Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

751 results about "Two-stroke engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

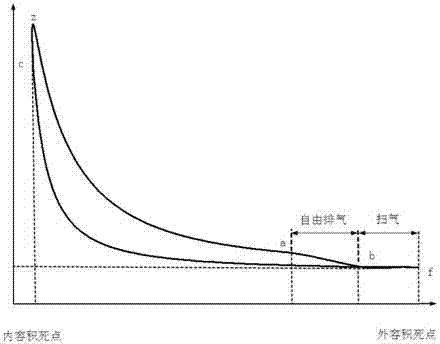

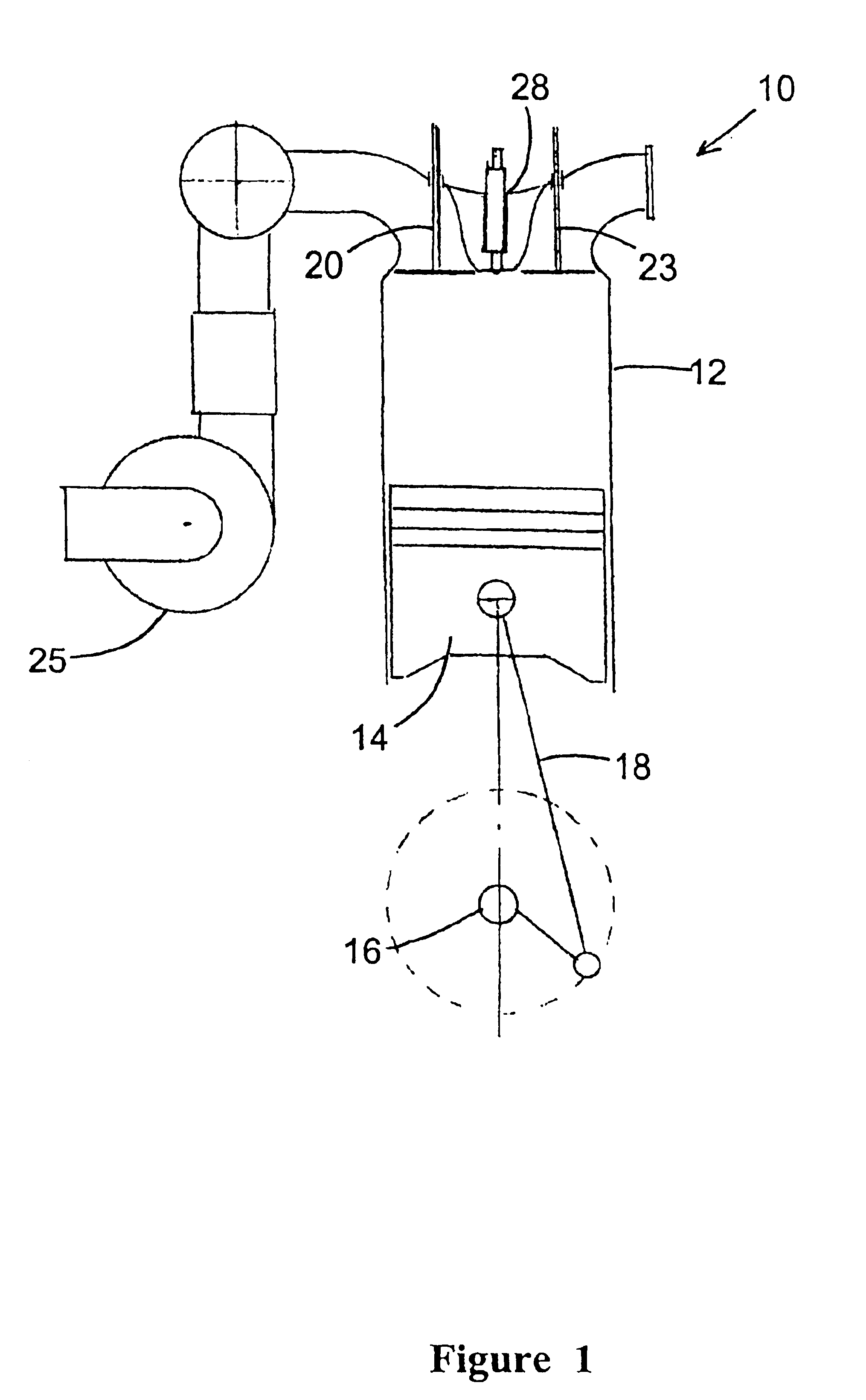

A two-stroke (or two-cycle) engine is a type of internal combustion engine which completes a power cycle with two strokes (up and down movements) of the piston during only one crankshaft revolution. This is in contrast to a "four-stroke engine", which requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time.

Split-cycle four-stroke engine

InactiveUS6952923B2Improve efficiencyImprove performanceInternal combustion piston enginesGas pressure propulsion mountingReciprocating motionFour-stroke engine

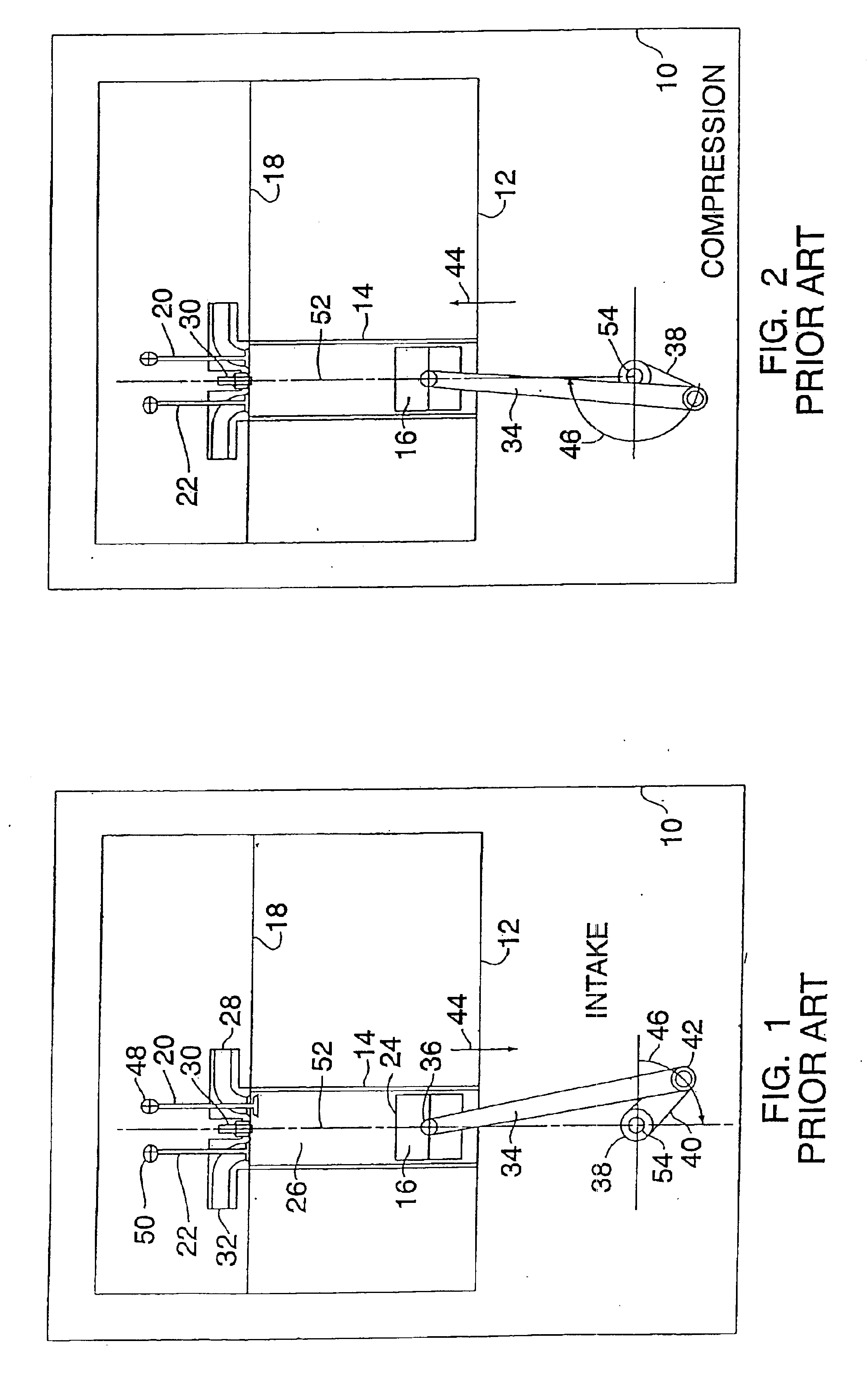

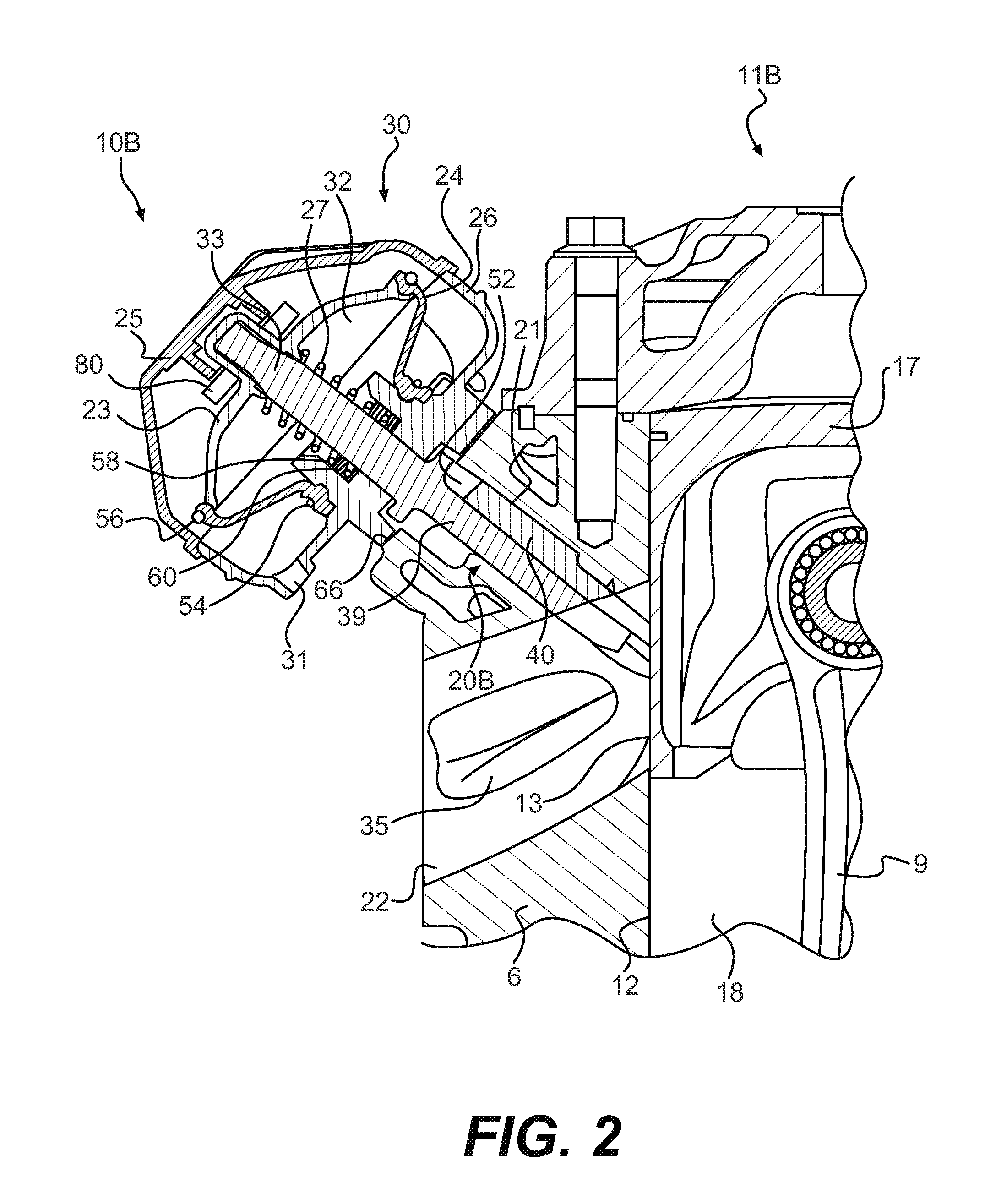

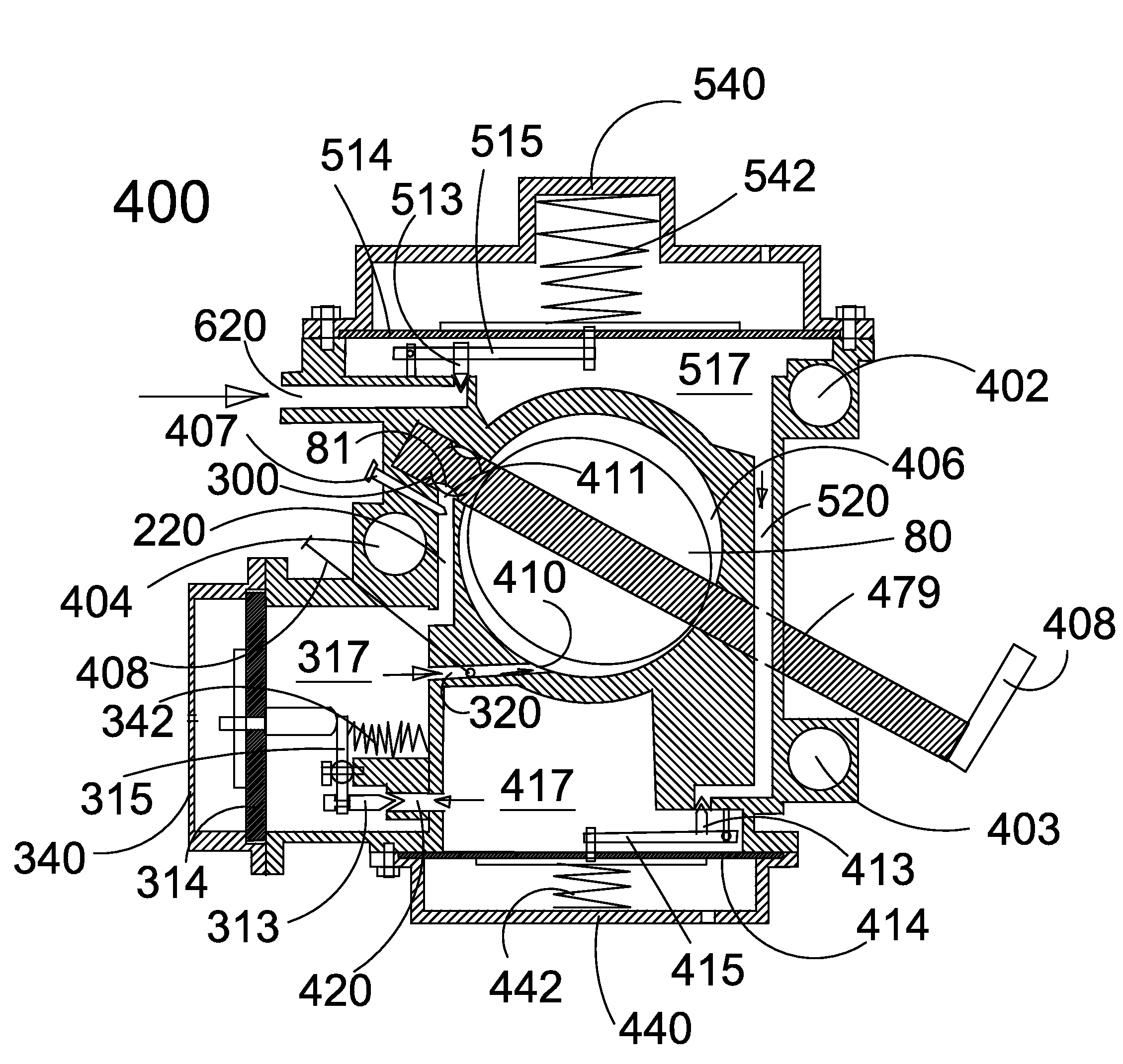

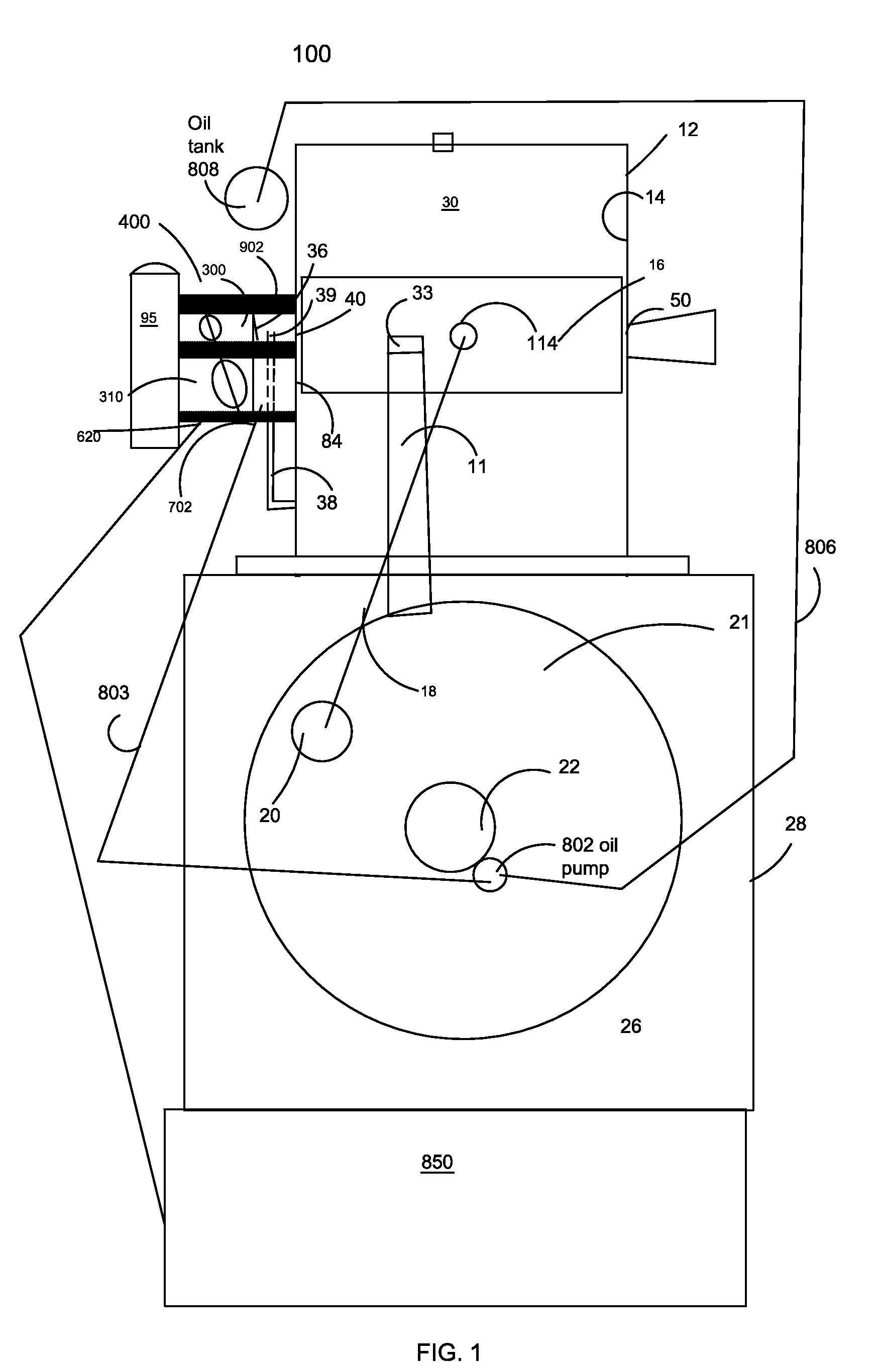

An engine has a crankshaft, rotating about a crankshaft axis of the engine. An expansion piston is slidably received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston reciprocates through an expansion stroke and an exhaust stroke of a four stroke cycle during a single rotation of the crankshaft. A compression piston is slidably received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke of the same four stroke cycle during the same rotation of the crankshaft. A ratio of cylinder volumes from BDC to TDC for either one of the expansion cylinder and compression cylinder is substantially 20 to 1 or greater.

Owner:SKADERI GRUP LLC

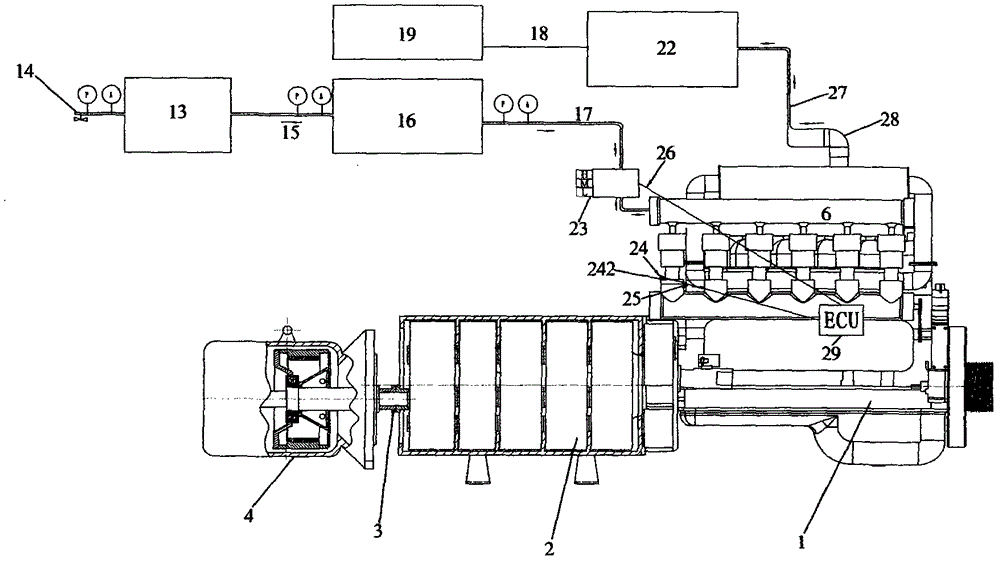

Compressed air engine assembly with tail gas recovery loop

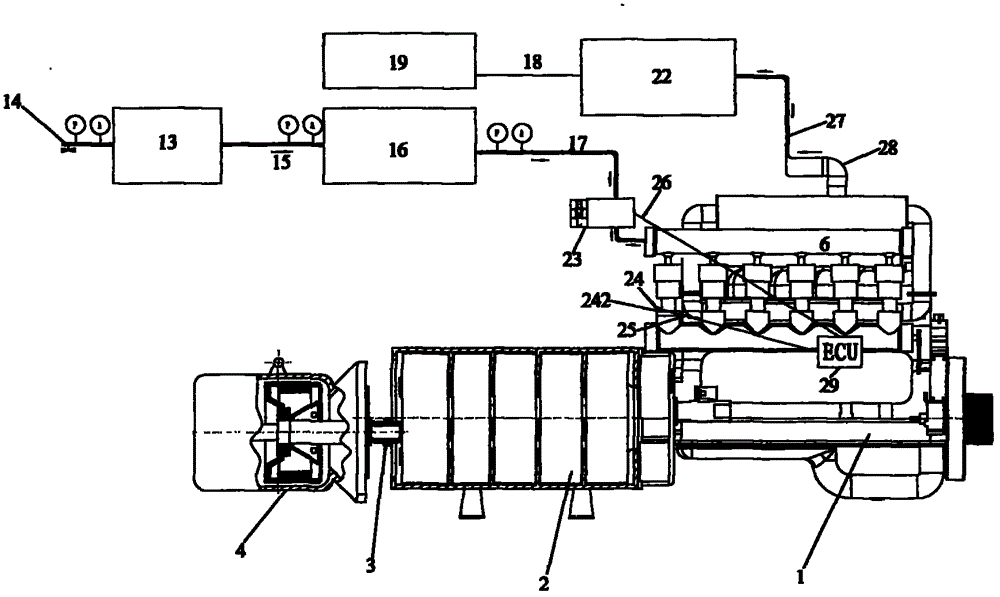

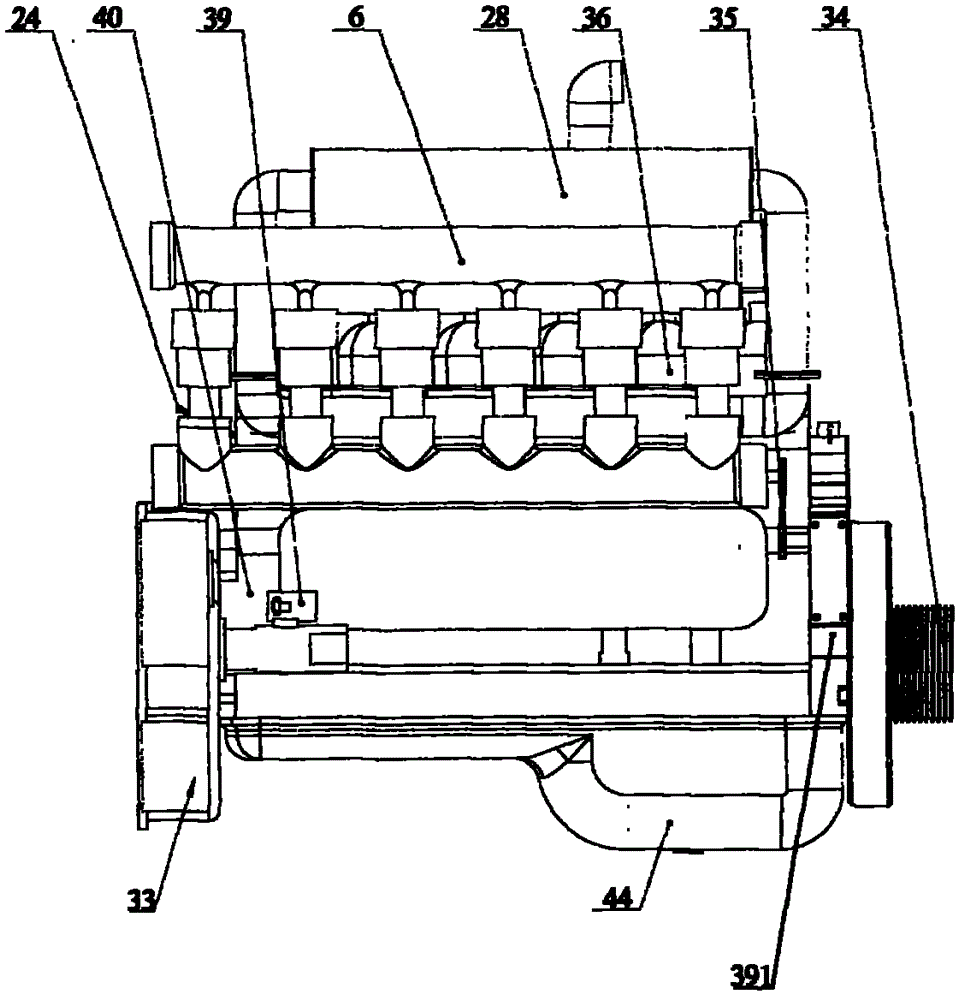

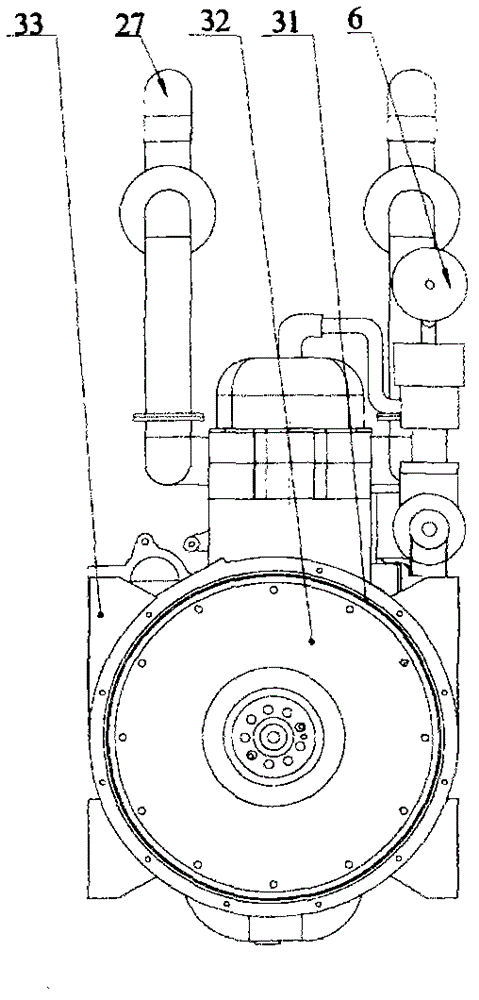

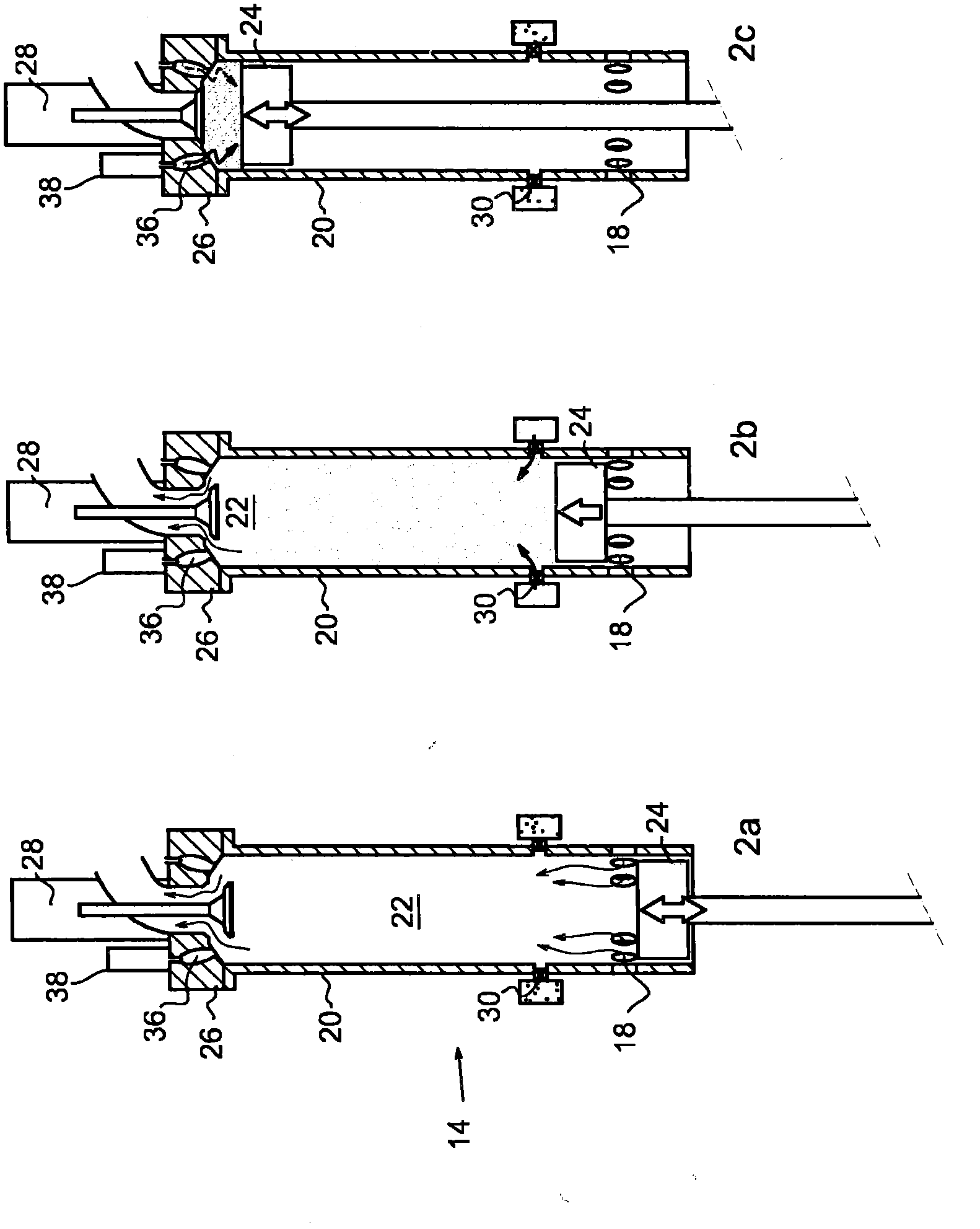

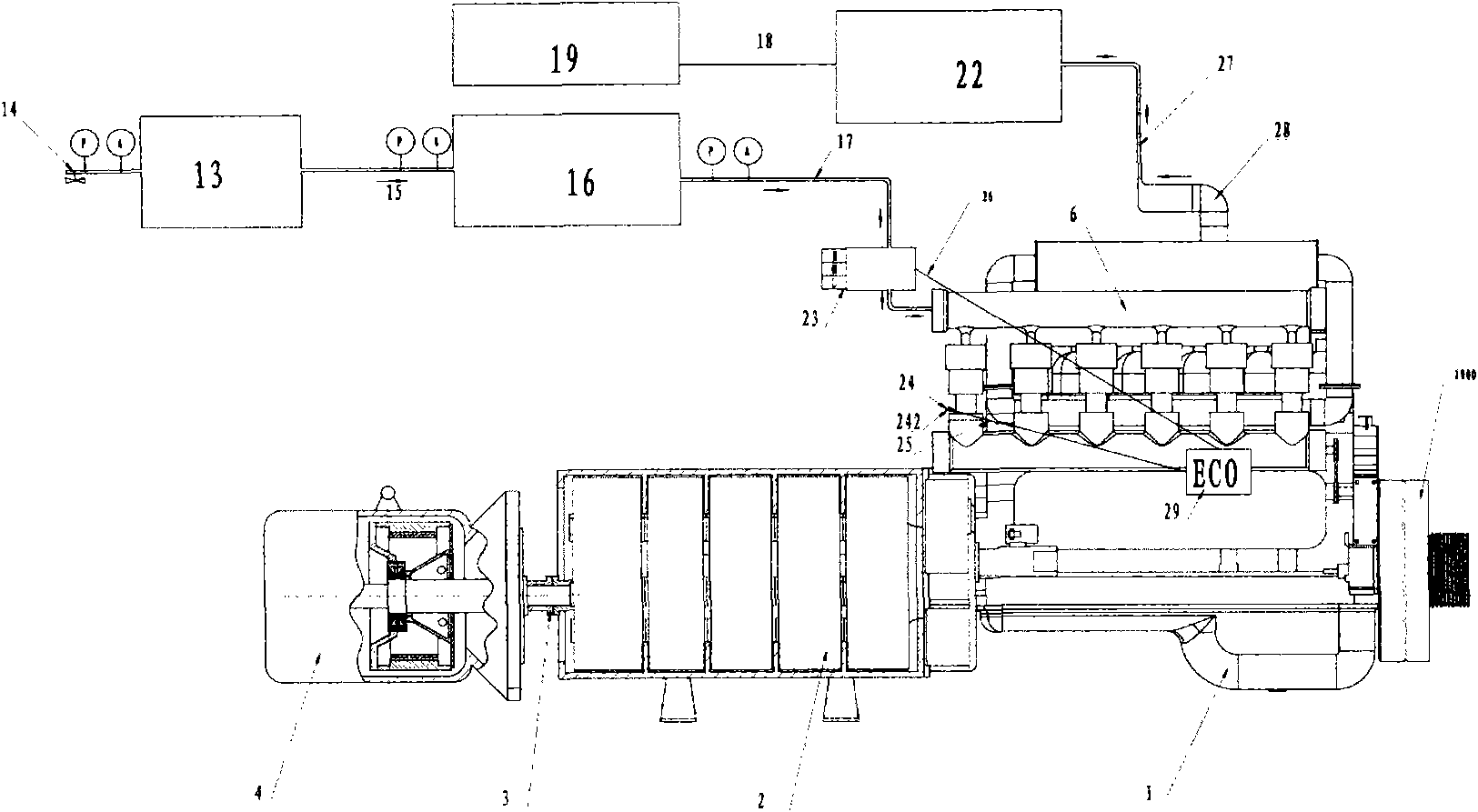

The invention relates to a two-stroke engine, in particular to a two-strike compressed air engine assembly which takes compressed air as a power source. The compressed air engine assembly comprises an engine body (1), a multi-cylinder power divider (2), a power plant (4), a controller system (6), an air inlet control and speed regulation valve (23), a high-pressure gas tank group (13), a constant-pressure tank (16), an electronic control unit (ECU) (29) and a tail gas recovery loop. The tail gas recovery loop comprises an air compressor (7), a condenser (11), a tail gas recovery tank (9), an electric turbine one-way air pump (19) and a tail gas noise deadener (22).

