Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce head pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

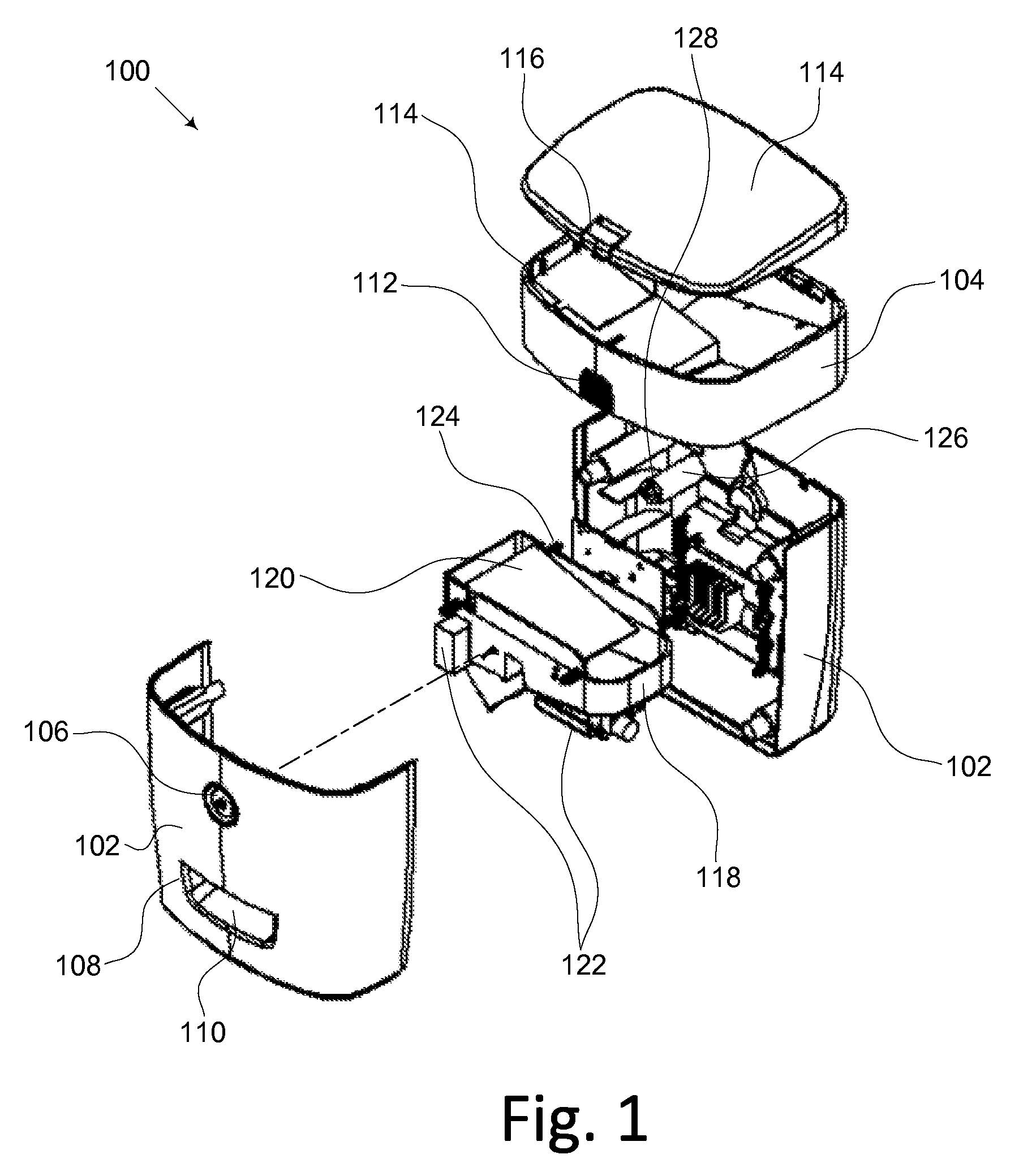

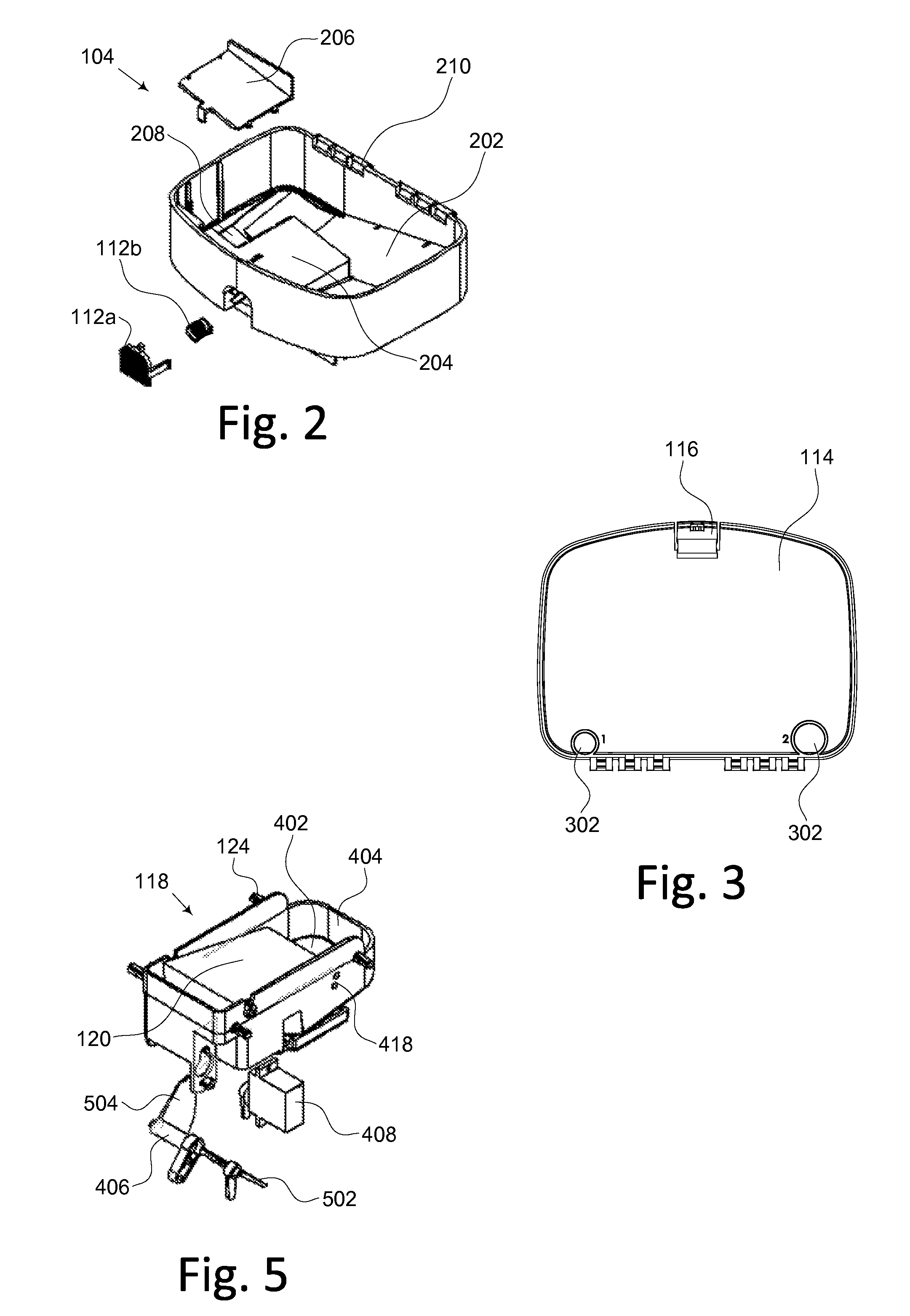

Remotely activated reward dispenser

ActiveUS8807089B2Prevent accidental releaseReduce noiseAnimal feeding devicesAnimal housingEngineeringRemote dispensing

A remotely activated reward dispenser. The remote dispenser delivers consumable rewards in response to a trigger signal from a remote triggering device. The reward dispenser uses a two stage delivery system to prevent unintentional release of the consumable reward. A vibration stage moves a portion of the consumable reward from a reservoir to a staging platform without crushing the consumable reward. The second stage transfers the consumable reward from the staging platform to an area accessible by the animal. A vibration damping system reduces the noise generated by the reward dispenser. An adjustable transition varies the feed rate for the consumable reward.

Owner:RADIO SYST CORP

Centrally gated cast metal rotary friction plates and method of manufacture

InactiveUS7753103B1Shorten speedShort flow distanceFoundry mouldsFoundry coresLow frictionMolten metal

A method of casting a rotary friction plate includes preparing a casting mold with a cavity and a core shaped to form the friction plate. Molten metal is poured into the mold through a central sprue where a portion of the metal flows radially outward across the top of the core to fill friction plate forming regions of the cavity from above, while another portion flows through a central opening in the core to fill a hub forming region at the bottom of the cavity as well as additionally supply metal to the lower friction plate forming region from below. The metal is allowed to cool, which begins at the radially outer regions of the at least one friction surface and progresses radially inward to develop a uniform cast structure.

