Linear type fast-assembling peristaltic pump assembly

A peristaltic pump, a linear technology, applied in the field of peristaltic pumps, can solve the problems of the fluid can not be transported in a straight line, the liquid flow distance is long, and the replacement of the hose is complicated, and the flow distance and residence time are short, the operation is simple, and the service life is extended. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

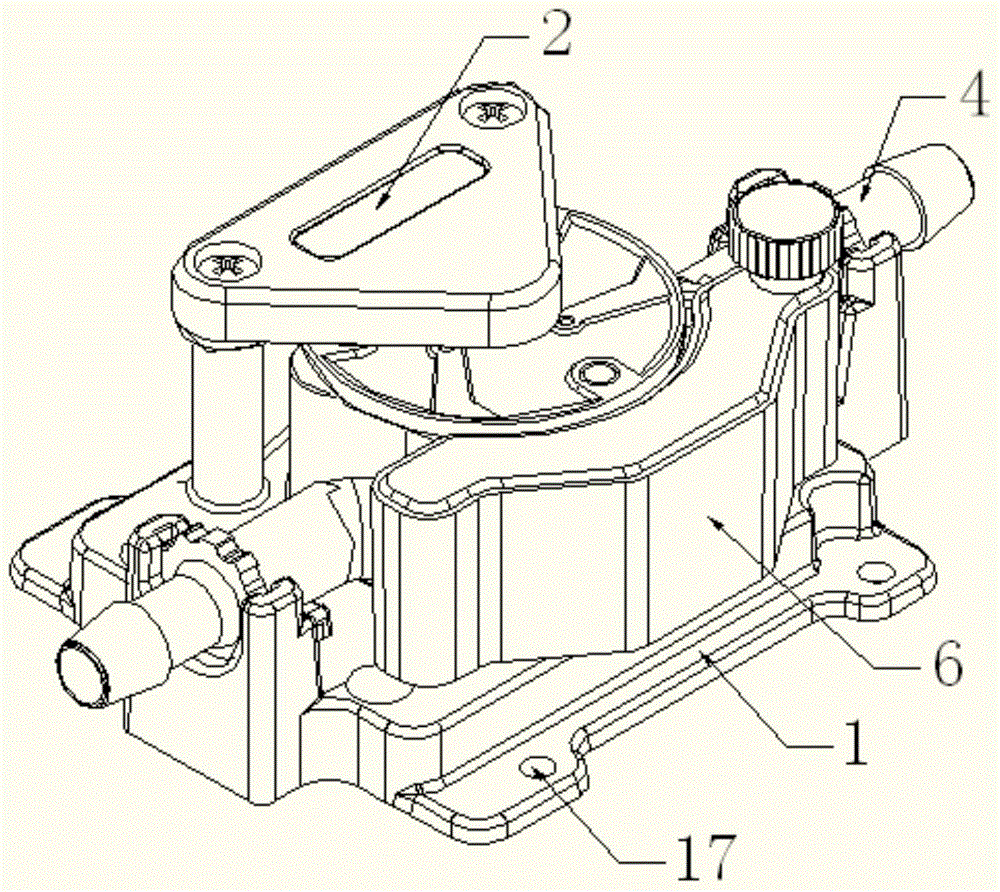

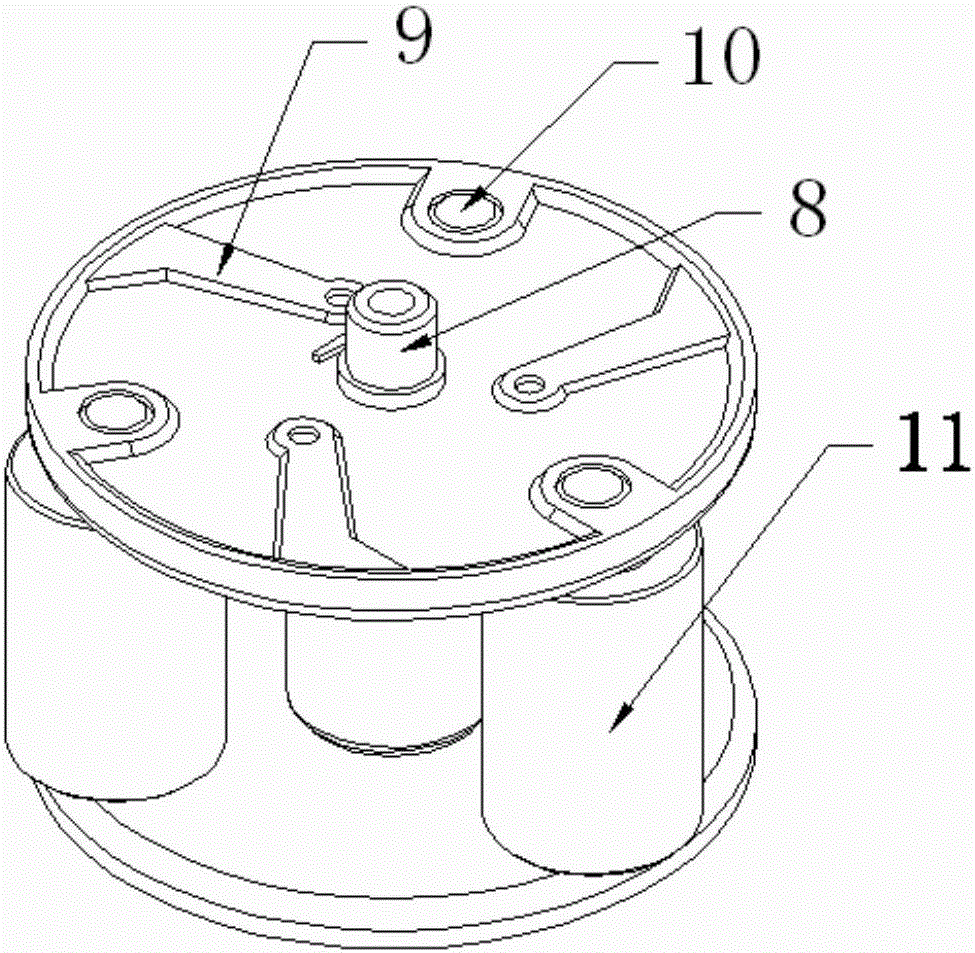

[0032] like Figure 1 to Figure 6 As shown, a linear fast-installed peristaltic pump assembly includes a base 1, a squeeze roller assembly fixed on the base 1, and an upper support cover 2 above the squeeze roller assembly. The left and right sides of the base 1 Mounting grooves 3 are respectively fixed on the edges of both sides, and a hose 4 with a joint is installed in the installation groove 3, and the inner surface of the hose 4 is in interference fit with the extrusion surface of the extrusion roller assembly. The two ends of the hose 4 are located on the same straight line, and a positioning column 5 is also fixed on the base 1, and the positioning column 5 is connected to one end of the pressing block 6 in rotation, and the other end of the pressing block 6 is screwed by a thumb screw 7 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com