Owner:周登荣 +1

High efficiency low-pollution engine

InactiveUS6026568AEliminate needCasingsInternal combustion piston enginesExternal combustion engineCylinder head

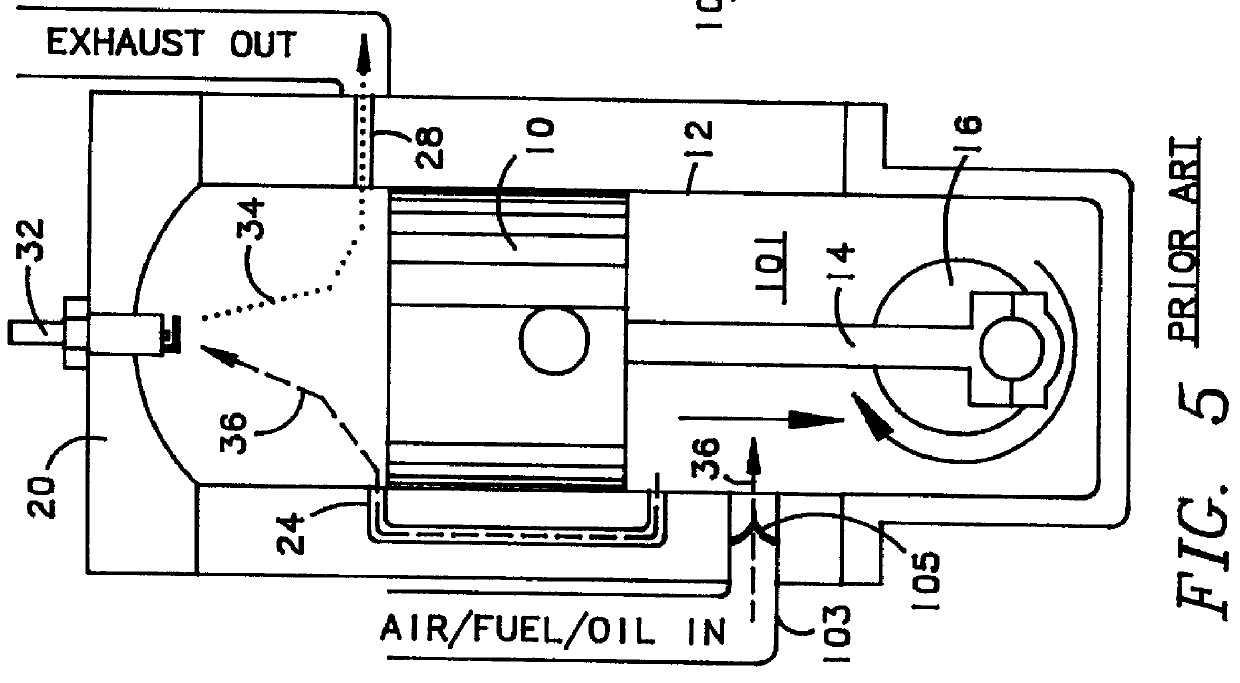

An internal combustion engine of either two-cycle or four-cycle construction including a block having at least one cylinder bore therein having sidewalls carrying a liner of a structural fiber reinforced ceramic matrix composite material disposed in sealed fiber reinforced sliding relationship within the cylinder bore, and a cylinder head sealing atop end of the cylinder bore to form a closed combustion chamber in combination with the piston. The cylinder head also has the structural fiber reinforced ceramic matrix composite material disposed on an inner surface thereof facing the combustion chamber. The preferred engine is a two-cycle engine having an externally scavenged intake system and an oil sump lubricating system thereby eliminating the need to separately mix or inject lubricating oil. Higher operating temperatures and closer tolerances allow higher fuel efficiency and less pollutant production. A preferred structural fiber reinforced ceramic matrix composite material and the method of making same is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

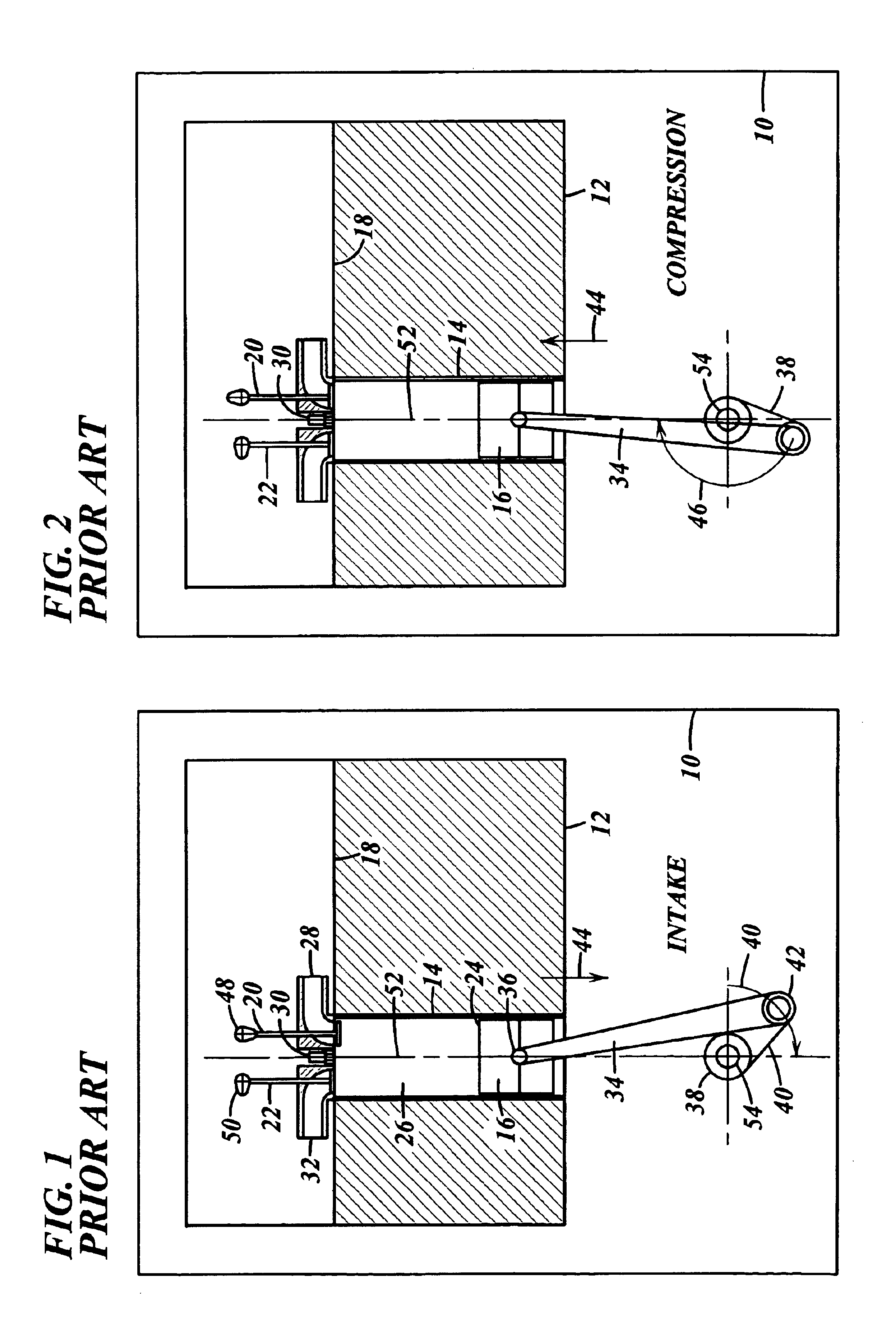

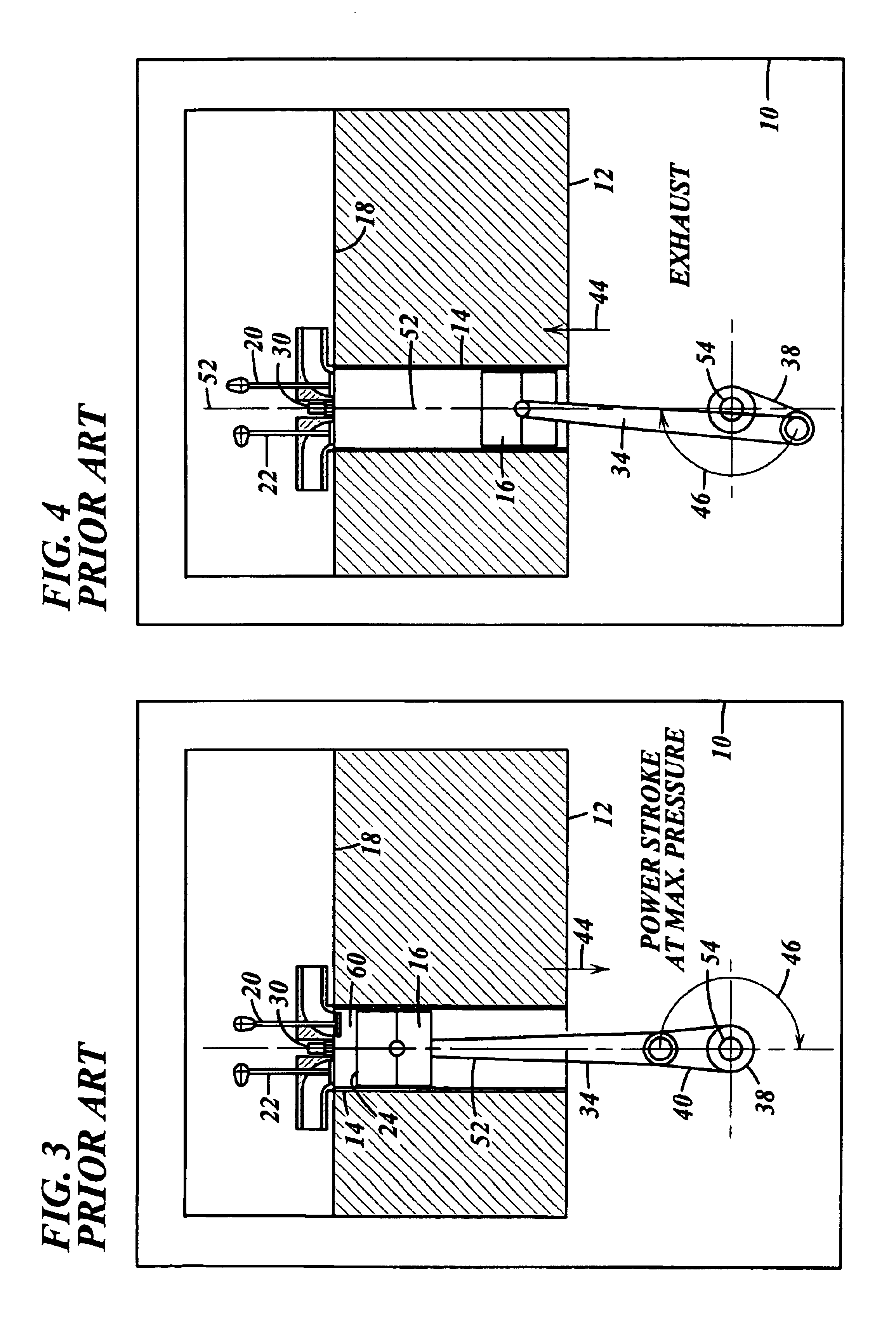

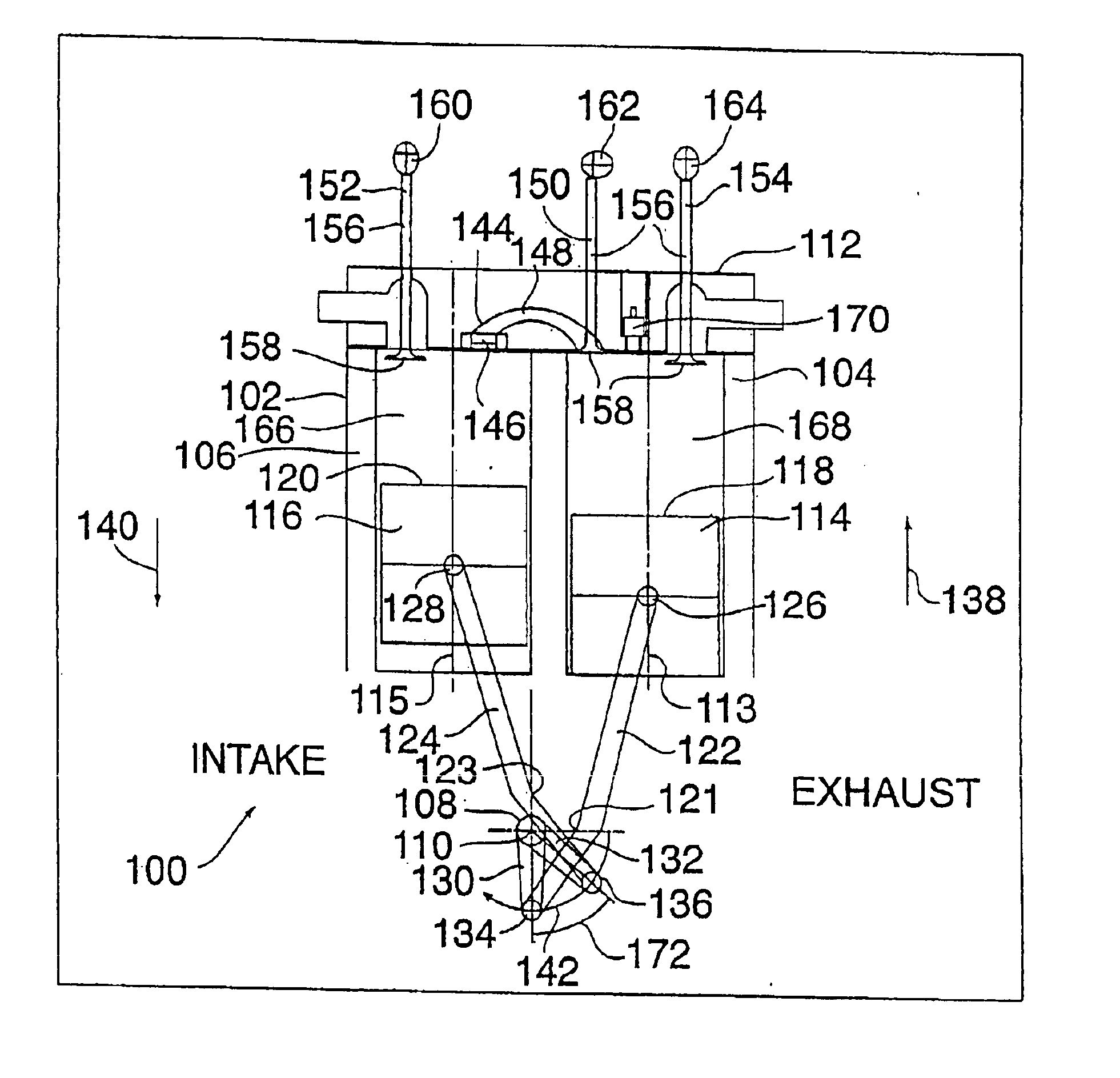

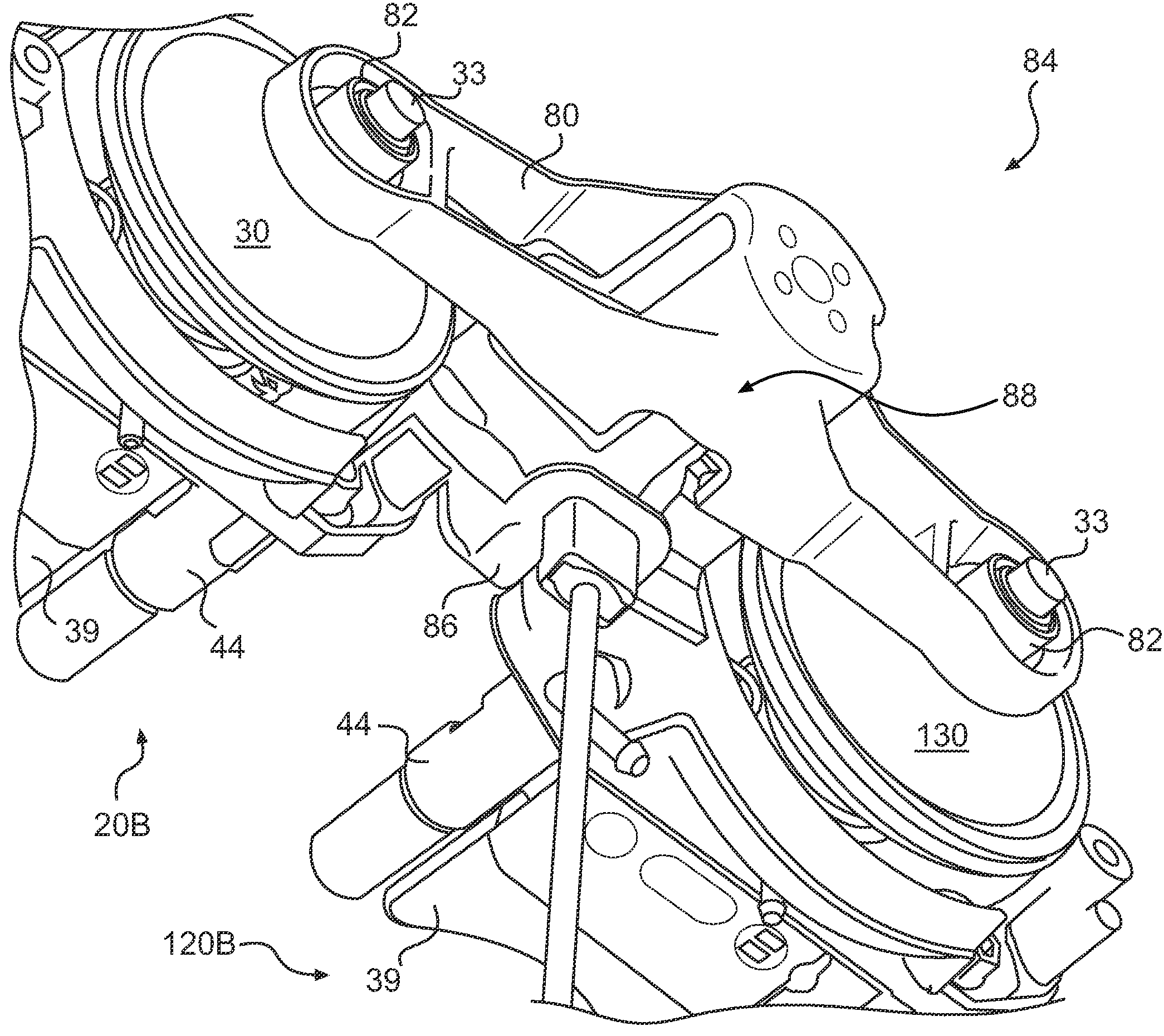

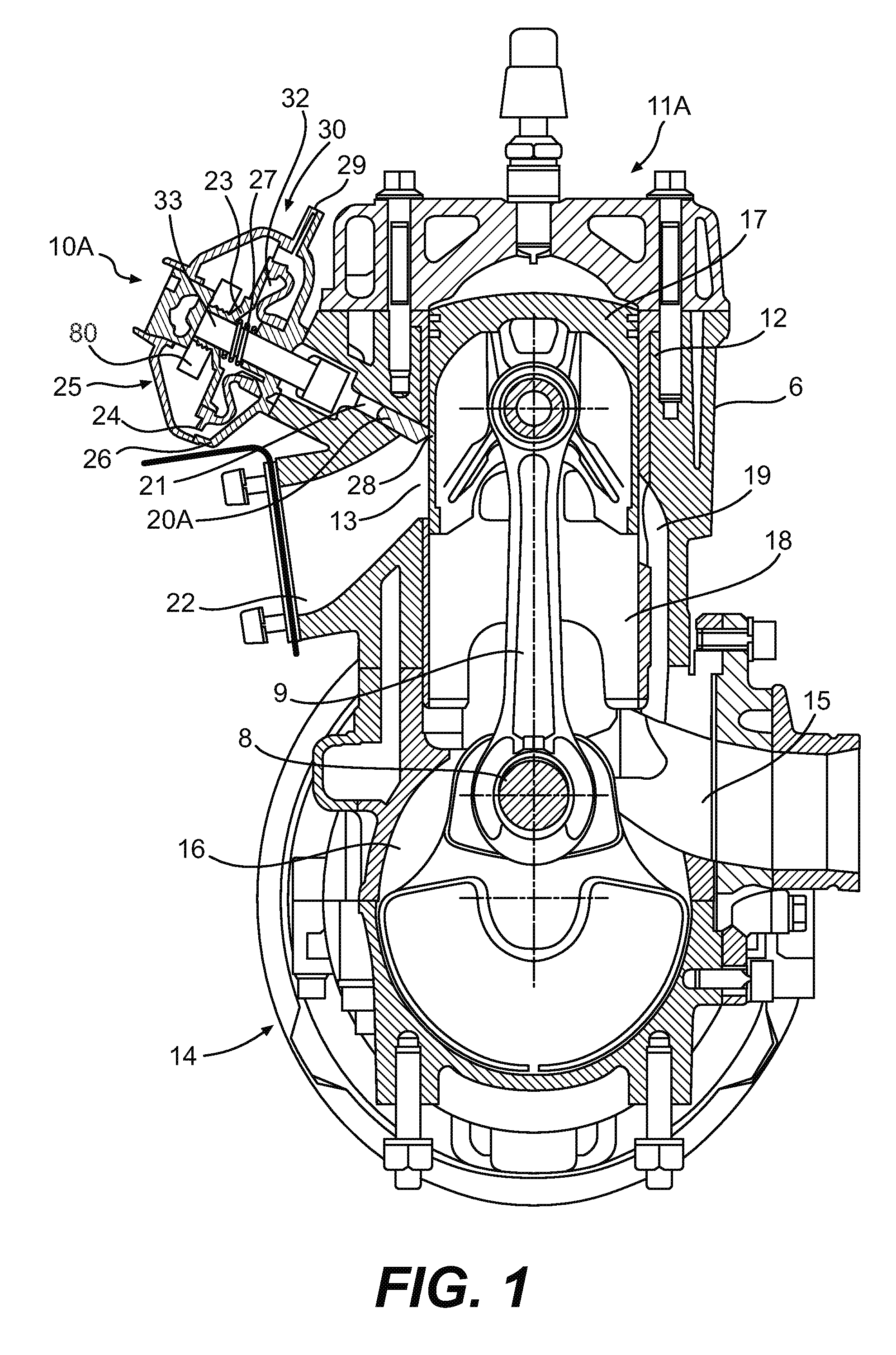

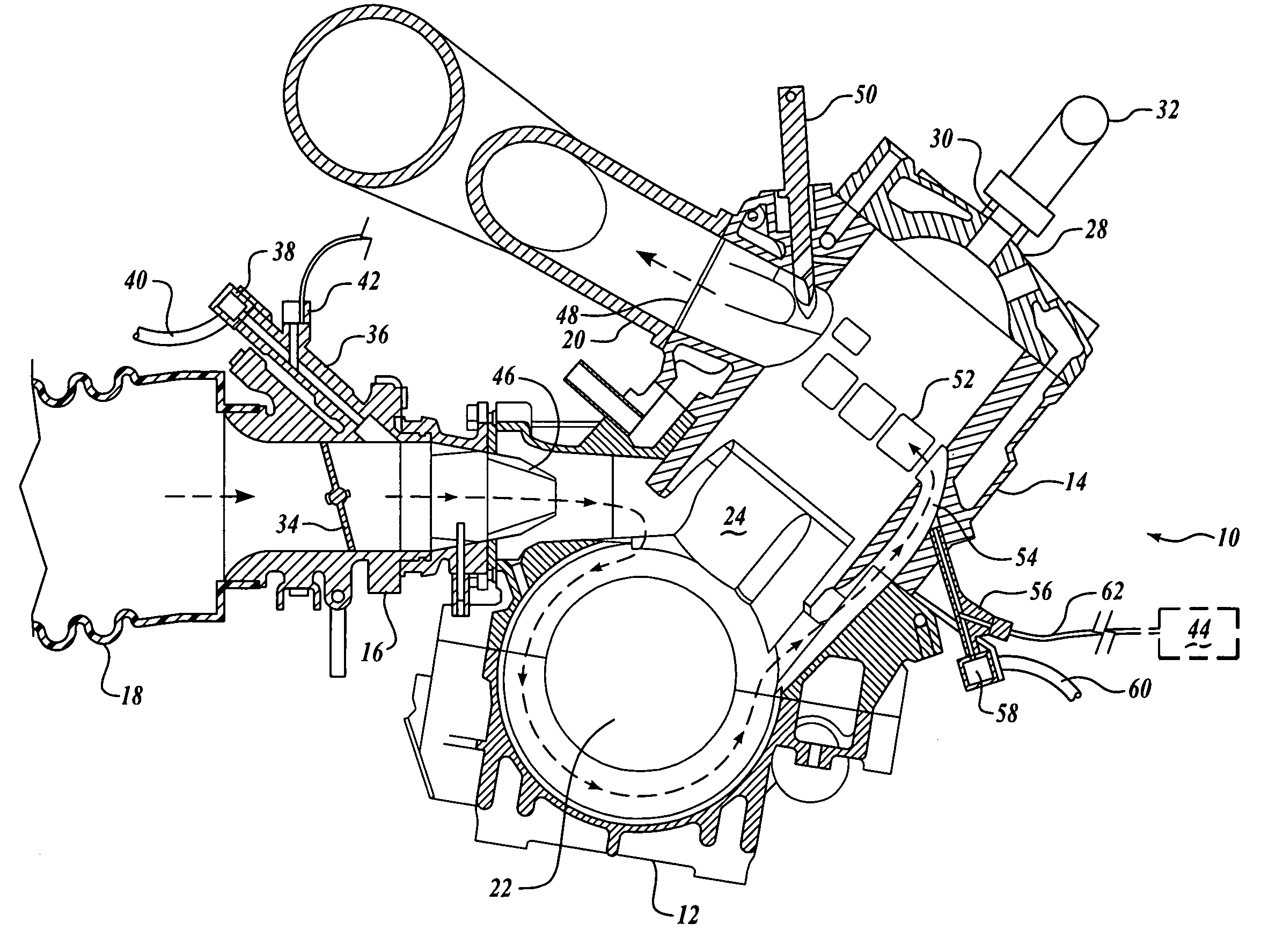

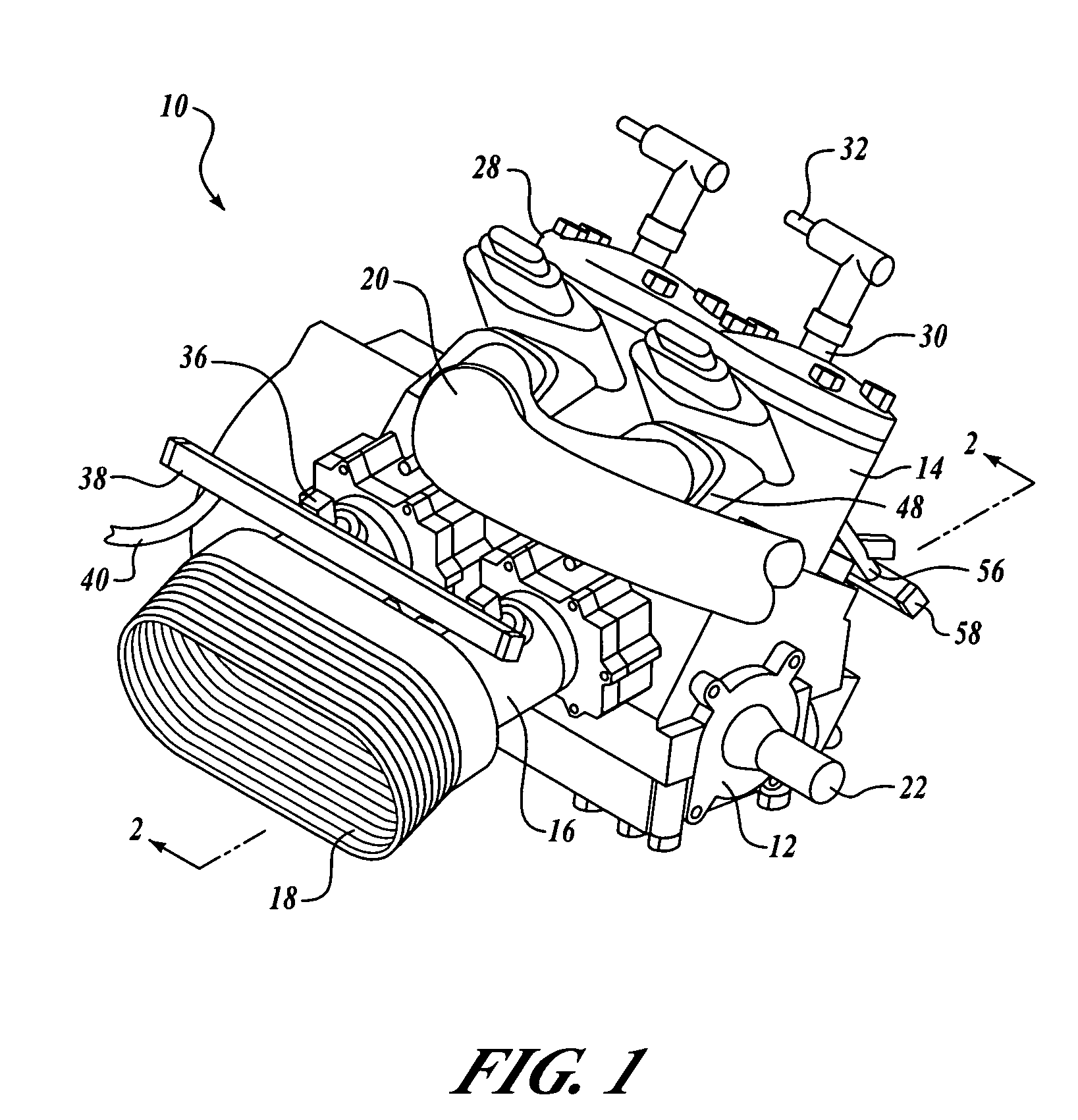

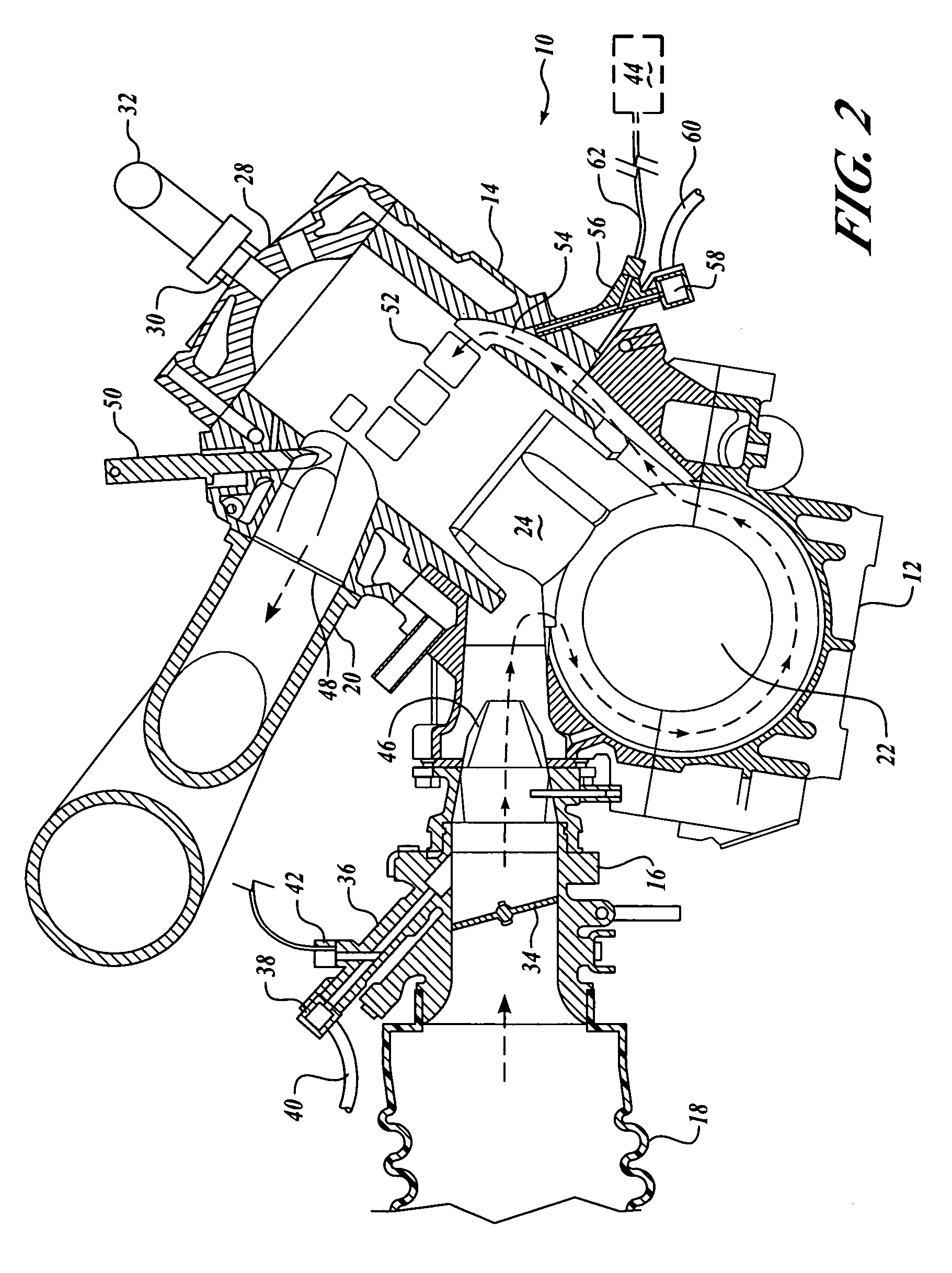

Split-cycle four-stroke engine

InactiveUS20050268609A1Improve efficiencyImprove performanceInternal combustion piston enginesGas pressure propulsion mountingReciprocating motionFour-stroke engine

An engine has a crankshaft, rotating about a crankshaft axis of the engine. An expansion piston is slidably received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston reciprocates through an expansion stroke and an exhaust stroke of a four stroke cycle during a single rotation of the crankshaft. A compression piston is slidably received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke of the same four stroke cycle during the same rotation of the crankshaft. A ratio of cylinder volumes from BDC to TDC for either one of the expansion cylinder and compression cylinder is fixed at substantially 26 to 1 or greater.

