Two stroke engine

An engine, two-stroke technology, applied in the direction of engine components, engine control, combustion engine, etc., to achieve the effect of high sealing, simple assembly, and small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

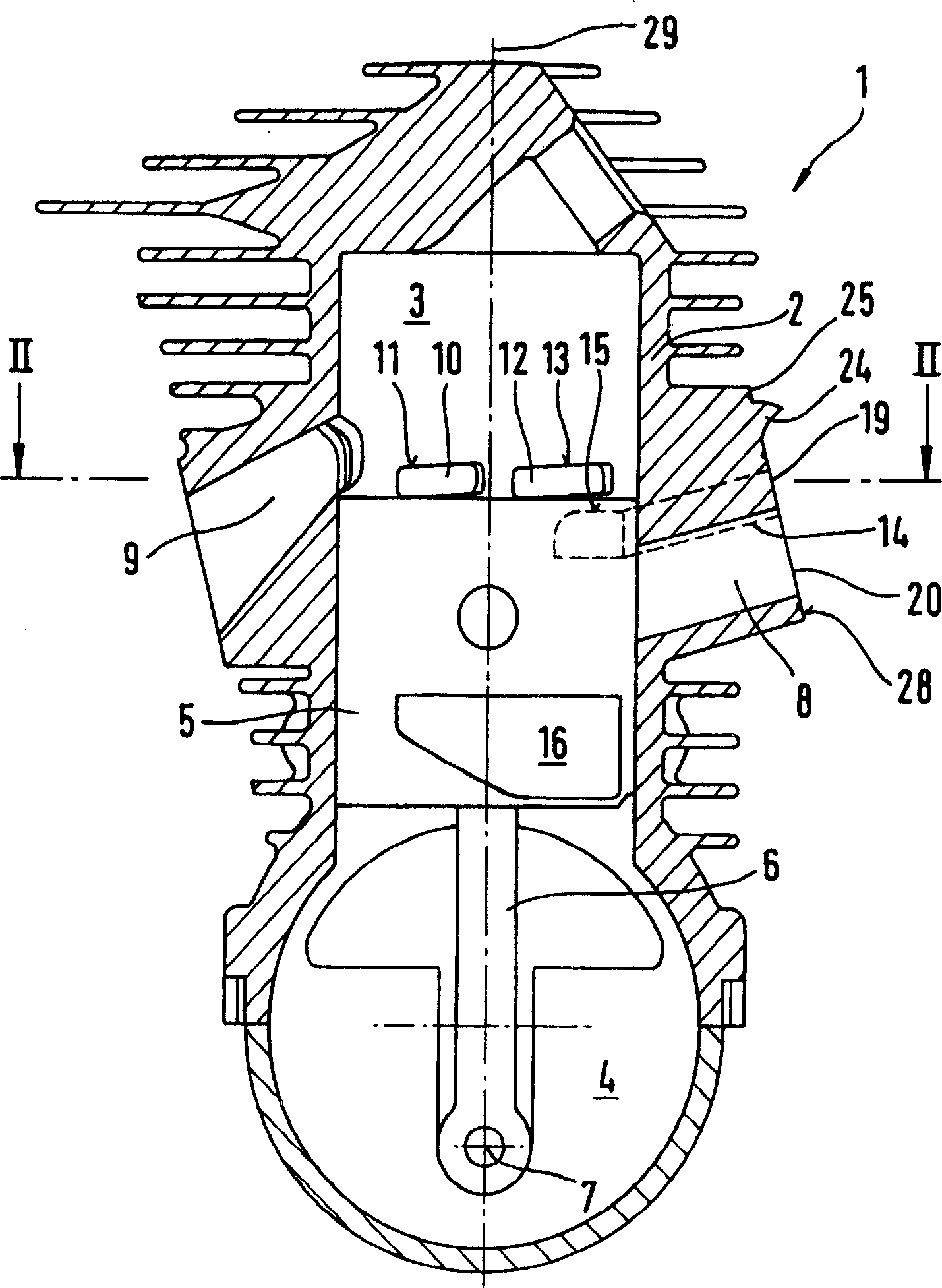

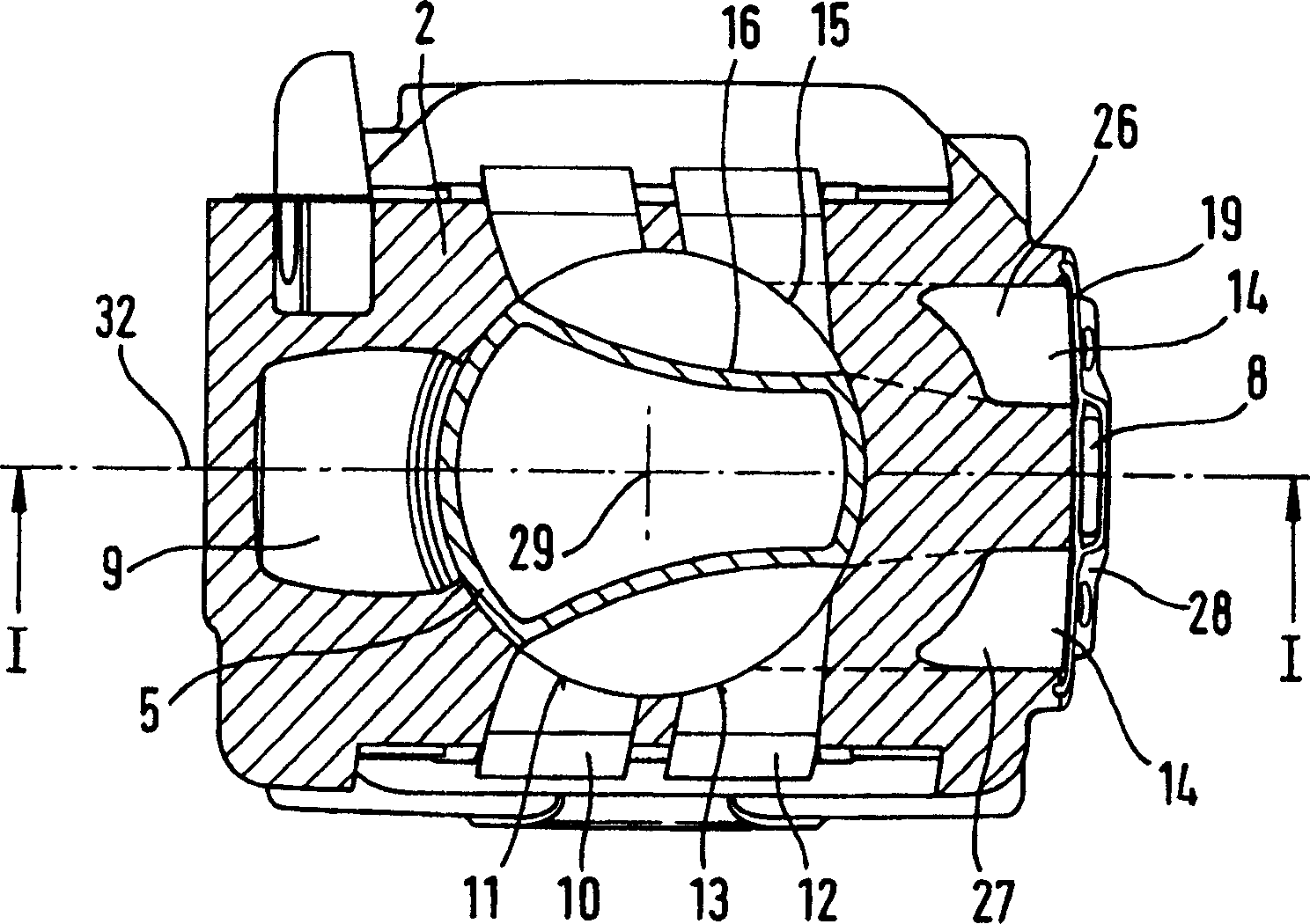

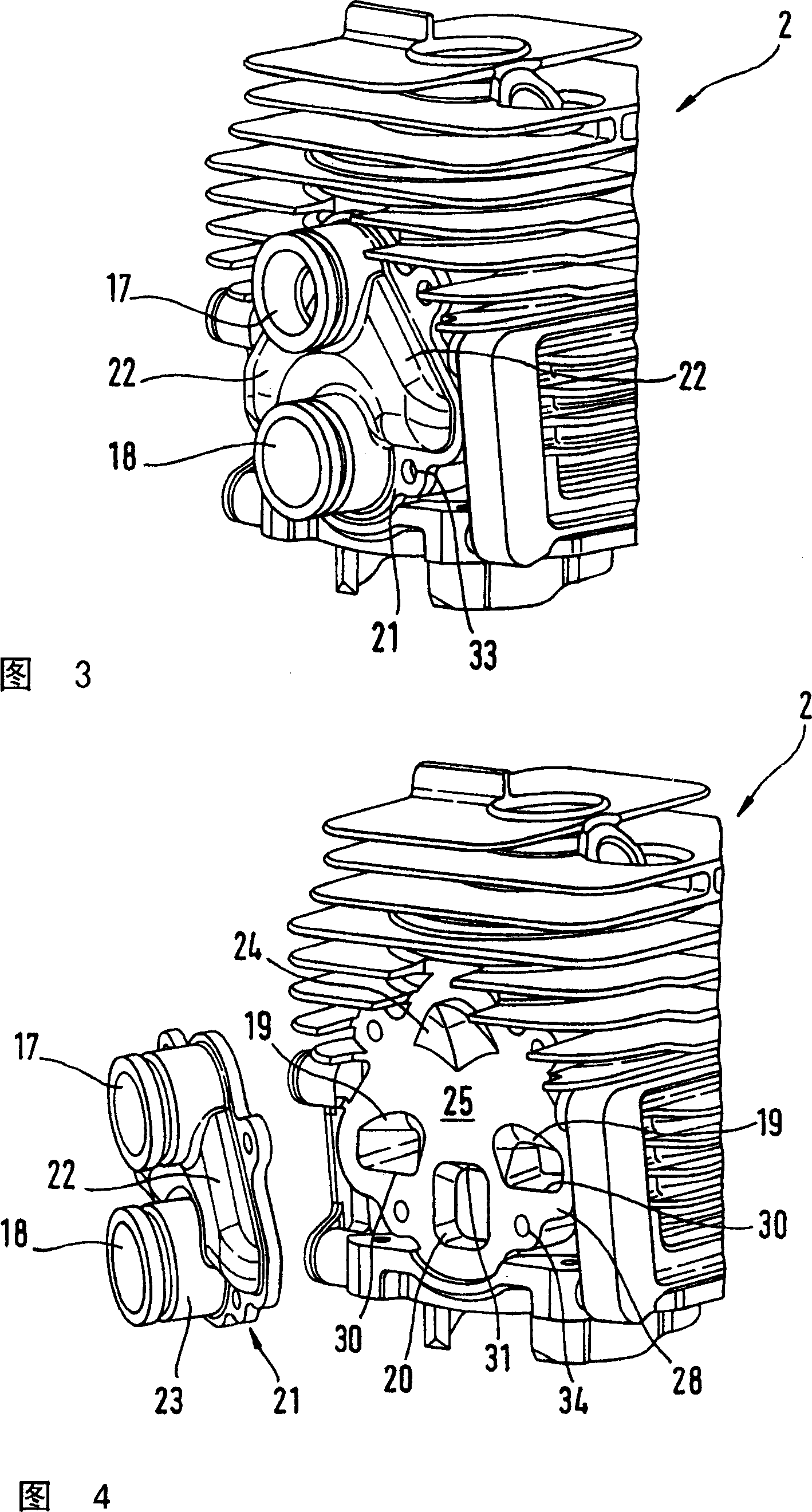

[0022] exist figure 1 and 2 The illustrated two-stroke engine 1 comprises a cylinder 2 in which a combustion chamber 3 is located. As shown in Figure 4, the combustion chamber 3 is defined by a piston 5 which moves up and down. The piston 5 is driven by the crank connecting rod 6 and is supported in the crankcase 4 figure 1 The crankshaft 7 is shown. The combustion chamber 3 has an exhaust gas outlet 9 outwards. at the predetermined position of the piston, e.g. figure 1 In the piston position shown in , the crankcase 4 is connected to the combustion chamber 3 via the overflow pipe grooves 10 and 12 . The overflow pipe groove 10 close to the exhaust port leads to the combustion chamber 3 through an overflow window 11 here, and the overflow pipe groove 12 far away from the exhaust port leads to the combustion chamber through an overflow window 13 . The cylinder 2 has a center plane 32 which roughly divides the exhaust port in the middle and which includes the cylinder long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com