding polishing solution can be provided for multiple stations in two rows, the layout is compact, and occupied space is small; and the sand blasting pipes are inclineddownwards, the grinding polishing solution downwards flows into the sand blasting pipes, on one hand, joints are not easily blocked, on the other hand, deposit, located nearby the joints, of the mainpipeline can flow to the sand blasting pipes, and therefore, the probability of blockage of the main pipeline is reduced.

Owner:宇晶机器(长沙)有限公司

A kind of cooling structure of turbine blade separation, lateral rotation and re-convergence

ActiveCN112943379BIncrease the heat exchange areaImprove cooling effectBlade accessoriesMachines/enginesCold airAviation

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade separation, lateral rotation, and then converging cooling structure. The hollow turbine blade of the cooling structure is provided with an inner cavity cold air channel for low-temperature cooling gas to flow inside the blade. Cool down. The trailing edge of the blade is evenly distributed with herringbone-shaped partition ribs and C-shaped partition ribs along the radial direction. A cold air separation channel is formed between two adjacent C-shaped ribs and its width is D 1 , the cold air flows downstream in this channel and is separated into two airflows that flow to the blade root and the blade tip respectively, and the first 180° rotation is performed in the two cold air rotation channels respectively, and the reverse flow in the direction of the incoming flow. The cold air of the present invention needs to be turned several times before it can flow out through the trailing edge split, and its flow distance is increased by about 40% compared with the conventional structure, thereby improving the utilization rate of the cold air and reducing the temperature of the blade.

Owner:DALIAN UNIV OF TECH

Integrated top cover assembly of hermetic compressor

InactiveCN1769685AReduce in quantityShorten the flow distancePositive displacement pump componentsMulti-stage pumpsWorking fluidAgricultural engineering

The invention discloses an integral pattern roof unit assemblage of closed-type compressor, which comprises the following parts: roof, base, discharge chamber lid, silencer lid and cover plate, wherein the roof contains multiple through-holes for working fluid; the base is composed of silencer base, which connects the roof to form part of silencer; the discharge chamber lid connects the roof to form the discharge chamber; the silencer lid connects part of silencer roof and base to form silencer; the cover plate is composed of silencer cover plate, which integrates with the discharge chamber. The invention can prevent working fluid in the silencer from overheating, which reduces the component quantity of compressor.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com