Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "Improve Chip Evacuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

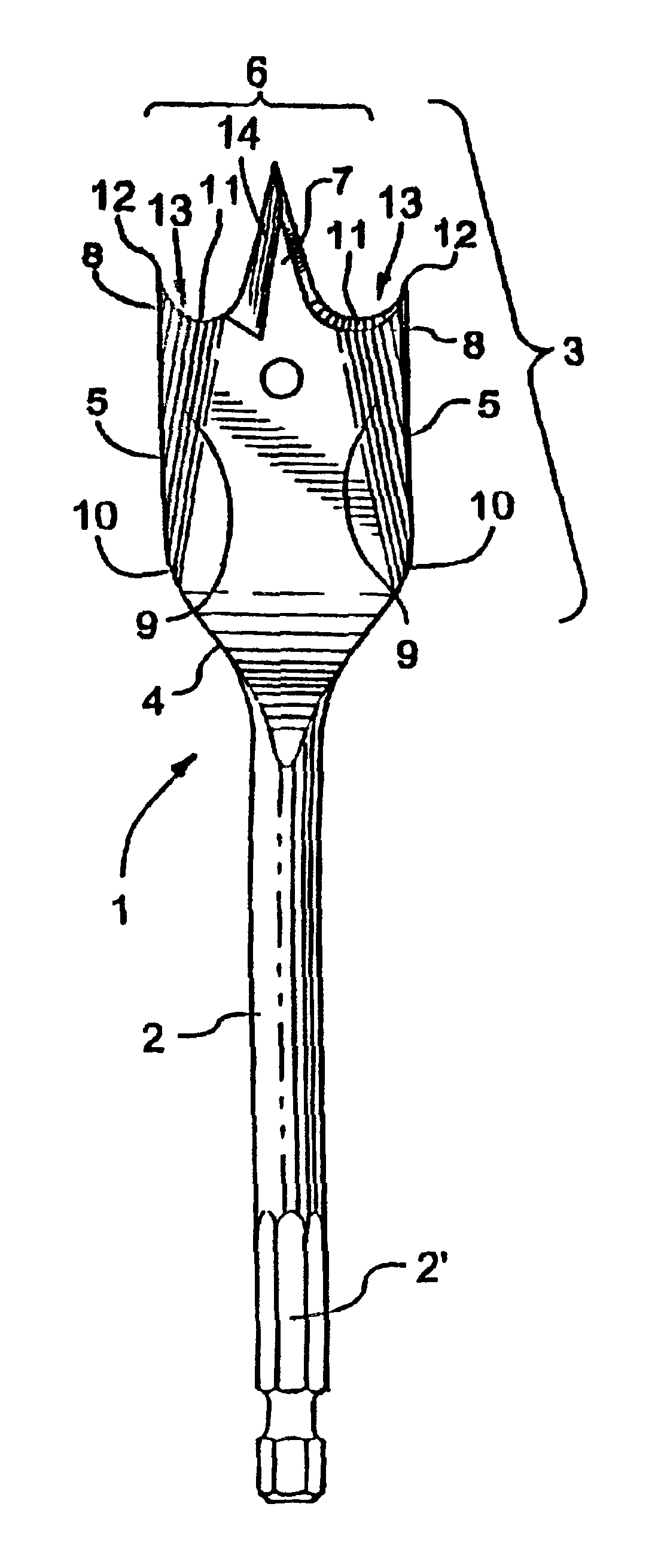

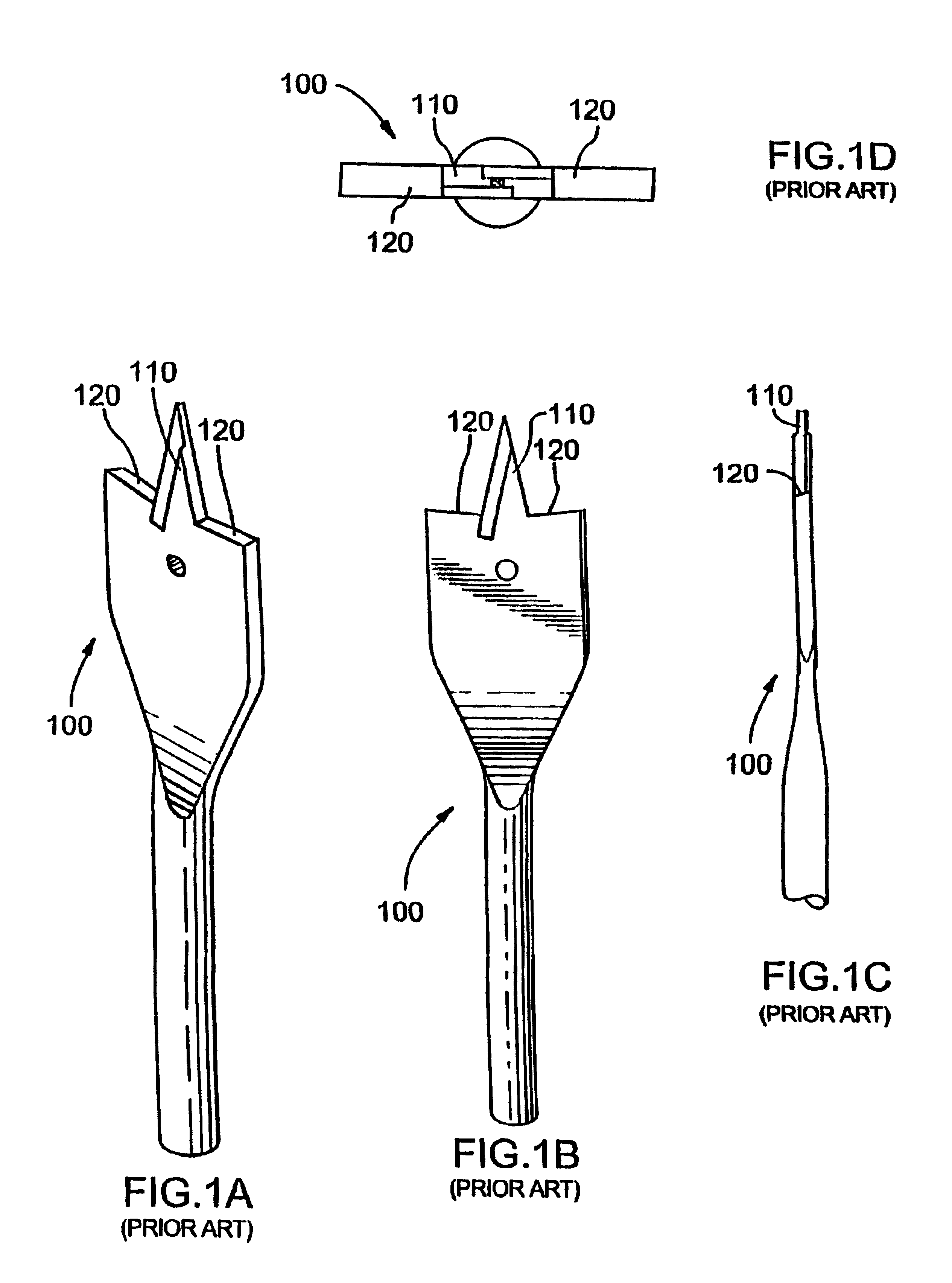

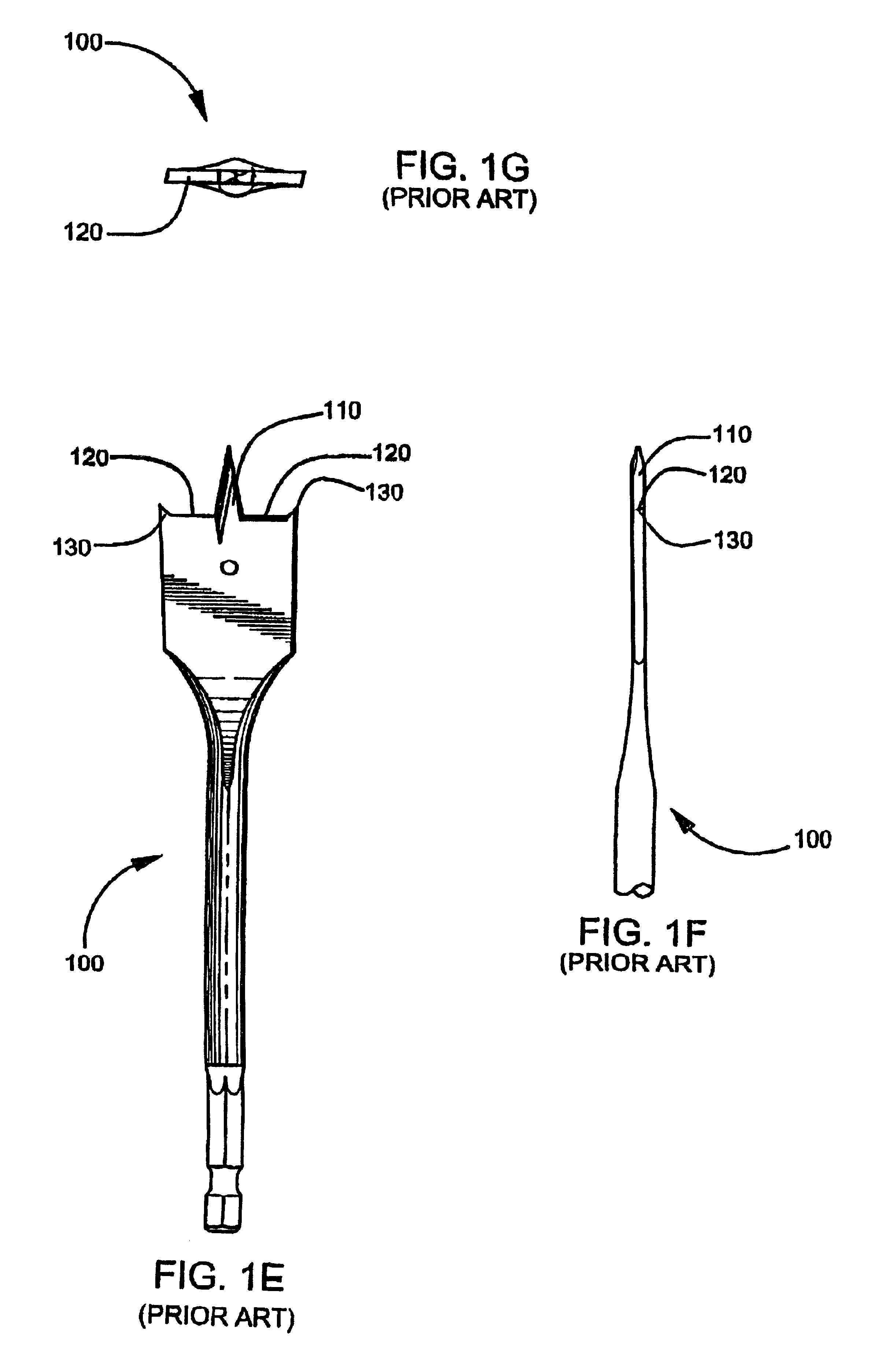

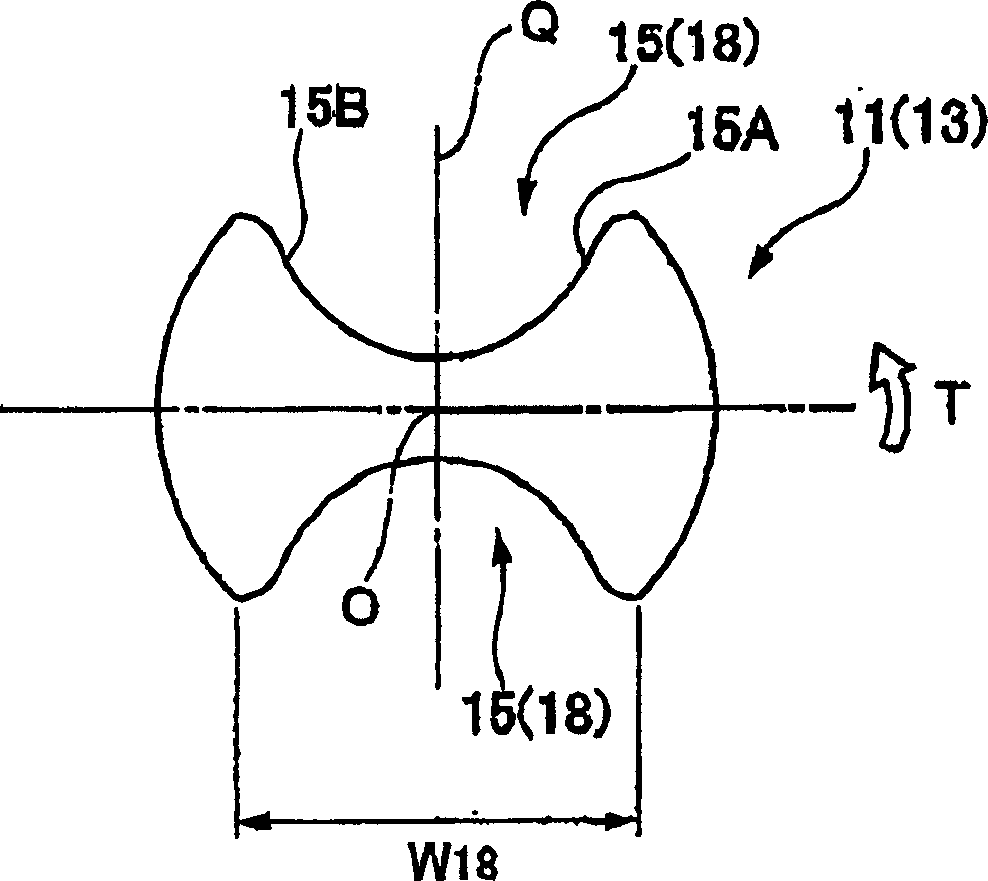

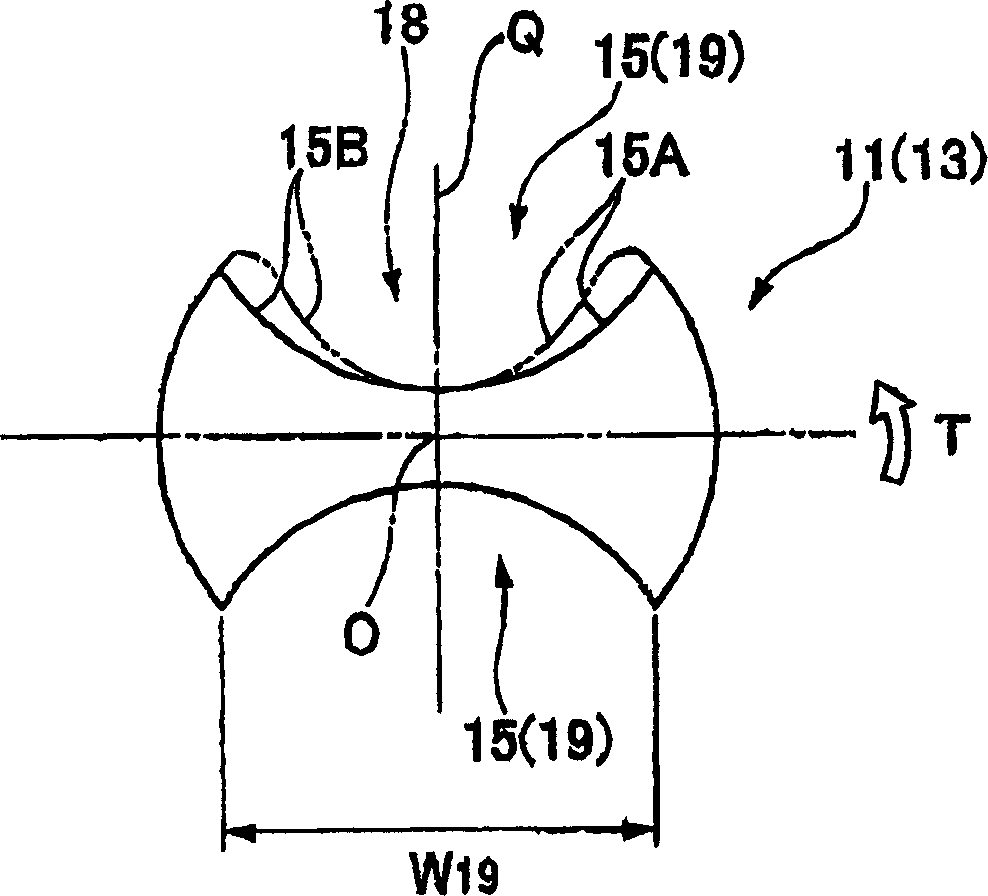

Spade bits with angled sides

InactiveUS6957937B2Improve Chip EvacuationDrawback mentionedWood turning toolsTransportation and packagingEngineeringMechanical engineering

A spade drill bit has a shaft and a spade head portion arranged on the shaft. The head portion has a rearward facing bottom edge, two longitudinal sides and a forward facing cutting edge. The cutting edge has a pointed, generally triangularly shaped tip and outer ends. The longitudinal sides of the head portion are bent along a bend in a direction of rotation of the drill bit during operation, so that the outer ends are bent forwards in the rotating direction. The bend runs from a first position at one of the longitudinal sides, closer to the bottom edge than to the cutting edge, and to a second position at the cutting edge between the outer end and the tip.

Owner:TEAM FAIR HLDG

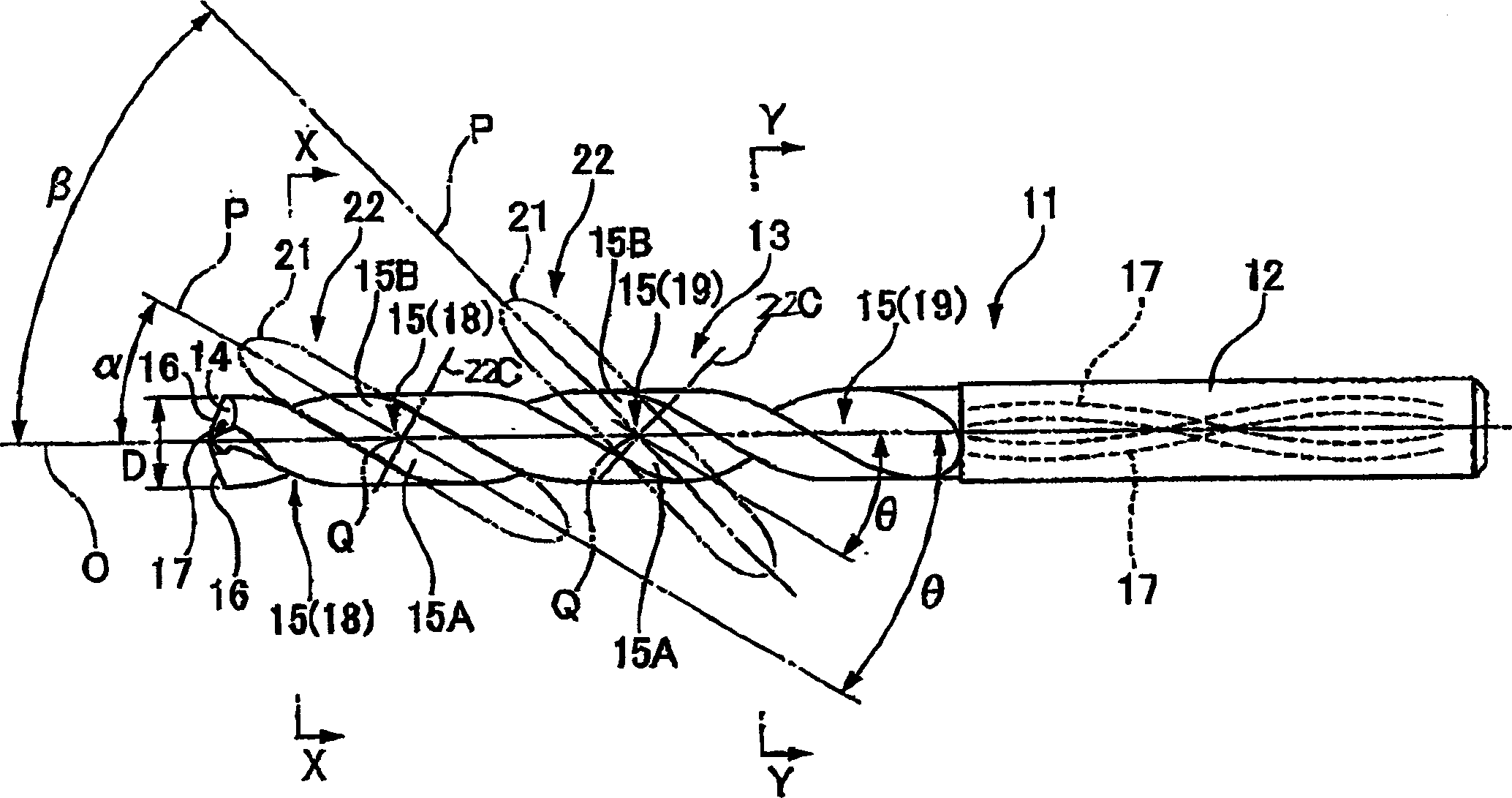

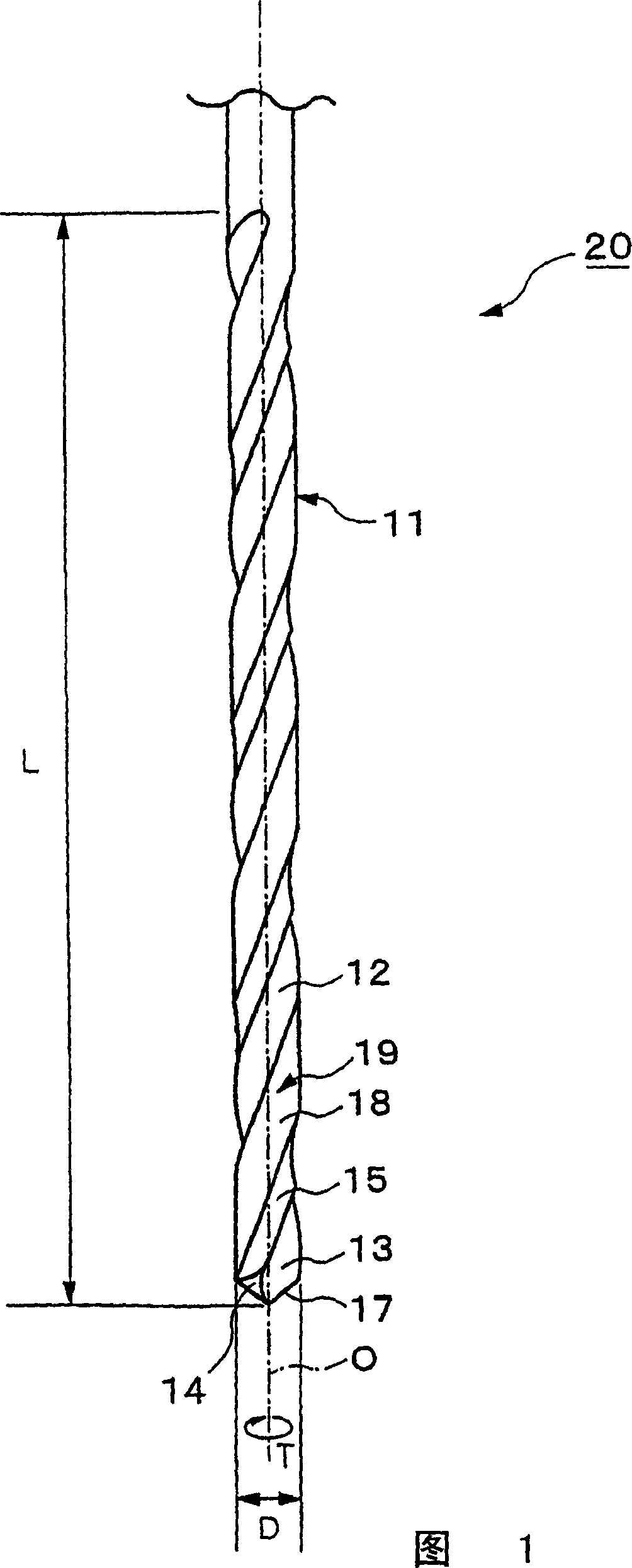

Drill and production method thereof

InactiveCN1618557AReliable dischargeImprove Chip EvacuationTransportation and packagingWorkpiecesMining engineeringStructural engineering

A drill comprising a first margin section, which is adjacent to the rear side in the direction of drill rotation of the chip discharge groove, and a second margin section, which is adjacent to the front side in the direction of drill rotation of the chip discharge groove, formed in a land section of the drilling end section; wherein a thinning section (140) is formed on the tip side of the inner wall surface of the chip discharge groove that is continuous with the inner peripheral edge of the cutting edge and extends to the land section.

