Centrally gated cast metal rotary friction plates and method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

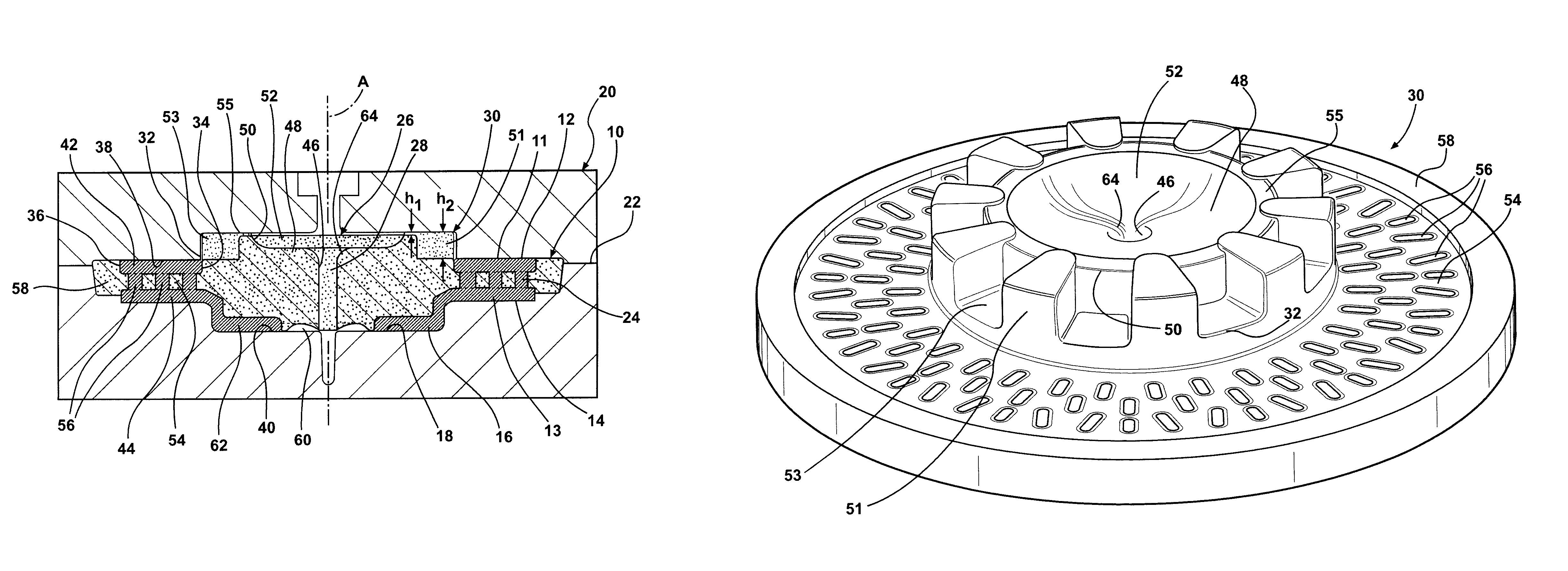

[0026]I have cast standard brake rotors and clutch plates using this central filling system through the open center of the casting, which routes the molten metal through the inside diameter, horizontally across the short feeding distance to the outside diameter. This produces no noticeable variation around the solid casting structure as the one thermal gradient solidified in one circular flow of heat extraction. This horizontal orientation can be adapted for vertically parted molds but it best suited for horizontally parted molds, and is adaptable to all rotary friction plates and other devices where uniform development of cast metal properties is desired in the circumferential direction across the friction surfaces.

[0027]The way I have done this is to use the horizontal orientation of the mold cavity but pour all the melt in through a central gating and outward through the cavity, (not from outside inward) of the volume to be cast, through several closely positioned inlets on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Distribution | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com