Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Reduce the probability of short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer composite diaphragm and its preparing method

InactiveCN1851957AReduce the probability of short circuitImprove electrical performanceCell component detailsTextiles and paperPolymer compositesOrganic solvent

This invention discloses a polymer compound membrane and its preparation method, in which, the method includes: mixing strengthening bodies of a matrix film and inorganic nm materials in an organic solvent to get a uniform slurry to be coated on both sides of a non-woven cloth to get a polymer compound membrane, in which, said strengthening bodies are selected from the following three: 1, an organic monomer and its related initiator, 2, two or more than two polymers, 3, organic monomers and their related initiators and two or more than two polymers, 4, organic monomers and two or more than two polymers.

Owner:PEKING UNIV

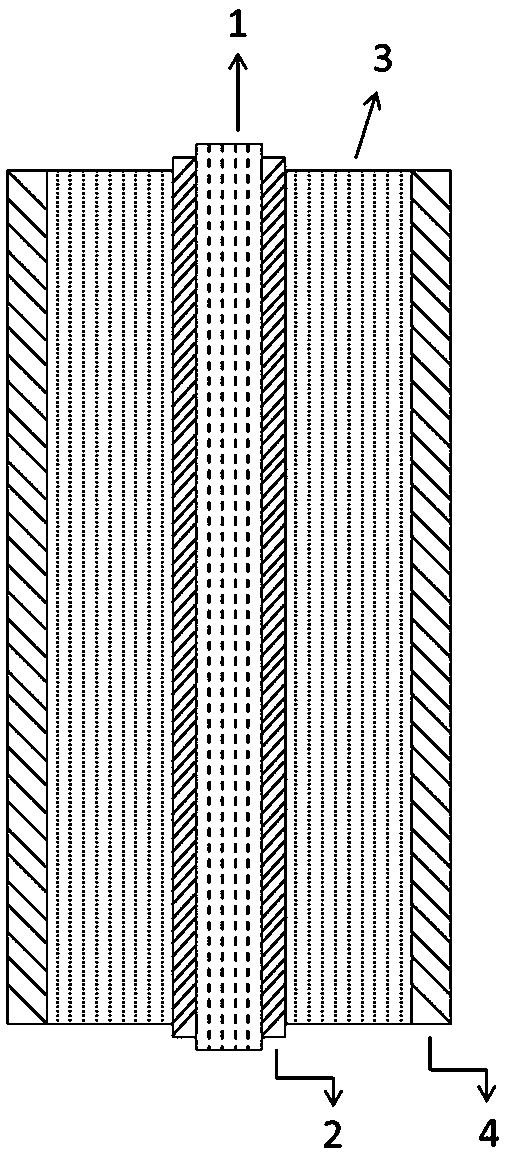

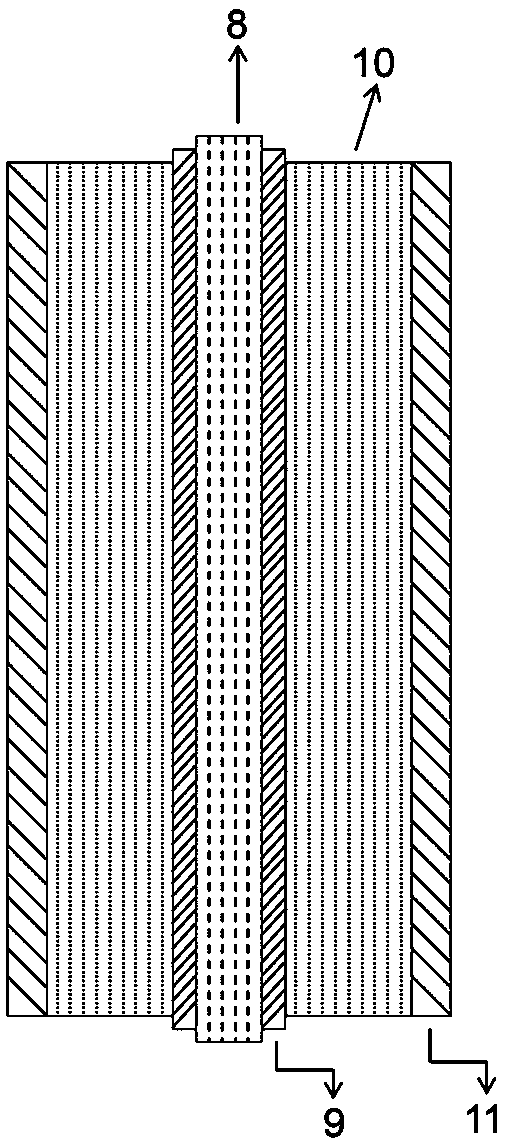

Composite lithium ion battery diaphragm and preparation method thereof

InactiveCN104766938AReduce the probability of short circuitImprove performanceCell seperators/membranes/diaphragms/spacersSecondary cellsNonwoven fabricLithium-ion battery

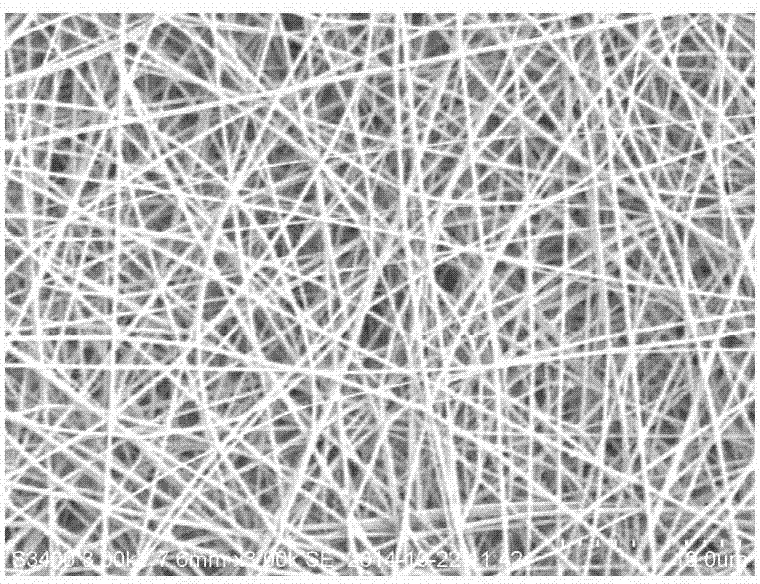

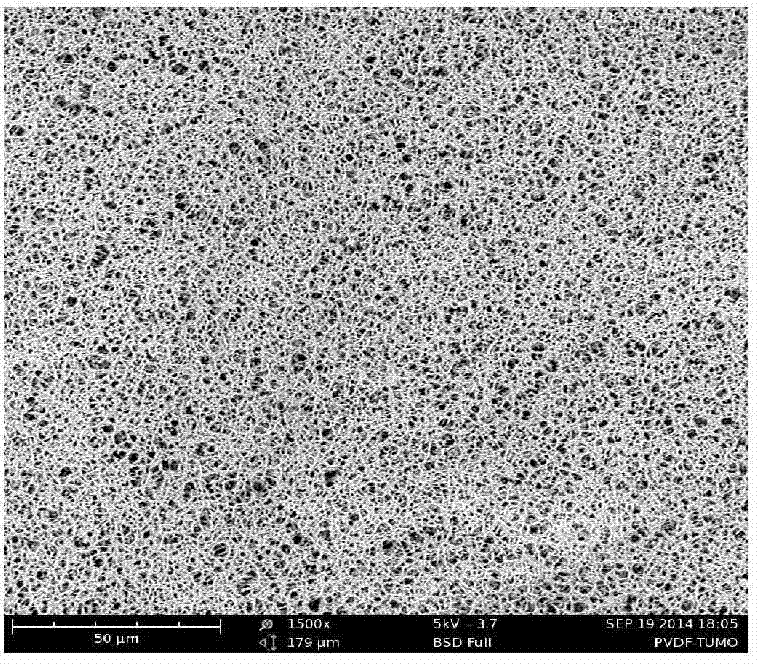

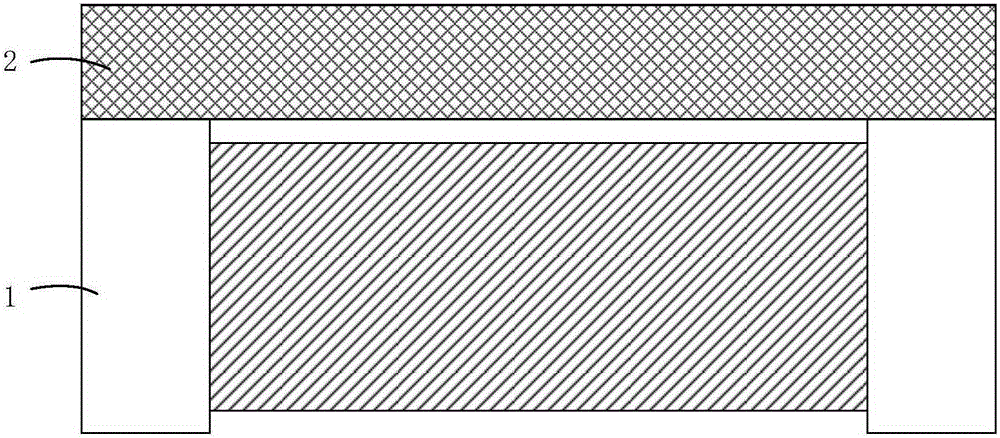

The invention discloses a composite lithium ion battery diaphragm comprising a nonwoven fabric substrate layer, an electrostatic spinning layer and a polymer porous coating, and the structure compound mode is as follows: polymer porous coating / electrostatic spinning layer / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; or polymer porous coating / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating. The composite lithium ion battery diaphragm uses nonwoven fabric as a substrate to ensure the diaphragm high porosity and heat resistance, electrostatic spinning layers are arranged on the upper and lower surfaces of the nonwoven fabric substrate, the nonwoven fabric pore diameter can be reduced, the pore diameter is uniform, and the problem of short circuit caused by local macropore of the nonwoven fabric diaphragm can be solved, and by the arrangement of the polymer porous coating, the absorption and electrolyte maintaining capacity of the diaphragm can be improved, battery positive and negative electrodes can be bonded, battery mechanical properties can be improved, and the battery safety can be ensured. The prepared composite lithium ion battery diaphragm can satisfy the security requirements of large current charging discharging and running in harsh environments of a high-capacity high-power power battery.

Owner:LONGYAN ZIJIN INNOVATION RES INST +1

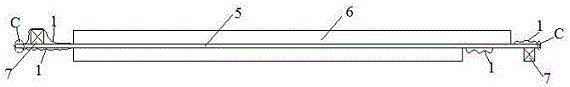

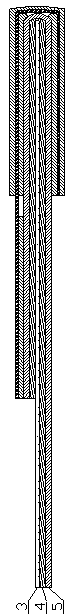

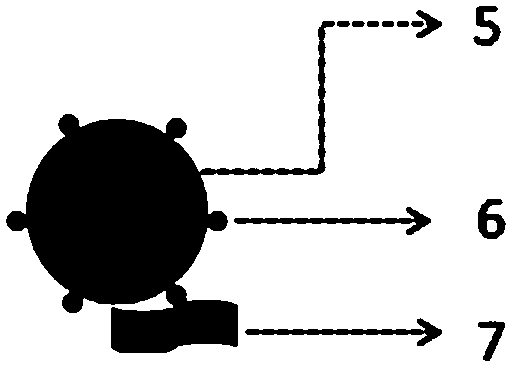

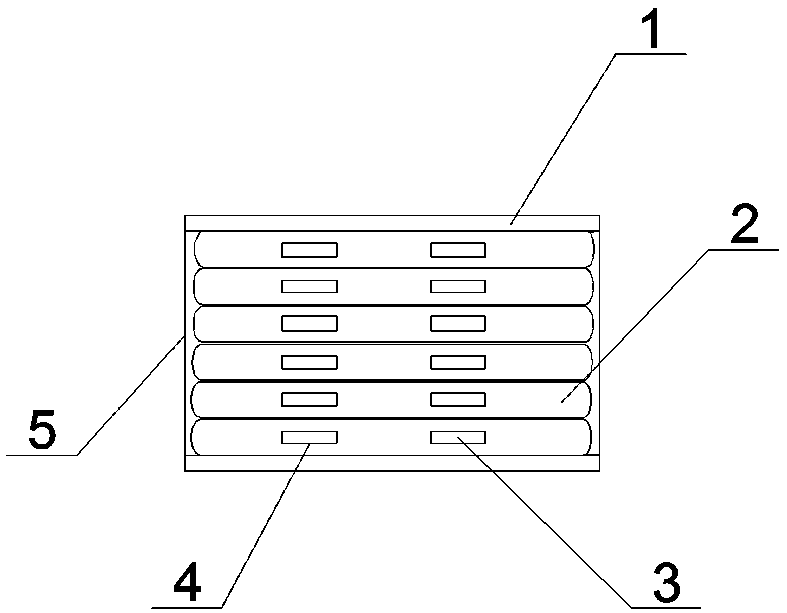

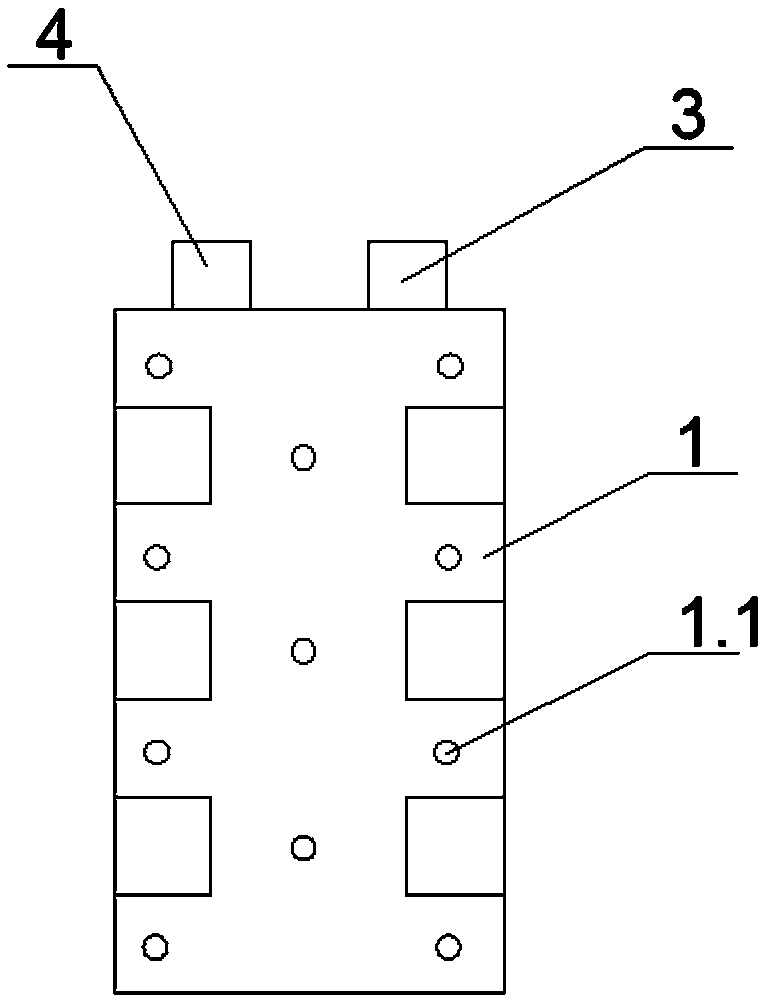

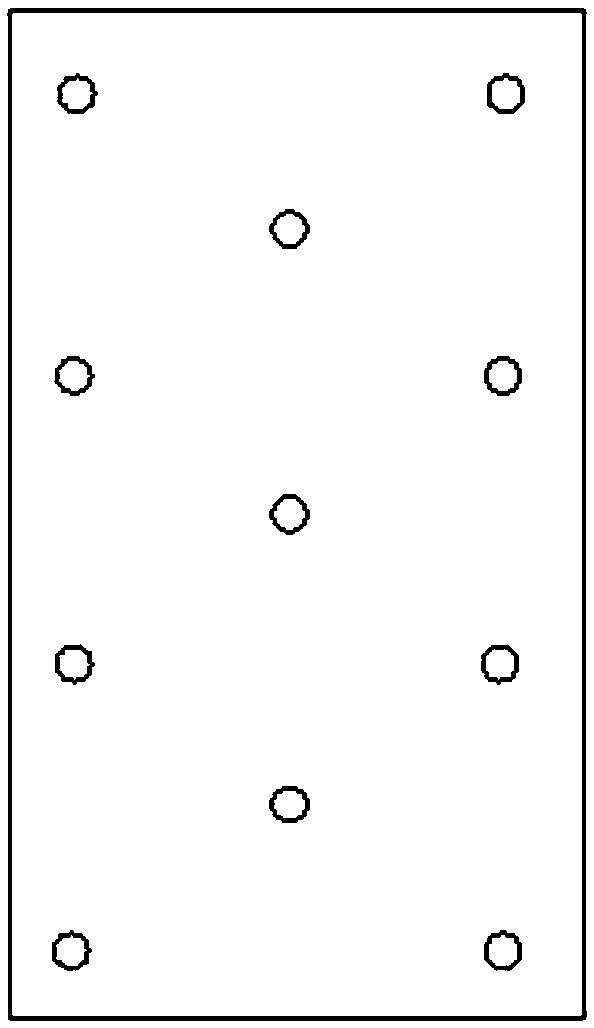

Internal liquid-flushing cluster shaping electrode for electrospark machining

ActiveCN1657208AReduce preparation timeIncrease profitElectrical-based machining electrodesEngineeringElectrical discharge machining

An internal liquid-flushing type shaping cluster electrode for electrospark machining is composed of rod-shaped electrode units and an electrode base for holding a cluster of said electrode units. Said electrode base consists of electrode fixture interface, main body and holding module. Its advantages are easy manufacture, and high utilization rate of electrode material.