Owner:MITSUBISHI MATERIALS CORP

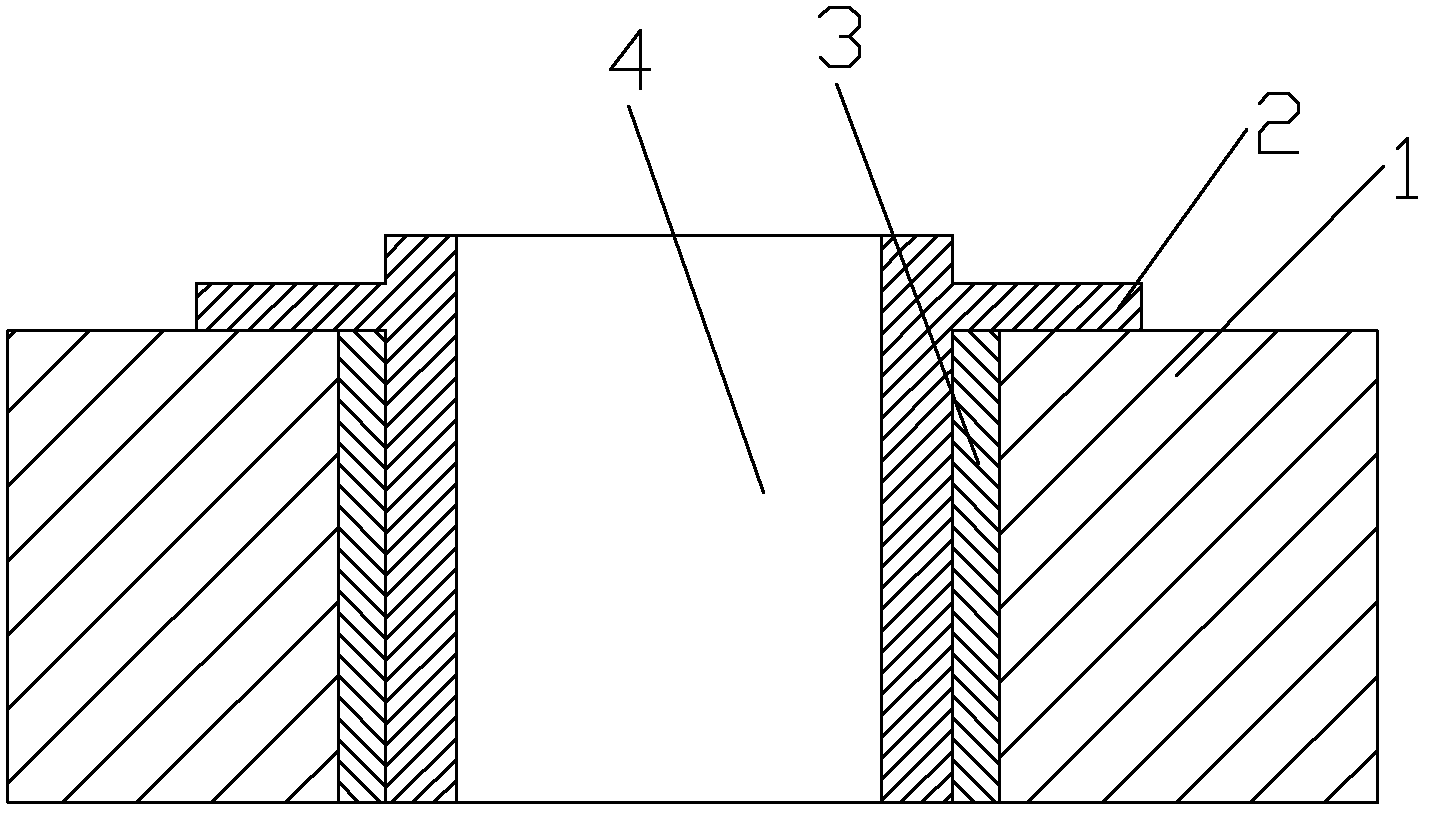

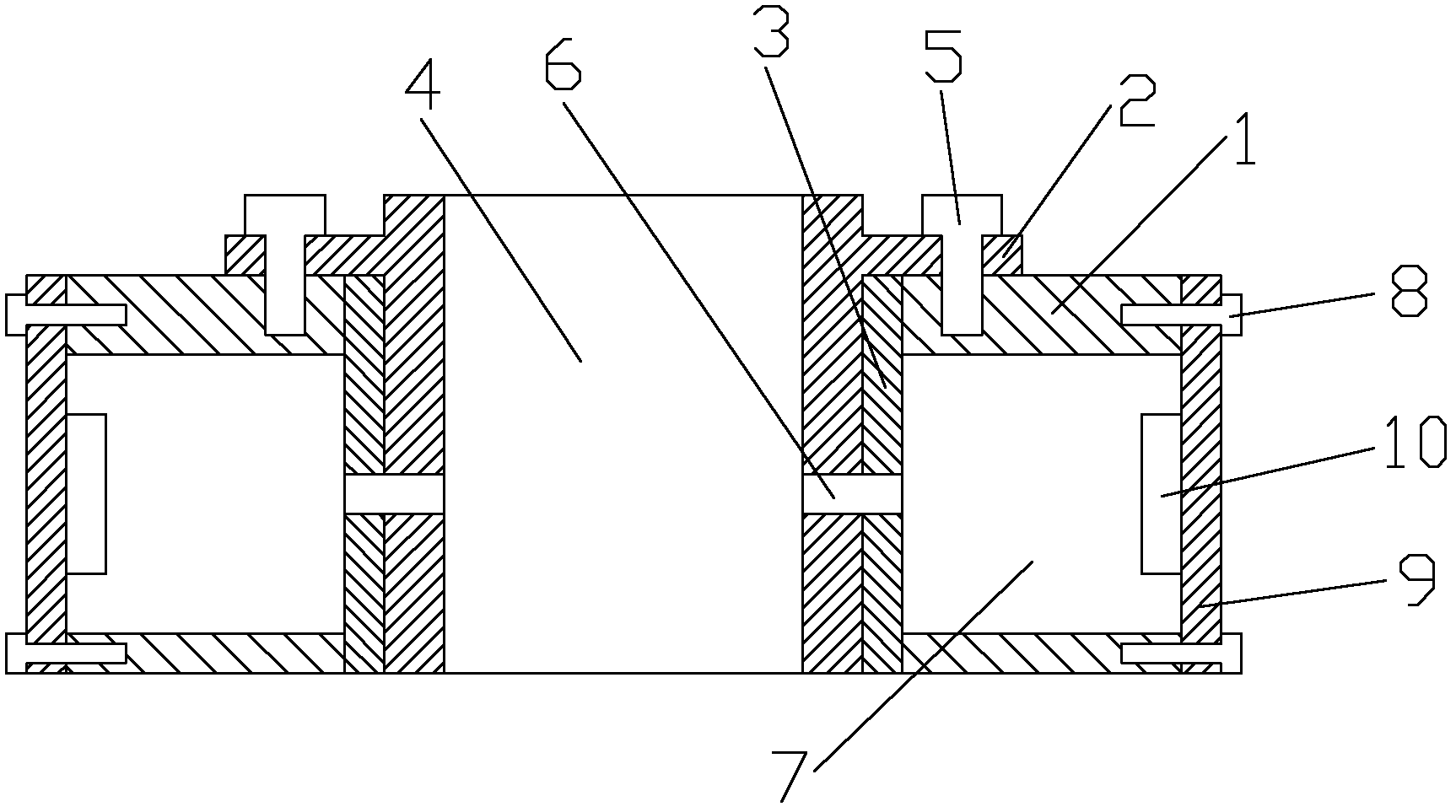

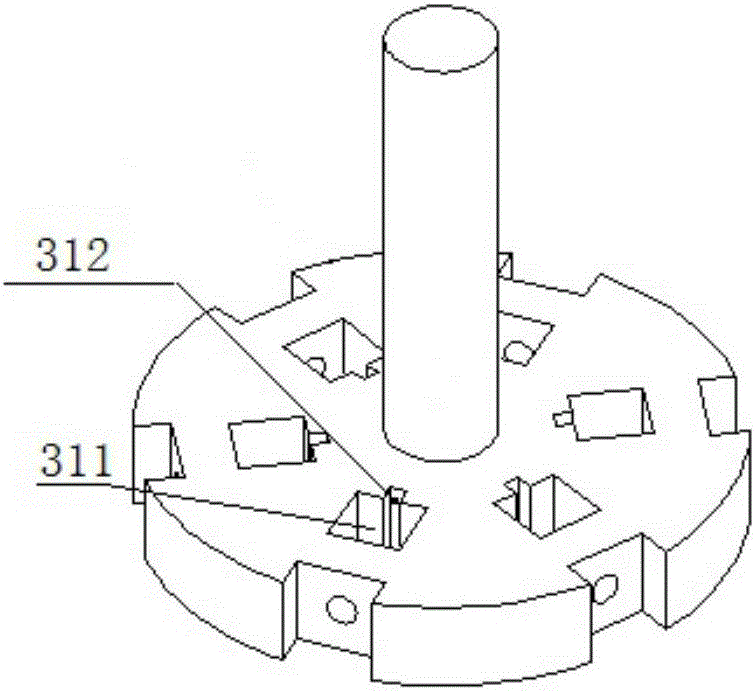

Internal liquid-flushing cluster shaping electrode for electrospark machining

ActiveCN1657208AReduce preparation timeIncrease profitElectrical-based machining electrodesEngineeringElectrical discharge machining

An internal liquid-flushing type shaping cluster electrode for electrospark machining is composed of rod-shaped electrode units and an electrode base for holding a cluster of said electrode units. Said electrode base consists of electrode fixture interface, main body and holding module. Its advantages are easy manufacture, and high utilization rate of electrode material.

Owner:SHANGHAI JIAO TONG UNIV

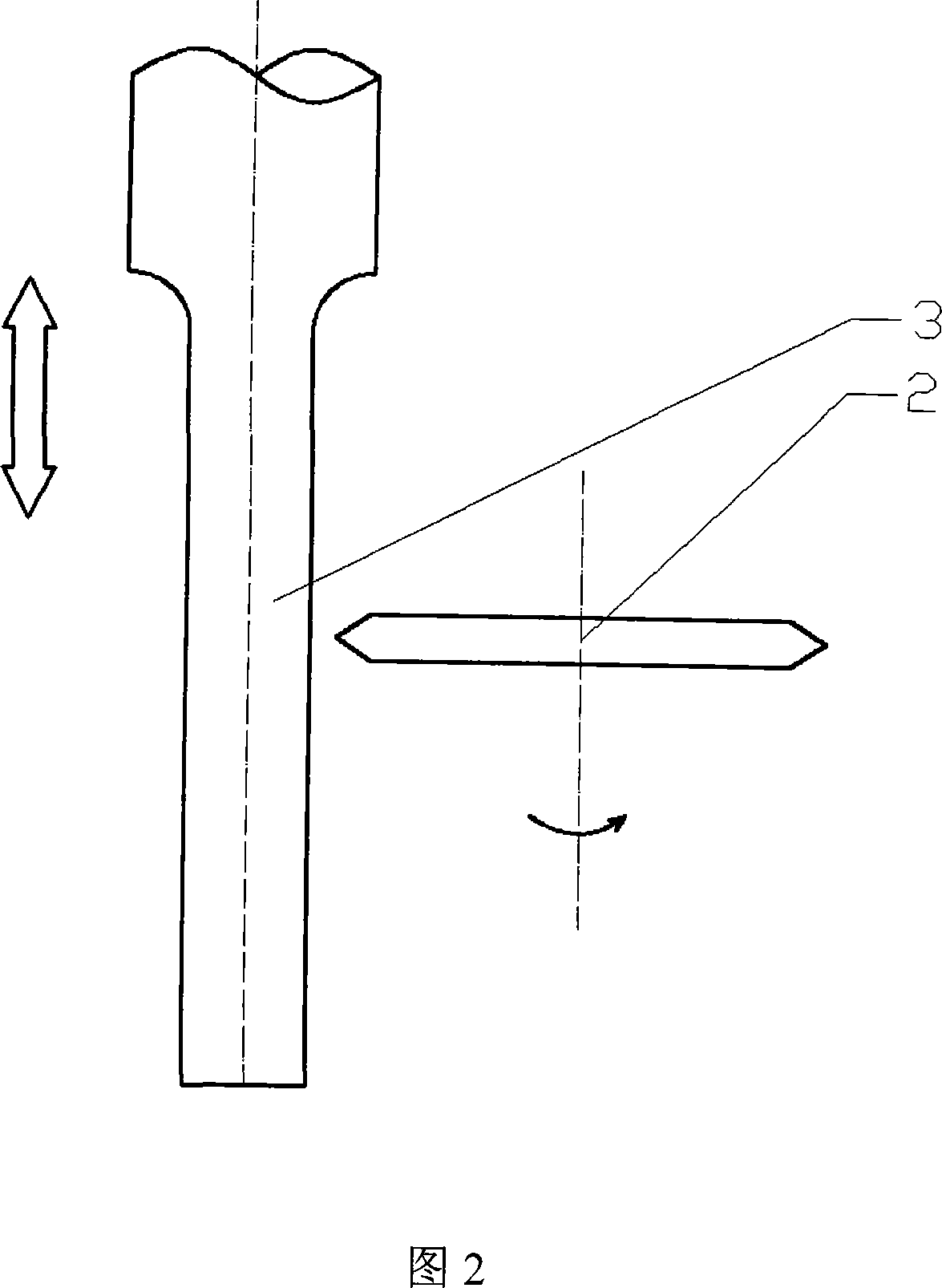

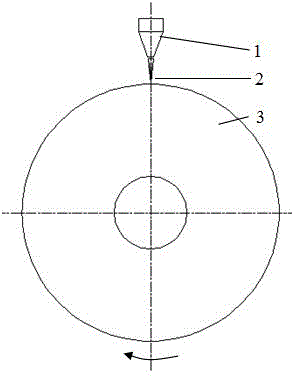

Minuteness milling tool spark-erosion machining method and electrode special for the same

InactiveCN101108433AOvercome the disadvantage of easy disconnectionIncrease energy densityElectrical-based machining electrodesCircular discMilling cutter

The invention discloses an anu milling cutter electrical sparkle process method and the special electrode, which belongs to the anu process filed. The method is characterized in that: the invention adopts formed anu opening groove round plate electrode, which utilizes high speed main axle to drive the anu opening groove round plate electrode rotate, process a cutter and a cutting blade of the anu milling cutter by the method of discharging milling way at the rotating outer edge; wherein, according to the diameter and length of the cutter of the anu milling cutter, ensure the discharge index of electrical sparkle process. The process method in the invention is simple, which can change the structure of the cutter conveniently, and achieve small diameter of the cutter, at the same time, the process surface has good quality and high material removing rate, the manufacture cost of the cutter is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Miniature PVD coat miller cutter for PCB, and making method thereof

InactiveCN103737092AReduce coefficient of frictionAnti-oxidation temperature is highMilling cuttersVacuum evaporation coatingMilling cutterWear resistant

The invention discloses a miniature PVD coat miller cutter for PCB, and a making method thereof. The miniature PVD coat miller cutter for PCB comprises a substrate and one or more layers of a hard and wear-resistant coat deposited on the substrate through a physical vapor deposition process; the hard and wear-resistant coat is an MeCxNyOz coat, Me is one or more of Al, Cr, Ti, Zr, Si, Hf, Nb, Ni, W, Ta, B, V, Y and Cu, and x+y+z is 1; and the total thickness of the one or more layers of the coat on the substrate is 0.1-10mum. The substrate is made by using a cemented carbide material, a ceramet material, a ceramic material, a cubic boron nitride based material or a high-speed steel material. By improving the structure of the PVD coat in the invention, a processing problem that printed circuit boards are difficult to process is overcome, and a problem that the service life of a common miniature milling cutter is short is prolonged.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

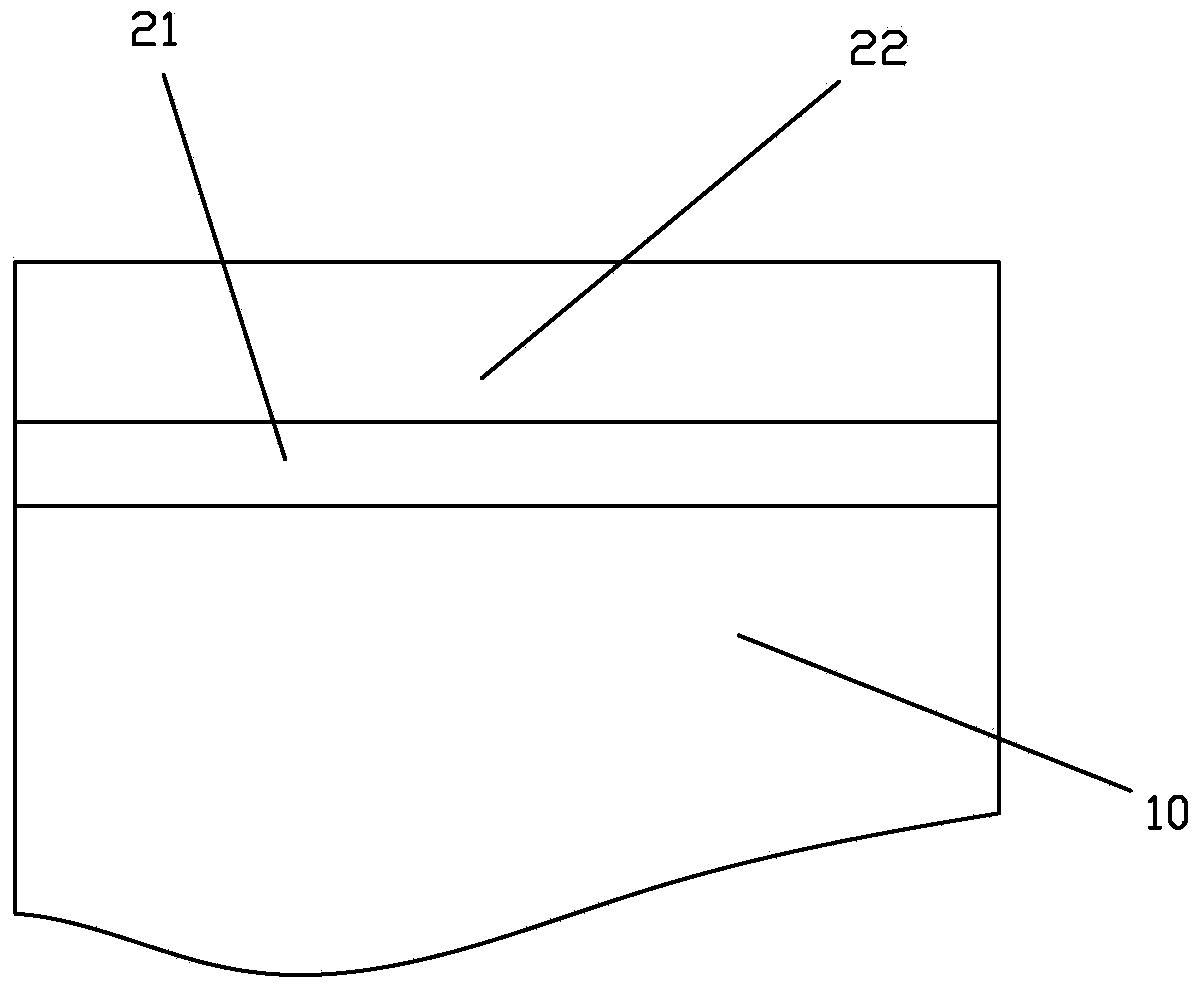

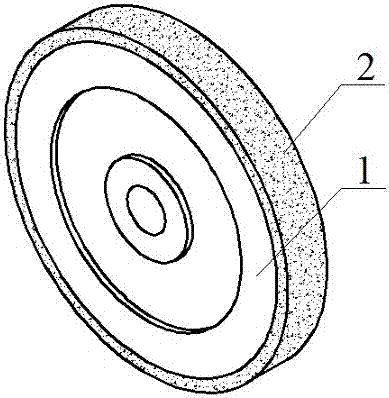

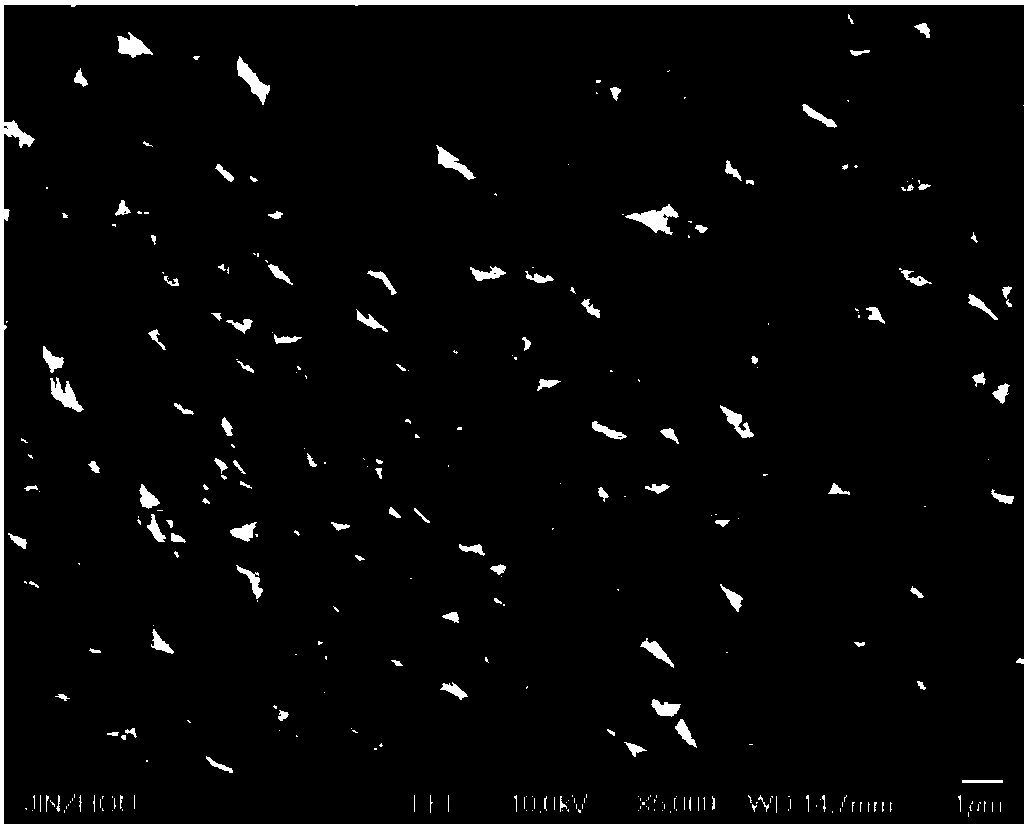

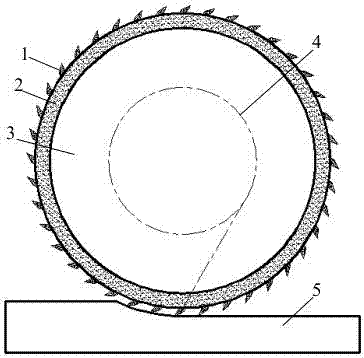

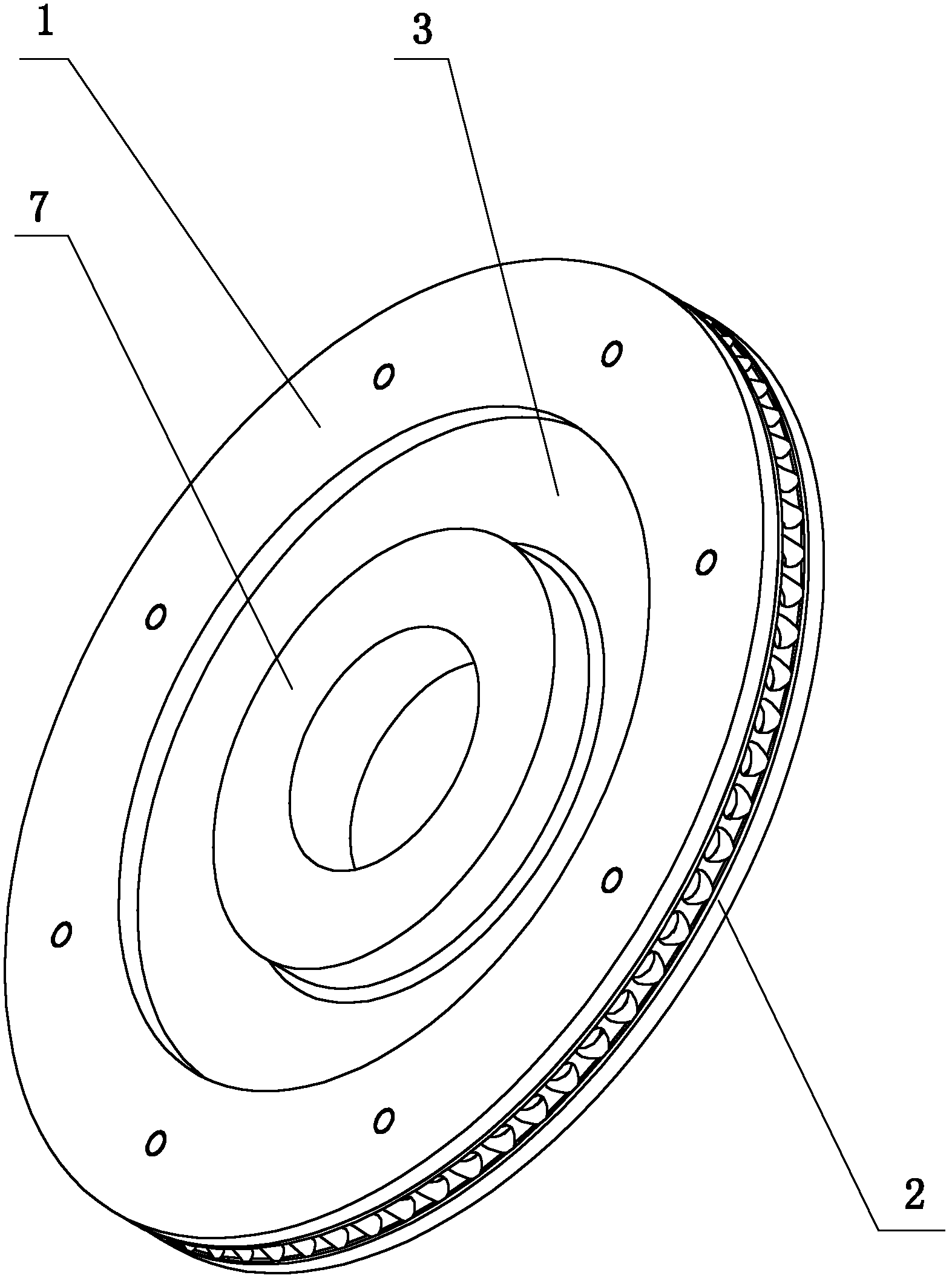

Manufacturing method of electroplated grinding wheel of ordered structure

The invention discloses a manufacturing method of an electroplated grinding wheel of an ordered structure. The method includes: adopting a pulse laser beam to process a fine spiral groove with the pitch of hundreds of micrometers and the notch size of dozens of micrometers in the working surface of the outer annulus of a grinding wheel base body made of metal, filling the groove with epoxy resin, and enabling the metal and the epoxy resin on the working surface of the outer annulus of the grinding wheel base body to be in spiral regularly-spaced layout; then electroplating the working surface of the outer annulus of the grinding wheel base body with abrasive grains by adopting an electroplating method. Since the groove is filled with the non-conductive epoxy resin, the region cannot be electroplated with the abrasive grains. By the steps, the electroplated grinding wheel with the abrasive grain layer and the epoxy resin being in spiral regularly-spaced layout can be obtained. The manufactured electroplated grinding wheel of the ordered structure is in favor of solving the problems that the grinding wheel is blocked easily during grinding and grinding fluid cannot enter the grinding region easily, workpieces can be prevented from being burnt, and the grinding quality is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