Owner:SOUTHWEST RES INST +1

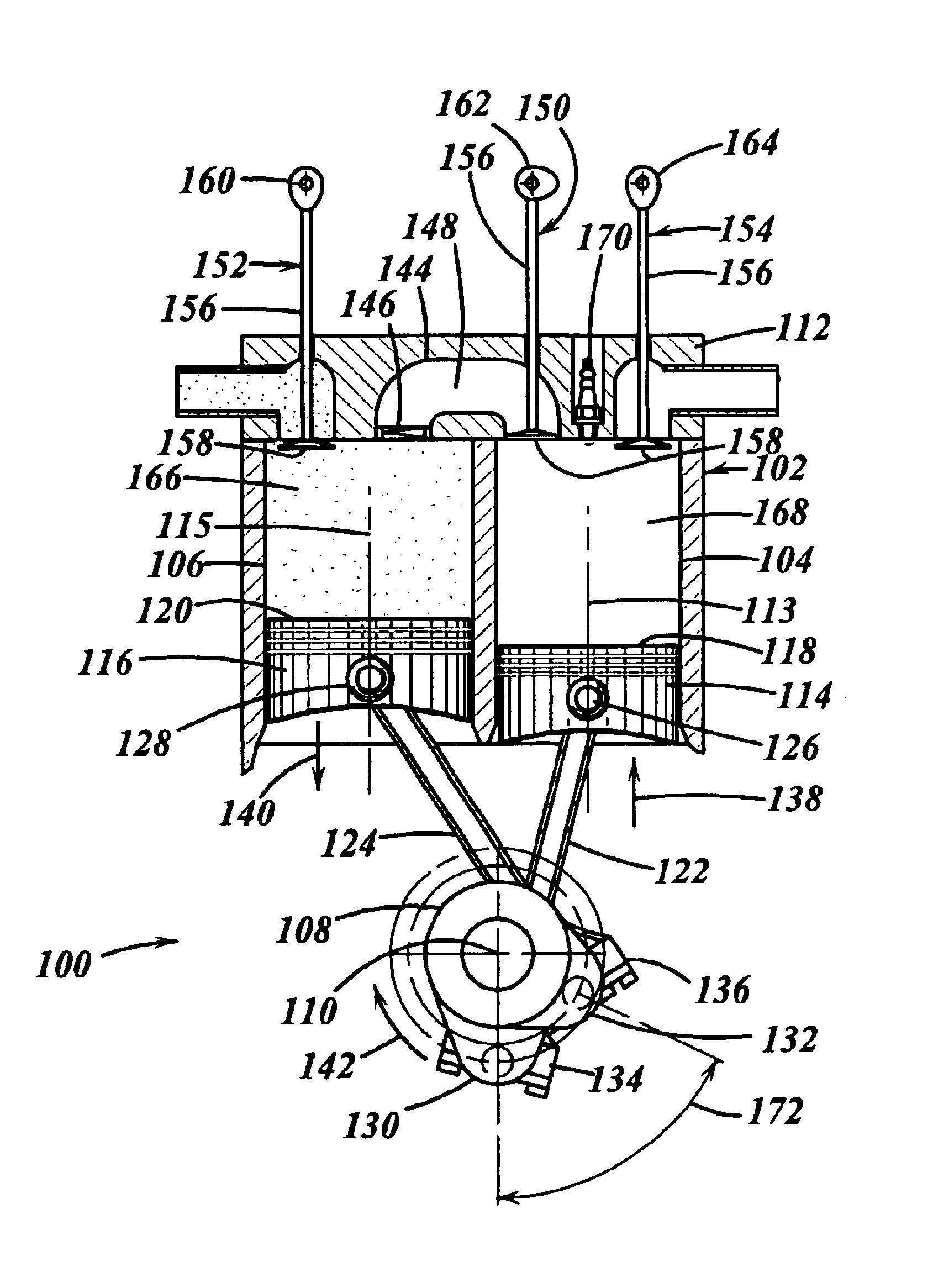

Split four stroke engine

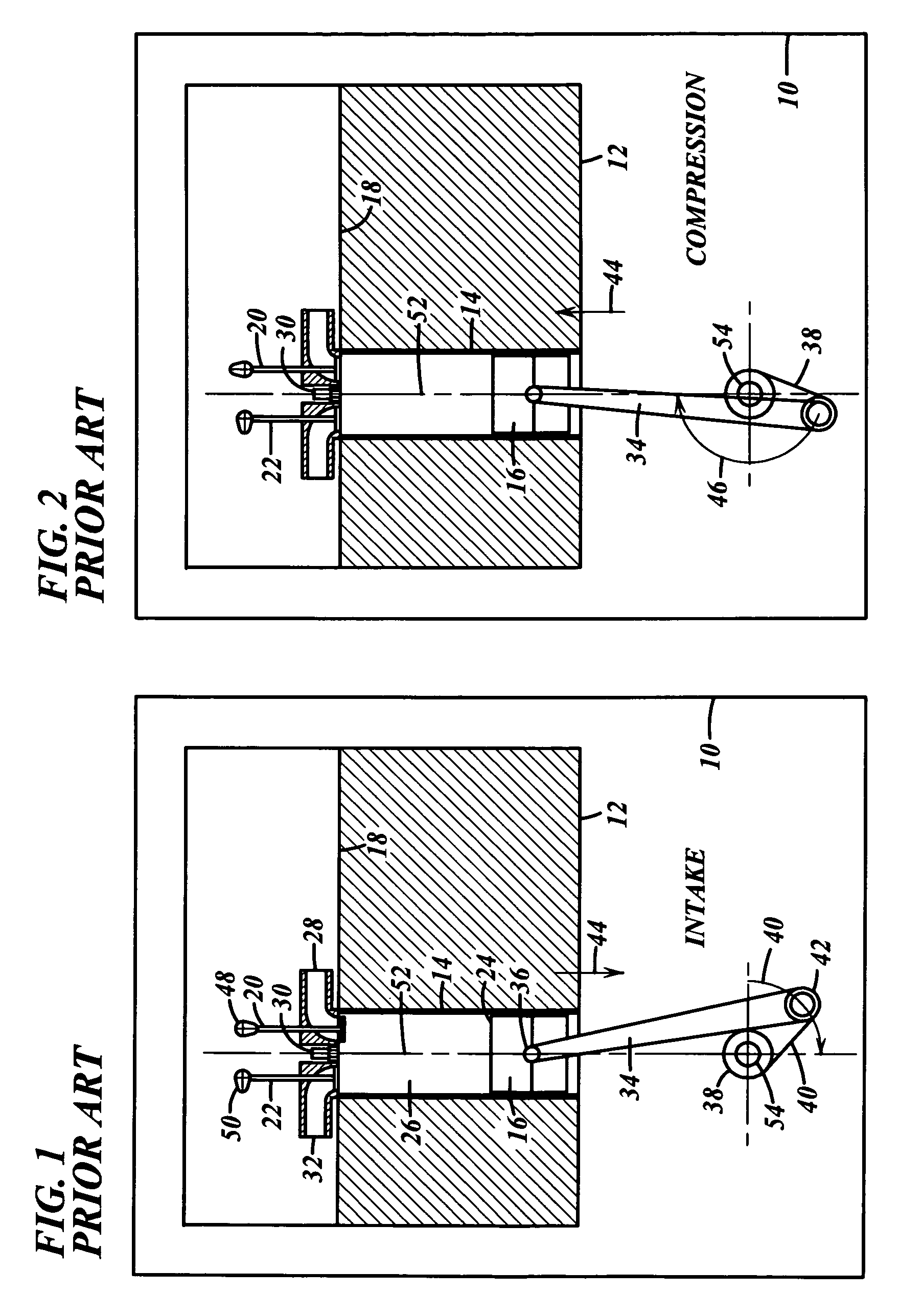

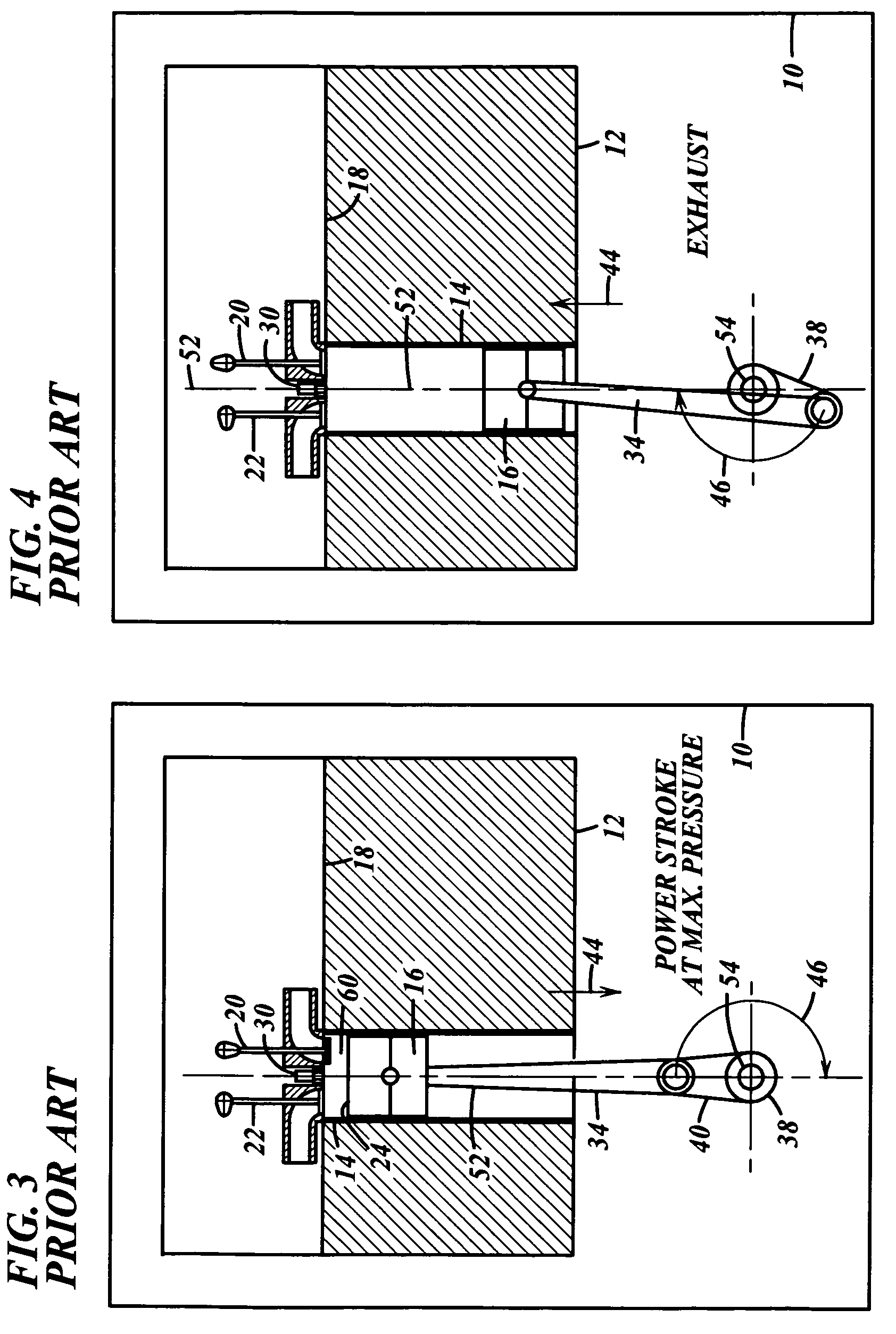

InactiveUS6880502B2Improve efficiencyIncrease the compression ratioCasingsInternal combustion piston enginesPhase shiftedReciprocating motion

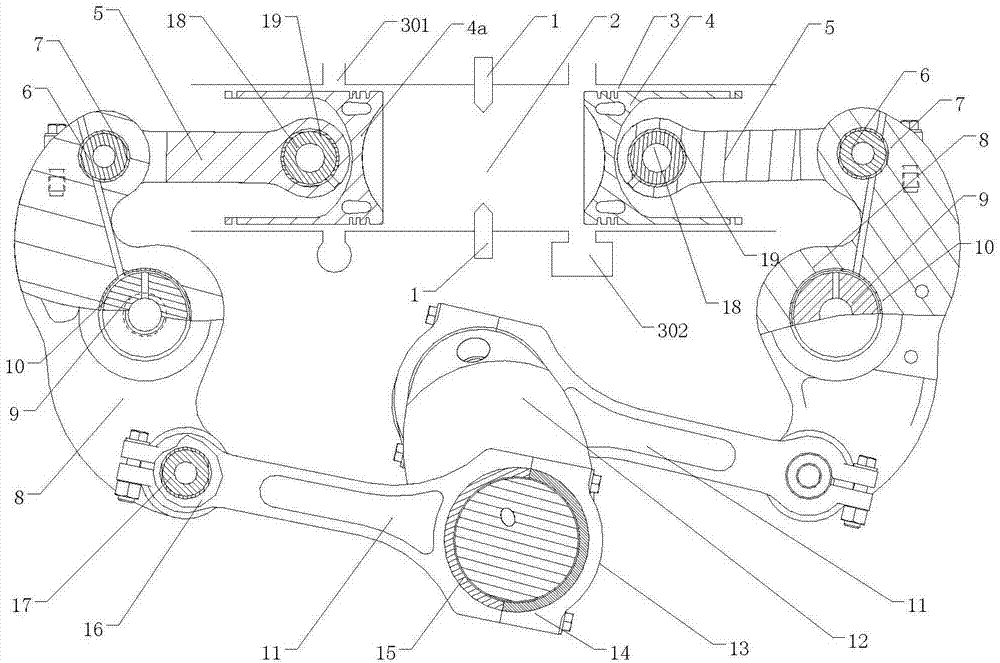

An engine includes a crankshaft, rotating about a crankshaft axis of the engine. A power piston is slidably received within a first cylinder and is operatively connected to the crankshaft via first linkage system. The power piston reciprocates through a power stroke and an exhaust stroke of a four stroke cycle during a single rotation of the crankshaft. A compression piston is slidably received within a second cylinder and operatively connected to the crankshaft via second linkage system. The first and second linkage systems share no common mechanical link. The compression piston reciprocates through an intake stroke and a compression stroke of the same four stroke cycle during the same revolution of the crankshaft. The power piston leads the compression piston by a phase shift angle that is substantially equal to or greater than zero degrees and less than 30 degrees.

Owner:SKADERI GRUP LLC

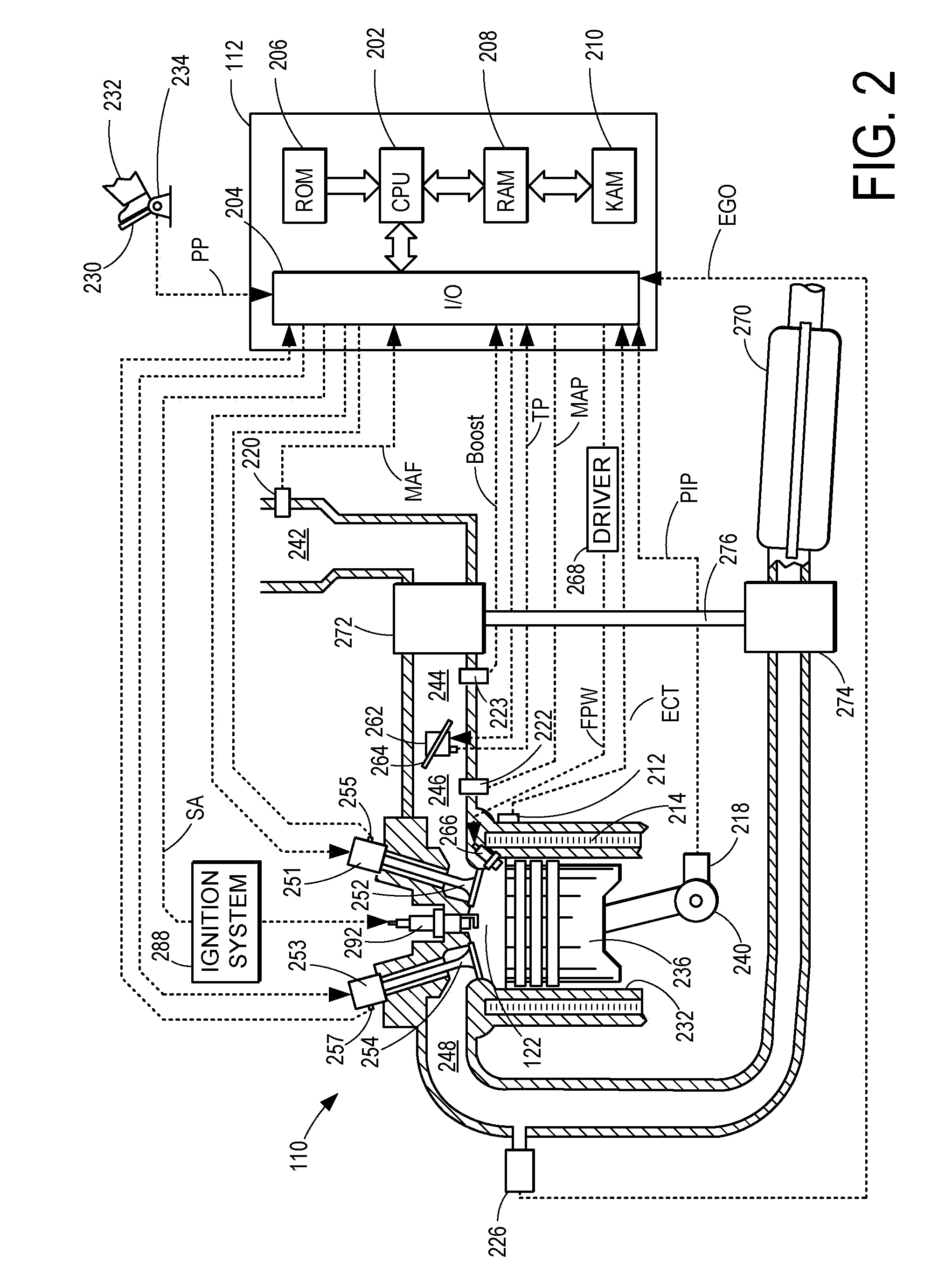

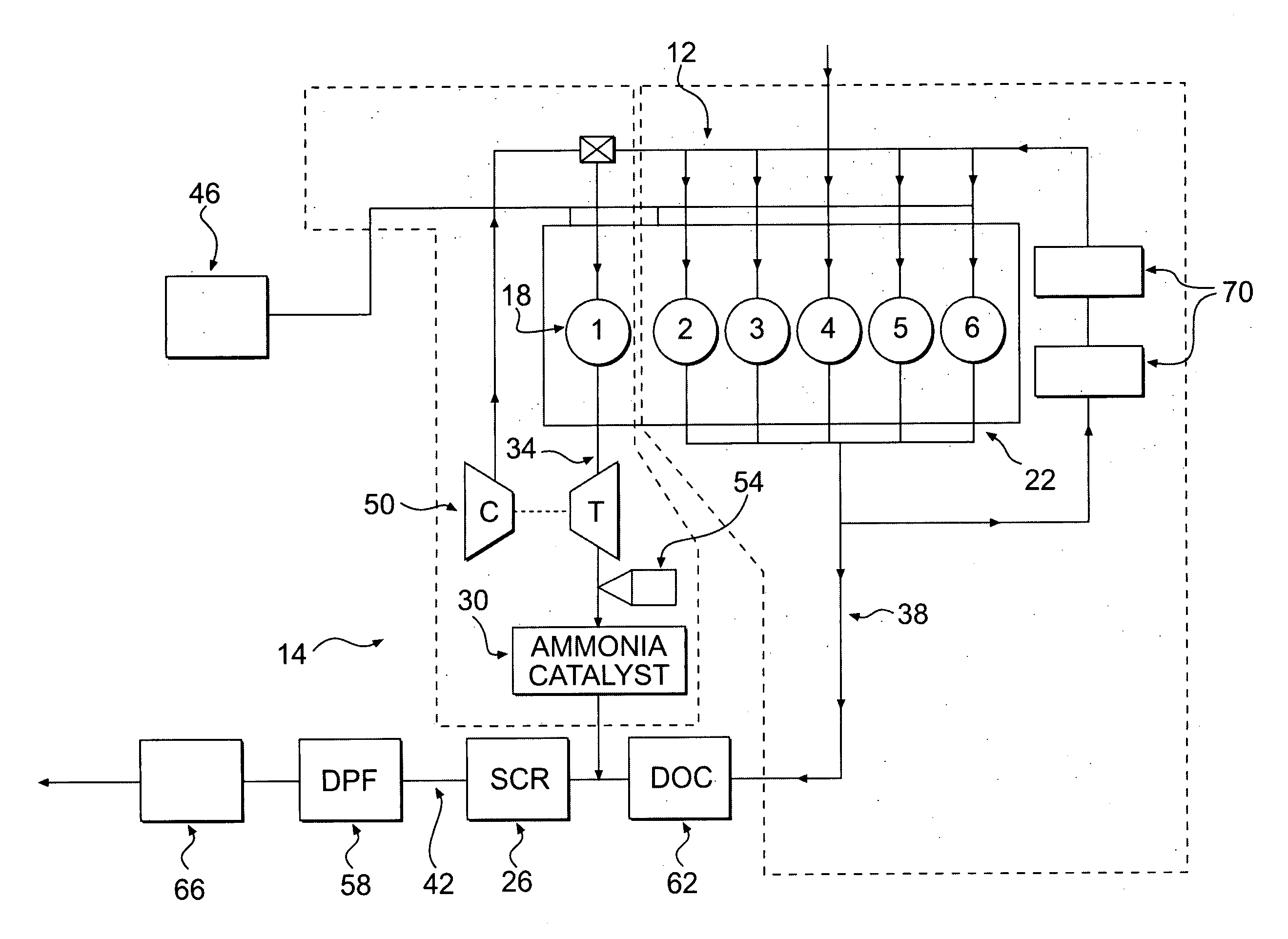

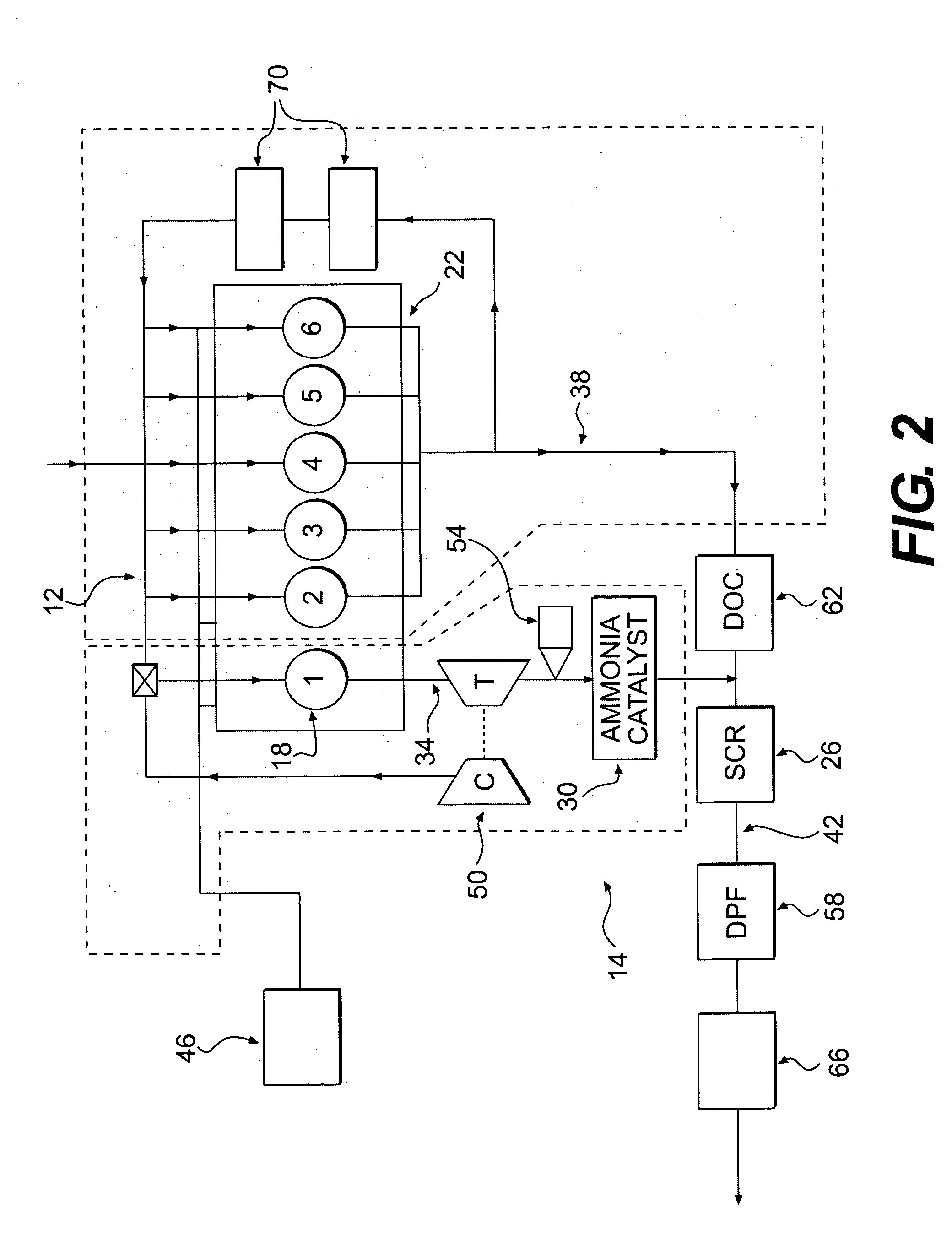

Control strategy for multi-stroke engine system

ActiveUS20090277434A1Improve engine efficiencyHigh outputElectrical controlInternal combustion piston enginesFour-stroke enginePoppet valve

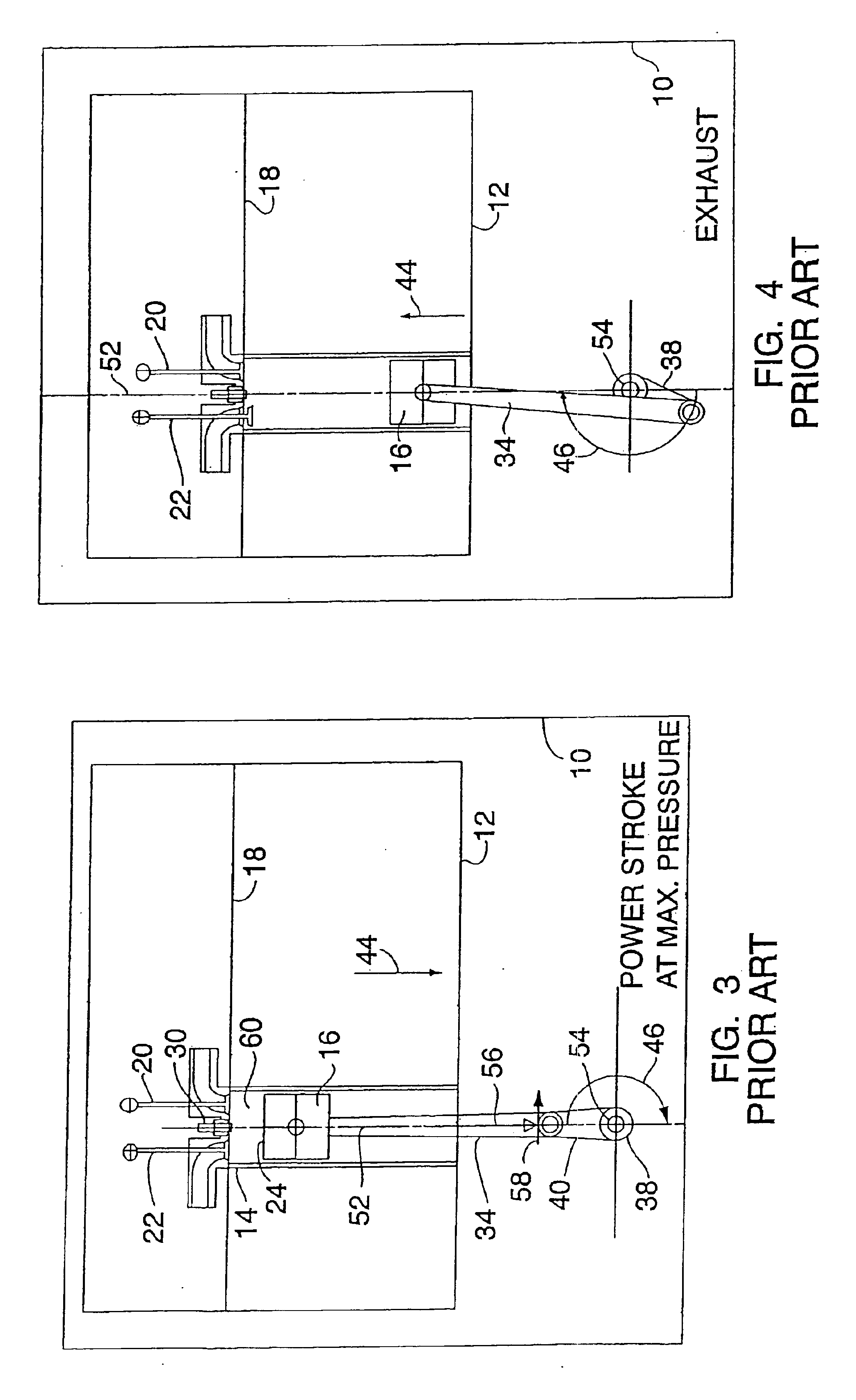

An engine system and a method of operation are described. As one example, the method may include: during a first operating condition, operating a cylinder of the engine in a two stroke cycle to combust a first mixture of air and fuel, and adjusting an opening overlap between an intake poppet valve and an exhaust poppet valve of the cylinder to vary a composition of exhaust gases exhausted by the cylinder via the exhaust poppet valve; and during a second operating condition, operating a cylinder of the engine in a four stroke cycle to combust a second mixture of air and fuel, and adjusting a relative amount of fuel contained in the second mixture of air and fuel to vary the composition of exhaust gases exhausted by the cylinder via the exhaust poppet valve.

Owner:FORD GLOBAL TECH LLC

Stratified scavenged two-stroke engine

InactiveUS20050139179A1Increase volumeCombustion enginesEngine controllersCharge injectionFour-stroke engine

A two-stroke internal combustion engine includes at least one gaseous communication charge passage between a crankcase chamber and a combustion chamber of the engine and a piston to open and close the top end of the passage and a rotary valve to open and close the lower end of the transfer passage. The air inlet port to the transfer passage for stratified scavenging is opened and closed by the crank-web that has passages and cutouts. The rotary valve replaces the one-way reed valve used in stratified scavenged and charged two-stroke engines. The air passes from the lower end of transfer passage to the top end and into the crankcase through the piston passage, alternatively air may also pass through the adjacent transfer passage directly or through a passage in the piston into the crankcase. A two-stroke engine also consists of a charge injection system controlled by the crank web eliminating the one-way valve.

