Gravity casting process of lead-free brass tap

A gravity casting, lead-free brass technology, used in manufacturing tools, casting equipment, molds, etc., can solve the problems of thermal stress micro-strikes, temperature imbalance, uneven temperature of various parts of the product, etc., to reduce heat Effects of cracks, short flow distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

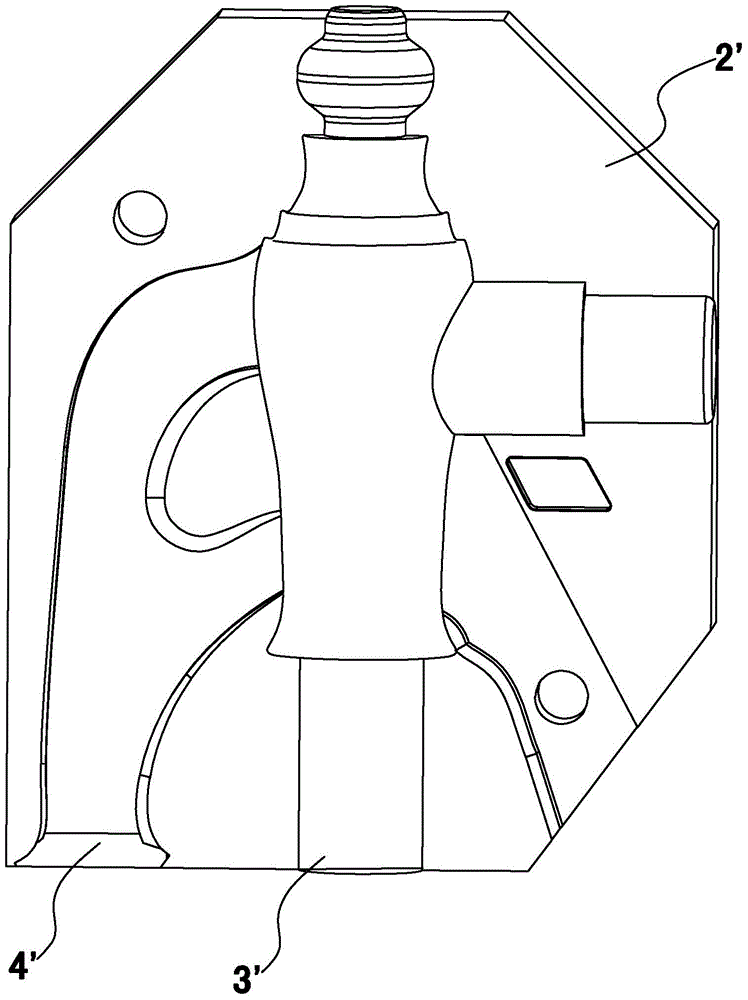

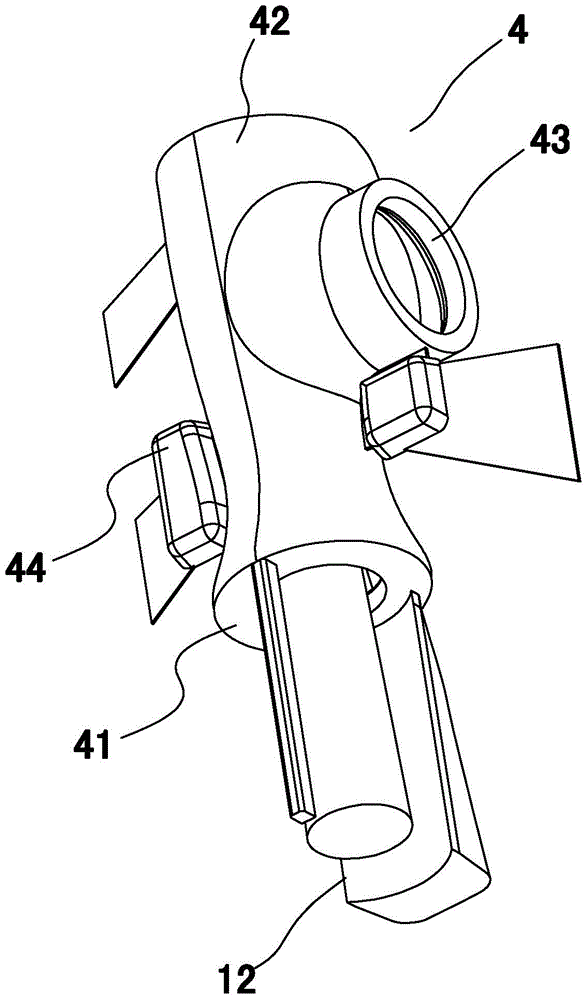

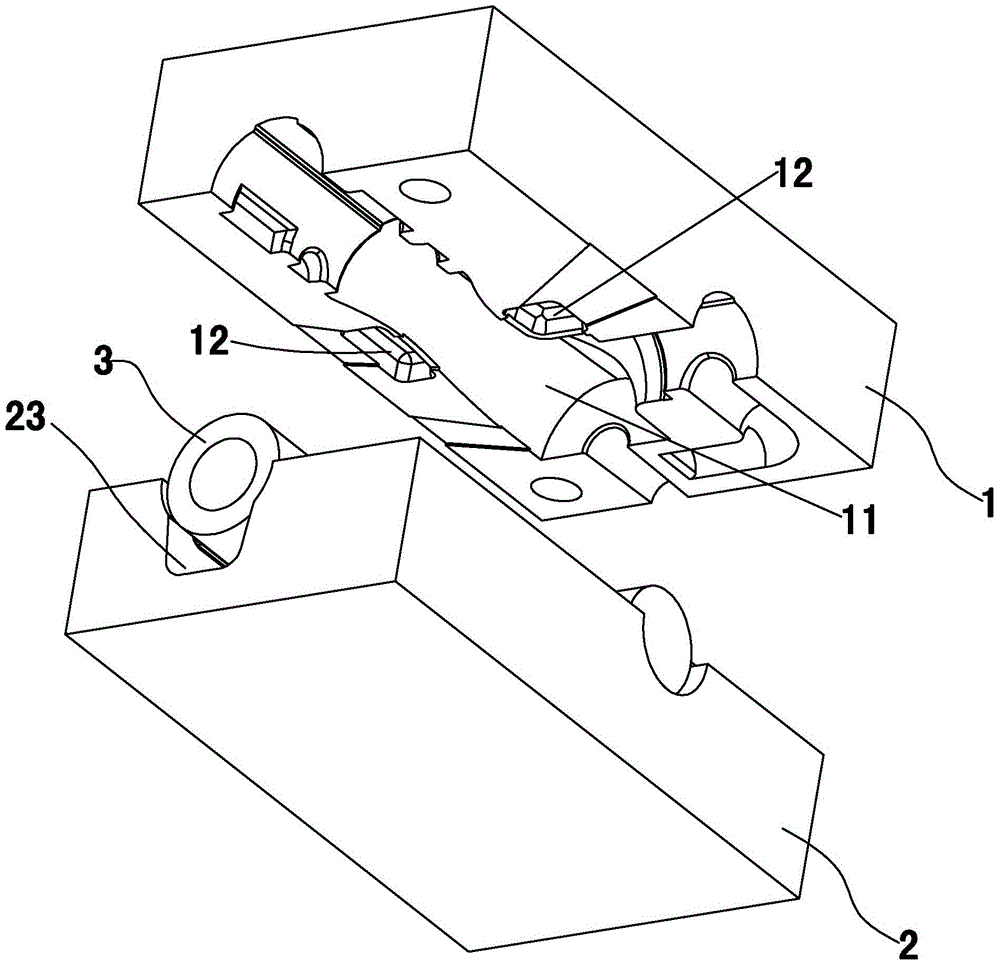

[0021] refer to Figure 2 to Figure 6 , this embodiment discloses a gravity casting process for a lead-free brass faucet, including the step of pouring the lead-free brass liquid through a gravity casting device. The molding step is known and will not be described in detail here. The device includes an upper half-mold 1, a lower half-mold 2 and a sand core 3. Between the upper half-mold 1 and the lower half-mold 2, a mold cavity 11 matching the shape of the faucet body 4 is respectively provided, and the sand core 3 is set on the upper half. In the mold cavity 11 between the mold 1 and the lower half mold 2, the shape of the sand core 3 matches the shape of the inner cavity of the faucet body 4 water inlet 41, water outlet 42 and valve core installation part 43, and the sand core 3 and A pouring cavity is formed between the mold cavities 11. The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com