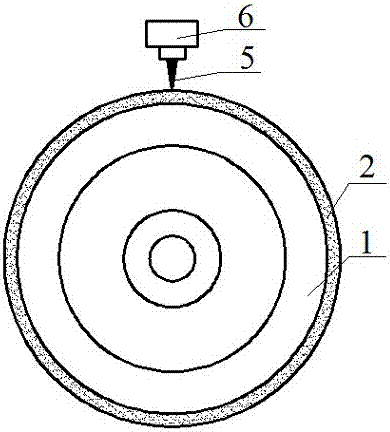

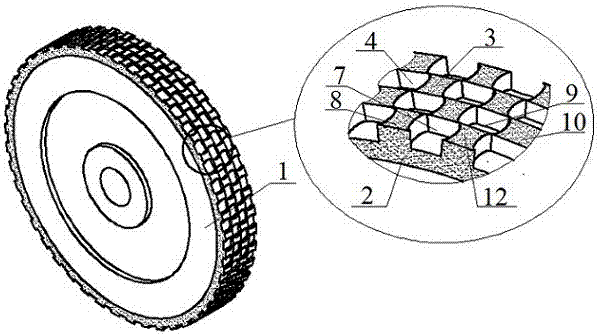

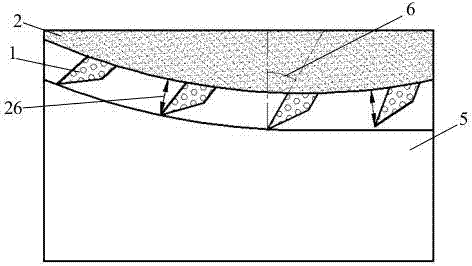

CVD diamond grinding wheel with ordered micro-structured surface and making method thereof

ActiveCN107962510AIncrease the number of effective sharpeningImprove surface qualityBonded abrasive wheelsGrinding devicesMaterial removalGas phase

The invention discloses a CVD diamond grinding wheel with an ordered micro-structured surface and a making method thereof. The grinding wheel is characterized in that a layer of diamond film is deposited on the outer circumferential face of a grinding wheel hub, a large number of staggered in-order micro grinding units are machined on the whole outer circumferential face of the diamond film, and the top ends of the grinding units are in kidney shapes. The making method is characterized in that through the chemical vapor deposition that is CVD, the diamond film is deposited on the outer circumference face of the grinding wheel hub, a pulse laser beam is adopted to machine the large number of micro grooves with the same geometric dimensioning in the outer circumference face of the whole diamond film, and the large number of micro grinding units are formed; the grinding units are arranged in a staggered and in-order manner, the top face of each grinding unit is in a kidney shape, according to the grinding wheel, the effective sharpening number of the grinding wheel during grinding can be improved, the chip formation efficiency and the surface material removal rate are improved, the cutting performance is improved, the surface machining quality and the cutting efficiency can be improved, the holding force of the grinding wheel hub to the grinding units can be increased, and the service life of the grinding wheel can be obviously prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

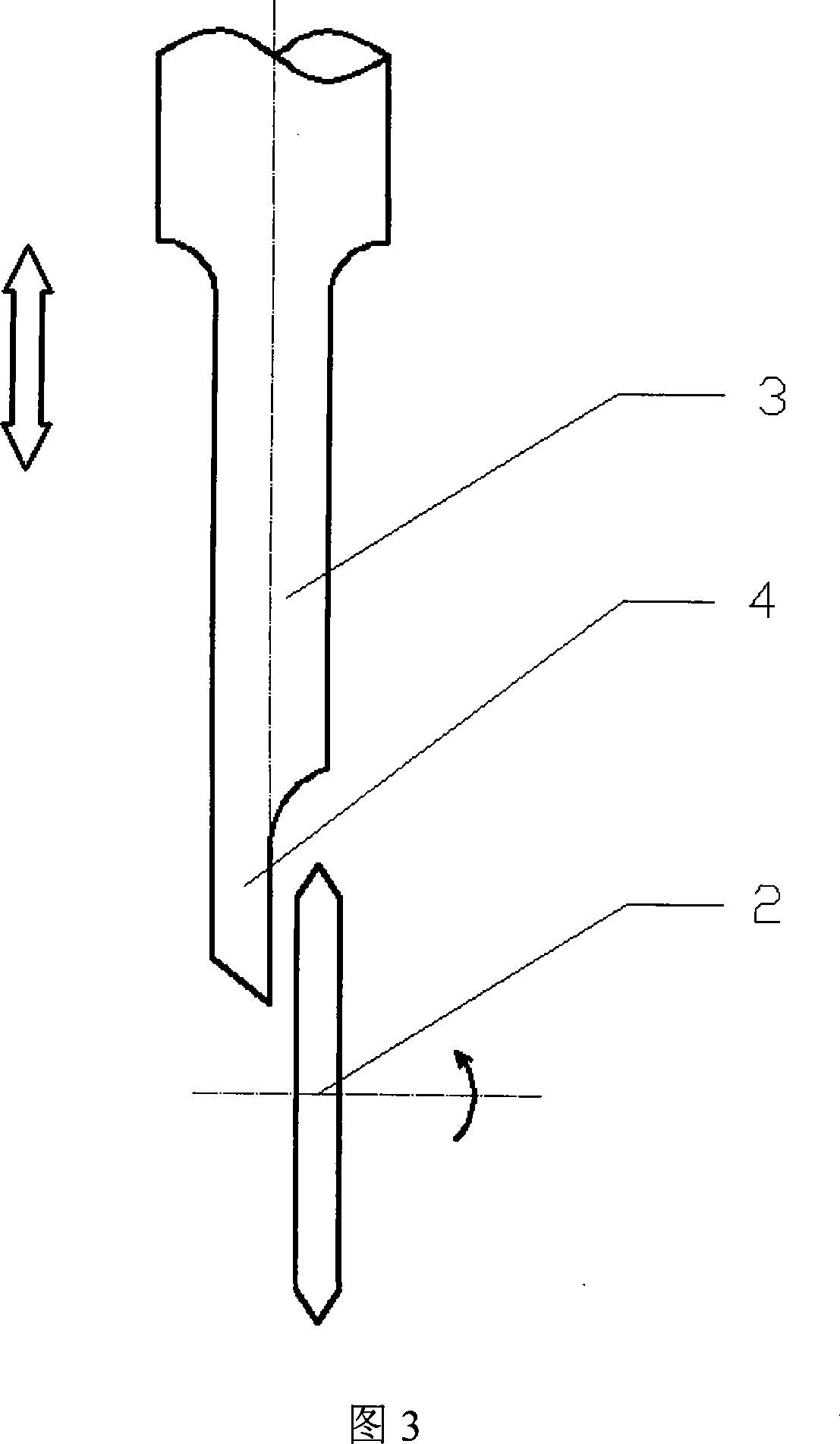

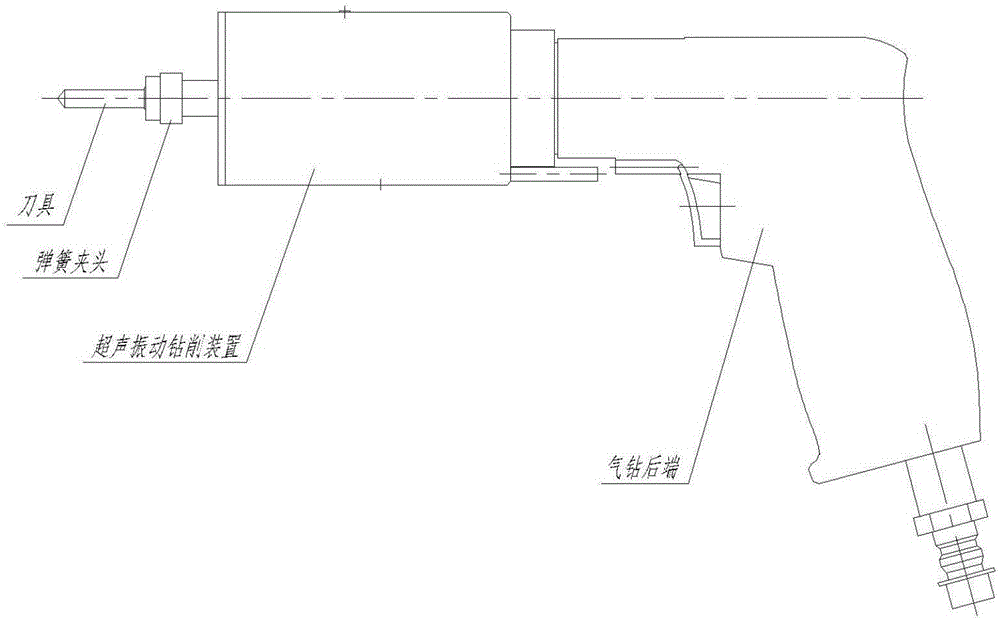

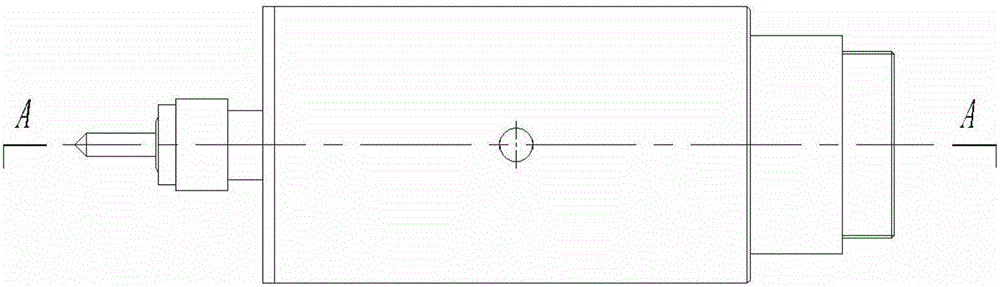

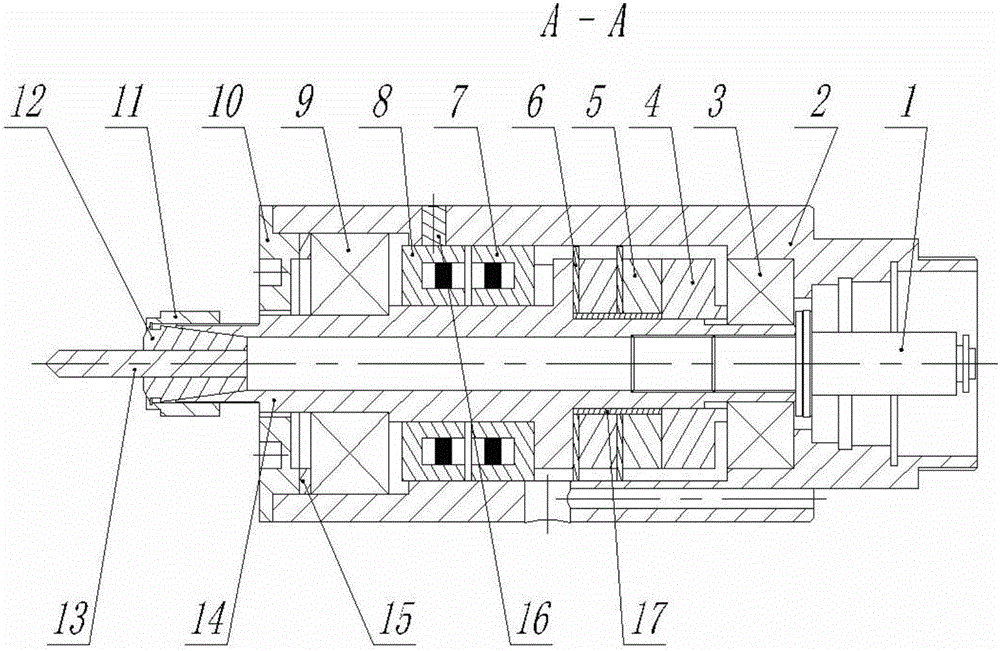

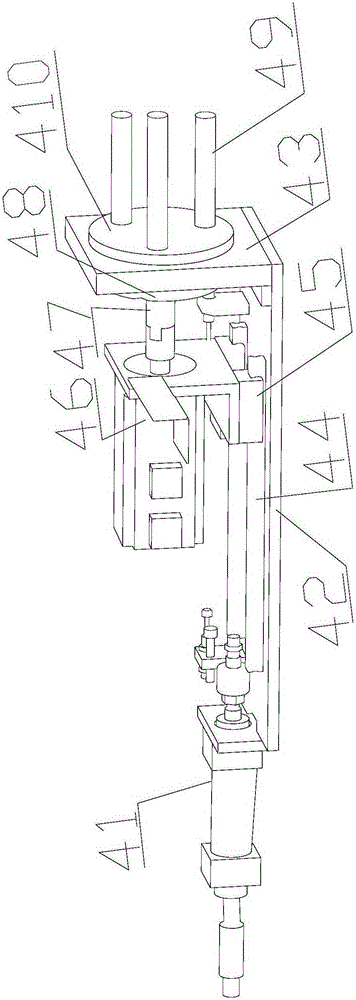

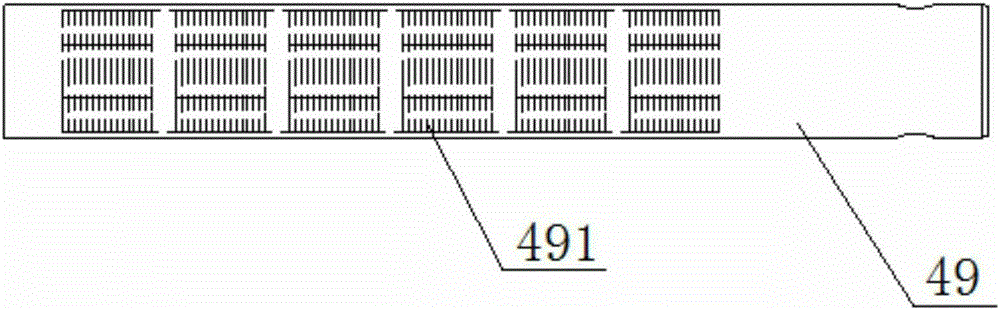

Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

InactiveCN106825679AKeep it workingImprove processing qualityCircuit arrangementsPortable drilling machinesElectric power transmissionSmall amplitude

The invention discloses an ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission. The ultrasonic vibration pneumatic drill comprises a rotary wireless electric power transmission assembly, an ultrasonic transduction assembly, an amplitude-change pole, a spring chuck assembly and a connecting assembly, wherein the rotary wireless electric power transmission assembly is used for realizing electric power transmission between two mechanisms rotating oppositely and comprises a wireless electric power transmission primary unit and a wireless electric power transmission secondary unit; the ultrasonic transduction assembly is used for converting ultrasonic-frequency electric signals into ultrasonic-frequency mechanical vibration; the ultrasonic vibration amplitude-change pole is used for amplifying small-amplitude mechanical vibration into large-amplitude mechanical vibration to meet requirements of ultrasonic vibration drilling machining; the spring chuck assembly is used for clamping tools; the connecting assembly is used for connecting ultrasonic vibration drilling parts with the rear end of the pneumatic drill so as to realize power transfer and electric power transmission. Ultrasonic vibration is applied to the traditional drilling machining process, and a combined machining mode of coupling of ultrasonic vibration and traditional drilling motion is formed, so that machining quality is effectively improved and machining efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Minitype diamond-tooth milling cutter and processing technology thereof

InactiveCN102120275AGuaranteed milling strengthImprove sharpnessMilling cuttersEngineeringMilling cutter

The invention belongs to the field of milling cutters, in particular to a minitype diamond-tooth milling cutter which is used for processing the minitype slotted hole of a multilayer printed wiring board, and a processing technology thereof. On the basis of the prior art, a step of semi-accurately cutting a spiral groove is added in the processing technology, and thus the cutting mill with the minimum external diameter can be favorably processed. The invention also provides a minitype diamond-tooth milling cutter which is suitable for processing the minitype slotted hole of the multilayer printed wiring board; the helical angles of the left spiral groove and the left spiral groove are respectively 18-22 degrees; and the external diameter phi d of the head of the milling cutter is 0.4-0.7mm. Under the condition that the external diameter of the milling cutter is smaller, a proper spiral angle is chosen; force borne by the head of the milling cutter is reduced while chip removal space is reasonably designed; the phenomenon of excessive wearing or'snapping' because force borne by the head of the milling cutter is too big is avoided; and the milling cutter still has bigger milling strength. The minitype diamond-tooth milling cutter and the processing technology thereof can be used for processing minitype slotted holes.

Owner:ZHEJIANG RICHVERTEX PRECISION TOOLS

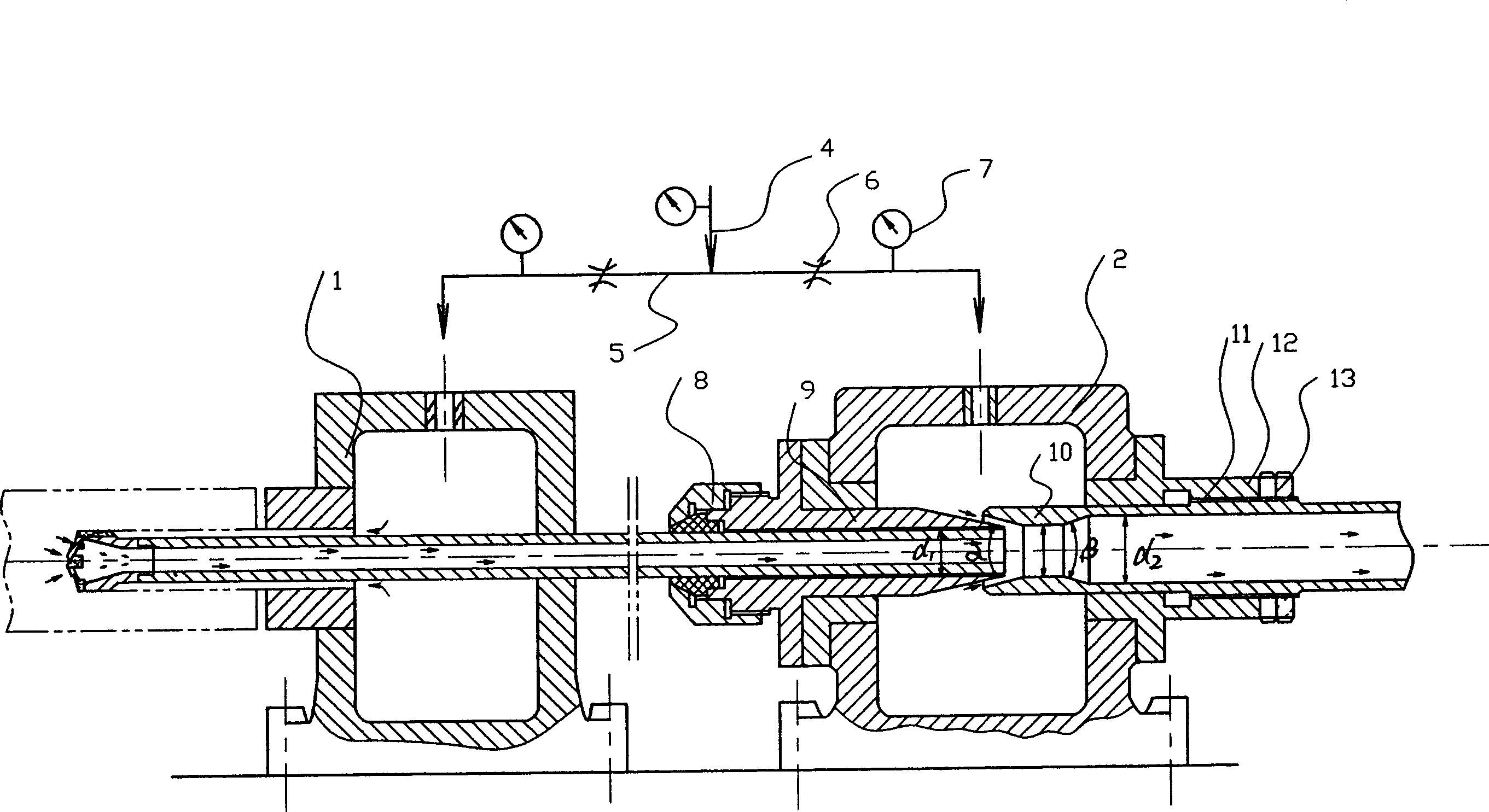

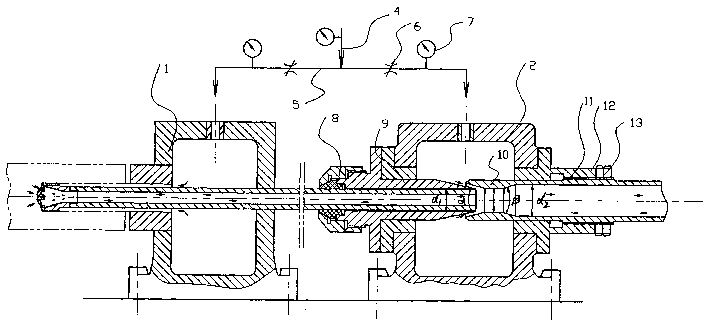

Power enlargement type apparatus for removing dust of ejecting drilling

InactiveCN1393312AGood Chip EvacuationGood chipping effectBoring/drilling componentsBoring/drilling machinesFuel tankDrill

A separate-regulatable powder-boosting type drilling chip extracting device for ejection drill is composed of oil delivering unit and drilling chip extractor. The sealed oil tanks for the said oil delivering unit and drilling chip extractor are respectively connected to the oil trank of oil pump via their branch pipes with throttle valves. Regulating of throttle valves can make the device be in optimal state to extract the drilling chip.