Owner:SHANGHAI JIAO TONG UNIV

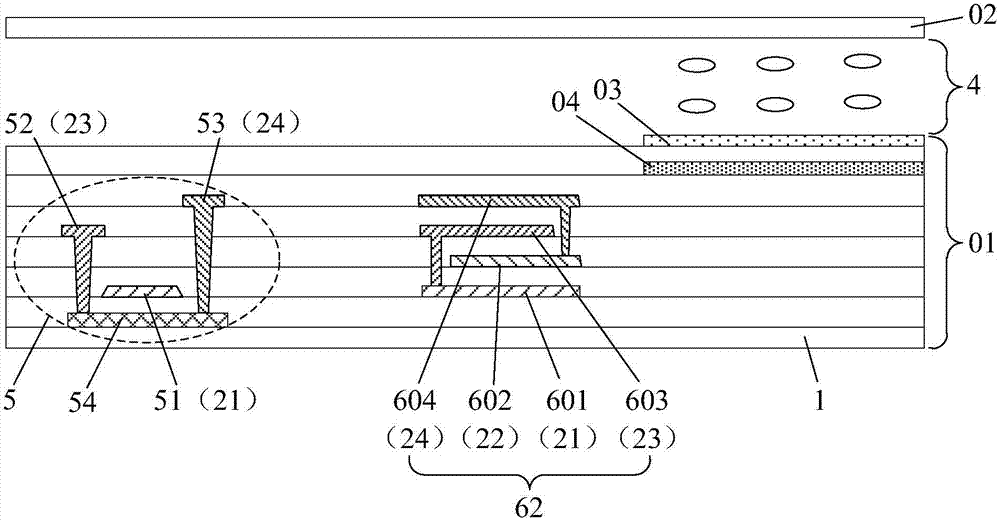

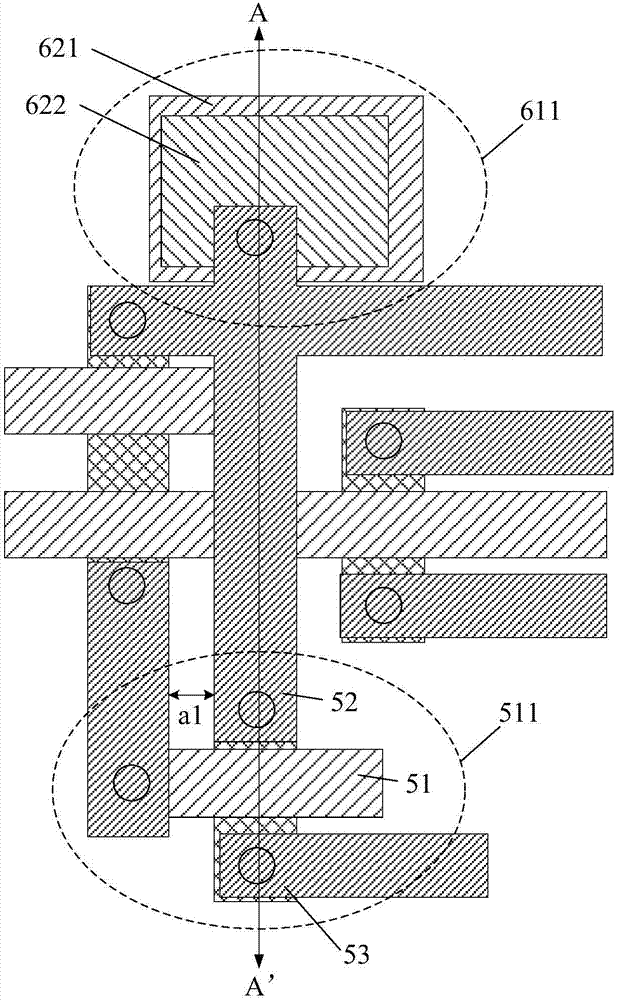

Laminated Li-ion secondary battery and method for producing the battery

InactiveCN101212070AReduce the probability of short circuitIncrease capacityElectrode manufacturing processesFinal product manufactureMetal foilCurrent collector

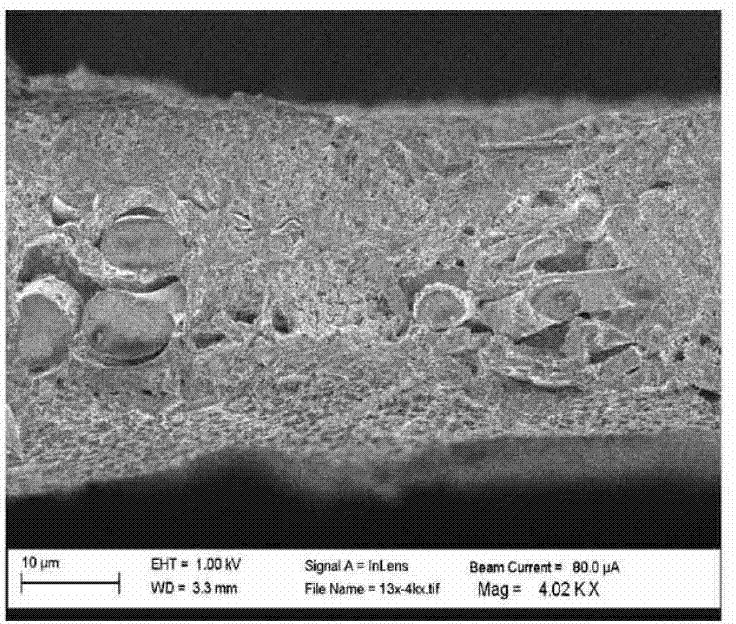

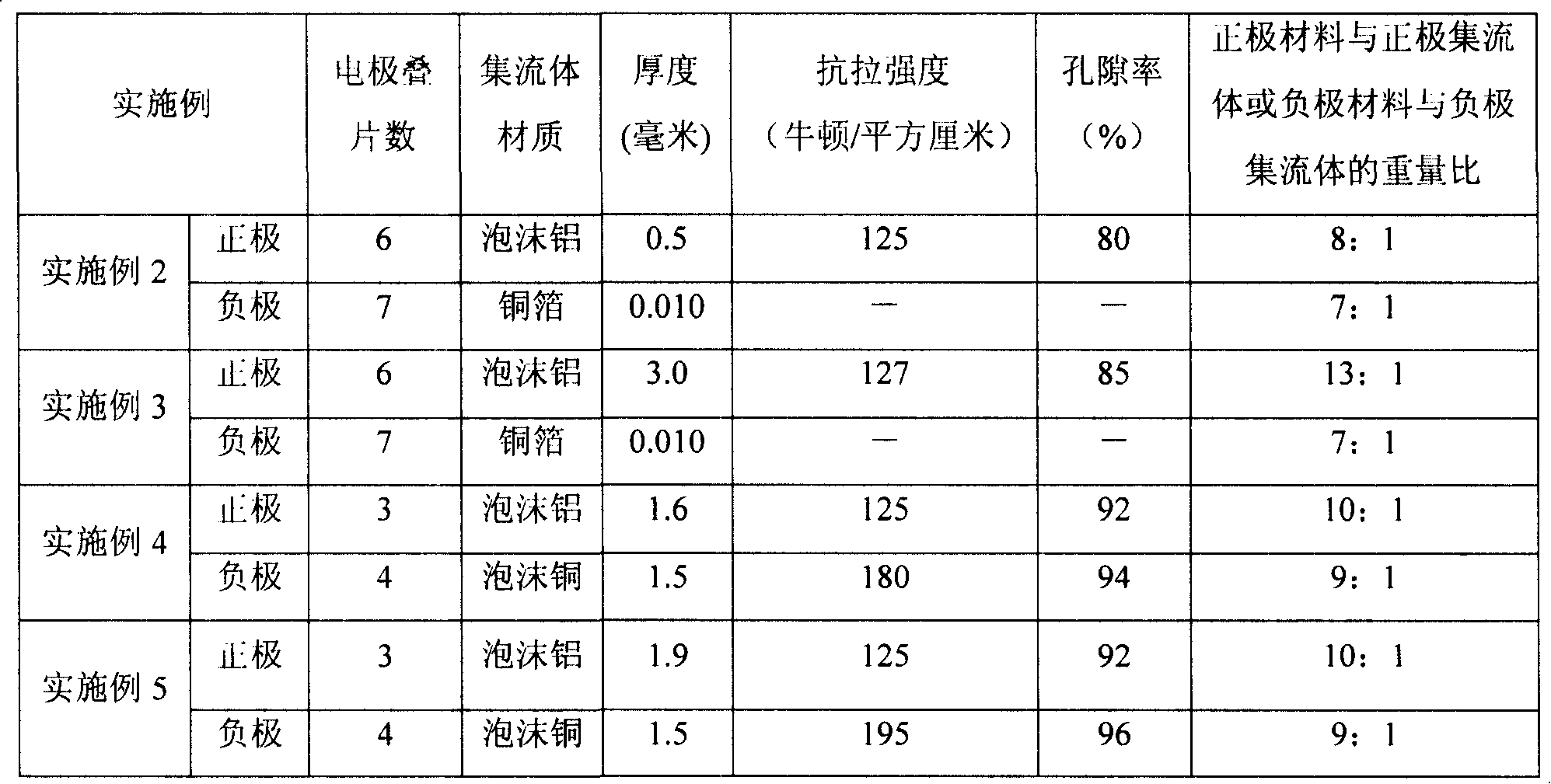

The invention relates to a lamination core lithium iron secondary battery. The battery comprises a battery shell and an electrode group and electrolyte which are sealed in the battery shell. The electrode group comprises an anode, a cathode and a diaphragm arranged between the anode and the cathode. The anode comprises an anode current collector and anode material carried on the current collector and the cathode comprises a cathode current collector and cathode material carried on the current collector; the anode current collector and / or the cathode current collector are / is foam metal and the thickness of the foam metal is 0.5-3 millimeter, the tensile strength is not less than 120n / square meter and the porosity is not less than 80 per cent. The lamination core lithium iron secondary battery of the invention, by adopting the foam metal instead of the metal foil as the electrode current collector, increases the strength of the battery electrode and thereby reducing the short circuit rate of the battery as well as increases the specific capacity of the electrode quantity, thus increasing the battery capacity. Furthermore, the electrode material is easier to be drenched by the electrolyte, thus improving the circulation performance of the battery.