Owner:ROCHESTER WILLIAM R

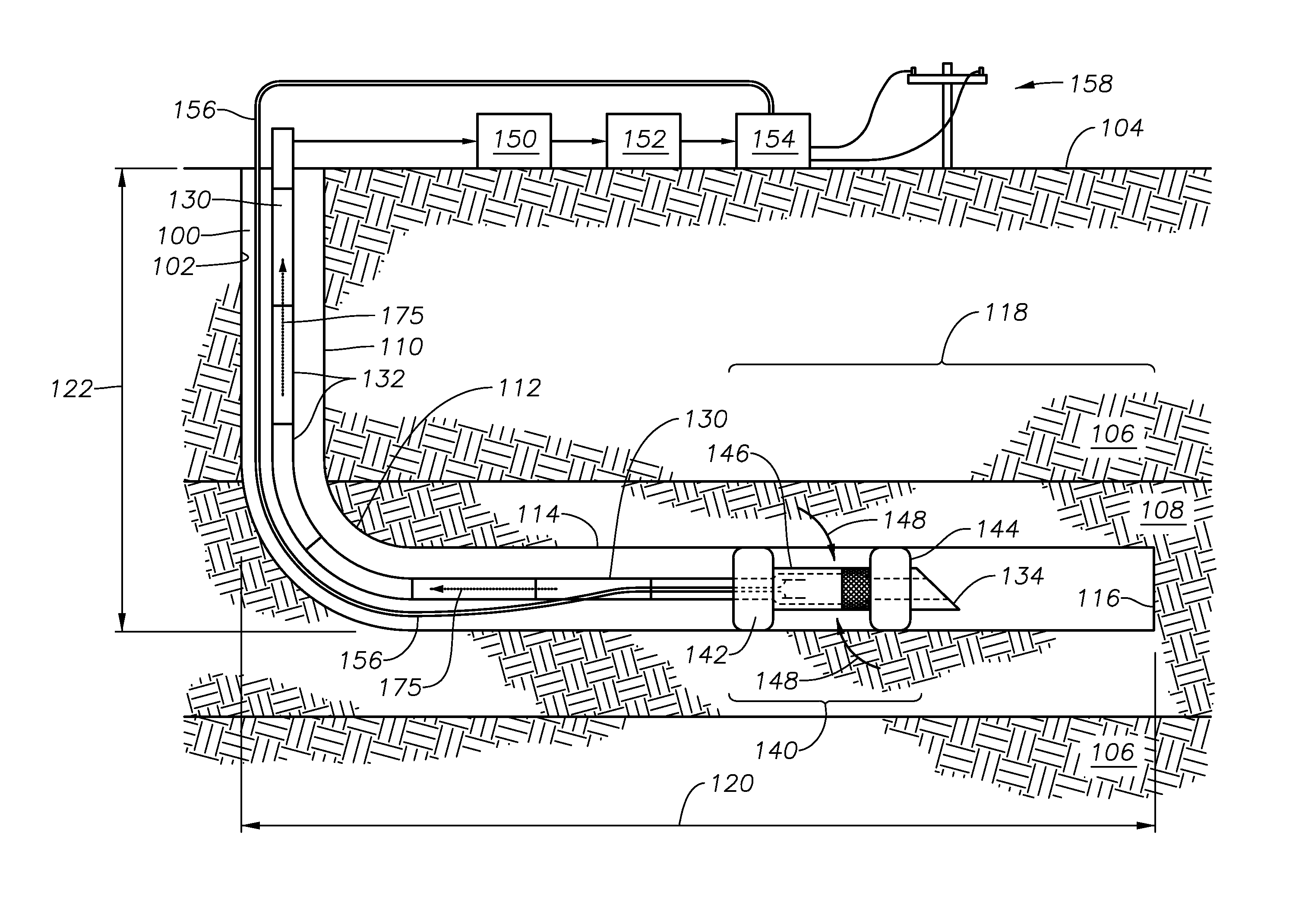

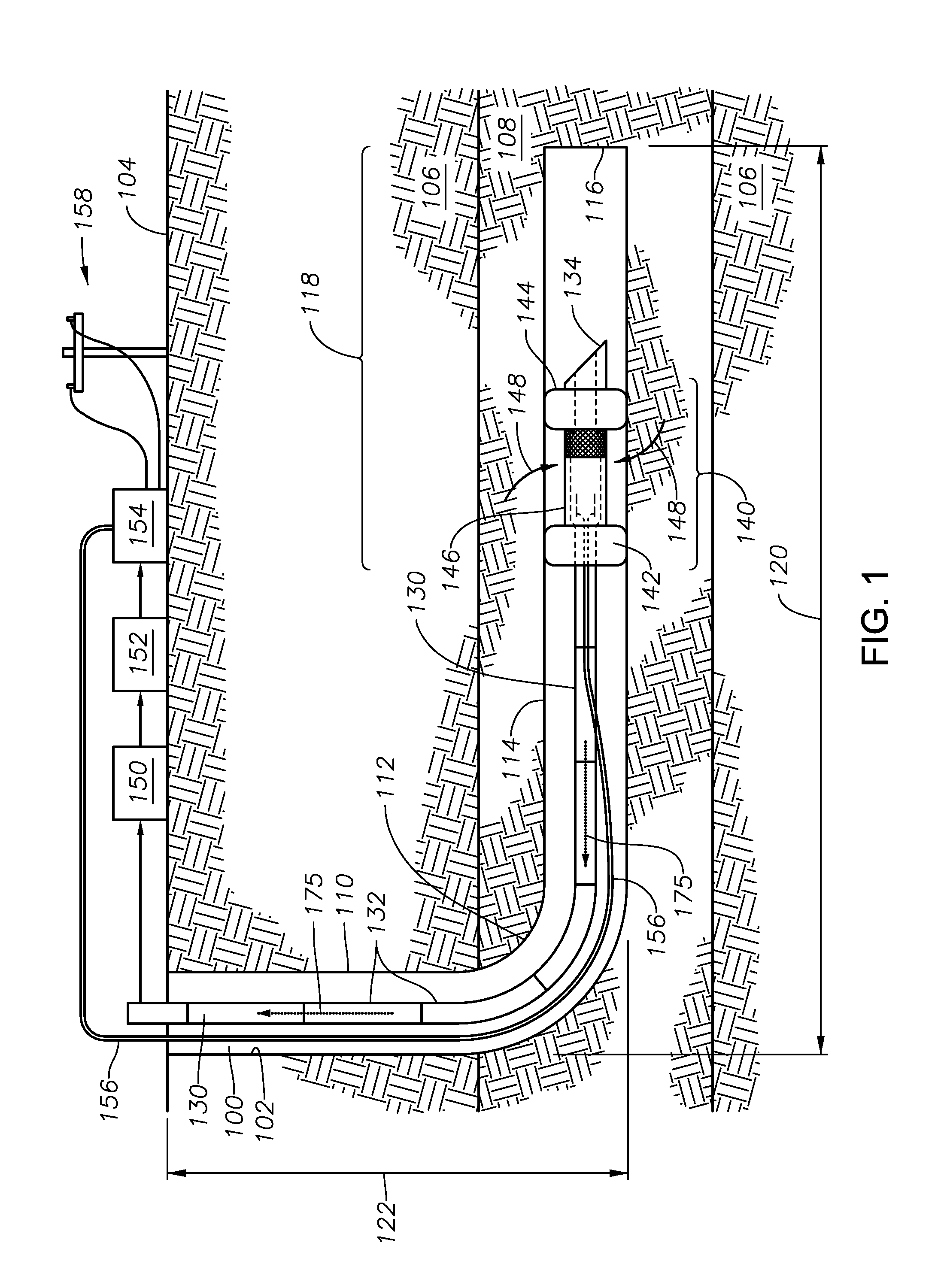

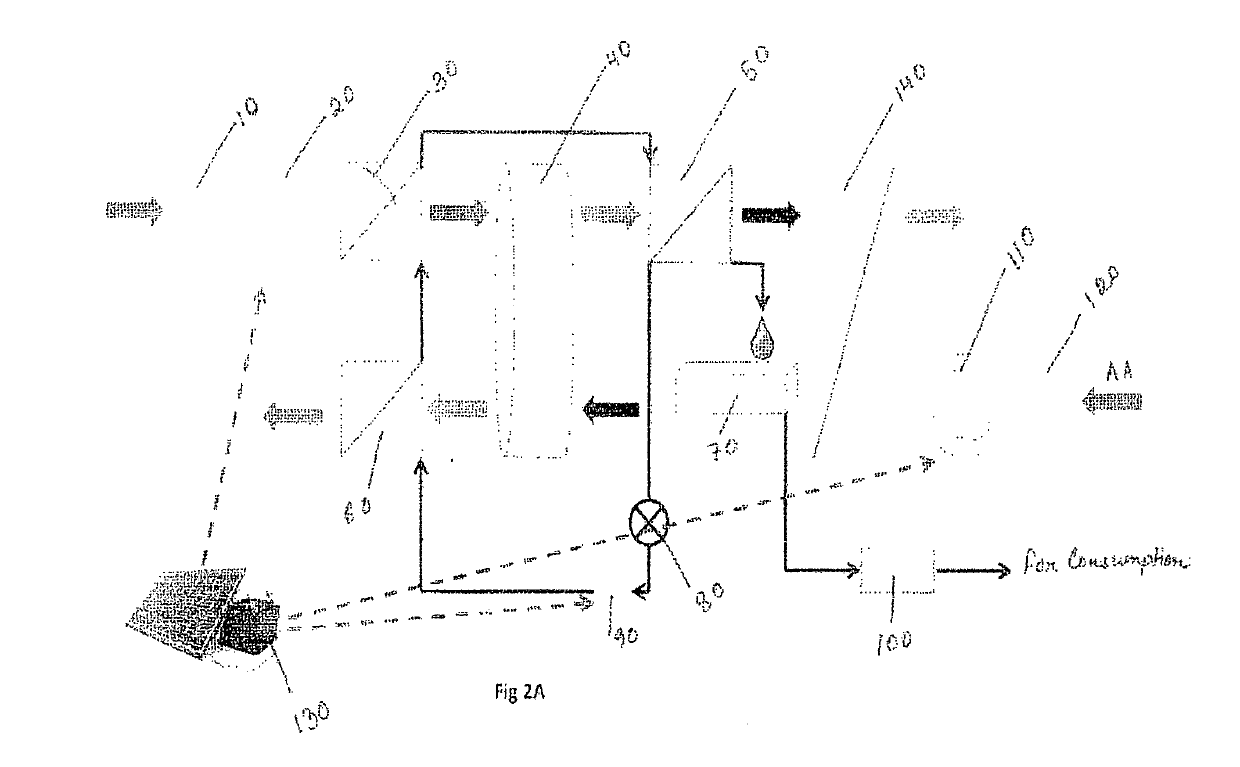

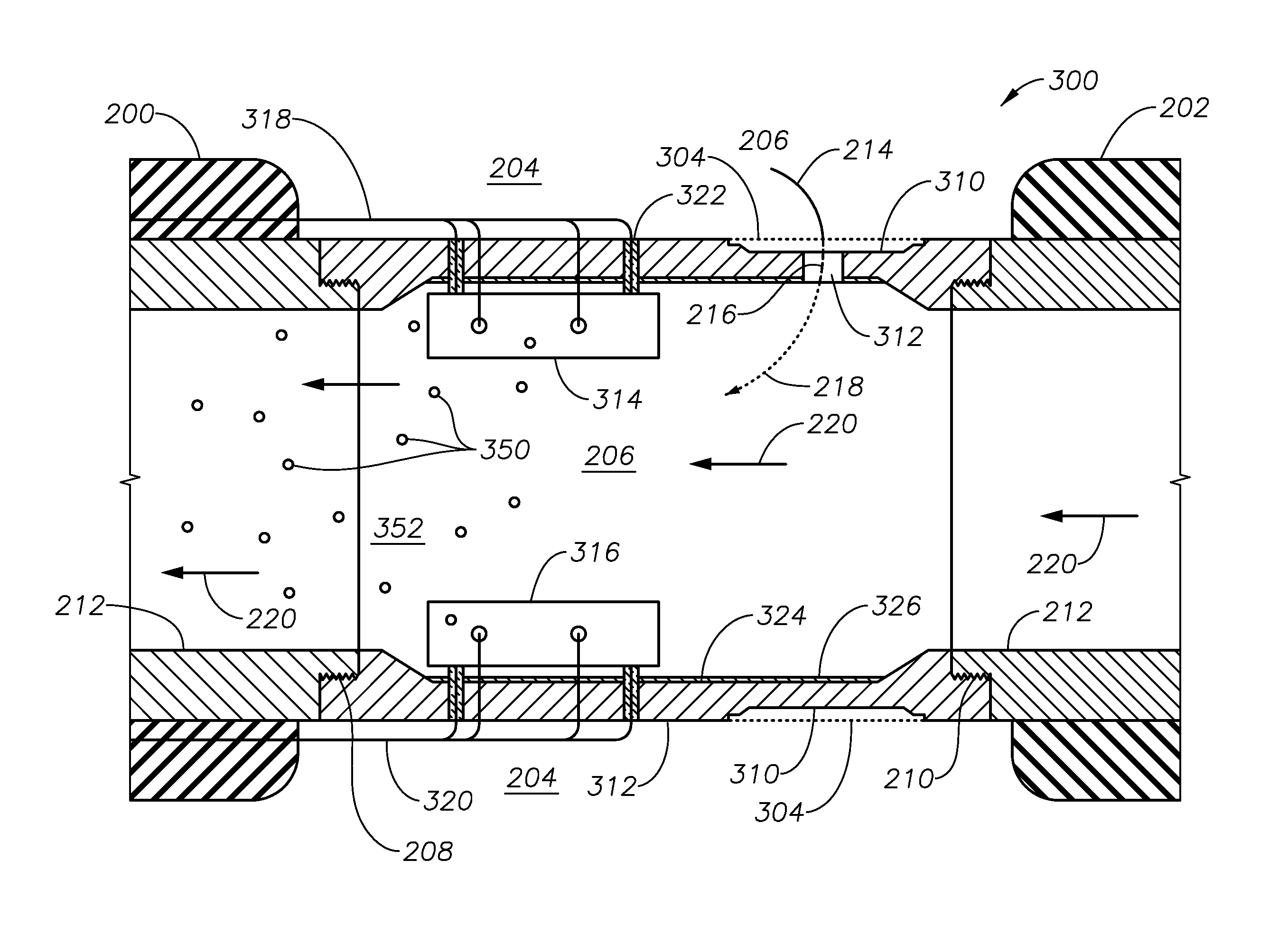

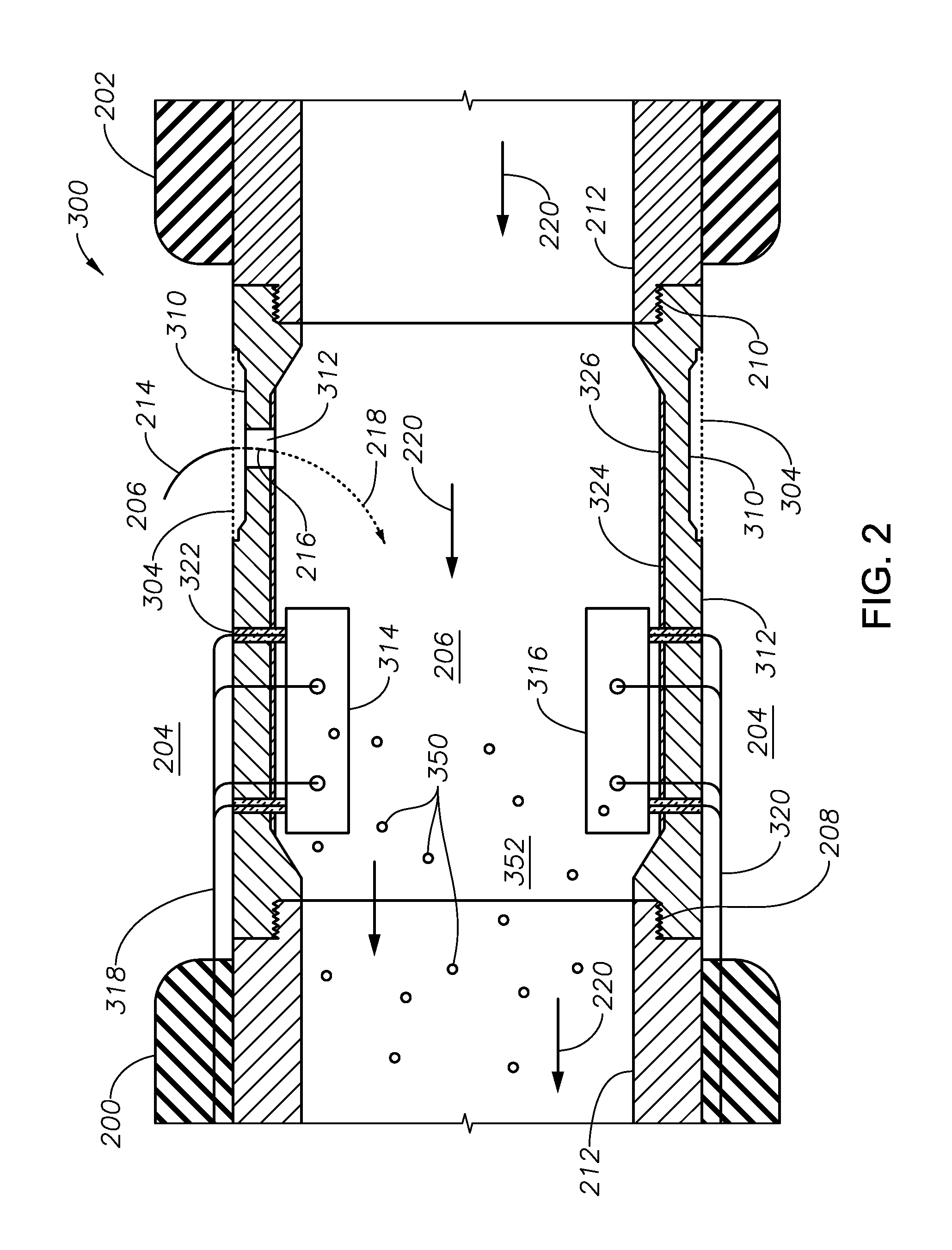

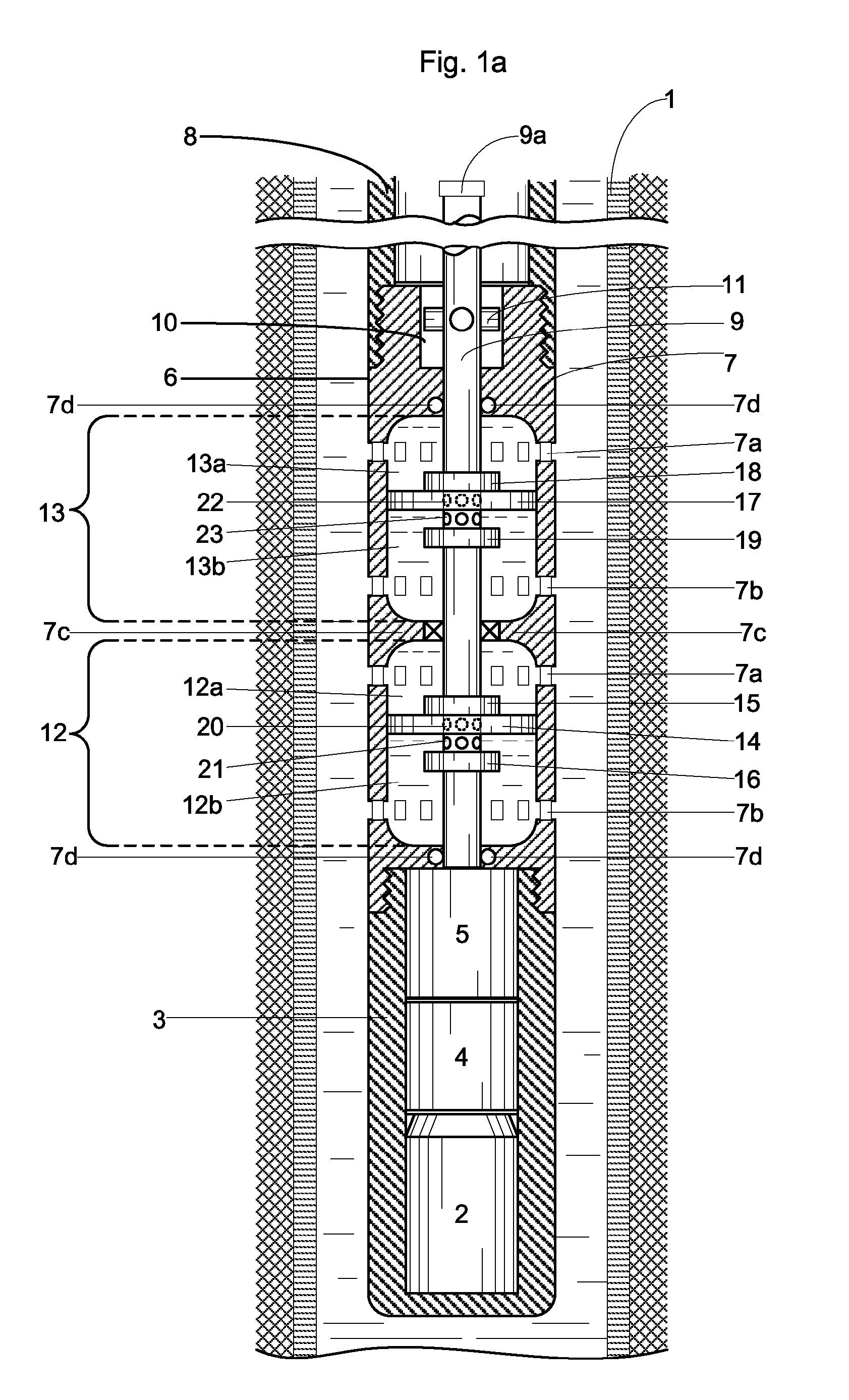

Oil Well Gas Lift by Hydrogen Production Through Produced Water Electrolysis Completion

ActiveUS20150027722A1Reduce head pressureReduce hydrostatic pressureFluid removalProduct gasProcess engineering

A method of using an electrochemical gas lift apparatus to induce artificial gas lift in a production fluid includes introducing the electrochemical gas lift apparatus into a well bore having a production zone, operating the electrochemical gas lift apparatus such that a combination of hydrocarbon fluid and formation water is introduced into the interior of the electrochemical gas lift apparatus, introducing electrical power to the electrochemical gas lift apparatus such that at least a portion of formation water in the interior of the electrochemical gas lift apparatus converts into product gases, operating the electrochemical gas lift apparatus such that the product gases form product gas bubbles in the interior of the electrochemical gas lift apparatus, and operating the electrochemical gas lift apparatus such that production fluid forms in the interior of the electrochemical gas lift apparatus. The production fluid comprises hydrocarbon fluid, unconverted formation water and product gas bubbles.