Owner:王峻

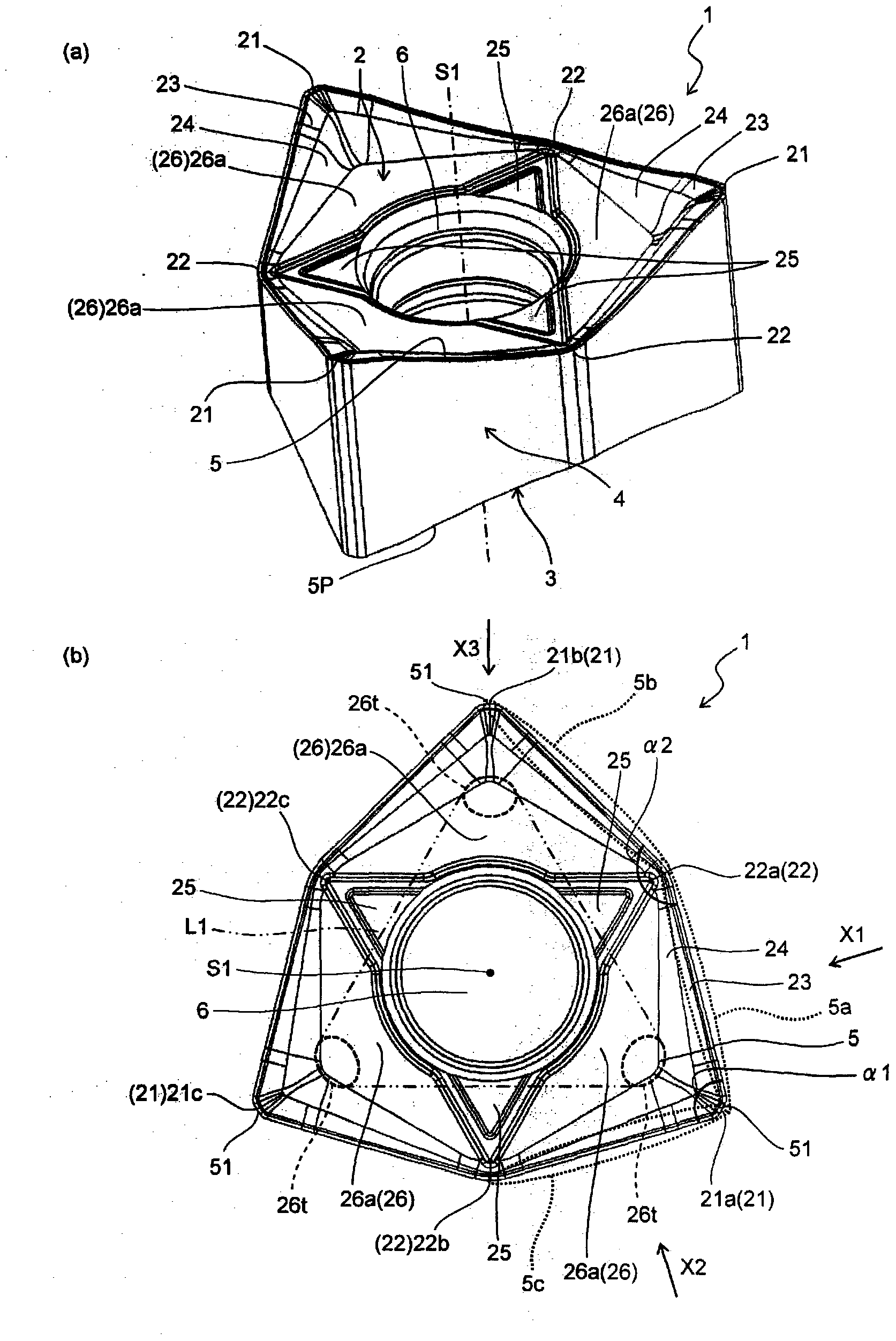

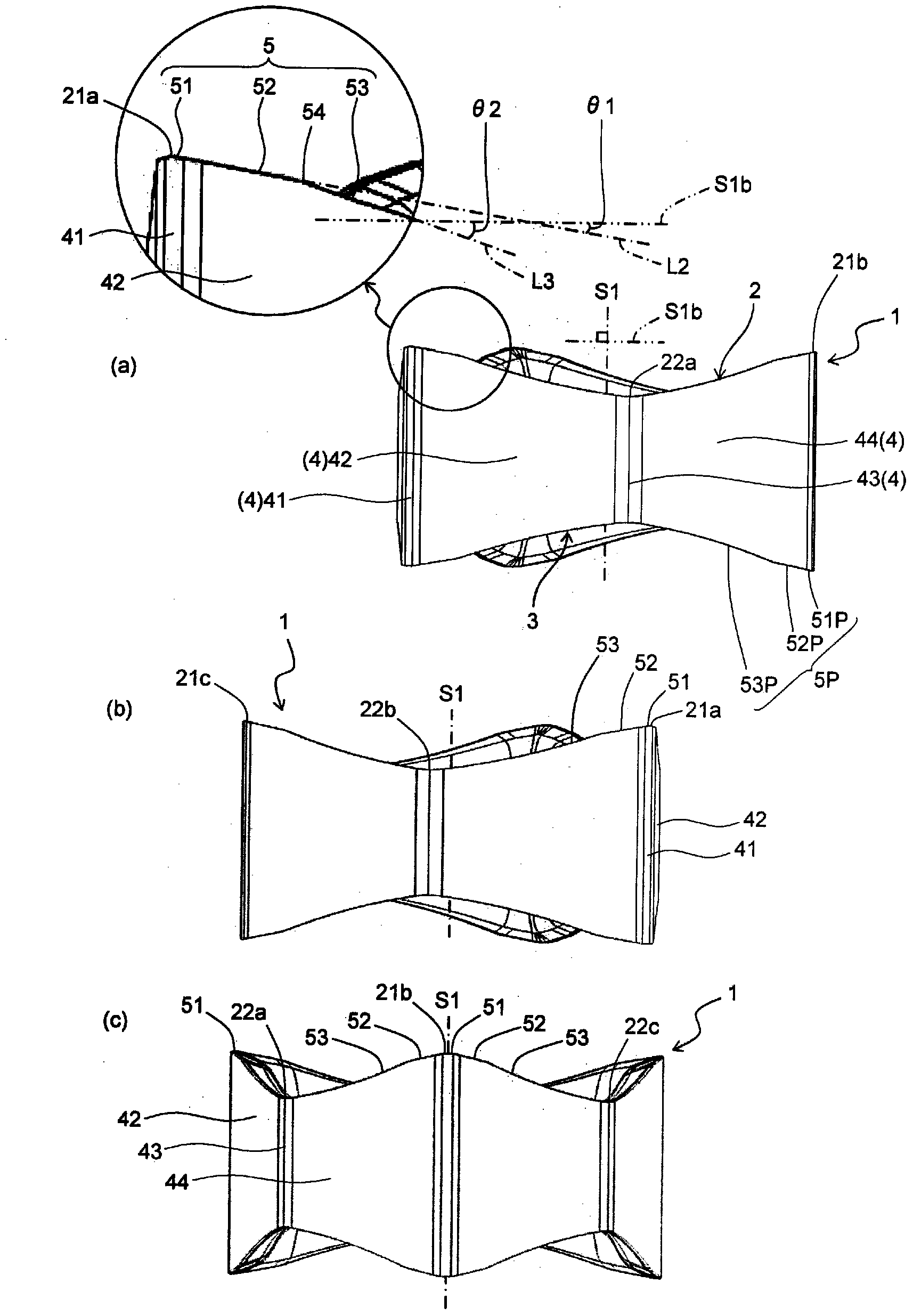

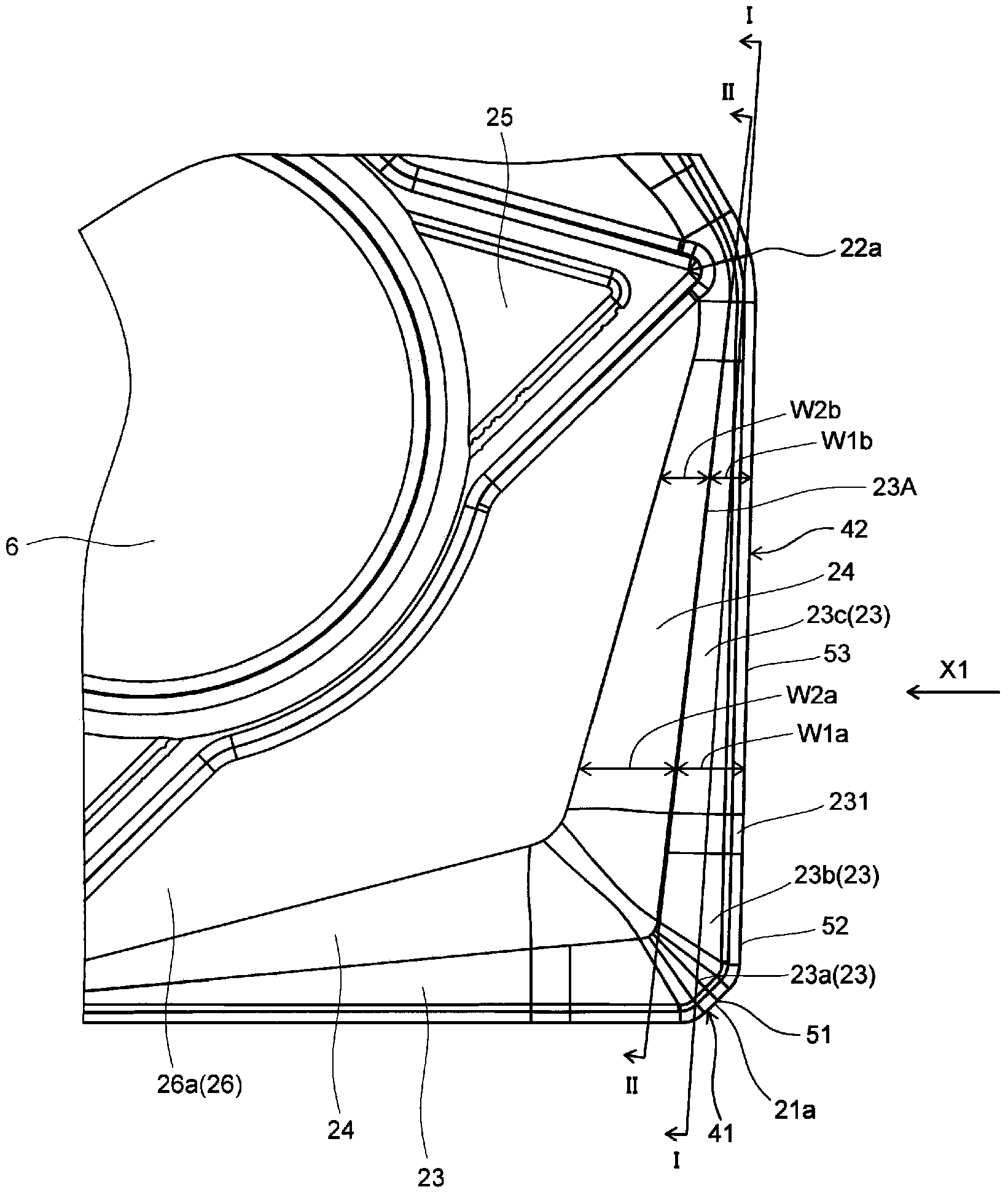

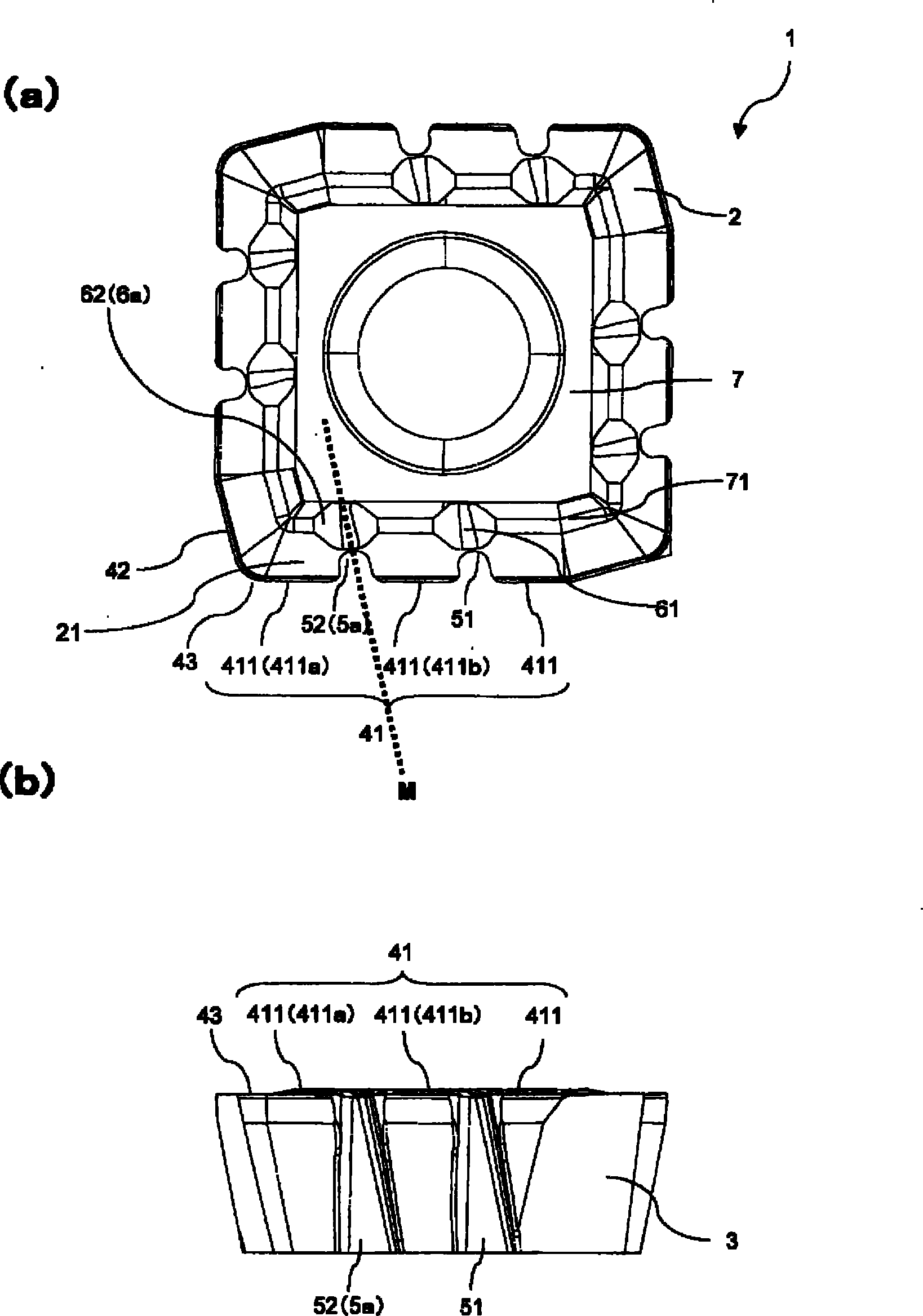

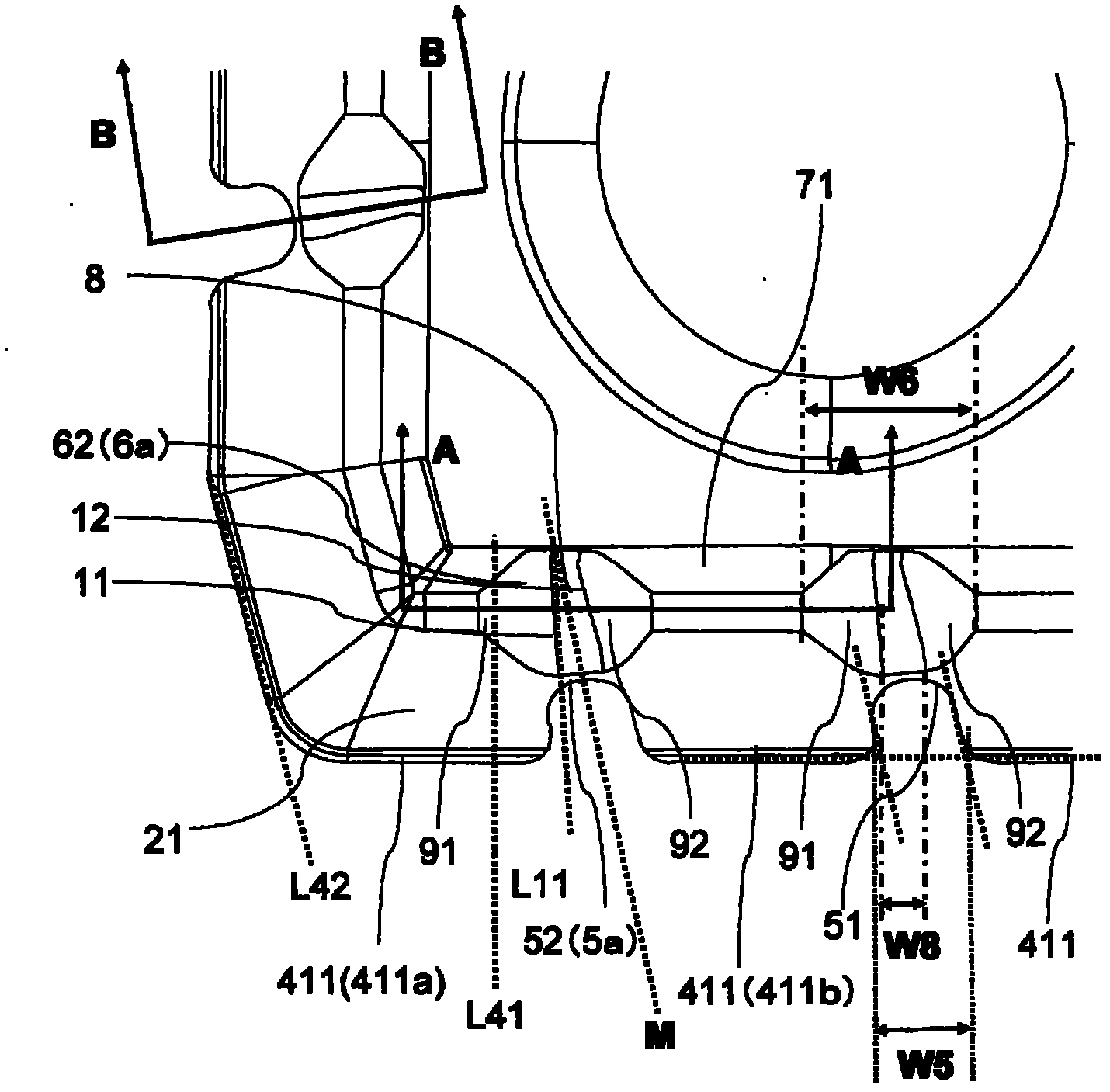

Cutting insert, cutting tool, and method for manufacturing cut product using cutting tool

ActiveCN103619517ACurl stableImprove Chip EvacuationTransportation and packagingMilling cuttersLower faceMechanical engineering

The cutting insert according to an embodiment of the present invention is configured in such a manner that an upper cutting edge comprises, in order from a first corner toward a second corner: a corner cutting edge; a secondary cutting edge tilted from the corner cutting edge at a first tilt angle with reference to a perpendicular plane which is perpendicular to the center axis penetrating through the upper and lower faces; and a primary cutting edge tilted from the secondary cutting edge toward the lower face side at a second tilt angle with reference to the perpendicular plane, the second tilt angle being greater than the first tilt angle of the secondary cutting edge. A cross-section of a rake face taken along the direction of the center axis at the end of the rake face which is located on the inner side has a rectilinear or recessed shape in a region bridging at least a secondary rake face and a primary rake face. A cutting tool provided with the cutting insert and a method for manufacturing a cut product using the cutting tool are also provided.

Owner:KYOCERA CORP

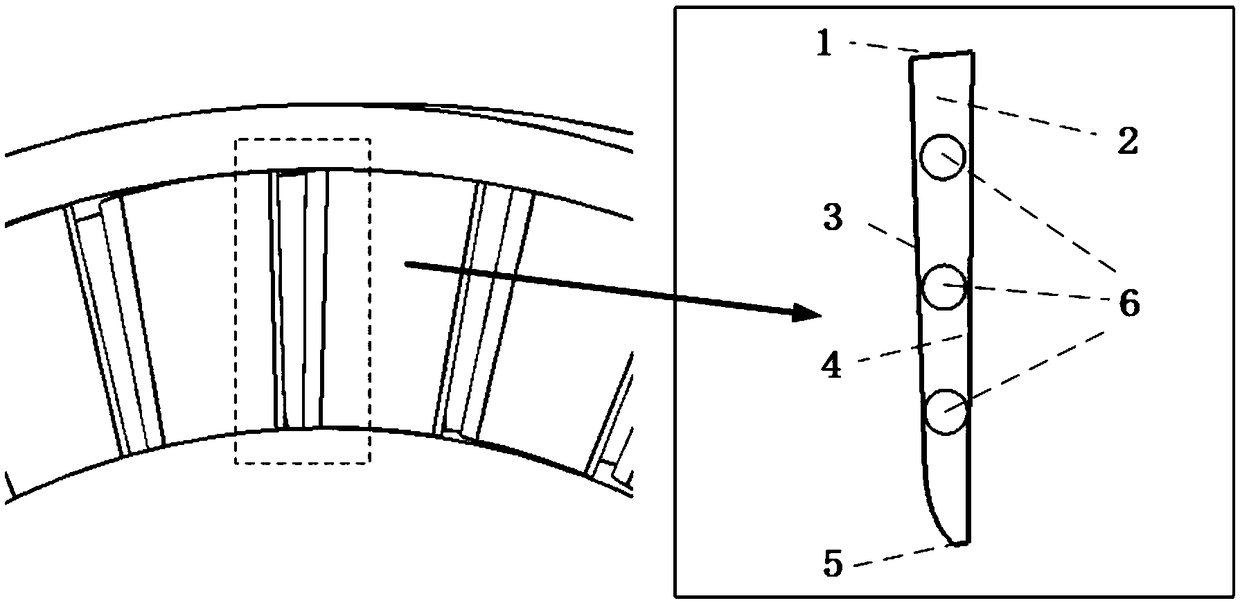

Pre-punching, draining and chip discharging method for electrical discharge machining of enclosed integral blade disc

A pre-punching, draining and chip discharging method for electrical discharge machining of an enclosed integral blade disc comprises: designing a pre-punching parameter combination according to a geometric model of the enclosed integral blade disc, providing an enclosed integrated blade disc blank with pre-punched holes for drainage, using a multi-shaft linkage electrical discharge machine to perform electrical discharge machining on each passage in the enclosed integrated blade disc blank having the pre-punched holes, and extracting a working liquid with electro-corrosion products, generatedin machining, through the pre-punched holes from the side opposite to a tool electrode during passage machining, so that the working liquid in the discharge machining area is renewed; machining efficiency of the enclosed integral blade disc is evidently improved. The method herein has the advantages that electro-corrosion products from electrical discharge machining of an enclosed integral blade disc can be effectively discharged, and machining efficiency of the enclosed integral blade disc is improved.

Owner:上海交通大学深圳研究院 +1

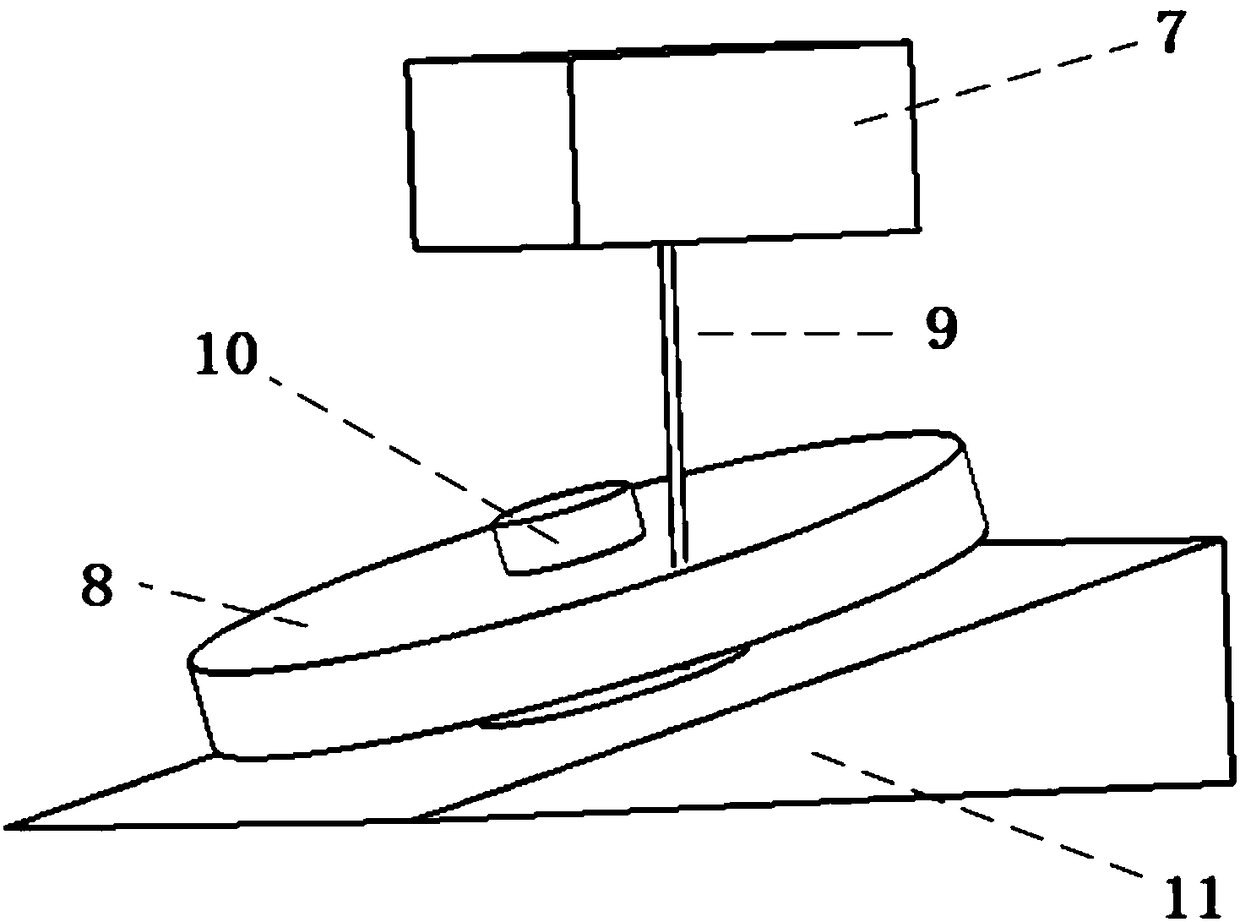

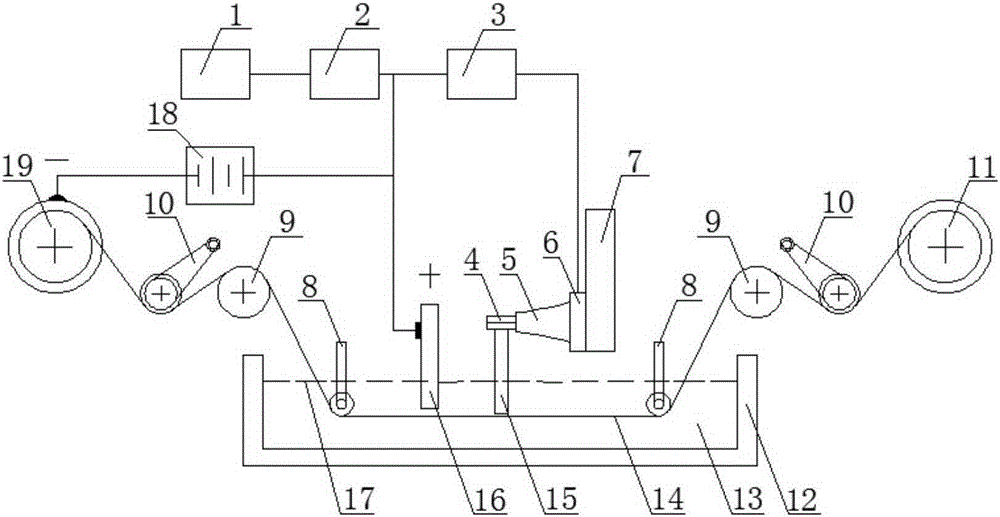

Ultrasonic vibration auxiliary micro-electrochemical electrical discharge wire-cutting machining method and device

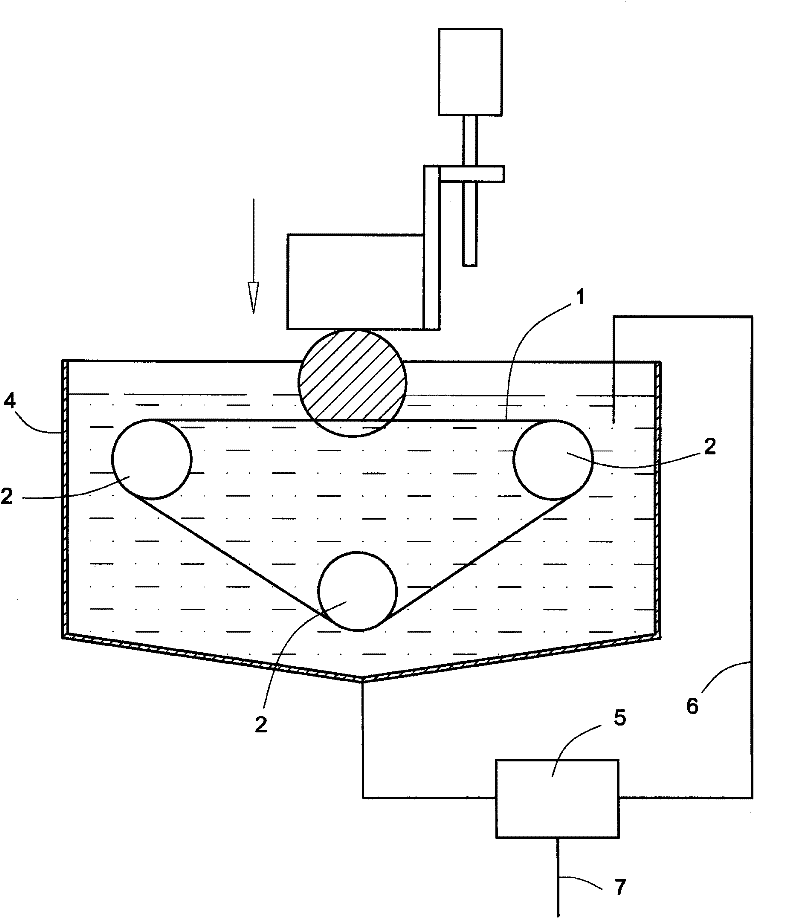

The invention belongs to the field of combined micro-machining and relates to an ultrasonic vibration auxiliary micro-electrochemical electrical discharge wire-cutting machining method and device for non-conductive hard and brittle material machining. The machining method comprises the steps that ultrasonic vibration is utilized for exciting a workpiece in the axial direction of an electrode wire, the electrode wire and an auxiliary electrode are subjected to an electrolytic reaction in an electrolytic solution so that hydrogen gas is separated out around the electrode wire, and then a gas film is formed so that the electrode wire and the electrolytic solution can be insulated. The machining device comprises a machine tool bed, an electrolysis-electrical discharge wire cutting device, an ultrasonic vibration unit and a workbench. A wire storage cylinder, a driving wheel, a tensioning device and a guide wheel support are arranged on the machine tool bed. The electrolysis-electrical discharge wire cutting device comprises a clamping device for fixing the workpiece, the workpiece, a main shaft, a wire driving device, the electrode wire, a working solution box containing the electrolytic solution, an auxiliary electrode and an electrolysis-electrical discharge power source. The auxiliary electrode is connected with a positive electrode of the electrolysis-electrical discharge power source. The electrode wire is connected with a negative electrode through an external wire feeding device. According to the method and device, implementation is easy, the production cost is lowered while the precision and efficiency are ensured, and the method and device can be widely applied to micro-machining of various non-conductive hard and brittle materials.