Owner:BYD CO LTD

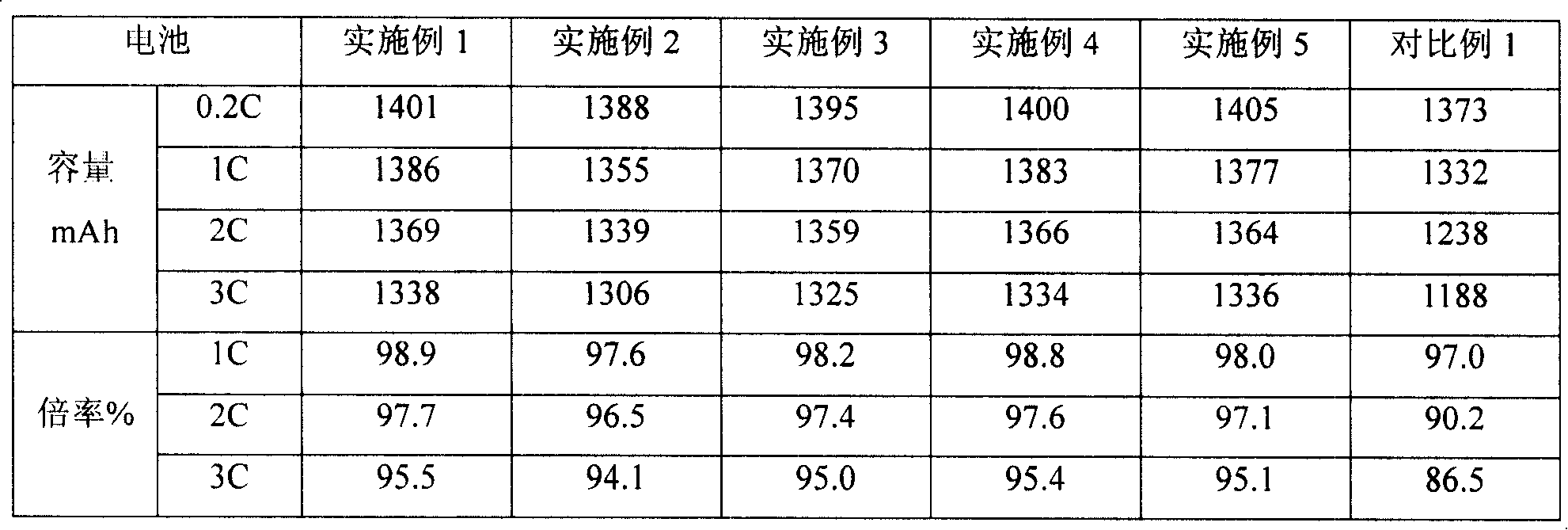

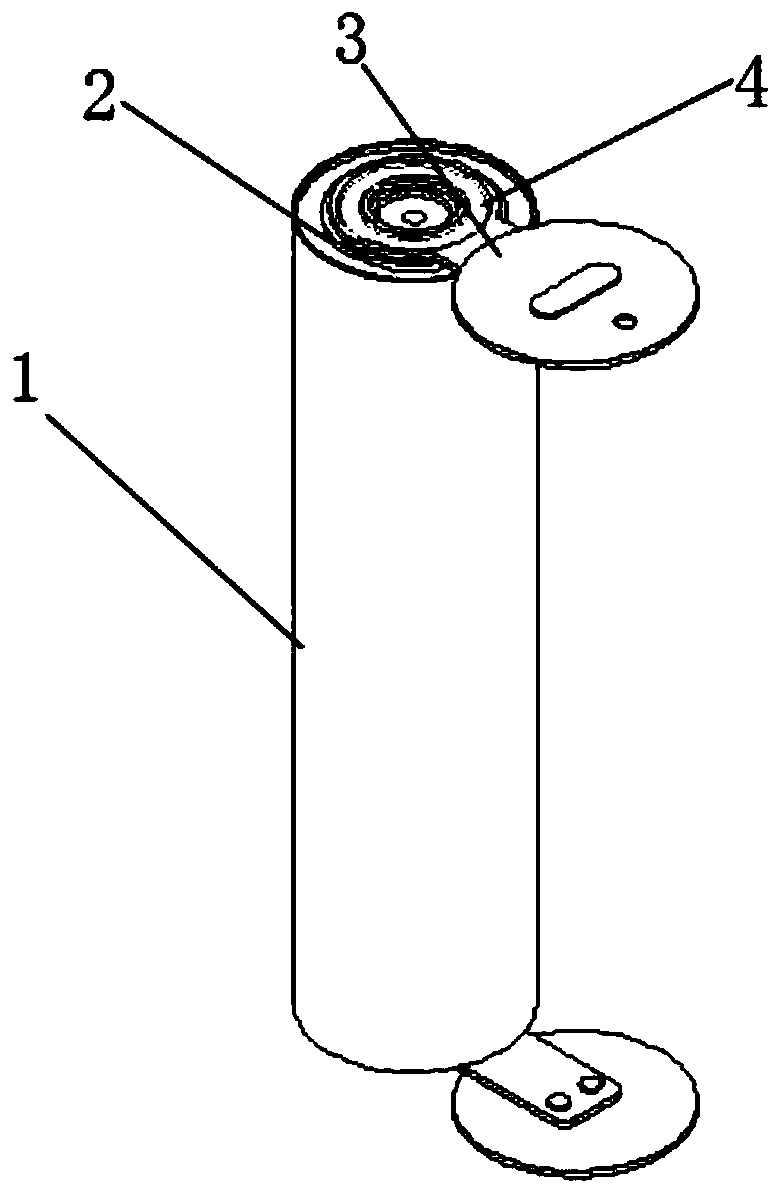

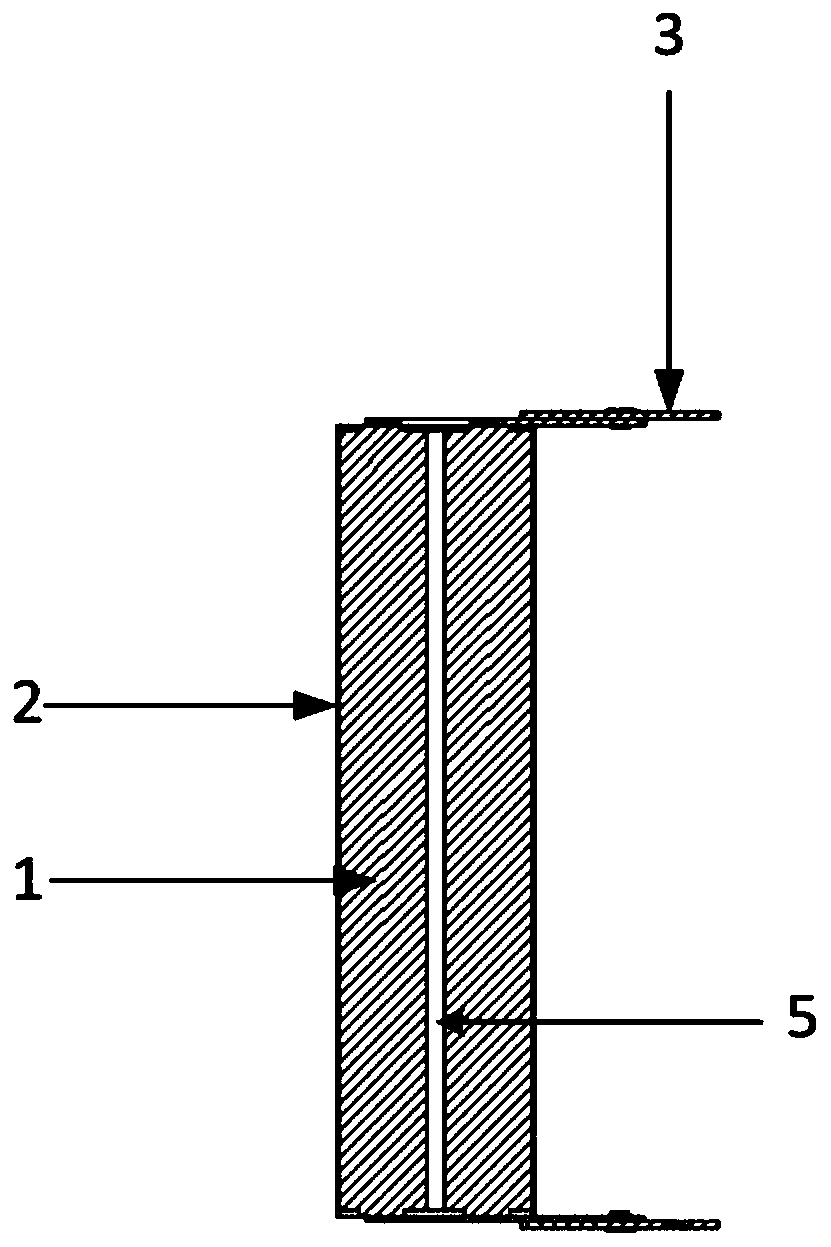

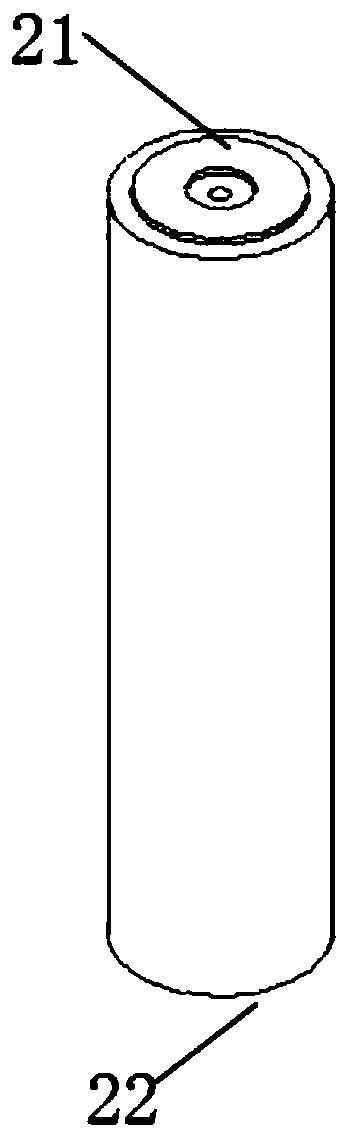

Cylindrical lithium ion battery and processing method thereof

ActiveCN110600795AAvoid short circuitAvoid foldingFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention discloses a cylindrical lithium ion battery and a processing method thereof, which can solve the technical problems that because space inside an existing lithium battery is reduced, battery liquid injection is difficult and a certain safety risk exists. The cylindrical lithium ion battery comprises a roll core, a shell and current collecting discs, wherein the height of the roll coreis smaller than that of the shell; the shell is cylindrical; the roll core is located inside the shell; tabs are arranged at the two ends of the roll core; one end of the roll core is provided with the positive tab, and the other end of the roll core is provided with the negative tab; the end surfaces of the tabs of the roll core are annular step surfaces; annular grooves are formed in the current collecting discs of positive and negative electrodes; the grooves are welding areas; the annular step surfaces on the tabs are welded with the annular grooves in the current collecting discs in a fitted manner; and a set spacing is reserved between the head and the tail of a welding track during welding. Compared with the prior art, the cylindrical lithium ion battery has the advantages that theshort circuit rate can be effectively reduced; the length of each tab is reduced, so that the weight of the battery is reduced and the liquid injection space of electrolyte is expanded; and by adopting an annular welding mode, the welding efficiency is improved compared with other multi-track welding modes.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