Owner:SAUDI ARABIAN OIL CO

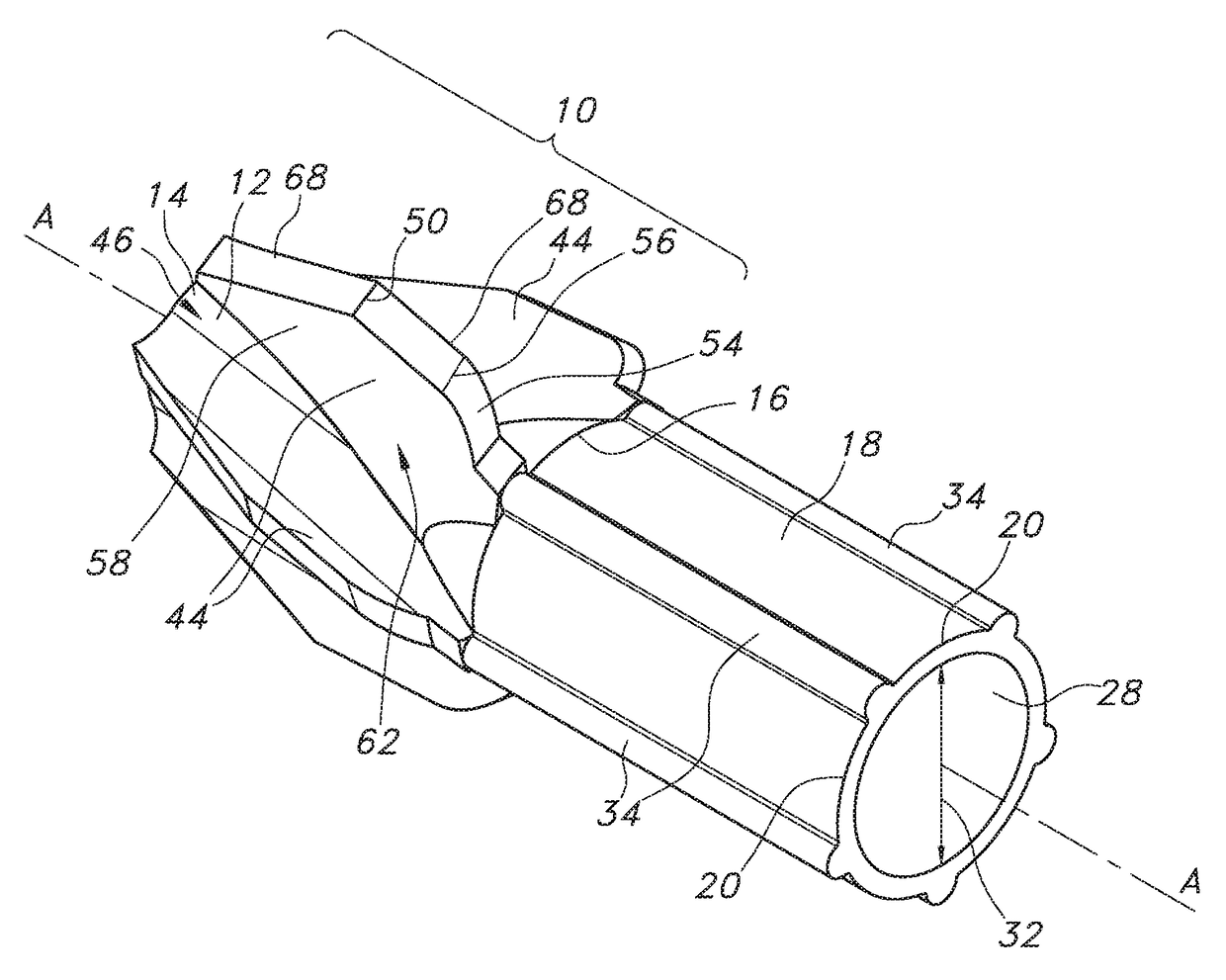

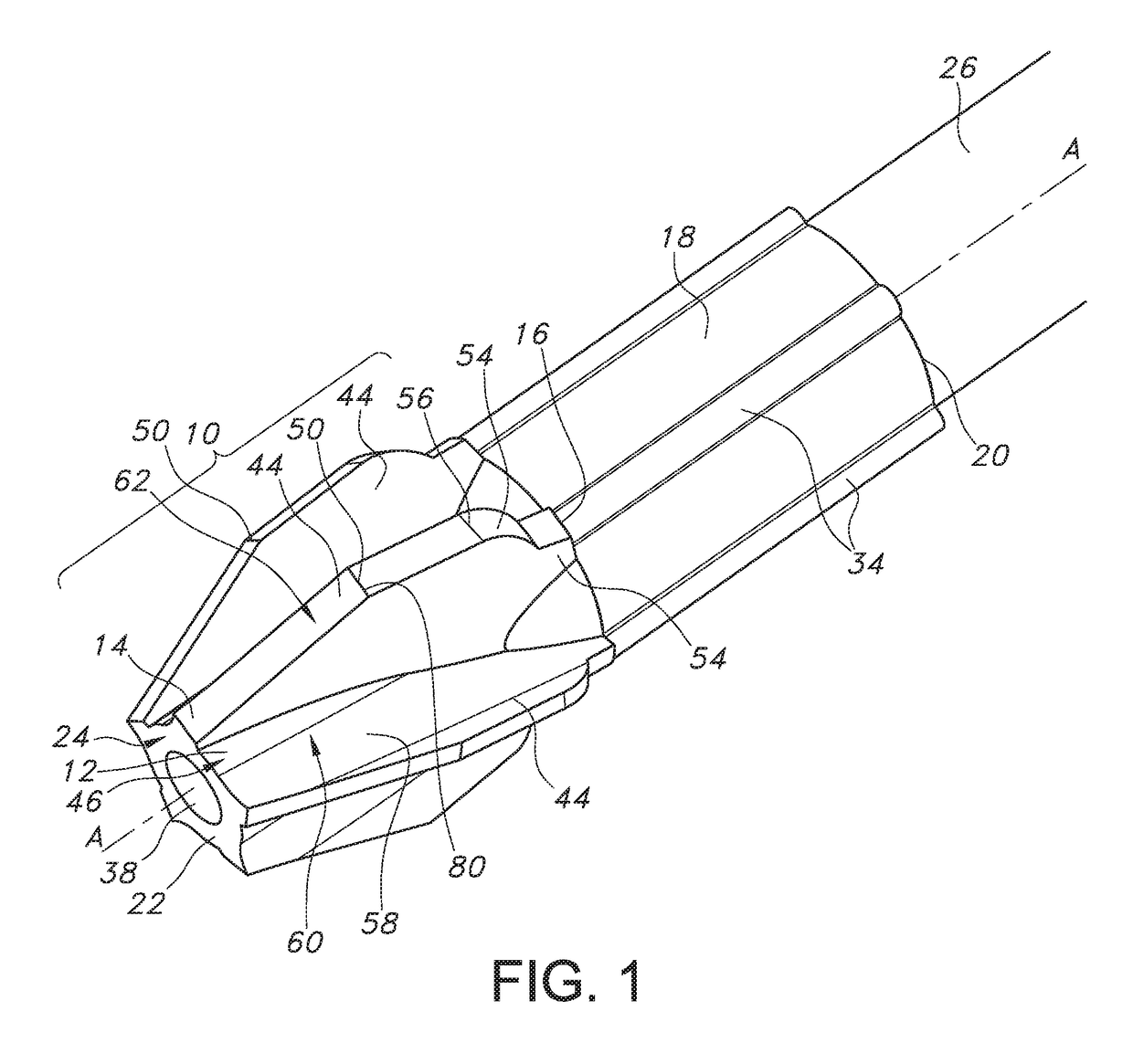

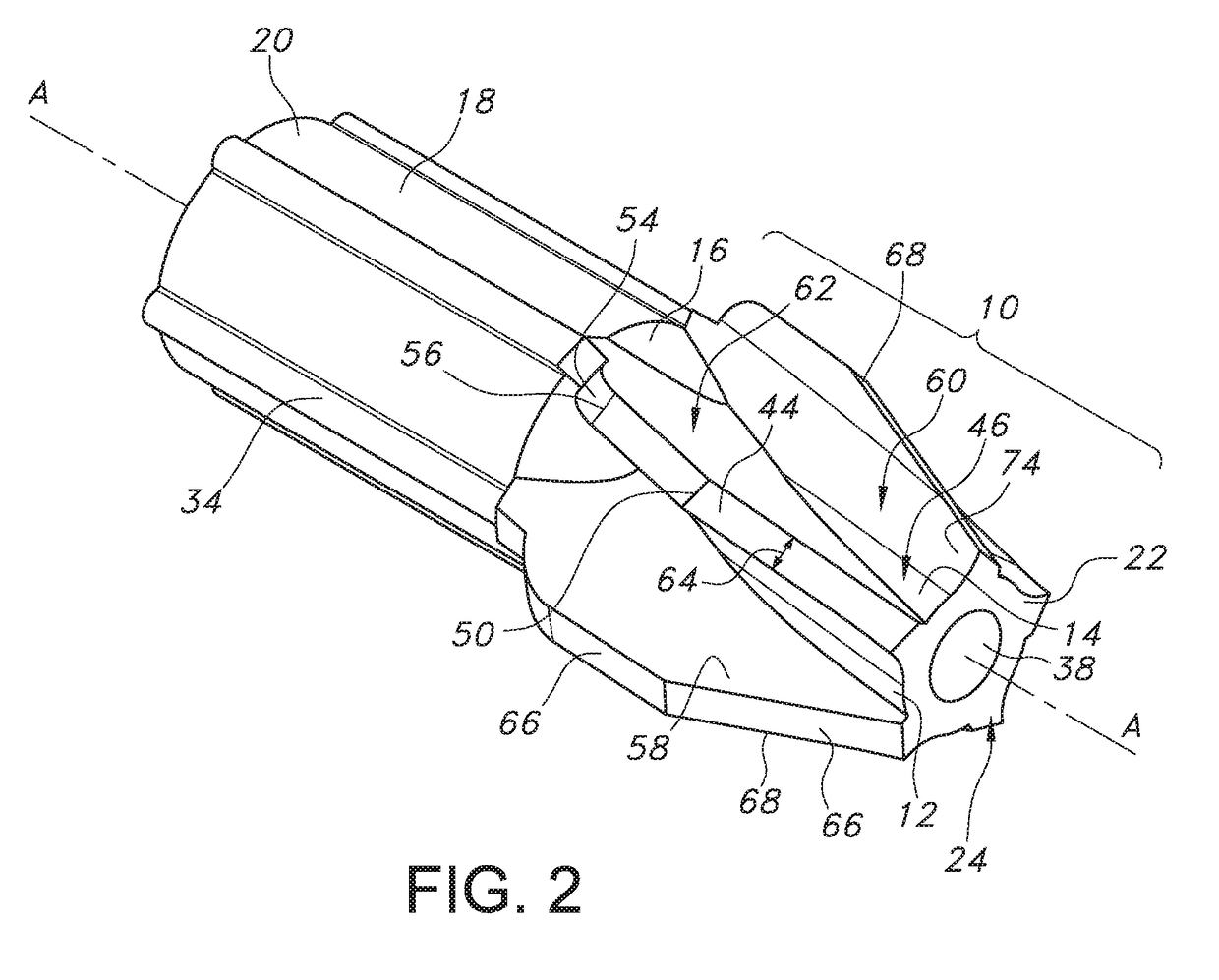

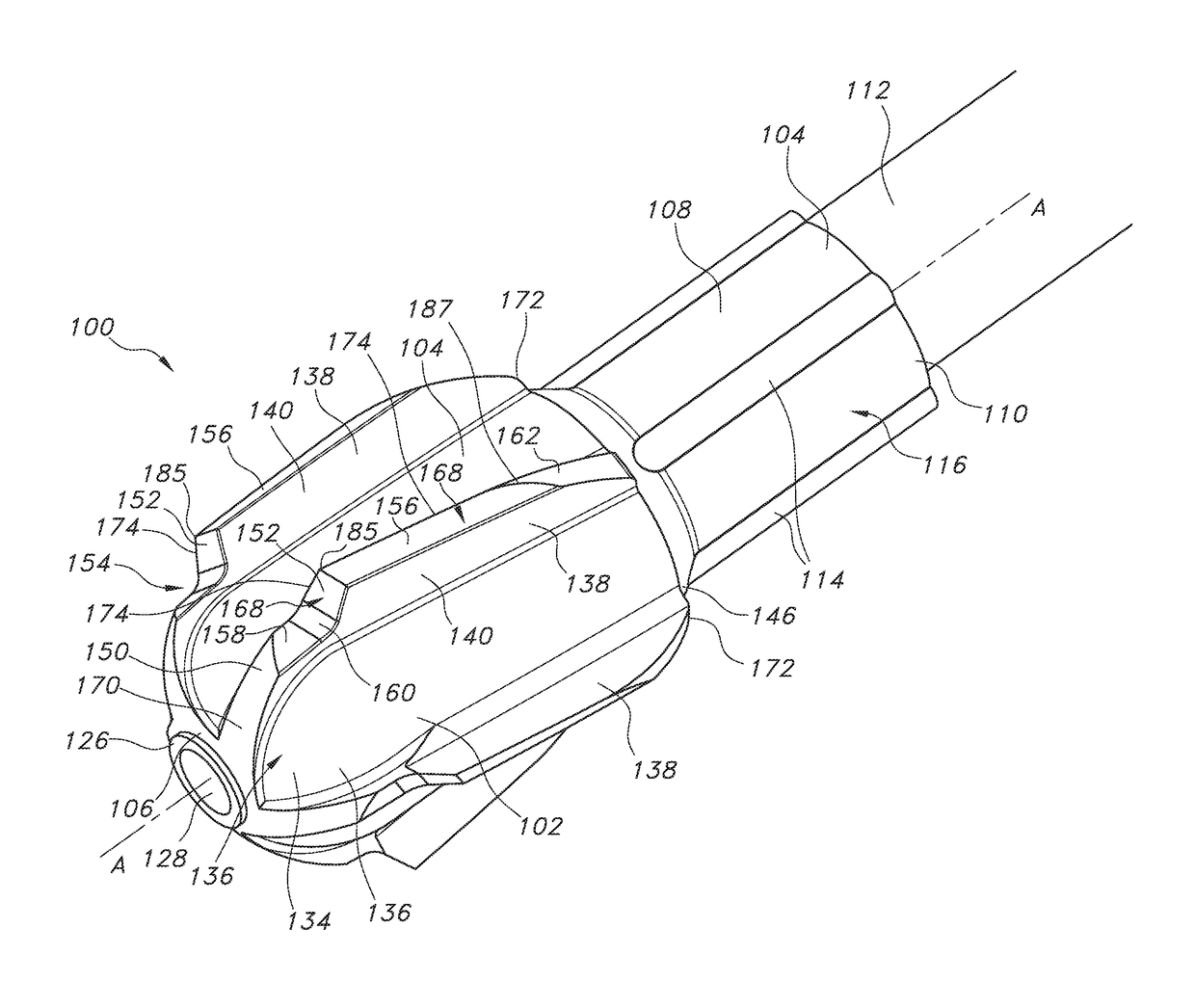

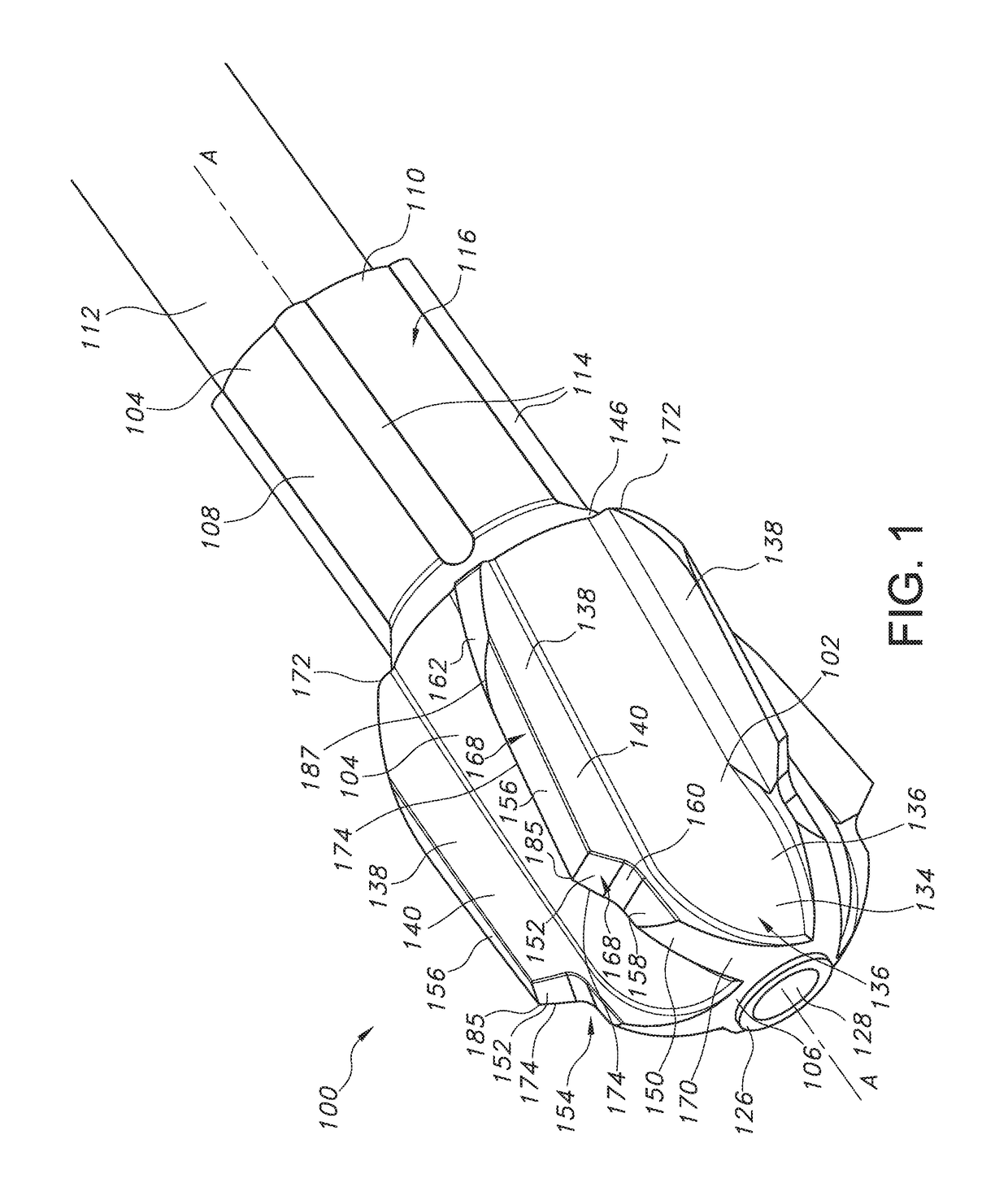

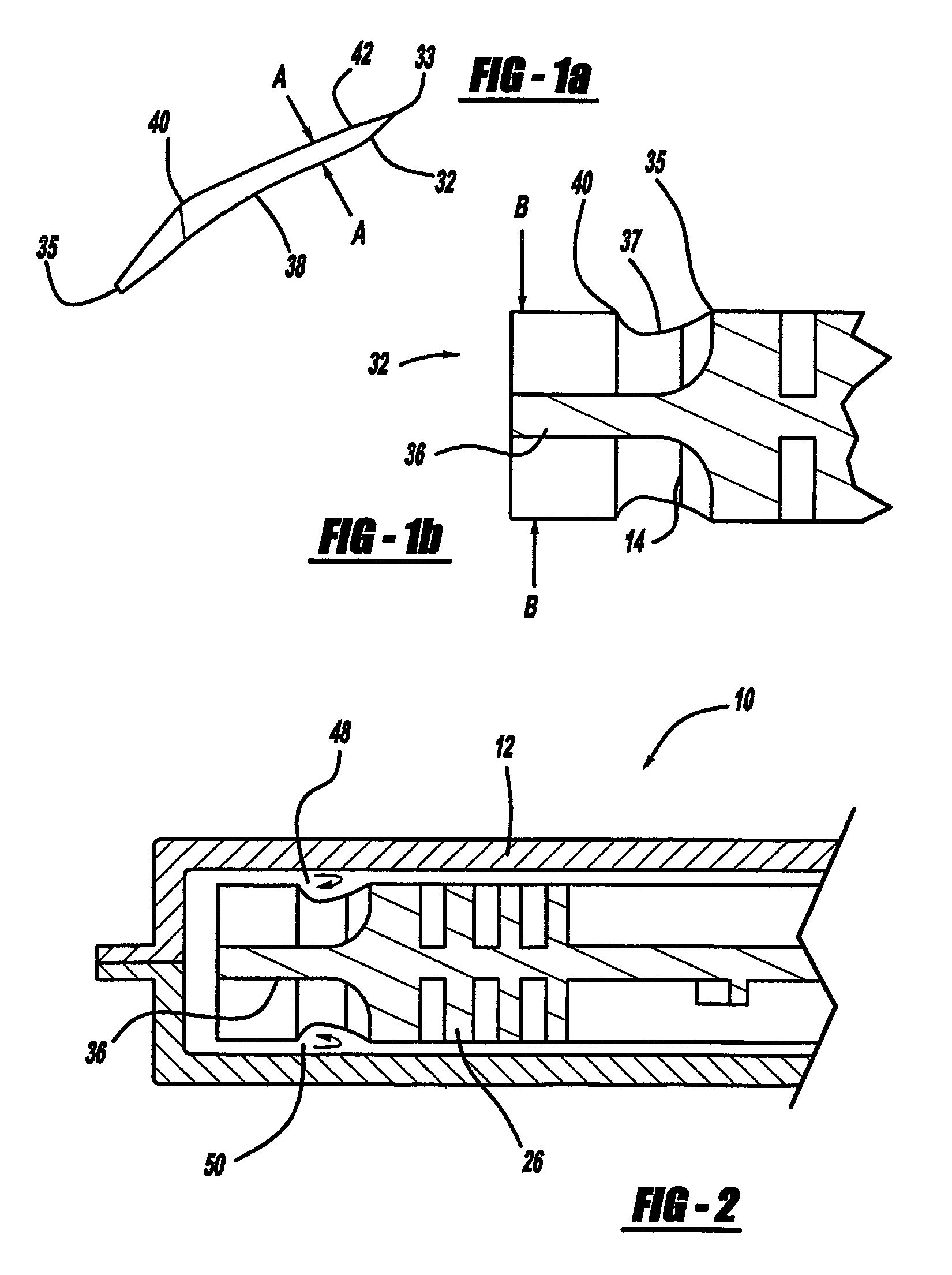

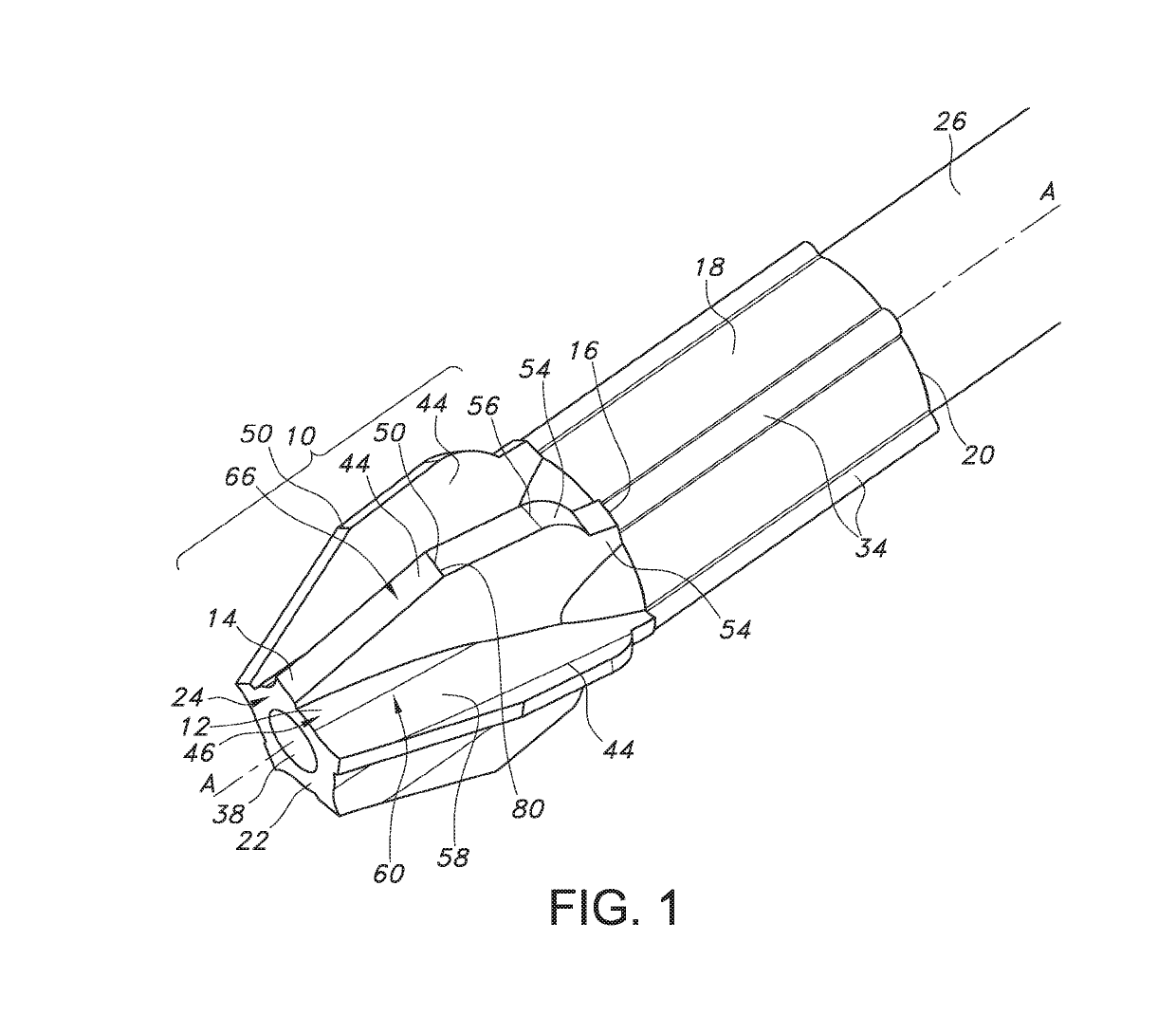

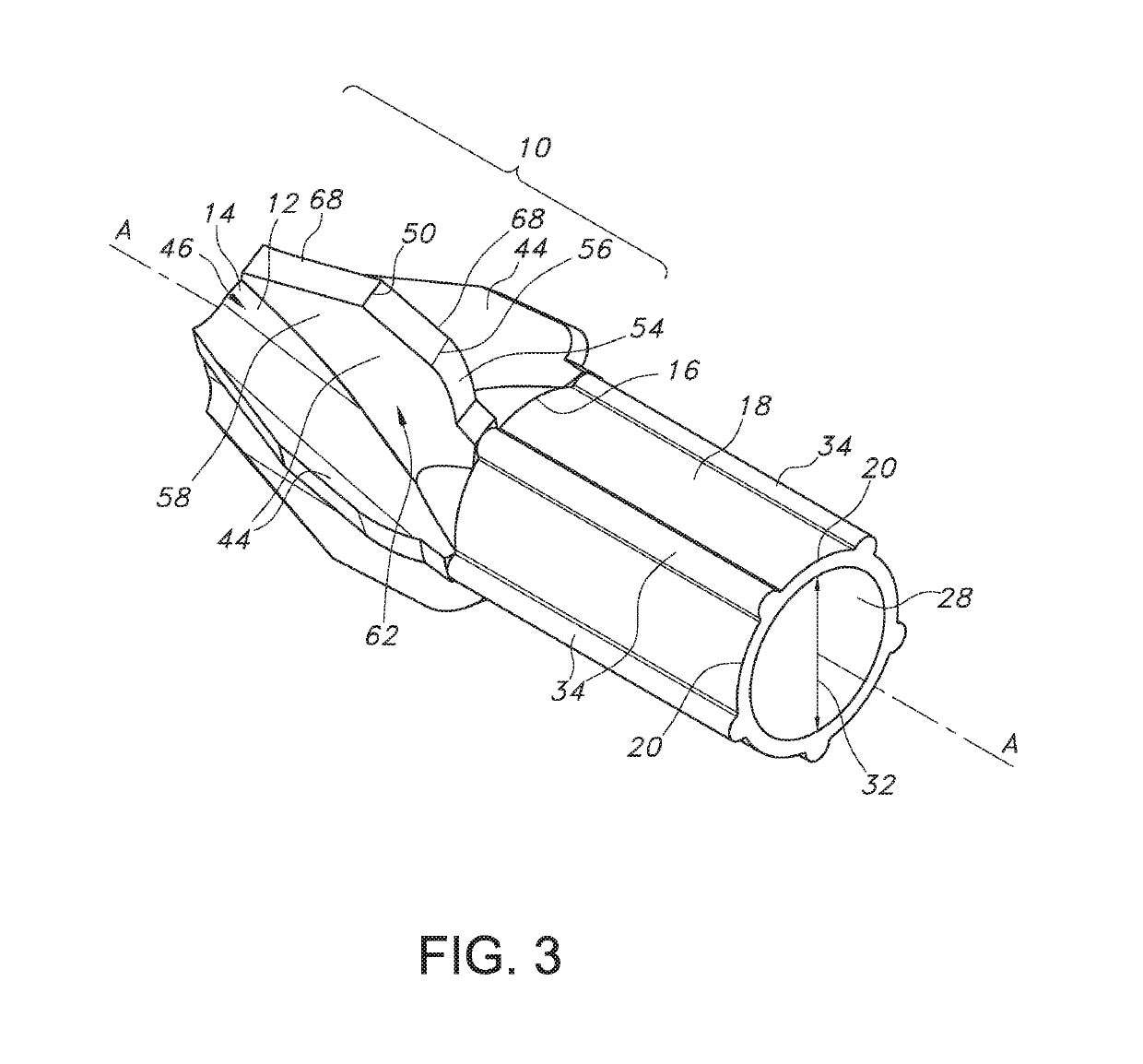

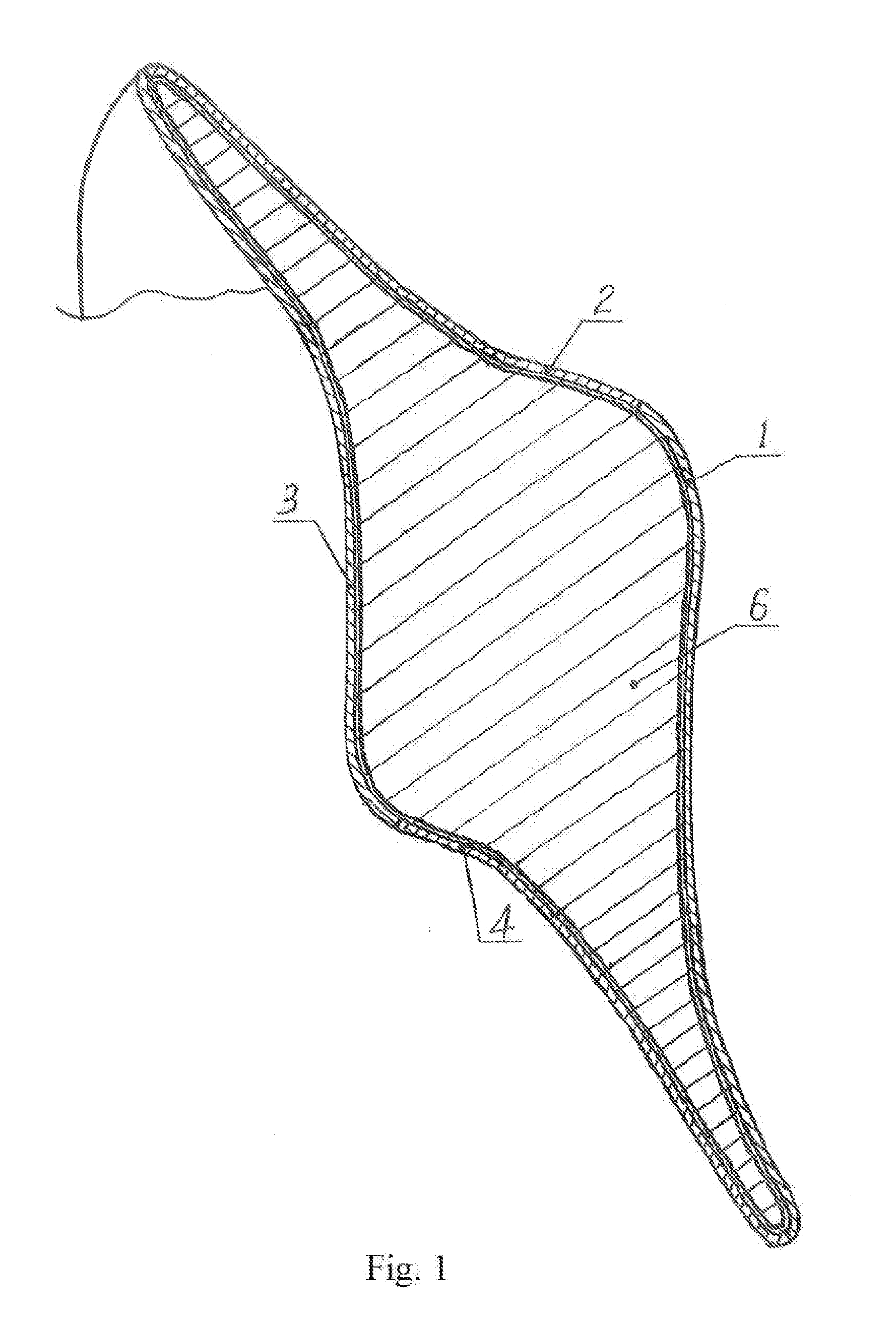

Cutting heads for intramedullary reamers

ActiveUS20170231643A1Minimizes disengagementReduce manufacturing timeSurgeryBiomedical engineeringSurgical procedures

A bone cutter for use within the intramedullary canal is described. The bone cutter comprises a frusto-conical cutting head that extends to a barrel portion for attachment to a drive shaft. The cutting head comprises a plurality of spaced apart blades having a tissue cutting edge that extends radially from the exterior surface of the cutting head. The plurality of blades are arranged at prescribed angular relationships that are designed to increase cutting efficiency and debris removal, thereby reducing reactive torque, axial loading, and head pressure during a surgical procedure.