Owner:SHANDONG UNIV

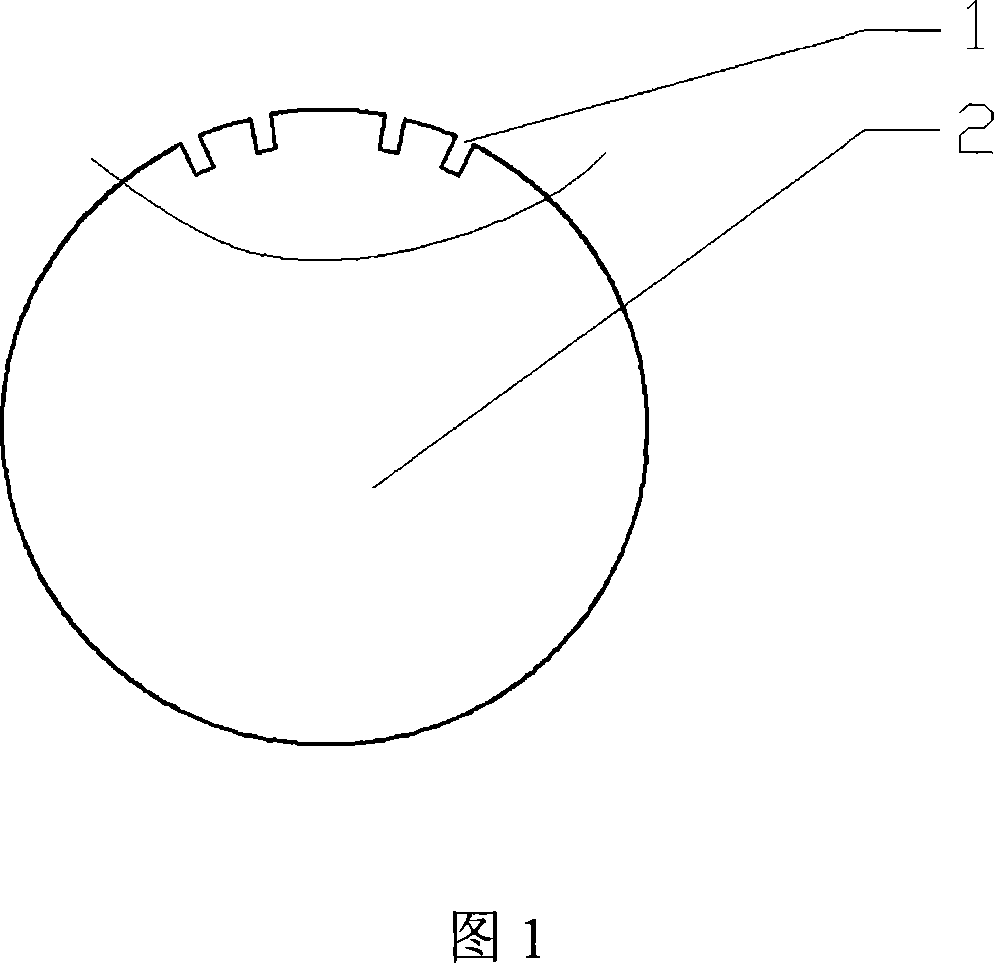

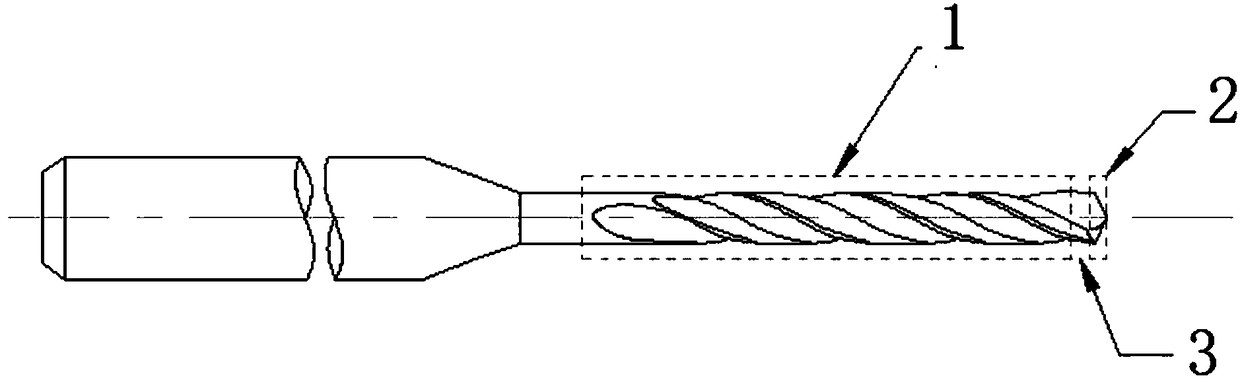

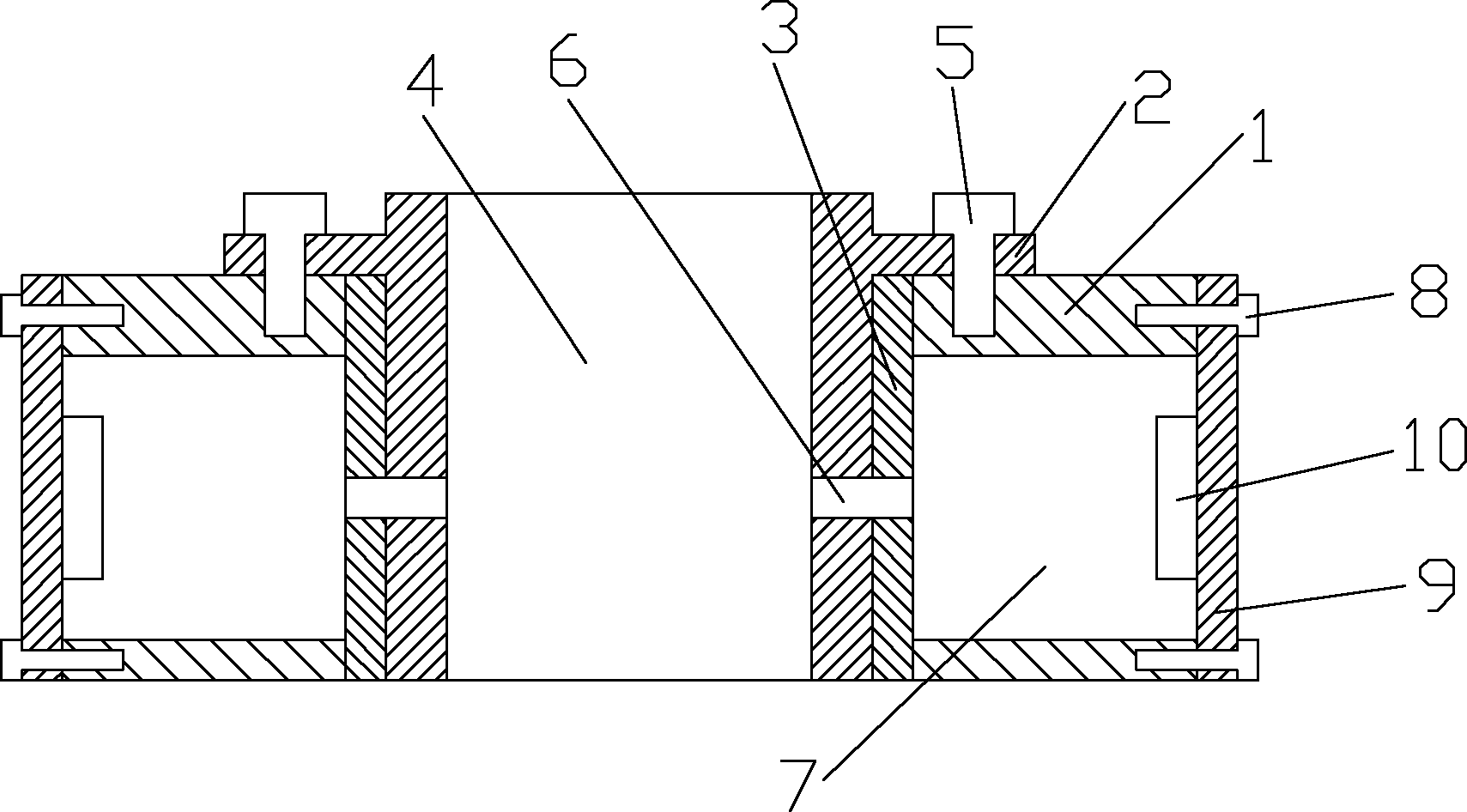

Diamond coating drill bit and preparation method thereof

ActiveCN108179398AImprove work efficiencyExtended service lifeChemical vapor deposition coatingTwist drillsGas phaseWear resistance

The invention relates to a diamond coating drill bit and a preparation method thereof. The drill bit comprises a drill body (1) and a drill tip (2); the drill body (1) is coated with a carbon base coating layer such as a nanocrystalline diamond coating layer or a diamond-like coating layer; and the drill tip (2) is coated with a micron crystalline diamond coating layer. A heat stop cylinder is arranged on a heat wire chemical vapor deposition device; and the coating layers are obtained by using chemical vapor deposition. The drill tip and the drill body are respectively coated with the microncrystalline diamond coating layer and the carbon base coating layer with low friction coefficient such as the nanocrystalline diamond coating layer or the diamond-like coating layer; excellent wear resistance of the micron crystalline diamond coating layer and excellent chip discharge performance of the nanocrystalline diamond coating layer are fused to obtain the diamond coating drill bit with excellent wear resistance and chip discharge performance; the working efficiency of the drill bit is improved; the service life is prolonged; and excellent application prospect is achieved.

Owner:SHENZHEN JINZHOU PRECISION TECH

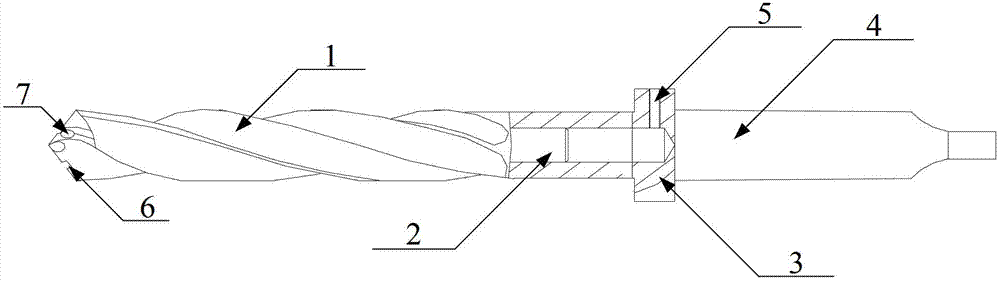

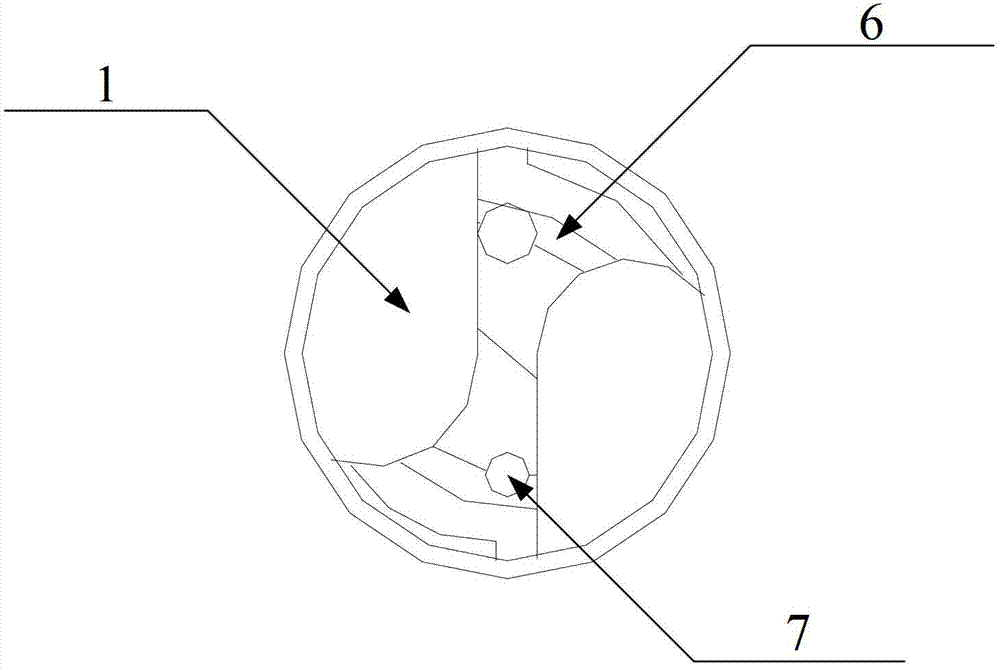

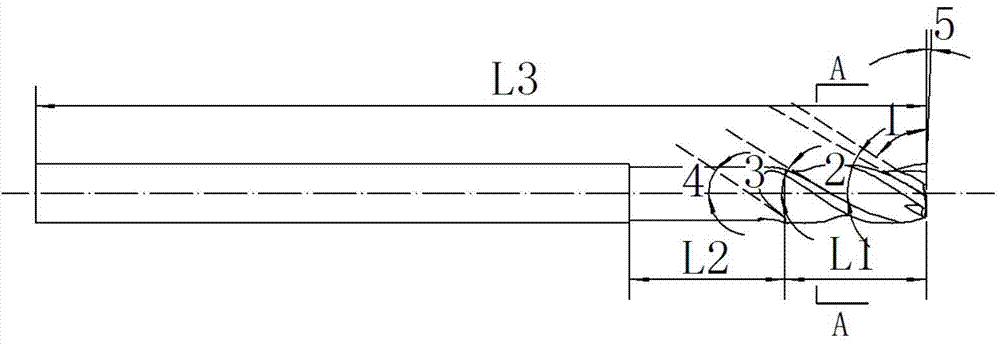

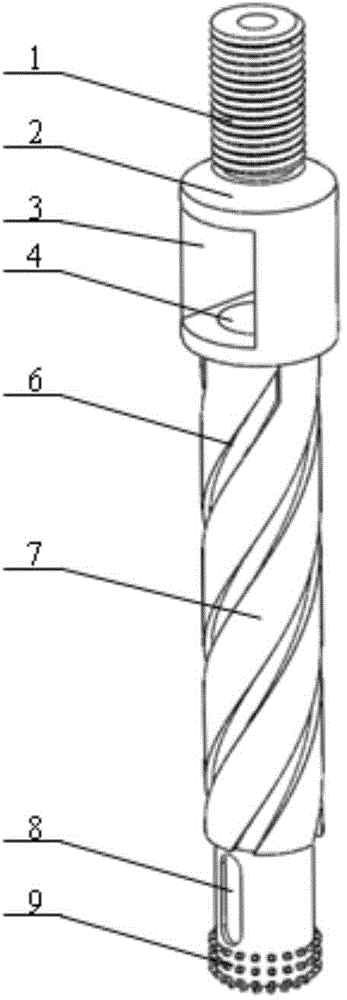

Longhole double-spiral inner-cooling drill bit

ActiveCN103157833ALow affinityImproved resistance to adhesive wearTransportation and packagingTwist drillsTitanium alloyWear resistance

The invention discloses a longhole double-spiral inner-cooling drill bit comprising a drill bit body. The rear end of the drill bit body is further connected with a drill handle, wherein the drill handle is fixed with the drill bit body integrally through welding. The drill bit body comprises a drill bit main body, wherein inner-cooling spiral holes are formed inside the drill bit main body, and meanwhile chip dividing grooves and the inner-cooling spiral holes are further arranged in the drill bit main body. The drill handle comprises a handle body and a connection end which is fixed with the handle body integrally. A blind hole is formed in the middle portion of the connection end. A cooling liquid inlet communicated with the blind hole is further arranged in the connection end, wherein the diameter of the blind hole is identical to the diameter of the lower end of each inner-cooling spiral hole. According to the longhole double-spiral inner-cooling drill bit, abrasive resistance of a titanium alloy deep hole working cutter is improved, rigidity of the cutter is improved, stability in machining is strengthened and cutting resistance in machining is reduced.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

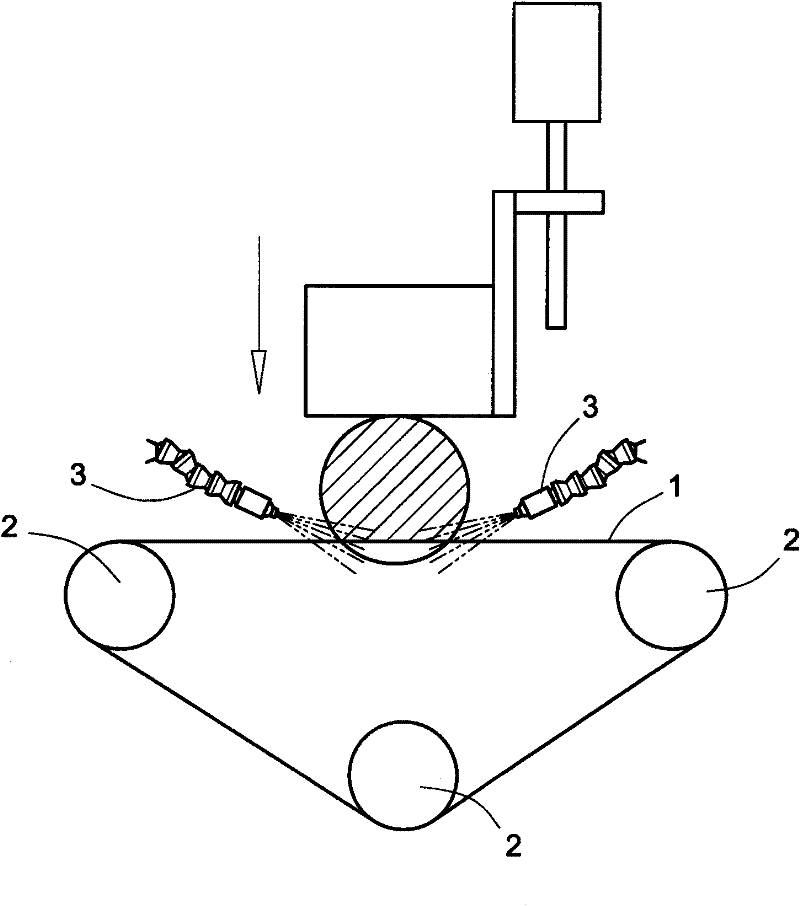

Cooling device for diamond-wire cutting system

InactiveCN102528955AAvoid damageImprove cutting effectSemiconductor/solid-state device manufacturingMetal sawing toolsSemi openWire cutting

A cooling device for a diamond-wire cutting system includes a fluid retarding space as a cooling tank enclosed and defined by one or more surfaces for temporarily holding a cooling fluid. The surfaces provide a closed or semi-open sidewall that allows a cutting part of a diamond wire for cutting a workpiece to pass through the cooling tank and get immersed in the cooling fluid. A sorting collector is connected to the cooling tank. Thereby, cutting the hard-brittle workpiece is always performed in the cooling fluid, so as to prevent the cooling fluid and cutting chips from splashing, and improve heat dissipation and dust removal, thereby enhancing the cutting capability and efficiency. The tooled workpiece has cut surfaces with improved smoothness. The sorting collector performs solid-liquid separation to the cooling fluid containing cutting chips, so that the cutting chips and the cooling fluid can be recycled.

Owner:MICRON DIAMOND WIRE & EQUIP

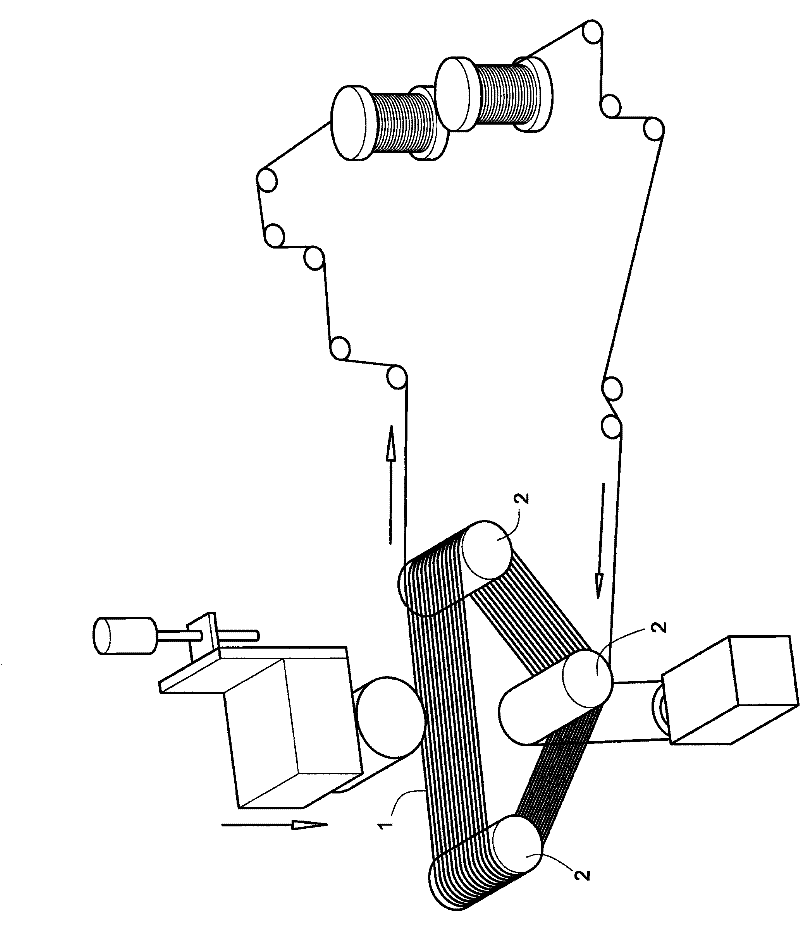

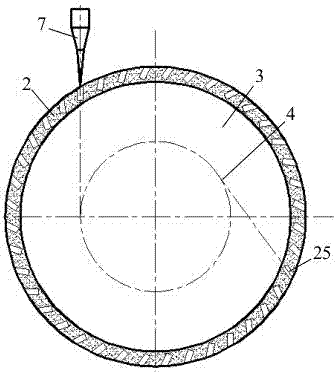

Spiral and orderly arranging fiber tool capable of conducting positive rake angle machining and preparation method thereof

InactiveCN107243848AImprove efficiencyImprove processing efficiencyBonded abrasive wheelsGrinding devicesFiberHelical line

The invention discloses a helically and orderly arranged fiber cutter capable of positive rake angle processing and a preparation method thereof. The fiber cutter includes fiber, carcass and steel matrix; the fiber is tangent to the base circle in the steel matrix, and the fiber can process the workpiece with a positive rake angle during cutting; Arranged in an orderly manner. The preparation method is as follows: the fiber is prepared by wire electric discharge cutting technology; the series of fibers are clamped and sharpened by special clamps; the matrix is prepared on the prefabricated steel base by pressing and sintering technology; A series of small holes arranged in a helical line are processed on the body; epoxy resin is injected into the small holes, the fibers are inserted into the small holes, and the embracing device is used to ensure that the blade height of the fibers is consistent; the fiber cutter is prepared by heating and curing. The helical and orderly arranged fiber cutter prepared by the invention can realize positive rake angle processing, significantly reduce cutting force and cutting temperature, and improve cutting performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

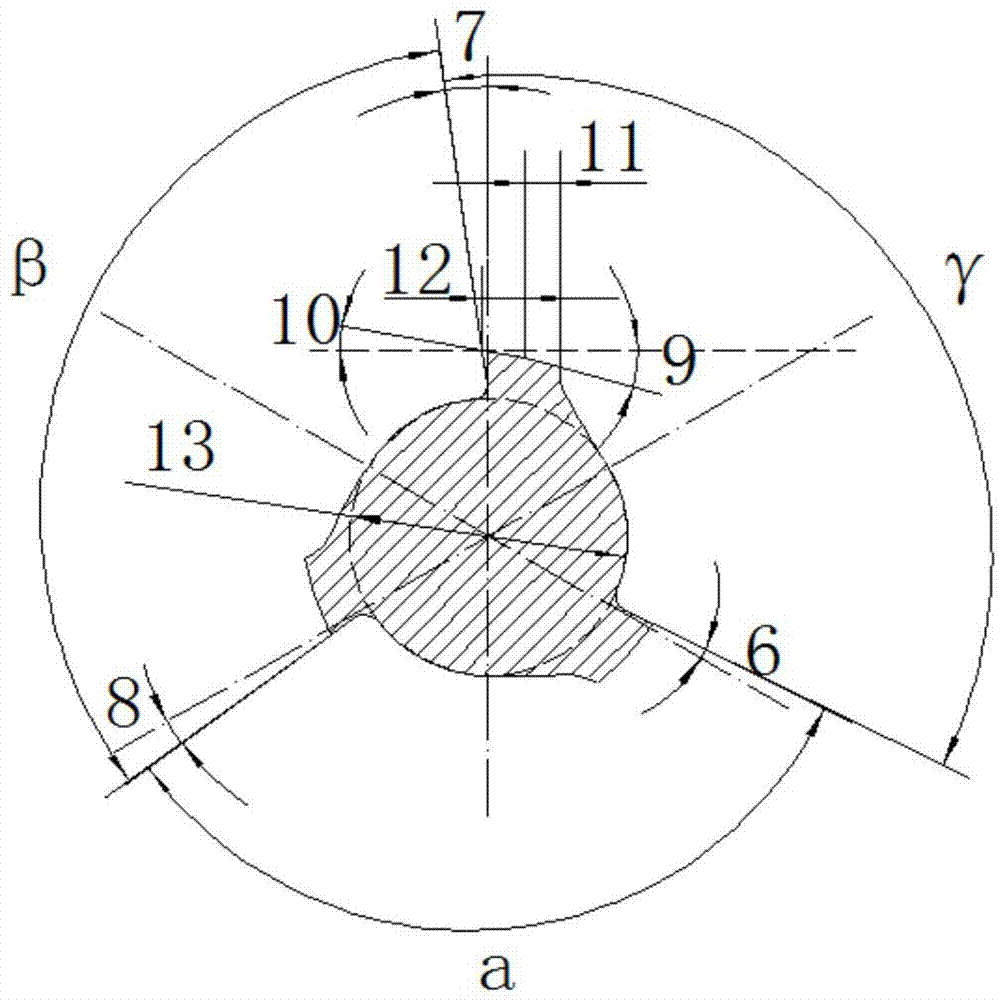

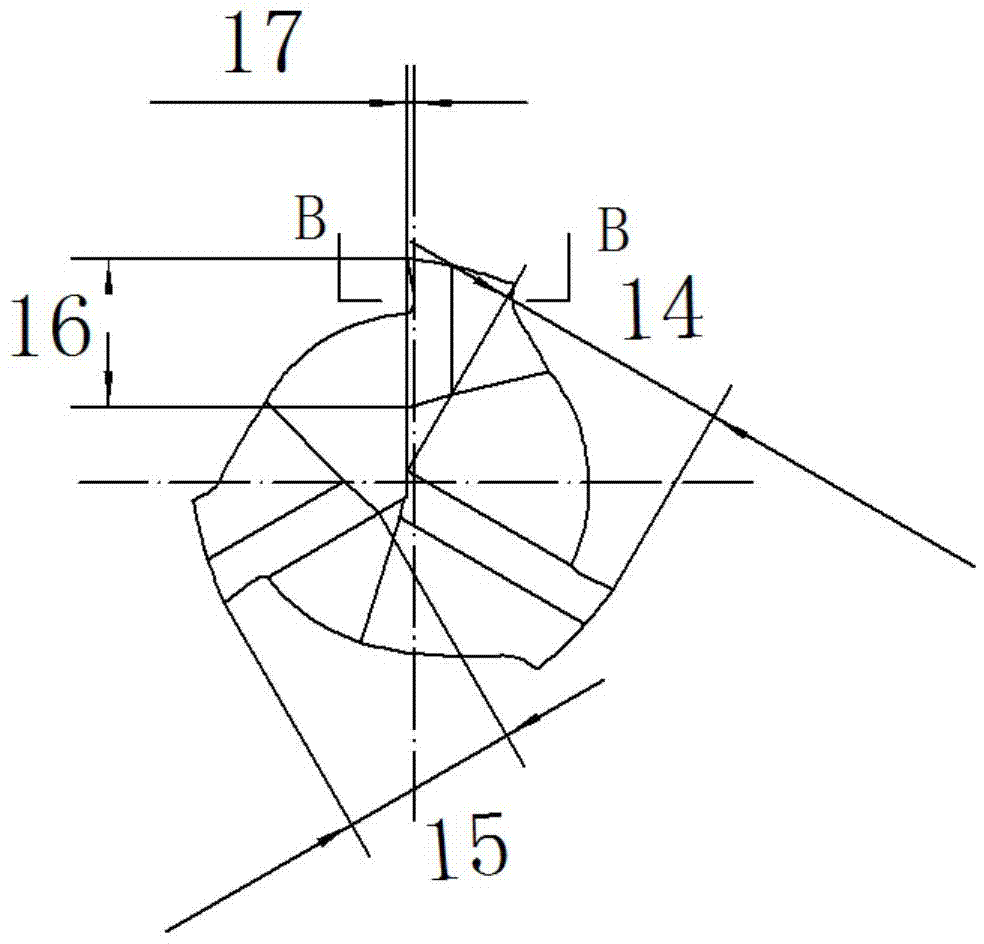

Special cutter for machining small-diameter pore helical milling of composite material

InactiveCN104708098AIncrease stiffnessImprove Chip EvacuationMilling cuttersWorkpiecesMilling cutterEngineering

The invention discloses a special cutter for machining the small-diameter pore helical milling of a composite material. A first cutting edge, a second cutting edge and a third cutting edge are arranged on the cutting part of the cutter, and the included angles of the first cutting edge, the second cutting edge and the third cutting edge are different; the edge lengths of the three cutting edges are different; the back cutter faces of the three cutting edges are double back cutter faces with edge strips; the distances between the bottom edges of the three cutting edges and the center line of the cutter are different due to helical angles formed by the three cutting edges; the thickness of a milling cutter core is 70%-80% of the diameter of the cutter. The cutter comprehensively considers various problems of the geometrical shape of the cutter in helical milling machining of carbon fiber composite material small-diameter pores, the proportion of the thickness of the milling cutter core in the diameter of the cutter is improved, and the whole rigidity of the cutter is improved; by adopting the front angle of the cutter larger than an ordinary milling cutter, the cutting performance of the cutter for helical milling machining of the carbon fiber composite material is improved, the measures of reducing the back angle and the like are adopted, the strength of the small-diameter cutter cutting edge is improved, and the service life of the cutter is prolonged.