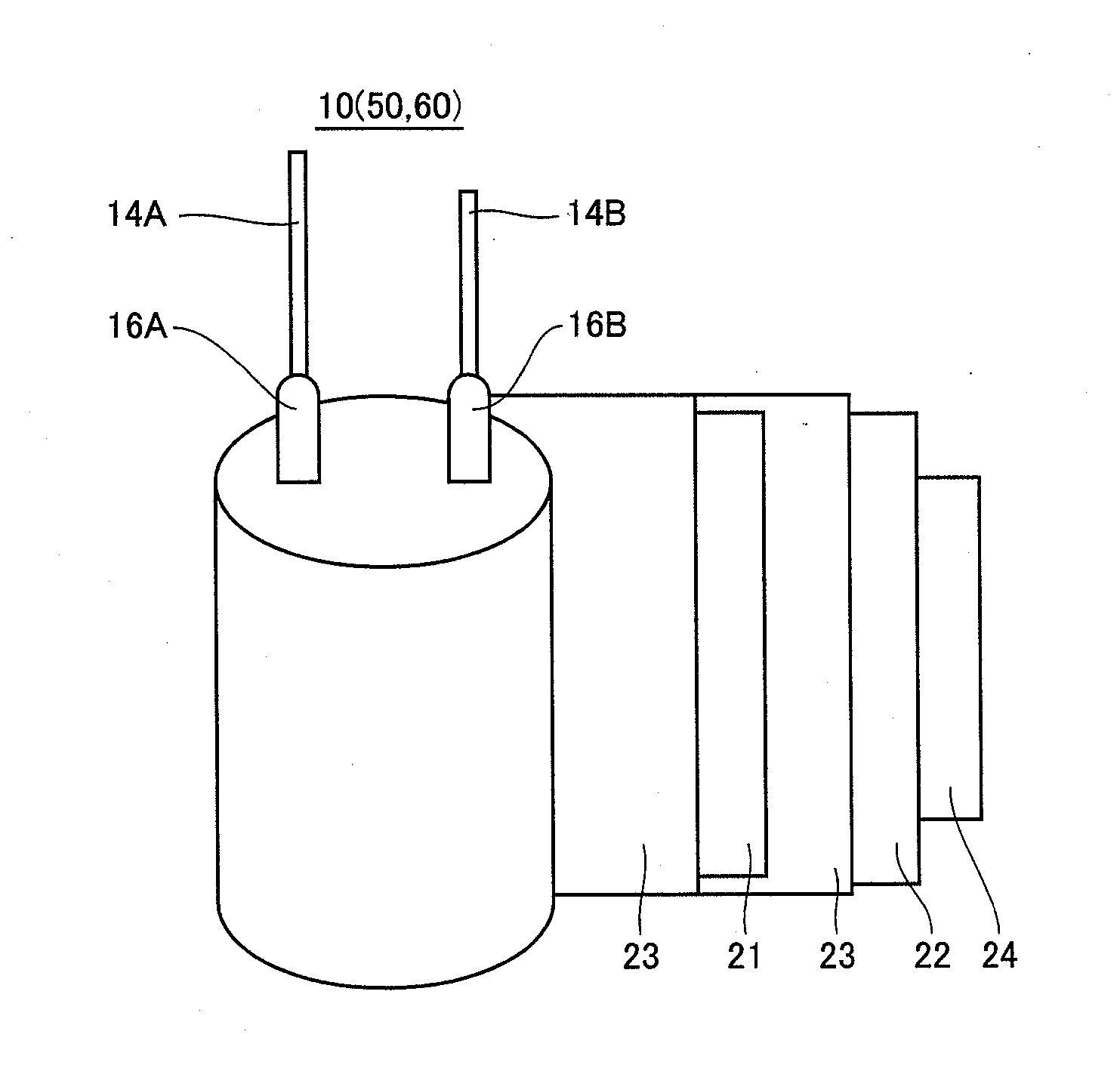

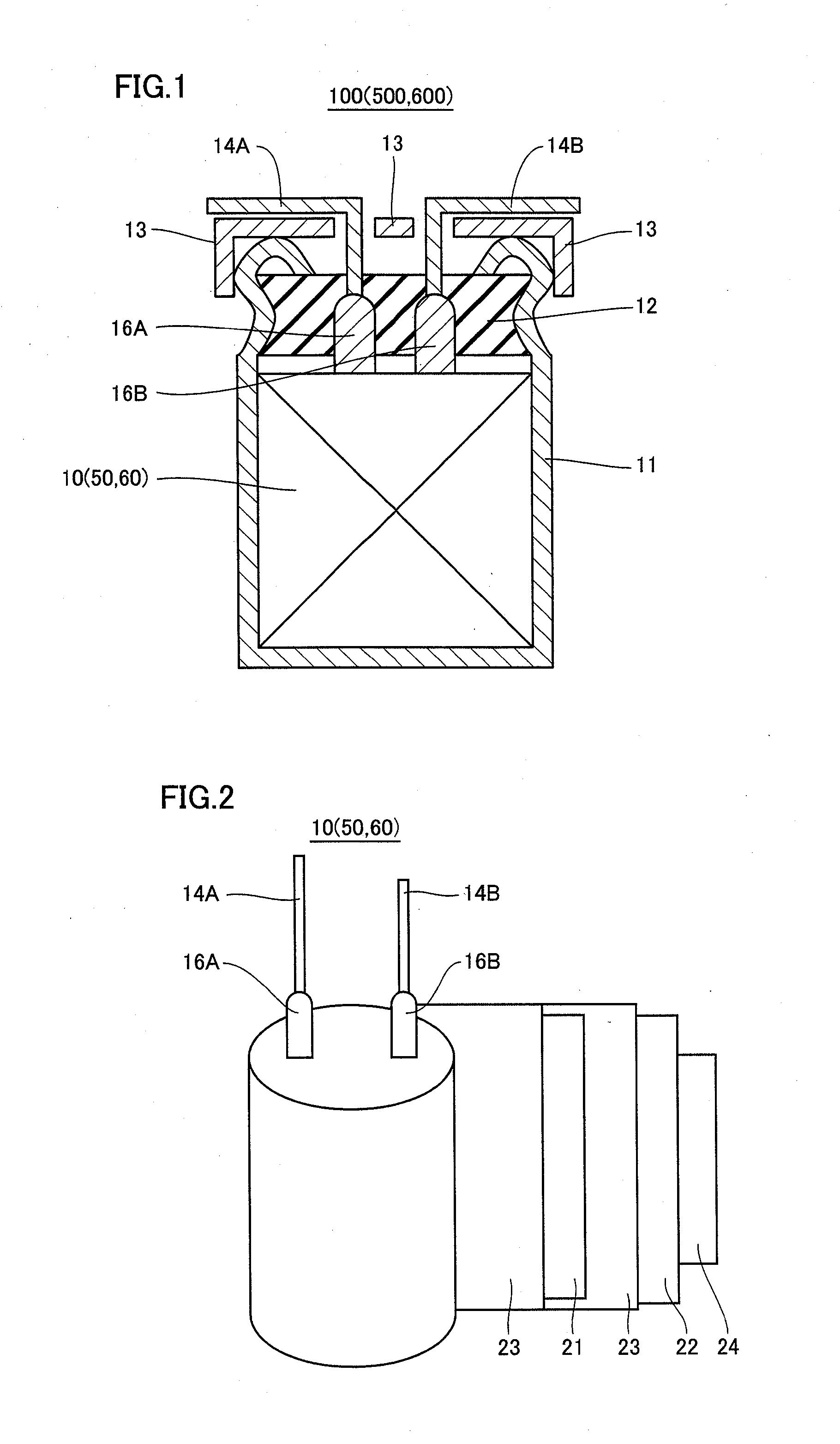

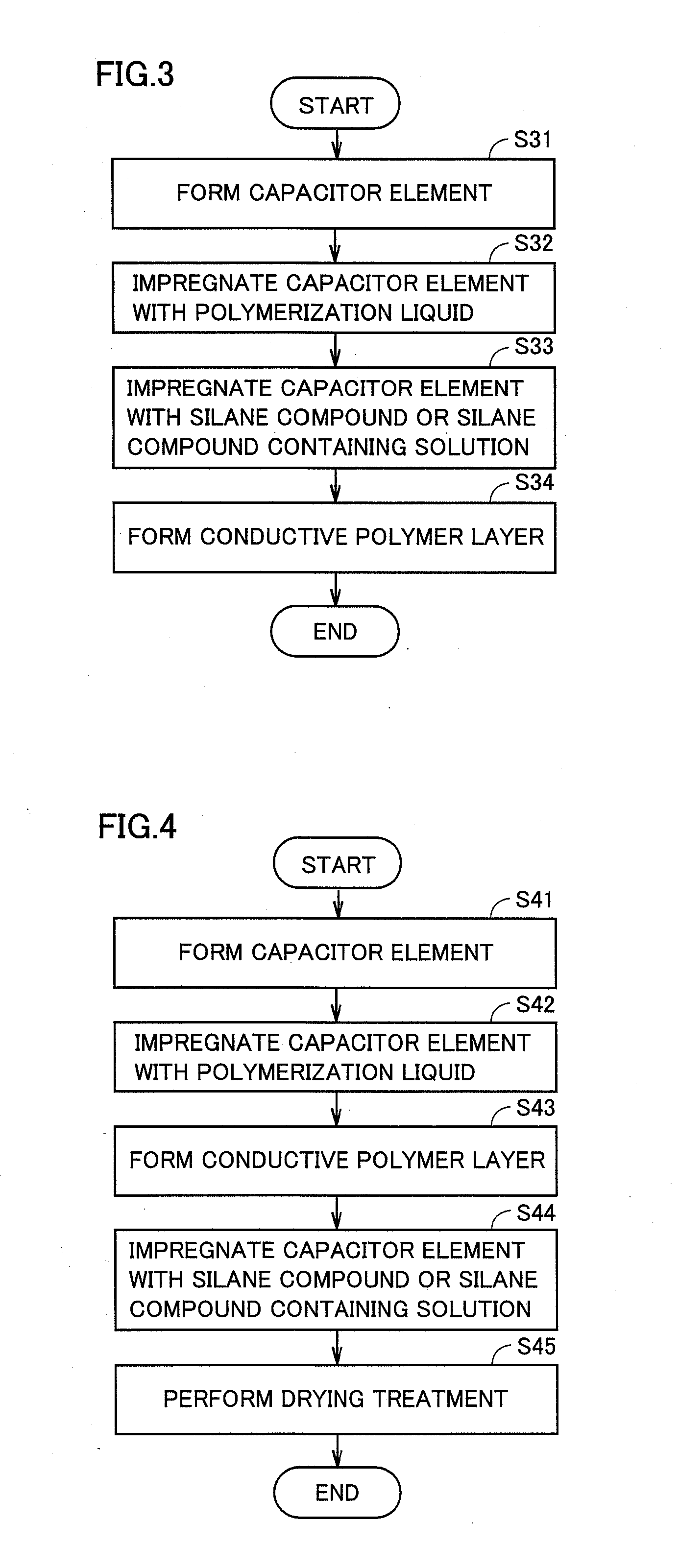

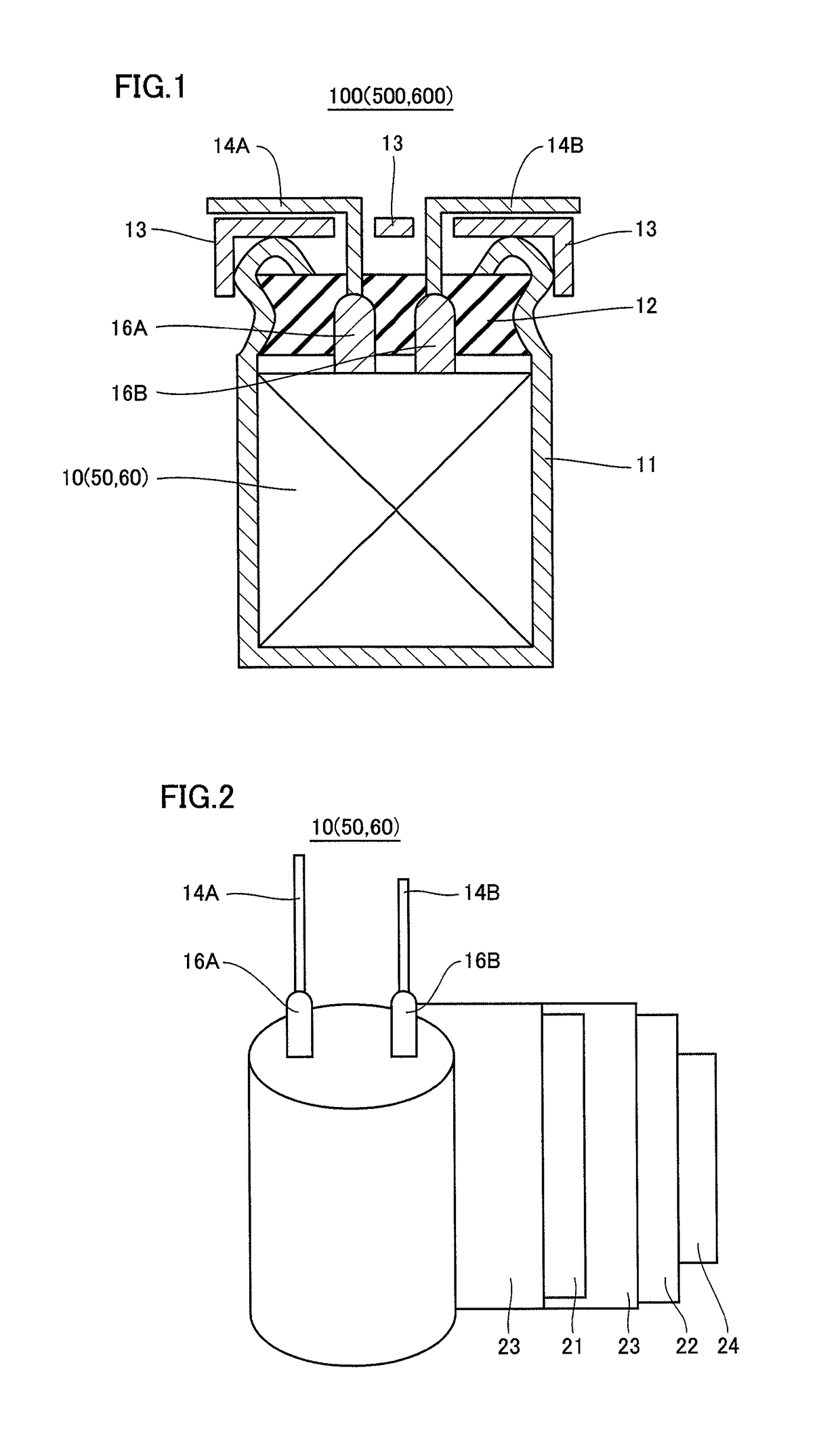

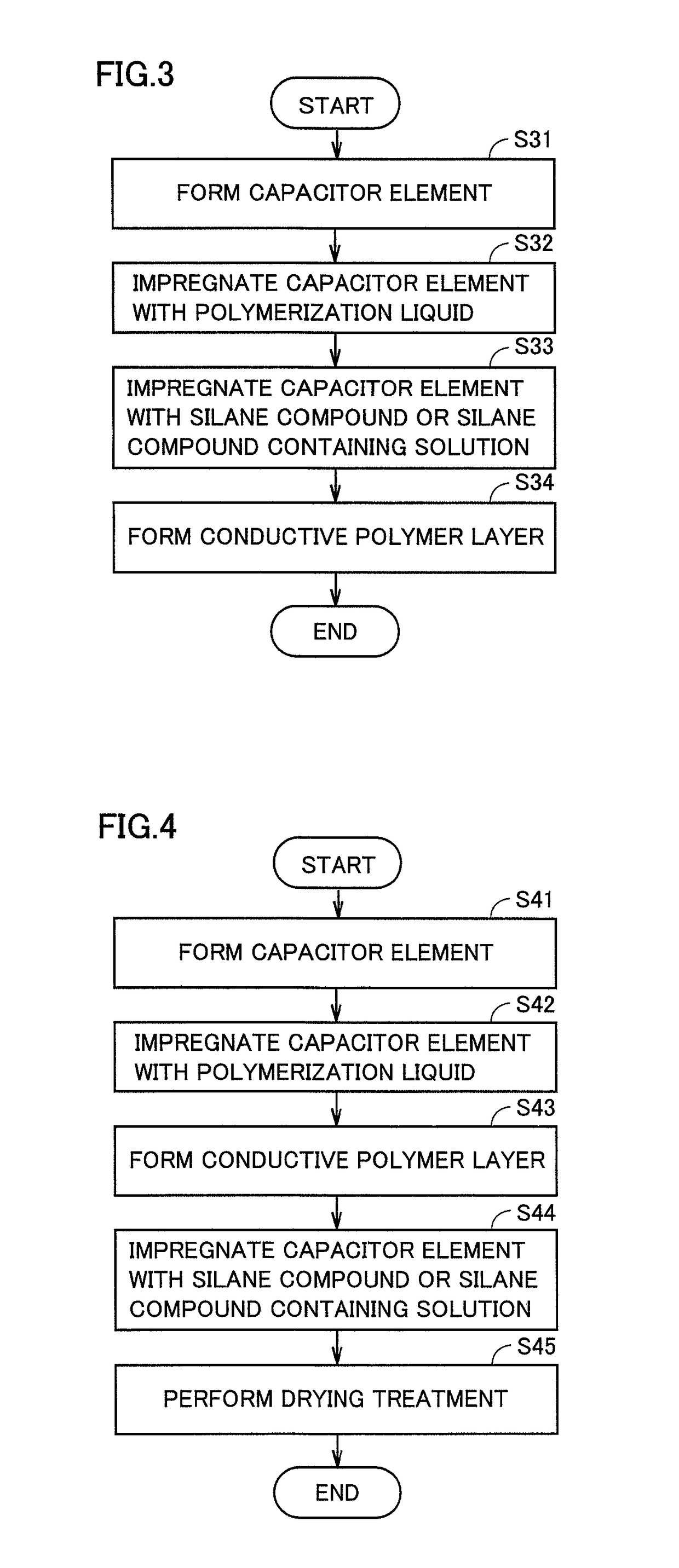

Method of manufacturing solid electrolytic capacitor

ActiveUS20100136222A1Small leak currentReduce the ratioSolid electrolytic capacitorsLiquid electrolytic capacitorsSilane compoundsElectrolysis

Provided is a method of manufacturing a solid electrolytic capacitor, including the steps of: forming a capacitor element including an anode body having a dielectric coating film on a surface thereof; impregnating the capacitor element with a polymerization liquid containing a precursor monomer of a conductive polymer and an oxidant; impregnating the capacitor element impregnated with the polymerization liquid with a silane compound or a silane compound containing solution; and forming a conductive polymer layer by polymerizing the precursor monomer after impregnating the capacitor element with the silane compound or the silane compound containing solution.

Owner:SANYO ELECTRIC CO LTD +1

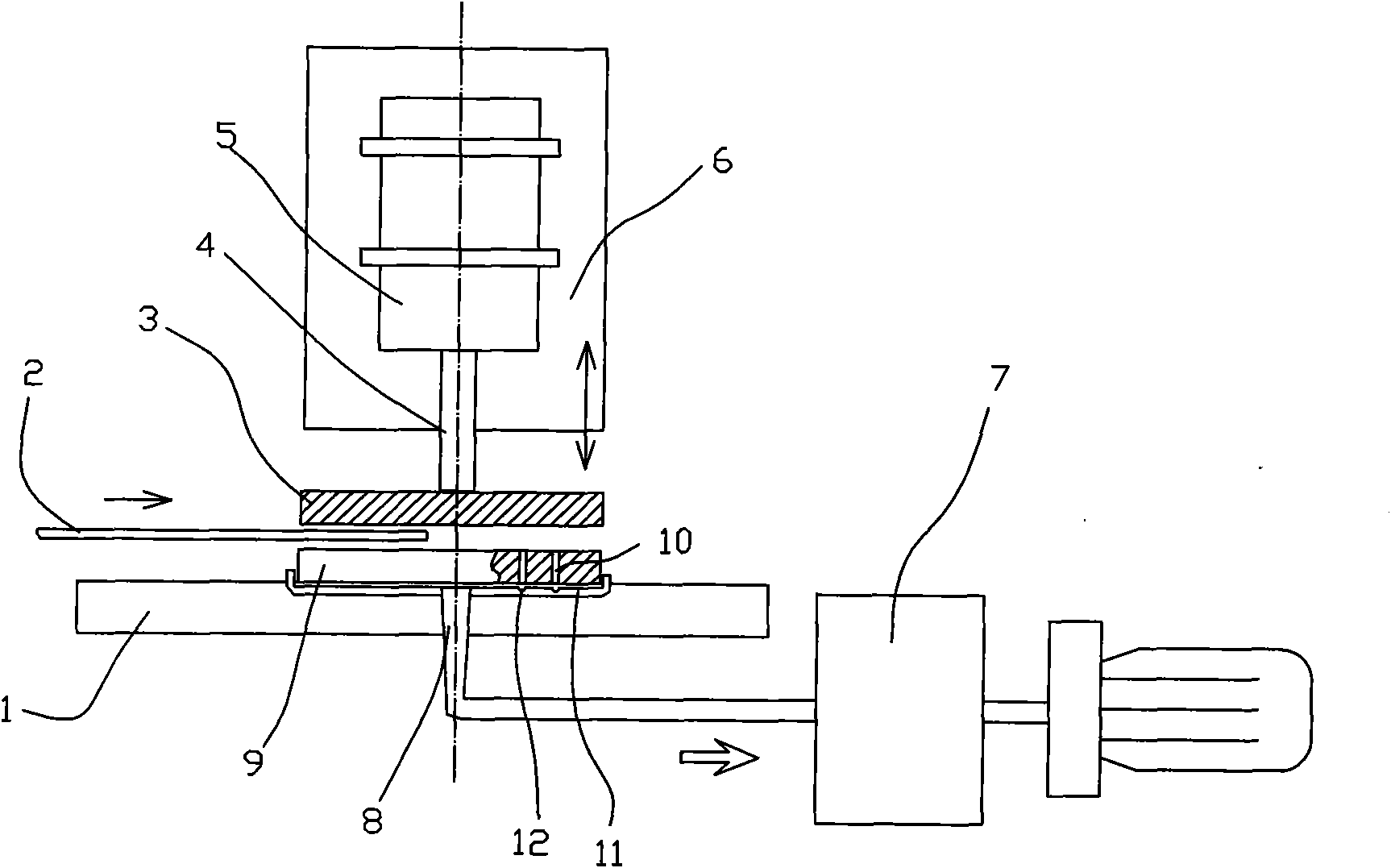

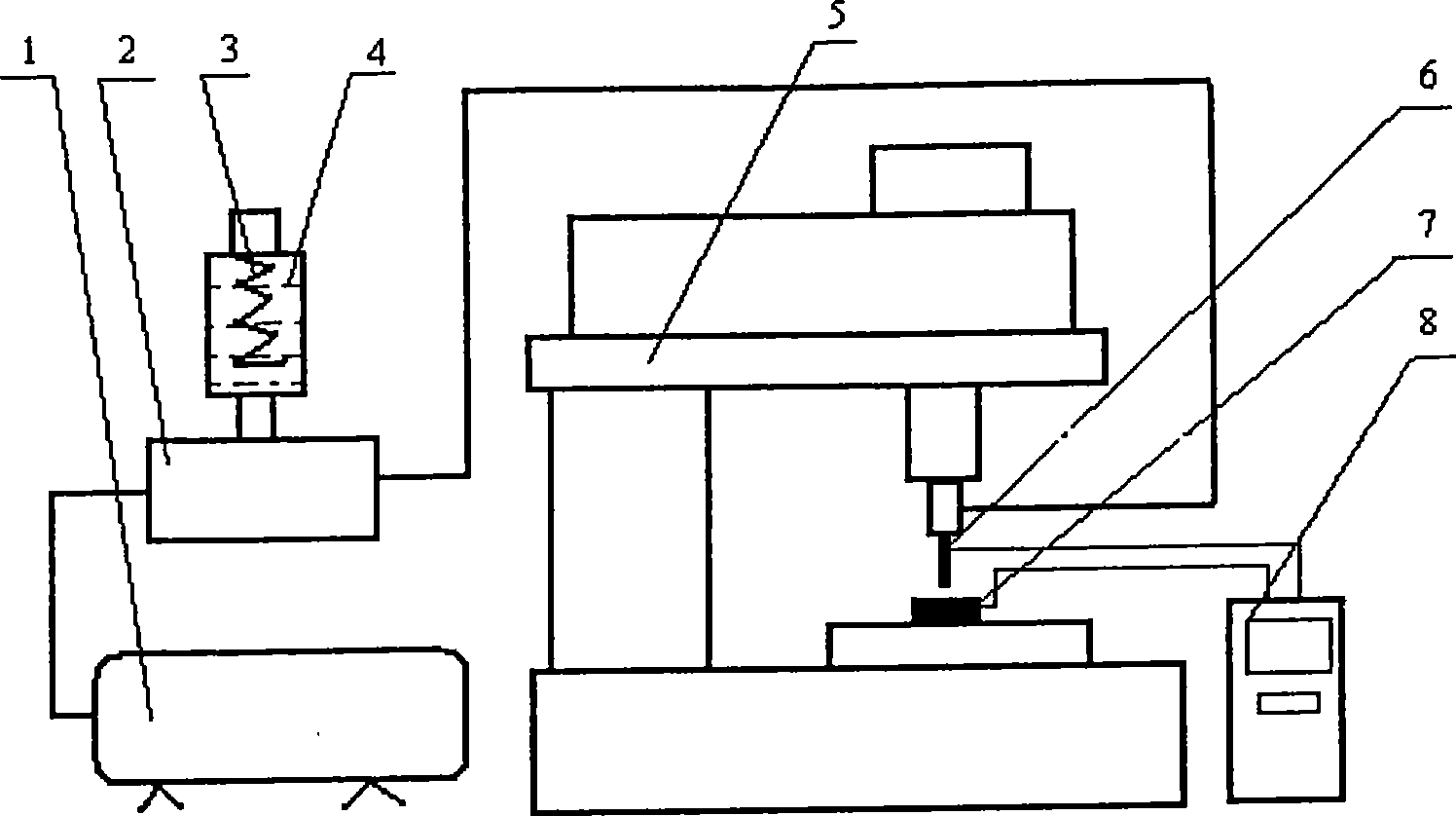

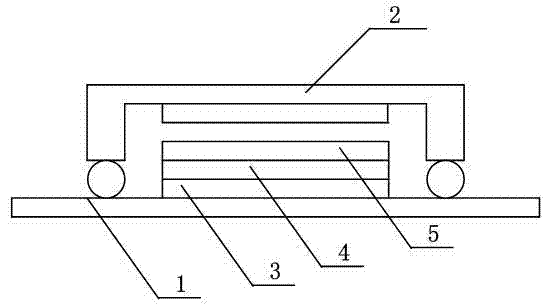

Device for performing surface treatment on pole piece of lithium battery

InactiveCN102151665AQuality improvementReduce short circuit rateCell electrodesCleaning using toolsTreatment qualitySurface finishing

The invention discloses a device for performing surface treatment on a pole piece of a lithium battery. In one piece-brushing process, the front side and the reverse side of the pole piece can be treated simultaneously, so that the treatment efficiency can be improved and the treatment quality can be guaranteed. The device comprises a machine frame, a workbench, an upper sponge, a lower sponge, a negative pressure device and an upper sponge driving cylinder; the lower sponge is fixed on the workbench; the upper sponge driving cylinder is arranged on the machine frame; a piston rod of the upper sponge driving cylinder faces downward; the bottom of the piston rod is fixedly connected with the upper sponge; the upper sponge is positioned above the lower sponge; the negative pressure device comprises an air compressor and a suction pipe; the suction pipe is inserted upward from the bottom of the workbench; and the pipe orifice of the suction pipe is positioned in the lower sponge. The process for brushing the piece is improved, a technology for automatically brushing the two sides of the piece simultaneously is adopted, two sponge plates which are correspondingly arranged up and down are used and when dust adsorbed to the sponge plates is more, the sponge plates can be replaced at any time. The device is high in quality for cleaning the pole piece, and high in yield, and can timely remove the dust and debris and obviously improve the quality of the pole piece, and the battery manufactured by the pole piece is low in short circuit rate.