Owner:VIANT AS&O HLDG LLC

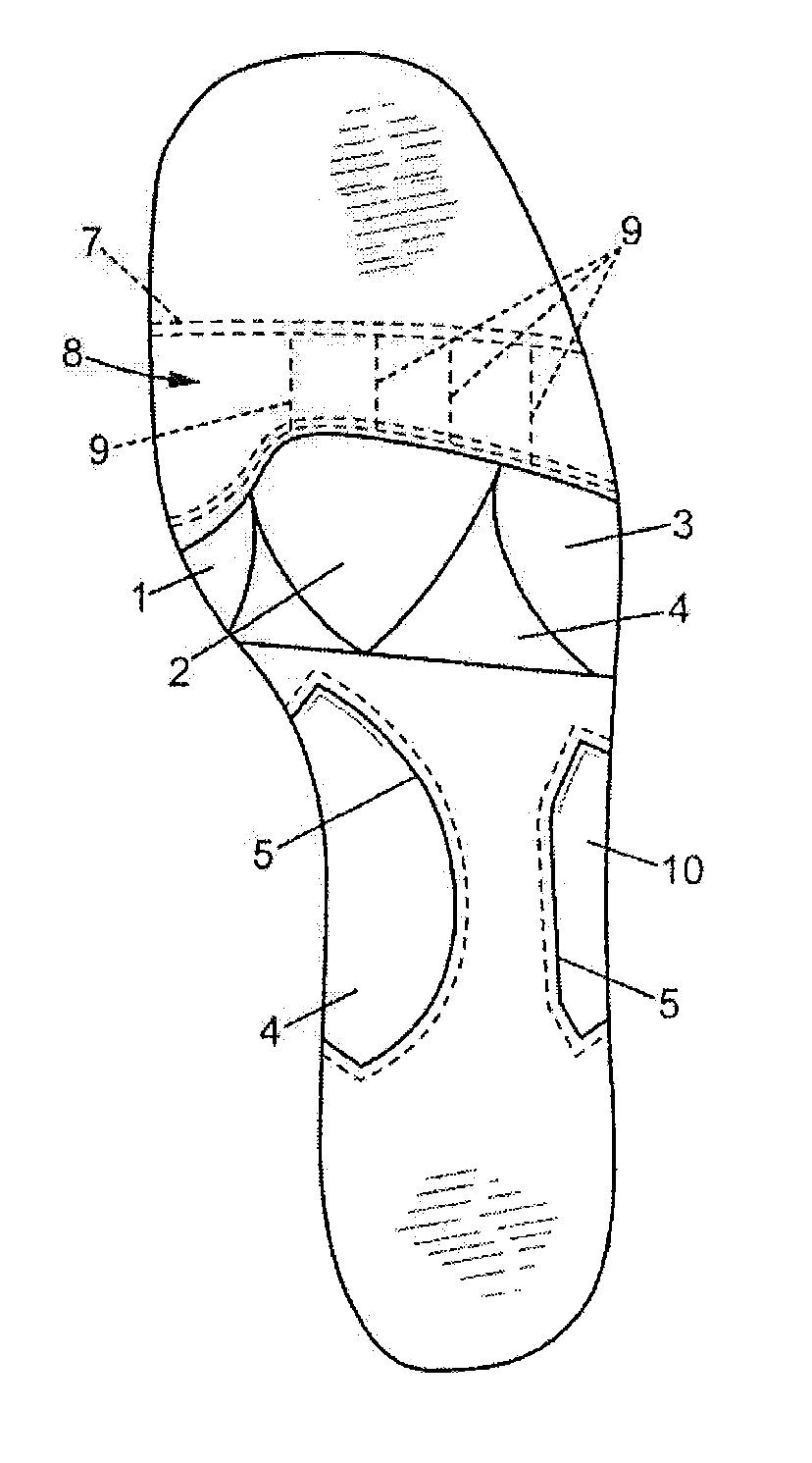

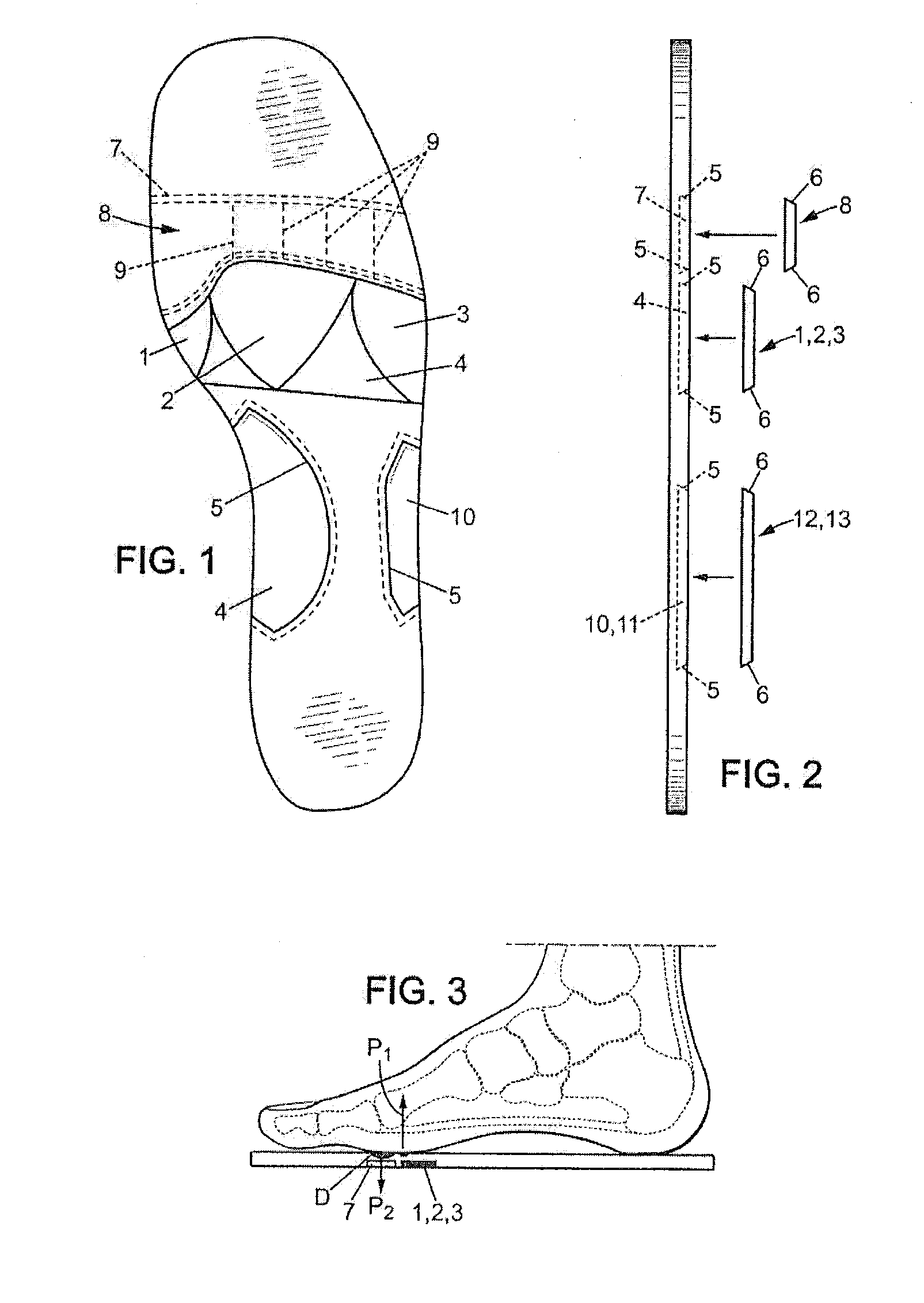

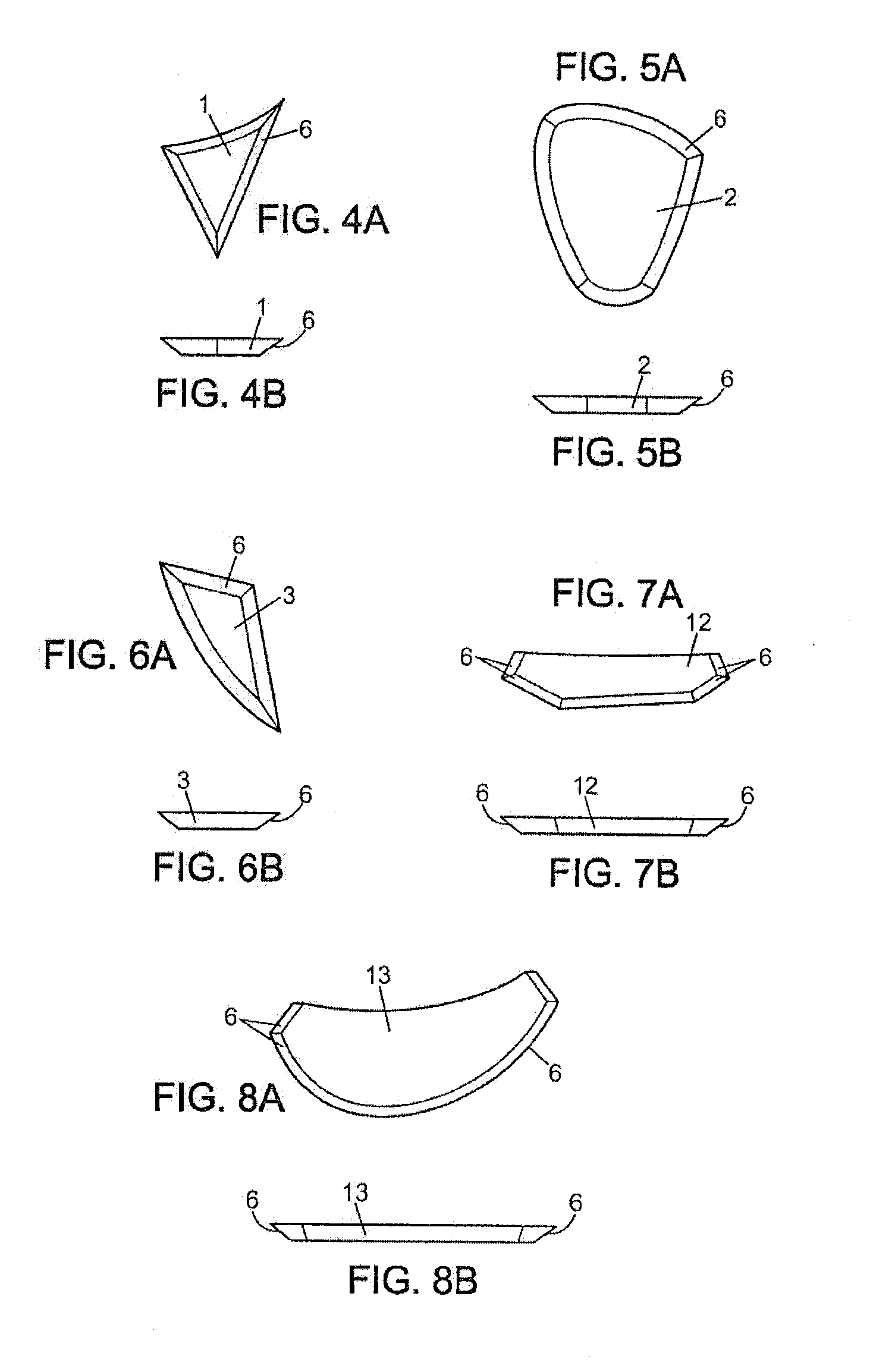

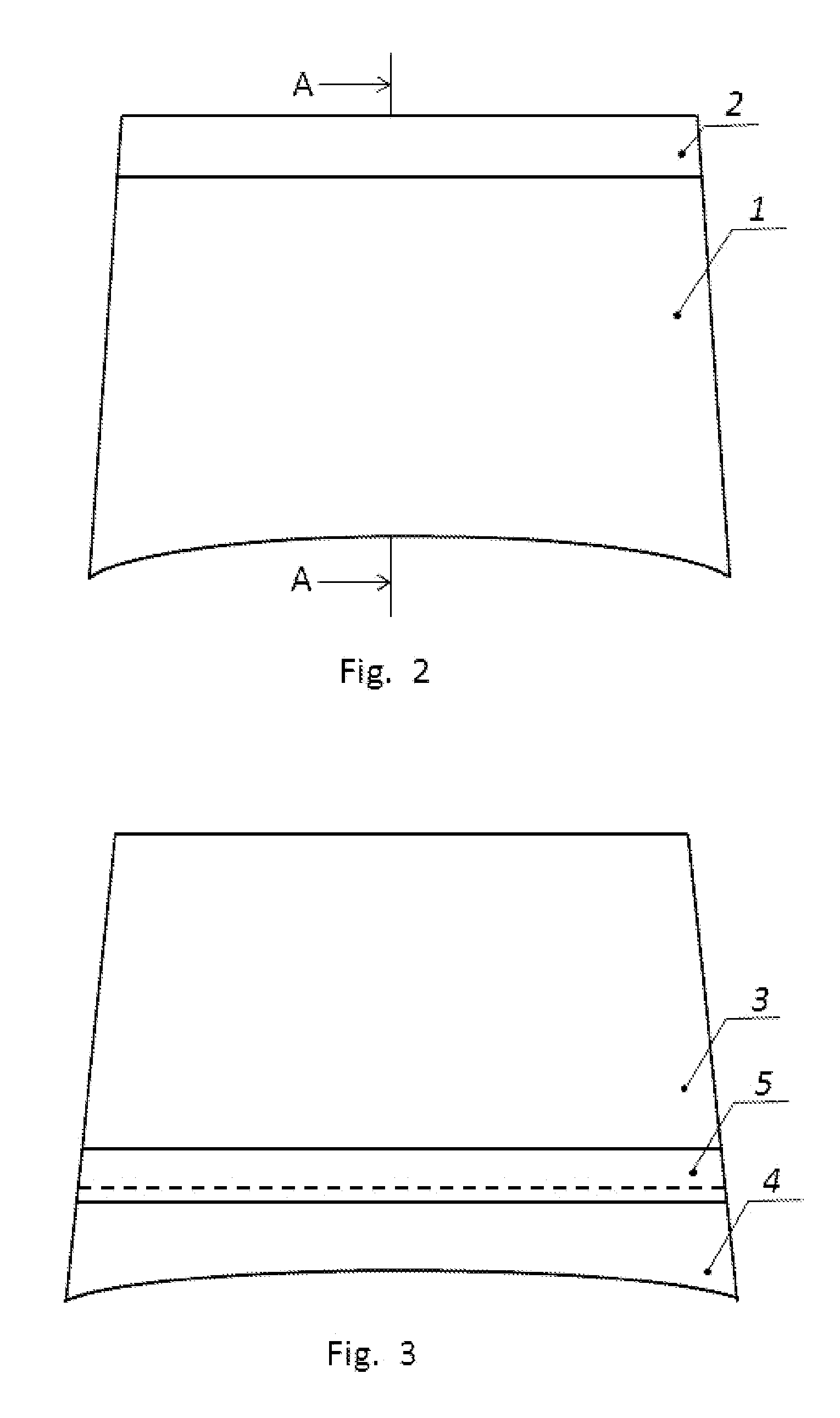

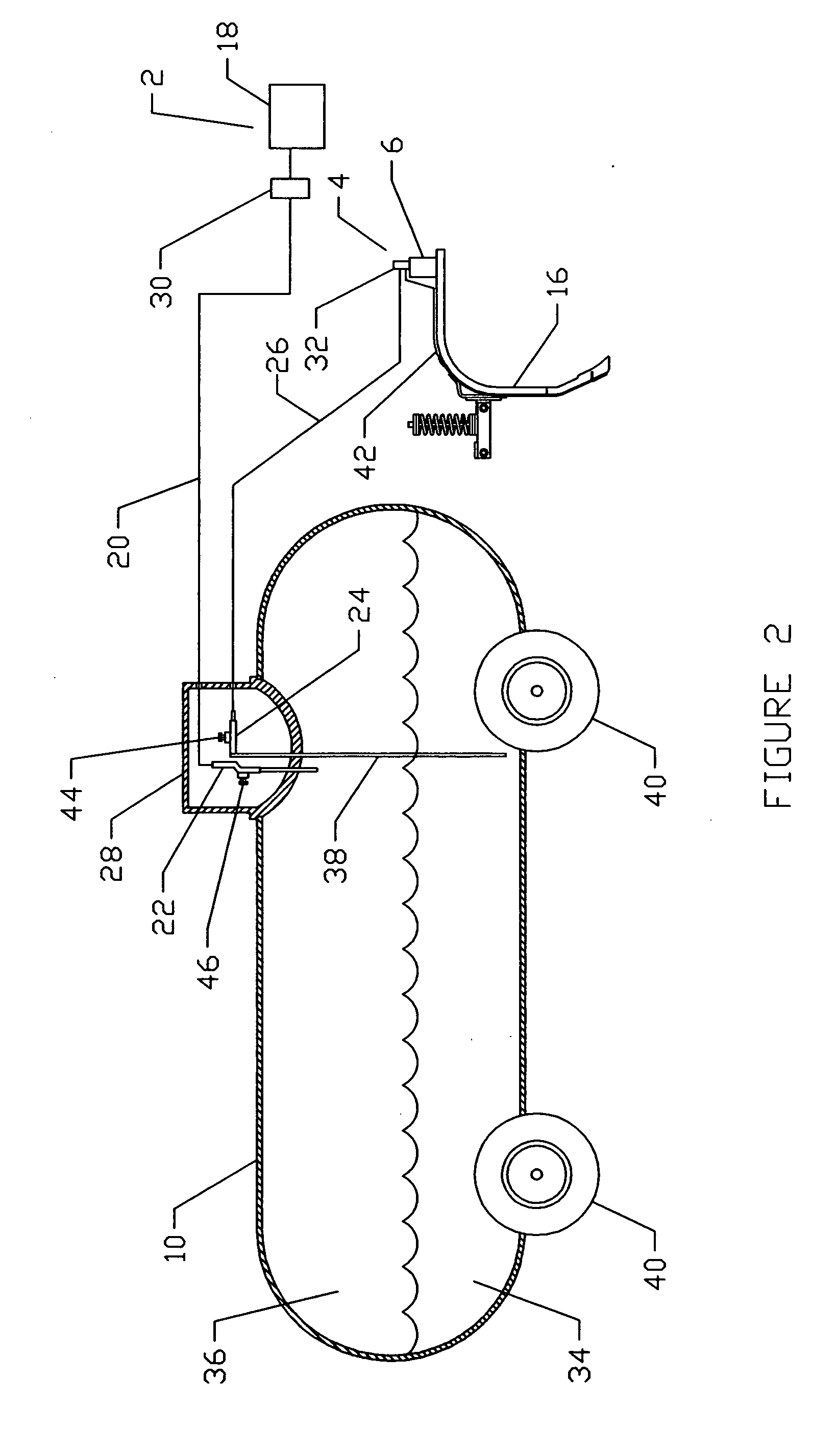

Orthopedic sole including corrective means for treating metatarsalgia and plantar skin disorders

An orthopedic insole capable of being inserted into a shoe or the like for relieving and / or treating skin disorders and / or calluses and / or metatarsal pain comprises at least one semi-rigid corrective element capable of producing an inner metatarsal support, over the rear portion of the head of the first metatarsal, and / or a median metatarsal support, over the rear portion of the second and / or third and / or fourth metatarsal head, and / or an external metatarsal support, over the rear portion of the fifth metatarsal head.

Owner:CHENUT PASCAL

Cutting head for an intramedullary reamer

ActiveUS20180042618A1Minimizes potential disengagementShorten production timeSurgerySurgical proceduresIntramedullary reamer

A cutting head for use with an intramedullary reamer is described. The reamer cutting head is of a unitary body construction that comprises a conically-shaped body having a bone cutting portion spaced from a barrel portion for attachment to a drive shaft. The bone cutting portion comprises a plurality of blades having a tissue cutting edge that outwardly extends from the cylindrical body. The plurality of blades is positioned about the cutting head in a spaced apart manner. The various plurality of blades are arranged at prescribed angular relationship that increases cutting efficiency and debris removal, thereby reducing reactive torque, axial loading, and head pressure during a surgical procedure.

Owner:VIANT AS&O HLDG LLC

Remotely Activated Reward Dispenser

ActiveUS20140033990A1Prevent accidental releaseReduce noiseAnimal housingTaming and training devicesEngineeringRemote dispensing

A remotely activated reward dispenser. The remote dispenser delivers consumable rewards in response to a trigger signal from a remote triggering device. The reward dispenser uses a two stage delivery system to prevent unintentional release of the consumable reward. A vibration stage moves a portion of the consumable reward from a reservoir to a staging platform without crushing the consumable reward. The second stage transfers the consumable reward from the staging platform to an area accessible by the animal. A vibration damping system reduces the noise generated by the reward dispenser. An adjustable transition varies the feed rate for the consumable reward.

Owner:RADIO SYST CORP

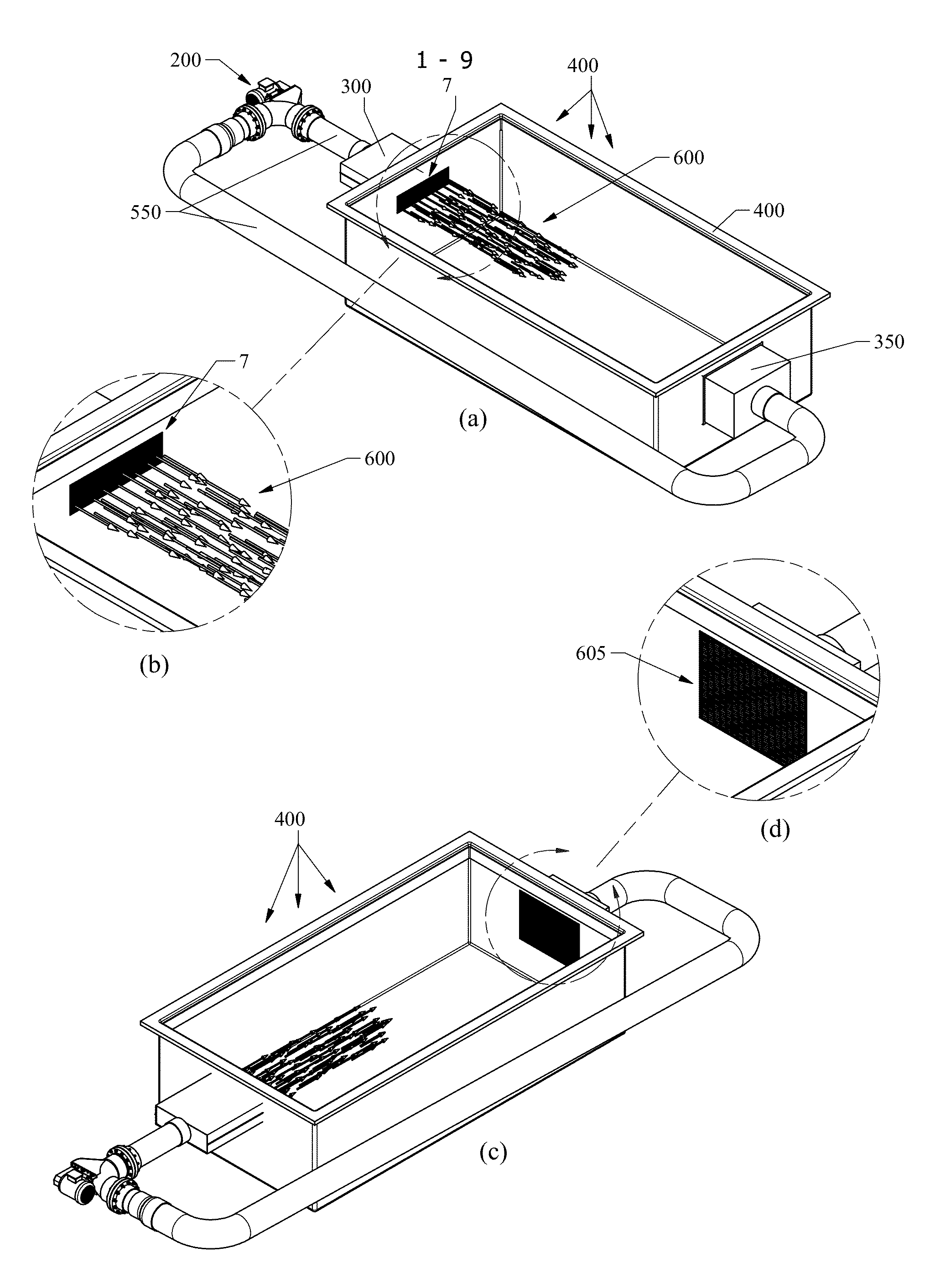

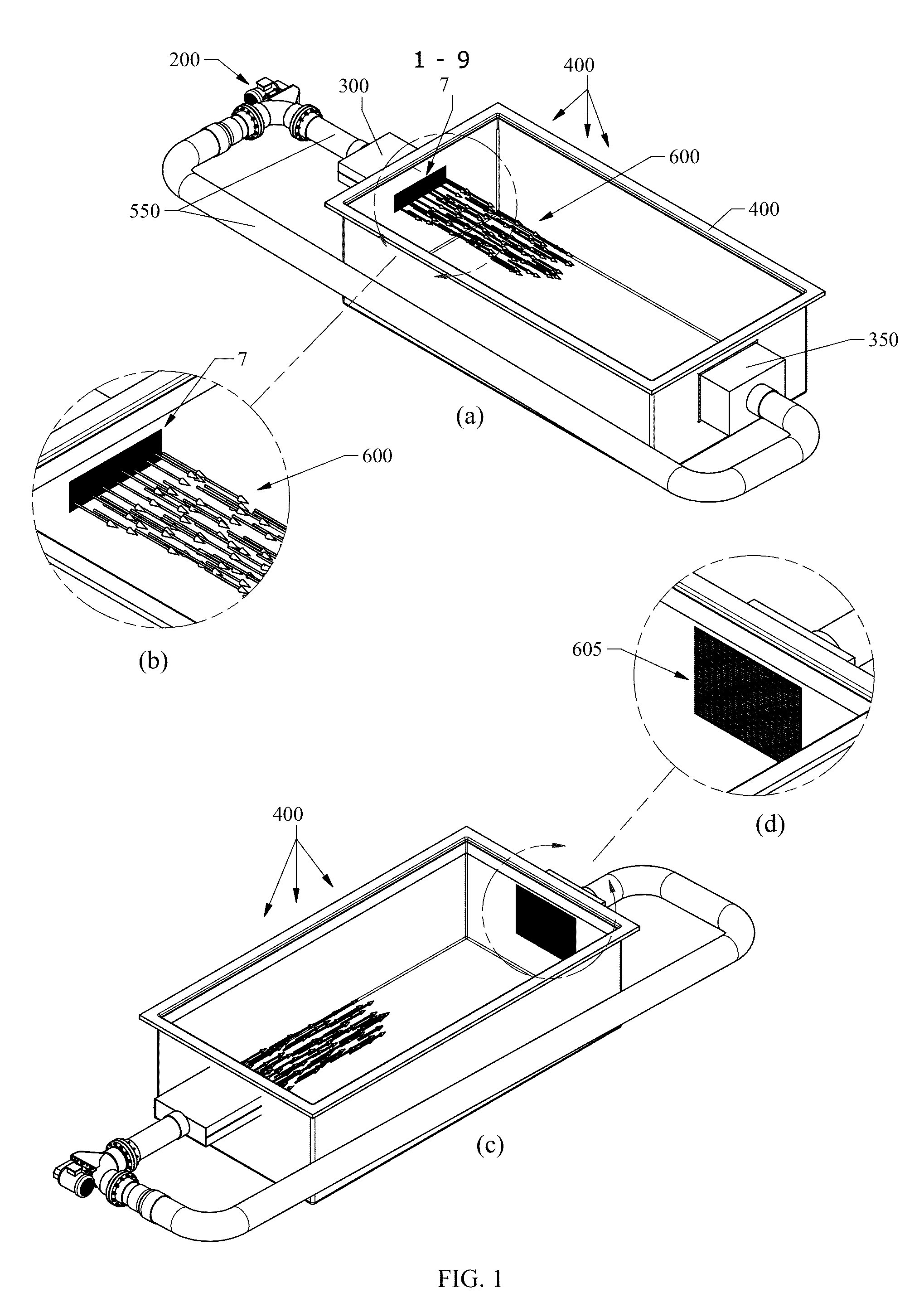

Propulsion system

ActiveUS8702387B2Energy efficiencyExcessive velocityFlow mixersPump componentsDiagnostic Radiology ModalityWater velocity

The present invention relates generally to propulsion systems, and, more particularly, to a propulsion system including an axial flow water pump assembly and a laminar flow box assembly for generating a streamline laminar slipstream of water velocity that is used in aquatic therapy, aquatic sport fitness rehabilitation, aquatic rehabilitation, swimming, and a variety of other functional therapy and training modalities.