Owner:TIANJIN UNIV

Drilling fixture

InactiveCN102581348AImproved Chip EvacuationExtended service life and replacement intervalsDrilling/boring measurement devicesDrill holeFastener

The invention discloses a drilling fixture, which comprises a fixture body, a guide and a bushing. The fixture body is provided with a mounting hole, the guide is arranged in the mounting hole, the bushing is arranged between the fixture body and the guide, the guide and the bushing are provided with communicated chip discharge holes, the fixture body is provided with a chip containing groove which is communicated with the chip discharge holes, and a baffle is arranged at the outer end of the chip containing groove through a fastener and provided with a blowing device. When drillings generated during drilling enter the guide along with a drill, the drillings can be sucked into the chip containing groove by the blowing device through the chip discharge holes, so that chip discharging performance is improved, jamming of the drill into the guide due to untimely chip discharging can be avoided, and abrasion of the fixture body caused by the fact that the guide and the bushing are driven by the jammed drill to rotate together is avoided. The service life and the replacement cycle of the drilling fixture are prolonged, and production cost is reduced. Further, the baffle is arranged at the outer end of the chip containing groove through the fastener, and the drillings sucked in the chip containing groove can be cleaned by demounting the baffle, so that maintenance is convenient.

Owner:SUZHOU FUMAI PRECISION MACHINERY

Super-hard wear-resisting chromium-based compound coating micro drill bit for PCB (Printed Circuit Board) and preparation method thereof

InactiveCN102975418AStrong hardnessStrong toughnessLayered productsVacuum evaporation coatingAlloy substrateHardness

The invention discloses a super-hard wear-resisting chromium-based compound coating micro drill bit for a PCB (Printed Circuit Board) and a preparation method thereof. An inner layer and an outer layer are respectively deposited on a hard alloy substrate by adopting an ion plating technology and improved magnetic filtering ion plating; the inner layer is a CrN transition layer and is combined with the hard alloy substrate to have very good calorific, hardness and chemical matching properties, so that the good bonding strength between the CrN transition layer and the substrate is guaranteed; and the outer layer is an AlCrTiN compound layer and has the characteristics of high hardness, strong toughness and low friction coefficient. A PCB micro drill bit of a compound coating, which has the advantages of strong bonding strength, high hardness, good toughness and low friction coefficient, is obtained by carrying out compound design on CrN and AlCrTiN and utilizing interface strengthening, solid solution strengthening, double-phase strengthening and nano strengthening.

Owner:SHANGHAI CREWELL MATERIAL TECH

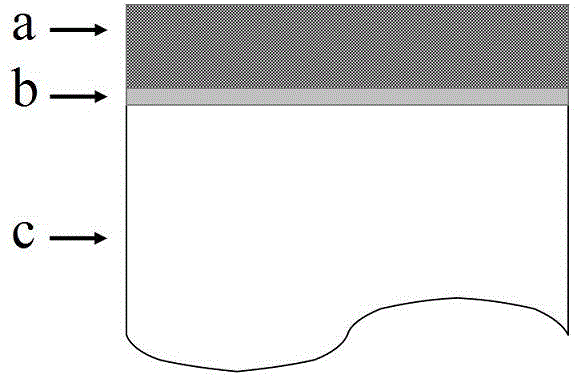

Chip tracking type automatic telescopic chip remover

ActiveCN105328213AGood suction and chip removalImprove Chip EvacuationAuxillary equipmentMaintainance and safety accessoriesNumerical controlUltimate tensile strength

The invention relates to auxiliary equipment of numerical control machine tools, in particular to a chip tracking type automatic telescopic chip remover. The chip remover comprises a bracket, a module, a control electric cabinet and a chip removing system, wherein the module is transversely mounted on the bracket; the control electric cabinet is mounted on the bracket, is positioned on the side surface of the module, and is used for controlling the module and the chip removing system; and the chip removing system is mounted on the module. The chip remover can wind a lot of thread-shaped chips on chip winding keys, and in particular, is better in chip removing effect of iron thread-shaped chips through attraction force of magnets in the chip winding keys; and the chip winding keys rotating at a high speed enable the chip removing capacity to be greatly enhanced. The chip remover fits a numerical control lathe generating the thread-shaped chips, to realize full automation of production and chip removal, so that manual chip removal is not needed, the production efficiency is greatly improved, and the labor intensity and the danger are reduced.