Owner:JIANGSU YINGTAI ELECTRONICS

Method of manufacturing solid electrolytic capacitor

ActiveUS8470389B2Small leak currentReduce the ratioHybrid capacitor electrolytesSolid electrolytic capacitorsSilane compoundsConductive polymer

Provided is a method of manufacturing a solid electrolytic capacitor, including the steps of: forming a capacitor element including an anode body having a dielectric coating film on a surface thereof; impregnating the capacitor element with a polymerization liquid containing a precursor monomer of a conductive polymer and an oxidant; impregnating the capacitor element impregnated with the polymerization liquid with a silane compound or a silane compound containing solution; and forming a conductive polymer layer by polymerizing the precursor monomer after impregnating the capacitor element with the silane compound or the silane compound containing solution.

Owner:SANYO ELECTRIC CO LTD +1

Powder-mixed near-dry type electric spark machining device and method thereof

The invention discloses a mixed powder quasi-dry typed electric spark processing device and a method, which has the advantages of low processing roughness, high precision, good processing stability, quick processing speed and the like. The structure of the electric spark processing device comprises an electric spark processing machine tool; the pipe-shaped tool electrode of the electric spark processing machine tool is connected with a slight lubrication device which is connected with an air compressor.

Owner:SHANDONG UNIV

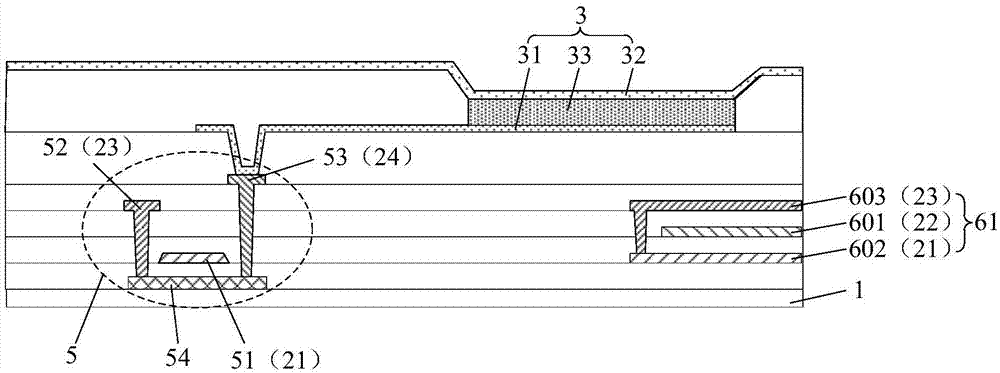

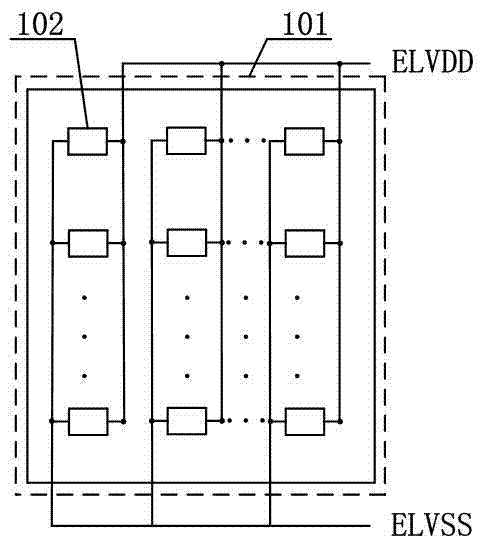

Display panel and display device

ActiveCN108010945AReduce the probability of short circuitIncrease distanceSolid-state devicesSemiconductor devicesOptoelectronicsSurface plate

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of display. By the display panel and the display device, the distance between metal ofdifferent signals can be increased within a limited space, so that the short-circuit probability between the metal of different signals caused by metal reside is reduced. The display panel comprisesa substrate, wherein a first metal layer, a second metal layer, a third metal layer and a fourth metal layer are sequentially arranged at one side of the substrate along a direction far away from thesubstrate, a light-emitting device layer is arranged at one side, far away from the substrate, of the fourth metal layer and comprises a first electrode, a second electrode and a light-emitting functional layer, insulation layers are arranged between two arbitrary layers of the first metal layer, the second metal layer, the third metal layer and the fourth metal layer, the display panel comprisesa circuit assembly, the circuit assembly comprises a plurality of parts, and the plurality of parts are respectively arranged in the first metal layer, the second metal layer, the third metal layer and the fourth metal layer.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

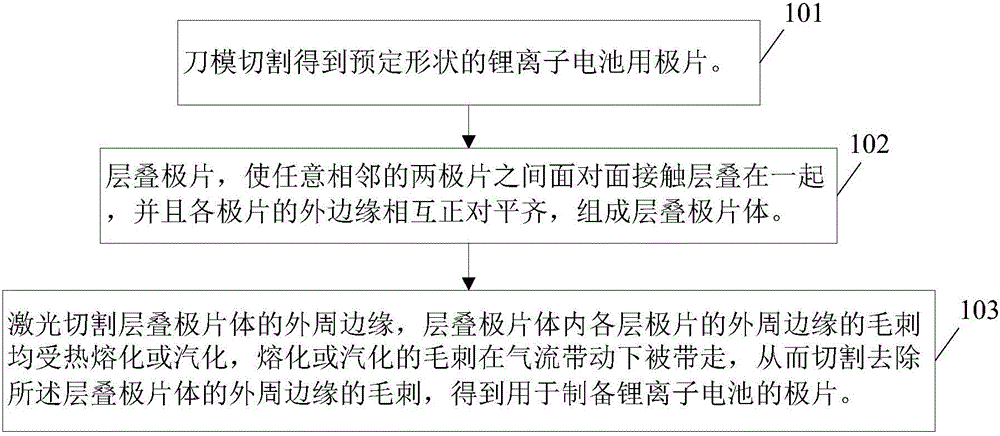

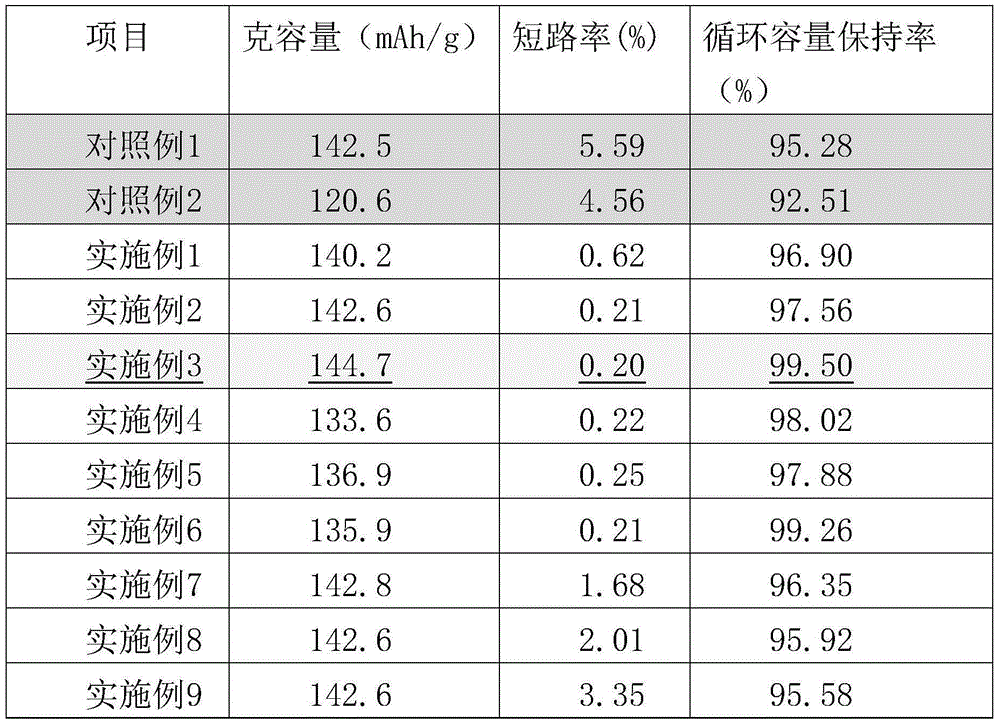

Electrode piece processing technique for lithium ion battery

The invention relates to an electrode piece processing technique for a lithium ion battery. The electrode piece processing technique comprises the following steps of: cutting to obtain electrode pieces in predetermined shapes for the lithium ion battery by a cutting die; laminating the electrode pieces in a manner that arbitrary two adjacent electrode pieces are laminated in a face-to-face contact way and outer edges of all the electrode pieces are right flush with one another so as to form a laminated electrode piece body; and cutting the peripheral edge of the laminated electrode piece body with laser such that burrs at the peripheral edge of the laminated electrode piece body are melted or vaporized due to heating, and the burrs melted or vaporized due to heating are taken away under the driving of airflow, thereby cutting and removing the burrs at the peripheral edge of the laminated pole piece body to obtain the electrode piece used for the lithium ion battery. With the application of the technical scheme, the remove of the burrs at the edge of the electrode piece is facilitated, a diaphragm is prevented from being penetrated, and the improvement of the electrochemical performance and the safety of the battery are promoted.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Electrolyte of water system lithium zinc battery

InactiveCN102769151AUniform and smooth deposition effectReduce short circuitSecondary cellsElectrolytic agentZinc ion

The invention discloses electrolyte of a chargeable water system lithium zinc battery. The existing water system lithium zinc battery is apt to occur zinc deposition of dendritic crystals in a charging and discharging process for a long period along reversible redox reaction of zinc on one side of a negative electrode so as to cause piercing of a membrane and efficacy losing caused by battery short circuit. The electrolyte comprises water, electrolyte salt and zinc-plating additive. The electrolyte salt is zinc salt and lithium salt which are soluble in water, and concentration of lithium ion and concentration of zinc ion in the electrolyte are both 0.5-5mol / L. The electrolyte enables the water system lithium zinc battery to obtain even and smooth zinc deposition effects, is good in reversibility, effectively avoids production of the dendritic crystals, and greatly reduces probability of battery short circuit.

Owner:刘昊

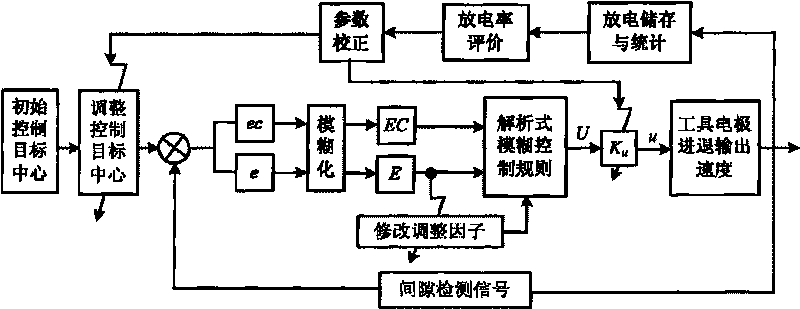

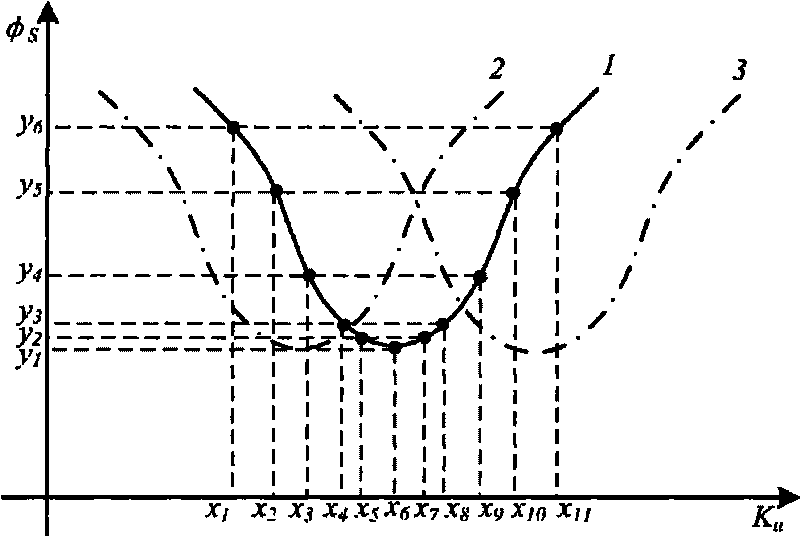

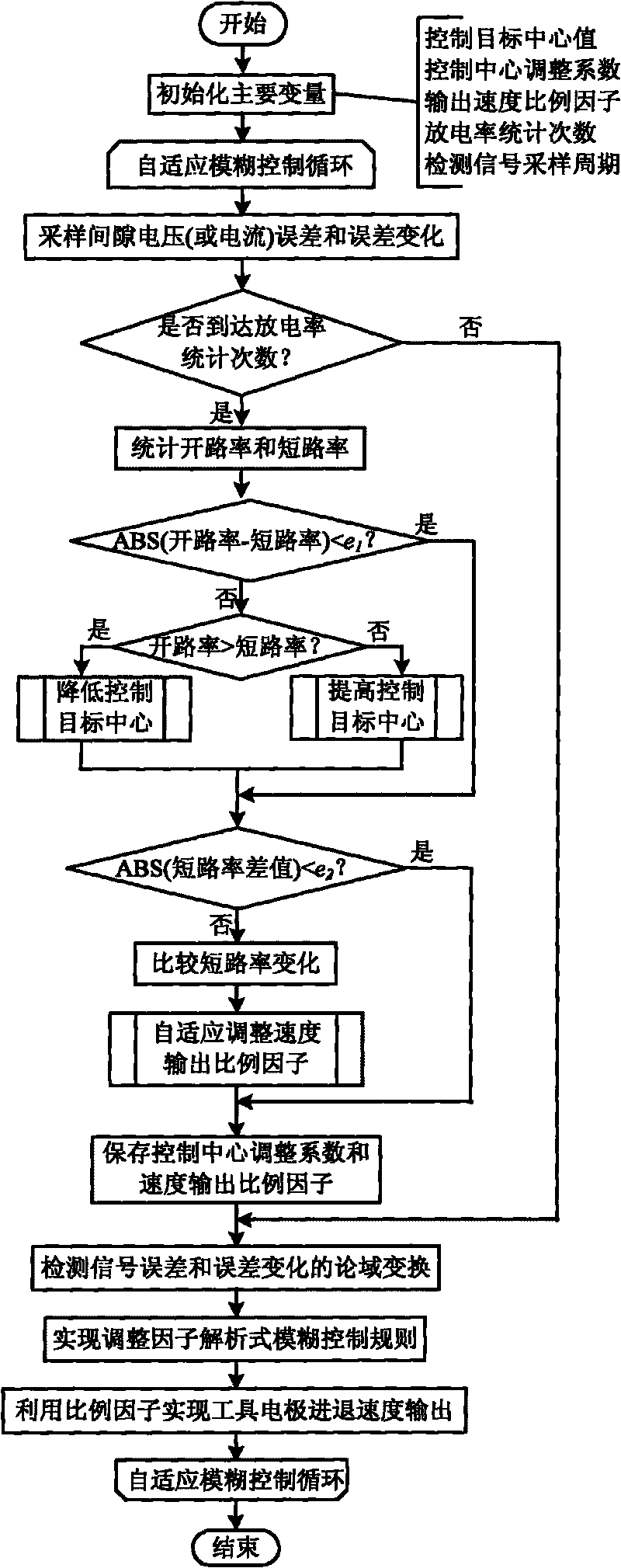

Tiny discharge gap bi-feedback adaptive analytic fuzzy servo control method

InactiveCN101695777AImprove servo control performanceAchieve rapidityElectric circuitsDischarge rateControl theory

The invention discloses a tiny discharge gap bi-feedback adaptive analytic fuzzy servo control method, and belongs to the technical field of non-traditional micromachining. In the method, interpolar voltage or current signals which are fed back in real time are compared with a control target center so as to obtain signal errors and the change of the errors; a self regulating factor of an analytic fuzzy control rule in the whole field is dynamically adjusted, and the discharge gap servo control performance is improved; and then, in order to adapt to machining conditions and control errors introduced by process random change, a discharge statistics and parameter correction feedback channel is utilized to store and count an open circuit rate and a short circuit rate, and a fast convergence algorithm directly proportional to the open circuit rate and the short circuit rate is adopted, so that the control target center and an electrode advancing and retreating speed scale factor adaptively tend to be optimal simultaneously, and the open circuit rate tends to be equal to the short circuit rate and is the minimum, namely the discharge rate tends to be optimal. The method realizes the quickness, stability and accuracy of tiny discharge gap servo control and improves micro electrical discharge machining efficiency.

Owner:TSINGHUA UNIV

GaN-based LED integrated chip with multiple light-emitting sub areas

InactiveCN103730479AReduce the probability of breaking the circuitImprove reliabilitySolid-state devicesSemiconductor devicesReflection lossQuantum well

The invention discloses a GaN-based LED integrated chip with multiple light-emitting sub areas, and belongs to the technical field of LED chip structures. The GaN-based LED integrated chip with the multiple light-emitting sub areas comprises a substrate, an n-GaN layer, a quantum well active area, a p-GaN layer, a current spreading layer, a P electrode and at least two light-emitting sub areas. Grooves which are mutually isolated are formed between adjacent light-emitting sub areas, and the bottoms of the grooves are placed on the surface of the substrate. According to the GaN-based LED integrated chip with the multiple light-emitting sub areas, the open circuit probability is lowered to the maximum degree when an interconnecting wire stretches across the grooves, the emergent probability of internal total reflected light of the chip can be improved, internal reflection loss is reduced, and therefore light extraction efficiency is improved.

