Double sealing face fin plate-type heat exchanger

A plate heat exchanger, double-sealed technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as failure, loss, environmental and safety accidents, and achieve short flow distance and reliable products Enhanced performance and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the drawings and specific embodiments:

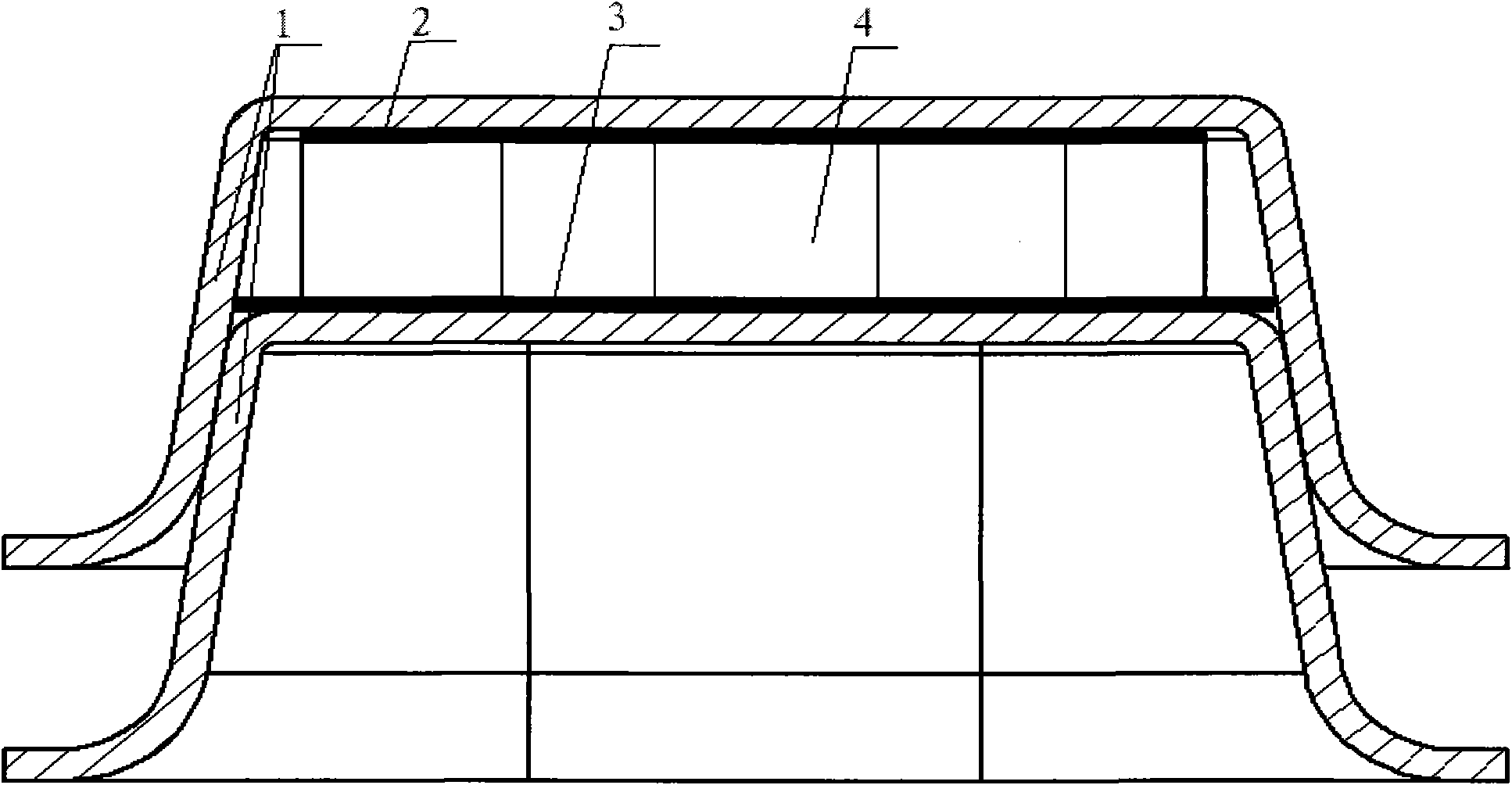