Owner:HOMELITE TECH

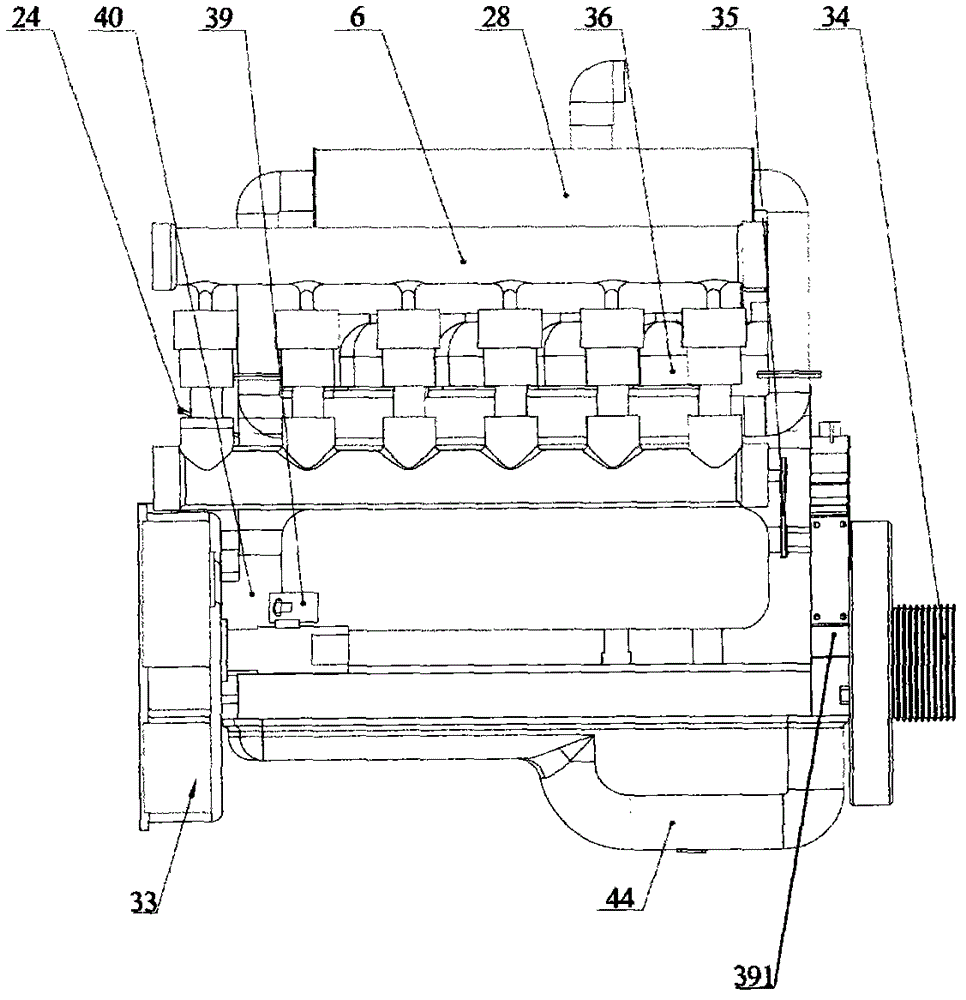

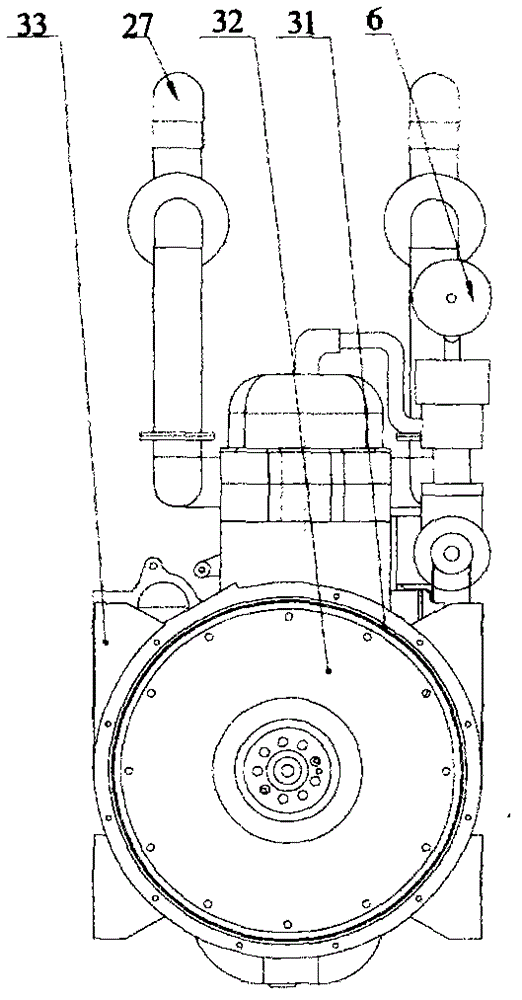

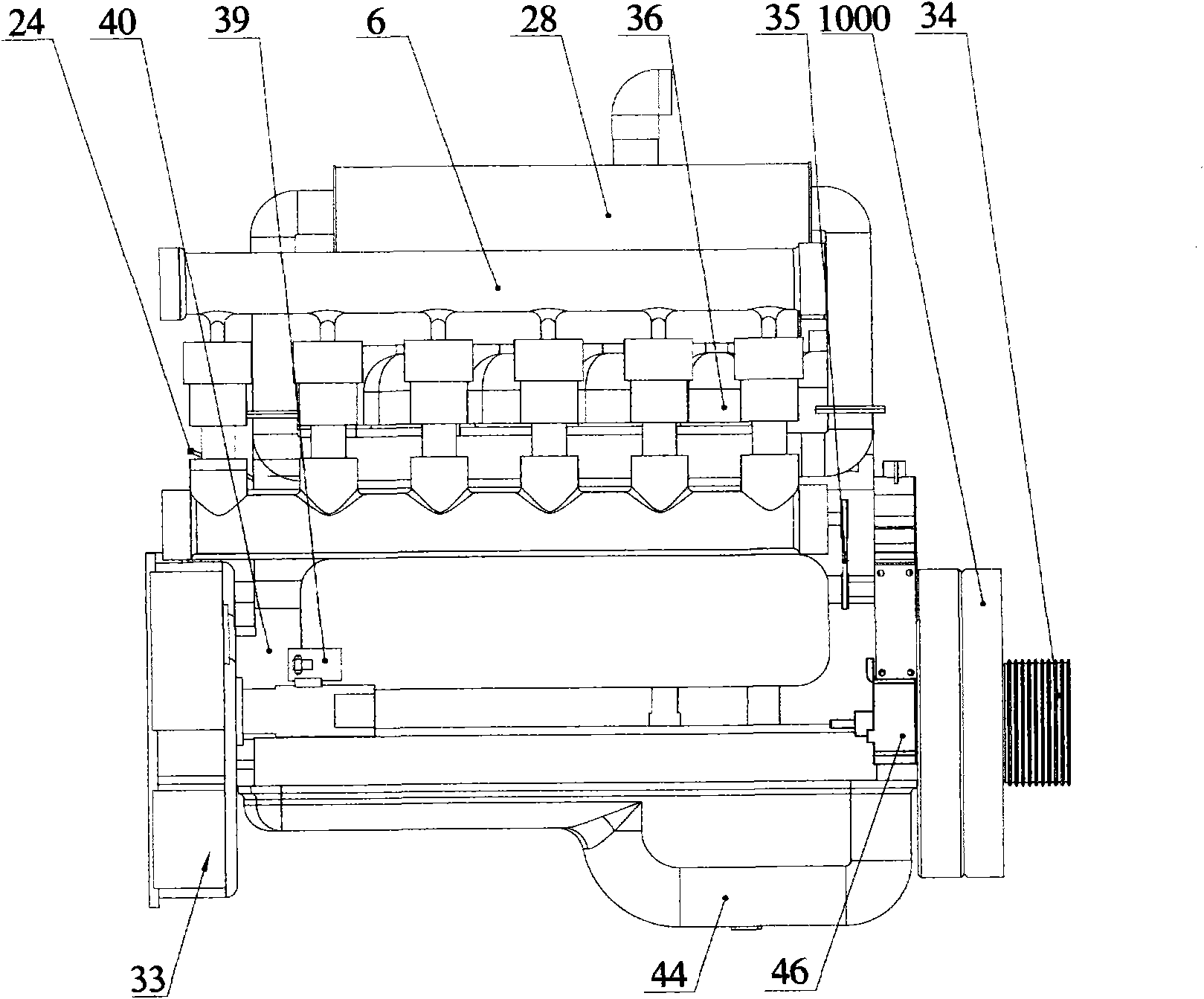

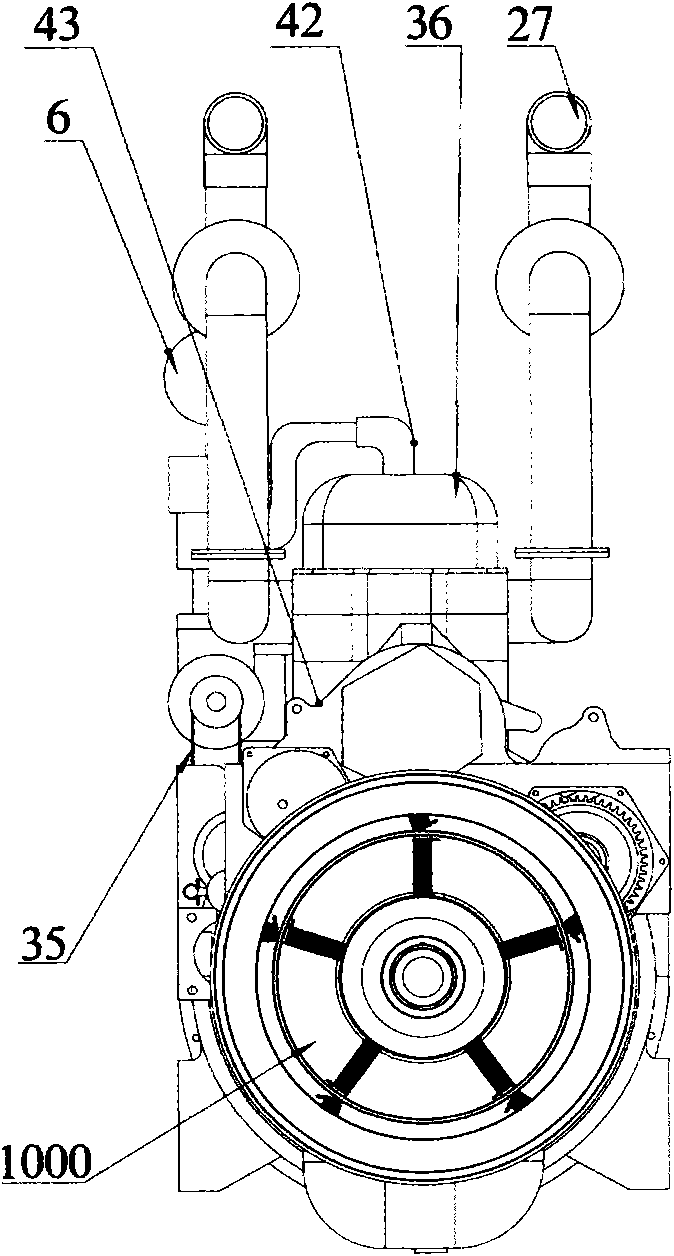

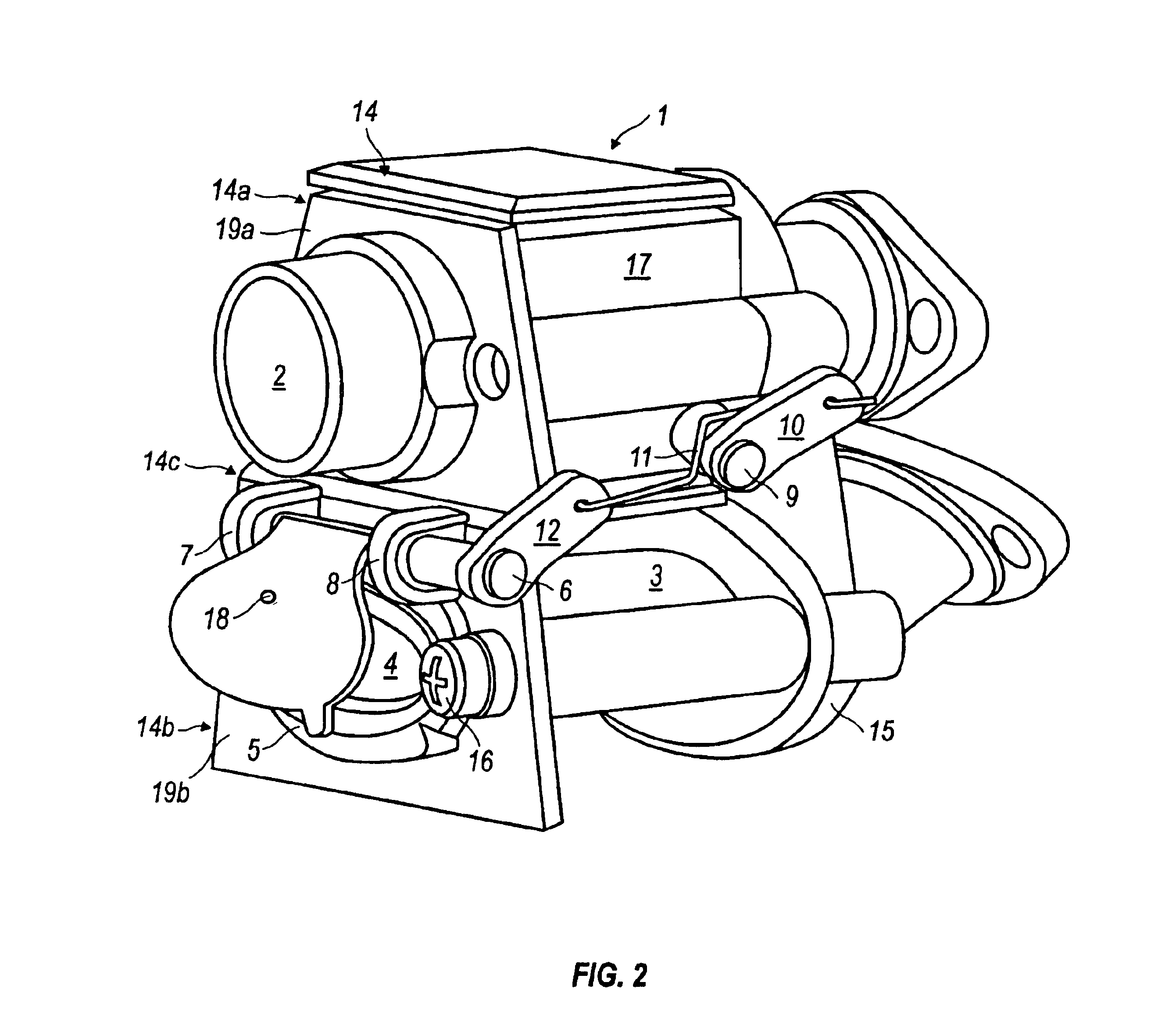

Two-stroke aerodynamic engine assembly

The invention relates to a two-stroke engine, in particular to a two-stroke aerodynamic engine assembly which takes compressed air as a power source. The two-stroke aerodynamic engine assembly comprises an engine body (1), a multicolumn power distributor (2), a power device (3), a controller system (6), an air inlet control compensated flow control valve (23), a high-pressure air tank set (13), a constant-pressure tank (16) and an electric control unit (ECU) (29).

Owner:周登荣 +1

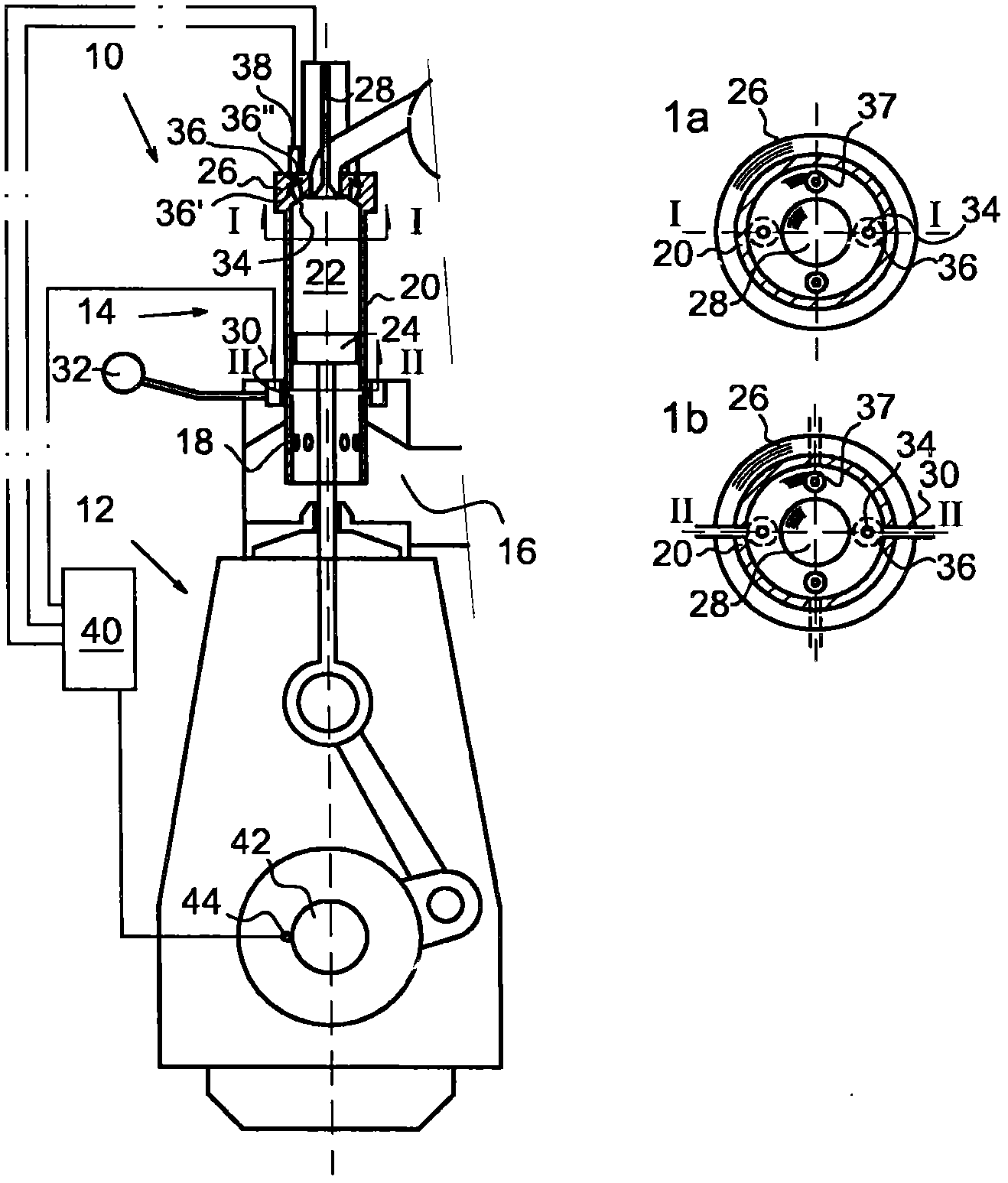

Two-stroke internal combustion engine, method of operating two-stroke internal combustion engine and method of converting two-stroke engine

ActiveCN103748334AEmission reductionSimple structureInternal combustion piston enginesGaseous engine fuelsExhaust valveTop dead center

The invention relates a two-stroke internal combustion engine (10) comprising at least one cylinder (20) with a piston (24) arranged reciprocateably between its top dead center and bottom dead center, and a cylinder cover (26) defining a combustion chamber (22), oxygen containing gas inlet (18) in the lower part of the cylinder (20) to be open into the combustion chamber (22) at least while the piston is at its bottom dead center position, a gaseous fuel inlet (30) arranged in the cylinder between the oxygen containing gas inlet (18) and the cylinder cover(26), and an exhaust valve (28) arranged to the cylinder cover at a center axis of the cylinder. The cylinder cover(26) is provided with pilot ignition pre-chambers (36) opening into the combustion chamber (22) through pre-chamber ports (34).The preset invention relates also to method of operating the two-stroke engine (10).

Owner:WAERTSILAE SCHWEIZ AG

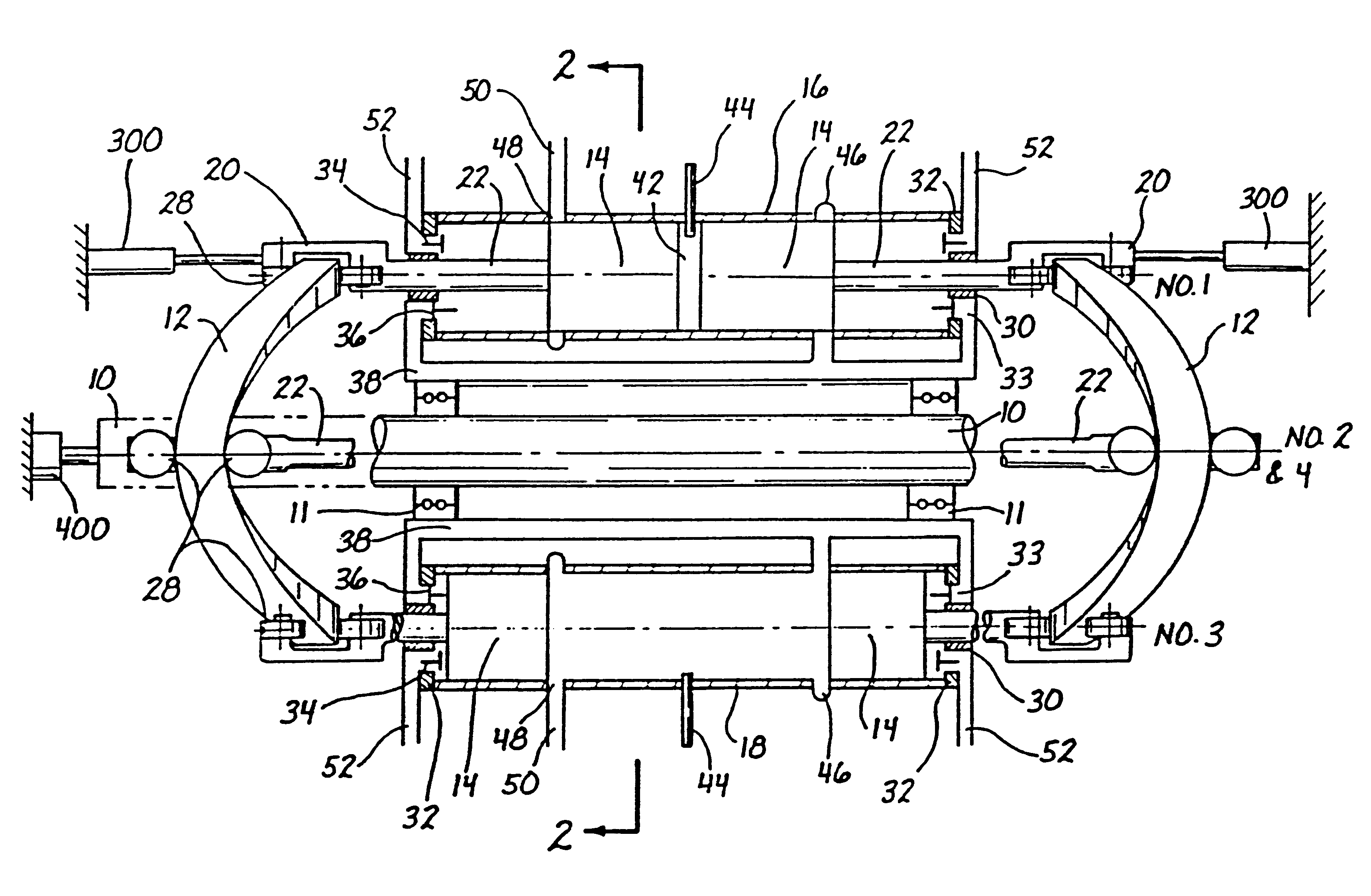

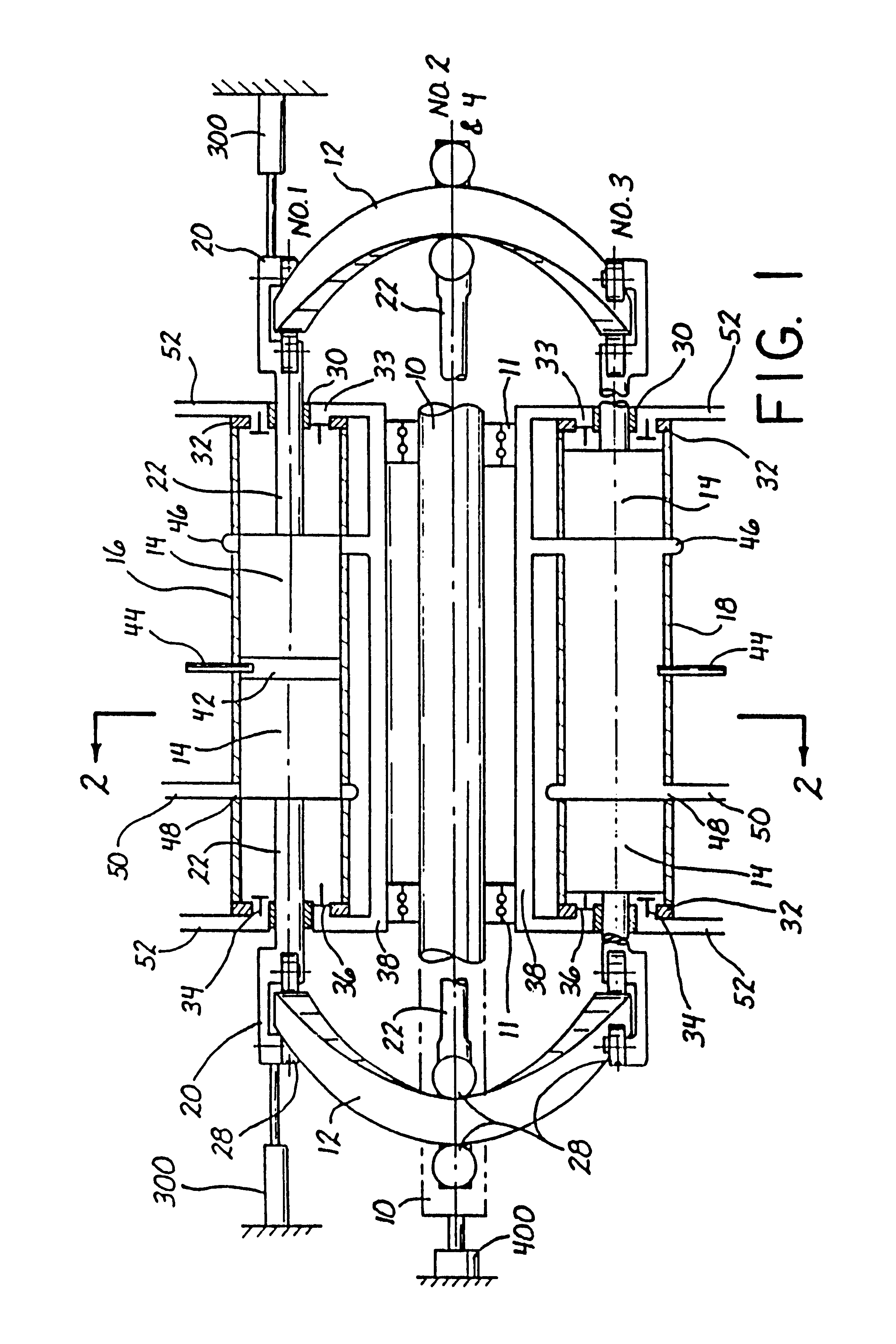

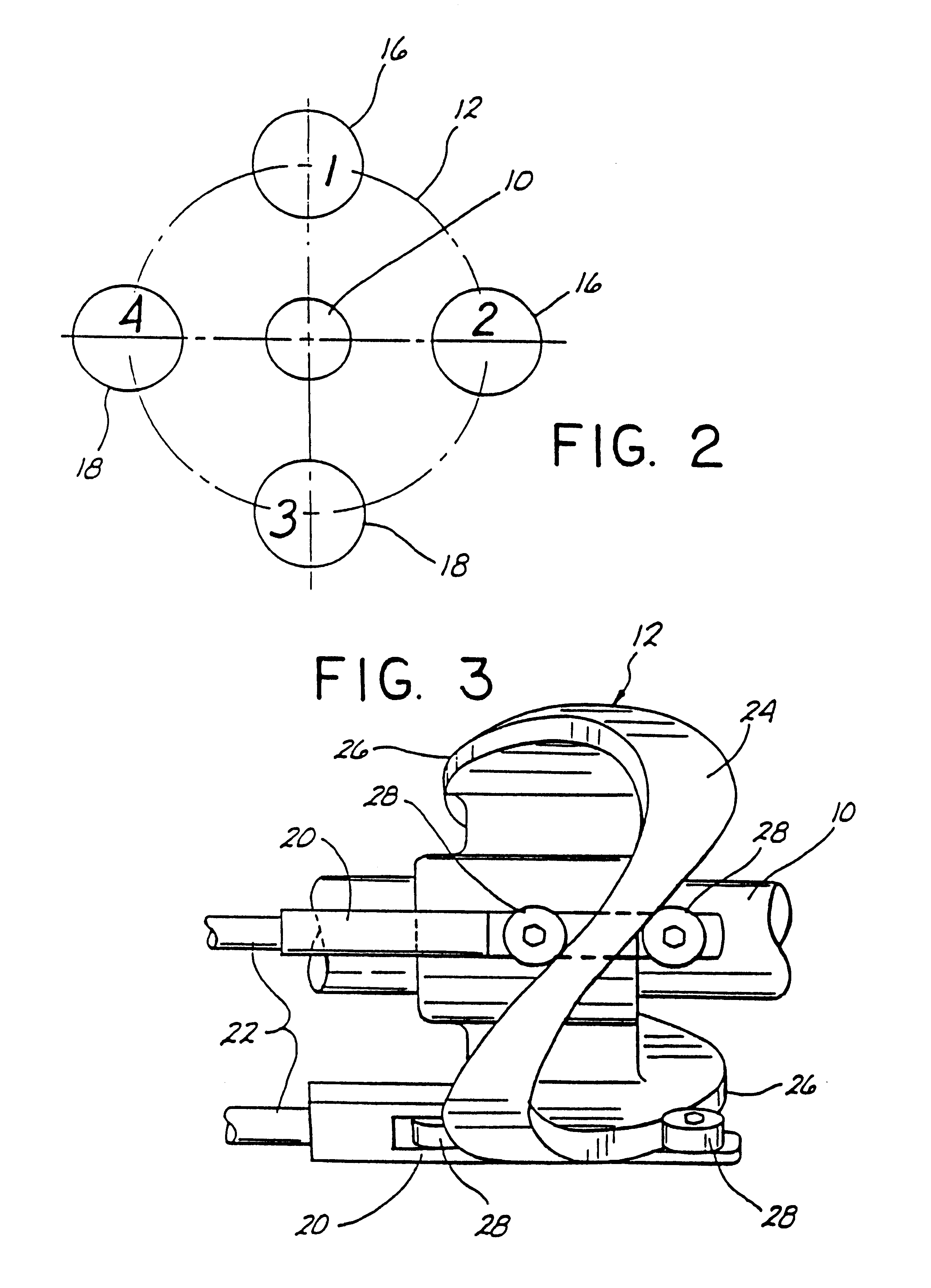

Adiabatic, two-stroke cycle engine having novel scavenge compressor arrangement

InactiveUS6279520B1Improve thermal efficiencyReduce heat lossReciprocating piston enginesAir compressionExhaust valve

An engine structure and mechanism that operates on various combustion processes in a two-stroke-cycle without supplemental cooling or lubrication comprises an axial assembly of cylindrical modules and twin, double-harmonic cams that operate with opposed pistons in each cylinder through fully captured rolling contact bearings. The opposed pistons are double-acting, performing a two-stroke engine power cycle on facing ends and induction and scavenge air compression on their outside ends, all within the same cylinder bore. The engine includes a novel compressor arrangement having an intake valve comprising a V-shaped double reed valve with an apex pointing toward the intake port and an exhaust valve having a V-shaped double reed valve with an apex pointing away from the exhaust port. The compressor arrangement may further include rectangular intake and exhaust ports, a rectangular piston rod and rectangular crosshead bearings.

Owner:LOWI JR ALVIN

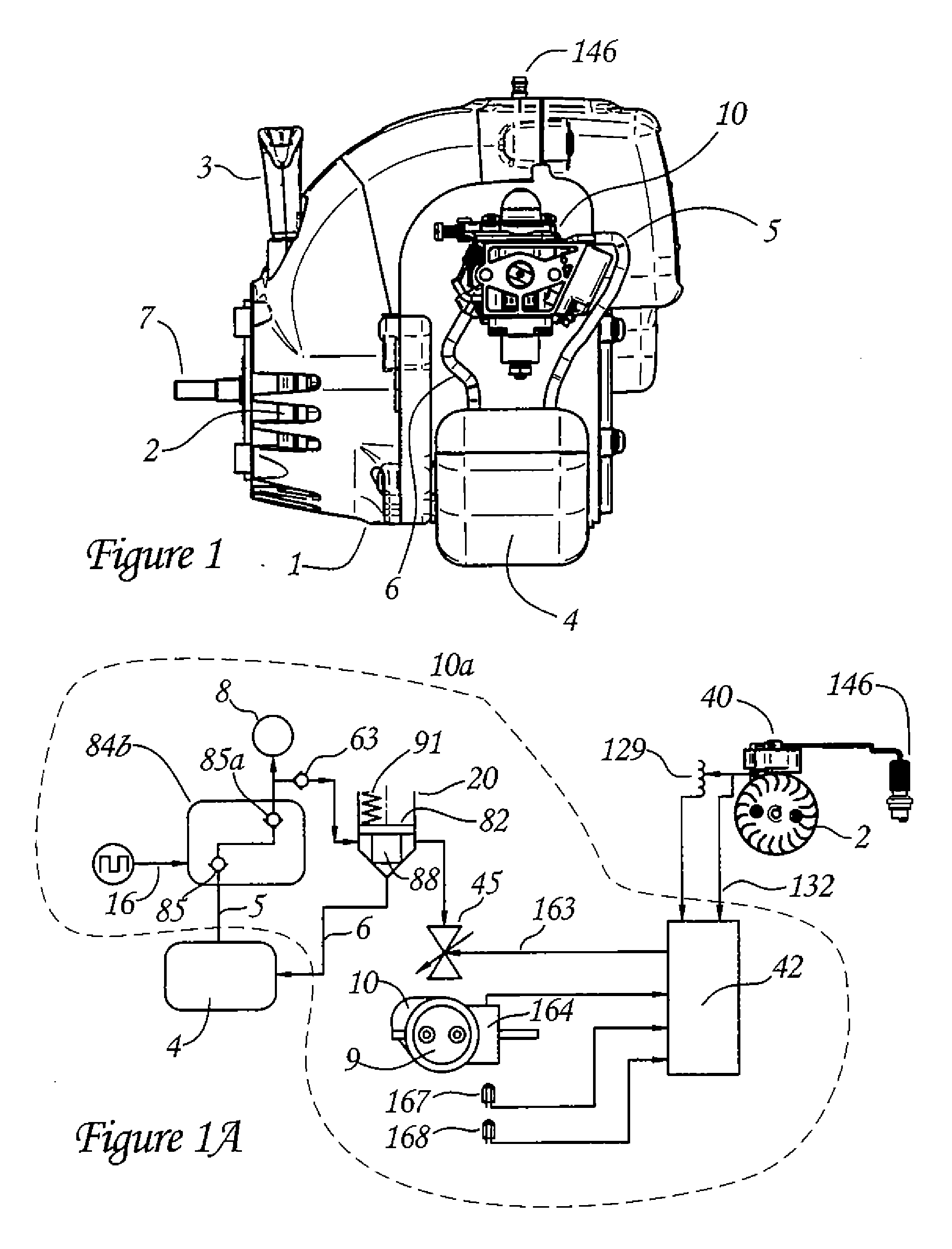

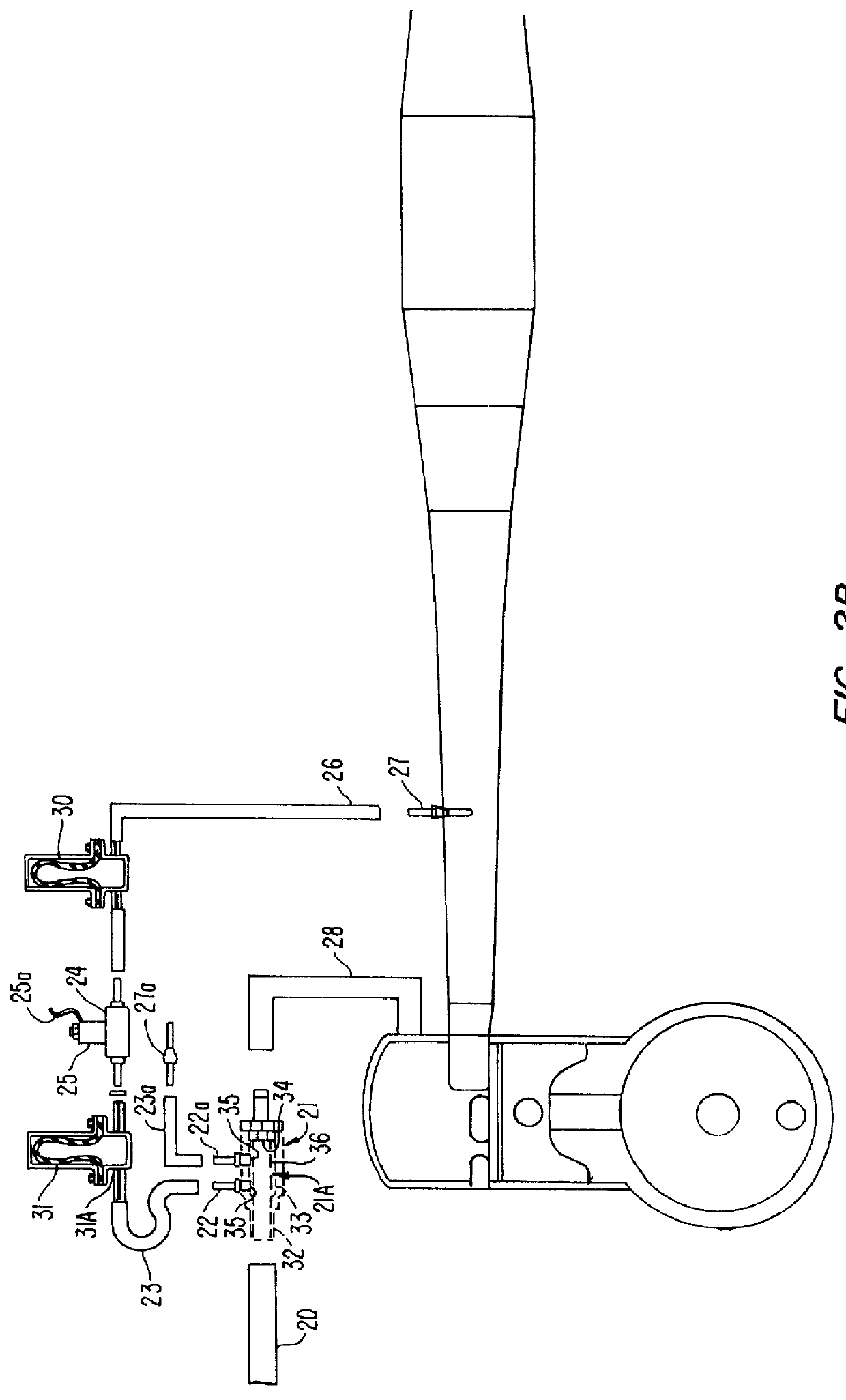

Small engine operation components

ActiveUS20100145595A1Easy to adjustLow costAnalogue computers for vehiclesElectrical controlHand heldAdaptive algorithm

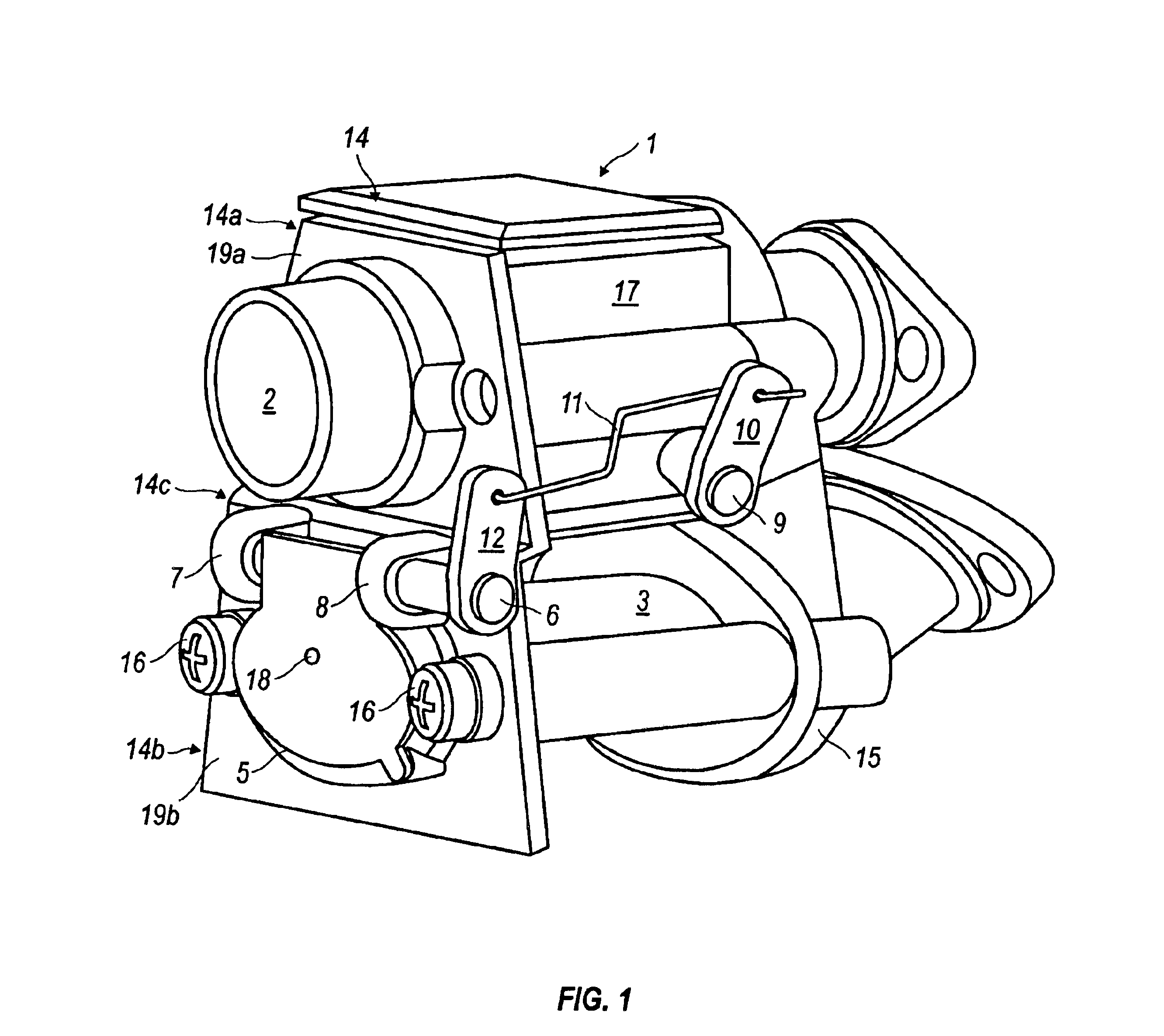

A low pressure, low cost electronic fuel injection system (18) for small hand-held two cycle engines (1) is provided which employs a number of improvements, including by way of example and not of limitation, an improved low cost injector construction (45), a throttle body integration (10) that includes mounting the operational components of the supply system on a single unit, an improved ignition module (40), a pressure regulated fuel system controlled by an electronic control unit (42) employing and an adaptive algorithm based on engine speed which controls the speed by varying the amount of fuel provided to the engine.