Owner:南京大学扬州光电研究院

Positive and negative electrode plates and positive and negative electrode plate covering structure during winding for improving safety of power battery

InactiveCN106169618AReduce security risksImprove securityFinal product manufactureSecondary cellsPower batteryElectrical battery

The invention provides positive and negative electrode plates and a positive and negative electrode plate covering structure during winding for improving safety of a power battery. Through a width design of positive and negative electrode plate covering gummed paper, blank foil exposure parts of the positive and negative electrode plates are ensured to fall into a covering gummed paper region for polarity pairing; and through a dislocated coating mode of the head of the positive electrode plate and a length design of a copper foil at the head of the negative electrode plate, roll core inner ring negative tabs are preferentially enabled to fall into a dislocated coating region of the positive electrode plate. According to the positive and negative electrode plates and the positive and negative electrode plate covering structure during the winding, under the condition that inner space design capacity of a cylinder is brought into full play, the short-circuit probability of the foil exposure parts of the positive and negative electrode plates and the safety risk caused by relatively large curvature of the inner ring negative tabs in dual-tab design of a negative electrode are lowered, high-safety design requirements of a cylindrical power battery are met, and a great practical significance is achieved.

Owner:SINOWATT DONGGUAN

Array substrate, display panel and display device

The invention provides an array substrate, a display panel and a display device. Common electrodes of the array substrate are only located in pixel regions, the common electrodes in the adjacent pixel regions are connected through a connecting electrode, the projection of the connecting electrode on a substrate body does not completely cover regions corresponding to data lines, the area of the electrodes above the data lines is reduced, in other words, the connecting electrode with a small area is arranged to make the common electrodes in the adjacent pixel regions communicated, and thus the probability of short-circuiting of the common electrodes and the data lines is reduced.

Owner:BOE TECH GRP CO LTD +1

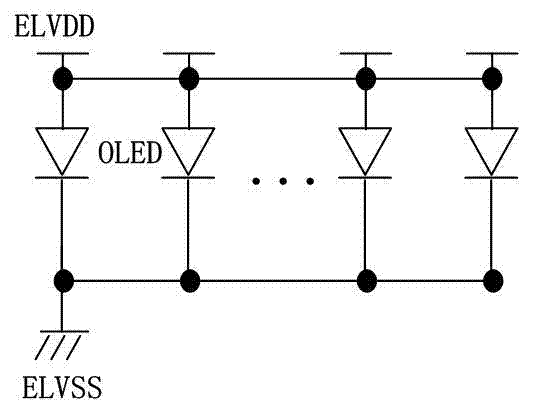

OLED (Organic light-emitting diode) lighting substrate and manufacture method thereof

ActiveCN102376895AReduce current crowding effectReduce the probability of short circuitSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsCurrent limiting

The invention discloses an OLED (organic light-emitting diode) lighting substrate and a manufacture method thereof. The OLED lightening substrate comprises a substrate, wherein a positive electrode, an organic functional layer and a negative electrode are sequentially arranged on the substrate; a resistance layer is arranged between the substrate and the positive electrode, and the resistance layer is divided into multiple block-shaped resistors; the positive electrode is divided into multiple sub positive electrodes, and each sub positive electrode is connected with a block-shaped resistor in series; and the multiple block-shaped resistors are connected together through interconnection lines. The OLED lighting substrate and the manufacture method thereof disclosed by the invention have the characteristics that: a series-connection resistance layer is arranged between a power supply and the positive electrode, thus a current limitation action is achieved; and a whole large-area positive electrode is divided into smaller-area sub positive electrodes, so that the intensity of the gathered current generated by the positive electrodes isolated by resistors is weakened, the current gathering effect is weakened and short-circuit probability of the negative and positive electrodes is reduced, thus the problems that the electrode is easy to burn out and the light emitting is nonuniform are solved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

High-current lithium manganese button battery and preparation method thereof

PendingCN108461820AShorten the lengthImprove space utilizationCell electrodesFinal product manufacturePower flowManganese

The invention discloses a high-current lithium manganese button battery and a preparation method thereof and belongs to the technical field of button batteries. The battery comprises a positive electrode cover, a negative electrode cover, a battery cell and electrolyte, wherein the battery cell and electrolyte are arranged in a sealed cavity formed between the positive electrode cover and the negative electrode cover; the battery cell is formed by stacking a positive plate, a diaphragm and a negative plate and folding; the positive plate consists of an aluminum net and manganese electrode materials laminated on the positive and reverse sides of the aluminum net, the reverse side of the positive plate is provided with N sub-positive plates separated by fold, and the positive side of the positive plate is provided with a positive electrode and (N-1) continuous sub-positive plates formed by exposing the aluminum net; the negative plate consists of a copper net and lithium electrode materials laid on the positive and reverse sides of the copper net, the positive side of the negative plate is provided with a negative electrode and (N-1) continuous sub-negative plates formed by exposingthe copper net, and the reverse side of the negative plate is provided with N continuous sub-negative plates; the diaphragm is arranged between the positive plate and the negative plate, so that the sub-positive plates and the sub-negative plates are separated and combined in a preset manner to be sequentially folded in the same direction along the fold so as to form the battery cell.

Owner:YICHANG LIJIA TECH

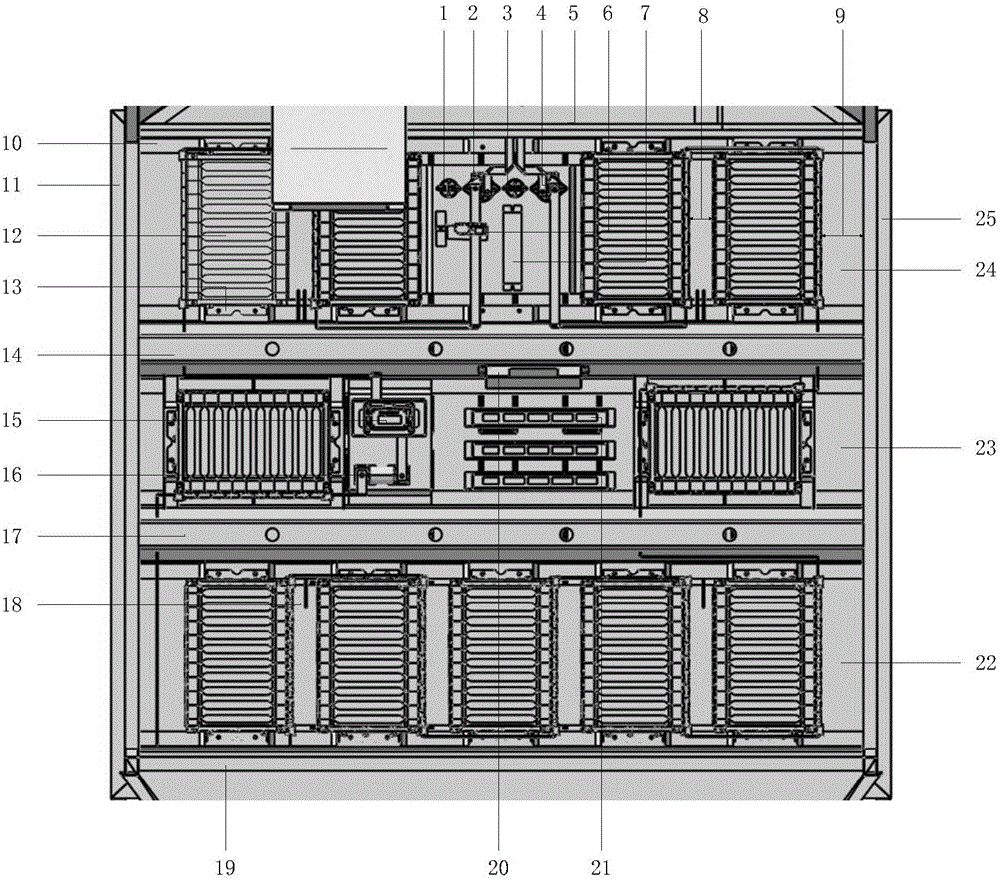

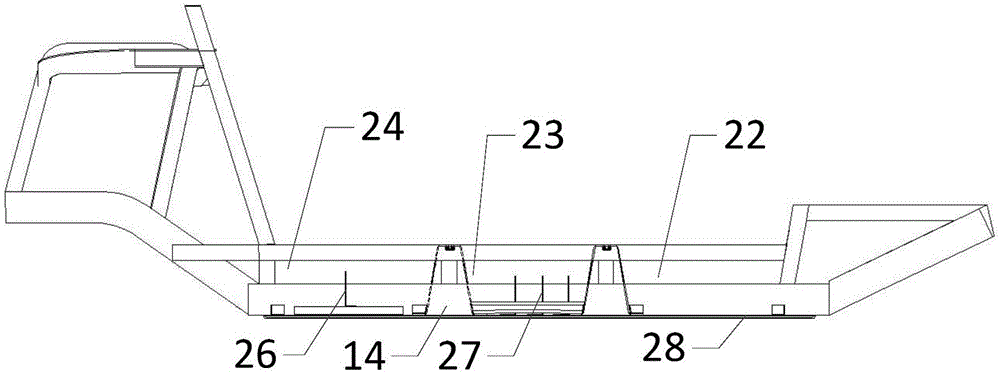

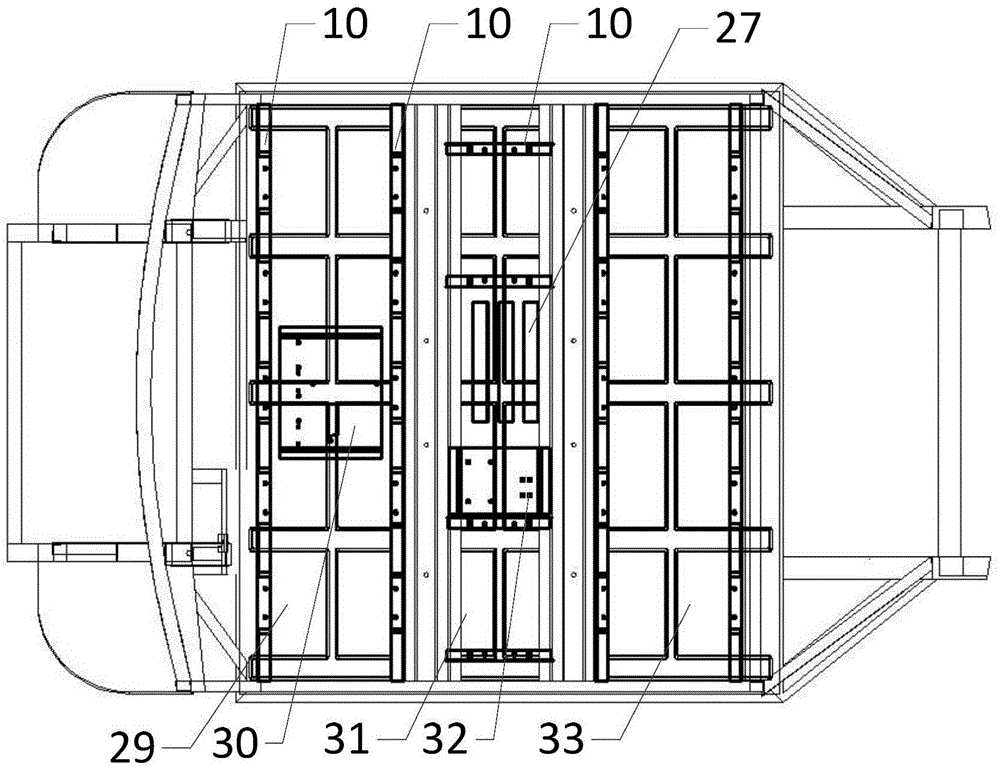

Distributed arrangement structure of power battery box group for four-in-wheel-motor driving electric automobile

ActiveCN105128644AEnsure safetyAchieve lightweightElectric propulsion mountingPower batteryInterior space

The invention provides a distributed arrangement structure of a power battery box group for a four-in-wheel-motor driving electric automobile. The battery box comprises a closed space defined by a front floor, a rear floor, a left doorsill beam, a right doorsill beam, upper floors and a lower floor. According to parameters of an ergonomic arrangement requirement, an auto body structure, a seat mounting structure and arrangement requirements of battery cells and electric components inside power batteries, battery packs are designed to be laid between the upper floors and the lower floor, so that according to the lower bottom surfaces of the battery packs, a finished automobile minimum ground clearance is ensured, and longitudinal passing angles can meet related requirements of finished automobile design. Through reasonable arrangement and a simply fixing manner, a maximum power volume is ensured, the utilization rate of interior spaces of the power batteries is ensured, and reasonable distribution of load of both a front axle and a real axle of the finished automobile is facilitated; in addition, the strength of a connection structure of the power battery pack and the auto body is high, the stability of the power battery packs is improved, and stable operation of the automobile is facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-energy and high-safety lithium ion battery

ActiveCN110890521AGuaranteed anti-acupuncture safety performanceReduces the risk of internal short circuitsNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceHigh energyCarbon nanotube

The invention discloses a lithium ion battery with high energy and high safety performance, which comprises a negative plate, a diaphragm and a battery cell formed by laminating or winding a positiveplate, and is characterized in that the positive plate contains a positive current collector, a positive active material, a positive conductive agent, a positive binder and a positive additive; the negative plate contains a negative current collector, a negative active substance, a negative conductive agent, a negative binder and a negative additive; the positive electrode current collector is characterized in that coating layers on two sides of the surface of the positive electrode current collector are made of a PTC material, aluminum powder and carbon nanotubes; the positive electrode additive is a mixture of a PTC material, aluminum powder and graphene; coating layers on the two sides of the surface of the positive plate are made of a PTC material and graphene; coating layers on the two sides of the surface of the negative electrode current collector are made of PTC materials, copper powder and carbon nanotubes; the negative electrode additive is a mixture of a PTC material, copperpowder and graphene; and coating layers on two sides of the surface of the negative plate are made of a PTC material and graphene. According to the invention, high safety performance is obtained, thesafety is ensured, the energy density of the battery is improved, the electrical performance of the battery is improved, and the production process level is improved.