Owner:VISION AQUATICS

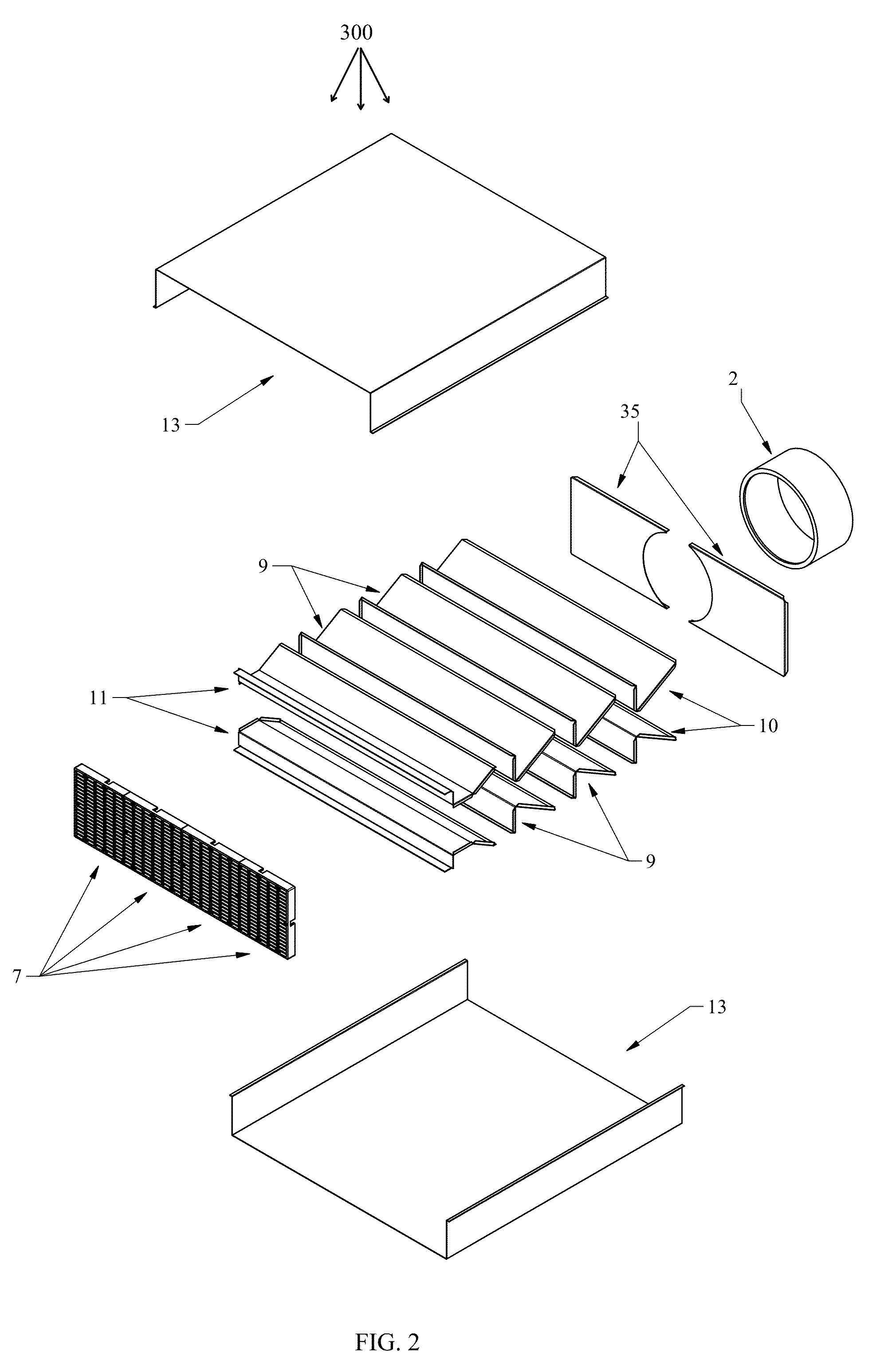

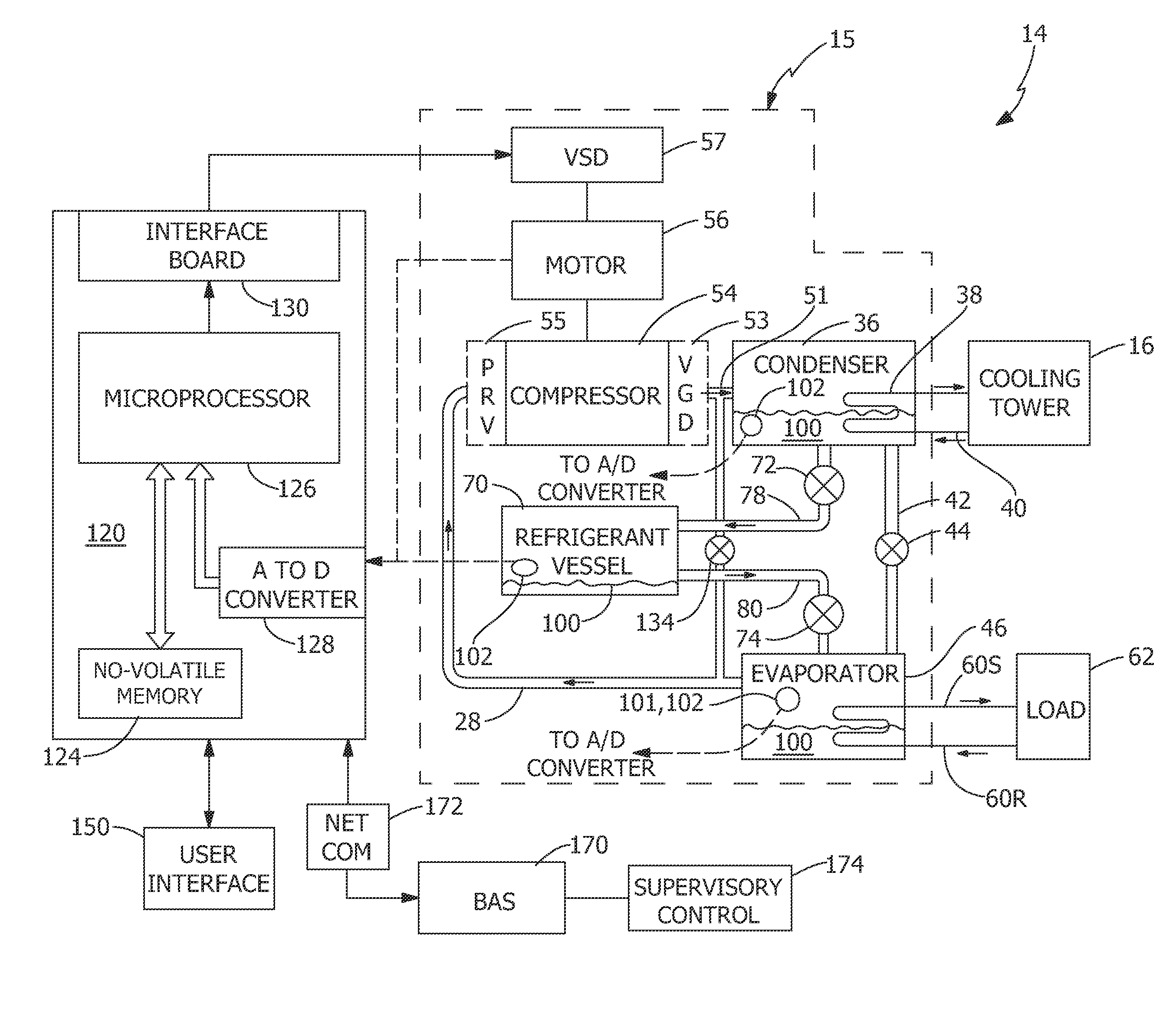

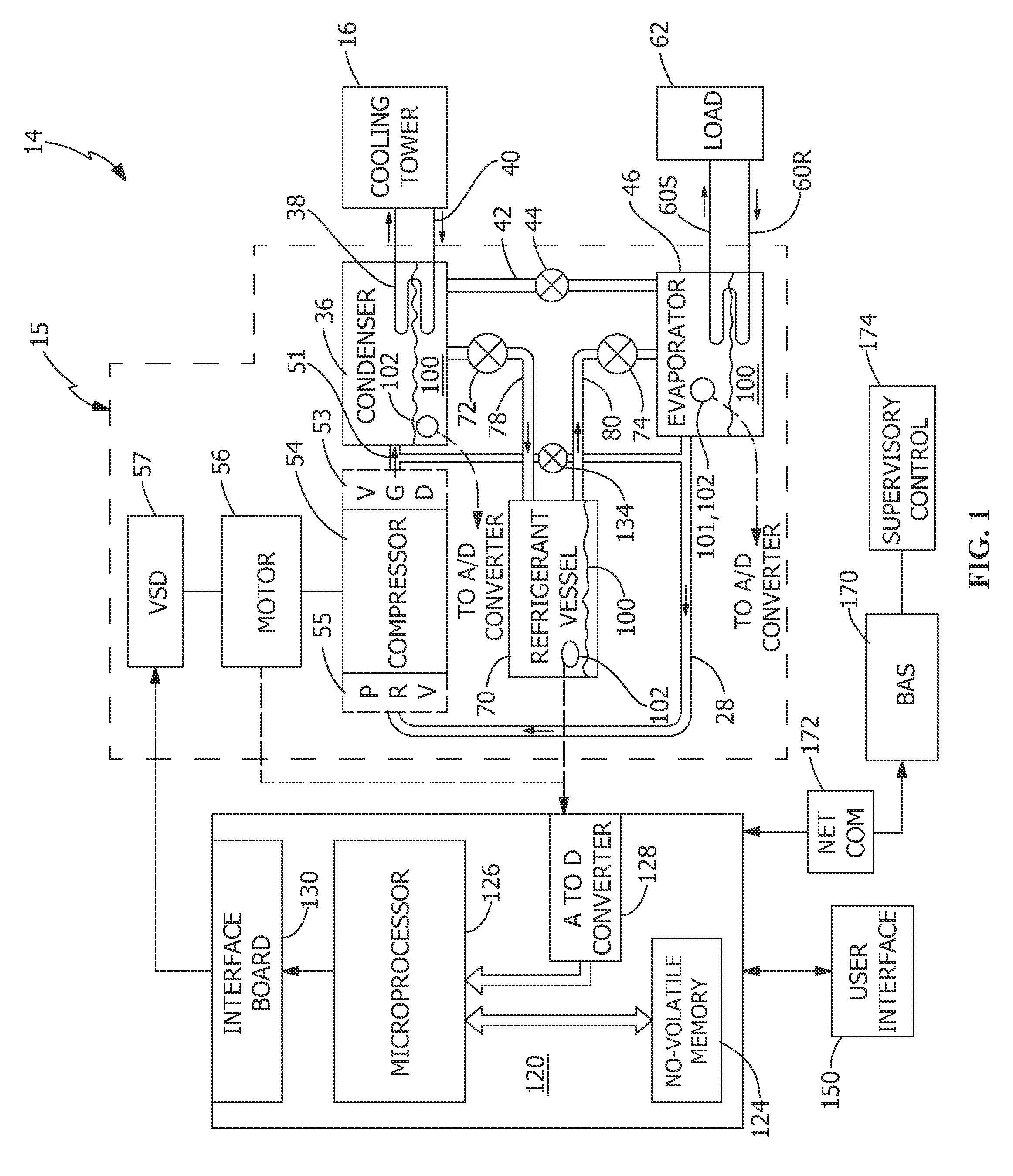

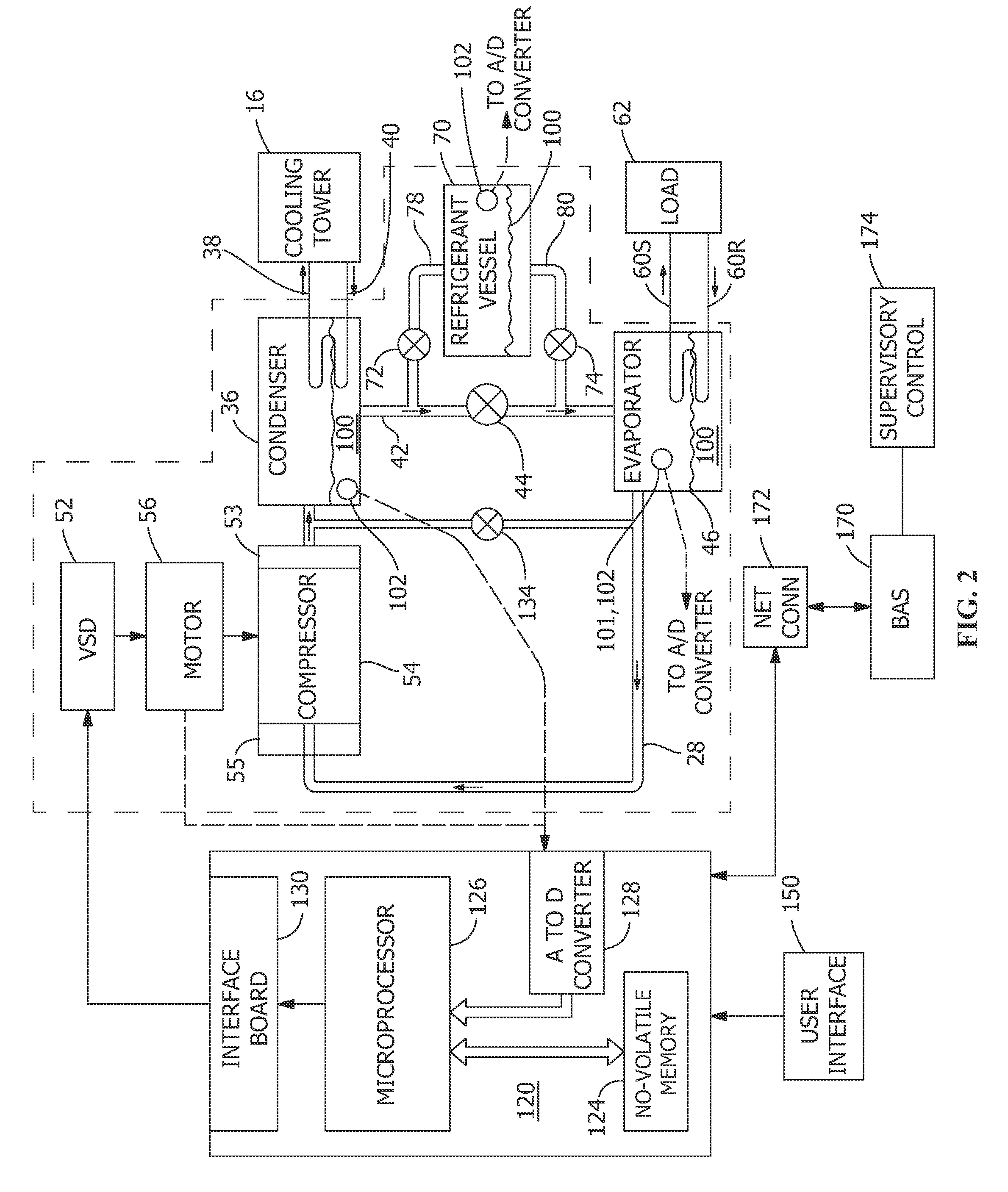

Method and apparatus for variable refrigerant chiller operation

ActiveUS9217592B2Alleviate the conditionAvoid adjustmentCompression machines with non-reversible cycleRefrigeration safety arrangementEngineeringHigh pressure

A refrigeration system includes a compressor, a condenser, an expansion device, an evaporator, and an additional refrigerant vessel connected in a closed refrigerant loop. The additional refrigerant vessel is connected to the condenser at the high pressure side by a first valve and to the evaporator at a low pressure side by a second valve. A controller controls operation of the first valve and the second valve. Only one of the first valve and the second valve may be open at the same time. Refrigerant from the additional refrigerant vessel may be added to the closed refrigerant loop when the controller receives a low refrigerant level indication of in the evaporator. Refrigerant may also be removed from the closed refrigerant loop when the controller receives a high refrigerant level indication in the evaporator.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Cutting head for an intramedullary reamer

A cutting head for use with an intramedullary reamer is described. The reamer cutting head is of a unitary body construction that comprises a conically-shaped body having a bone cutting portion spaced from a barrel portion for attachment to a drive shaft. The bone cutting portion comprises a plurality of blades having a tissue cutting edge that outwardly extends from the cylindrical body. The plurality of blades is positioned about the cutting head in a spaced apart manner. The various plurality of blades are arranged at prescribed angular relationship that increases cutting efficiency and debris removal, thereby reducing reactive torque, axial loading, and head pressure during a surgical procedure.

Owner:VIANT AS&O HLDG LLC

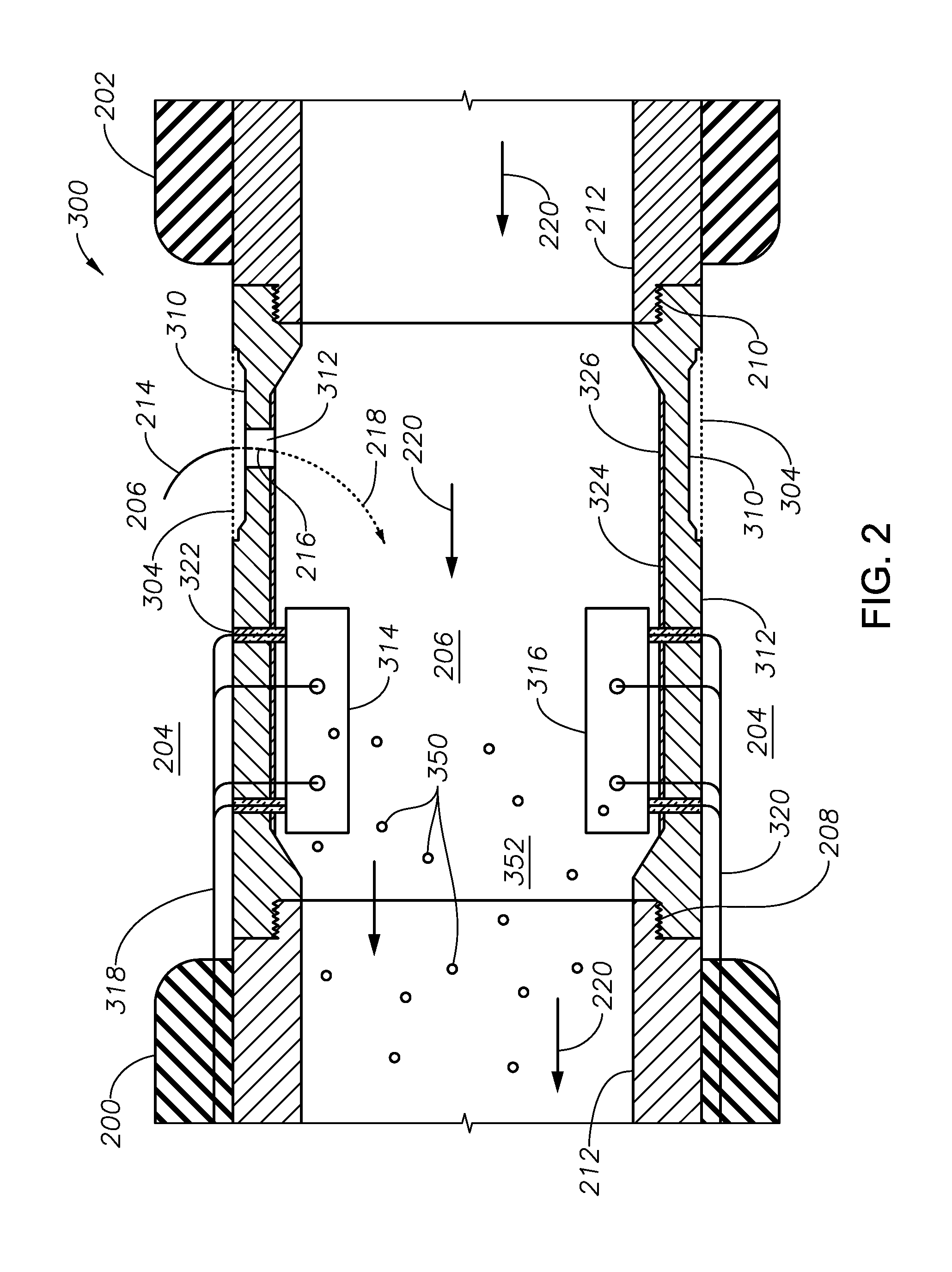

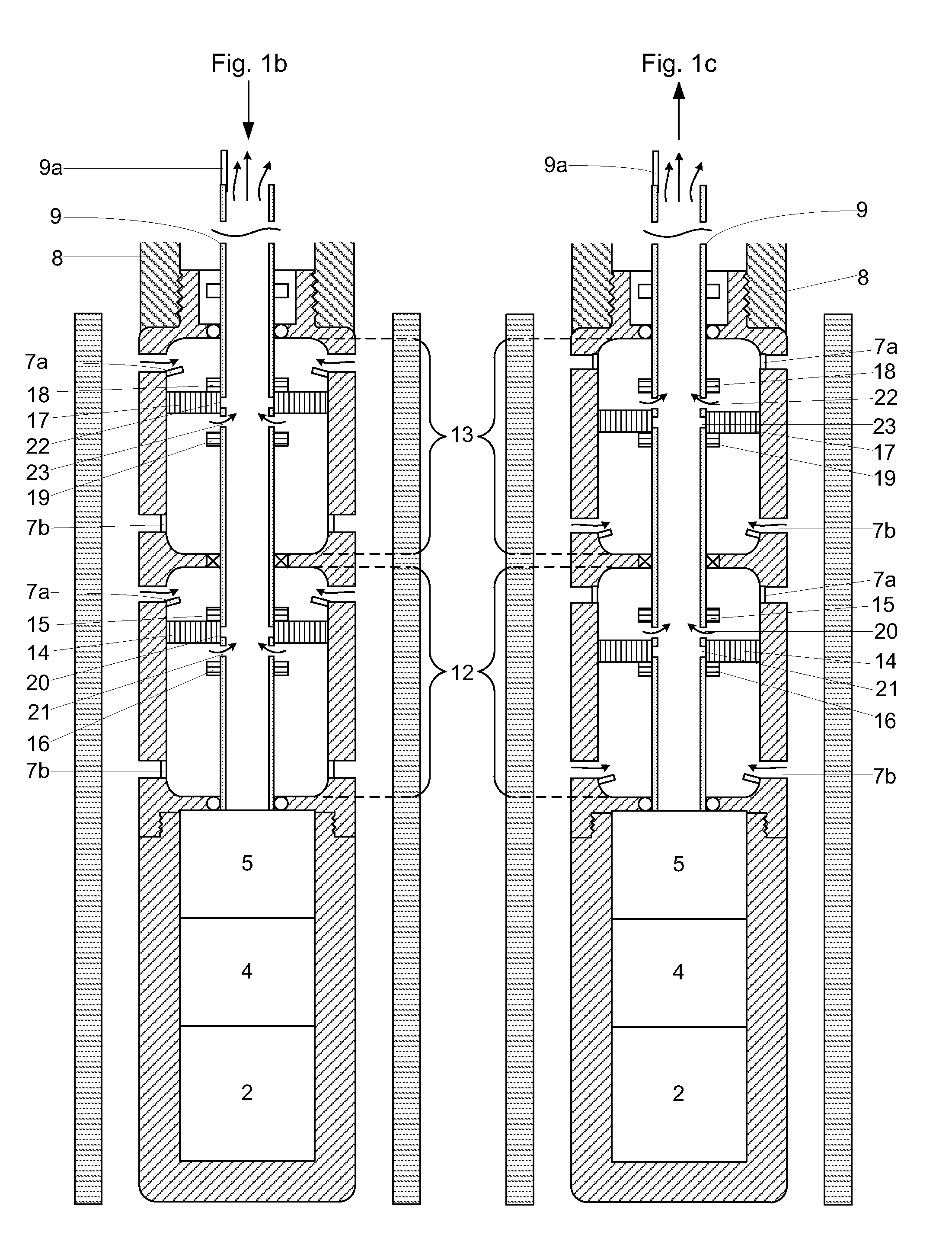

Positive Displacement Pumping System

InactiveUS20100316504A1Effectively reducing head pressureEliminate needFlexible member pumpsFluid removalFluid intakeReduction drive

A positive displacement pumping system for use in deep wells includes a drive system and one or two pumps. In the preferred embodiment, the drive system includes an electrical motor, a speed reducer, and a rotary-to-reciprocal motion converter. Alternatively, the drive system includes a windmill, a variable transmission, and a counterbalance. The counterbalance can be either weights or a second alternating pump. The pumps include a central hollow discharge tube and one or more vertically aligned pumping chambers in fluid communication with the central discharge tube. Within each pumping chamber, a valve arrangement, which includes a piston or shuttle member and fluid intakes, causes fluid to fill and then drain from the pumping chambers as the central hollow discharge tube reciprocates. In operation, the drive system causes the central hollow discharge tube in the pump to reciprocate and thereby cause the fluid to travel from each pumping chamber into to the central discharge tube. In the preferred embodiment, fluid is pumped on both the upstroke and downstroke of the central discharge tube. Alternatively, fluid is discharged on only the upstroke. Fluid from the central discharge tube is discharged from the pump into a discharge field. The amount of fluid discharged on each stroke depends on the number and size of pumping chambers and the length of the stroke. A greater number of pumping chambers causes a greater discharge of fluid at a higher velocity into the discharge field.

Owner:LACK LARRY

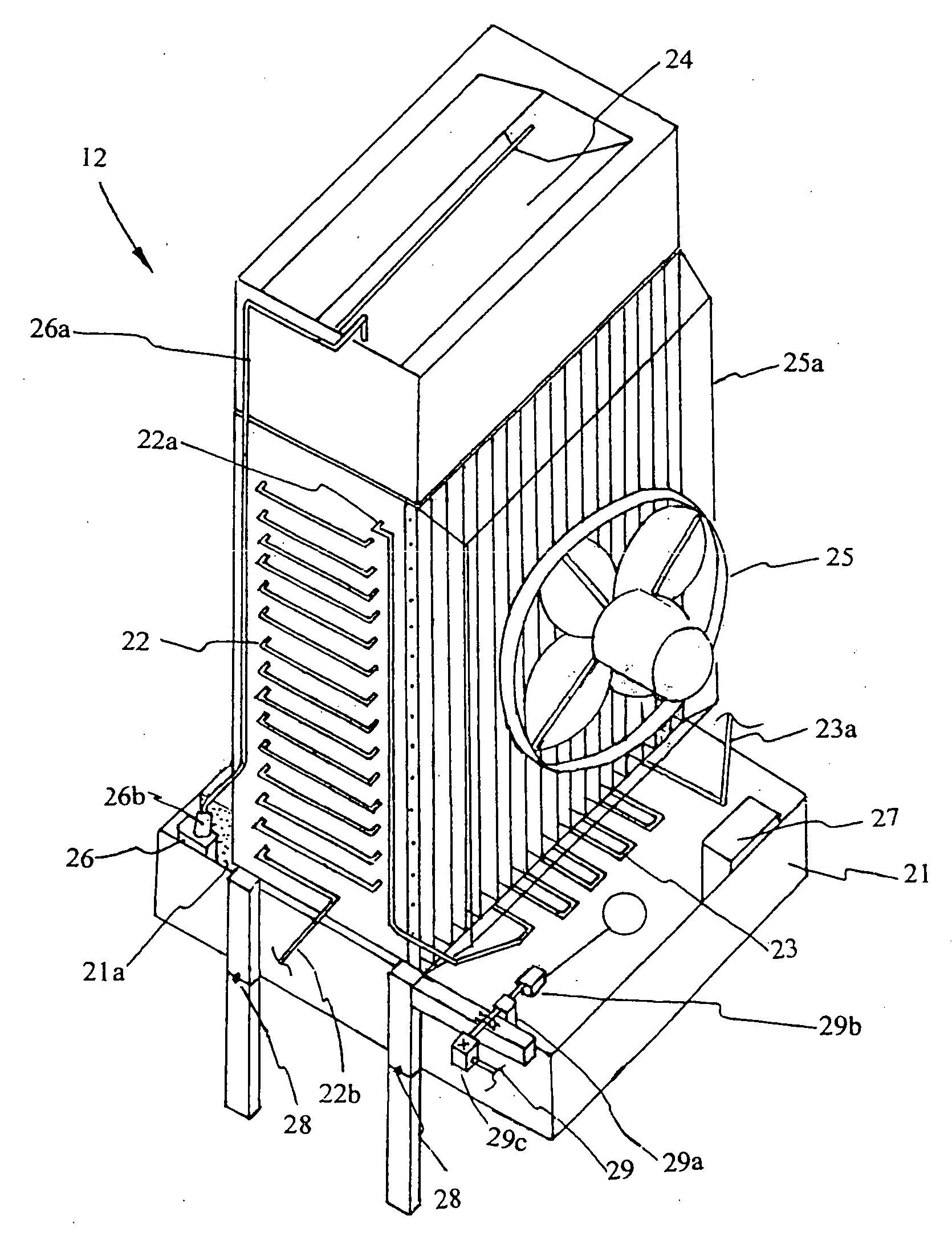

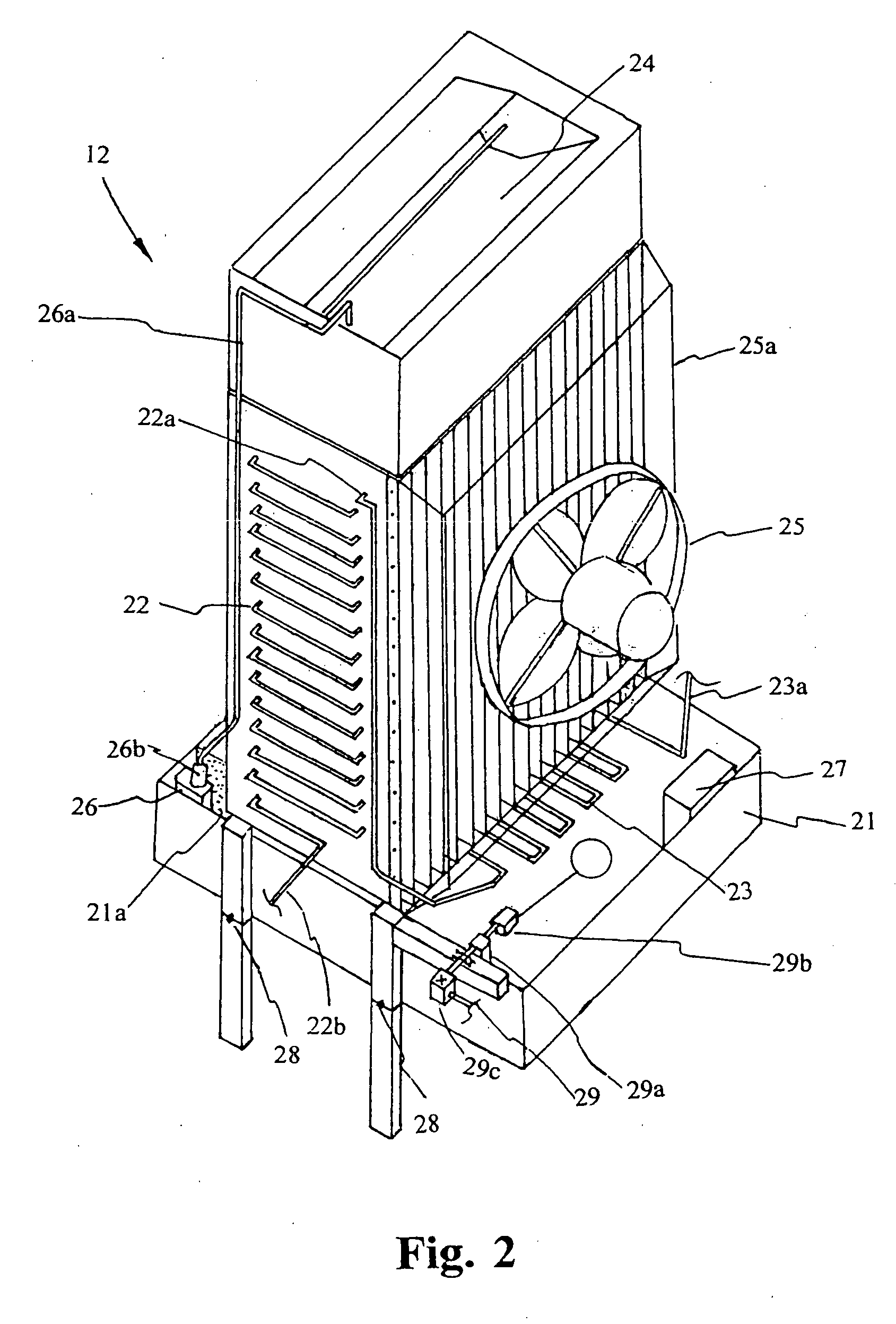

Condenser and metering device in refrigeration system for saving energy

InactiveUS20090173088A1Small sizeLess-expensiveFlow control using electric meansEvaporators/condensersComing outConservation energy

A refrigeration system includes an evaporator, a compressor compressing a refrigerant coming out of the evaporator, a condensing unit which includes a finned tube guiding the refrigerant from the compressor back to the evaporator; and an energy saving arrangement. The energy saving arrangement includes a water-cooling device frequently introducing a predetermined amount of water to a surface of the finned tube to water-cool the refrigerant within the finned tube for enhancing a cooling efficiency of the condensing unit while being energy efficient. The energy saving arrangement further includes a metering device for controllably pumping the refrigerant from the condensing unit to the evaporator especially when a pressure inside the condensing unit is lower than a threshold pressure.

