Multilayer casting filter

A filter and filter layer technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problem of filter strength, high temperature impact resistance, high temperature bearing capacity reduction, filter cannot withstand high temperature impact, and reduce the temperature of molten metal Filtration effect and other issues, to achieve the effects of not easy deformation and cracking, strong ability to remove impurities and slag, and improve pouring speed and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

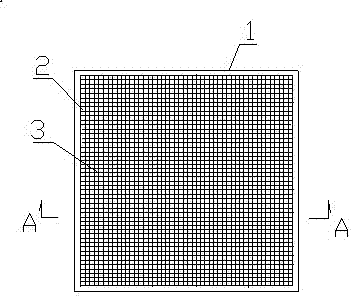

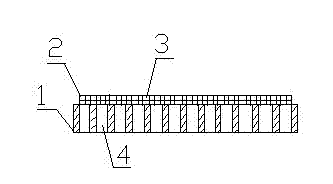

[0025] Example 1, in figure 1 and figure 2 Among them, the multi-layer casting filter sheet described in this embodiment 1 is in the shape of a cube, which is formed by bonding a square filter layer 2 and a square support layer 1 with an adhesive to form a whole, the filter layer is located above the support layer, and the filter layer The external dimensions are slightly smaller than the external dimensions of the support layer. The thickness of the filter layer is 3 mm, and the thickness of the support layer is 8 mm. There are honeycomb filter holes 3 on the filter layer. The cross-section of the filter holes is square. There are 289 filter holes per square inch (called 300 mesh in the ceramic industry), the pore diameter is 1.2×1.2 mm, the hole wall thickness is 0.3 mm, and the through-hole rate is 62.5%. According to the manufacturing process of honeycomb ceramics in the prior art, the filter layer is made of mullite ceramic material, which is pressed and formed in a str...

Embodiment 2

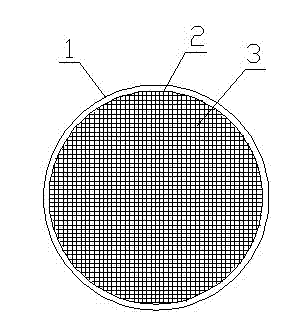

[0026] Example 2, in image 3 in, due to image 3 The cross-sectional structure of the figure 2 The cross-sectional structure is similar, thus omitting the image 3 The cross-sectional view of the cross-sectional view, the multi-layer casting filter described in the present embodiment 2 is cylindrical, and it is formed by a cylindrical filter layer 2 and a cylindrical support layer 1 bonding combination to form a whole, the filter layer is located above the support layer, and the filter The external dimensions of the layer are slightly smaller than the external dimensions of the support layer. The thickness of the filter layer is 4 mm, and the thickness of the support layer is 13 mm. There are honeycomb filter holes 3 on the filter layer. The cross-section of the filter holes is square. There are 196 filter holes per square inch (called 200 mesh in the ceramic industry), the pore diameter is 1.4×1.4 mm, the hole wall thickness is 0.4 mm, and the through-hole rate is 58.7%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com