Owner:SUZHOU PHYLION BATTERY

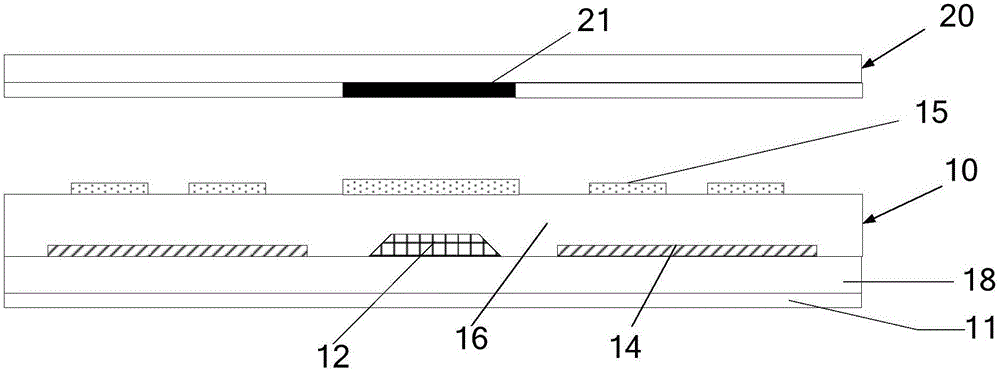

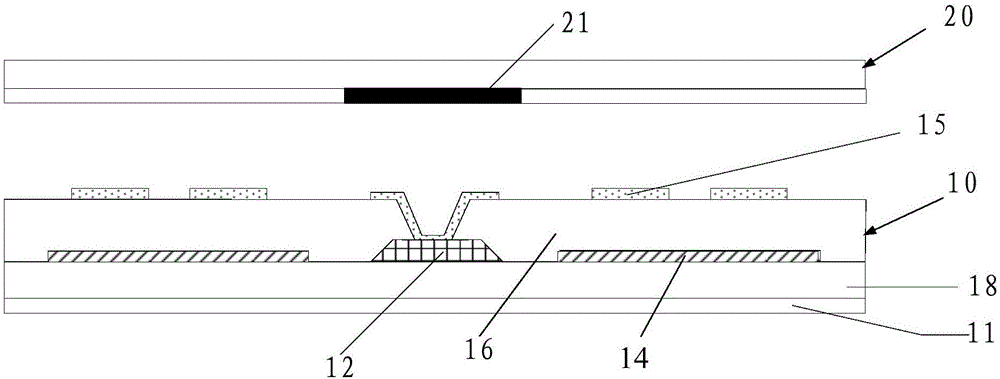

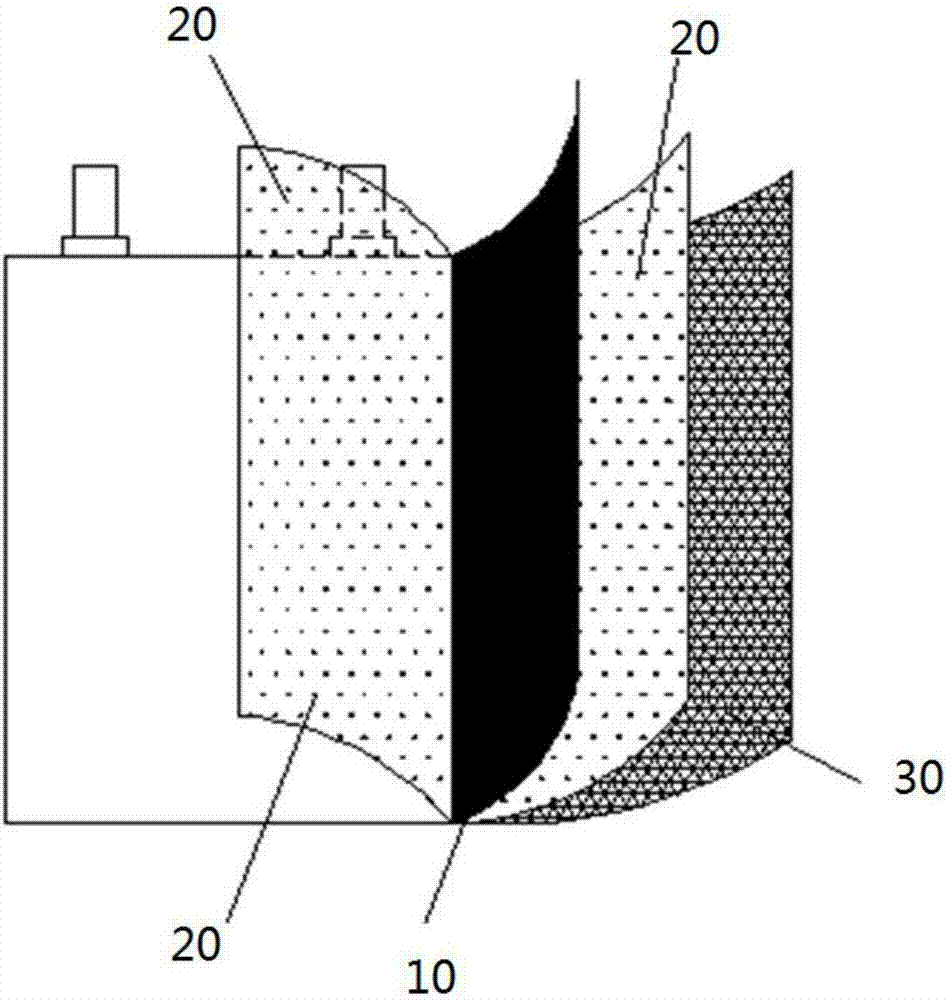

Two-sided adhesive membrane for lithium ion battery and lithium ion battery

PendingCN107275552AReduce adsorptionReduce the probability of short circuitCell seperators/membranes/diaphragms/spacersSecondary cellsWater basedSwelling ratio

The invention provides a two-sided adhesive membrane for a lithium ion battery and the lithium ion battery. The two-sided adhesive membrane for the lithium ion battery comprises a base membrane, wherein a water-based PVDF adhesion agent layer or a coating layer made of any material including substances capable of being adhered with a binder in a positive mixed material coats one face of the base membrane; a polyacrylate adhesion agent layer coats the other face of the base membrane. By adopting the technical scheme provided by the invention, the short circuit rate of a roll core is reduced, and the product percent of pass is improved; in addition, the hardness of a battery cell is remarkably improved, so that the swelling ratio is greatly reduced; the high-rate discharge property and the cycle performance of the lithium ion battery are improved, the service life is longer, and the lithium ion battery is more reliable.

Owner:SHENZHEN RUILONG NEW ENERGY TECH

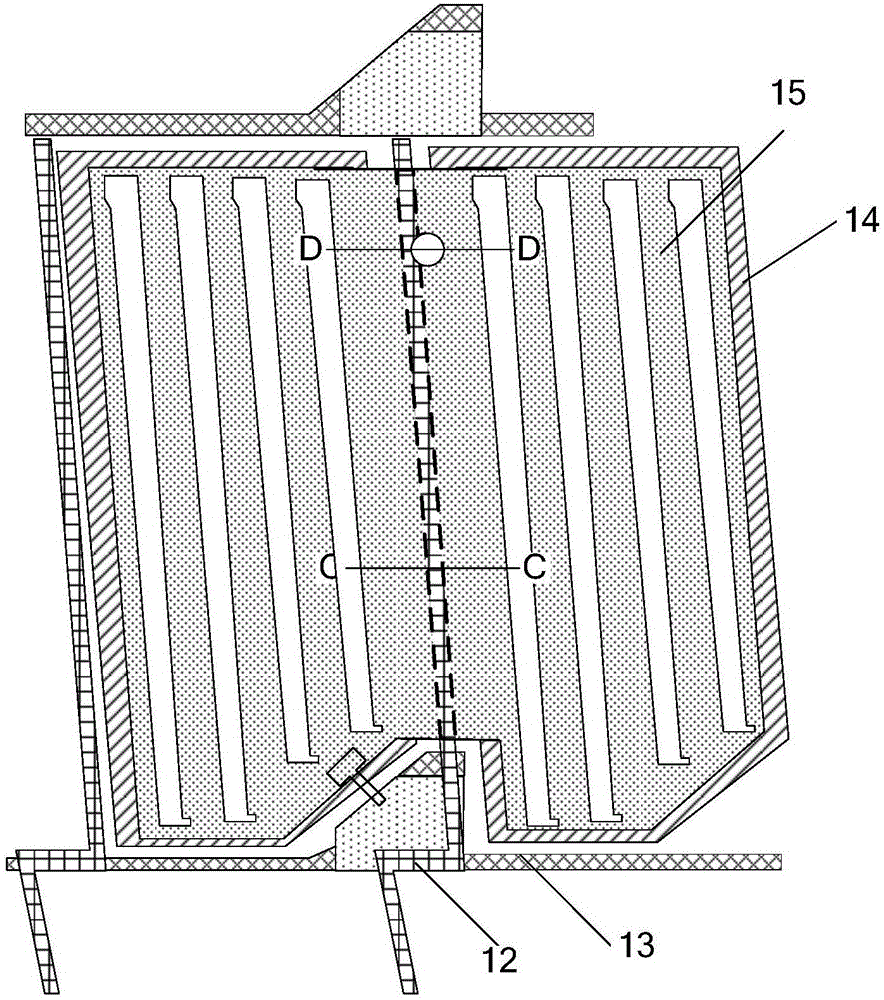

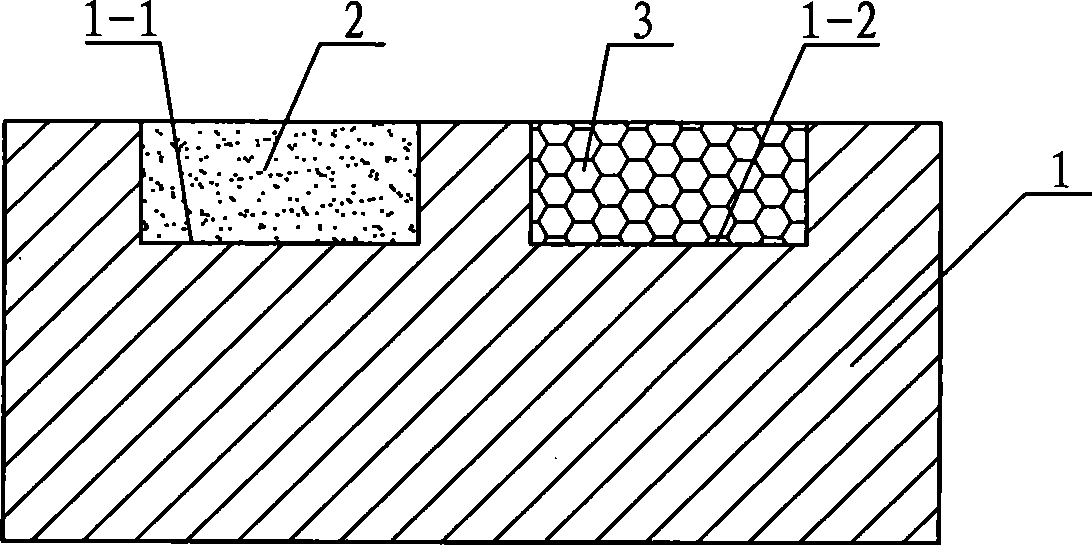

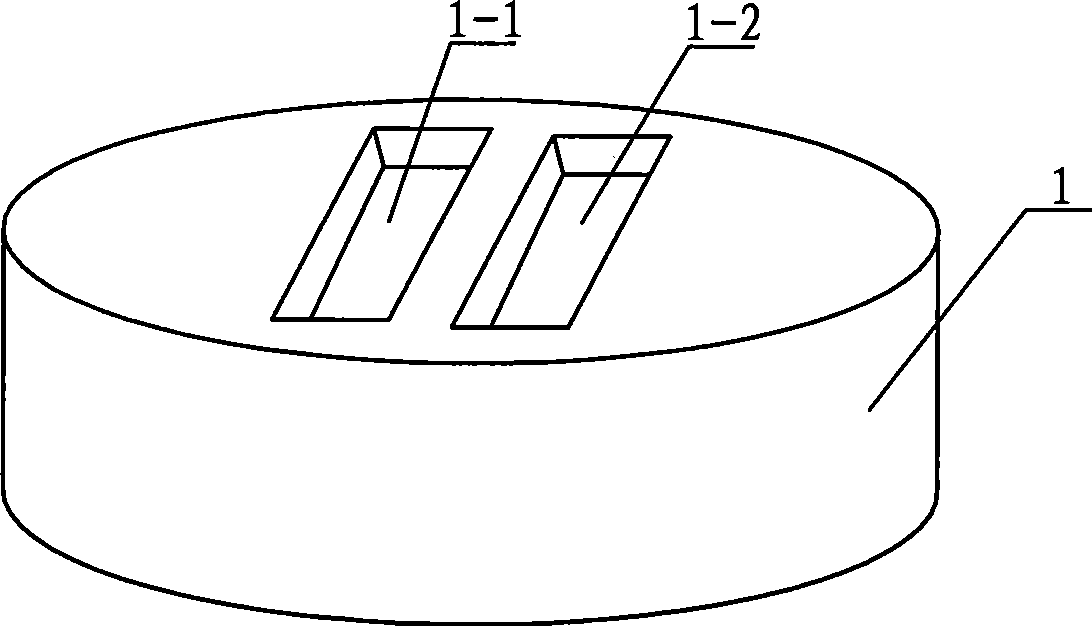

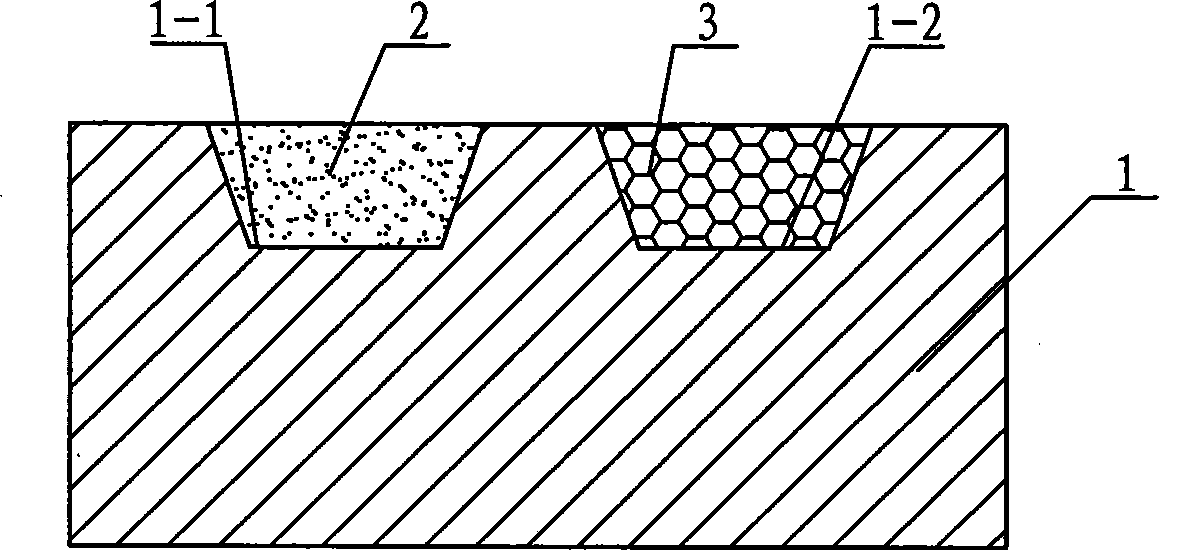

Single gas cell solid oxide fuel cell of electrolyte-supporting type

InactiveCN101521289ALower ohmic impedanceImprove output performanceCell electrodesSolid electrolyte fuel cellsFuel cellsSurface layer

The invention relates to a single gas cell solid oxide fuel cell, in particular to a single gas cell solid oxide fuel cell of an electrolyte-supporting type, solving the problems that an electrolyte of the prior single gas cell solid oxide fuel cell has great ohmic resistance to cause the poor output performance of the cell. The invention adopts the first technical scheme that the surface of a first electrolyte-supporting body is provided with at least one anode groove and at least one cathode groove, the interior of the anode groove is coated with anode slurry, and the interior of the cathode groove is coated with cathode slurry. The invention adopts the second technical scheme that the surface of a second electrolyte-supporting body is provided with at least one lug boss, and both sides of the lug boss are respectively coated with the anode slurry and the cathode slurry. The single gas cell solid oxide fuel cell of an electrolyte-supporting type changes a single path for a current between electrodes of a traditional single-side cell to only flow on the surface layer of the electrolyte-supporting body, enables the current to flow by a groove wall between the grooves and enlarges the path area for the current to pass so as to reduce the ohmic resistance of the electrolyte and improve the output performance of the cell.

Owner:HARBIN INST OF TECH

Lasagna nano graphene and preparation method and application thereof

InactiveCN106653379AReduce voidsImprove stabilityHybrid capacitor electrodesGrapheneHigh energySupercapacitor

The invention discloses a lasagna nano graphene and a preparation method and application thereof. The graphene has a diameter of 50 to 300 nm and a thickness of 1 / 5 to 1 / 2 of the diameter. Small graphene sheets are vertically supported between slice layers, and the spacing between the slice layers is 0.7 to 1 nm. The preparation method comprises the steps of first, preparing nano slice layered precursor, and then performing high-temperature roasting to generate a porous pie oxide template; and after carbon deposition under a high temperature, removing the oxide template and conducting drying. The preparation method has the characteristics of simple operation, high yield, low cost and easy expansion. The performance advantage lies in that when a large amount of lasagna nano graphenes are stacked, the lasagna nano graphenes are anti-compression and hard to overlap, and the stacked structure is not easy to swell by an electrolyte. The lasagna nano graphene is suitable for use as an electrode material of a super capacitor under high voltage, and has the characteristics of having a high energy density per unit area and being not easy to attenuate.

Owner:TSINGHUA UNIV

Lithium ion battery casing, its manufacturing method and battery

ActiveCN1770495AReduce the chance of short circuitsImprove safety and yieldFinal product manufactureCell component detailsLithium electrodeEngineering

This invention discloses one lithium ion battery shell, which comprises battery shell and cover board with isolation layer inside wall. This invention discloses the battery shell process method and the lithium ion battery in use of battery shell. The advantages of this invention comprise the following: the battery shell inside wall is set with isolation layer to lower the shortcut rate of local battery to improve battery safety and product rate.