Owner:SU KUOJUI +1

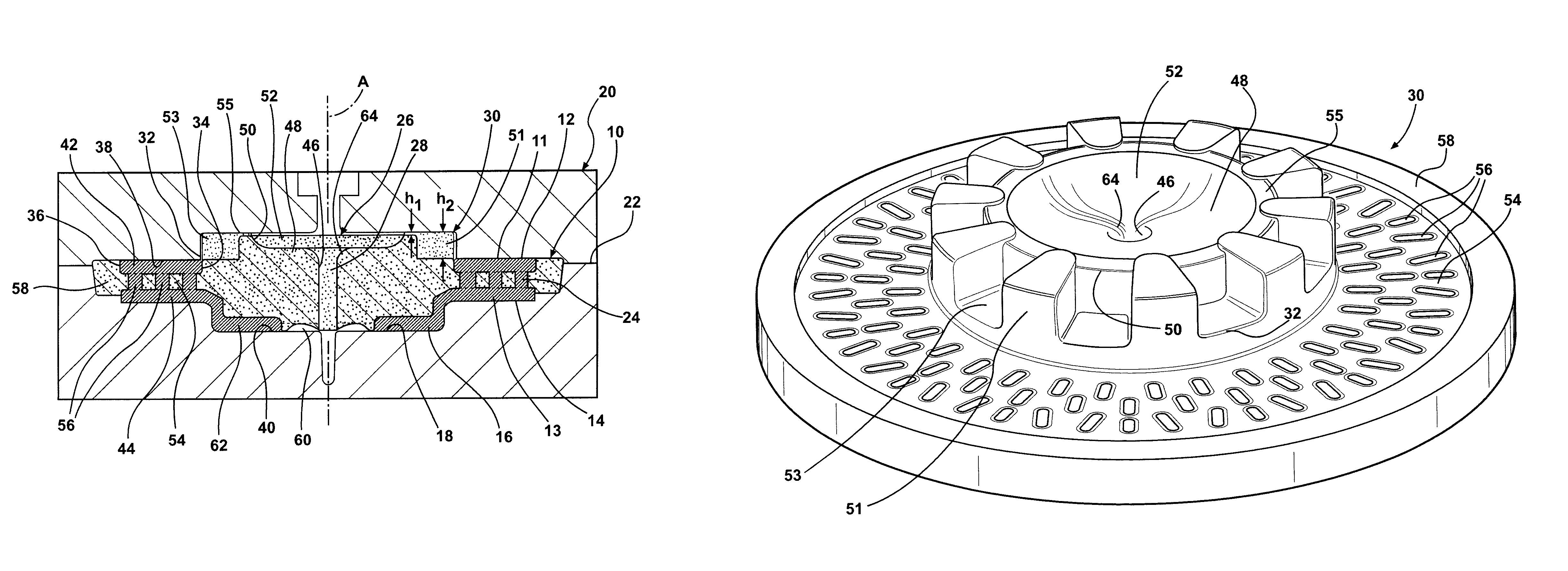

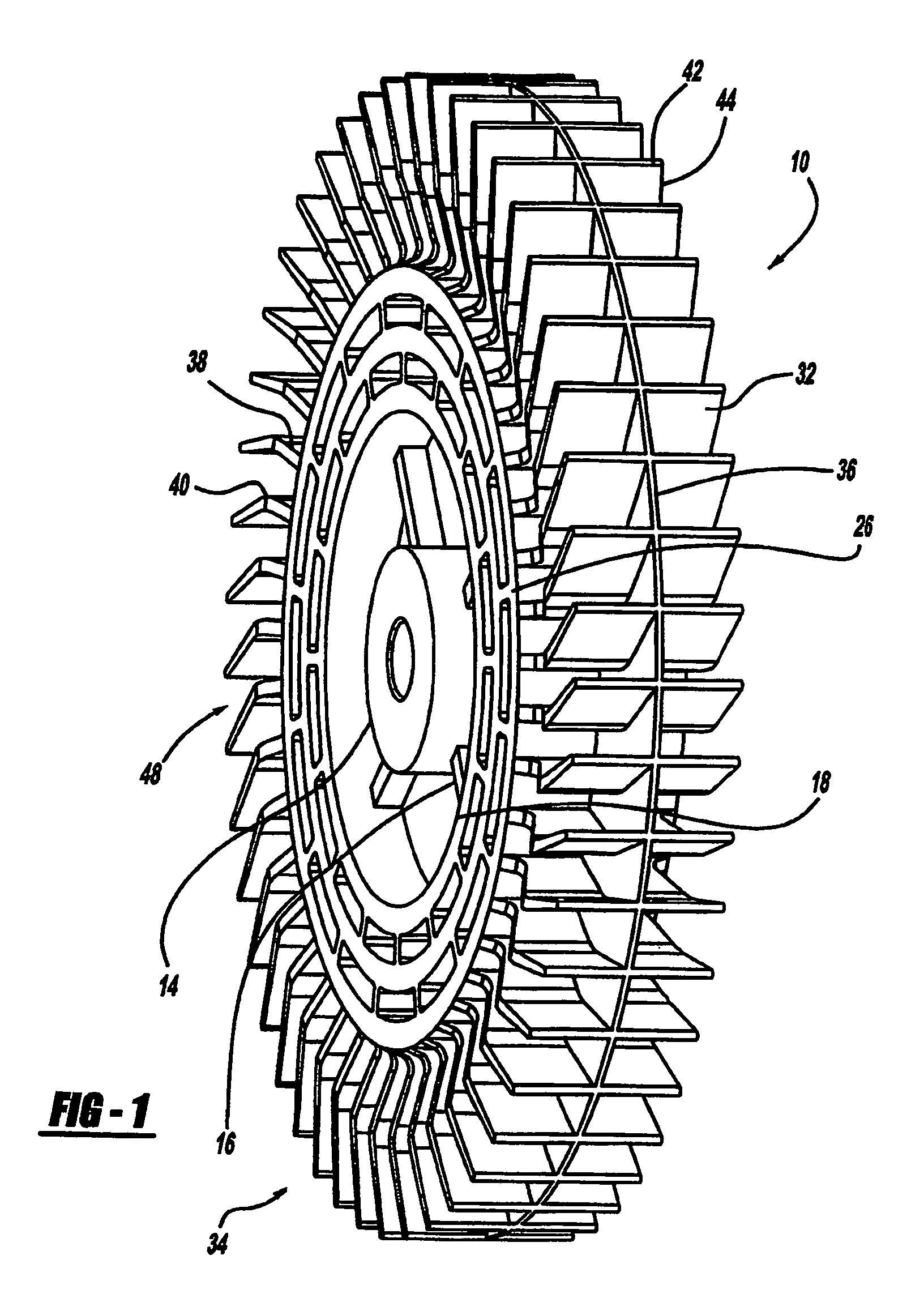

Pressure and current reducing impeller

InactiveUS7425113B2Suitable for operationReduce stressCircumferential flow pumpsPump componentsImpellerPower flow

A secondary air system providing a regeneration air pump wherein the vanes of the impeller are tapered from a point along the length of the vane to the root of the vane inside the air pump. The tapered vanes create desirable flow characteristics. The tapered vanes create a non-linear flow versus pressure characteristic. Thus, the tapered vanes in combination with a divider that extends circumferentially around the impeller and through the vanes causes the flow to increase. This non-linear characteristic created by the tapered vanes allows the secondary air system to maintain suitable operation at lower flow and pressure levels. Due to the tapered feature on the impeller, a dead head pressure is obtained at a lower pressure. The impeller arrangement also provides overall pump efficiency improvements.

Owner:BORGWARNER INC

Economically Viable Atmospheric Water Generator

ActiveUS20190100903A1Small sizeImprove scalabilityGas treatmentWater/sewage treatment by irradiationFiltrationDesiccant

A system and method of generating water from air in a cost effective manner is provided. In some embodiments, the water generating apparatus uses a combination of rotating pre-loader wheels of solid desiccants, fans, mechanical systems such as Vapor Compression Cycle (VCC) or Peltier coils, filtration and mineral addition units to create a cost effective system for generating water from ambient air. In other embodiments, the water generating apparatus include smart controls for optimizing water production as per consumer requirements at times of the day when utility rates are low.

Owner:PANDA PRIYADARSHI +1

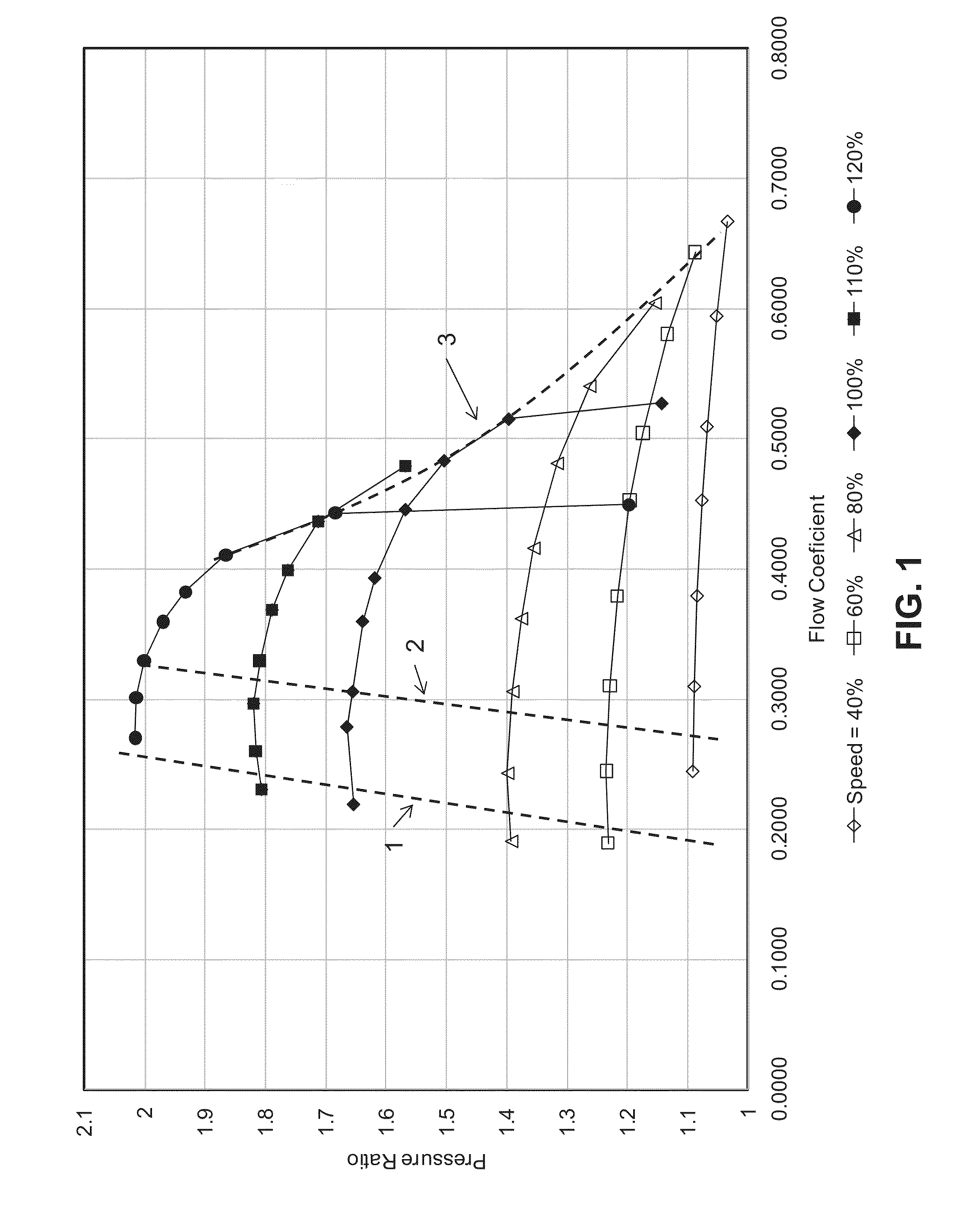

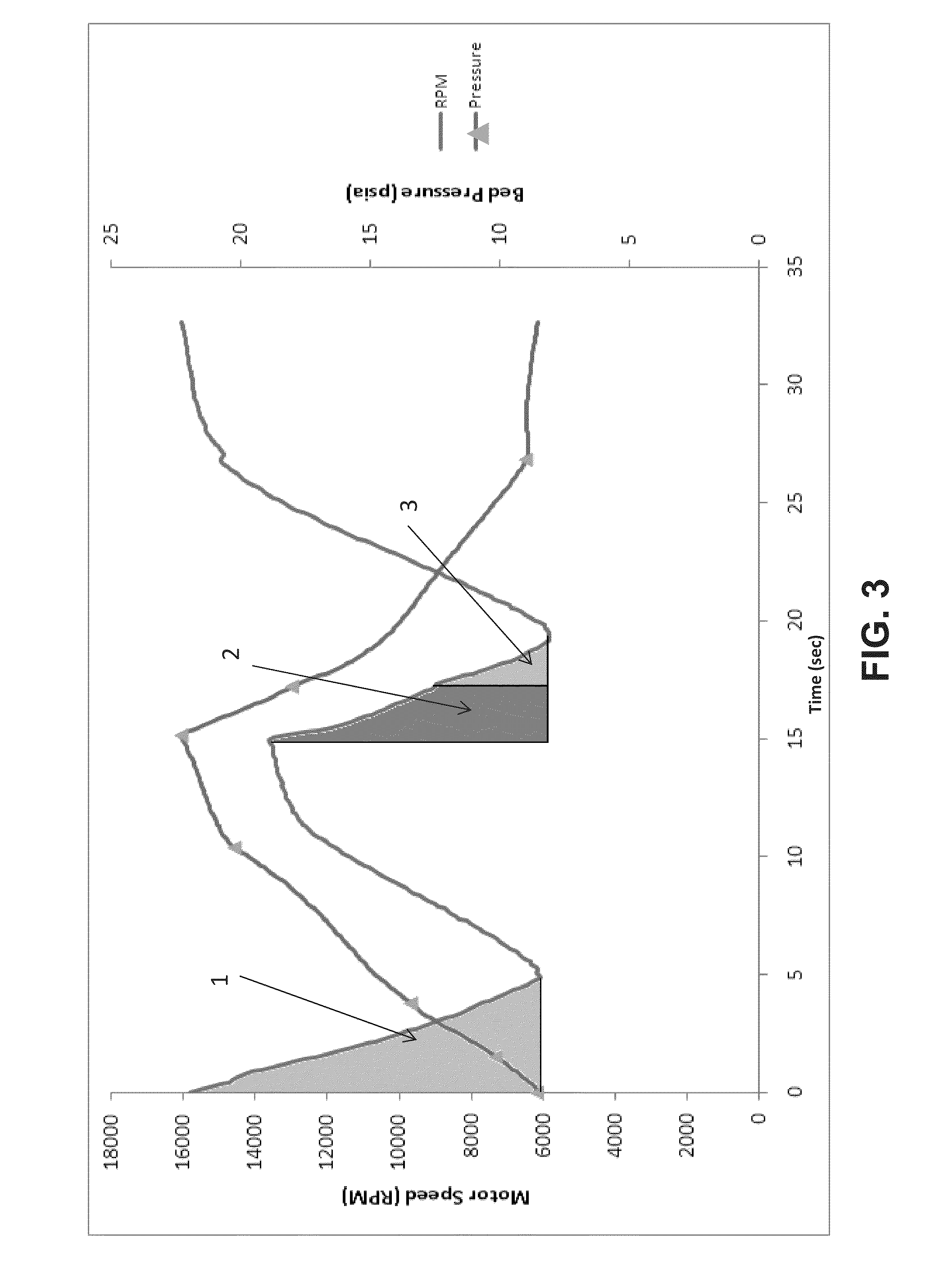

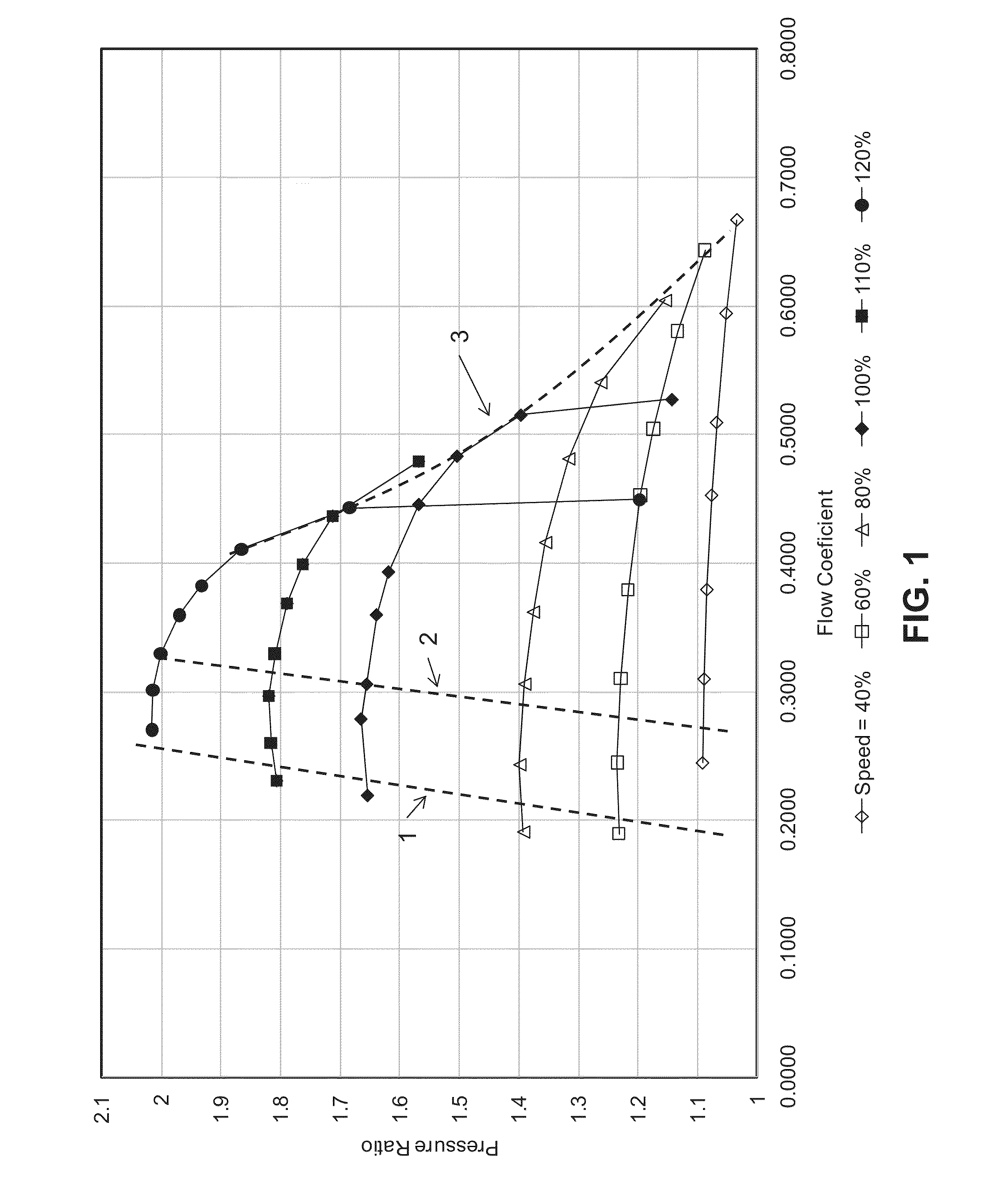

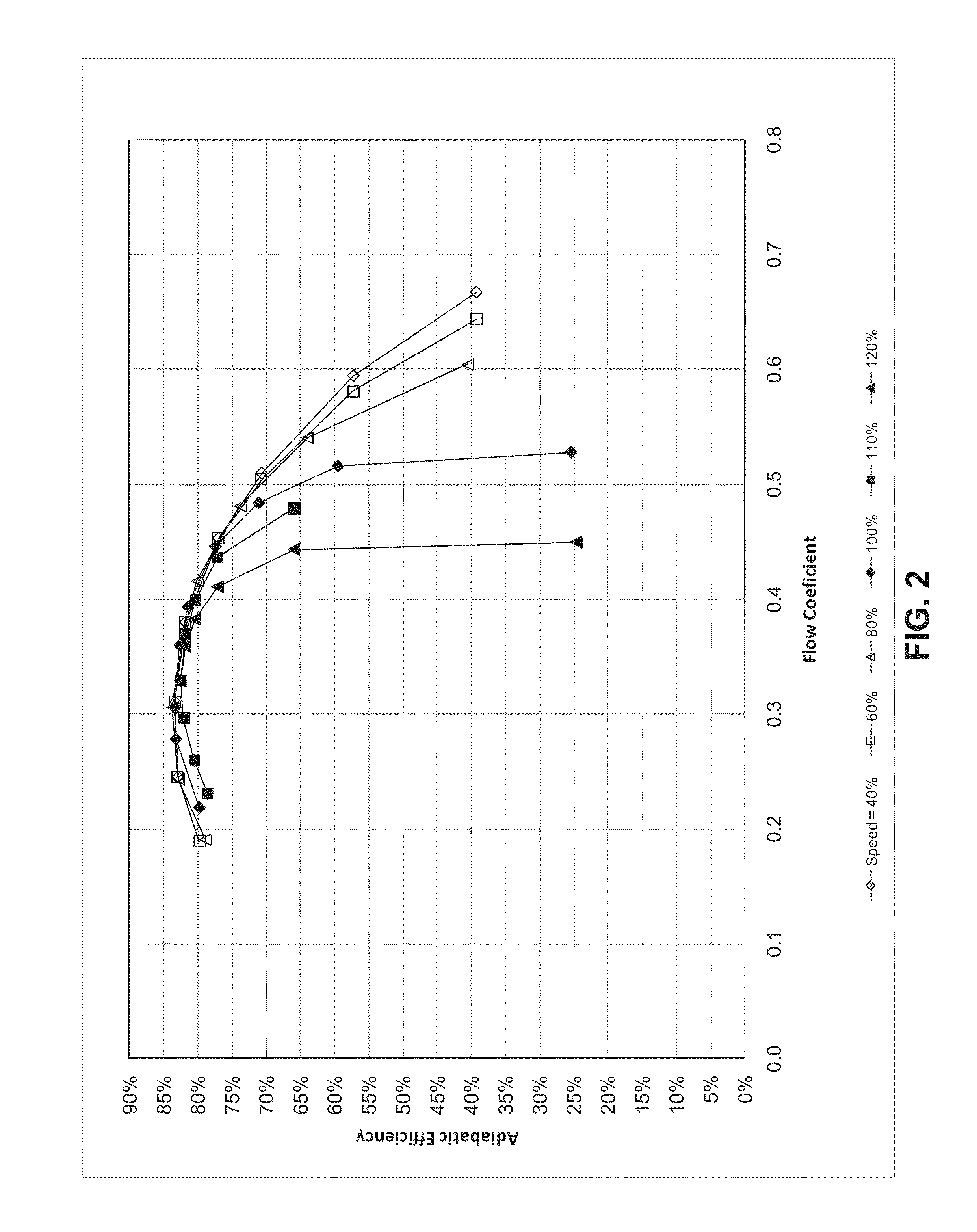

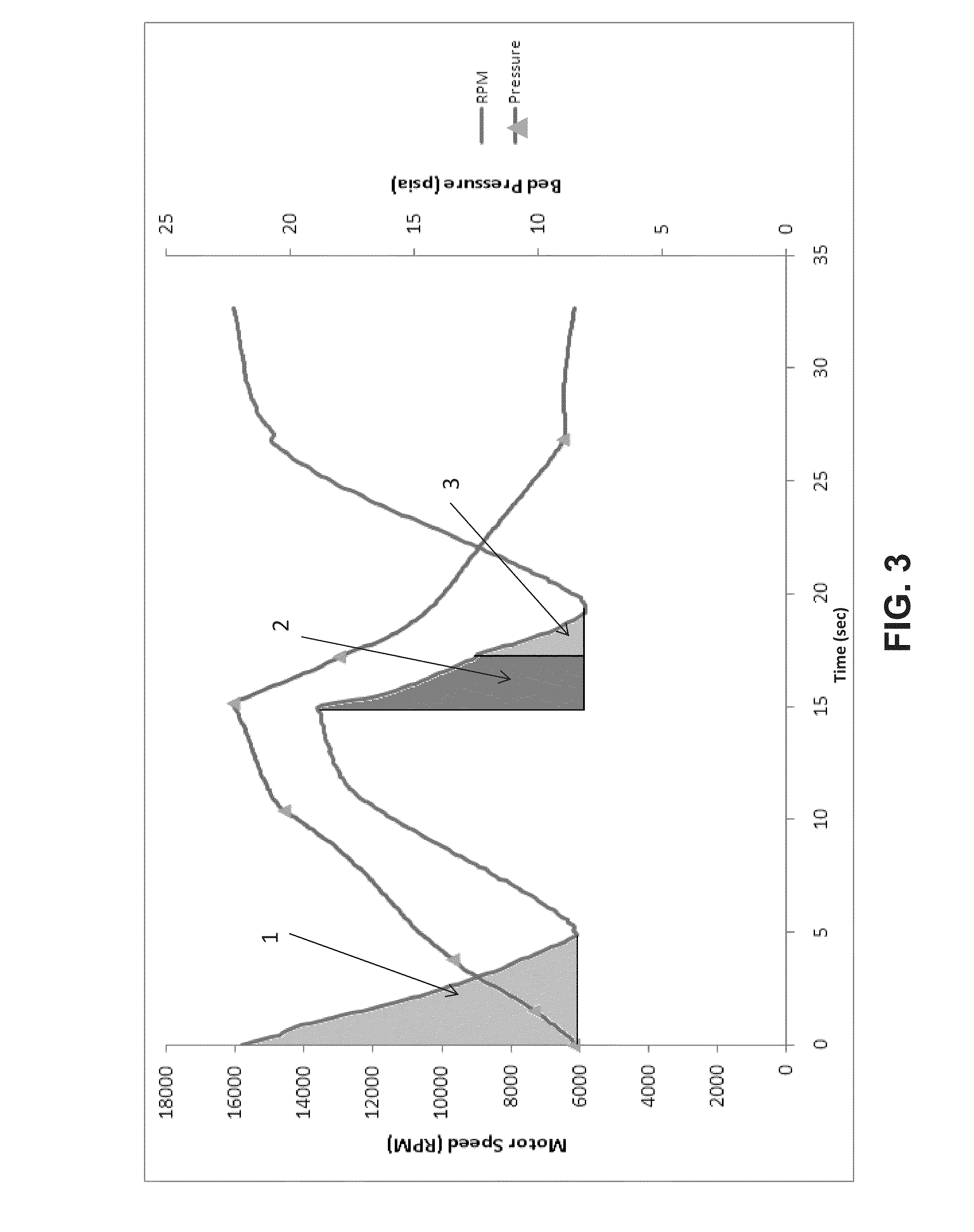

Cyclic adsorption process using centrifugal compressors

ActiveUS8623118B2Minimizing adverse conditionReduce head pressureGas treatmentDispersed particle filtrationInertial effectProcess engineering

A cyclic adsorption process is provided, the process containing one or more adsorber vessels undergoing the steps of at least pressurization and depressurization and driven by one or more variable speed centrifugal machines operating under acceleration and deceleration conditions and adjusted to the steps, vessel size, and process conditions employed, wherein the process cycle time is greater than the ratio of the change in inertia, defined the maximum energy that can be lost during a cycle due to inertia changes, to 0.3 times the total power of the one of more centrifugal machines that would be consumed in the absence of inertial effects.