Owner:PCRC PRODS

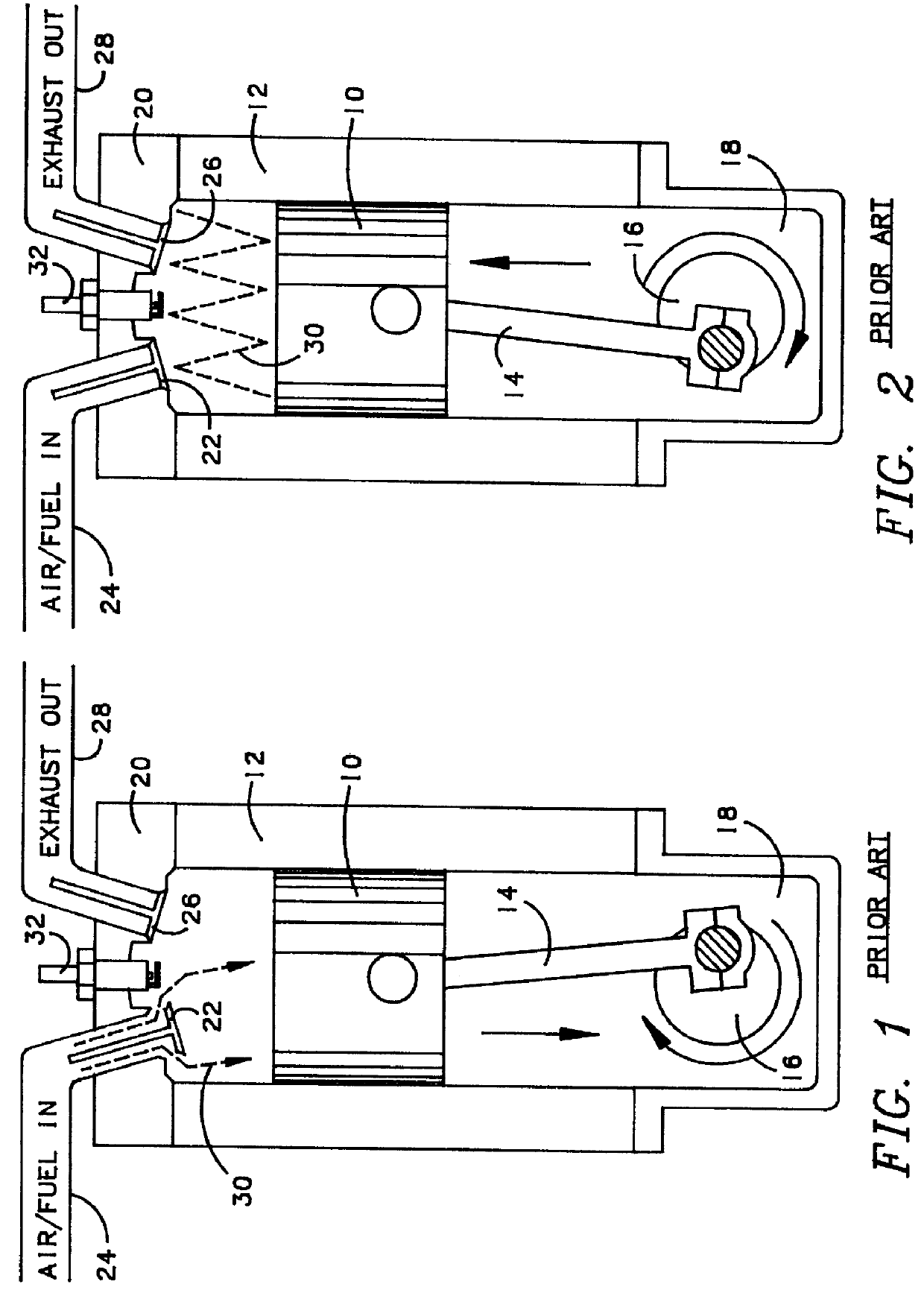

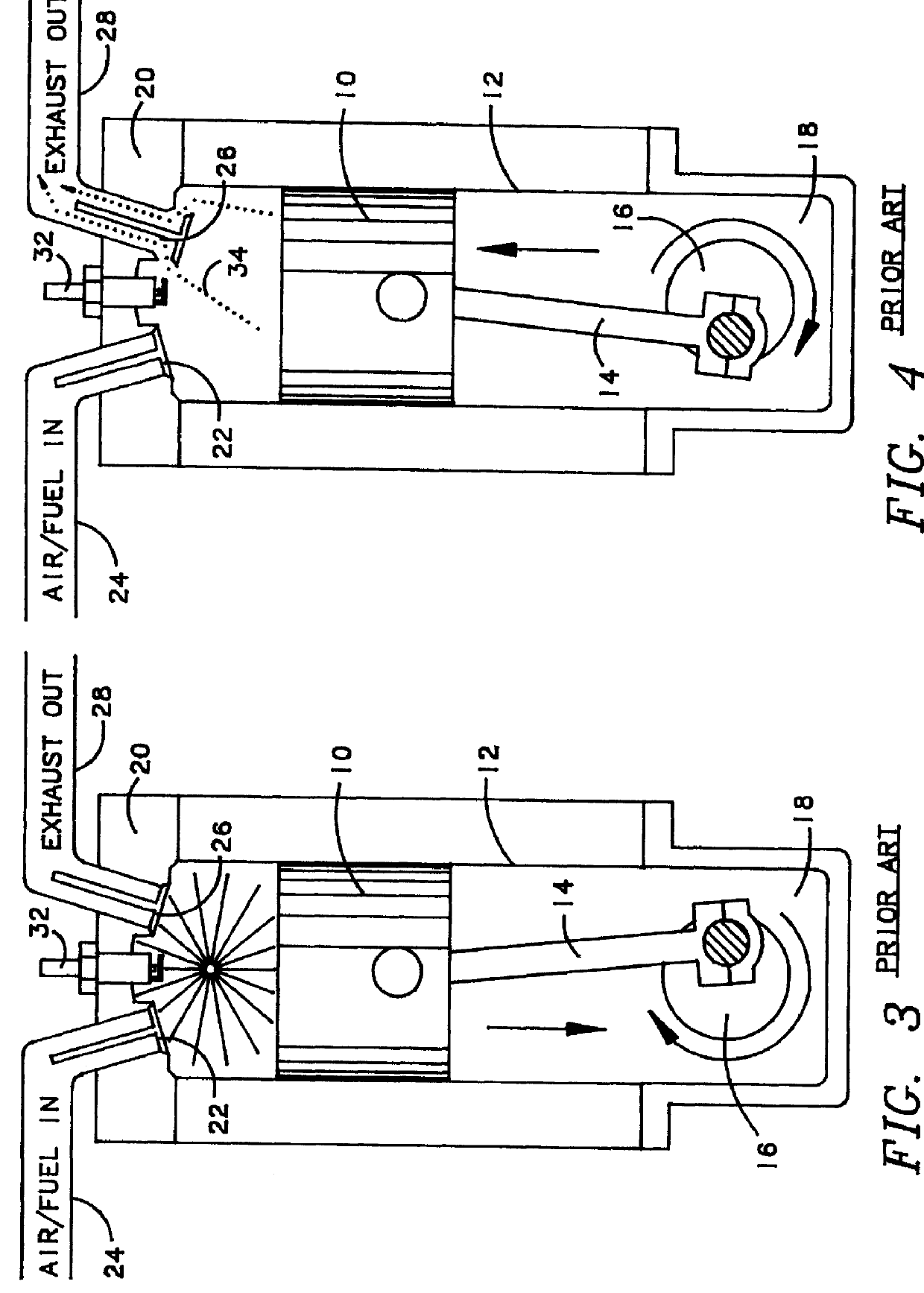

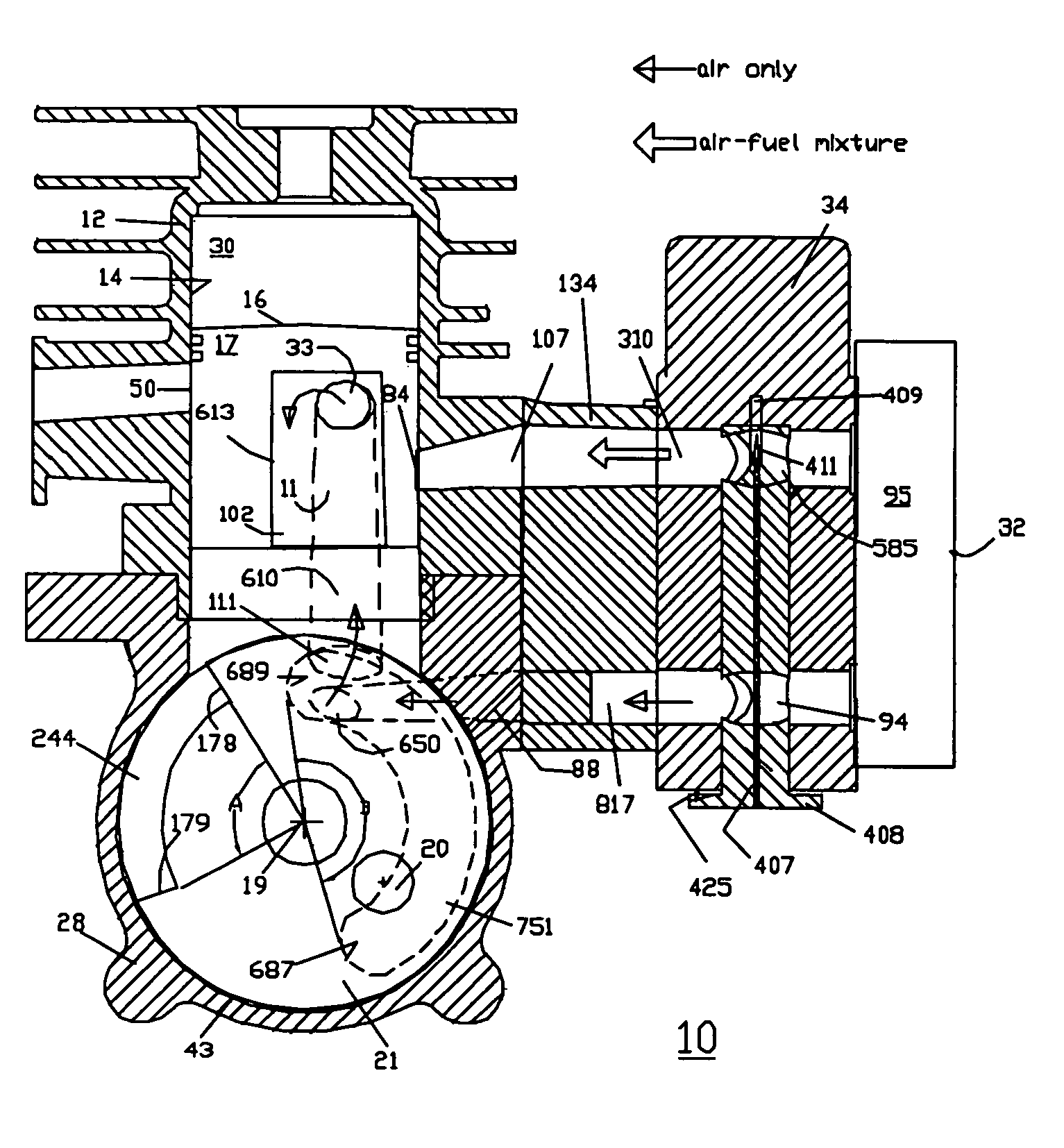

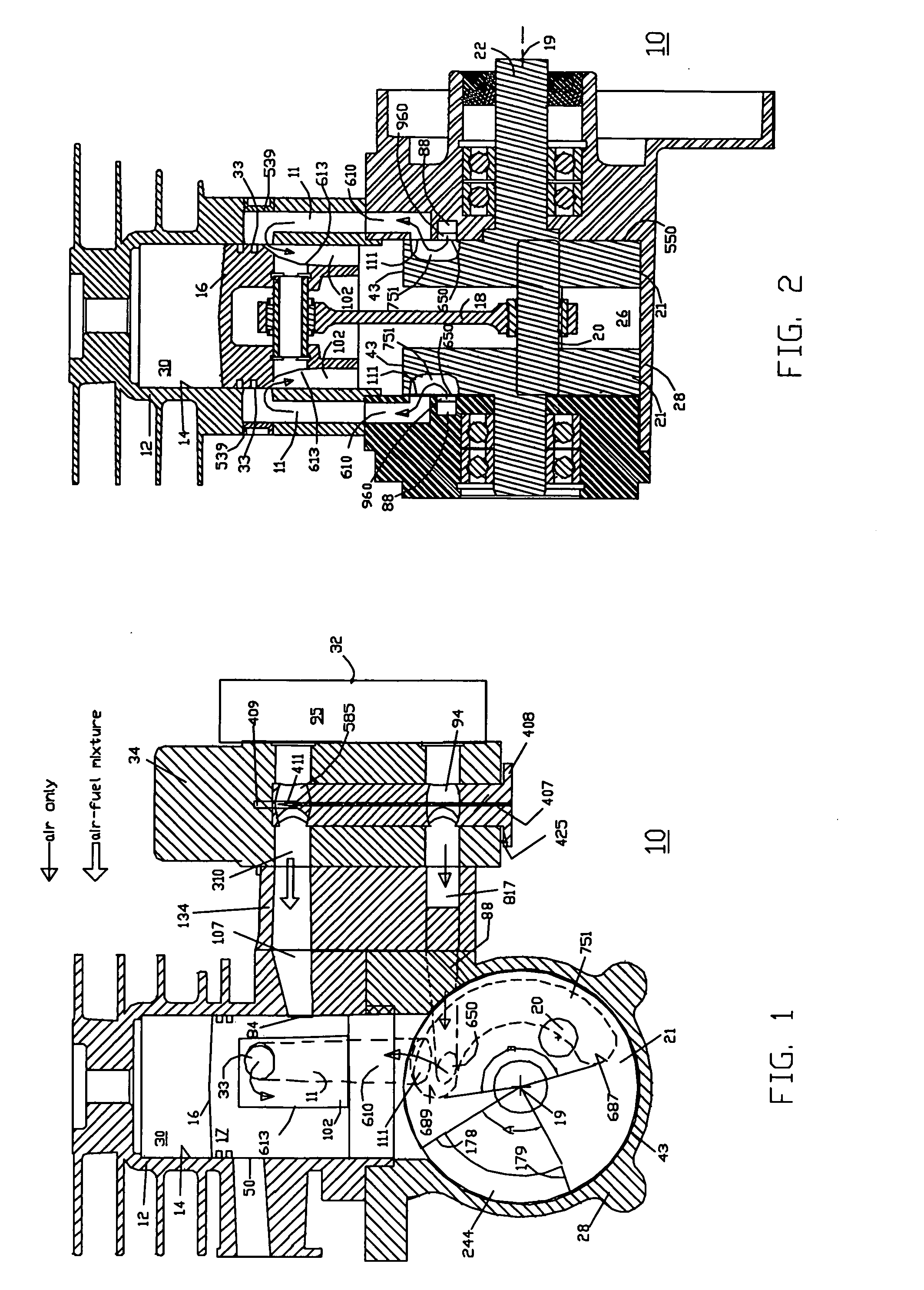

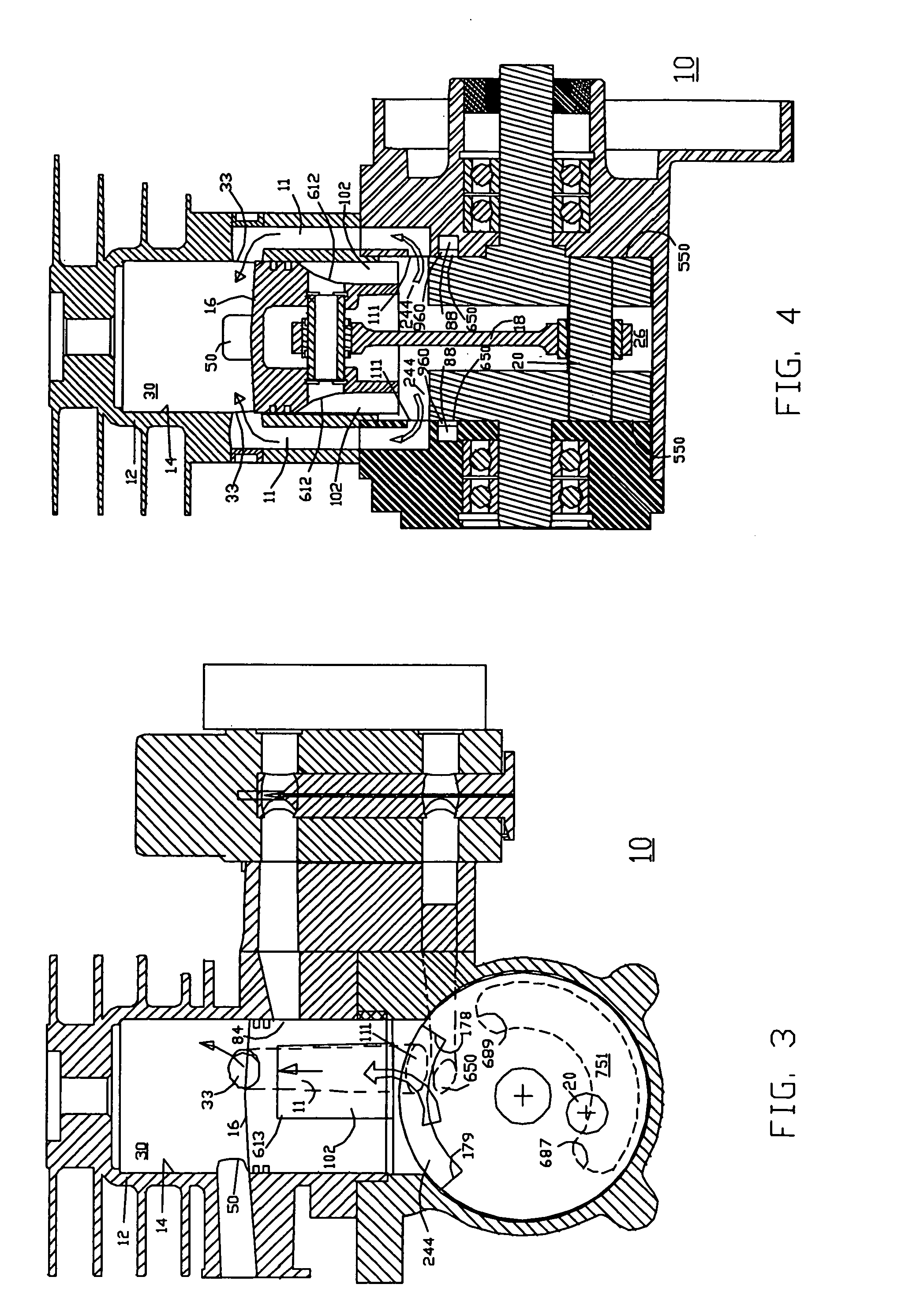

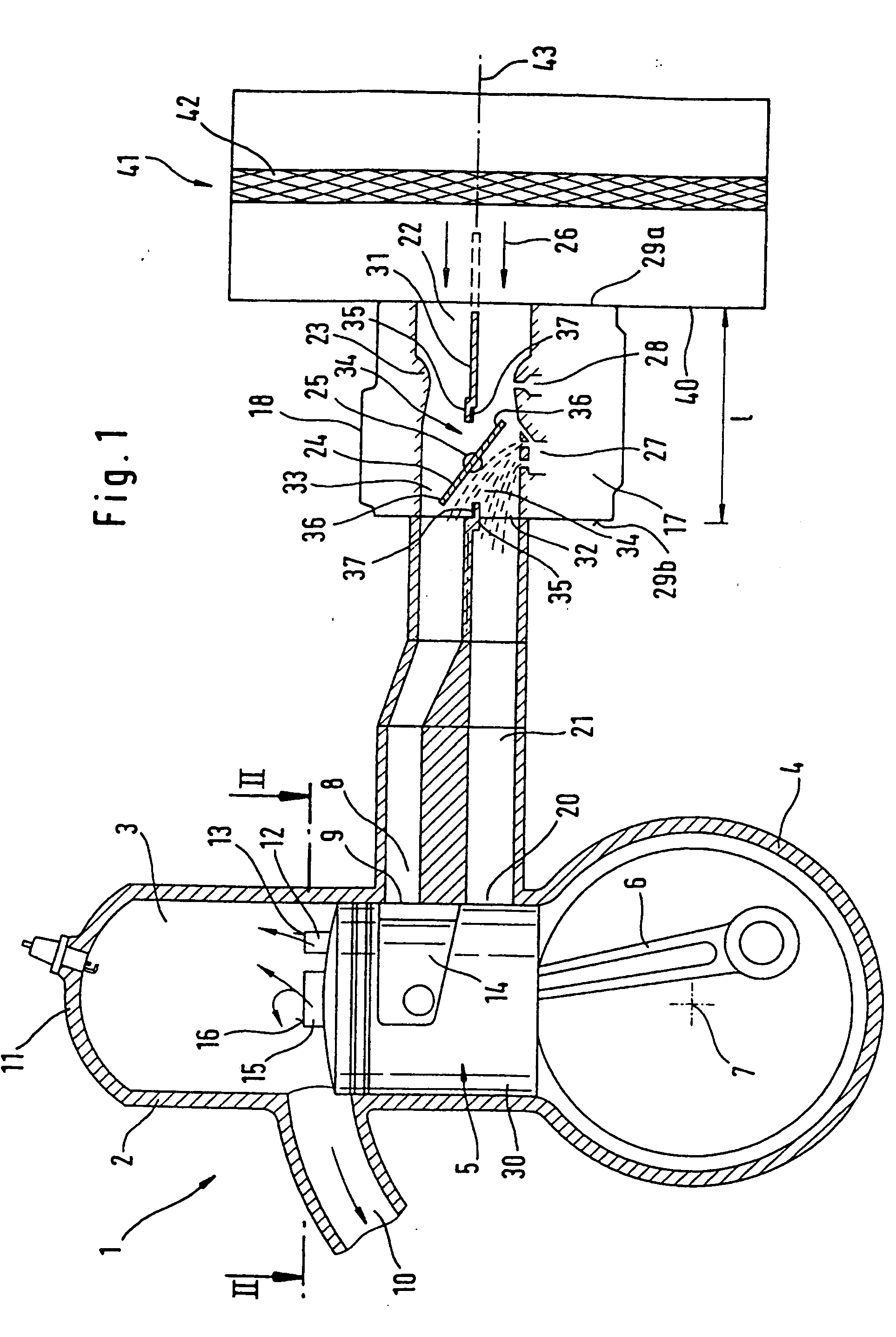

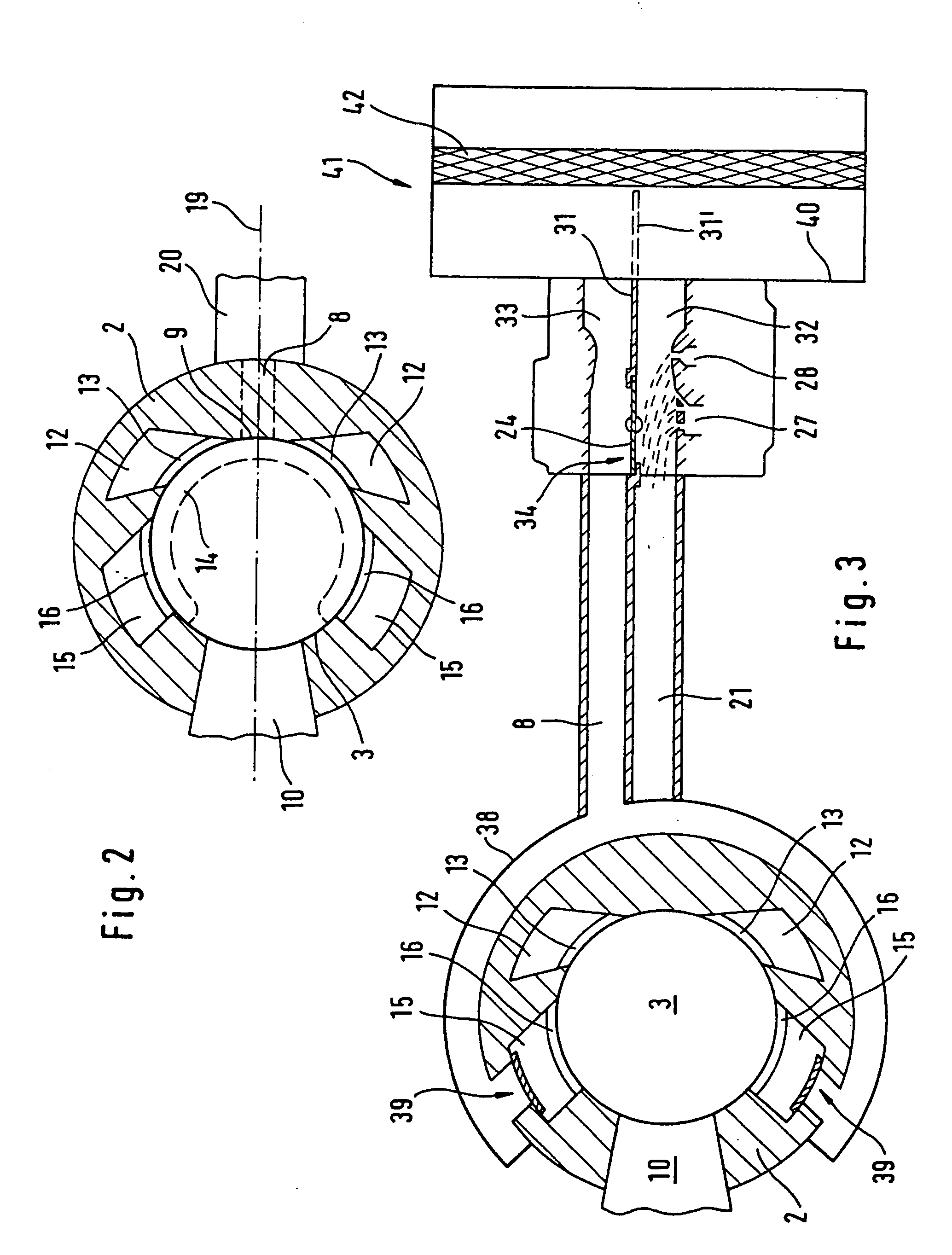

Two-cycle engine with forward scavenging air positioning and single-flow carburetor

InactiveUS20050120985A1Avoid burnsGood effectInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberEngineering

A two-cycle engine 1 is provided and has a cylinder in which is formed a combustion chamber that is delimited by a piston which, via a connecting rod, drives a crankshaft rotatably mounted in a crankcase. The engine has an air duct that communicates with a transfer channel, and a mixture channel via which fuel / air mixture is drawn into the crankcase. At least a portion of the length of the mixture channel is separated from the air duct by a dividing wall that extends in a direction of flow of the air. The dividing wall separates the channels from one another in such a way that the ratio of the cross-sectional area of the mixture channel to the cross-sectional area of the air duct is approximately in the range of 0.5 to 1.9.

Owner:ANDREAS STIHL AG & CO KG

Electromagnetic boosting two-stroke aerodynamic engine assembly

The invention relates to a two-stroke engine assembly, in particular to a two-stroke aerodynamic engine assembly with compressed air as a power source and adopting an electromagnetic booster. The two-stroke aerodynamic engine assembly comprises an engine (1), a multi-cylinder dynamic distributor (2), a dynamic device (4), a controller system (6), an air inflow control compensated flow control valve (23), a high pressure gas tank set (13), a constant pressure tank (16), an electronic control unit electronic coupled oscillator (ECO) (29) and the electromagnetic booster (1000).

Owner:周登荣 +1

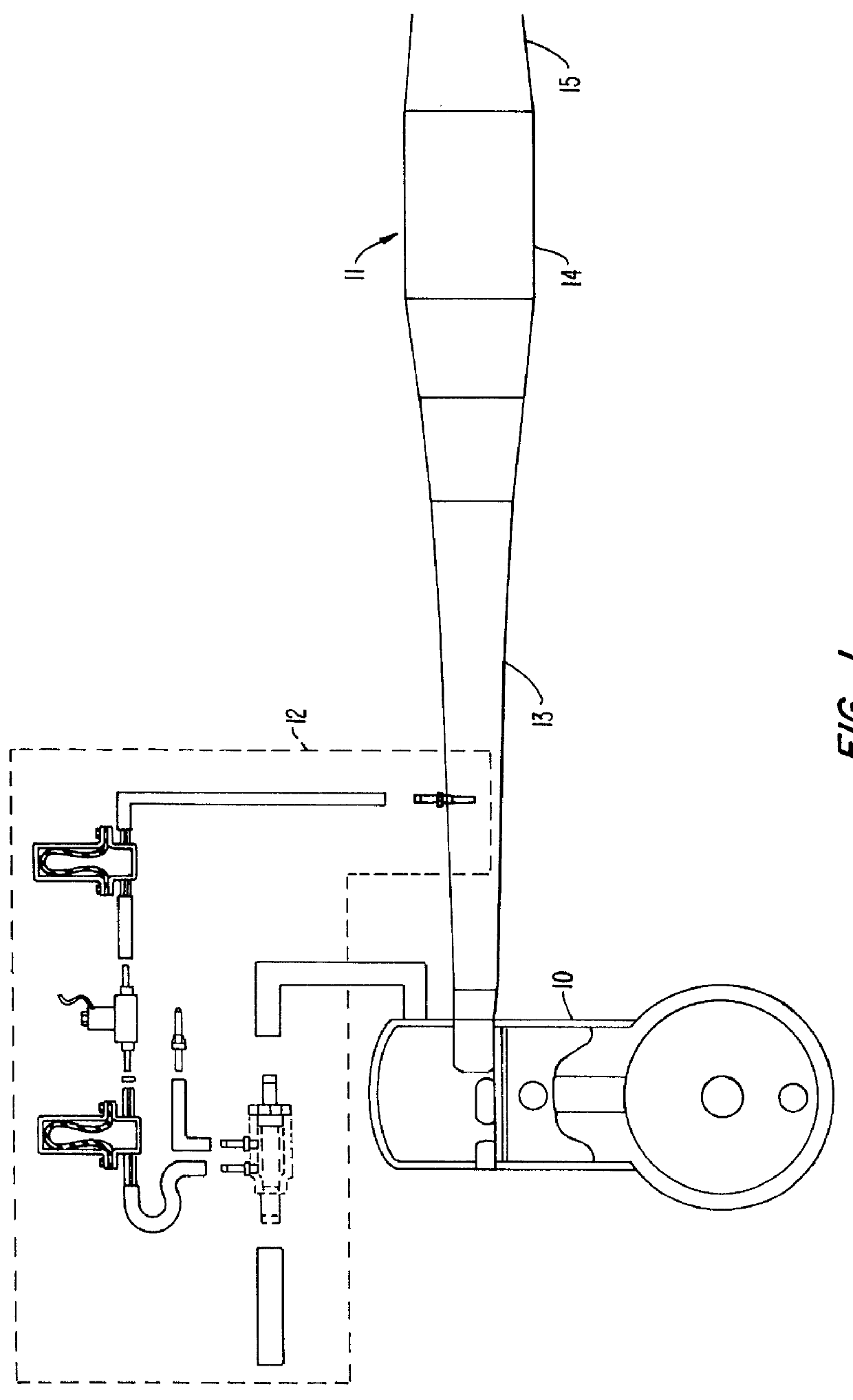

Method and apparatus for improved control of exhaust gas temperature from a two-stroke engine

An exhaust gas temperature control system for a two-stroke engine, the exhaust gas temperature control system including an electronically controlled water injection system. The electronically controlled water injection system includes a water supply conduit section for supplying water to a solenoid valve, and a spraying conduit section for injecting water into an exhaust pipe to thereby control exhaust gas temperature, and hence sonic wave speed within the exhaust pipe. A through-filter is provided as a splitting junction to provide filtered water to the electronically controlled water injection system and unfiltered water to the engine for cooling. A smoothing device in the form of an elastomer hose made of low durometer material or a pressurized bladder is included within the spraying conduit section for maintaining smooth water pressure within the water injected into the exhaust pipe. Additionally, a capturing device in the form of a pressurized bladder and check valve is provided within the supply conduit section in order to maintain ample water pressure supplied to the solenoid valve.

