Cross-flow air way module and air warmer

An air duct component and cross-flow technology, applied in the field of cross-flow air duct components and heaters, can solve the problems of low air volume and air speed of heaters, loss of gas speed, etc., and achieve increased air volume and air speed, short flow distance, and reduce loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

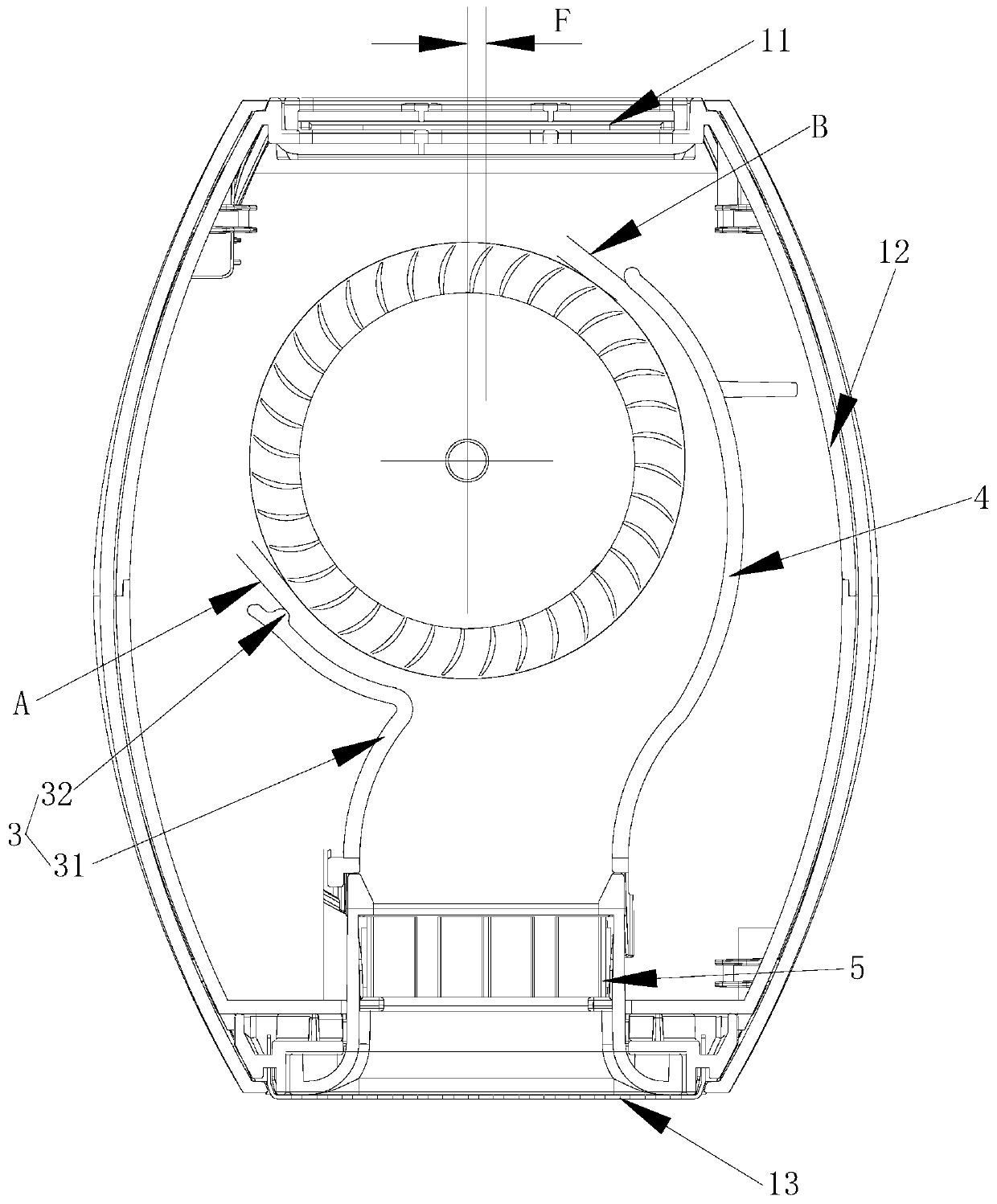

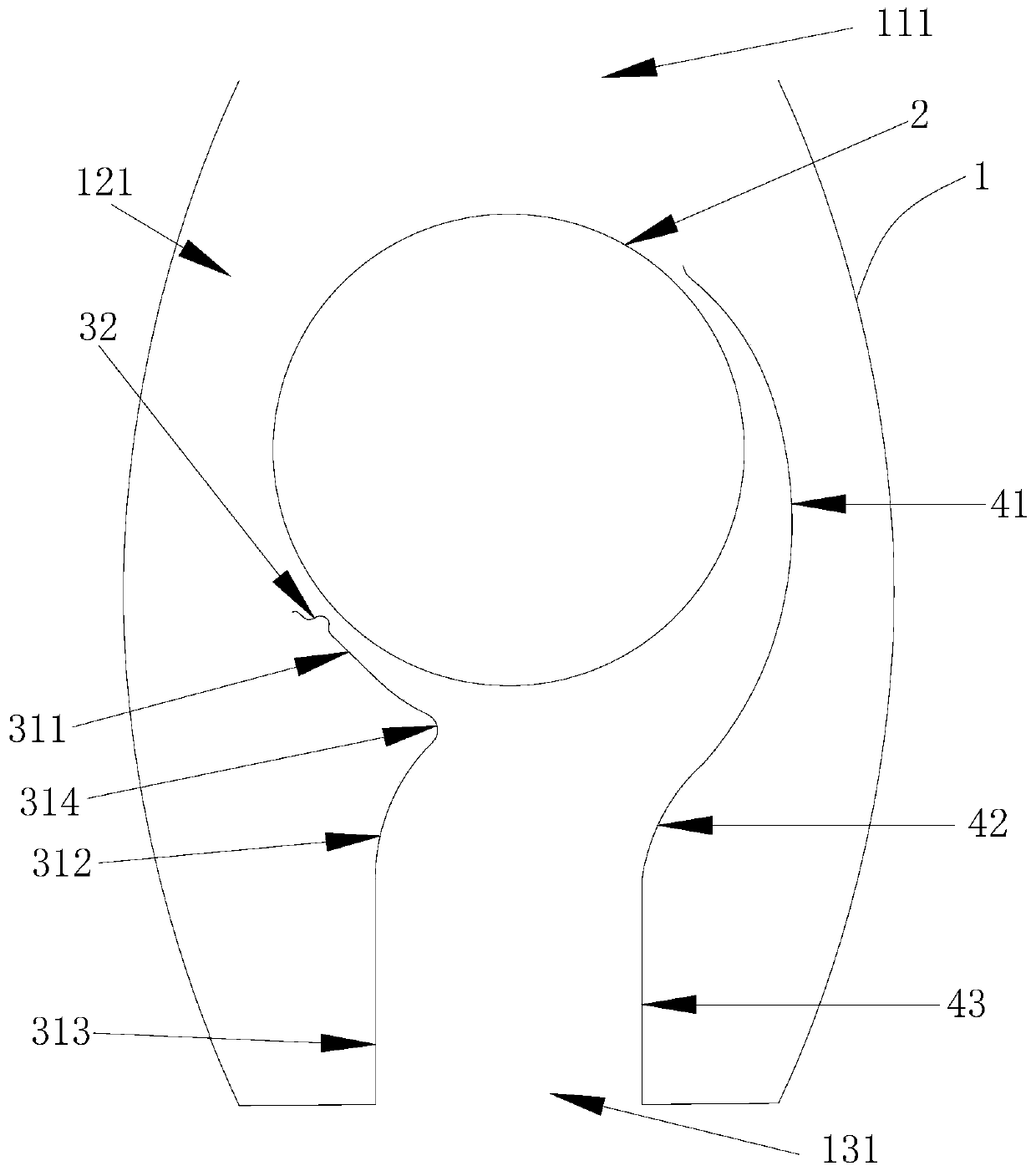

[0047] Such as figure 2 As shown, the present invention provides a cross-flow air duct assembly, which includes a housing 1, an impeller 2, a wind guiding volute 3 and a wind guiding volute 4, wherein the housing 1 has an air inlet 111, an air duct 121 and an air outlet 131, The impeller 2, the air guide volute 3 and the air guide volute 4 are all installed in the air duct 121, and the air inlet 111 and the air outlet 131 are all connected with the air duct 121, thereby forming a gas circulation channel, the air inlet 111 and the air outlet 131 They are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com