Fixing roll assembly of electronic photography image-forming device

A technology for fixing rollers and components, which is applied in the field of fixing roller components and can solve problems such as temperature deviation and complicated manufacturing of fixing rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

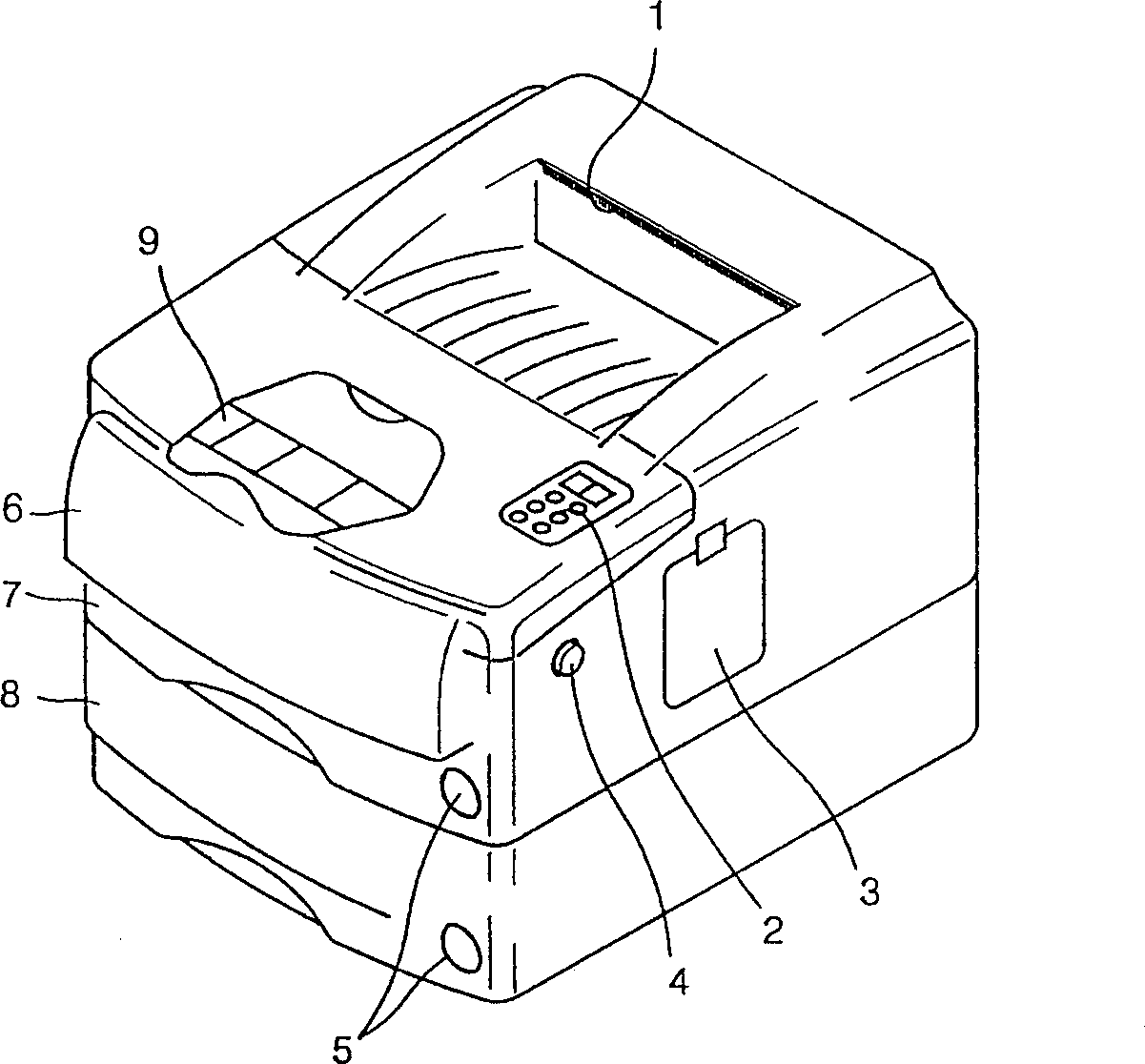

[0043] figure 1 Shown is a common electrophotographic imaging device, wherein the electrophotographic imaging device includes a paper outlet 1, a keypad 2, a control panel cover 3, a top cover open button 4, a paper display window 5, a multipurpose feeder 6, a paper cassette 7. Optional box 8 and auxiliary paper support 9.