Owner:LIBERTY ROSS H

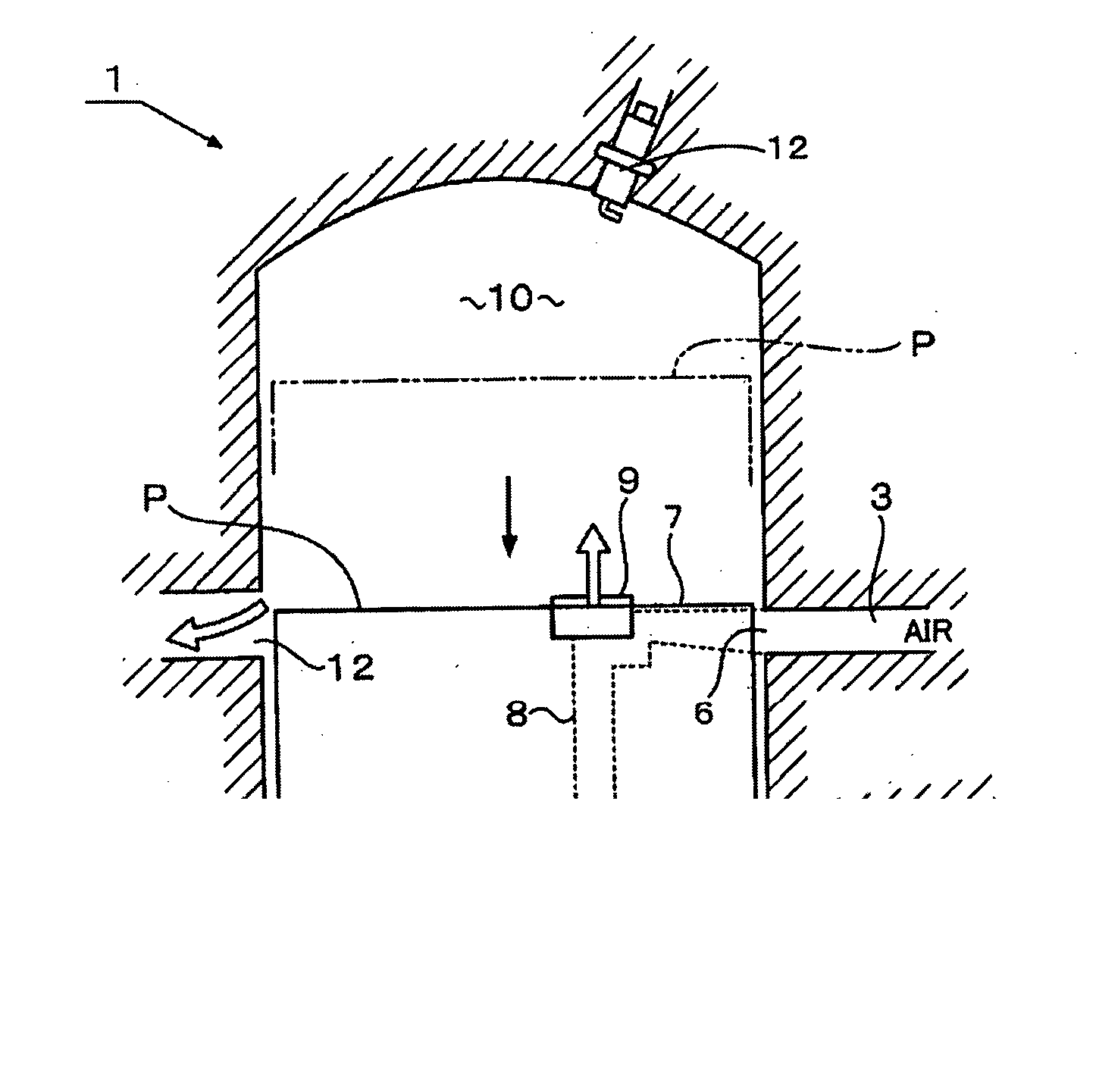

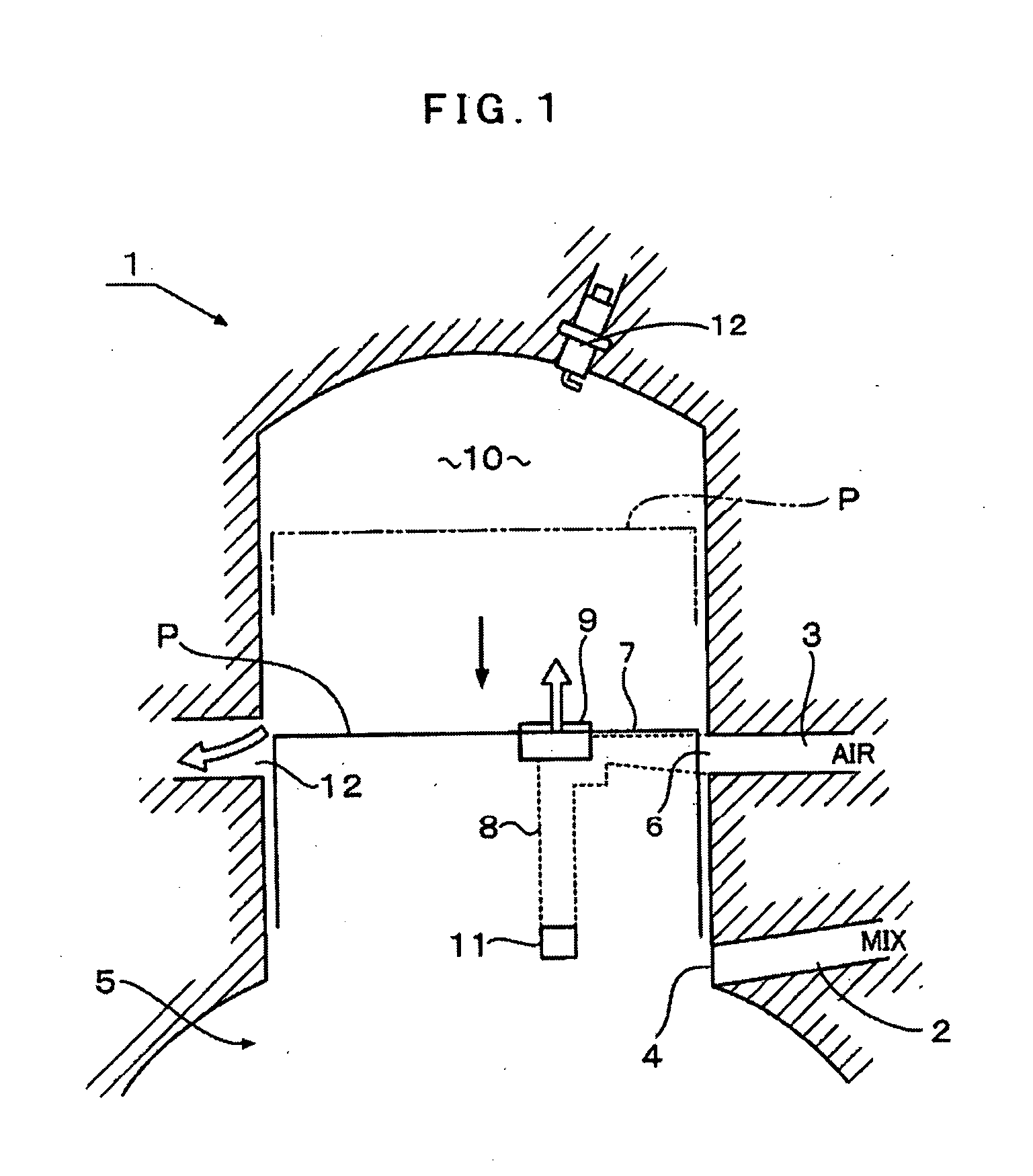

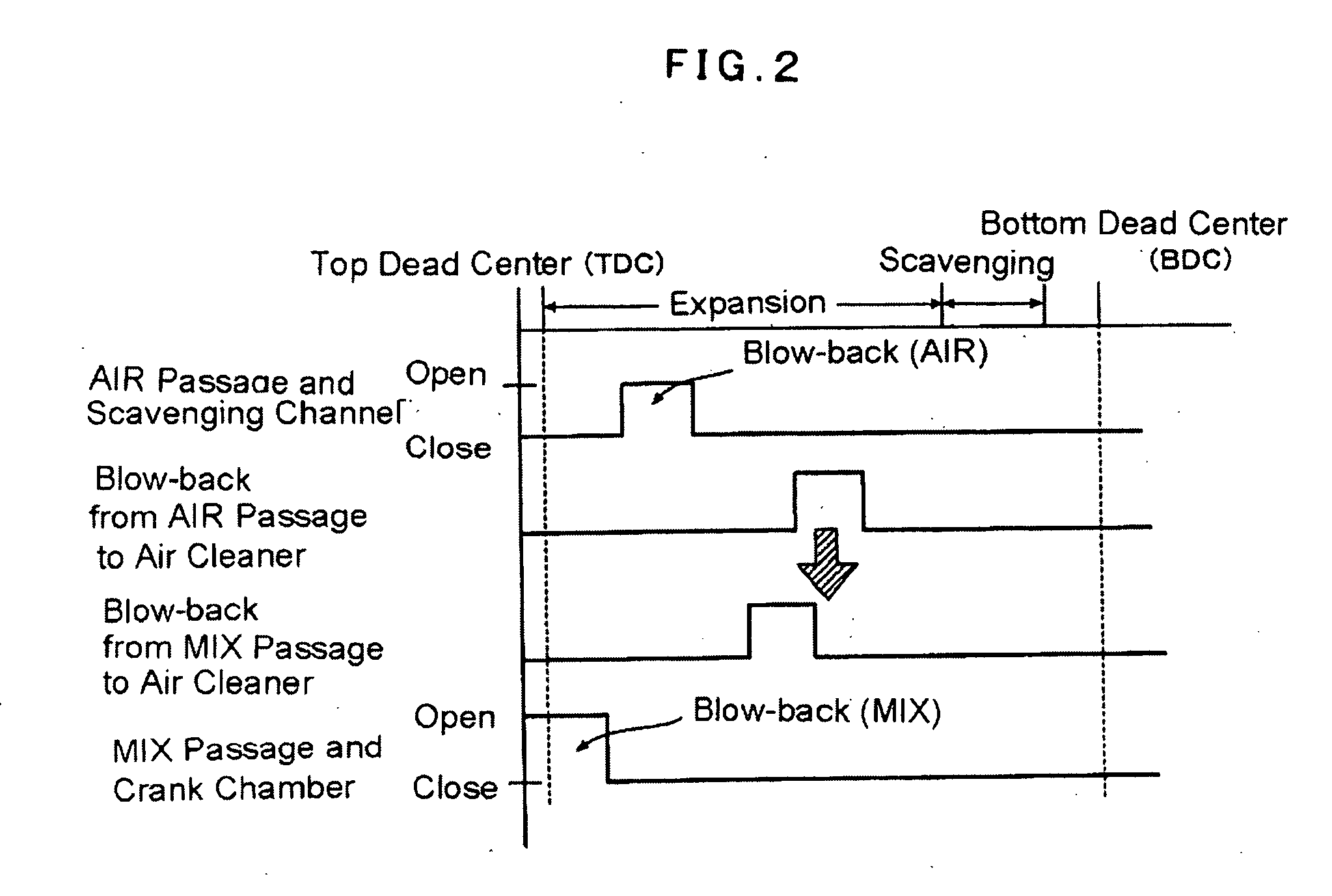

Air Cleaner For Stratified-Scavenging Two-Stroke Internal Combustion Engine

ActiveUS20090283079A1Extends the length of the air-fuel mixture passageEasy to adjustCombination devicesLiquid degasificationInternal combustion engineRisk stroke

Object It is intended to prevent intrusion of air-fuel mixture into an air cleaner by blow-back in an air-fuel mixture passage of a stratified-scavenging two-stroke engine.Solution The air cleaner (24) includes a guide member (30). A blow-back flow of air (20) flowing back to the air cleaner (24) through a first air opening (23A) due to blow-back of air is induced to a vicinity of a second air opening (23M) by the guide member (30). A blow-back flow of air-fuel mixture (21) occurring in an air-fuel mixture passage (2) prior to the blow-back phenomenon in an air passage (3) collides the air flow 20 moving toward the vicinity of the second air opening (23M), and retains the air-fuel mixture near the second air opening (23M).

Owner:YAMABIKO CORP

Contraposition two-stroke engine

InactiveCN102733947AInternal combustion piston enginesCylinder headsReciprocating motionFour-stroke engine

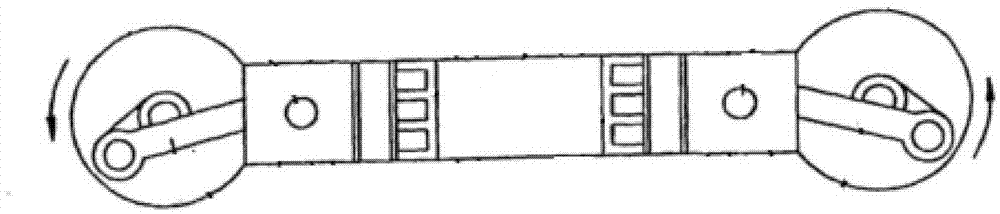

The invention discloses a contraposition two-stroke engine comprising a cylinder, a cylinder sleeve, an intake piston and an exhaust piston, upper connection rods, rocker arms, lower connection rods, and crankshafts, wherein the upper connection rods, the rocker arms and the lower connection rods are arranged on the same side as the intake piston and the exhaust piston; the cylinder sleeve and the top surfaces of the intake piston and the exhaust piston form a combustion chamber; the upper connection rods, the rocker arms and the lower connection rods on both sides are respectively arranged symmetrically; the rocker arms on both sides are respectively connected with the cylinder body by the respective rocker arm shafts; the intake piston is connected with the upper end of the rocker arm on the same side by the upper connection rod; the lower end of the rocker arm on the same side with the intake piston is connected with the crankshaft arranged right below the cylinder body by the lower connection rod on the same side with the intake piston; the connection relations between the exhaust piston and the upper connection rod, between the exhaust piston and the rocker arm, and between the exhaust piston and the lower connection rod on the same side are the same as those between the intake piston and the upper connection rod, between the intake piston and the rocker arm and the between the intake piston and the lower connection rod; the reciprocations of the intake piston and the exhaust piston drive the crankshafts by the rocker arms, the upper connection rods and the lower connection rods on the same sides. With the adoption of the engine, the shortages of the contraposition two-stroke engine are made up effectively.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

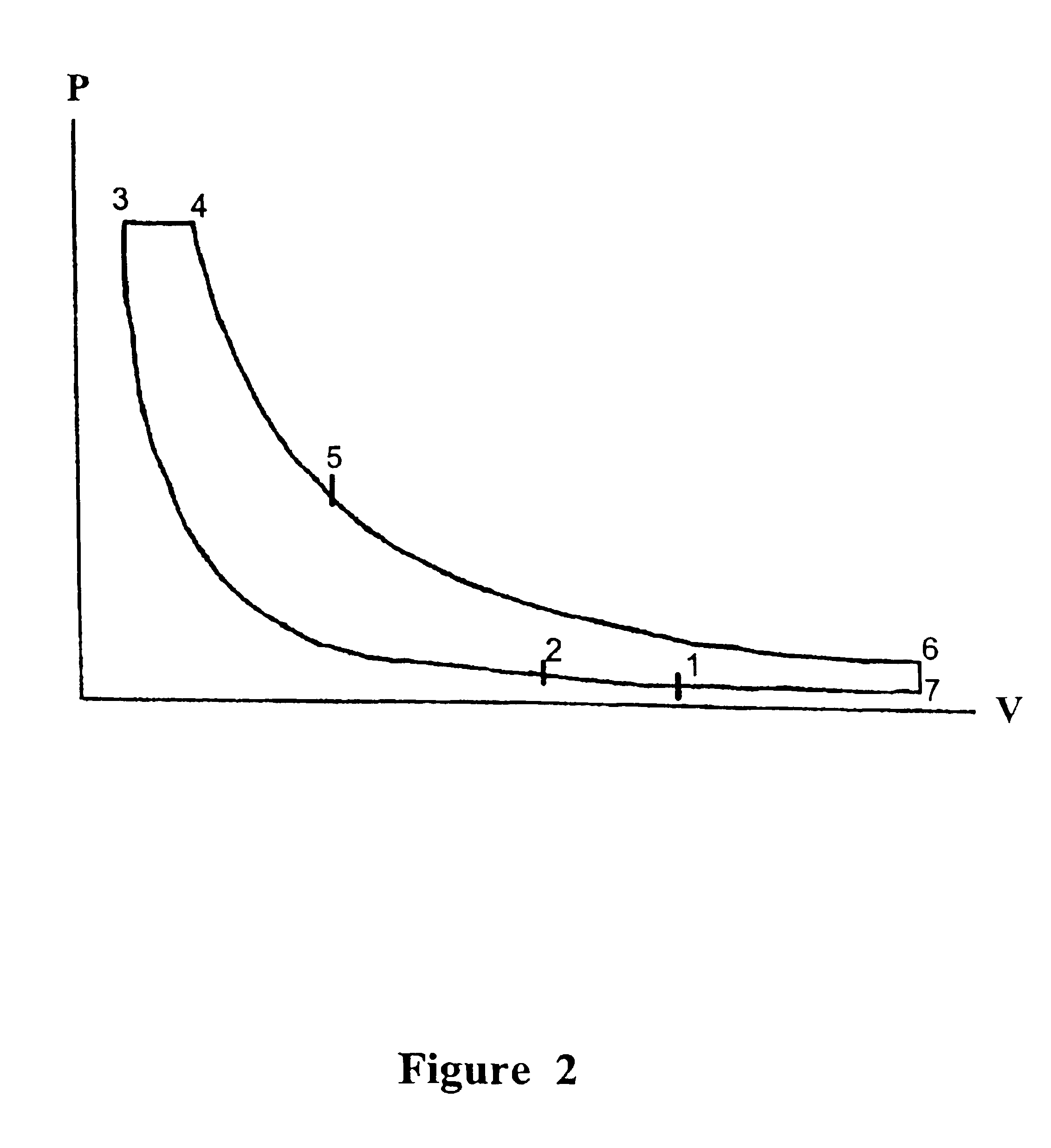

Over expanded limited-temperature cycle two-stroke engines

InactiveUS6848416B1Reduce NOx levelReducing post-combustion temperatureElectrical controlCombustion enginesPressure decreaseFour-stroke engine

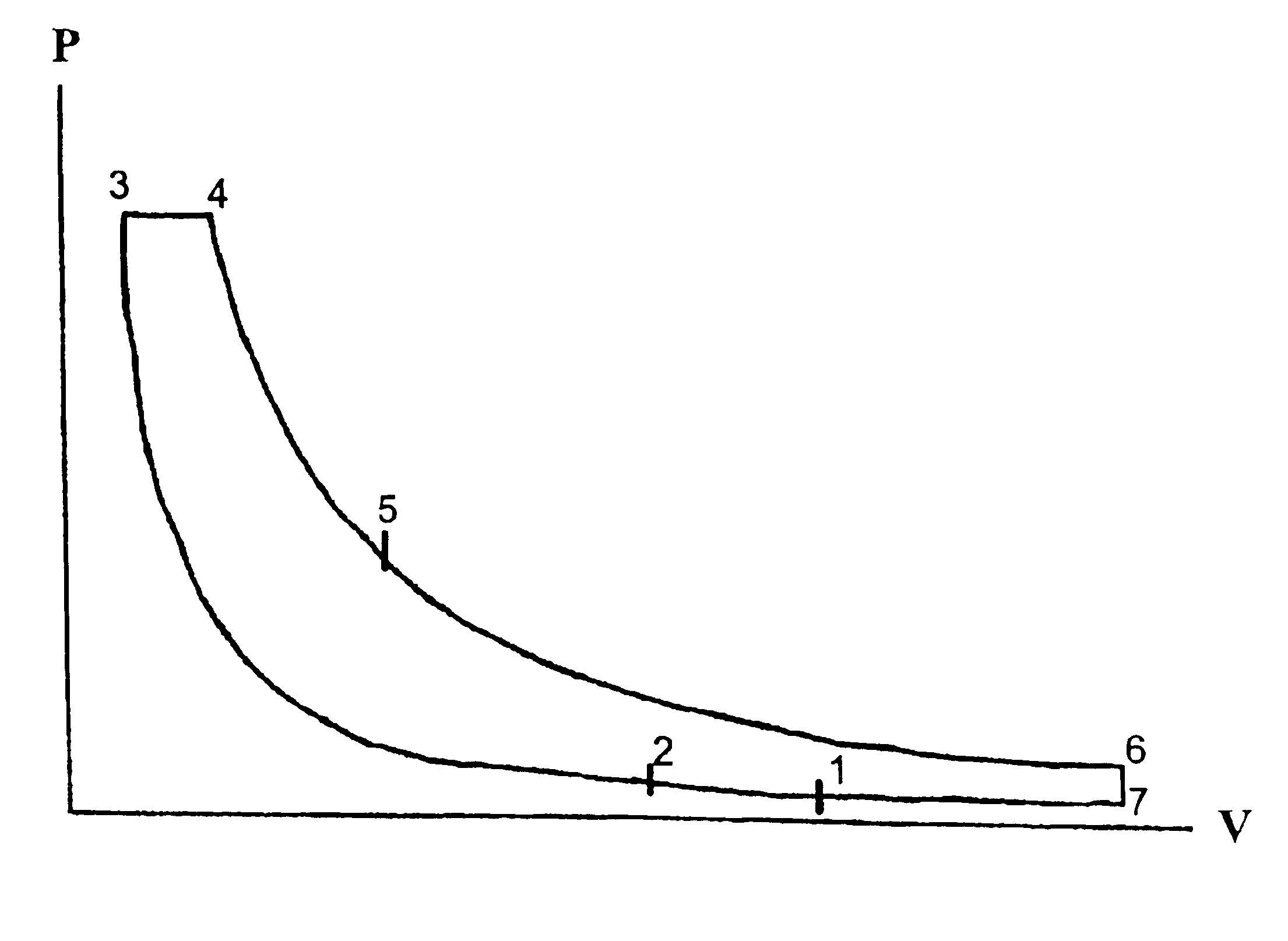

A method for combusting fuel in an engine involving decreasing a first volume of gas to a second volume, in two stages, while increasing the pressure and temperature of that volume of gas (a compression process having a chosen compression ratio), then increasing the second volume to a third volume at constant pressure while adding heat until a predetermined temperature is obtained, increasing the third volume of gas to a fourth volume, in two stages while decreasing the pressure at the predetermined temperature (an expansion process having a chosen expansion ratio much greater than the compression ratio), decreasing the pressure to atmospheric pressure while removing heat under constant volume, and finally decreasing the volume of gas to the first volume while removing heat under constant pressure to complete an over expanded, limited-temperature cycle. Also disclosed is an engine employing said over expanded, limited-temperature cycle.

Owner:PIEN PAO C

Valve assembly for a two-stroke engine

ActiveUS7762220B2Reduce the possibilityDiscrepancies in valve position between the exhaust ports are reducedAnalogue computers for vehiclesInternal combustion piston enginesValve actuatorFour-stroke engine

A two-stroke internal combustion engine is disclosed having first and second cylinders having respective exhaust ports. A valve assembly comprises at least one valve actuator. First and second valves are operatively connected to the at least one valve actuator. The first and second valves are each movable between a first position wherein the valve extends a first distance in the respective exhaust port and a second position wherein the valve extends a second distance in the respective exhaust port. A valve connecting member is rigidly connected to the first and second valves and movable therewith via a translational motion while maintaining a substantially constant angular orientation relative to the cylinder block. A position sensor has a first portion connected to the cylinder block and a second portion connected to the valve connecting member. An electronic control unit (ECU) electrically connected to the position sensor.

Owner:BRP ROTAX

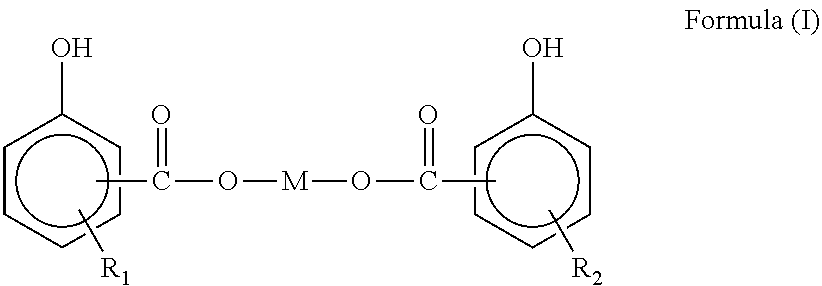

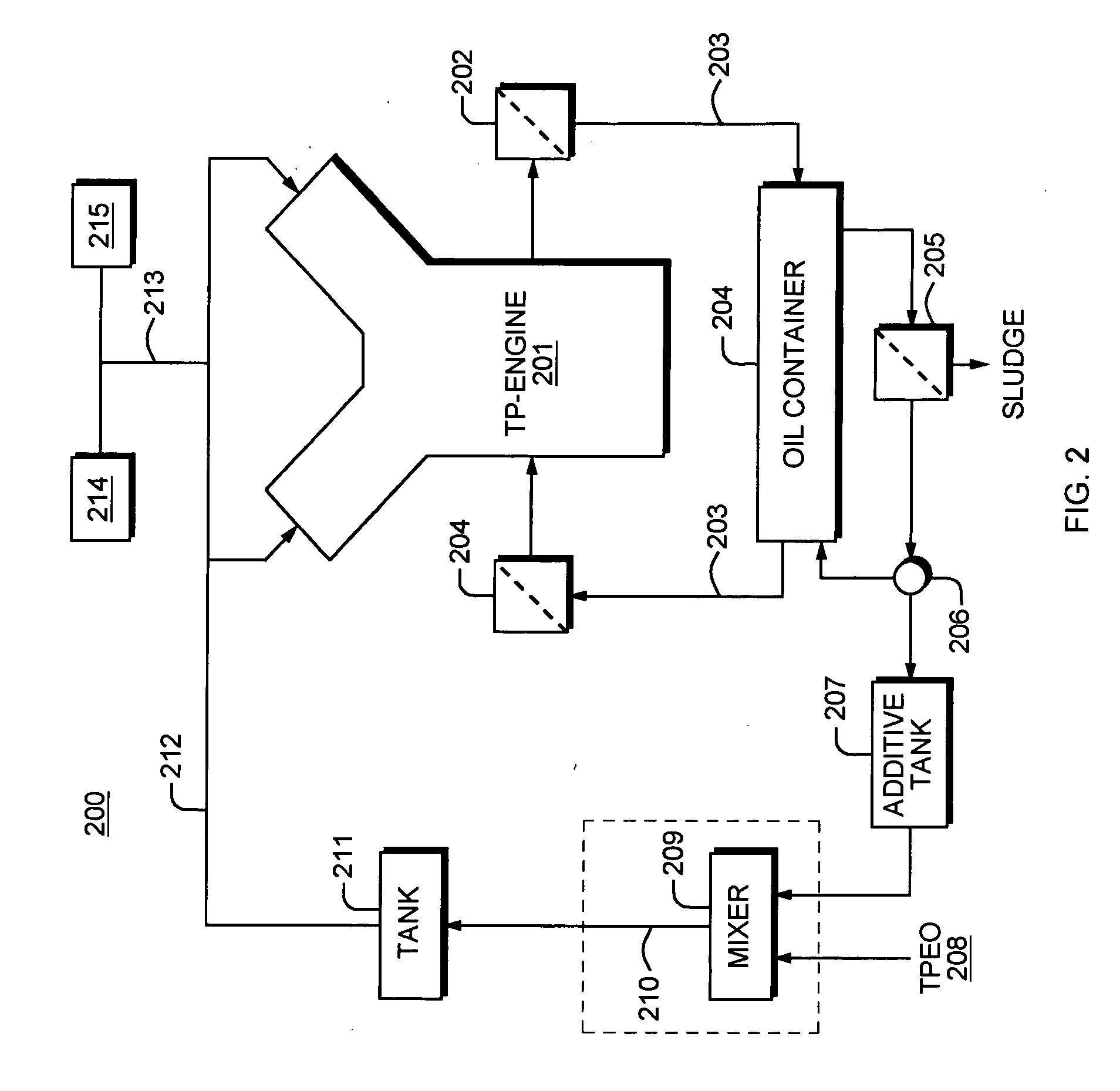

System oil formulation for marine two-stroke engines

ActiveUS20110077182A1Improve protectionEasy to controlOrganic compound preparationLiquid carbonaceous fuelsMechanical componentsCarboxylic salt

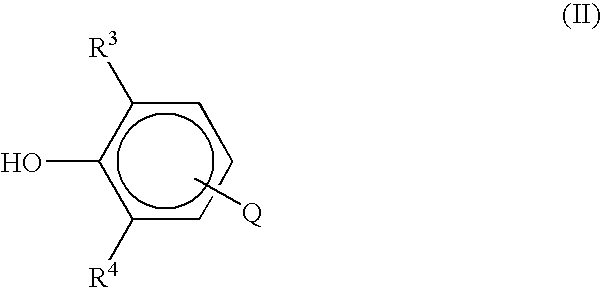

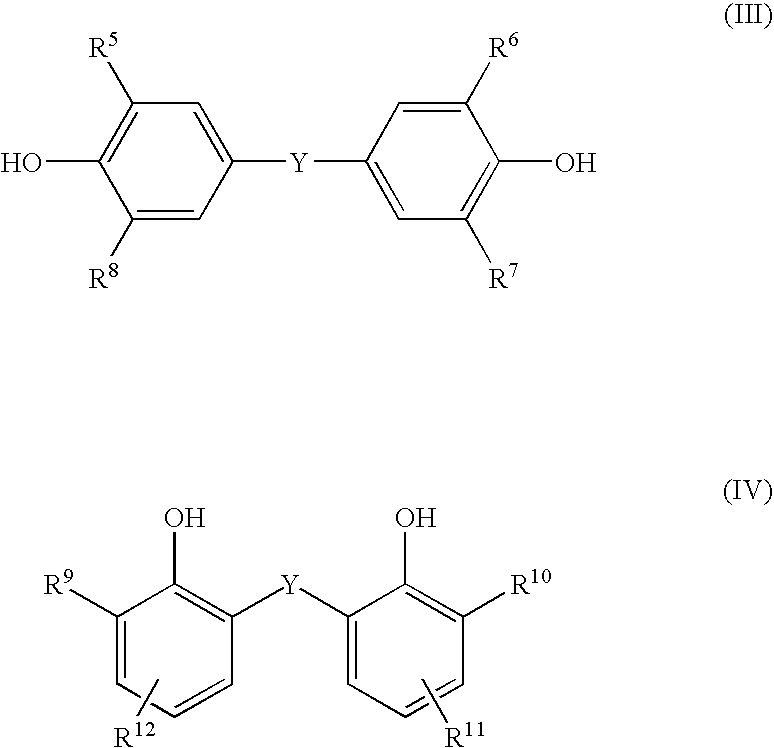

In one aspect of the present invention, a marine system oil composition is provided for lubrication of mechanical components in marine engines, for example, two-stroke, cross-head marine diesel engines and methods / additives for using the marine system oil composition in the same. In one aspect of the present invention, a marine system oil composition is provided that has salt of a carboxylate-containing detergent comprising at least one alkyl-substituted hydroxyaromatic carboxylic acid, wherein at least 50 mole % of, the alkyl groups are C20 or greater.

Owner:CHEVRON ORONITE TECH BV

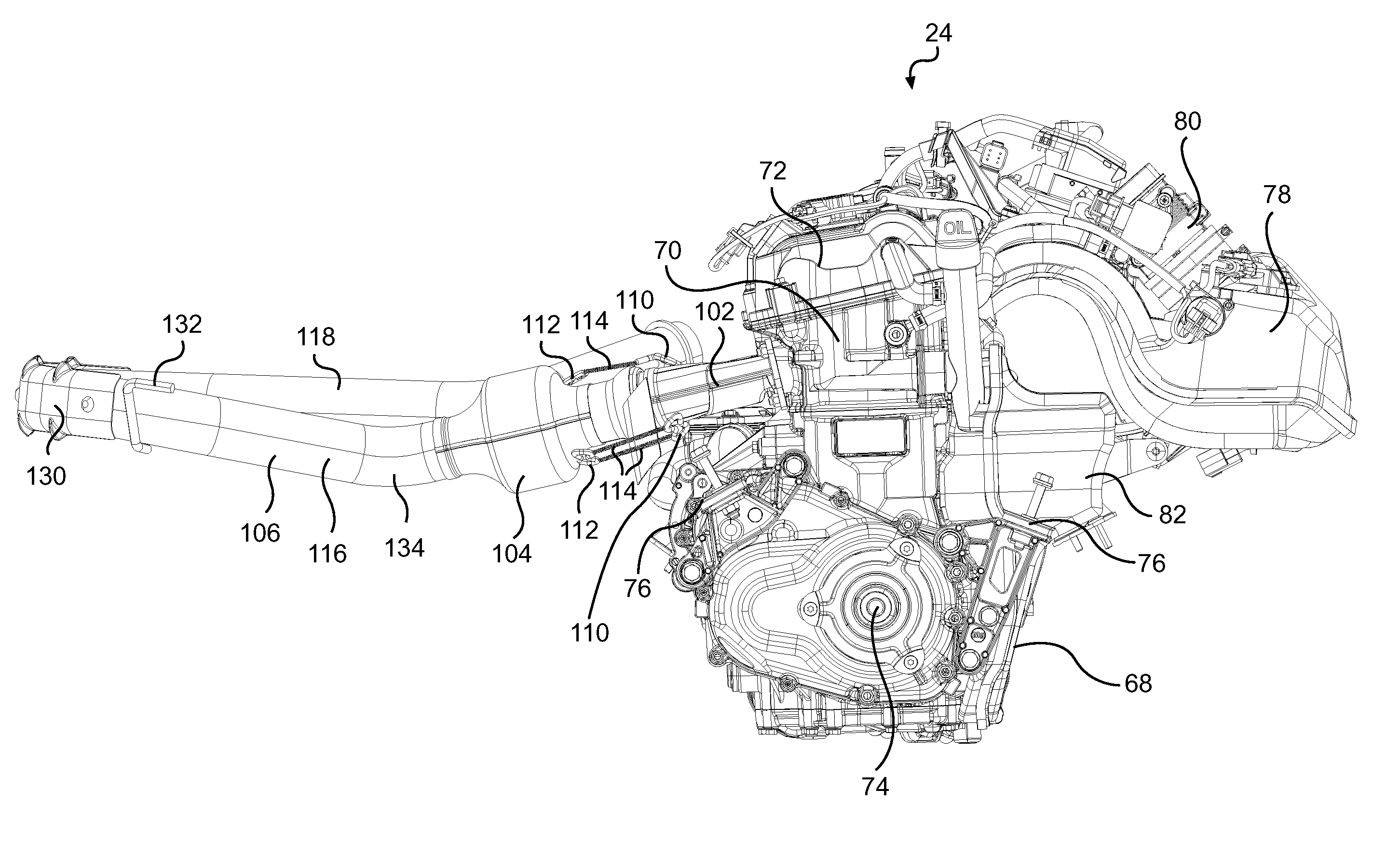

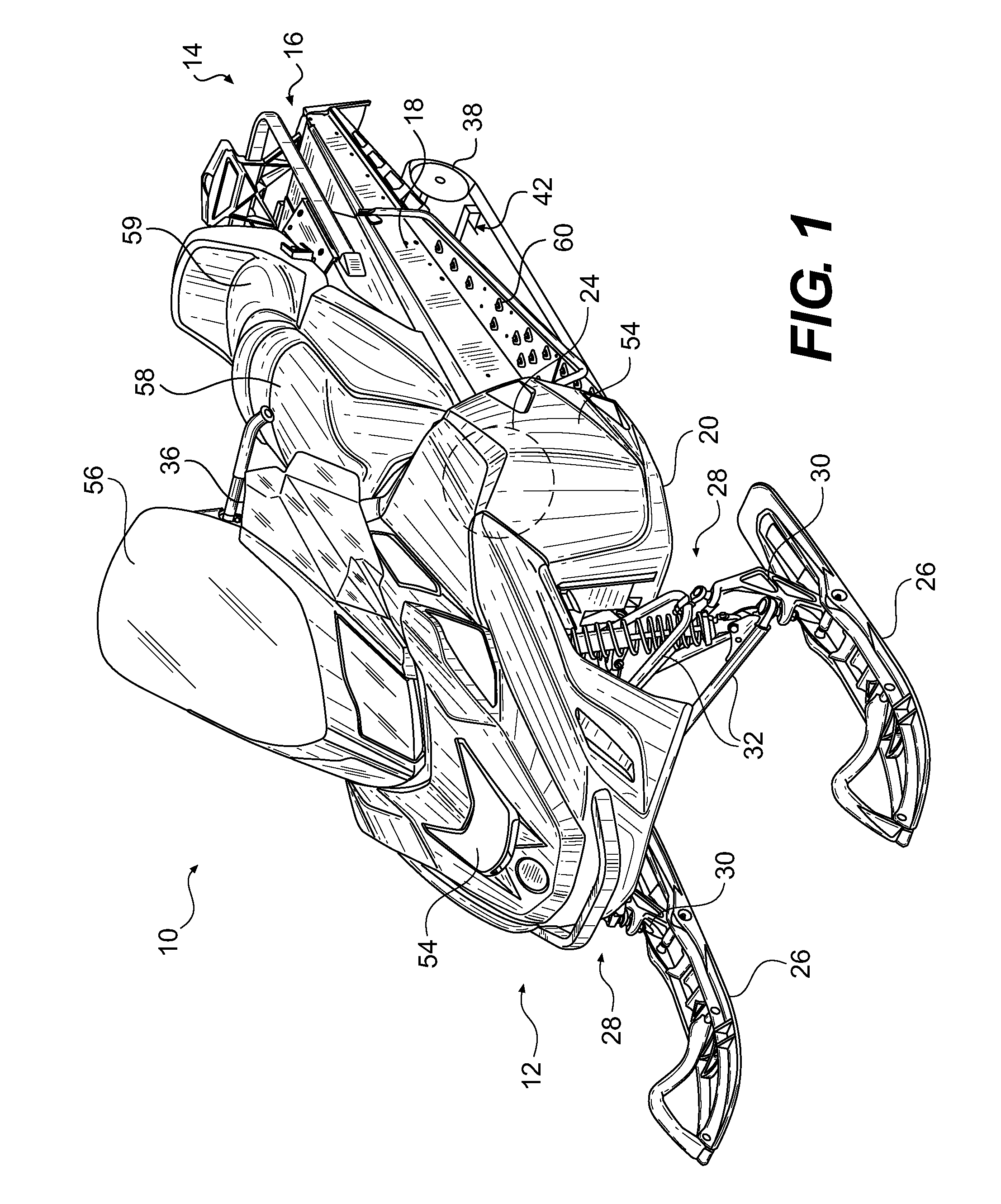

Snowmobile Exhaust System

ActiveUS20100108427A1Reduce engine noiseReduce the amount requiredSnowmobilesSledgesFour-stroke engineEngine mount

A snowmobile has a four-stroke engine mounted in an engine cradle and an exhaust system connected to the engine. The exhaust system includes a generally U-shaped exhaust pipe extending forwardly from the engine to a first point disposed forwardly of the engine cradle, and of suspension assemblies of the skis, and extending rearwardly from the first point to a second point disposed rearwardly of a front of the engine cradle.