Owner:PRAXAIR TECH INC

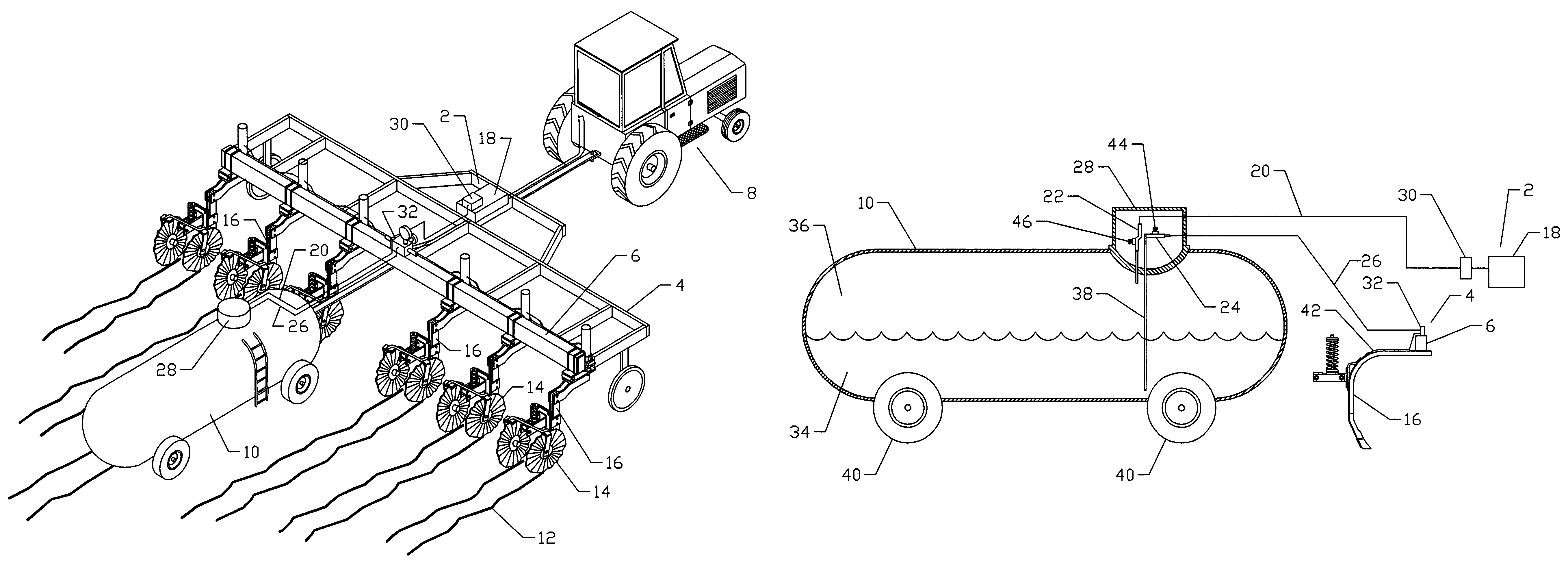

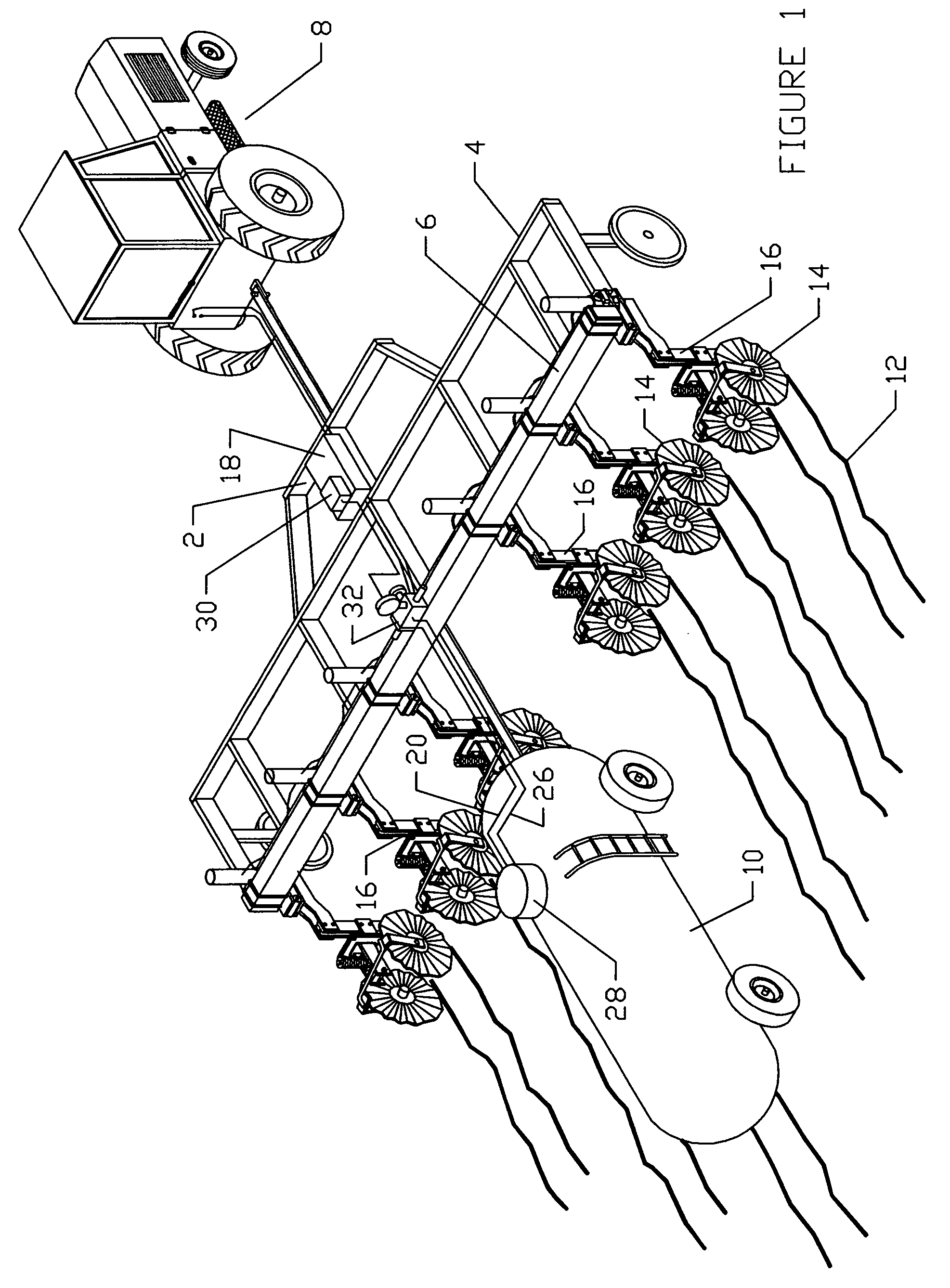

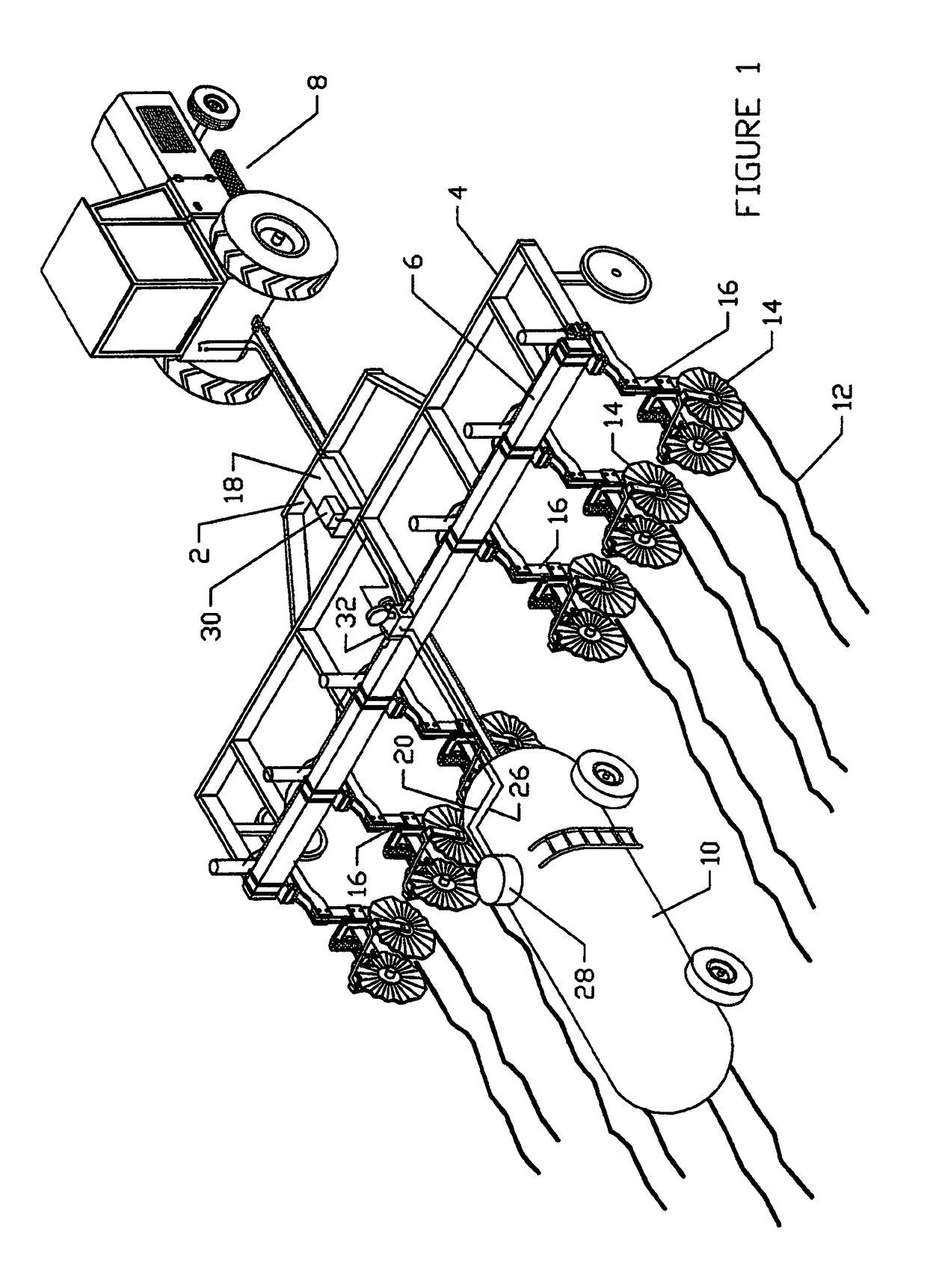

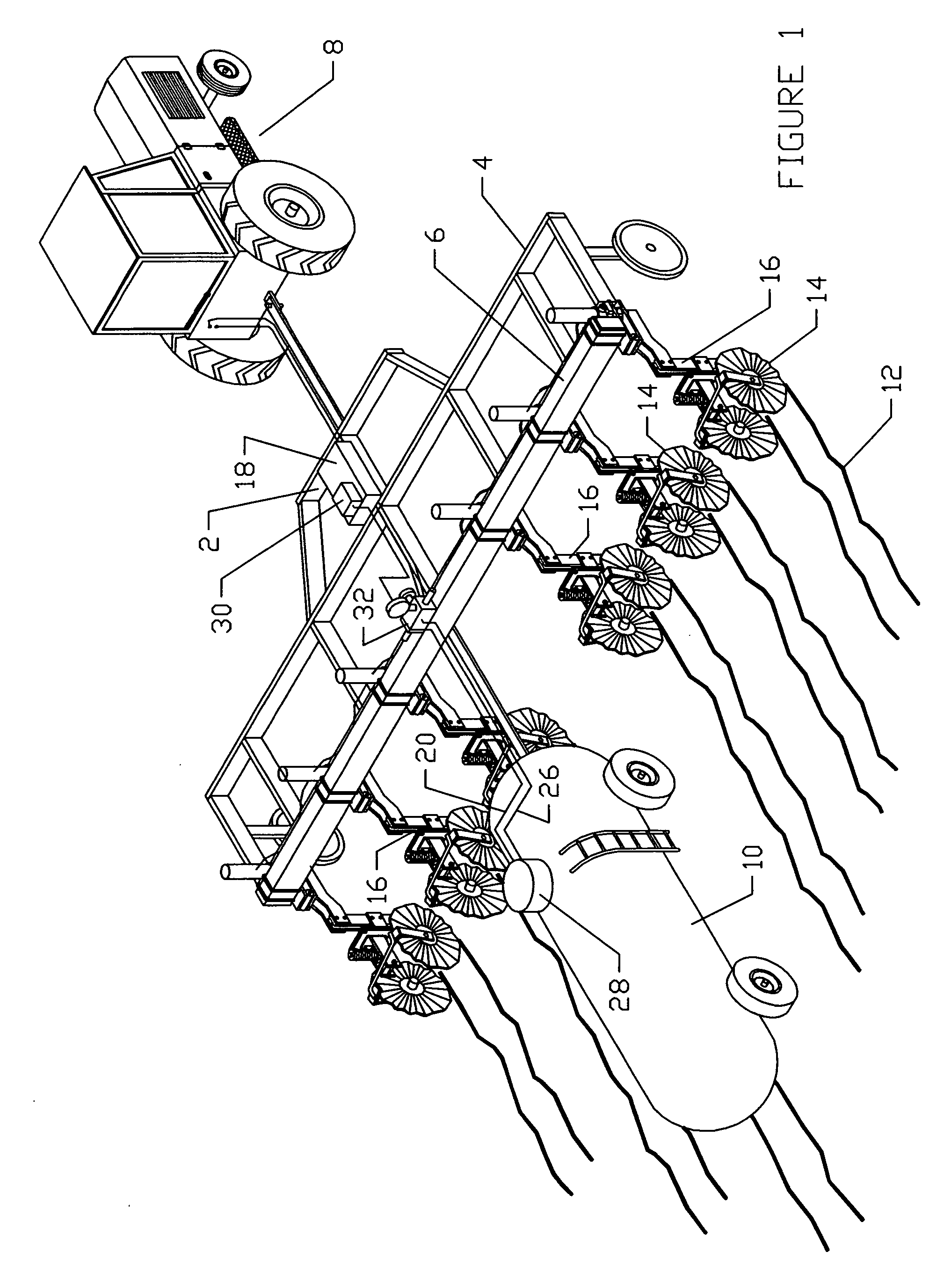

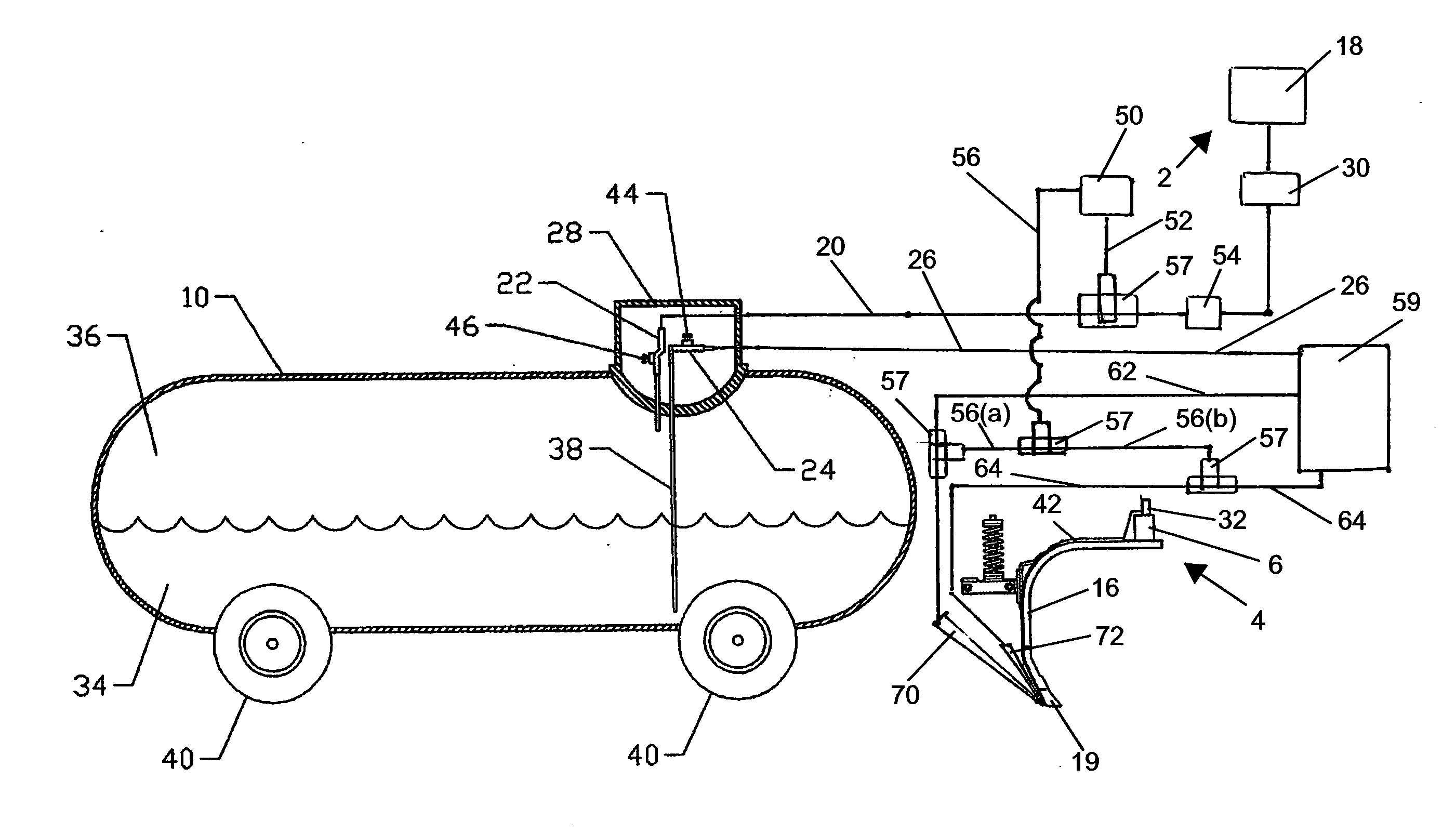

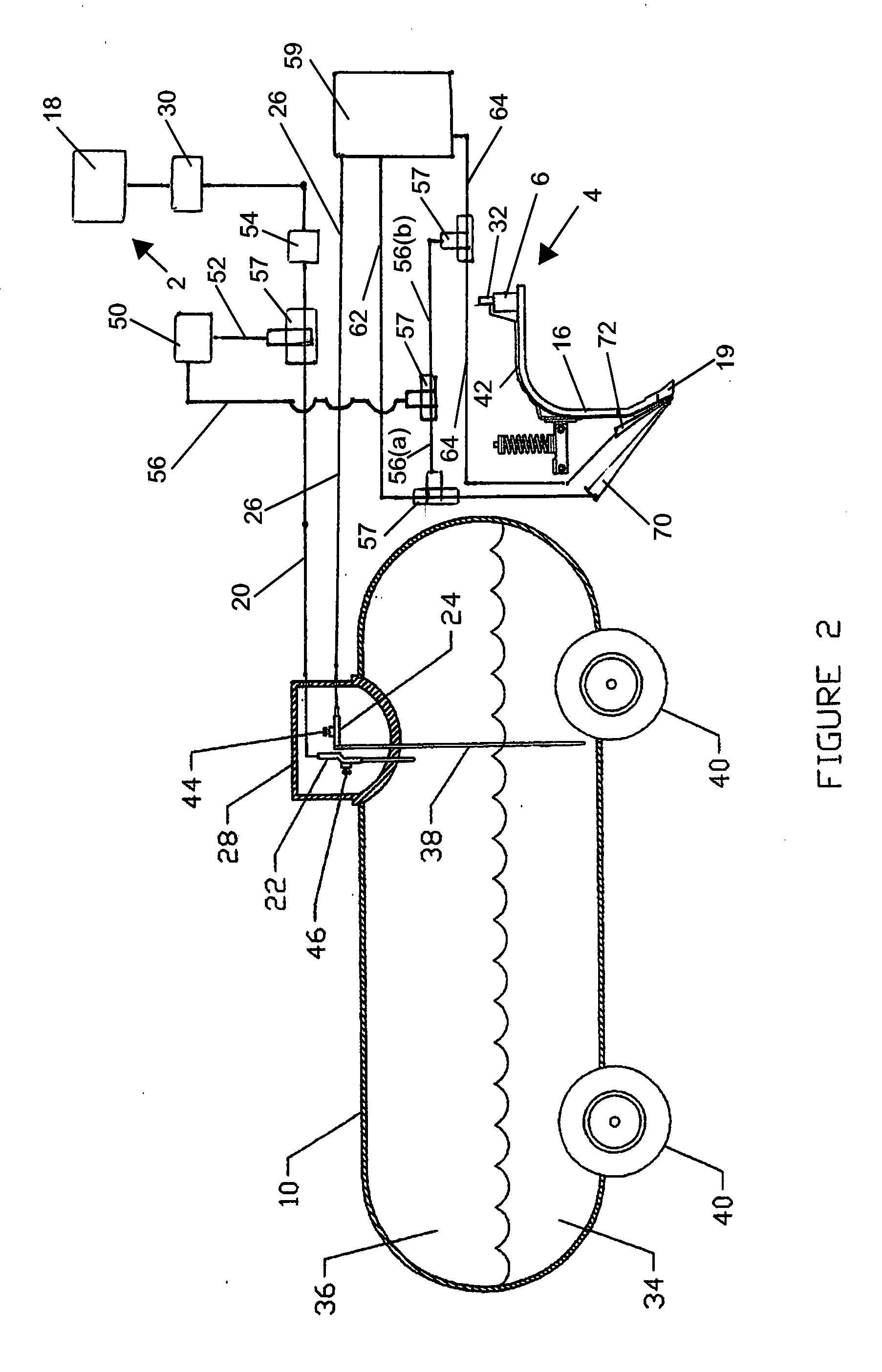

Apparatus and method to improve field application of anhydrous ammonia in cold temperatures

ActiveUS7779768B2Reduce head pressureIncrease pressureLiquid fertiliser distributionAtmospheric temperatureAir compressor

Apparatus and method to improve flow of liquid anhydrous ammonia from a portable liquid NH3 tank in cold temperatures includes an air compressor coupled to the vapor port of a portable liquid NH3 tank used to supply liquid anhydrous ammonia to an anhydrous ammonia fertilizer applicator. The air compressor injects compressed air into the tank to maintain head pressure within the tank at between 80 and 150 psi. to facilitate flow of liquid NH3 from the tank to the applicator when atmospheric temperatures are low as well as when the level of liquid NH3 present in the tank declines.

