Integrated top cover assembly of hermetic compressor

A closed compressor and integrated technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of overheating of working fluid, long distance, high manufacturing cost, etc., and achieve the reduction of flow distance Effects of small size, reduced number of parts, and improved assembly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The schematic diagram of the integrated top cover assembly of the hermetic compressor of the present invention will be described in detail below.

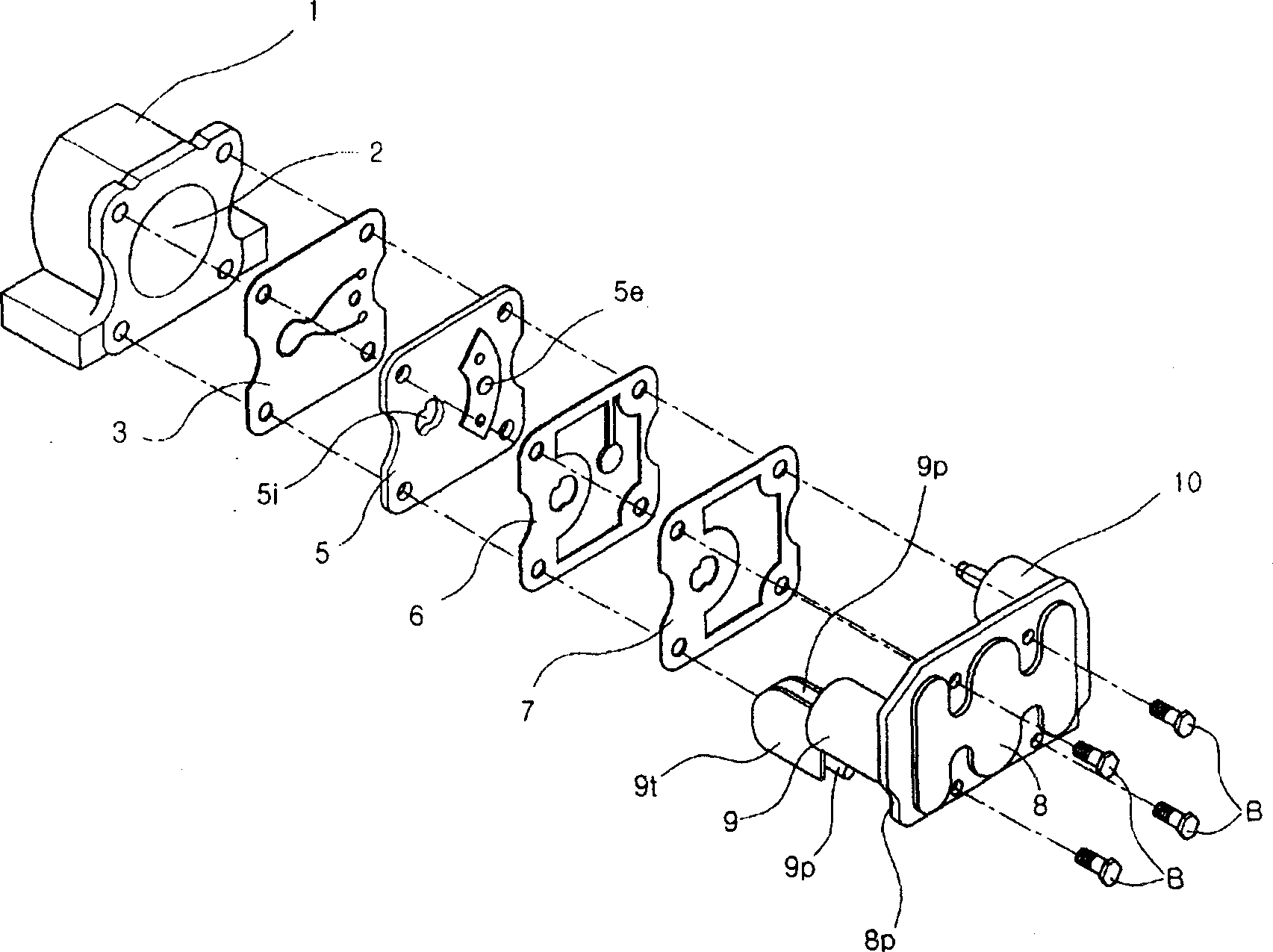

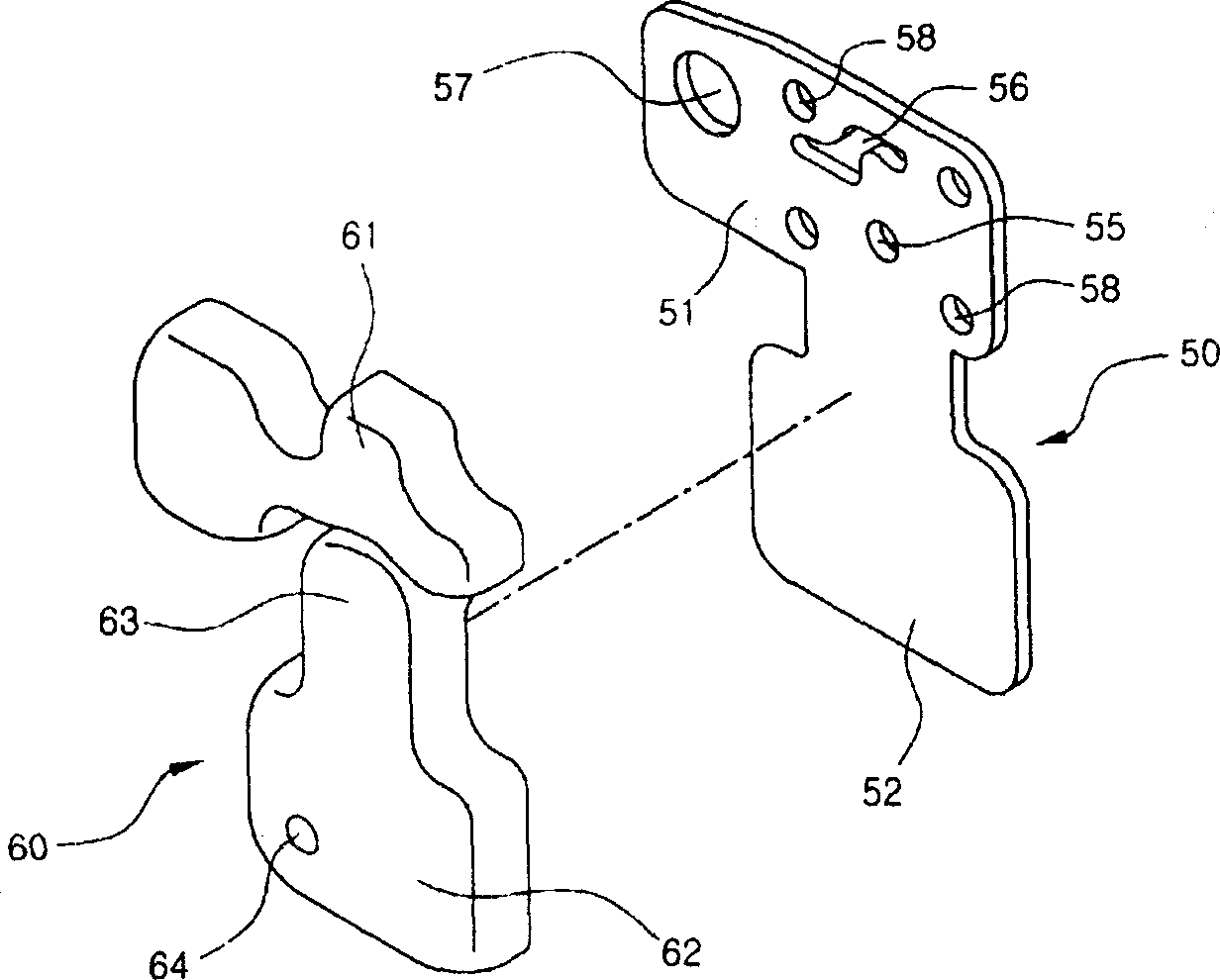

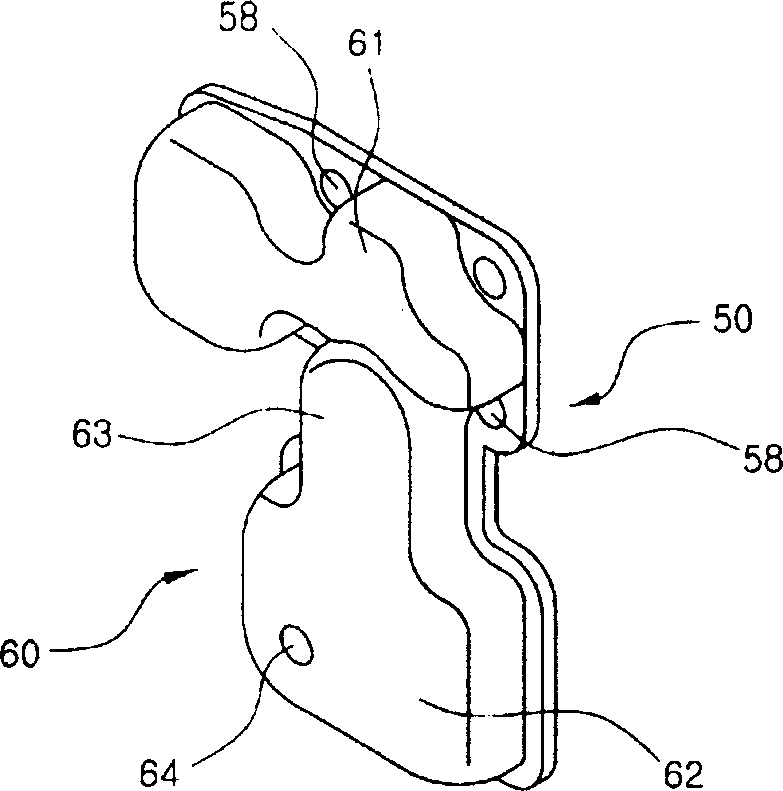

[0044] figure 2 It is an exploded schematic view of the integrated top cover assembly structure of the hermetic compressor of the present invention. image 3 It is a schematic diagram of the appearance of the compressor of the present invention. Figure 4 It is the front view of the appearance of the compressor of this invention.

[0045] As shown, the top cover assembly of the present invention is integrated with the muffler. The top cover assembly not only has a passage for the working fluid from the outside to flow into the compression chamber, but also has a discharge chamber through which the working fluid passes after being discharged from the compression chamber. The anechoic chamber plays the role of preventing the noise and pulsation of the working fluid.

[0046] First, the bottom plate 50 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com