Owner:BOMBARDIER RECREATIONAL PROD INC

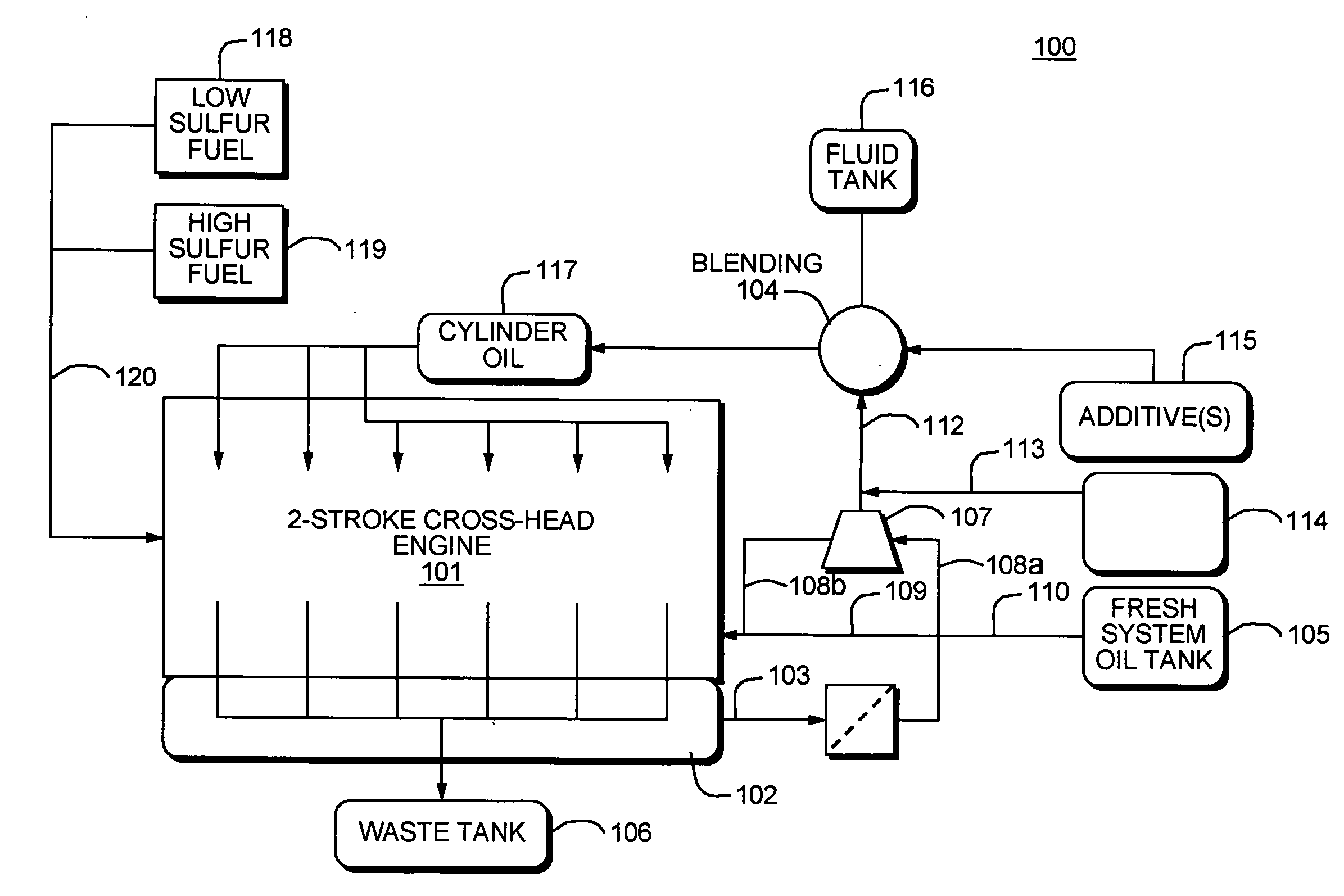

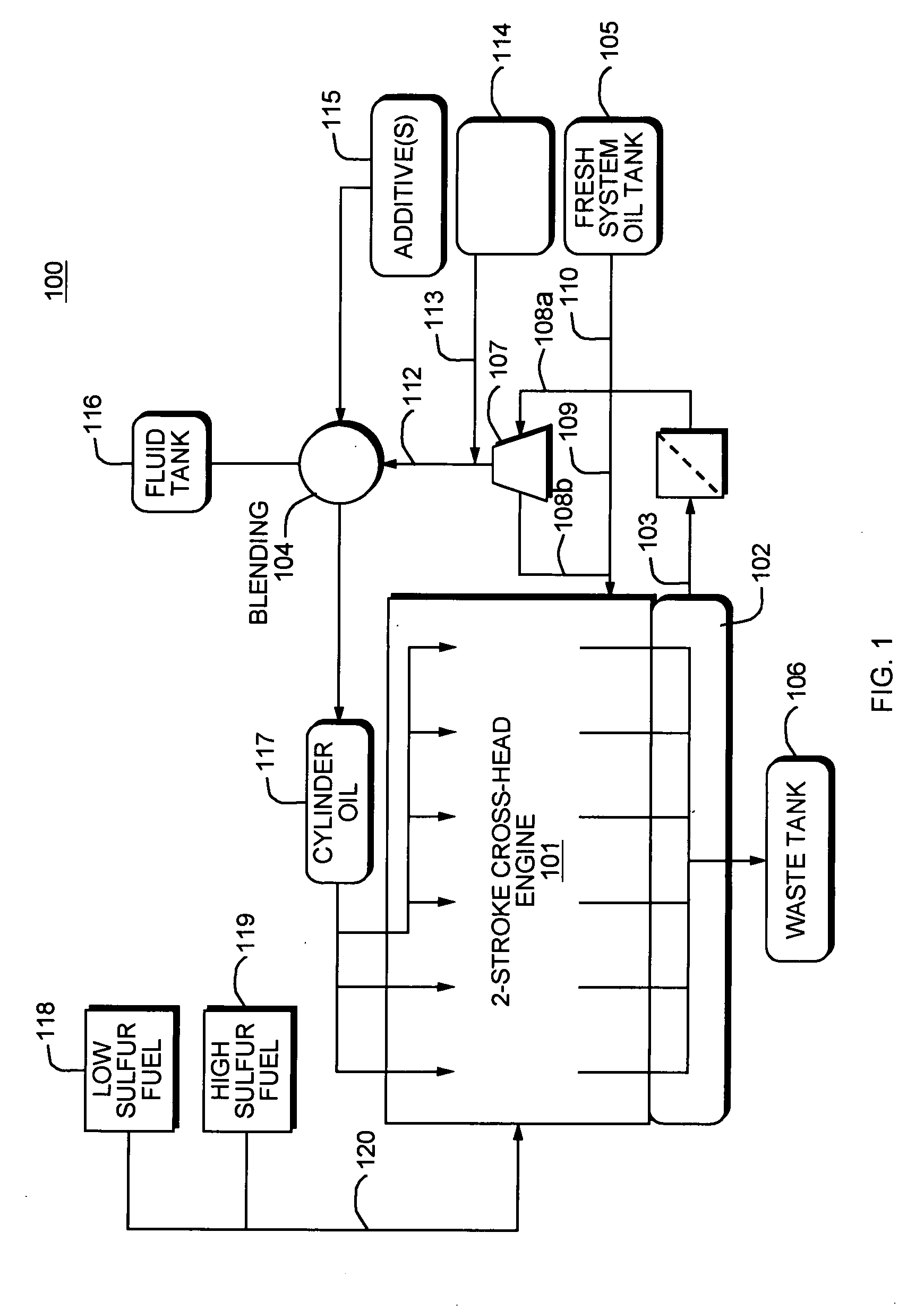

Method and system for operating two-and four-stroke engines using low sulfur fuels

InactiveUS20080153726A1Non-fuel substance addition to fuelInternal combustion piston enginesTotal Base NumberSulfur

A method for operating a two-stroke engine using low sulfur fuels. Blended cylinder oil is produced by blending base oil and at least one additive where the total base number (“TBN”) of the blended cylinder oil ranges from 1 TBN to 20 TBN. The engine is operated by supplying the blended cylinder oil and a fuel having less than 1.0% sulfur to the engine cylinders. The additive includes a low TBN calcium salts at a weight ratio ranging from 90:10 to 10:90; or any combination thereof.A method for operating a 4-stroke engine using low and high sulfur fuels. Blended oil, having a TBN that is greater than 20 TBN, is produced by blending base oil and at least one additive. The engine is operated by exchanging a low sulfur fuel having less than 1.0% sulfur with a high sulfur fuel. The engine lubricating system is switched to the blended cylinder oil in accordance with switching the fuel from a low sulfur fuel to a high sulfur fuel.

Owner:A P MOLLER AS

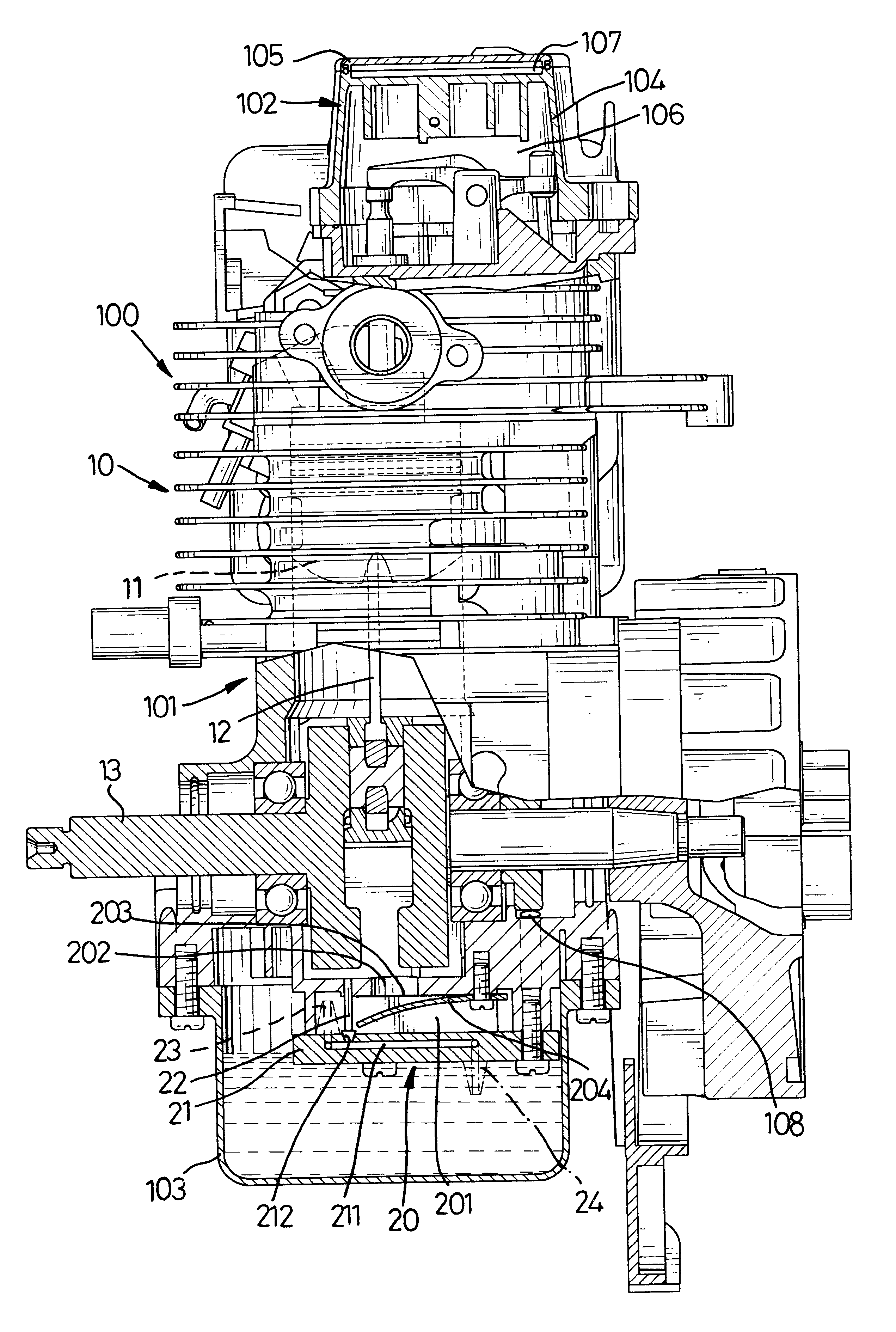

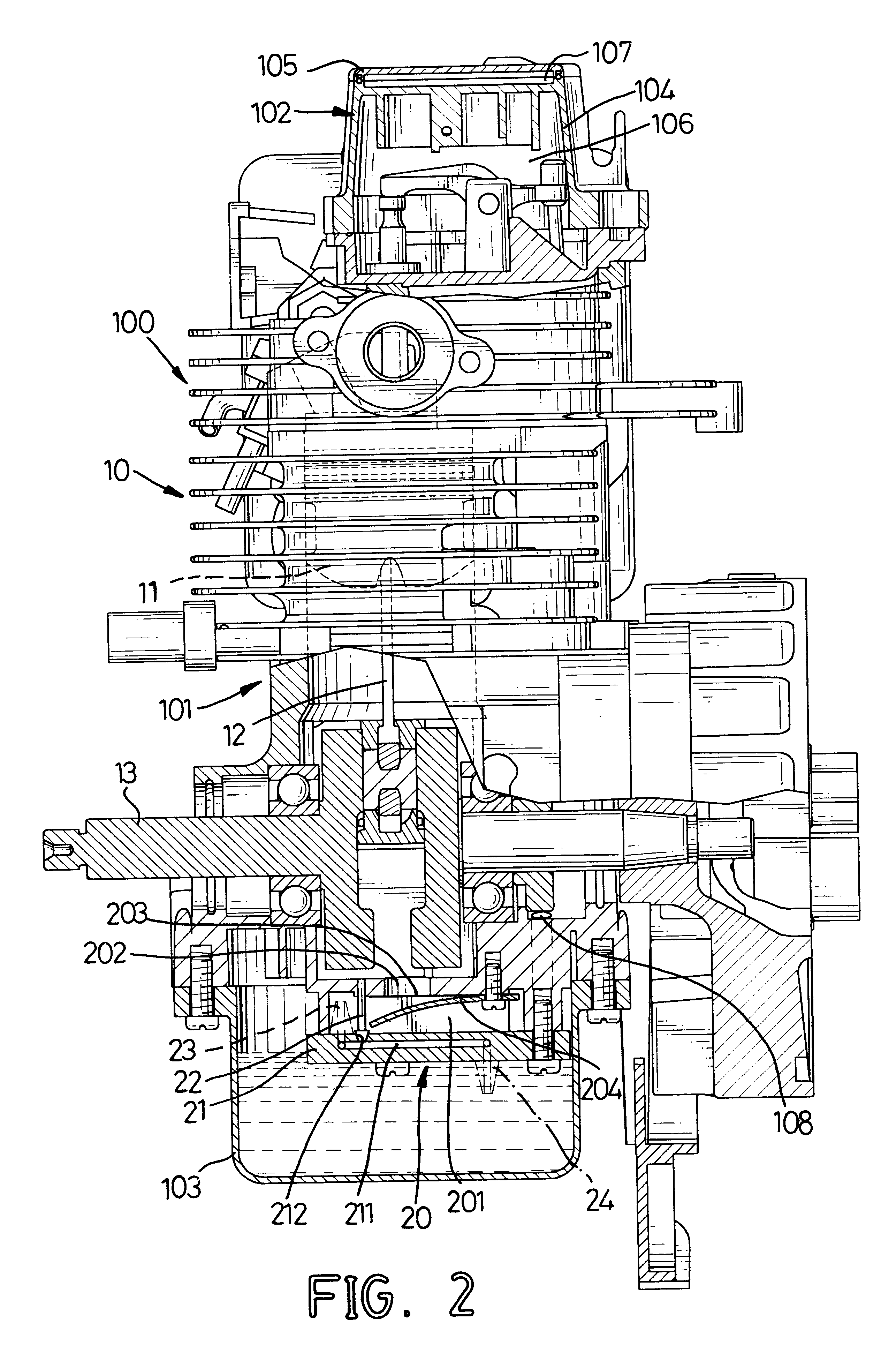

Four-stroke engine with an oil spray generating assembly for lubrication

InactiveUS6769391B1Lubrication of auxillariesLubricant conduit arrangementsFour-stroke engineEngineering

A four-stroke internal combustion engine includes a crankcase with a bottom, an oil pan and an oil spray generating assembly. The oil spray generating assembly having a closed sidewall, a valve, a bottom cap and nozzles is attached to the bottom of the crankcase and is enclosed by the oil pan. The closed sidewall is formed at the bottom of the crankcase to define a mist chamber enclosed by the bottom cap. The valve is mounted in the mist chamber with a valve port defined through the crankcase and a resilient valve flap corresponding to the valve port attached to the bottom of the crankcase. The nozzles are respectively mounted in the bottom cap out of the mist chamber inside the closed sidewall. The operation of the engine will produce an oil vapor for lubrication with the lubricating oil flowing out of the nozzles.

Owner:ECI ENGINE

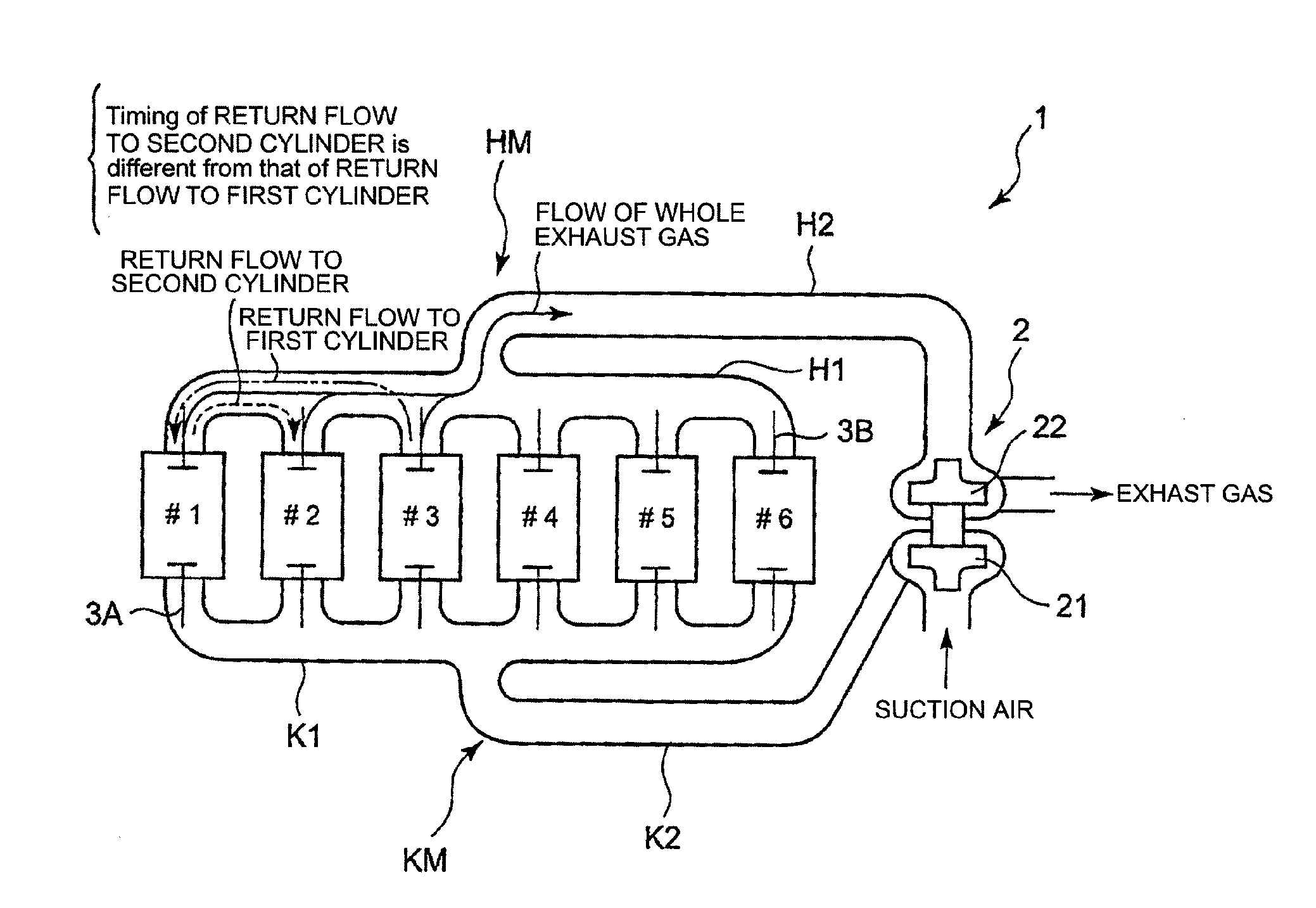

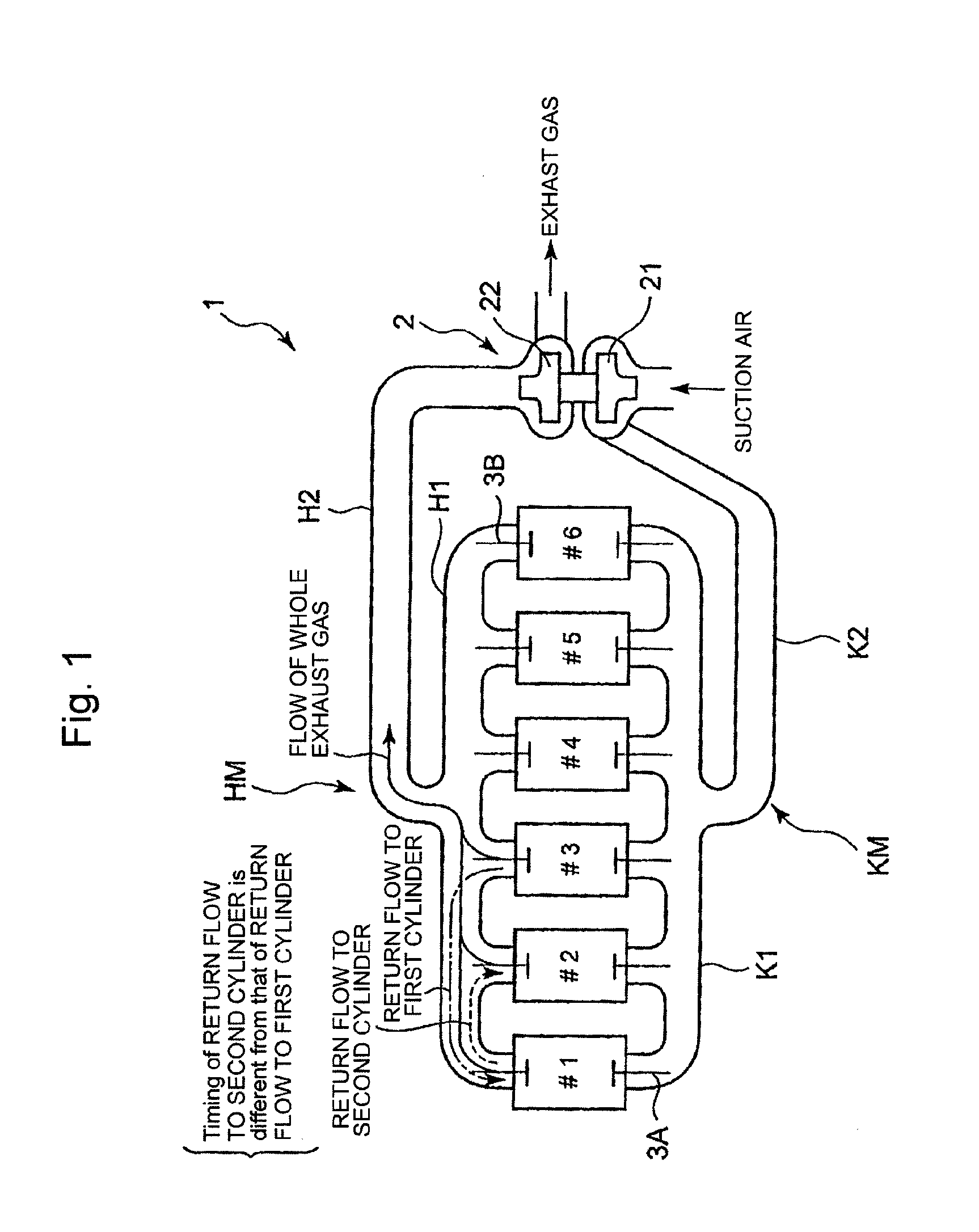

Exhaust-valve lifting and lowering cam, turbocharged four stroke engine and valve timing control method

InactiveUS20120042649A1Simple structureAppropriate arrangementElectrical controlNon-fuel substance addition to fuelExhaust valveFour-stroke engine

Providing a cam for lifting and lowering the exhaust valve so that the exhaust gas return-flow from one cylinder to another cylinder can be realized as greatly as possible, wherein the pistons and the exhaust valves do not come in contact with each other, and the valve control method does not depend on an electronic control approach. An exhaust cam for lifting and lowering the valve lift of the exhaust valve of one of the cylinders wherein the cam profile of the exhaust cam regarding the one of the cylinders including, but not limited to: a main exhaust lobe part for opening the exhaust valve so that the exhaust gas is discharged out of the cylinder; and, a gas return lobe part for opening the exhaust valve so that the quantity of the exhaust gas from the one of cylinders to the other cylinder is increased, the gas return lobe part being formed on the cam-follower descending part of the profile so as to delay the closing timing of the exhaust valve or maintain the valve lift-displacement regarding the exhaust valve larger, and wherein the cam profile is formed so that the interference between the exhaust valve and the piston is evaded and the overlap regarding the exhaust valve of the one cylinder and the exhaust valve of the other cylinder is increased by the manner that the main exhaust lobe part and the gas return lobe part rise outward from the base circle.