Owner:FORSYTH DANIEL L

Cutting heads for intramedullary reamers

Owner:VIANT AS&O HLDG LLC

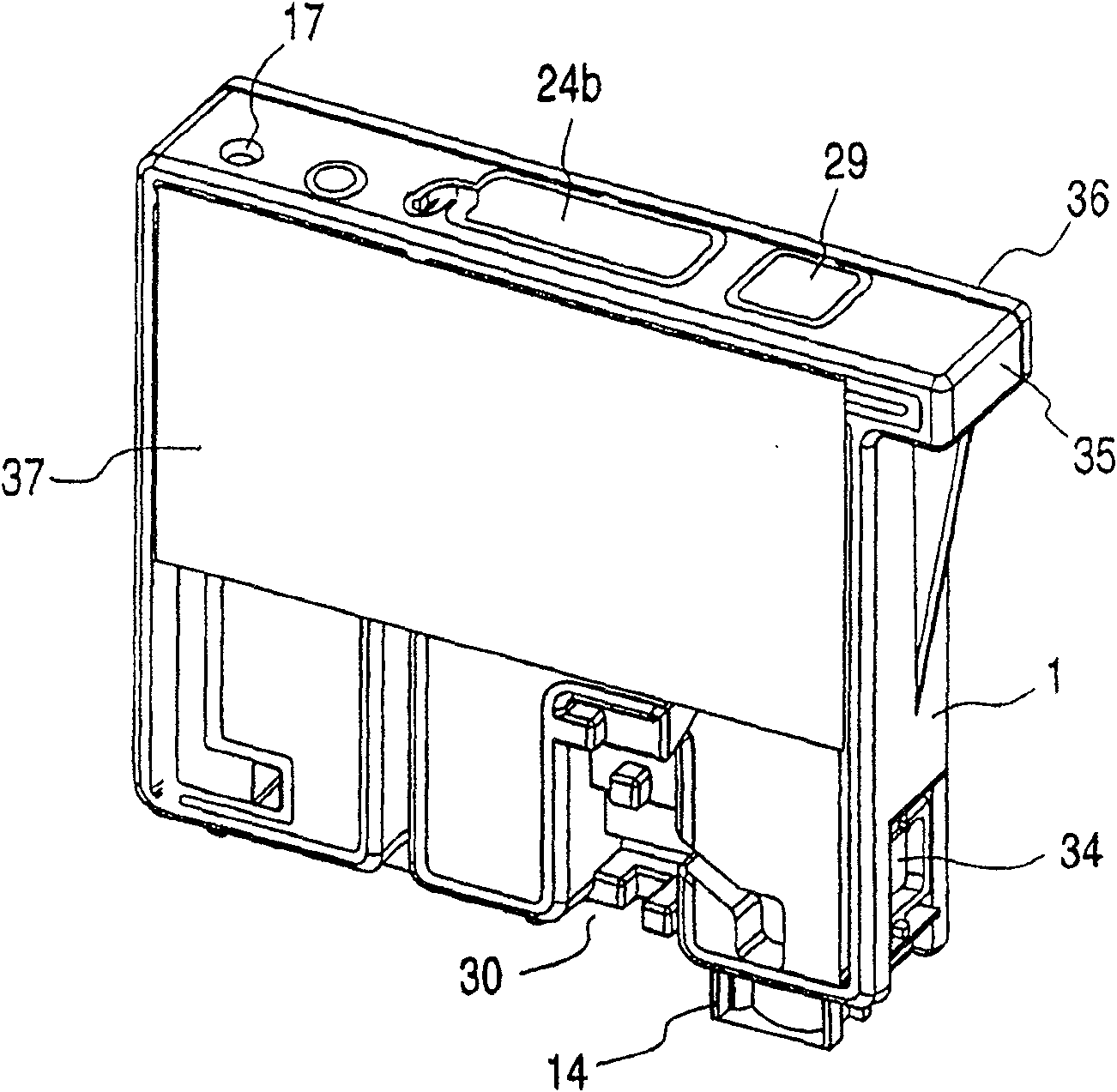

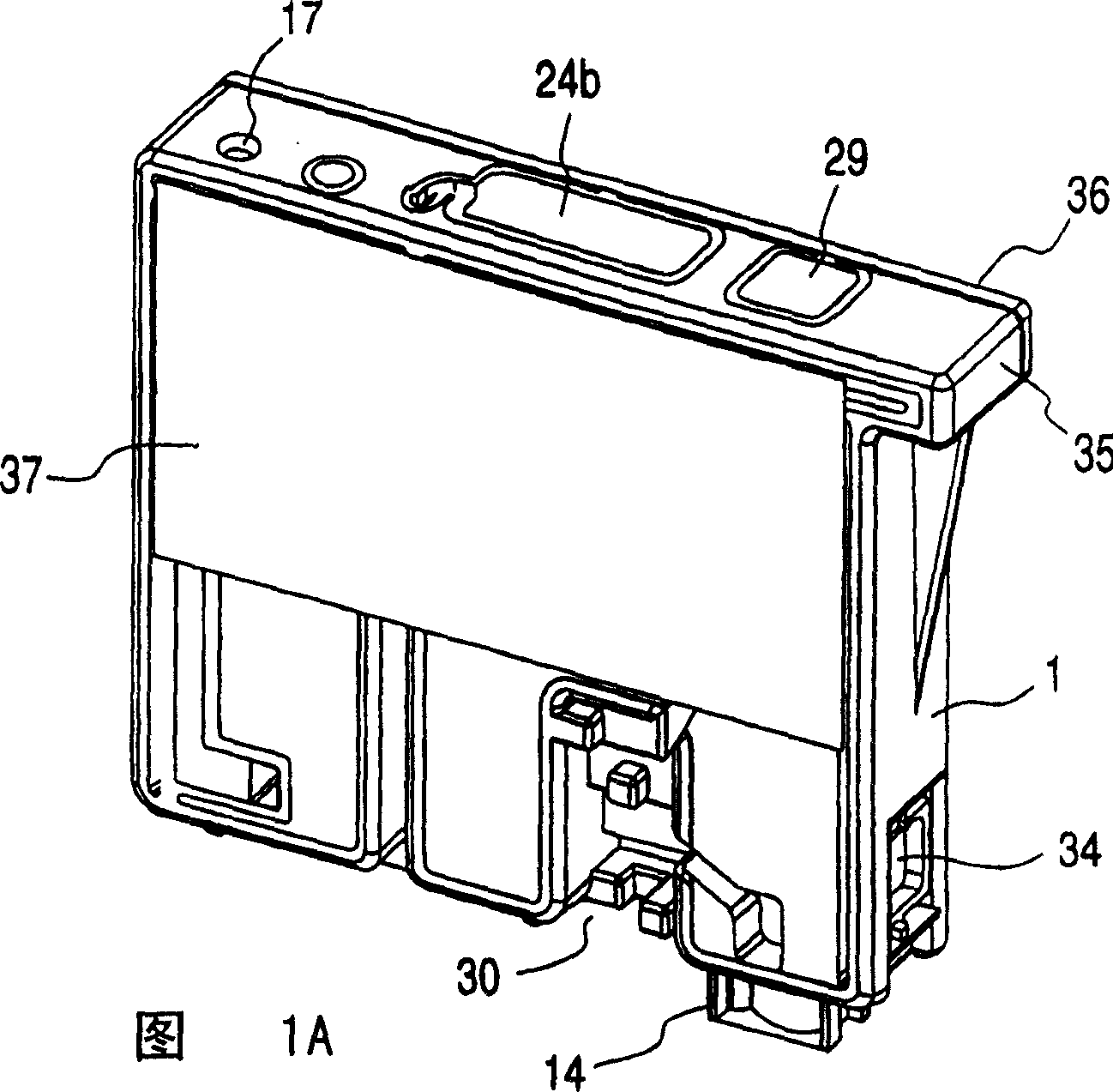

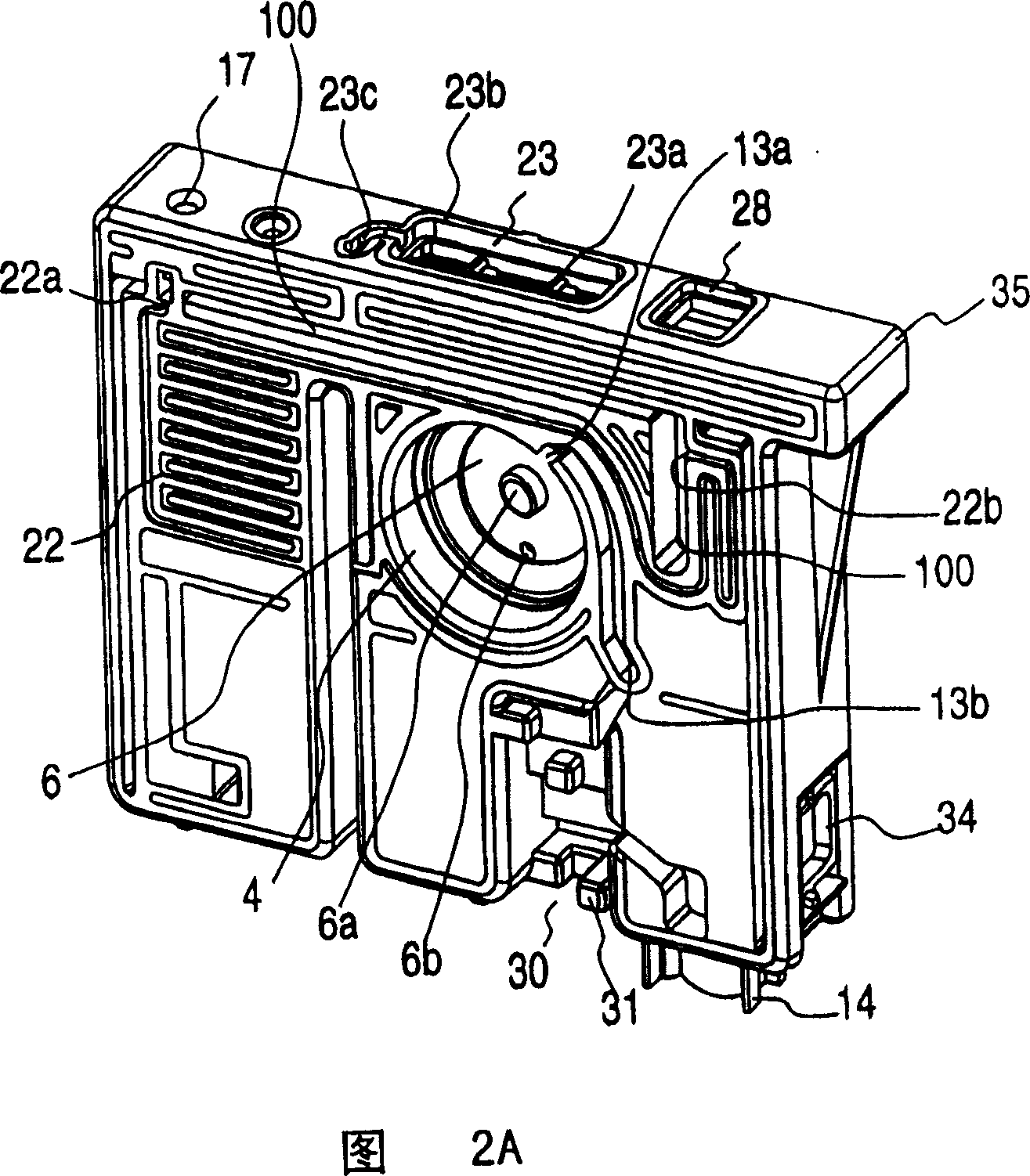

Ink cartridge for ink jet recording device

InactiveCN100548694CReduce head pressureNo need to increase the areaPrintingAtmospheric airEngineering

The present invention provides an ink cartridge for an ink jet recording device with a recording head, comprising: a container including: a lower ink chamber; an upper ink chamber; and an ink supply port for supplying ink to the recording head ; one ink suction channel that communicates the lower ink chamber with the upper ink chamber, and the lower ink chamber is located upstream of the upper ink chamber in relation to the direction in which the ink flows through the ink suction channel; one communicates the upper The ink chamber and the ink flow channel of the ink supply port; an air exchange part communicating with the lower ink chamber and the atmosphere; a negative pressure generating mechanism provided in the container and arranged in the ink flow channel.

Owner:SEIKO EPSON CORP

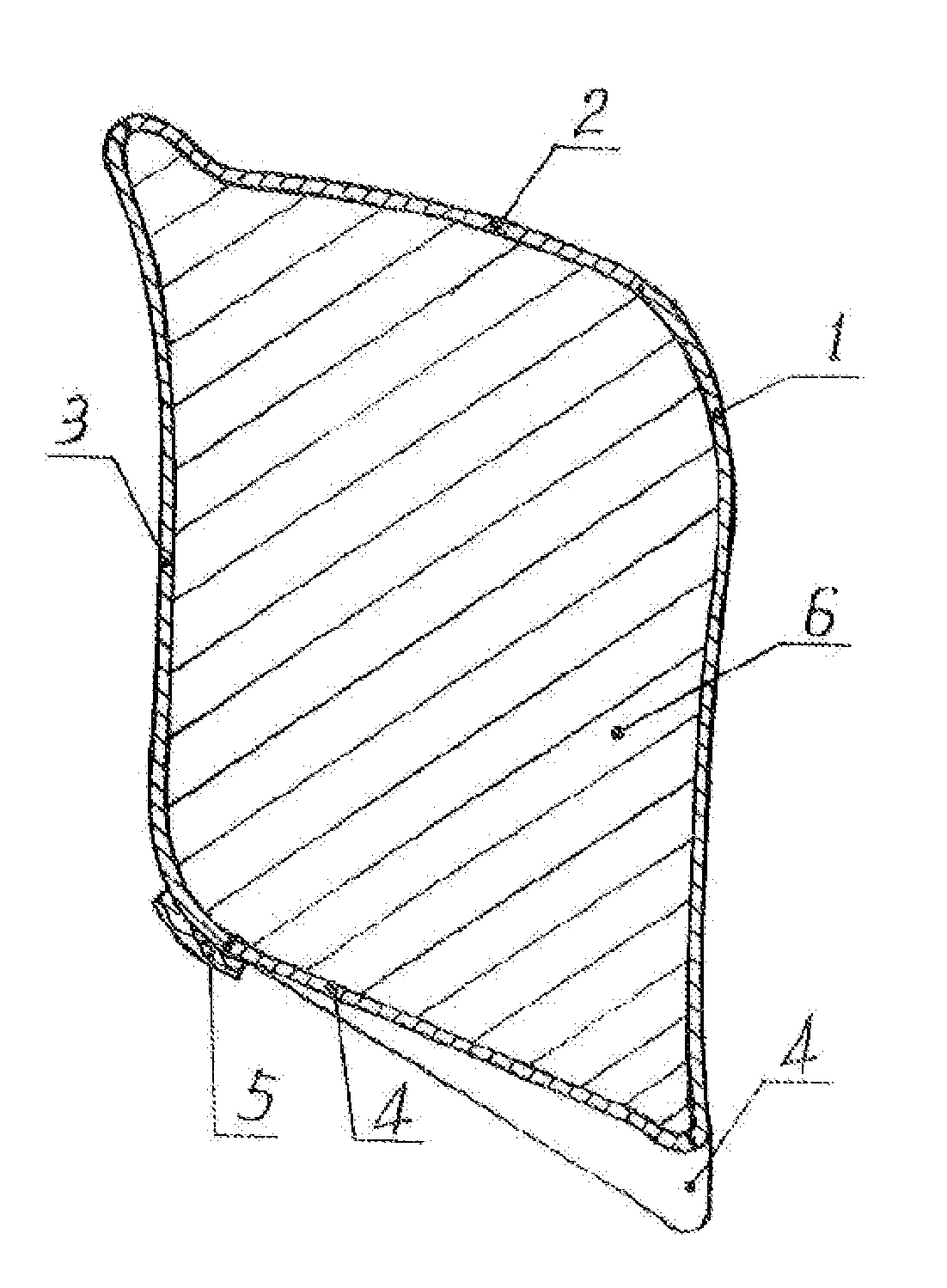

Automobile neck pillow

InactiveUS20130038111A1Improve air qualityFeel comfortableVehicle seatsOperating chairsOxygen ionsEngineering

An automobile neck pillow relates to an automobile seat articles technology field, which adopts a key technology truly adapted to human mechanical physiological curves and makes a multiple choice about materials of a core body and an elongated housing and a scientific measurement about shapes and sizes thereof to make the core body and the elongated housing match with each other, wherein the core body is soaked in medical liquids of health care to provide health care and healing to the neck, the core body is attached with a bamboo charcoal fiber cushion, an infra-red cloth, or a negative oxygen ion cloth while integrally being sprayed with perfume, and a brace provided in the elongated housing is mounted between a seat and a head cushion by a longitudinal fixation, a transverse fixation, a combination of longitudinal and transverse fixation, a head-sleeving fixation, or an integral fixation with the head cushion.

Owner:HUANG LEI

Apparatus to improve field application of anhydrous ammonia in cold temperatures

ActiveUS9668403B2Reduce head pressureIncrease pressureDirect liquid fertiliser deliveryAgriculture gas emission reductionProcess engineeringActuator

An apparatus and method to improve delivery of liquid anhydrous ammonia from a portable liquid NH3 tank in cold temperatures includes an air compressor coupled to the vapor port of a portable liquid NH3 tank used to supply liquid anhydrous ammonia to an anhydrous ammonia fertilizer applicator. The apparatus can include an actuator to relieve the tank of compressed air after the tank is empty of liquid anhydrous ammonia.

Owner:FORSYTH DANIEL L

Apparatus and method to improve field application of anhydrous ammonia in cold temperatures

ActiveUS20070022927A1Reduce head pressureReduce pressureLiquid fertiliser distributionAtmospheric temperatureAir compressor

Apparatus and method to improve flow of liquid anhydrous ammonia from a portable liquid NH3 tank in cold temperatures includes an air compressor coupled to the vapor port of a portable liquid NH3 tank used to supply liquid anhydrous ammonia to an anhydrous ammonia fertilizer applicator. The air compressor injects compressed air into the tank to maintain head pressure within the tank at between 80 and 150 psi. to facilitate flow of liquid NH3 from the tank to the applicator when atmospheric temperatures are low as well as when the level of liquid NH3 present in the tank declines.

Owner:FORSYTH DANIEL L

Methods for reducing evaporative loss from swimming pools

InactiveUS10336636B2Improve clarityReduce concentrationWater contaminantsSustainable biological treatmentEvaporationMicrobial composition

Owner:BIOWISH TECH

Automobile neck pillow

An automobile neck pillow relates to an automobile seat articles technology field, which adopts a key technology truly adapted to human mechanical physiological curves and makes a multiple choice about materials of a core body and an elongated housing and a scientific measurement about shapes and sizes thereof to make the core body and the elongated housing match with each other, wherein the core body is soaked in medical liquids of health care to provide health care and healing to the neck, the core body is attached with a bamboo charcoal fiber cushion, an infra-red cloth, or a negative oxygen ion cloth while integrally being sprayed with perfume, and a brace provided in the elongated housing is mounted between a seat and a head cushion by a longitudinal fixation, a transverse fixation, a combination of longitudinal and transverse fixation, a head-sleeving fixation, or an integral fixation with the head cushion.

Owner:HUANG LEI

Oil well gas lift by hydrogen production through produced water electrolysis completion

ActiveUS9458704B2Reduce head pressureReduce hydrostatic pressureFluid removalProduct gasProcess engineering

A method of using an electrochemical gas lift apparatus to induce artificial gas lift in a production fluid includes introducing the electrochemical gas lift apparatus into a well bore having a production zone, operating the electrochemical gas lift apparatus such that a combination of hydrocarbon fluid and formation water is introduced into the interior of the electrochemical gas lift apparatus, introducing electrical power to the electrochemical gas lift apparatus such that at least a portion of formation water in the interior of the electrochemical gas lift apparatus converts into product gases, operating the electrochemical gas lift apparatus such that the product gases form product gas bubbles in the interior of the electrochemical gas lift apparatus, and operating the electrochemical gas lift apparatus such that production fluid forms in the interior of the electrochemical gas lift apparatus. The production fluid comprises hydrocarbon fluid, unconverted formation water and product gas bubbles.

Owner:SAUDI ARABIAN OIL CO

Cyclic adsorption process using centrifugal compressors

ActiveUS20130199369A1Minimizing adverse conditionReduce head pressureGas treatmentDispersed particle filtrationInertial effectProcess engineering

A cyclic adsorption process is provided, the process containing one or more adsorber vessels undergoing the steps of at least pressurization and depressurization and driven by one or more variable speed centrifugal machines operating under acceleration and deceleration conditions and adjusted to the steps, vessel size, and process conditions employed, wherein the process cycle time is greater than the ratio of the change in inertia, defined the maximum energy that can be lost during a cycle due to inertia changes, to 0.3 times the total power of the one of more centrifugal machines that would be consumed in the absence of inertial effects.

Owner:PRAXAIR TECH INC

Apparatus to improve field application of anhydrous ammonia in cold temperatures

ActiveUS20150144040A1Reduce head pressureIncrease pressureSpadesDirect liquid fertiliser deliveryFertilizerChemistry

Owner:FORSYTH DANIEL L

Ink cartridge for ink jet recording device

An ink cartridge for an ink jet recording device, includes: a container having an ink supply port; at least two ink chambers partitioned in the container, one being located substantially in an upper section and the other being located substantially in a lower section; an ink suction passage connecting a bottom region of the lower section ink chamber to a bottom region of the upper section ink chamber; and a negative pressure generating mechanism provided to a flow passage connecting the upper section ink chamber to the ink supply port.

Owner:SEIKO EPSON CORP

Ink cartridge for ink jet recording device

InactiveCN1919609AReduce head pressureNo need to increase the areaPrintingAir exchangeMechanical engineering

An ink cartridge for an ink jet recording device having a recording head, comprises: a container having a lower ink chamber; an upper ink chamber; an ink supply port for supplying ink to the recording head; an ink suction channel connecting the lower ink chamber with the upper ink chamber, wherein the lower ink chamber is positioned on the upstream of the upper ink chamber relative to the direction of the ink passing through the ink suction channel; an ink flow channel connecting the upper ink chamber with the ink supply port; an air exchanging part communicating the lower ink channel with atmosphere; and a negative pressure generating mechanism provided in the container and in the ink flow channel.

Owner:SEIKO EPSON CORP

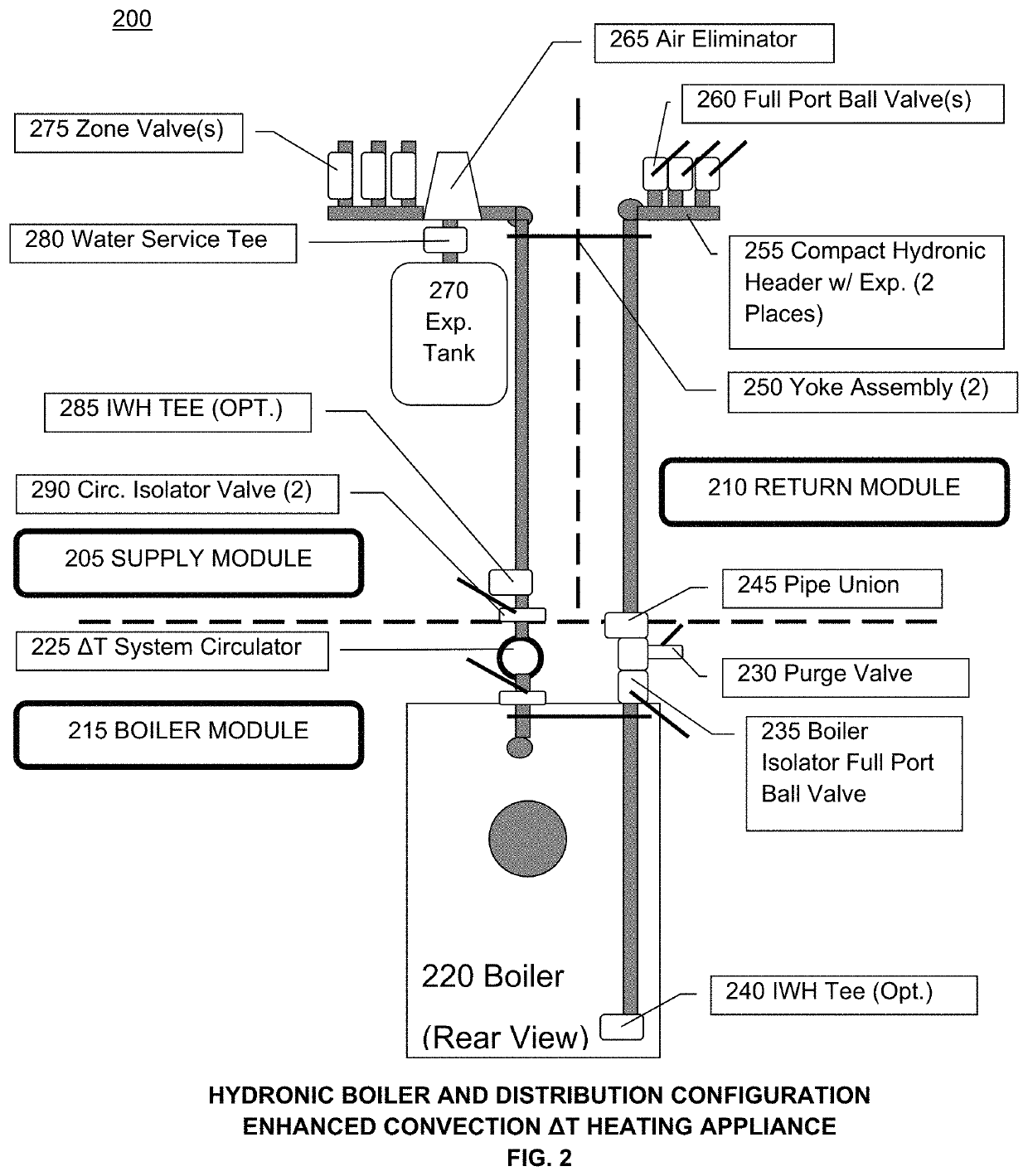

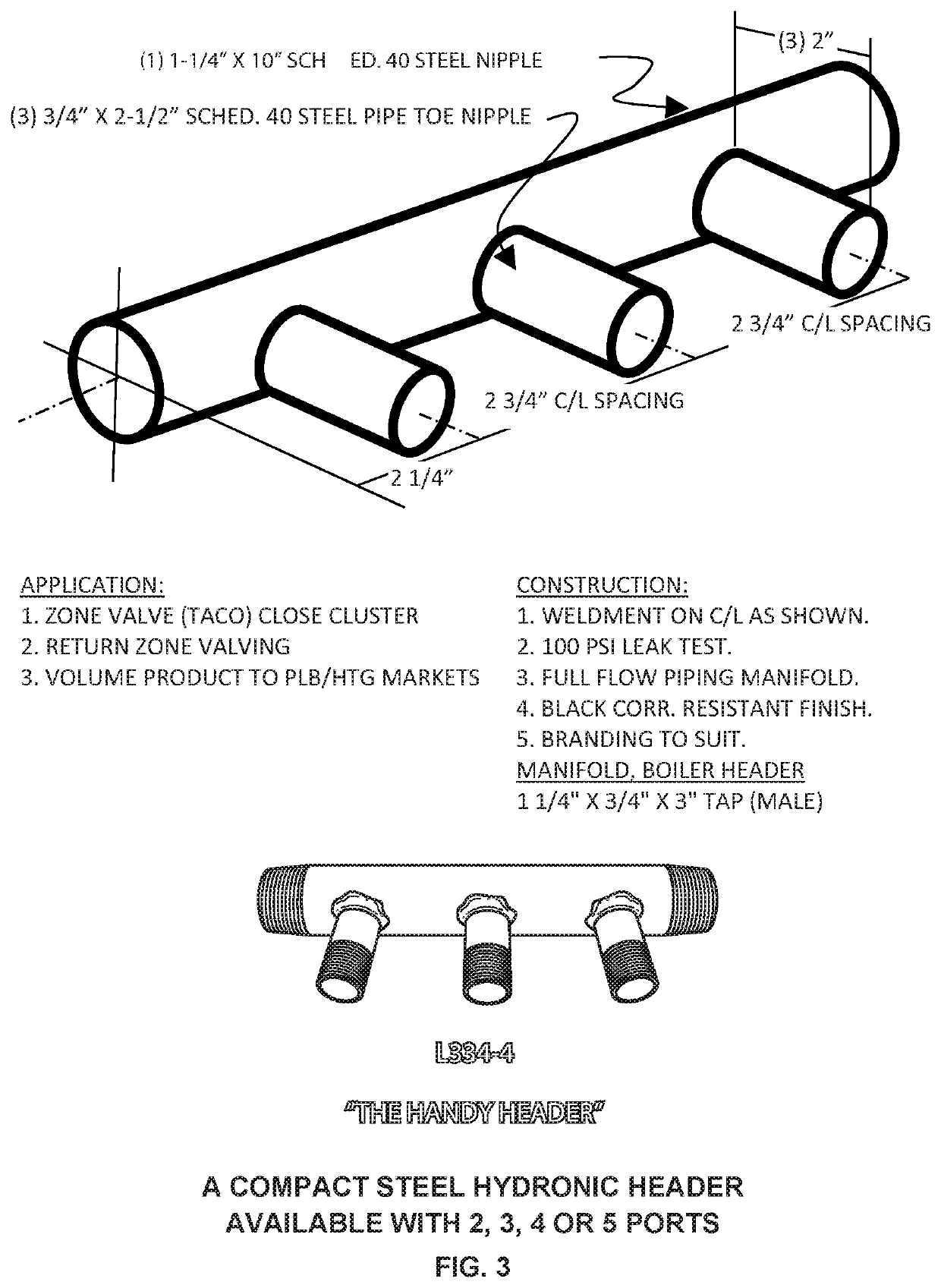

Enhanced convection, differential temperature managed, hydronic heating appliance

ActiveUS10690356B2Enhanced convectionIncrease temperatureLighting and heating apparatusCentral heating componentsIsolation valveZone valve

Owner:MERCIER SR PAUL D

Positive displacement pumping system

InactiveUS8591202B2Reduce head pressureEliminate needFlexible member pumpsFluid removalReciprocating motionPump chamber

A positive displacement pumping system for use in deep wells includes a drive system and one or two pumps. The drive system may include an electrical motor or a windmill. The pump include a central hollow discharge tube and one or more vertically aligned pumping chambers in fluid communication with the central discharge tube. Within each pumping chamber, a valve arrangement, which includes a piston or shuttle member and fluid intakes, causes fluid to fill and then drain from the pumping chambers as the central hollow discharge tube reciprocates. In operation, the drive system causes the central hollow discharge tube in the pump to reciprocate and thereby cause the fluid to travel from each pumping chamber into to the central discharge tube. In the preferred embodiment, fluid is pumped on both the upstroke and downstroke of the central discharge tube.

Owner:LACK LARRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com