A kind of precision plastic forming method of bevel gear

A plastic forming and bevel gear technology, applied in the direction of wheels, transportation and packaging, metal processing equipment, etc., can solve the problems of unstable forming, low precision of forgings, uneven filling, etc., to achieve short metal flow distance, improve mold life, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

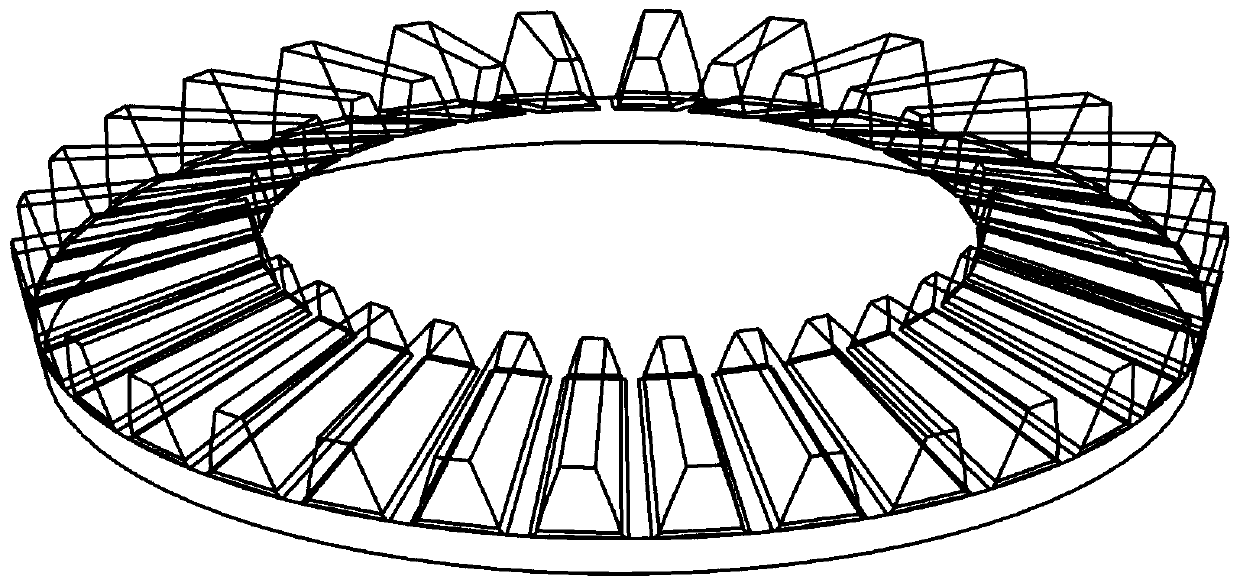

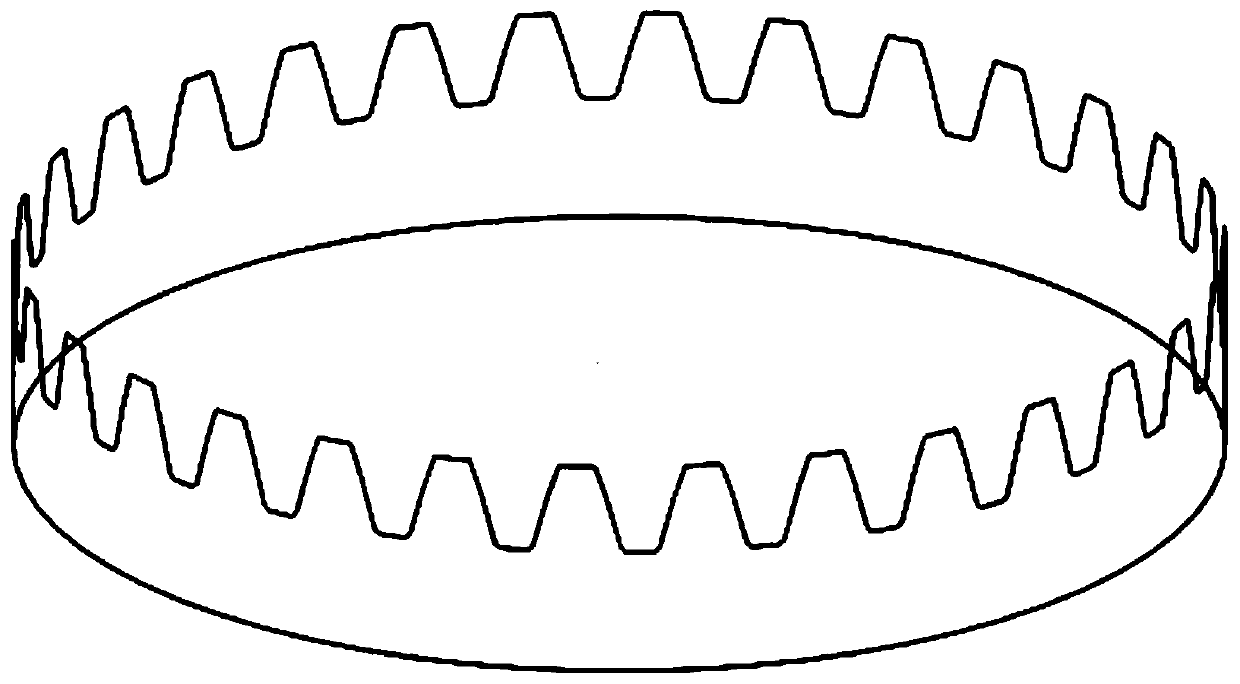

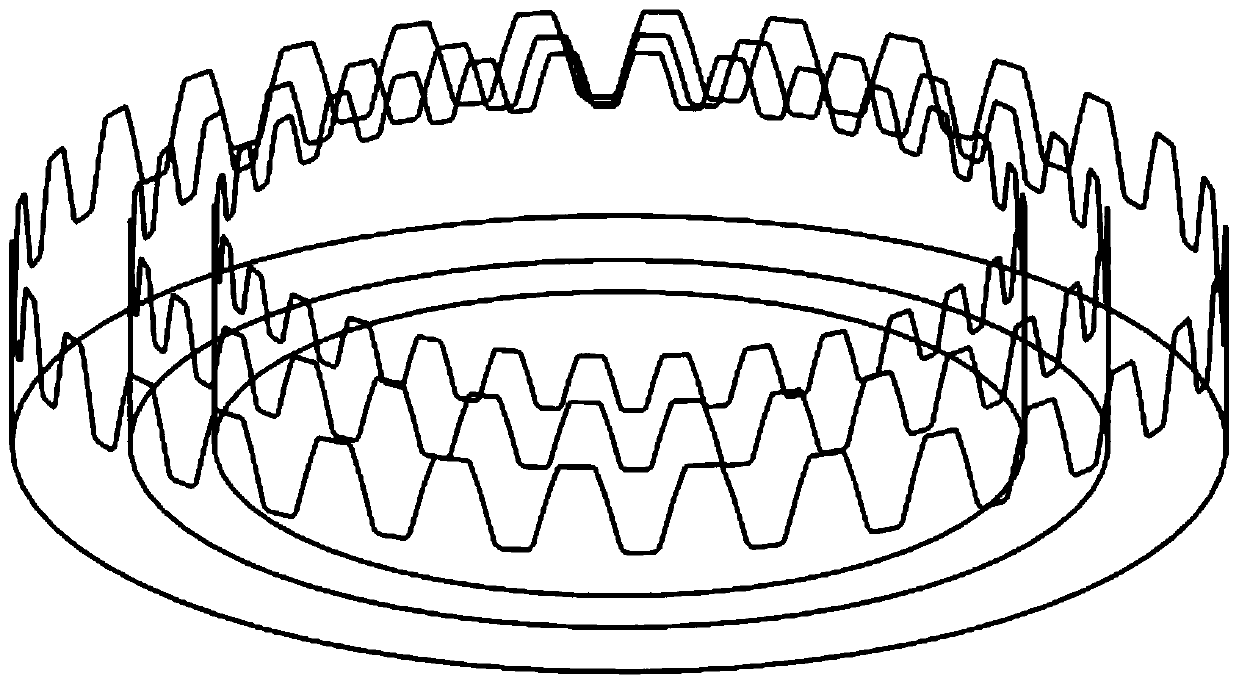

[0062] Such as figure 1 As shown, a precision forging of a bevel gear, the number of teeth z is 30, the modulus of the big end is m e is 2.5, the tooth width b is 15mm, and the sub-cone angle δ is 75°. When the cylindrical blank is directly formed, the tooth shape is difficult to fill, which affects the product quality. In order to solve this technical problem, the precision plastic forming method of the bevel gear as described below is adopted.

[0063] Blanking and billet pretreatment:

[0064] The surface of the 20CrMnTi round bar is peeled as Sawing and blanking a 15mm high bar to obtain a cylindrical blank of the required specification, and then performing phosphorus saponification lubrication and softening annealing treatment as required...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com