Owner:MITSUBISHI HEAVY IND LTD

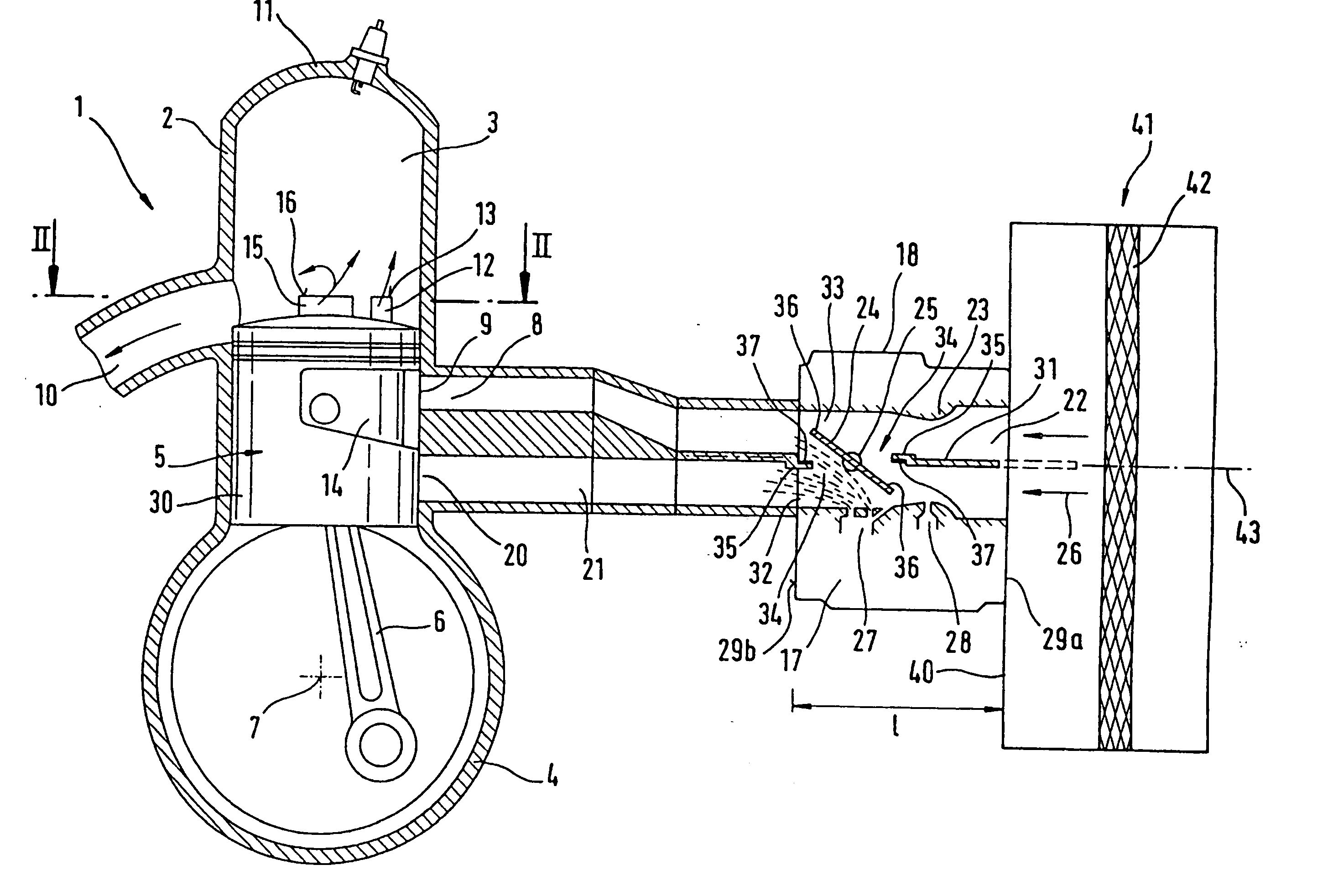

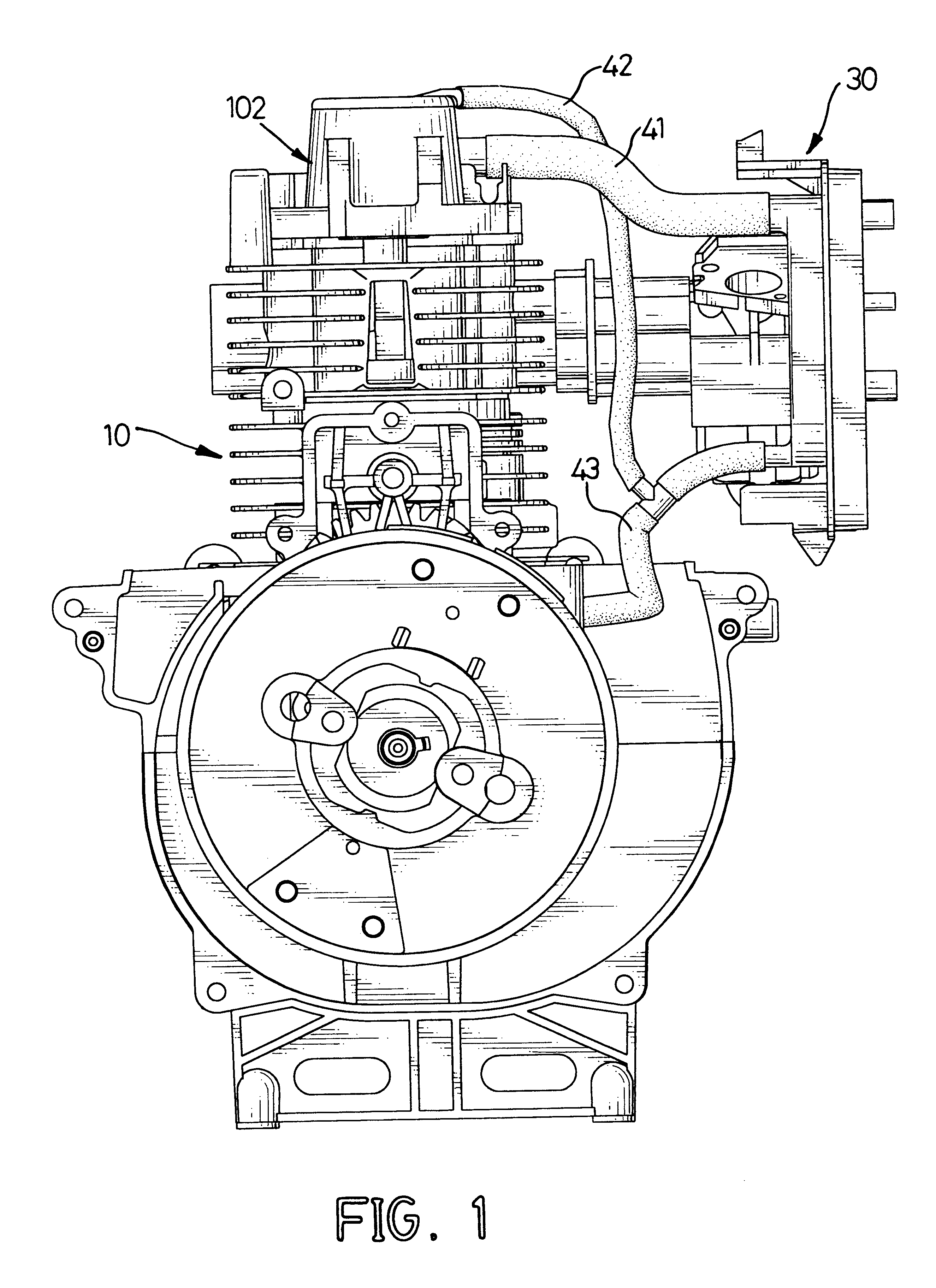

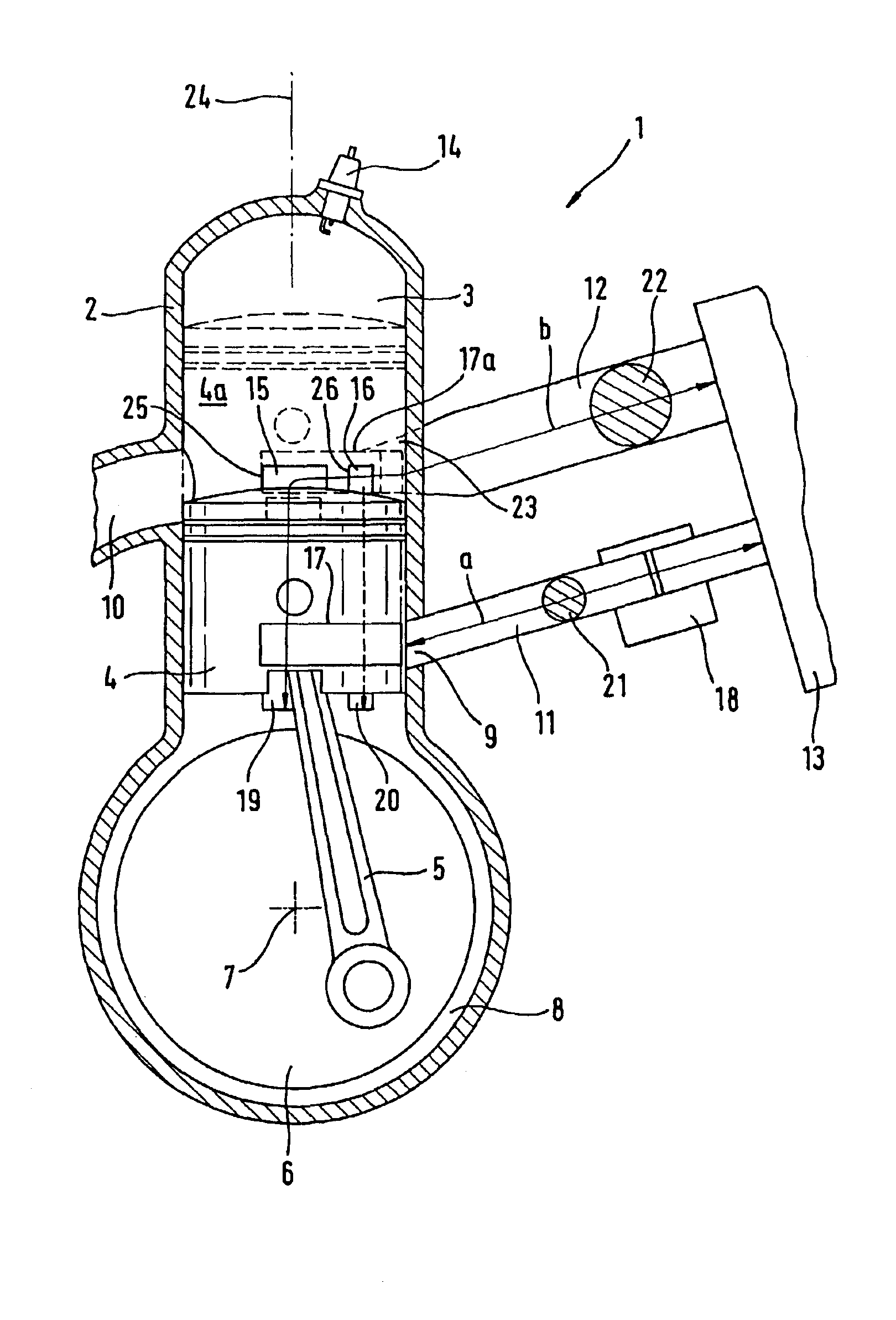

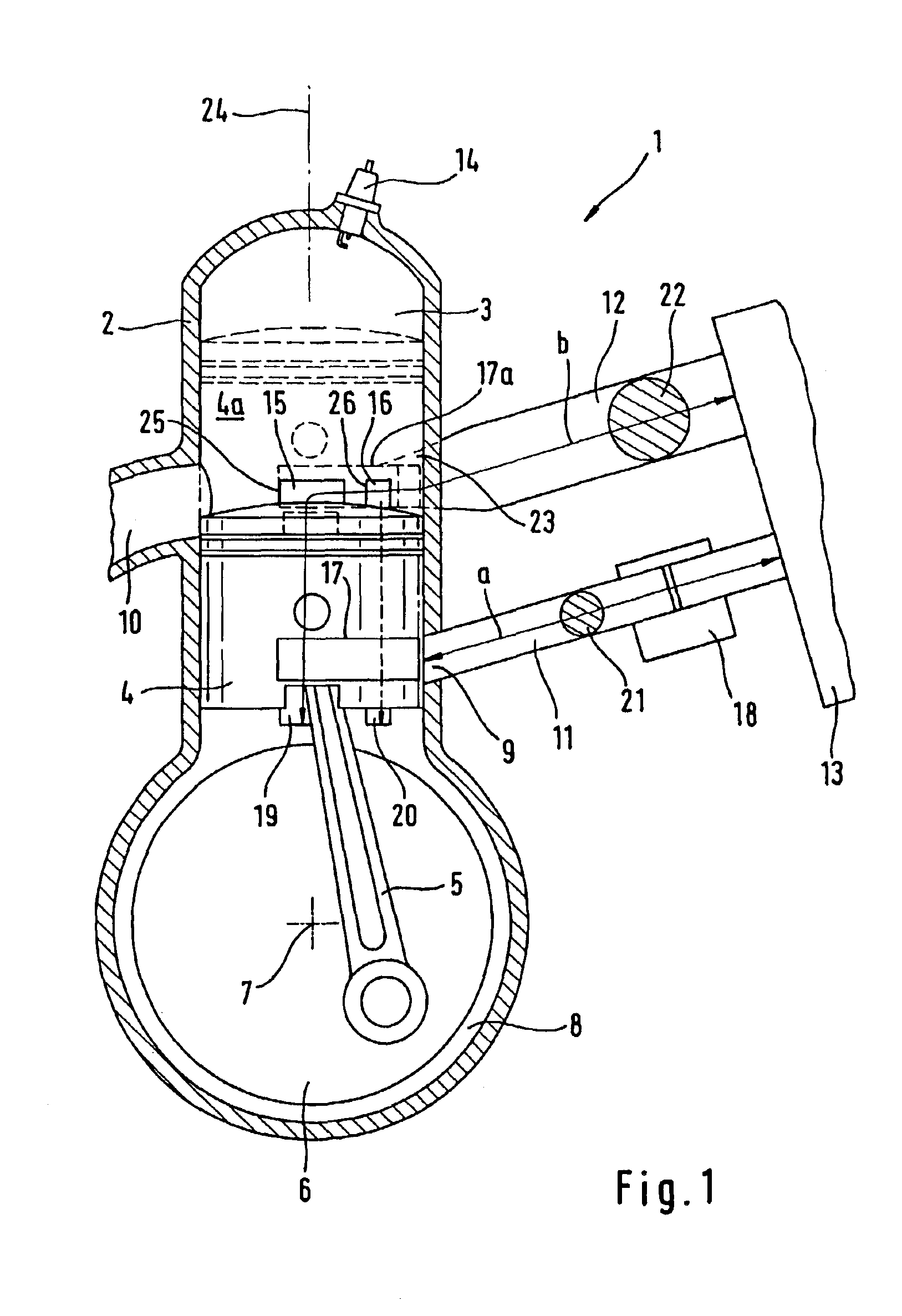

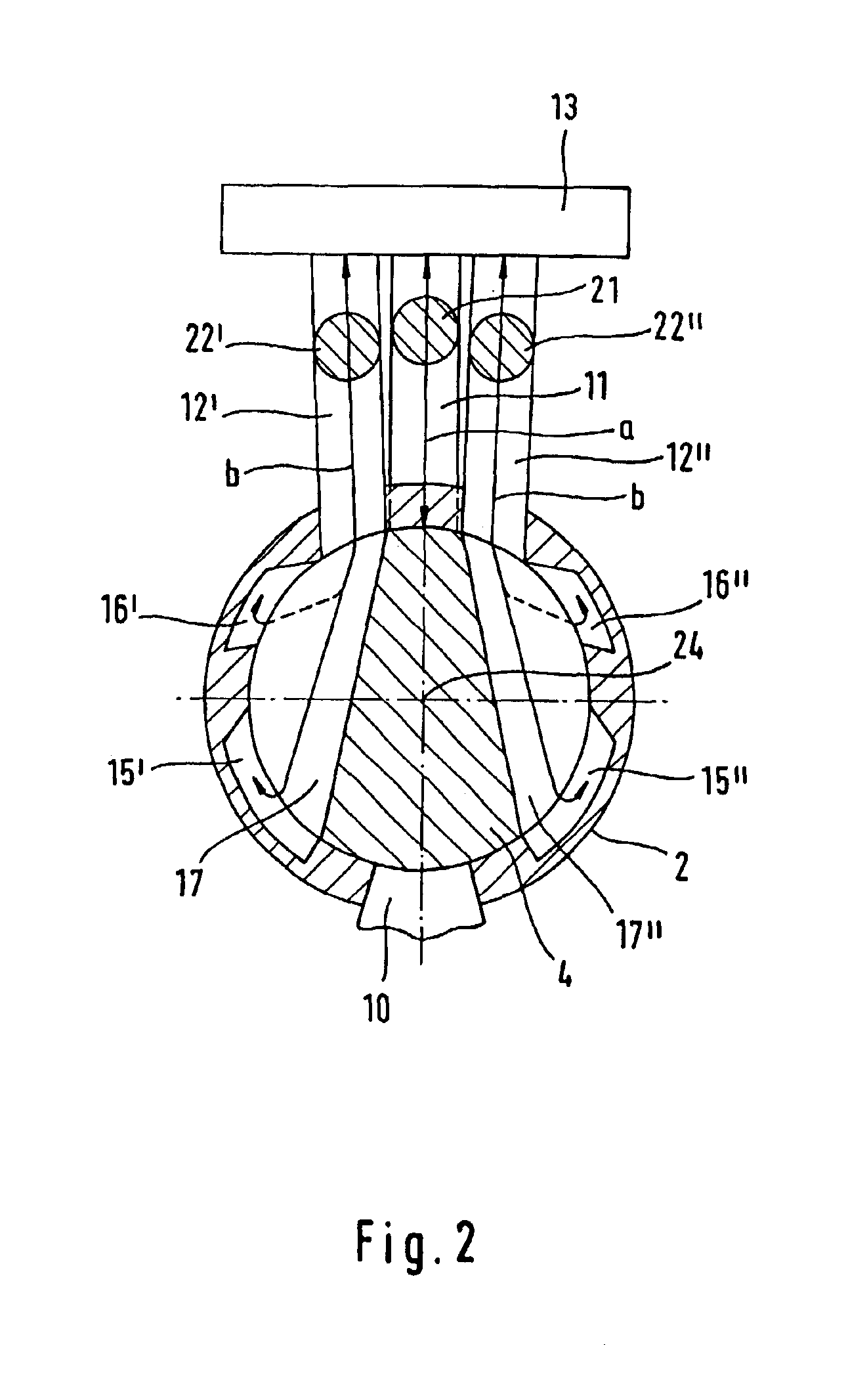

Two-stroke engine

InactiveUS6857402B2Improve dynamic performanceSimple structureInternal combustion piston enginesSecondary air addition to fuelCombustion chamberAir filter

A two-stroke engine, (1) is disclosed which includes (I) transfer channels (15, 15′, 15″, 16, 16′, 16″) which open into the crankcase (8) and fluidly connect the crankcase (8) to the combustion chamber (3) at specific positions of the piston (4) and (ii) an intake channel (11) for supplying an air / fuel mixture into the crankcase (8) via an inlet (9) and is connected to an air filter (13). At least one air channel (12) supplies additional combustion air into at least one transfer channel (15, 15′, 15″, 16, 16′, 16″). For a good load-independent air / fuel mixture ratio, the length (a) of the intake channel (11) is up to 60% of the length (b) of the clean air path; and, length (b) is the mean channel length from the air filter (13) to the opening (19, 20) of a transfer channel (15, 16) into the crankcase (8).

Owner:ANDREAS STIHL AG & CO KG

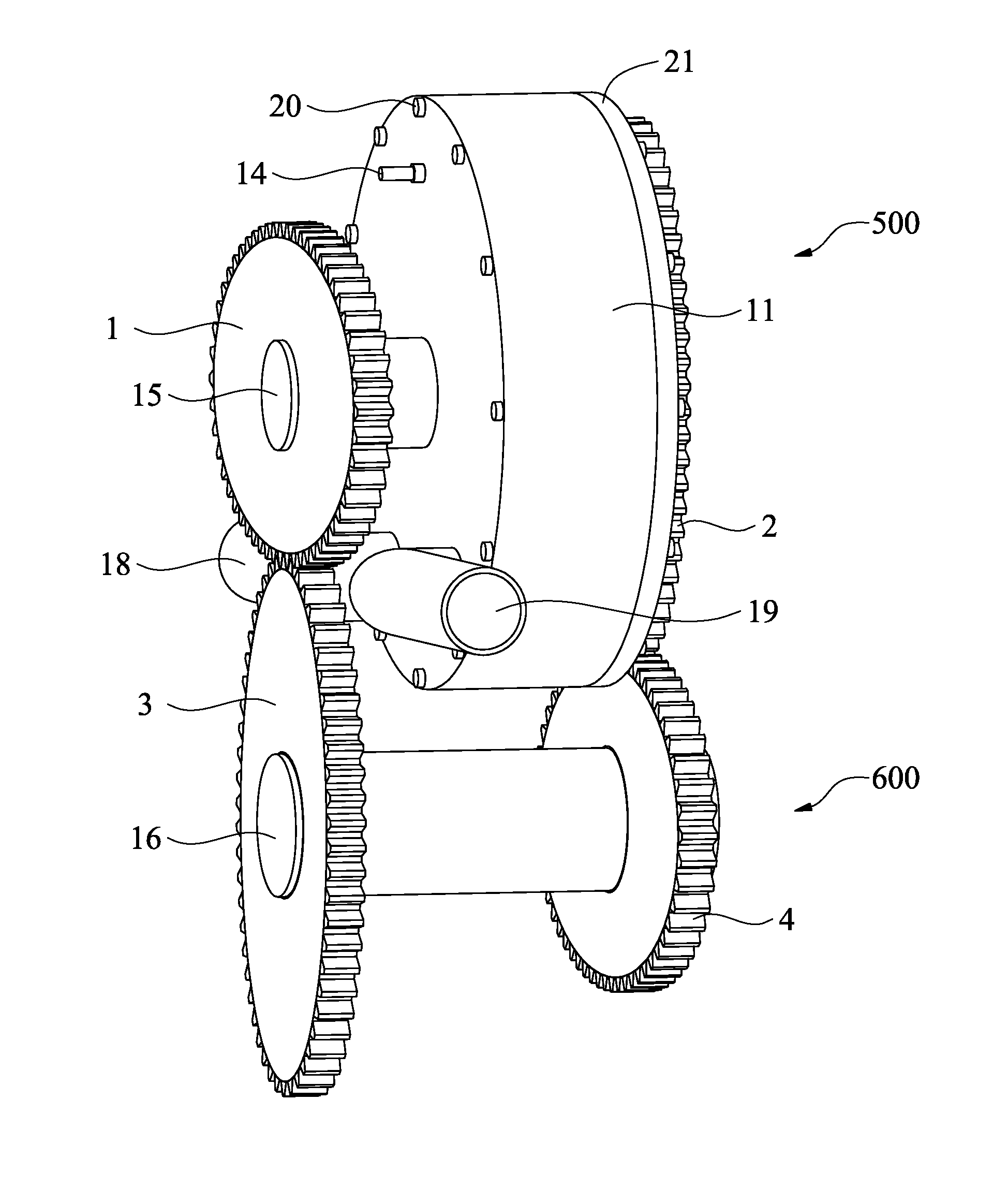

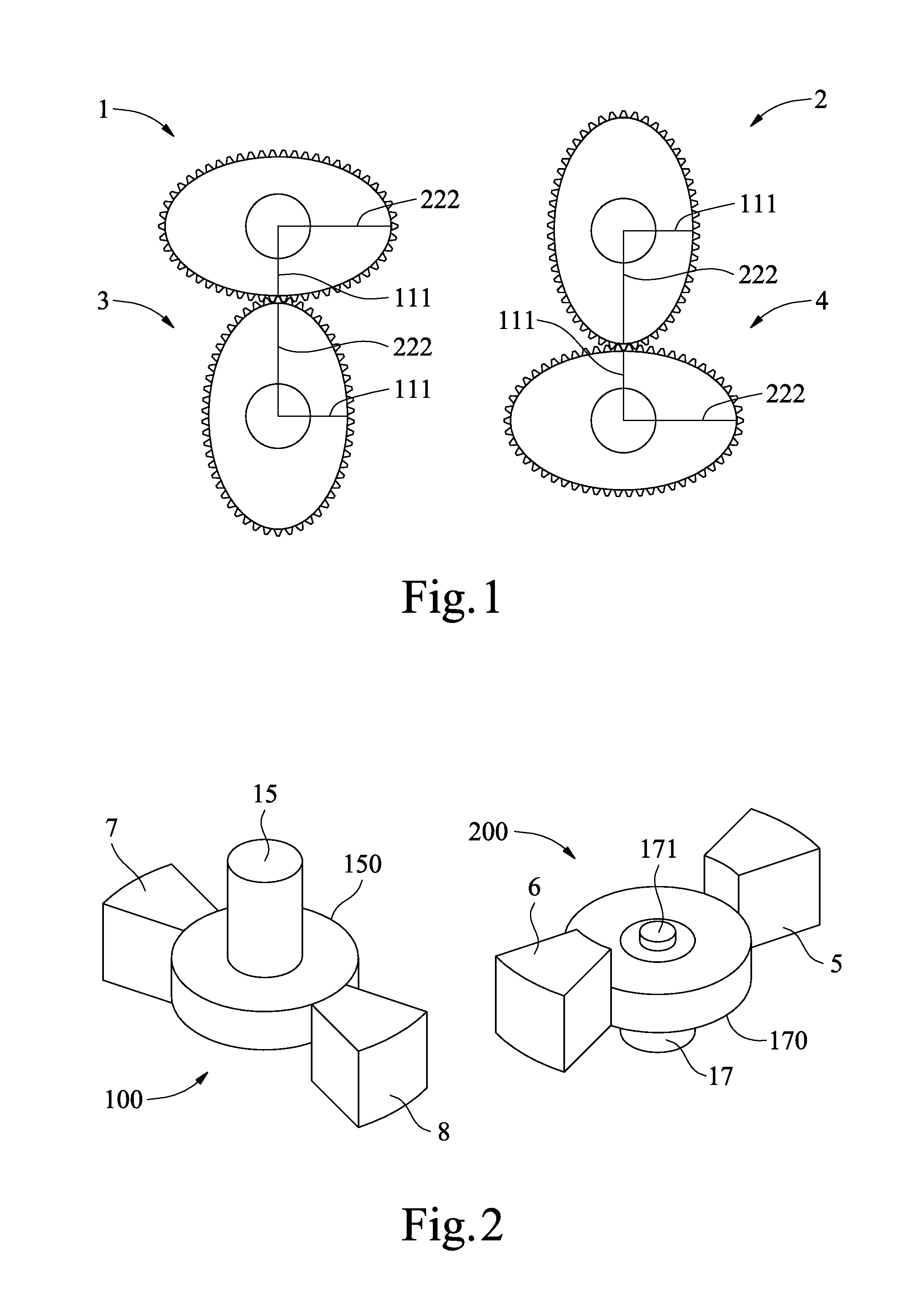

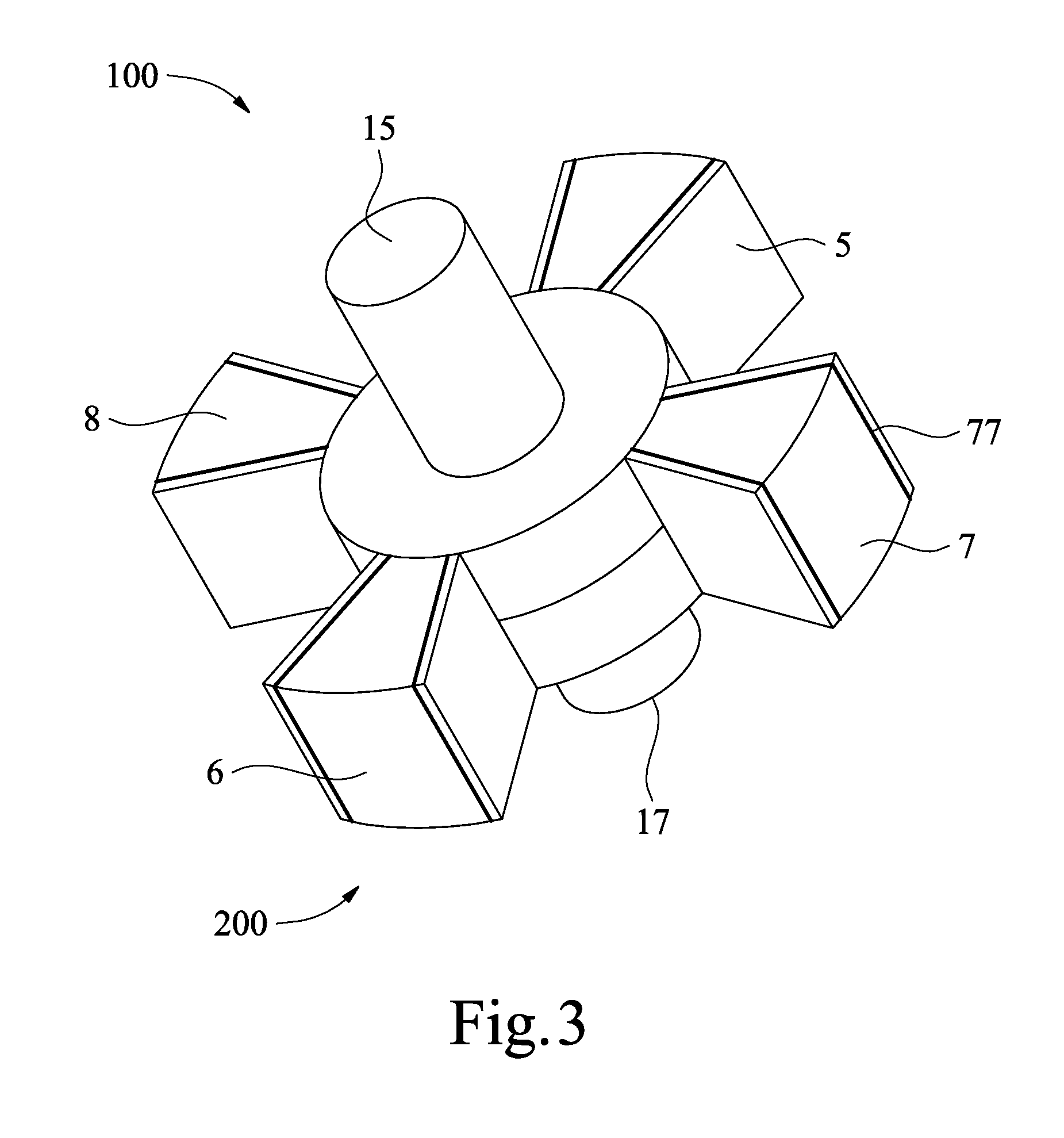

Rotary modulation engine

InactiveUS20120080006A1Reduce the number of partsReduce manufacturing costInternal combustion piston enginesEngine componentsRotation velocityFour-stroke engine

A rotary modulation engine enabling modulation of rotary pistons' rotational speeds is introduced. The rotary modulation engine utilizes four elliptical gears to drive two rotors that overlap each other with rotary pistons thereon alternating one another and rotating in the same direction. The elliptical gears also modulate the relative rotational speeds of these rotary pistons to thereby complete compression, power, exhaust and intake strokes four times in one revolution of a power output shaft of the engine. The rotary modulation engine with the above arrangements has smaller volume and improved efficiency as compared to the conventional four-stroke engine that requires two revolutions of the engine's crankshaft to complete four strokes. The rotary modulation engine can be applied to cars, ships, power generators and the like, and has reduced number of parts, volume and manufacturing cost while provides effectively upgraded operation efficiency.

Owner:YEH CHUN CHIANG

Stratified two-stroke engine and dual passage fuel system

InactiveUS20120247435A1Emission reductionSimple designInternal combustion piston enginesLighting and heating apparatusHydrogenFour-stroke engine

Owner:MAVINAHALLY NAH S

Valve for control of additional air for a two-stroke engine

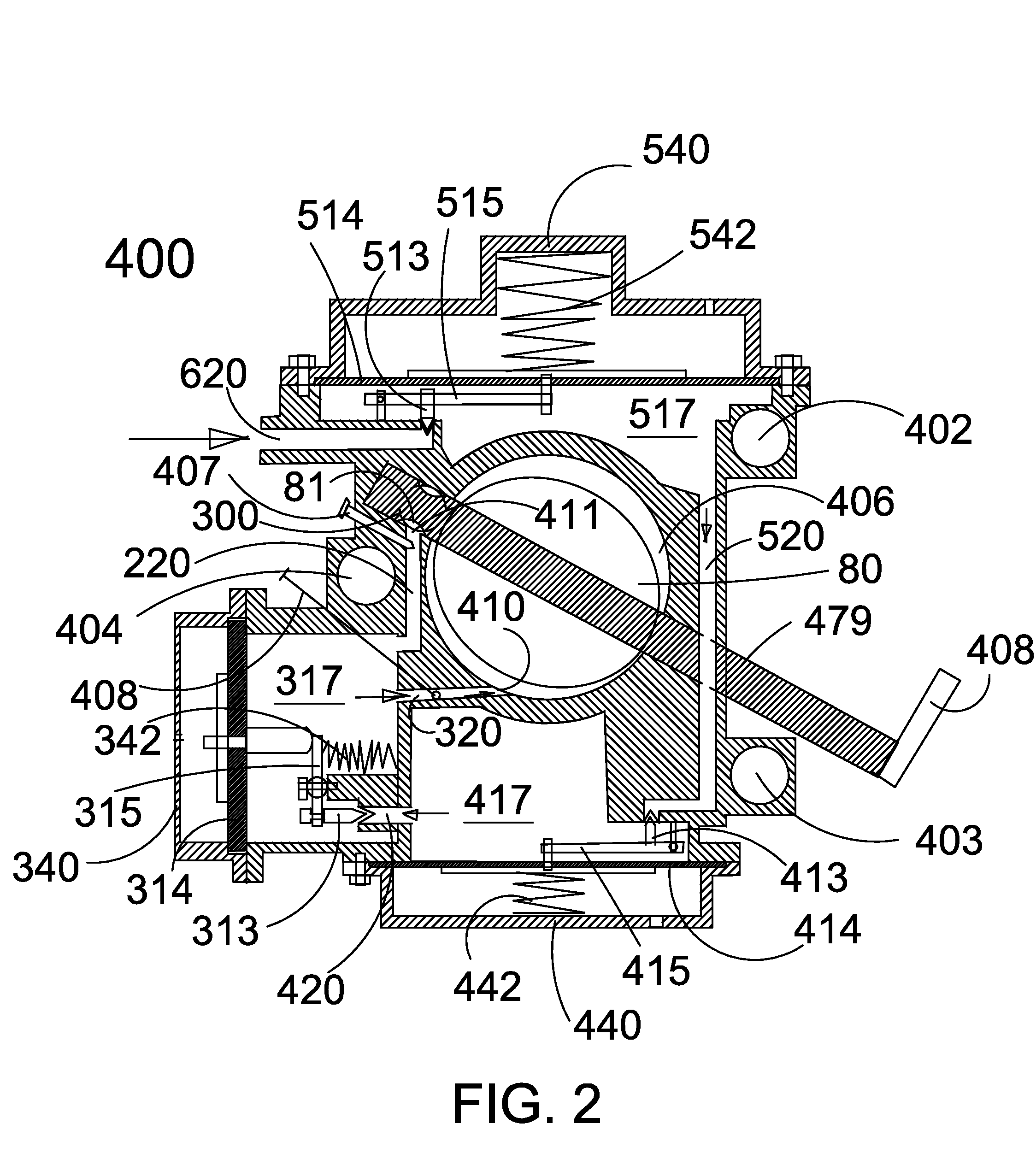

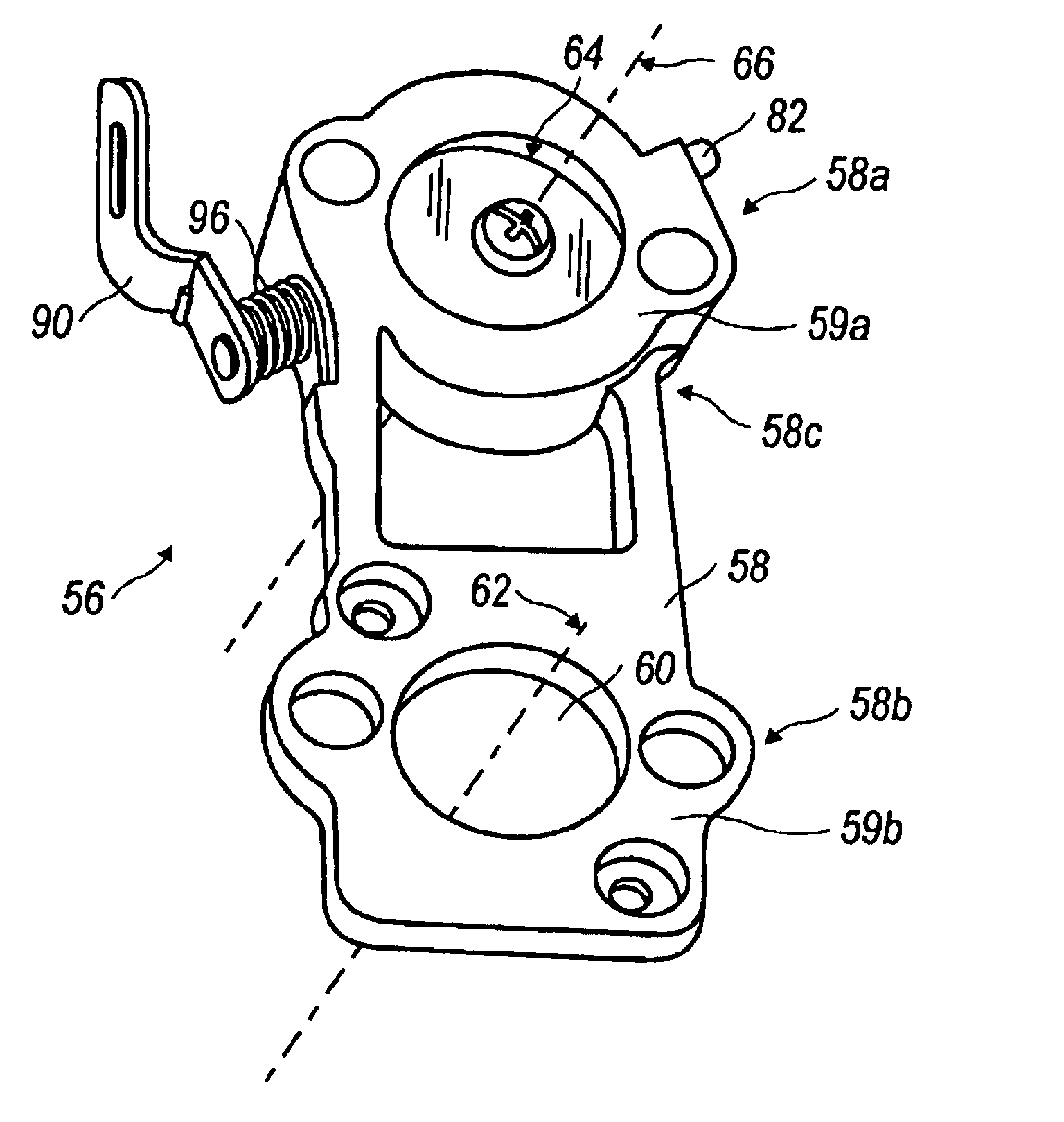

InactiveUS6877723B2Easy to modifySimple and elegant constructionInternal combustion piston enginesLighting and heating apparatusFour-stroke engineCarburetor

Flange assembly for supporting a structure that provides scavenging air supply to an internal combustion engine at the carburetor to the engine. The assembly includes a thin-body flange that is configured to be abuttingly installed upon an end surface of the carburetor. The carburetor has its combustion air intake or port exposed at an outer surface for intaking air for the combustion process. The thin construction of the flange enables advantageous positioning of the adaptive flange. The relative dimensioning of the thin-body flange also contributes to its low-impact as a modification to air inlet arrangement. A combustion air aperture is provided that extends through the thin-body flange. The combustion air aperture is located in the flange for alignment with the combustion air intake. By this alignment, fluid communication is established across the flange and into the carburetor when the flange is abuttingly installed upon the carburetor. A scavenging air aperture also extends through the thin-body flange and is spaced apart from the combustion air aperture. A valve assembly is operatively coupled to the thin-body flange and has a valve element positioned at the scavenging air aperture for opening and closing the scavenging air aperture.

Owner:HUSQVARNA AB

Multi-location fuel injection system

ActiveUS7168401B2Lower emission levelsSacrificing a potential peak horsepowerCombustion enginesLow pressure fuel injectionExhaust valveCrankcase

Owner:ARCTIC CAT

Balanced partial two-stroke engine

InactiveUS20080022666A1Improve responseInternal combustion piston enginesNon-fuel substance addition to fuelMarine engineeringFour-stroke engine

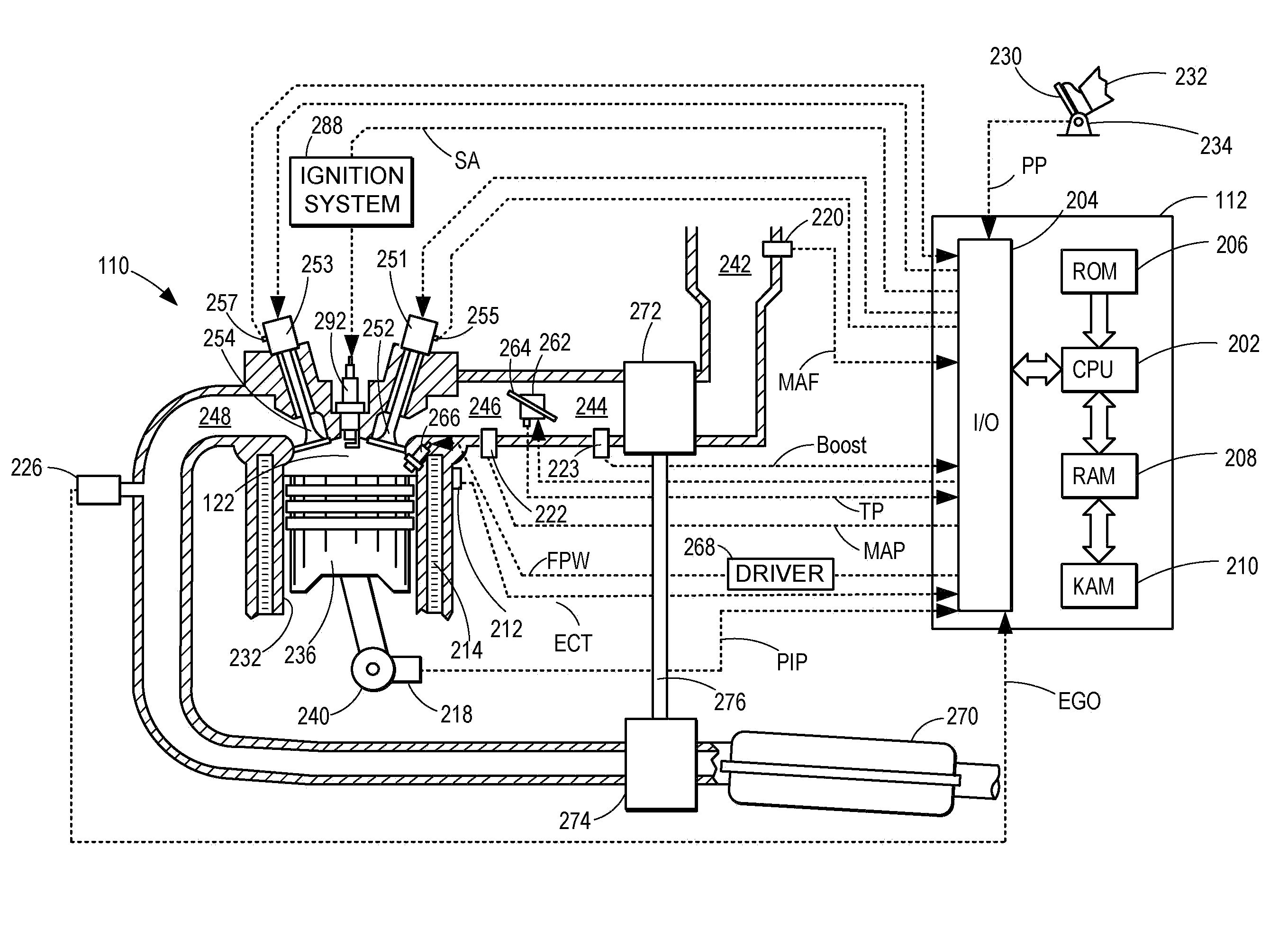

An engine is provided. The engine may comprise a first cylinder group including at least one cylinder configured to operate in a two-stroke engine operating mode and a second cylinder group including at least two cylinders configured to operate in a four-stroke engine operating mode. The power outputs of each of the cylinders in the first cylinder group and second cylinder group may be approximately equal.

Owner:CATERPILLAR INC

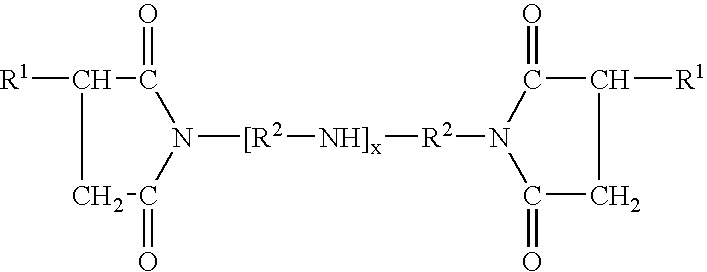

Lubricant composition suitable for direct fuel injected, crankcase-scavenged two-stroke engines

A lubricant composition suitable for lubricating a direct fuel injection two-stroke engine comprises at least one condensation product of a fatty acid with an amine or ammonia and of at least one Mannich dispersant, each in an amount of 0.5 to 8 percent by weight, along with an oil of lubricating viscosity.

Owner:THE LUBRIZOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com