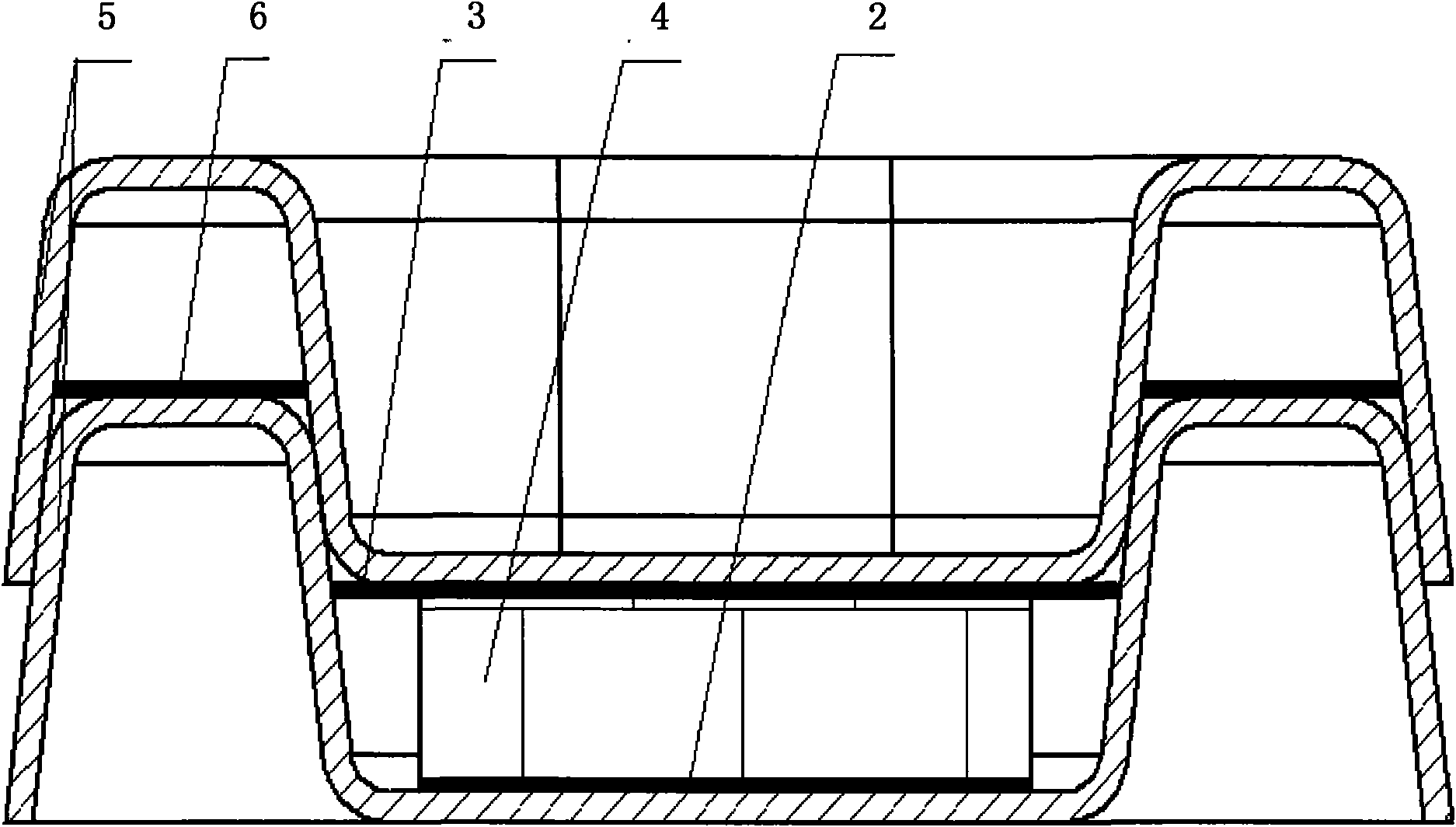

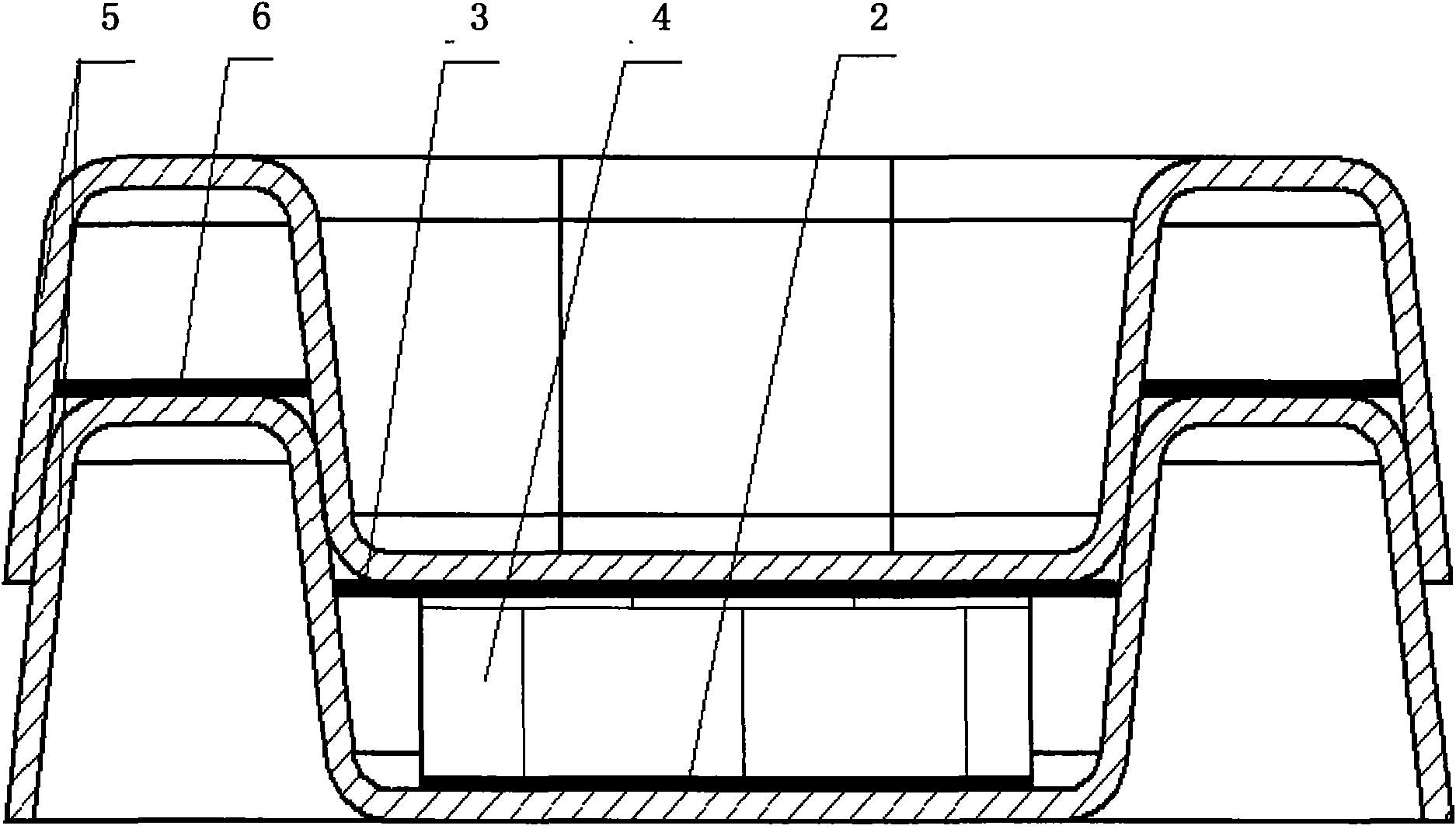

[0012] Such as figure 2 Shown: a double-sealed surface fin plate heat exchanger, including a double-sealed plate chip 5, a double-sealed solder plate 6, a lower solder plate 3, a fin 4 and an upper solder plate 2, above the double-sealed plate chip 5 There is an upper soldering piece 2, a lower soldering piece 3 is arranged under the double-sealed plate chip 5, a fin 4 is arranged between the upper soldering piece 2 and the lower soldering piece 3, and the double-sealing plate chip 5 is also provided Double sealing welding piece 6. The double-sealed plate chip 5 adopts two chamfers on the peripheral surface. The double sealing welding sheet 6 adopts a three-dimensional molding surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com