Owner:南京依纳科技有限公司

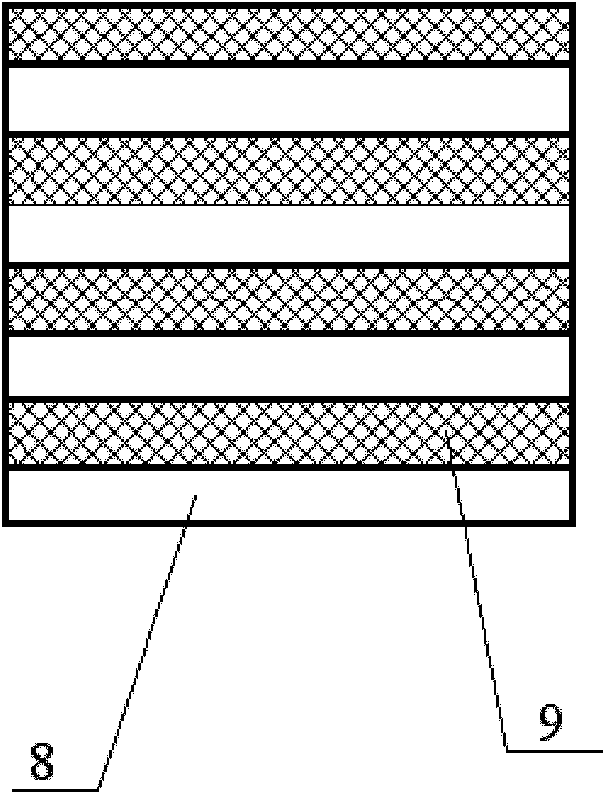

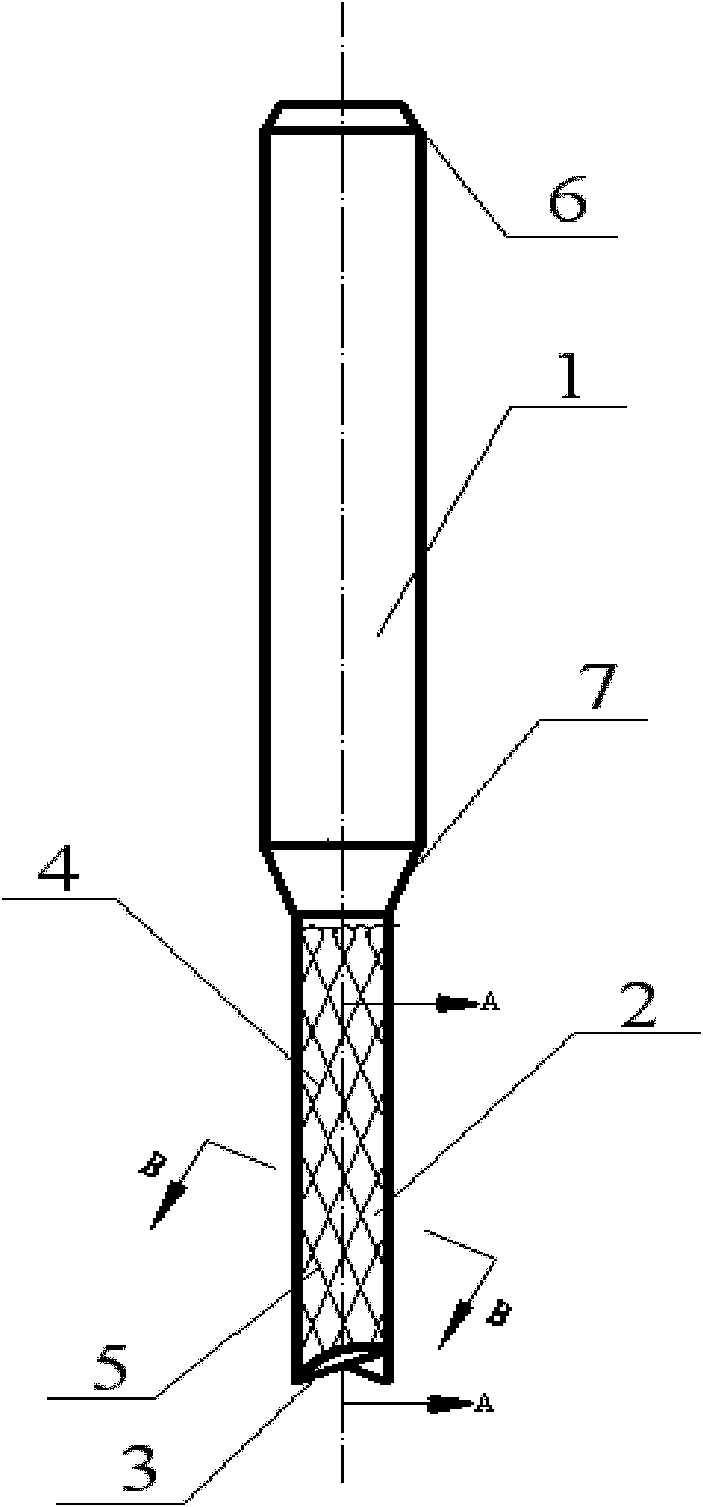

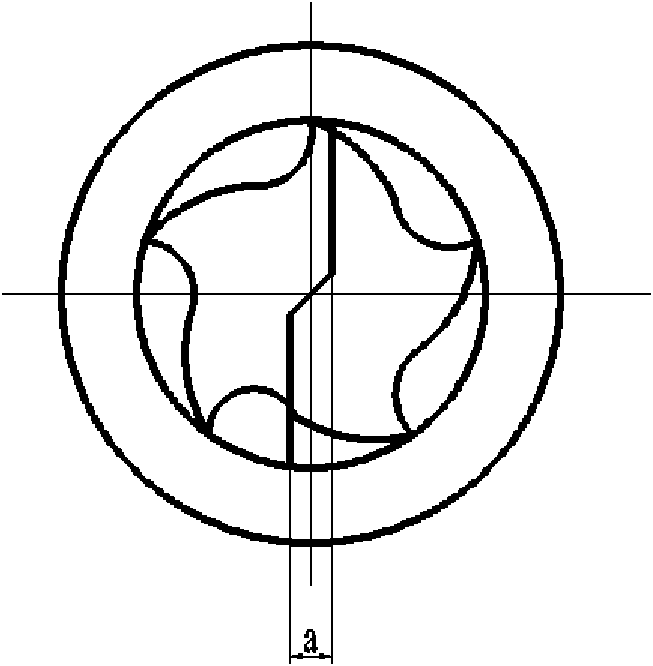

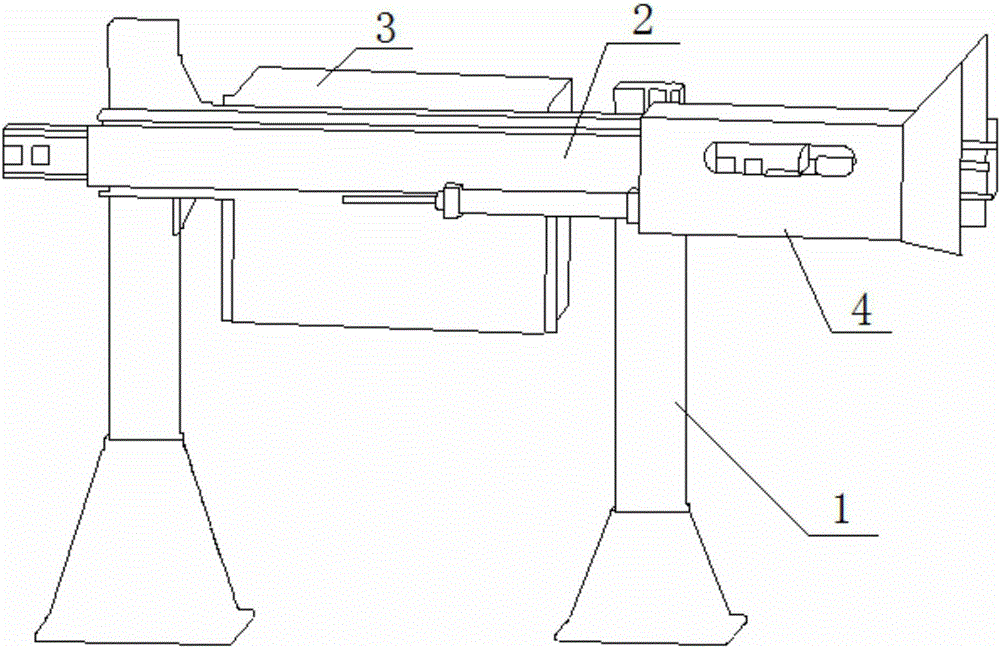

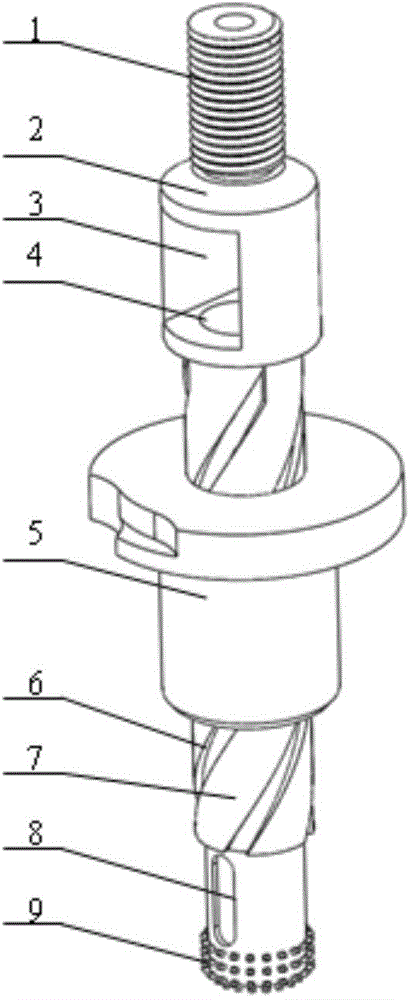

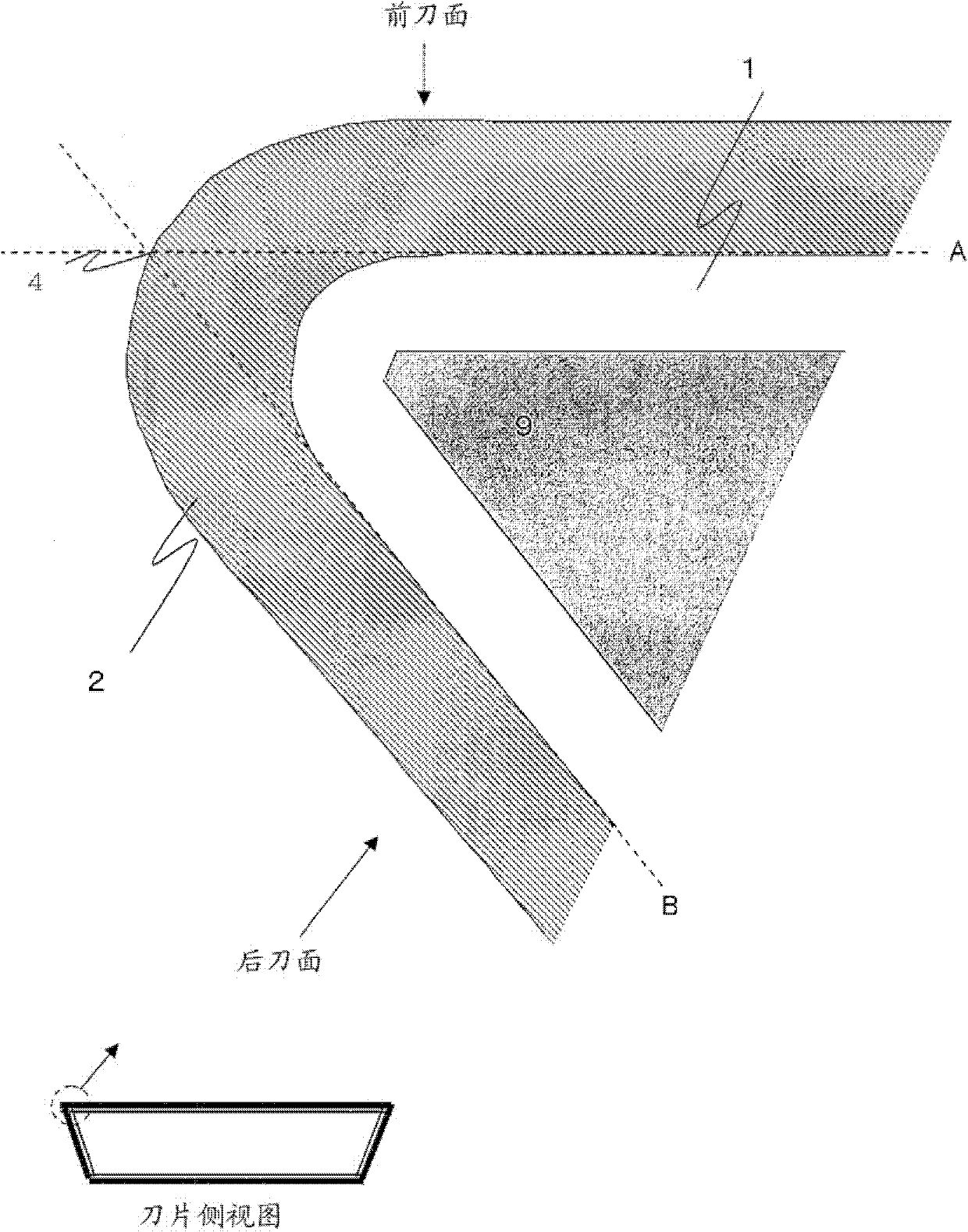

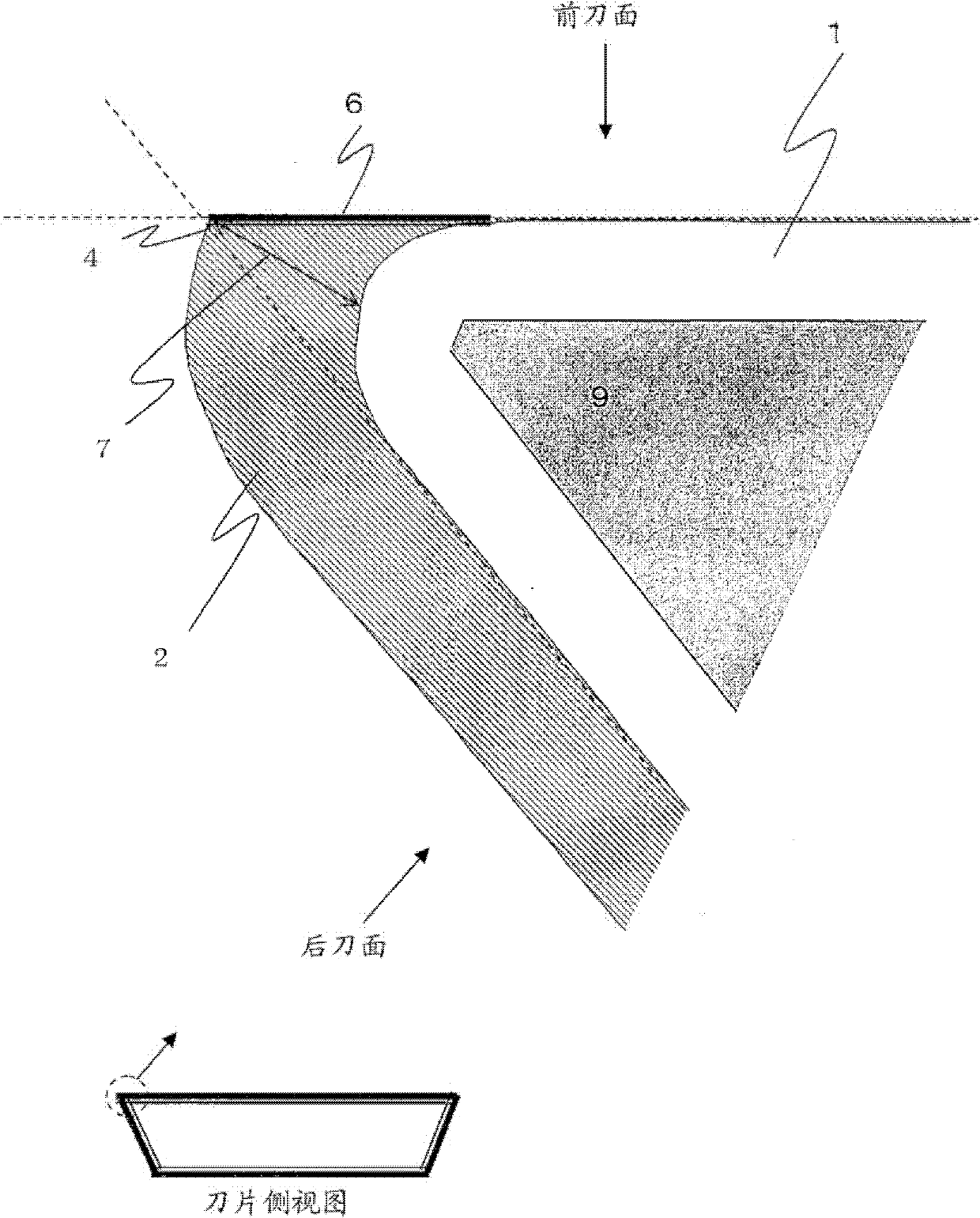

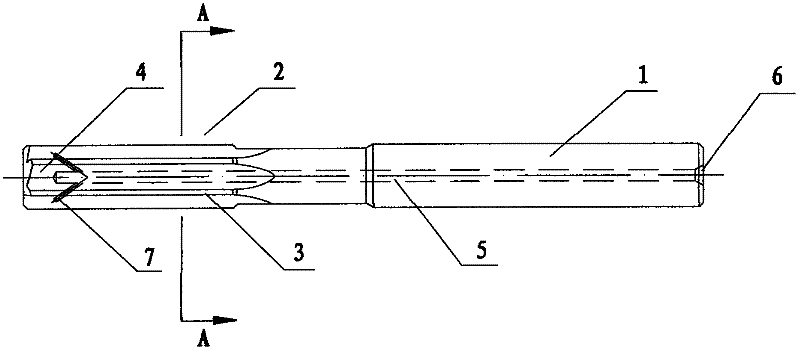

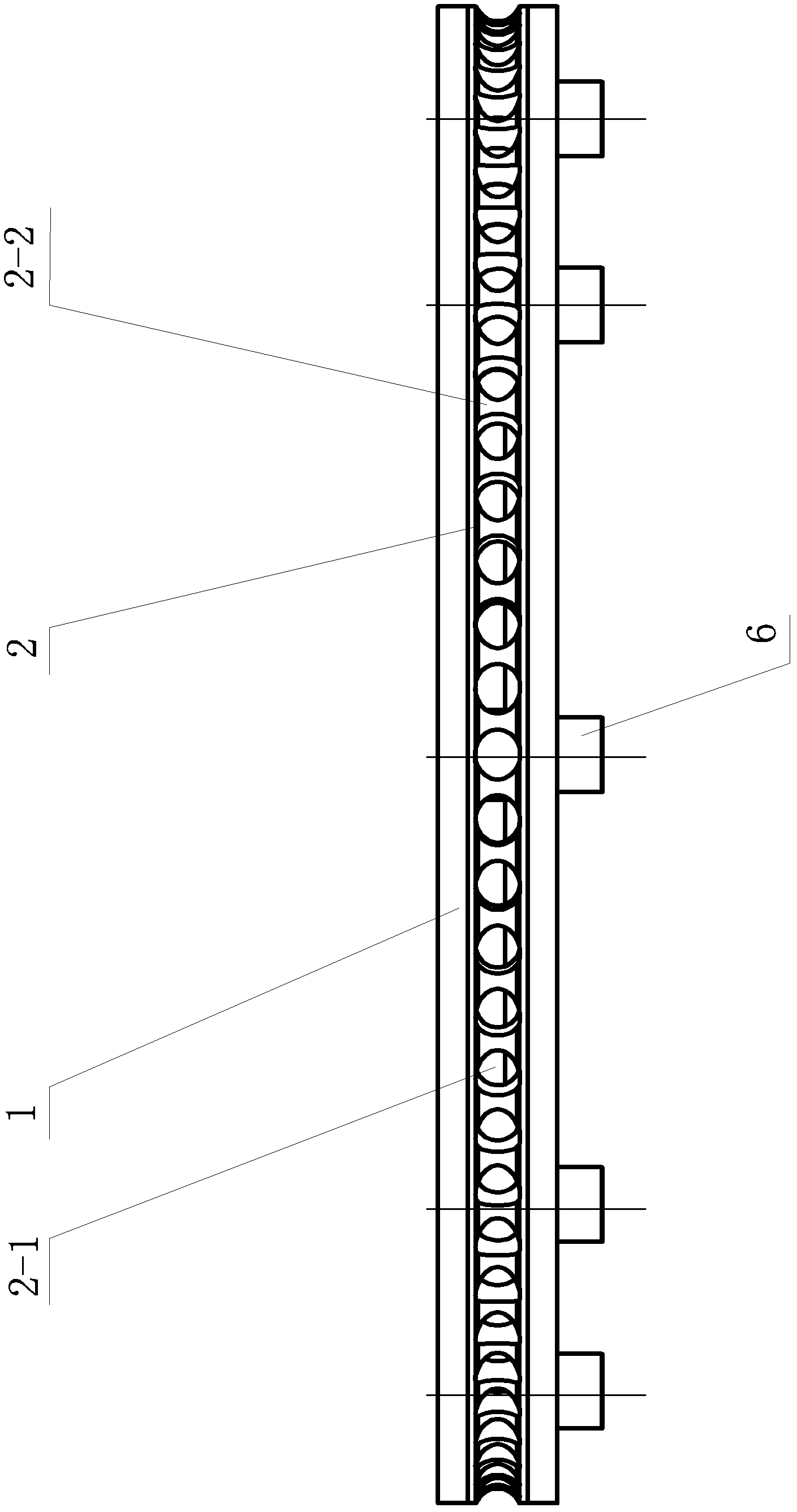

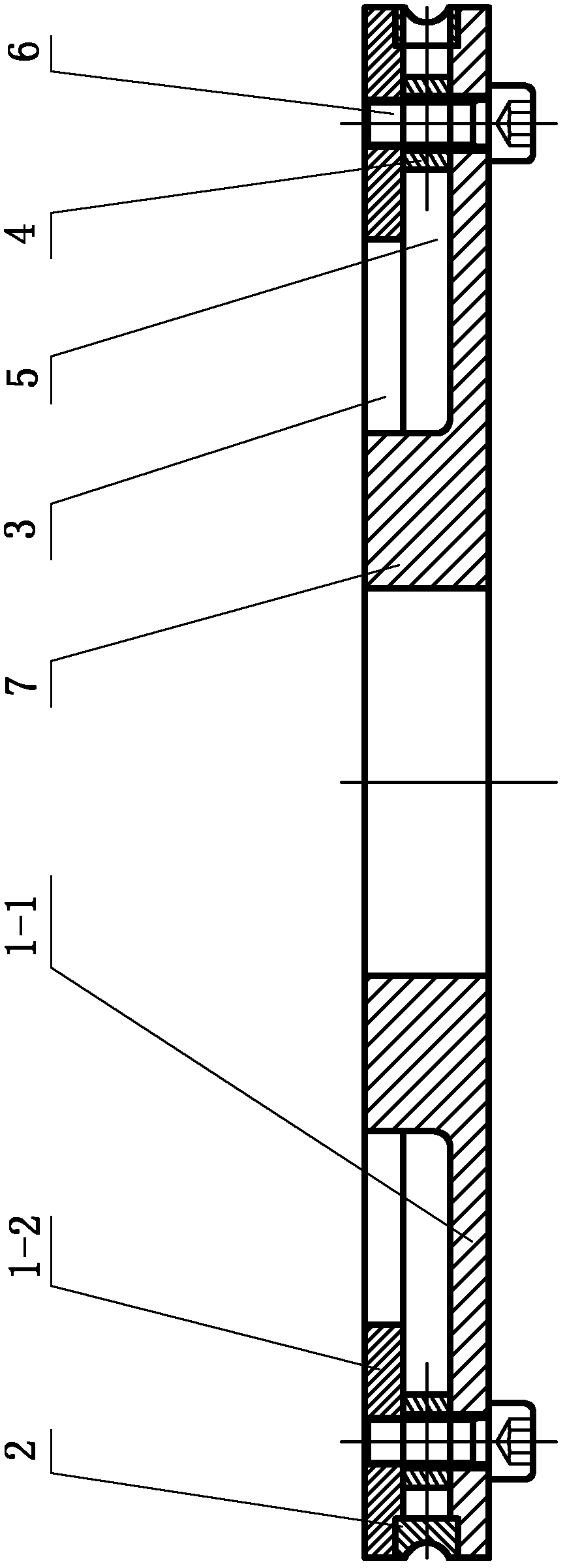

Diamond sleeve grinding cutter suitable for drill sleeve guide

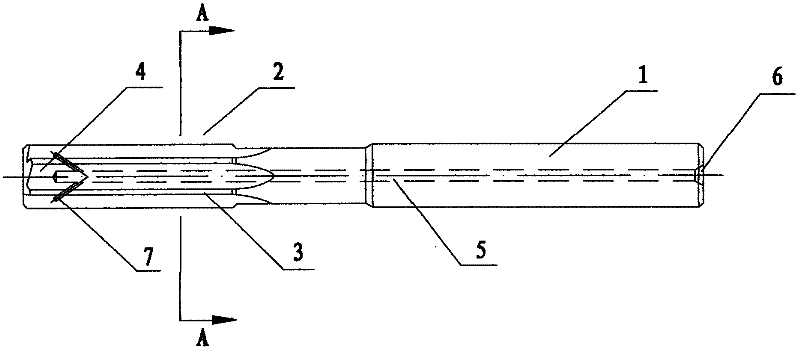

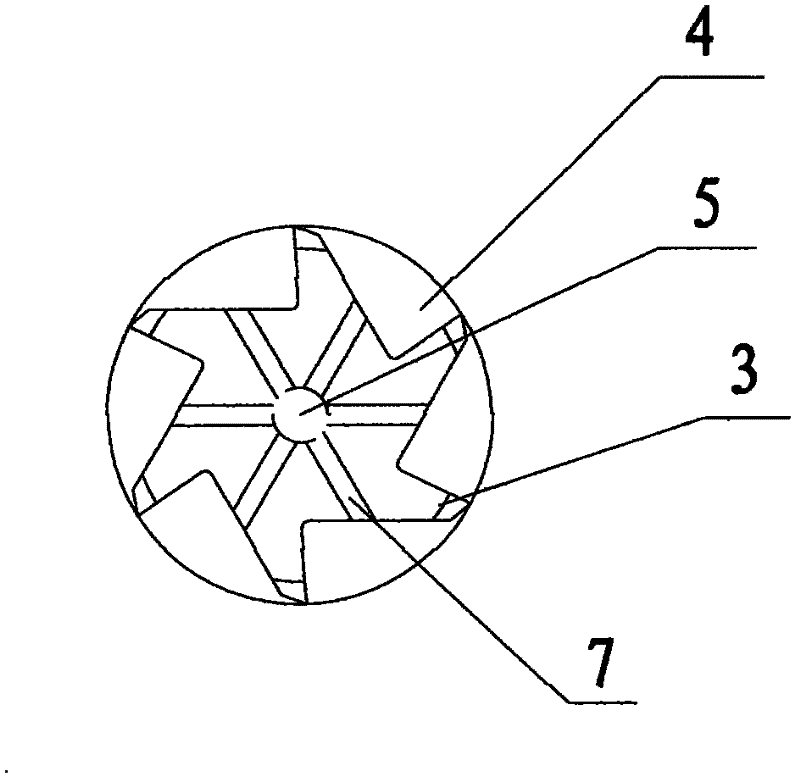

ActiveCN104475826APrevent sticking sleeveReduce wearDrilling/boring measurement devicesTransportation and packagingEngineeringScrew thread

A diamond sleeve grinding cutter suitable for drill sleeve guide comprises a circular drill rod and a guide drill sleeve. The guide drill sleeve is positioned on the middle lower portion of the drill rod and connected with a drill template, the drill rod comprises a threaded handle (1), a 120-degree positioning conical surface (2), a core discharging port (3), a core discharging guide hole (4), a dust chip discharging spiral groove (6), a spiral guide surface (7), a dust chip discharging straight groove (8) and a cutter cutting edge (9) from top to bottom, double cylindrical surfaces are combined to from the guide drill sleeve, and a through hole is formed in a core, so that the drill rod conveniently penetrates the through hole. The diamond sleeve grinding cutter is an integrated cutter, the quality of a machined hole is fine, defects are fewer, hole forming efficiency is high, a composite hole with a large diameter can be machined once, dust cuttings are fewer and almost discharged in the form of material cores, environmental pollution is low, and materials can be repeatedly used.

Owner:BEIHANG UNIV +1

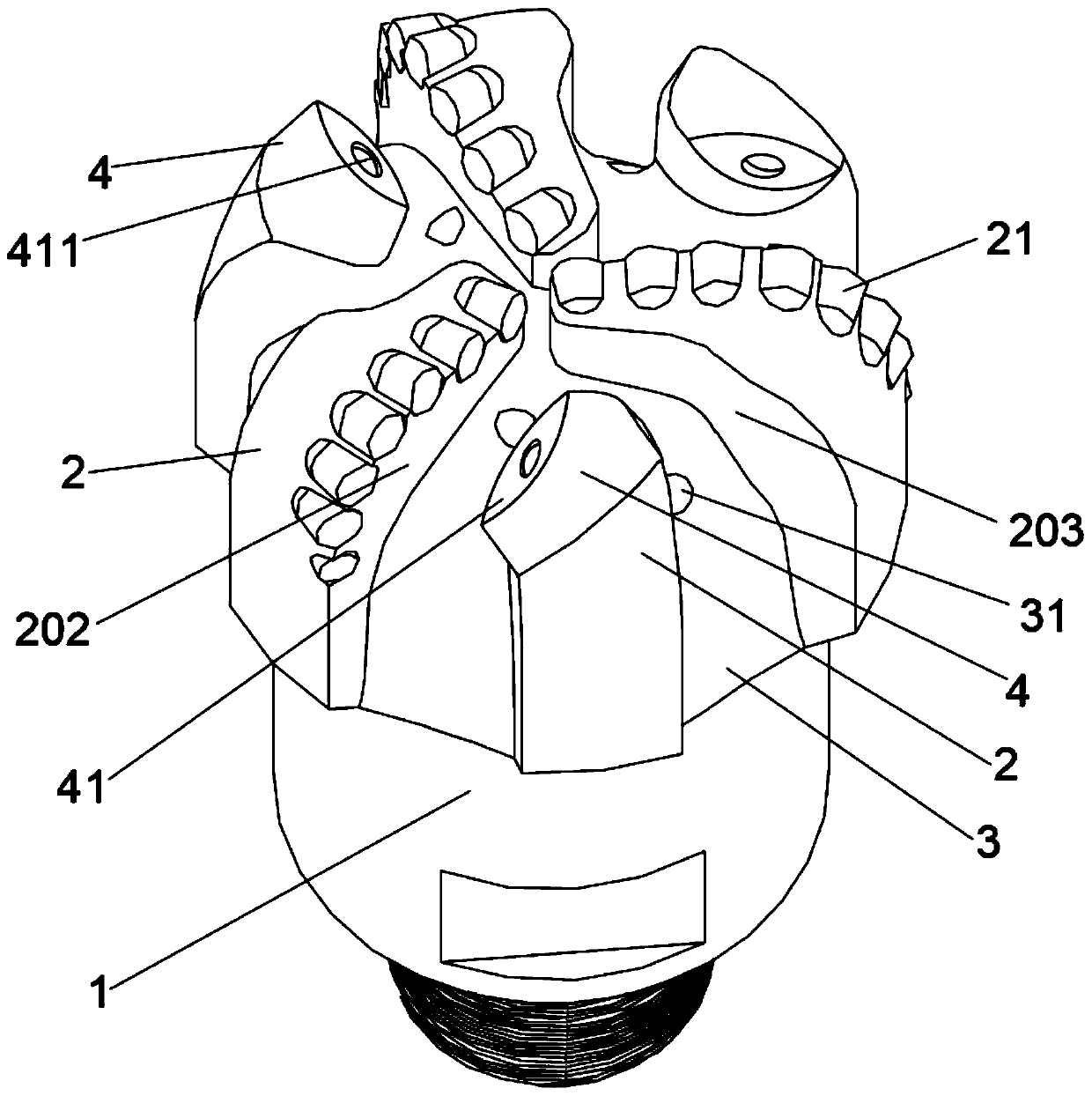

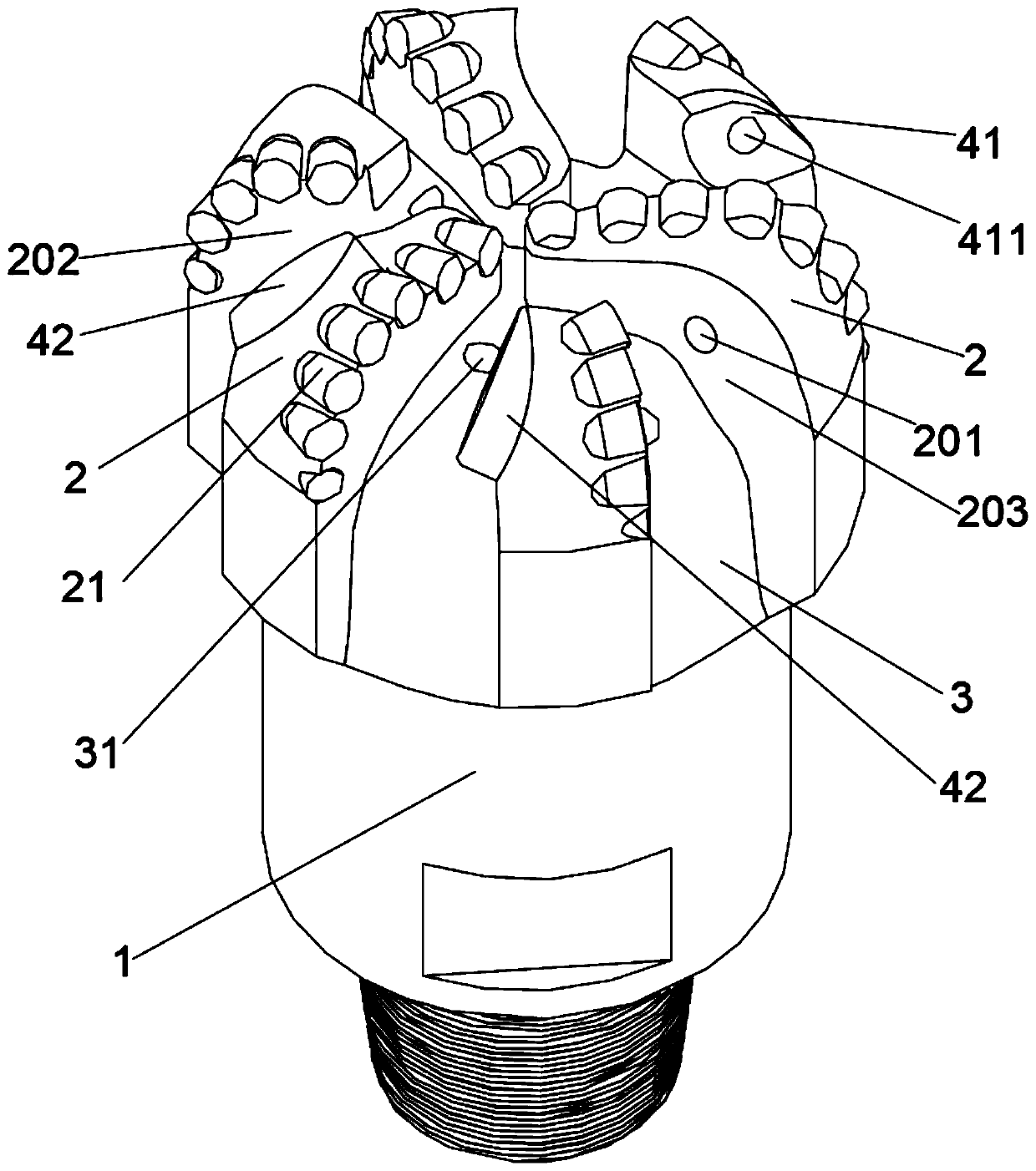

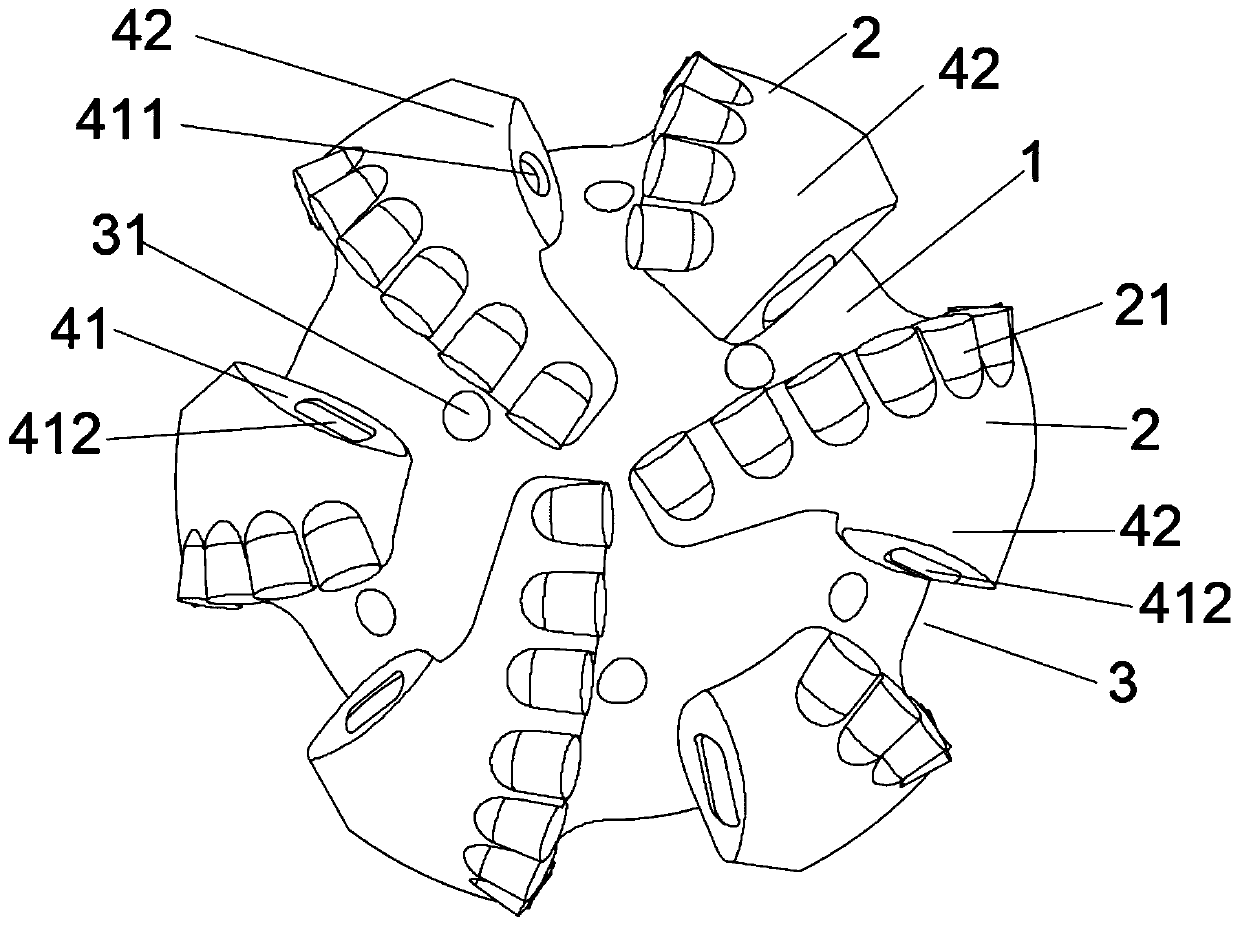

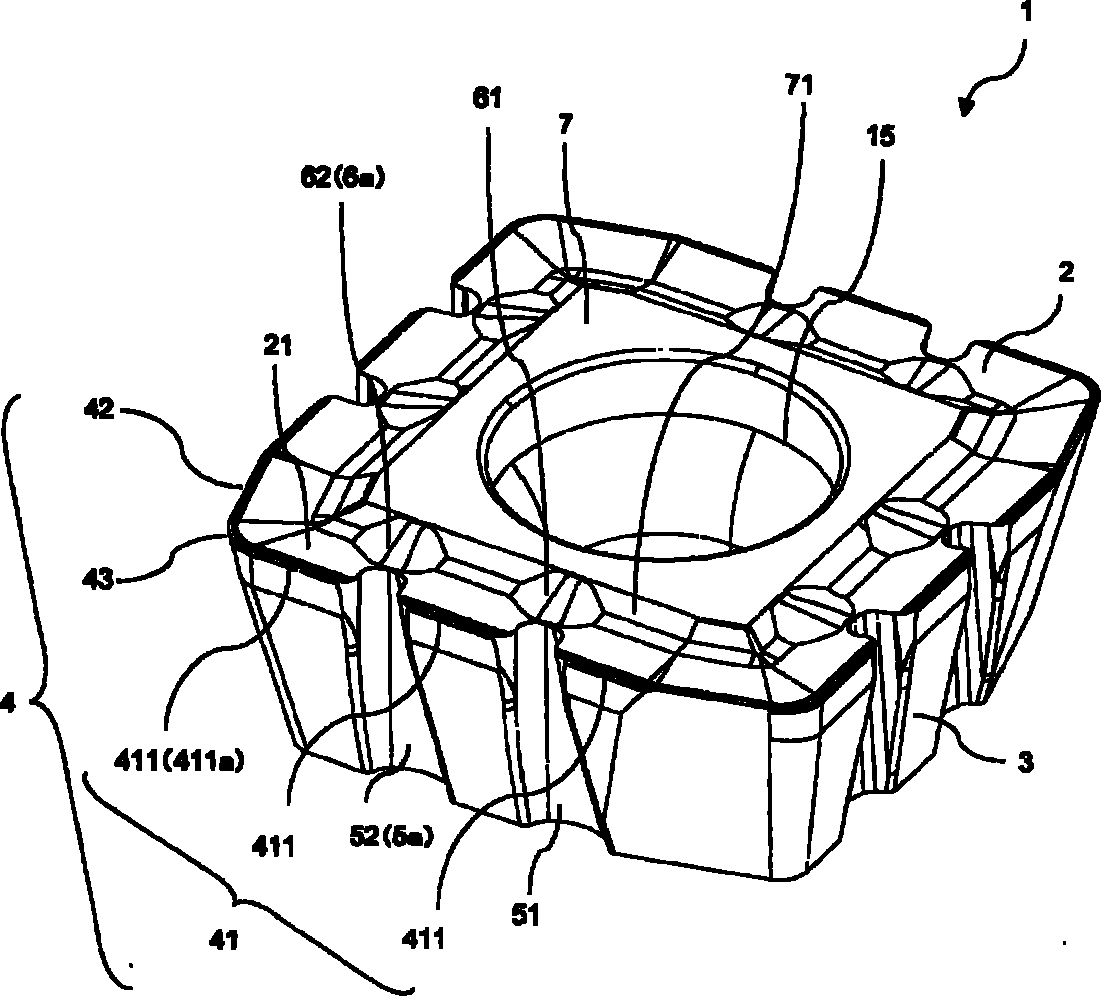

Diamond drill bit with high-efficiency water hole structure

PendingCN110107227AHigh rock breaking performanceShort spray distanceDrill bitsConstructionsWell drillingPetroleum

The invention relates to the technical fields of petroleum and natural gas, mine engineering, geothermal wells, building foundation engineering construction, geology and hydrological drilling, in particular to a diamond drill bit with a high-efficiency water hole structure. According to the diamond drill bit, a rear water spray hole seat extending to a drill bit body or connected to the drill bitbody is arranged in front of at least one of cutter wings, the rear water spray hole seat is provided with a rear water spray hole communicating with a flow channel in the drill bit, and the rear water spray hole can directly spray water onto cutting teeth on the cutter wings or rocks in front of the cutting teeth. According to the diamond drill bit with the high-efficiency water hole structure, the cutting teeth are fully cooled and cuttings are transported in time in high temperature well drilling, and the drilling performance of the drill bit is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cutting insert, cutting tool, and cutting method using the cutting tool

ActiveCN102119067ASuppress collisionReduce cutting resistanceMilling cuttersShaping cuttersEngineeringMechanical engineering

