Lining structure of rare earth electrolysis cell, and rare earth electrolysis cell

An electrolytic cell and lining technology, which is applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems of unfavorable cathode and anode structures in the electrolysis process, large-scale electrolytic rare earths, no reduction in the voltage of the rare earth electrolytic cell, and the bottom of the electrolytic cell is easily corroded. , to achieve the effect of reasonable material selection and layout of lining structure, reasonable thermal insulation design and good thermal balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

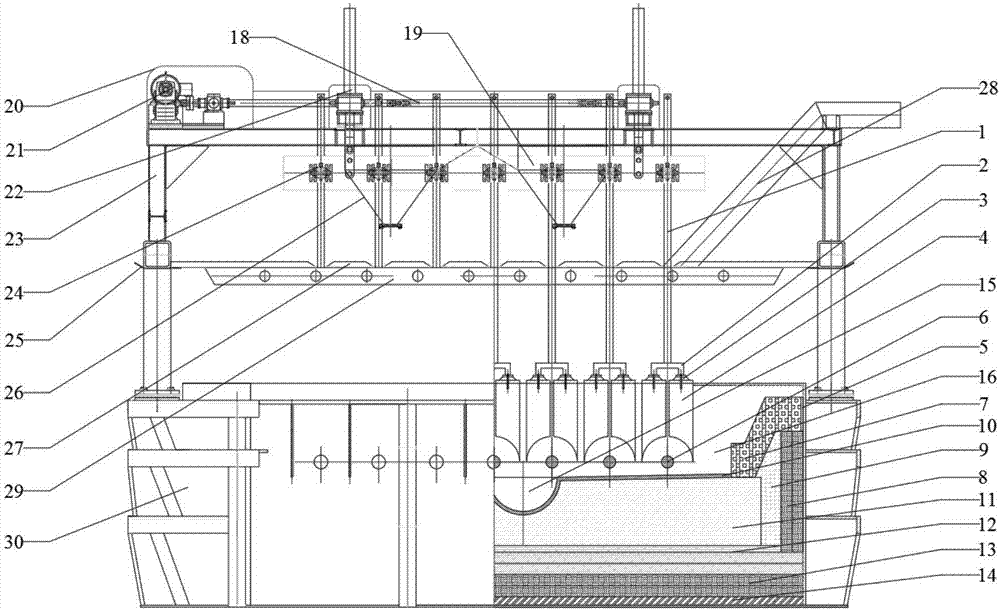

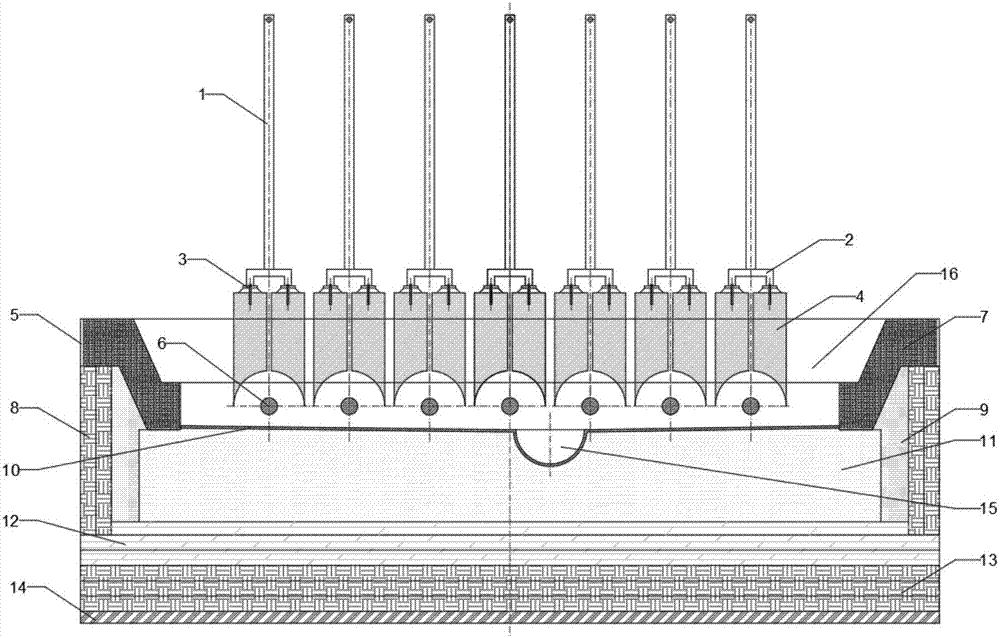

[0042]The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

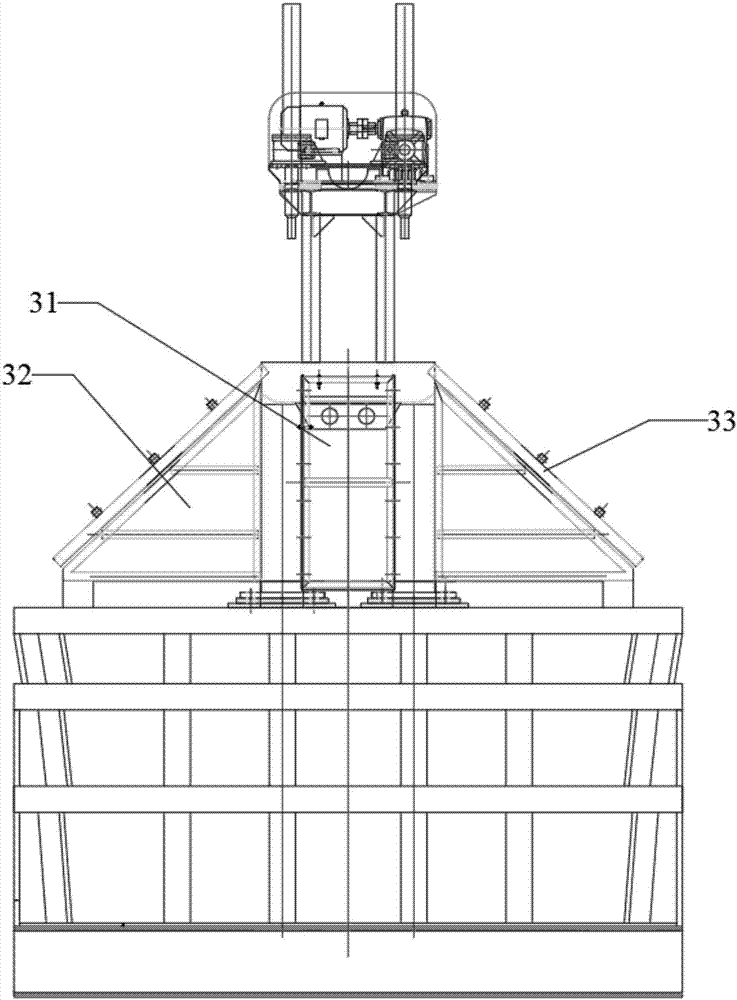

[0043] Such as Figure 1 to Figure 4 As shown, a rare earth electrolytic cell includes a cell upper structure, a cell shell 30, a bottom lining, a side lining, a cathode structure, and an anode structure. 23. A sealing system and other components, the anode lifting structure includes a lifting motor 21, a transmission guide rod 18, a lifting rod 22, a protective cover 20, a bus bar 19, a clamp 24, and a hook 25; the sealing system includes an end sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com