Parallel-connection pressure reducing valve type double-oil-way fast-oil-charging hydraulic gear shift system

A pressure reducing valve and double oil circuit technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of shortening the shift time and slowing down the oil filling process, so as to shorten the shift the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

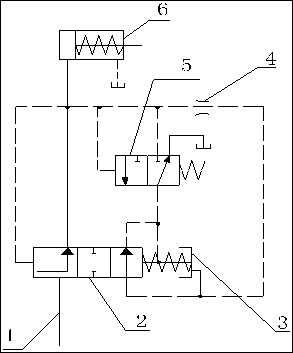

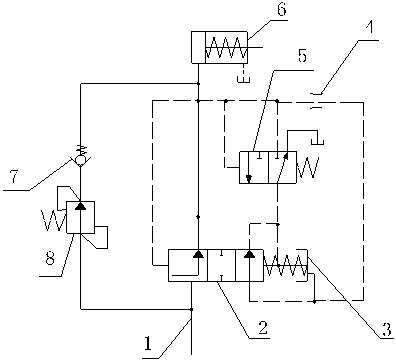

[0019] The utility model relates to a parallel decompression valve type dual-oil circuit rapid oil-filling hydraulic shifting system, which mainly includes a rapid oil-filling oil circuit and a pressure-regulating oil circuit.

[0020] The pressure regulating oil route is composed of the existing hydraulic shift pressure control valve.

[0021] The fast filling oil route is composed of a single valve (7) and a pressure reducing valve (8).

[0022] The oil inlet of the pressure regulating oil circuit is connected with the main oil circuit, and the oil outlet is connected with the shift clutch hydraulic cylinder (6). The oil inlet of the pressure reducing valve (8) is connected with the main oil circuit, the oil outlet is connected with the oil inlet of the one-way valve (7), and the oil outlet of the one-way valve (7) is connected with the shift clutch hydraulic cylinder (6) connected.

[0023] The nominal flow of the pressure reducing valve (8) and the one-way valve (7) is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com