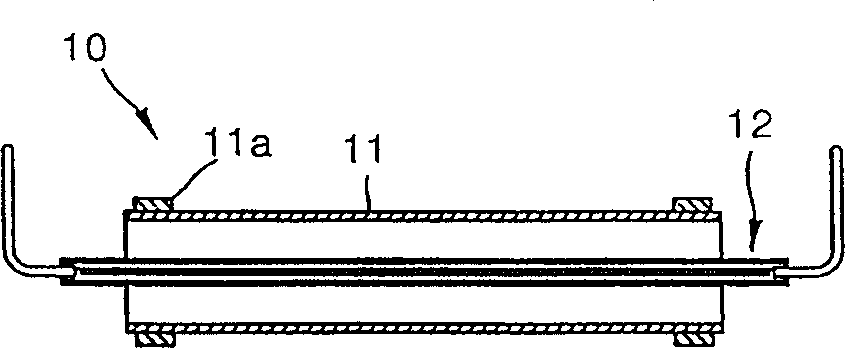

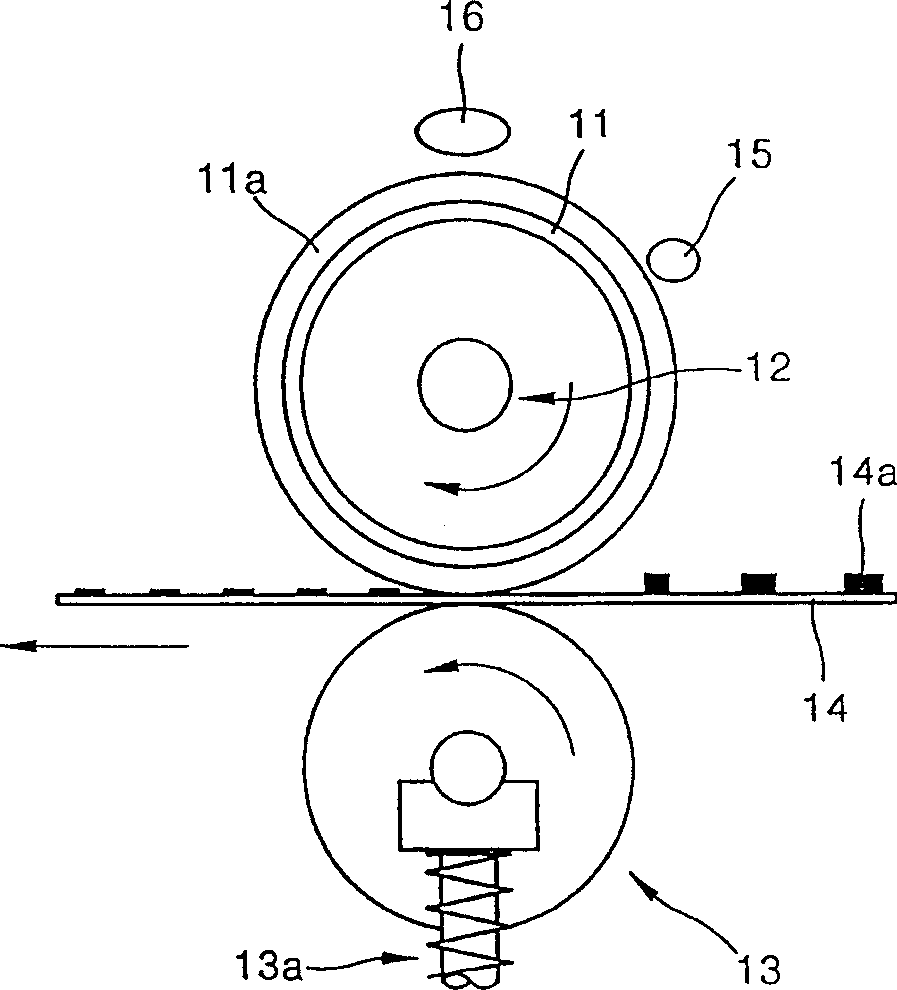

[0044] figure 2 is a sectional view of a conventional, electrophotographic image forming apparatus of a fixing roller unit using a halogen lamp as a heat source. image 3 is when figure 2 A cross-sectional view of a fixing roller in , which has a halogen lamp as a heat source and a pressure roller, when used in a general electrophotographic image forming apparatus. refer to figure 2 , the common fixing roller device 10 includes a cylindrical fixing roller 11 and a heat generator 12 , such as a halogen lamp, and the heat generator 12 is inside the fixing roller 11 . Since the outer surface of the fixing roller 11 must be able to generate heat, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com