Owner:KYOCERA CORP

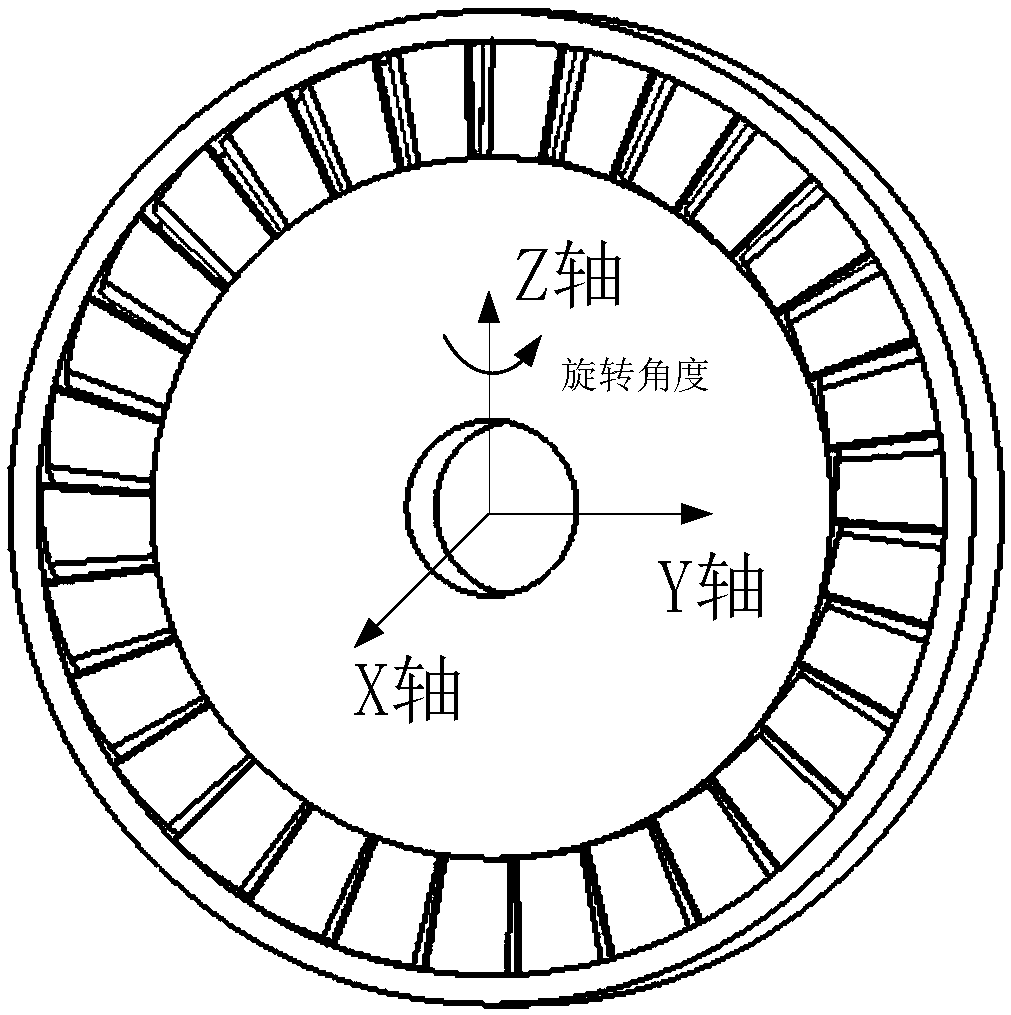

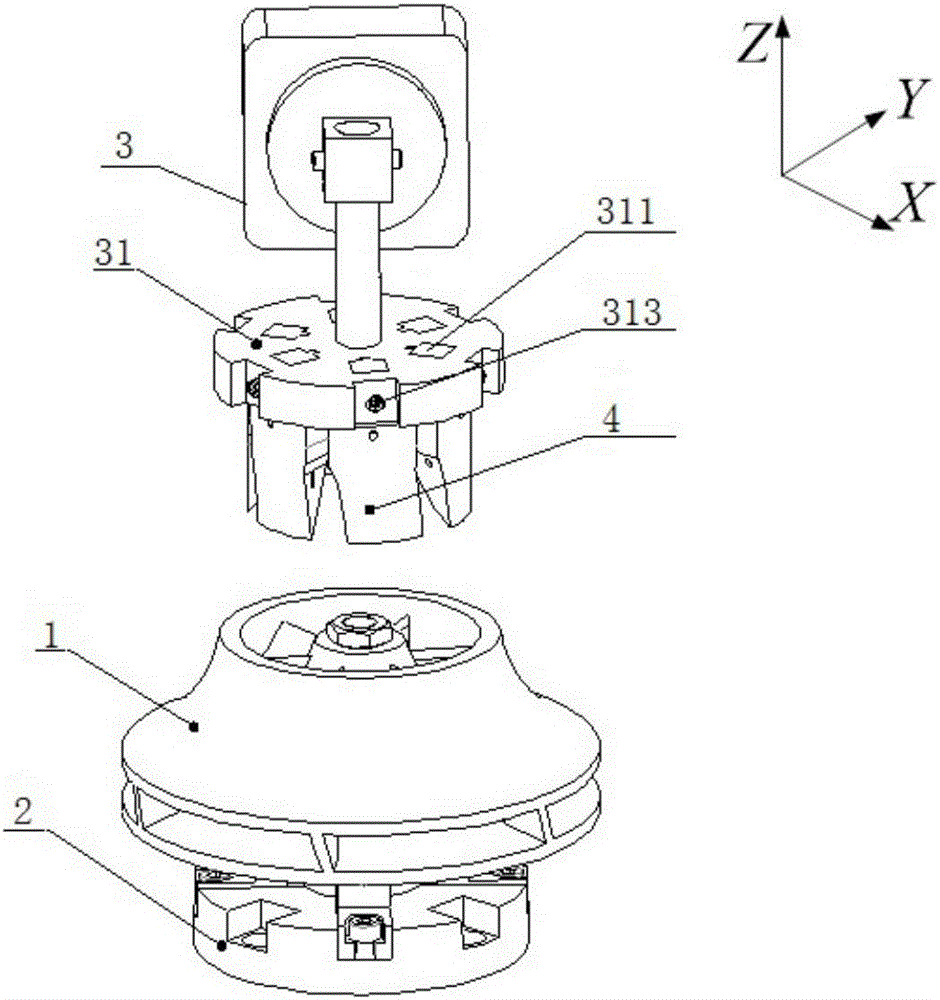

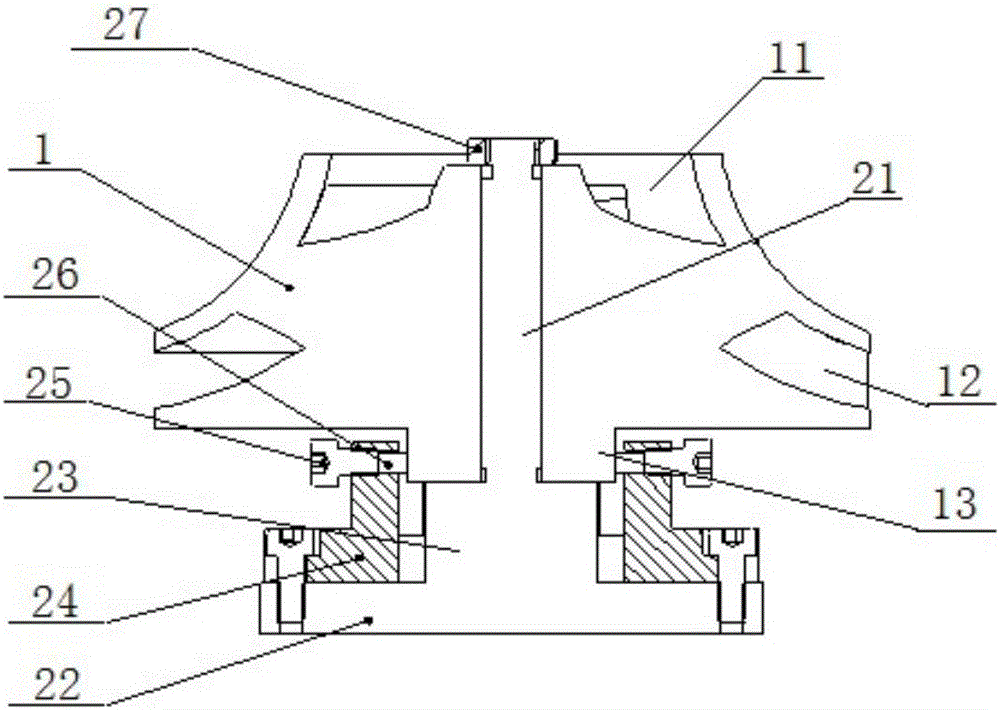

Closed impeller electric spark machining device and machining method

ActiveCN106735633AImprove processing efficiencyImprove machining accuracyImpellerSoftware engineering

The invention relates to the technical field of impeller machining, in particular to a closed impeller electric spark machining device and machining method. The closed impeller electric spark machining device comprises an impeller installation fixture for installing a closed impeller to be machined, a pre-machining electrode installation fixture and a plurality of pre-machining electrodes; the impeller installation fixture is provided with an installation shaft, the closed impeller to be machined is provided with a center positioning hole, and the closed impeller to be machined sleeves the installation shaft through the center positioning hole; the electrode installation fixture comprises a first electrode installation seat, the multiple pre-machining electrodes are all connected with the first electrode installation seat and arranged circumferentially, and the number of the pre-machining electrodes is the same as that of flow channels of the closed impeller to be machined; in the machining process, each pre-machining electrode corresponds to a flow channel inlet of the closed impeller to be machined; and the closed impeller electric spark machining device furthermore comprises a first drive mechanism for driving the electrode installation fixture to perform straight line movement in the Z-axis direction, and the Z axis is the extension direction of the installation shaft. By means of the closed impeller electric spark machining device and machining method, machining efficiency is improved, and machining precision is guaranteed.

Owner:北京市电加工研究所有限公司

Cutting tool covered with diamond

ActiveCN102626853AImprove the lubrication effectEasy chip removalTransportation and packagingMilling cuttersCarbon filmSurface layer

The invention provides a cutting tool covered with diamond. The tool substrate composed of tungsten carbide cemented carbide or titanium carbonitride base metallic ceramics is covered with a crystal diamond layer. Nanometer diamond film having average grain diameters of 1 to 50 nm and laminated alternatively at a lamination space of 0.2 to 2.0 micrometers and alternating lamination films of crystal diamond film having average grain diameters of 0.1 to 2 micrometers cover the crystal diamond layer. The shortest distance between the front end of a cutting blade to the crystal diamond layer is determined to be 3 to 15 micrometers. And a non-crystal carbon film having surface roughness less than 0.1 micrometer and thickness of 10 to 200 micrometers is formed on the surface layer of a front blade face of the nanometer diamond layer of the cutting blade.

Owner:MITSUBISHI MATERIALS CORP

Small drill

InactiveCN1474726AHigh bit rigidityImprove Chip EvacuationTransportation and packagingTwist drillsFluteDiameter ratio

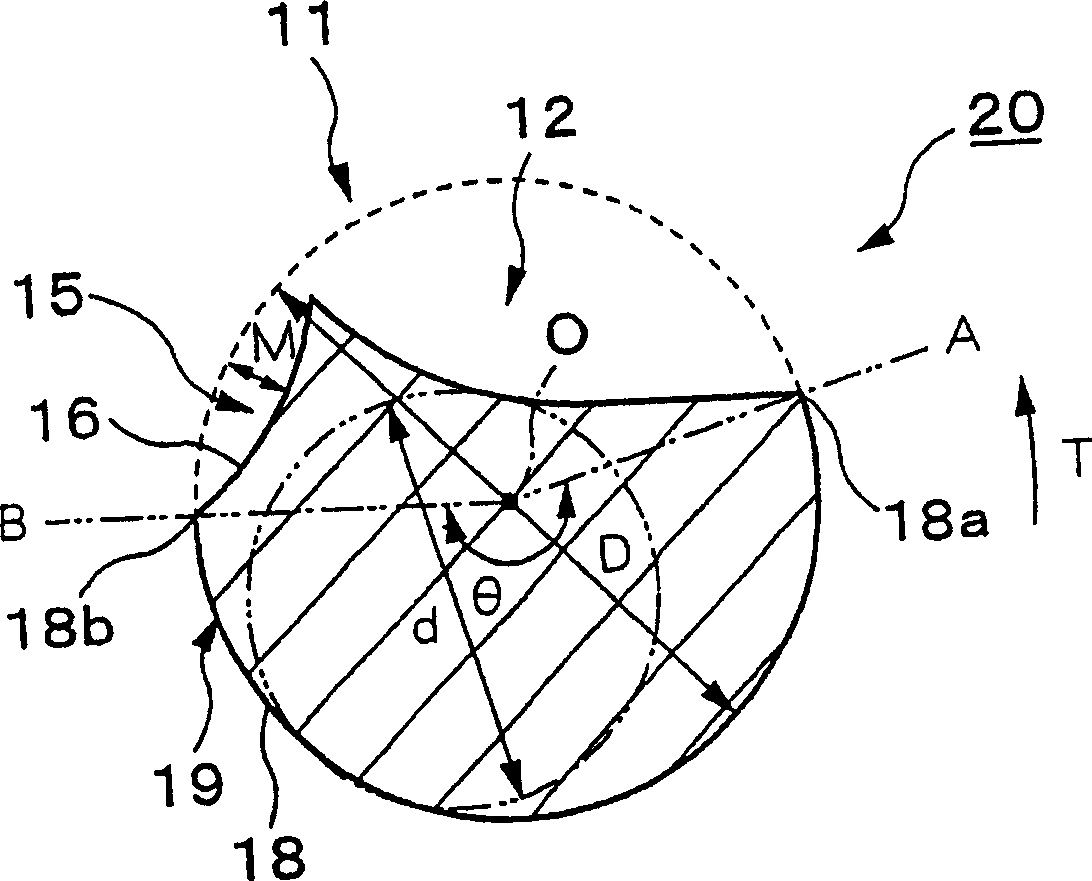

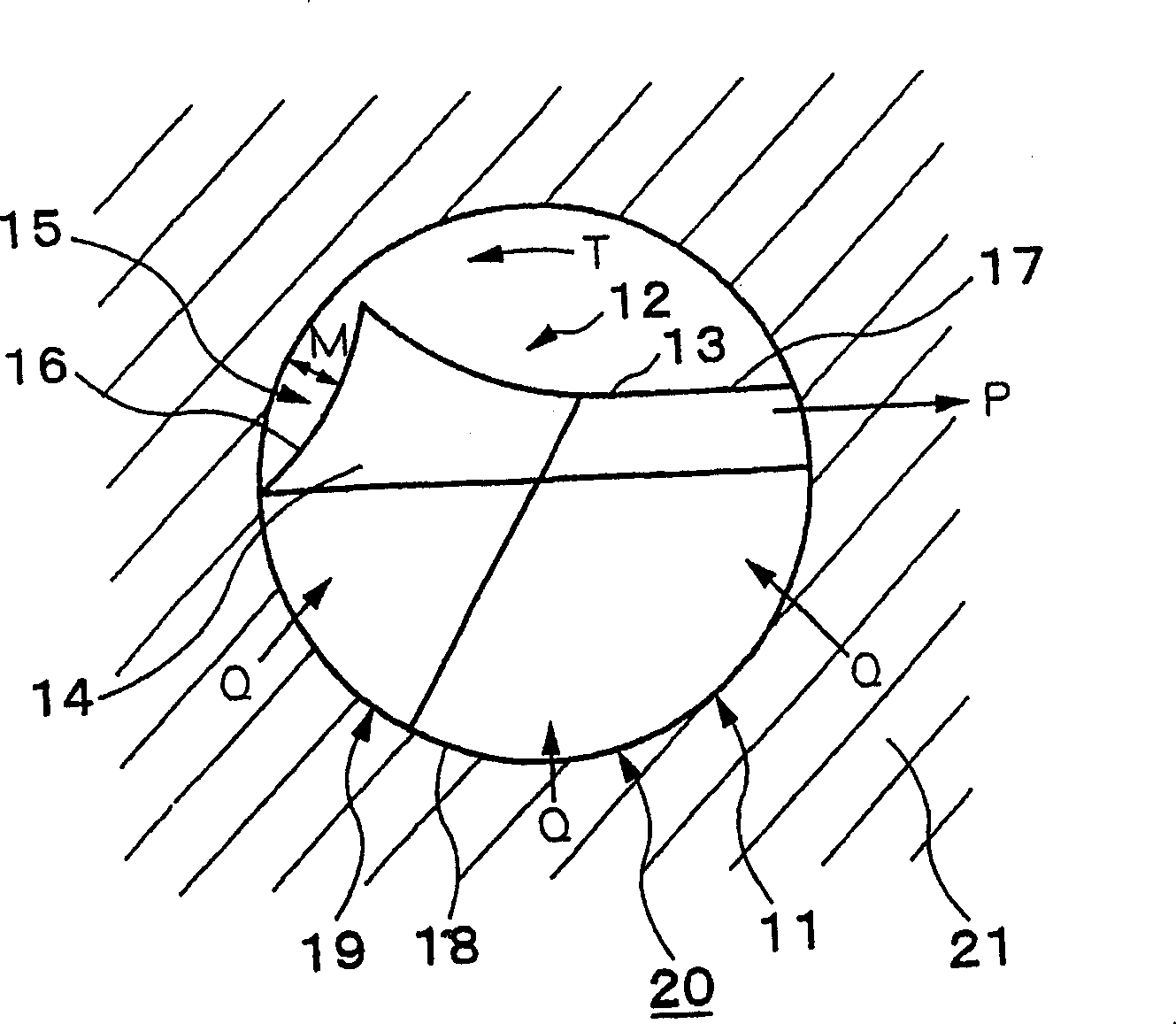

A small drill includes one chip-discharging flute which is helically formed in the exterior surface of a cutting portion of the small drill. The small drill also includes a flute-shaped portion which is formed in the front region of the chip-discharging flute in the rotating direction, which is connected to the chip-discharging flute, and which is open at the exterior surface of the cutting portion. The core diameter ratio d / D, in percent, of the small drill is set to 60% or more, and a margin angle θ thereof is set to 120 DEG or more.

Owner:MITSUBISHI MATERIALS CORP

a reamer

InactiveCN102266985AImprove cooling effectImprove Chip EvacuationReaming toolsMaintainance and safety accessoriesFluteWater flow

The object of the present invention is to propose a reamer, which can improve the cooling performance and chip removal performance of the internal cooling reamer, thereby improving the machining quality. The reamer of the present invention includes a shank and a blade. The blade is provided with a plurality of side edges, and chip removal grooves are arranged between adjacent side edges. An internal cooling hole, one end of the internal cooling hole is connected to the water inlet hole provided at the end of the handle, and the other end of the internal cooling hole is connected to the drain hole provided in the chip removal groove. During the processing, the reamer is injected with cooling water through the water inlet hole at the end of the shank, and the cooling water flows through the inner cooling hole to cool the reamer, and finally passes through the hole provided in the chip removal groove. Drain holes are used to discharge the iron chips accumulated in the chip removal groove, which greatly improves the chip removal performance, thereby improving the processing quality, prolonging the service life of the tool, and reducing the use cost of the tool.

Owner:锑玛(苏州)精密工具股份有限公司

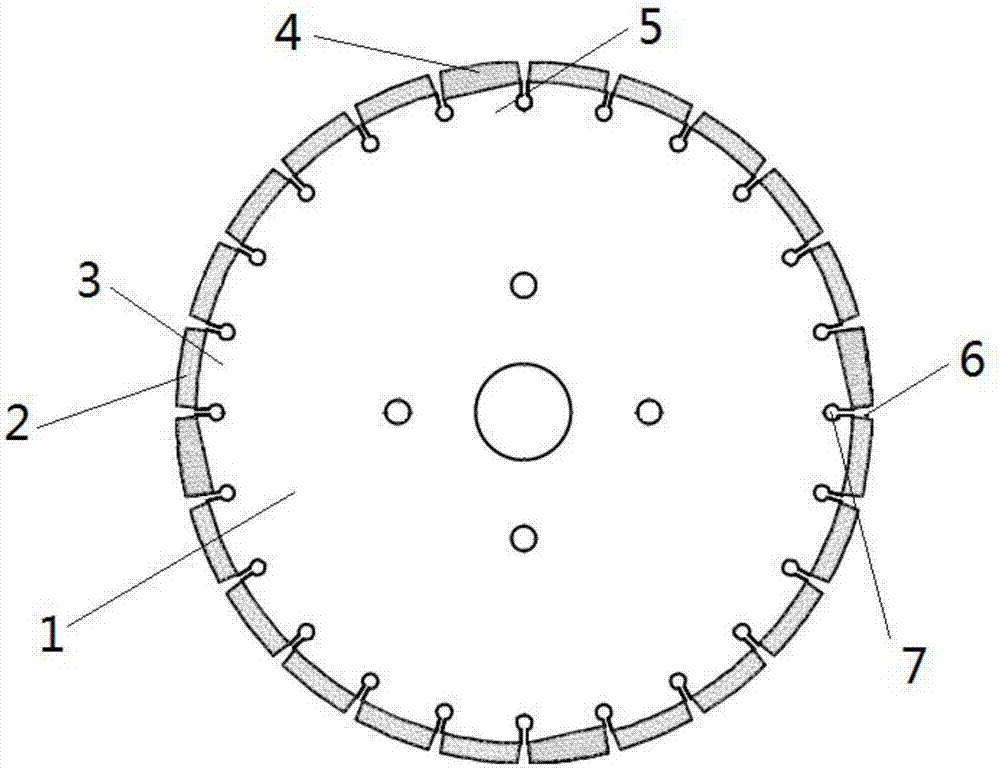

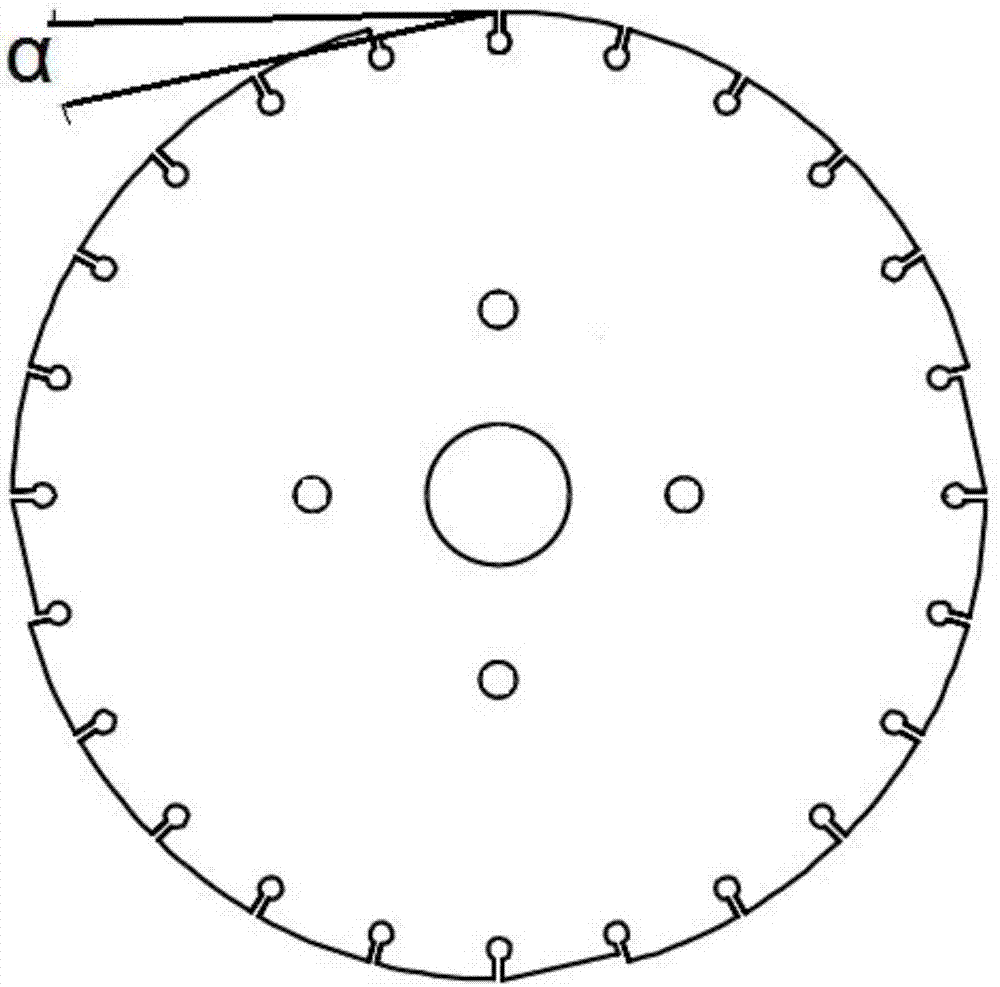

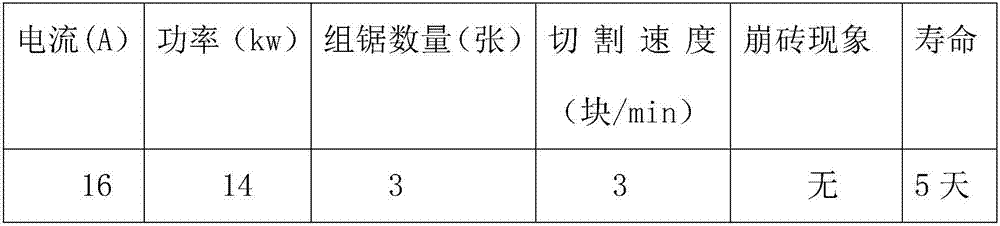

Formula for manufacturing of blank body of combined saw blade tip used for cutting black bricks and red bricks

InactiveCN107262709AImprove Chip EvacuationGuarantee personal safetyStone-like material working toolsBrickIron powder

The invention discloses a formula for manufacturing of a blank body of a combined saw blade tip used for cutting black bricks and red bricks and relates to the field of diamond saw blades. According to the formula, the blank body is formed by mixing diamond and metal powder and is characterized in that the concentration of the diamond is 20-35%, and the metal powder is prepared from the following components of, by weight, 25-50% of iron-copper-tin alloy powder, 15-30% of copper powder, 2-6% of tin powder, 5-15% of nickel powder, 2-10% of cobalt powder, 2-5% of 663 bronze powder and the balance iron powder in proportion. When the multiple saw blades manufactured according to the formula are used in a combined mode, the cutting speed is high, the cutting effect is good, and the problems that an existing saw blade is prone to breaking bricks during cutting, and the service life is short are solved.

Owner:河北小蜜蜂工具集团有限公司

High-efficiency cutting grinding wheel

ActiveCN102528677ASmooth dischargeEfficient exclusionBonded abrasive wheelsSurface roughnessWater flow

The invention discloses a high-efficiency cutting grinding wheel comprising a base body and a grinding ring. Water outlets are hollowed on the grinding surface of the grinding ring and communicated with water flow passageways correspondingly arranged in the base body; the water flow passageways are converged at water inlets arranged on the base body; in the circular arc length range randomly set on the grinding surface, the number of the water outlets is more than 0 and less than 30, and the circular arc length set randomly is one to three times of a contact line between the grinding ring and a workpiece when the workpiece to be processed is ground; and the base body comprises two layers of substrates, the grinding ring is clamped and fixedly connected between the substrates, a water storage area playing the role of the water flow passageway is formed between the substrates, and the water inlets are ring ports arranged on the substrates. Enough water outlets are arranged so that the cuttings generated in a grinding processing area can be discharged rapidly, the surface roughness of a surface to be processed and the sharpness of the grinding wheel can be improved substantially, the grinding wheel can be ensured to be suitable for the rapid and high-speed process, and the production efficiency is improved.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com