Owner:ZHENGZHOU BAK BATTERY CO LTD

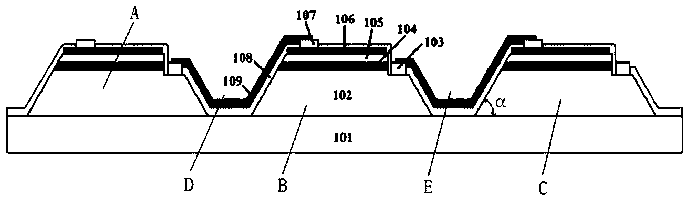

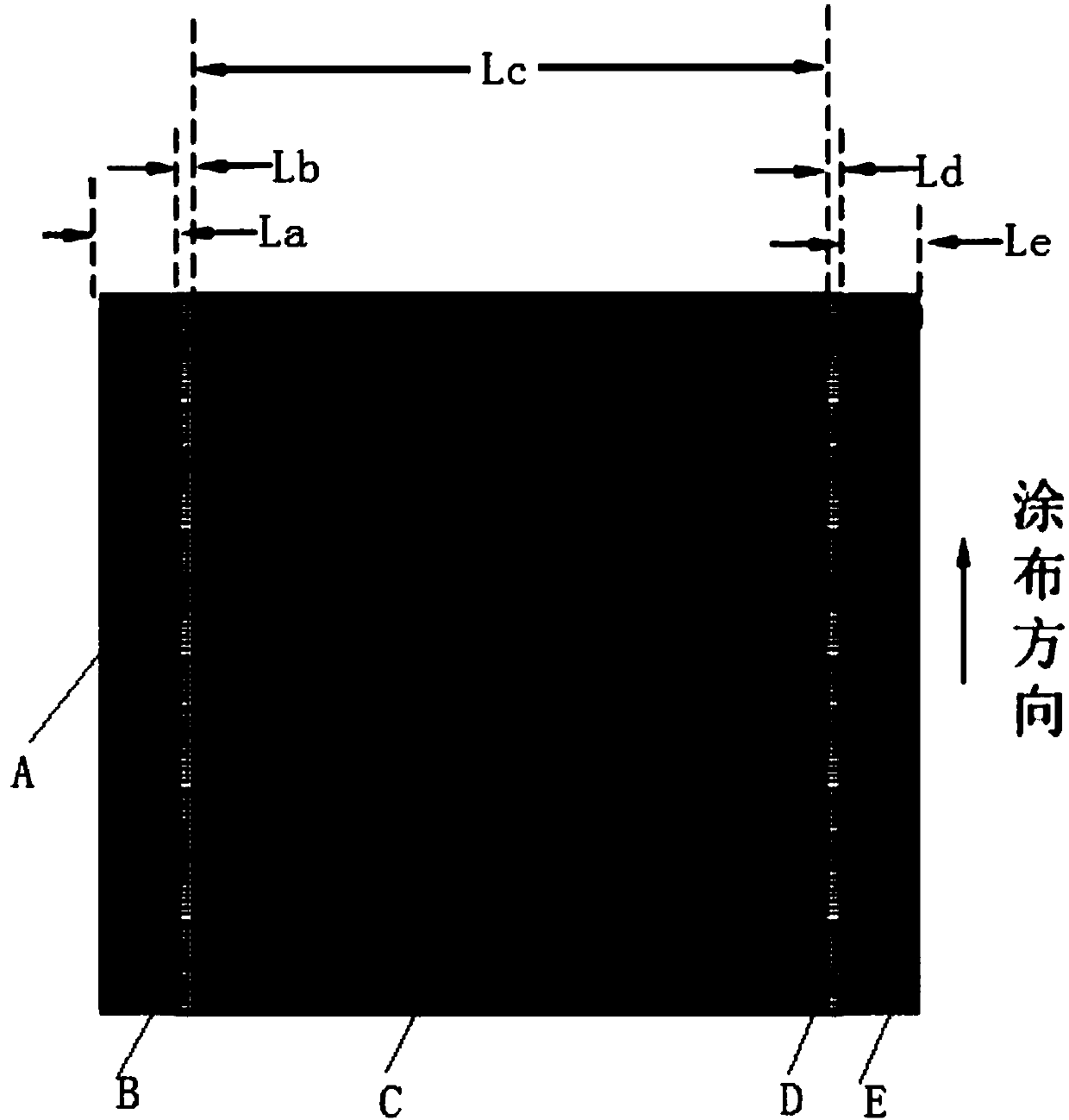

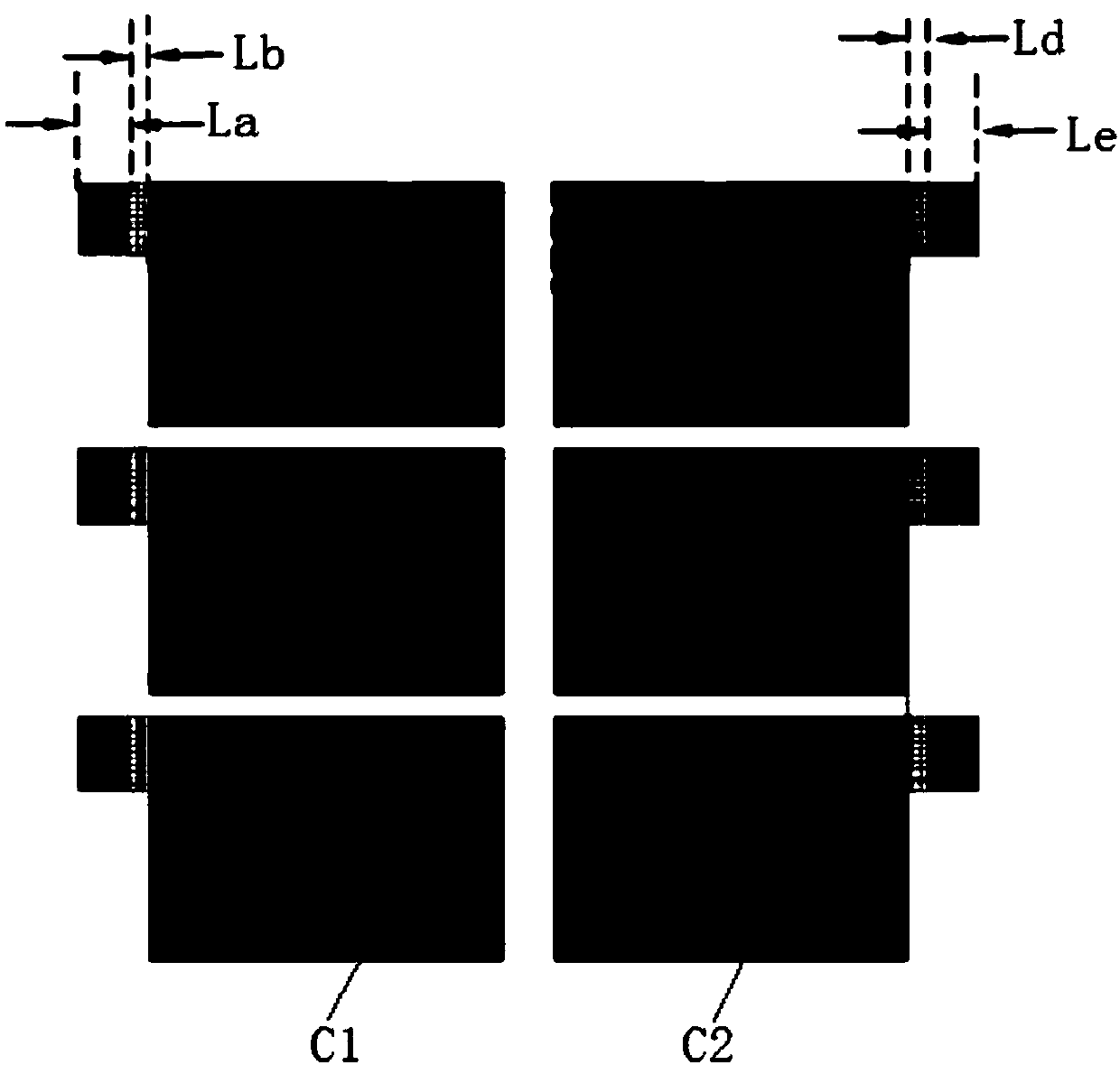

Coating design method for lowering battery short circuit rate

InactiveCN107895770AReduce glitchesReduce the probability of short circuitCell electrodesCell component detailsWrinkle skinMicrometer

The invention discloses a coating design method for lowering the battery short circuit rate. A coating area is alternately distributed into areas A, areas B, areas C, areas D and areas E transversely,that is, the coating area is in an ABCDE-ABCDE-ABCDE mode, wherein the width of the areas A is La, the width of the areas B is Lb<5 mm, the coating singe-face thickness is Hb<=5 micrometers, the width of the areas C is Lc, and the coating thickness is Hc; the width of the areas D is Ld<5 mm, the coating single-face thickness is Hd<=5 micrometers, and the width of the areas E is Le. After coatingof pole piece sizing agent in the areas C is completed, the areas B and the areas D are coated with a layer of sizing agent, and the areas A and E are lead areas. The coating design method has the advantages that by the adoption of the optimized pole piece coating method, burrs caused by pole piece slitting can be reduced to a great degree, and the short circuit rate of a battery is lowered; meanwhile, wrinkles when active material coating areas and copper aluminum foil are nonuniform in extension after being rolled are reduced greatly.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

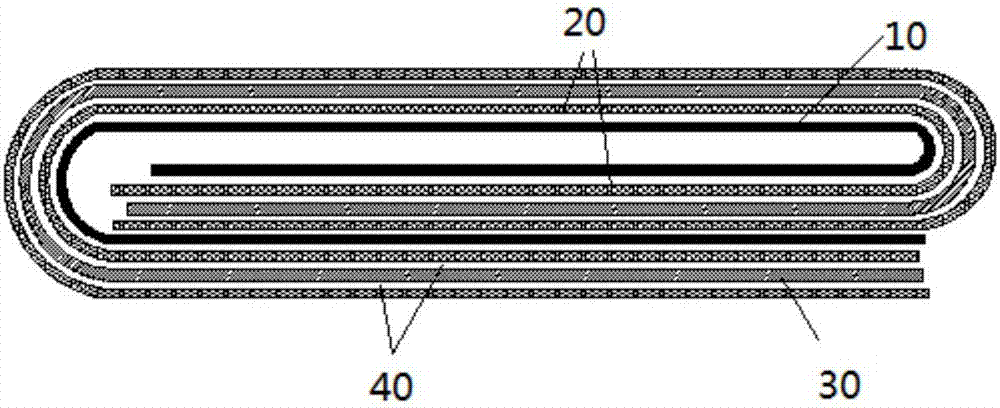

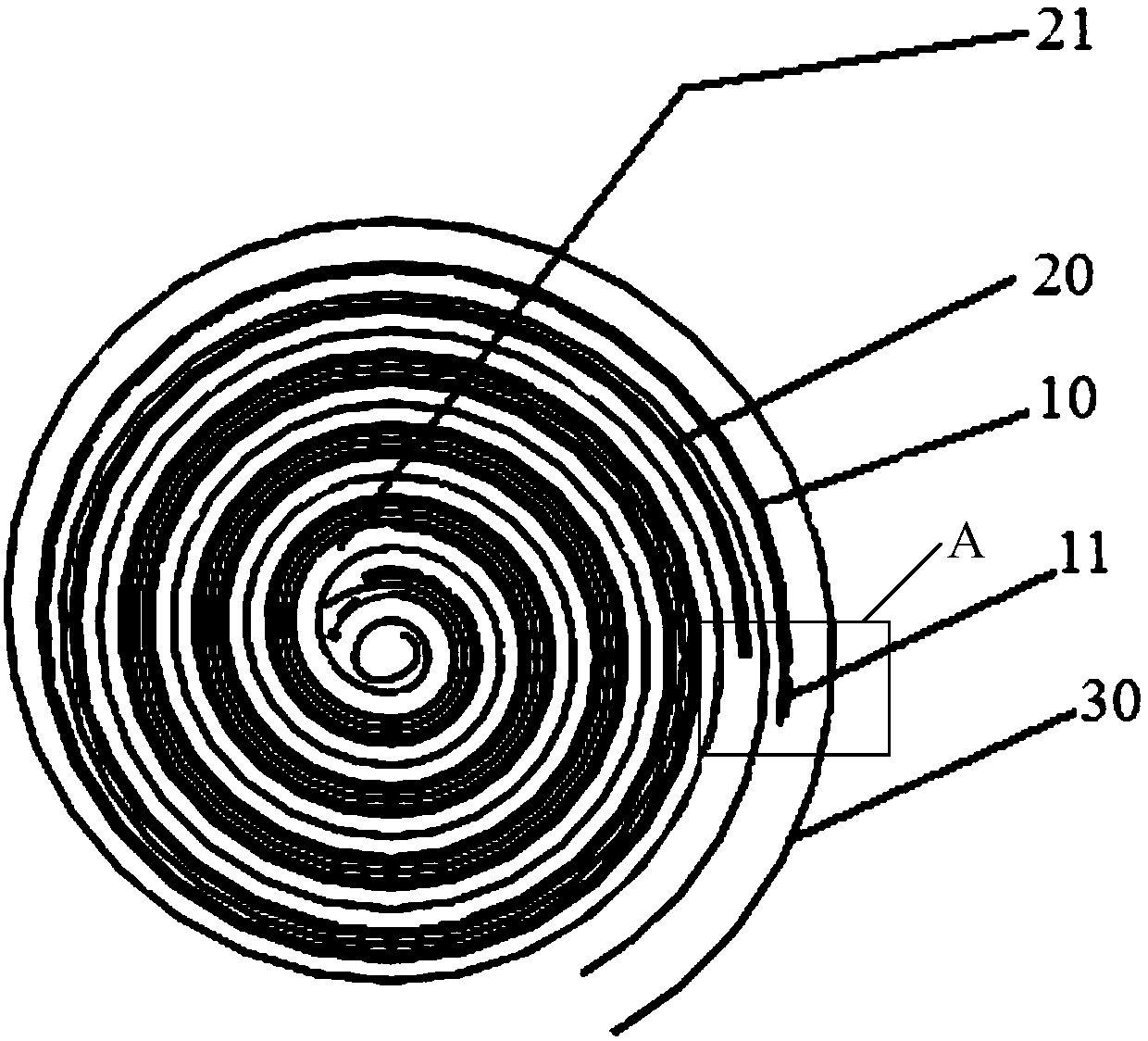

Safe lithium ion battery coil core and lithium ion battery

PendingCN107732318AHigh mechanical strengthImprove securityFinal product manufactureSecondary cellsEngineeringElectrochemistry

The invention discloses a safe lithium ion battery coil core and a lithium ion battery containing the safe lithium ion battery coil core. The safe lithium ion battery coil core is formed by winding anegative plate, a positive plate and a diaphragm stacked between the negative plate and the positive plate, wherein an electrode plate on the outer side of the safe lithium ion battery coil core is the negative plate; the tail end of the negative plate on the outer side of the safe lithium ion battery coil core is a blank tail end without a negative active layer; a negative tab is electrically connected to the surface, which deviates from the inner side of the safe lithium ion battery coil core, of the blank tail end; a temperature-resistant insulating layer is bound to the surface, which faces the inner side of the safe lithium ion battery coil core, of the blank tail end; and the temperature-resistant insulating layer and the negative tab are in negative correspondence at an electric connection point on the surface of the blank tail end. The safe lithium ion battery coil core and the lithium ion battery with the same disclosed by the invention have high safety and excellent electrochemical performance.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Sticky diaphragm for power battery and its preparation method

InactiveCN108039440AReduce heat shrinkabilityReduce the incidence of short circuitCell seperators/membranes/diaphragms/spacersSecondary cellsLithium ion intercalationWetting

The invention further discloses a sticky diaphragm for a power battery. At least one surface of a base film is coated with an oxide coating, and at least one surface of the base film coated with the oxide coating is coated with a sticky slurry layer. The invention further discloses a preparation method of the sticky diagram for the power battery, which includes steps of mixing inorganic solid oxide, assistant and water to obtain an inorganic solid oxide pre-dispersing fluid; coating the inorganic solid oxide pre-dispersing fluid on the surface of the base film, and drying to obtain a first diaphragm; mixing the sticky polymer solution, co-sticking agent, and wetting agent to obtain sticky slurry; coating the sticky slurry on the surface of the first diaphragm, drying to obtain the sticky diaphragm for the power battery. The sticky diaphragm adopts hydraulic sticky diaphragm as the power battery sticky diaphragm, positive and negative pole pieces of the electrode are bonded together, thus the sticky diaphragm can effectively avoid staggering of the diaphragm and a pole piece caused by battery falling and collision; the safety is high, the dead zone during the process of embedding and releasing a lithium ion is reduced; the sticky diaphragm is significant to improve the battery interface.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Battery core with external sheath of wound lithium-ion battery

InactiveCN107919443ASimple structureHighly integratedFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryLithium-ion battery

The invention discloses a battery core with an external sheath of a wound lithium-ion battery. The battery core comprises press plates, roll cores, positive plates, negative plates and an adhesive tape, wherein one positive plate and one negative plate which are arranged at an interval are inserted into an inner cavity of each roll core; a laminated installation structure is adopted by the roll cores; each press plate is a rectangular thin plate made of an insulating material and the sizes of long sides and wide sides are at least 1.0mm greater than those of the corresponding sides of the rollcores; one press plate is arranged on each of one upper end surface and one lower end surface of the laminated roll cores; and the adhesive tape is overlapped with the press plates located on the upper layer and the lower layer to form a constraint structure of the press plates on the upper layer and the lower layer on the laminated roll cores. Through the constraint structure, the laminated rollcores are more reliable, thereby facilitating improving the capacity of the battery and prolonging the cycle life of the battery. According to the battery core, the plane of each the press plate is slightly greater than the roll cores, the structure design plays a protecting role when the battery core is enclosed into a shell, and an external insulating layer for the roll cores can be prevented from being bumped without reason, so that the short circuit rate in the production process can be reduced.

Owner:JIANGSU FRONT NEW ENERGY +1

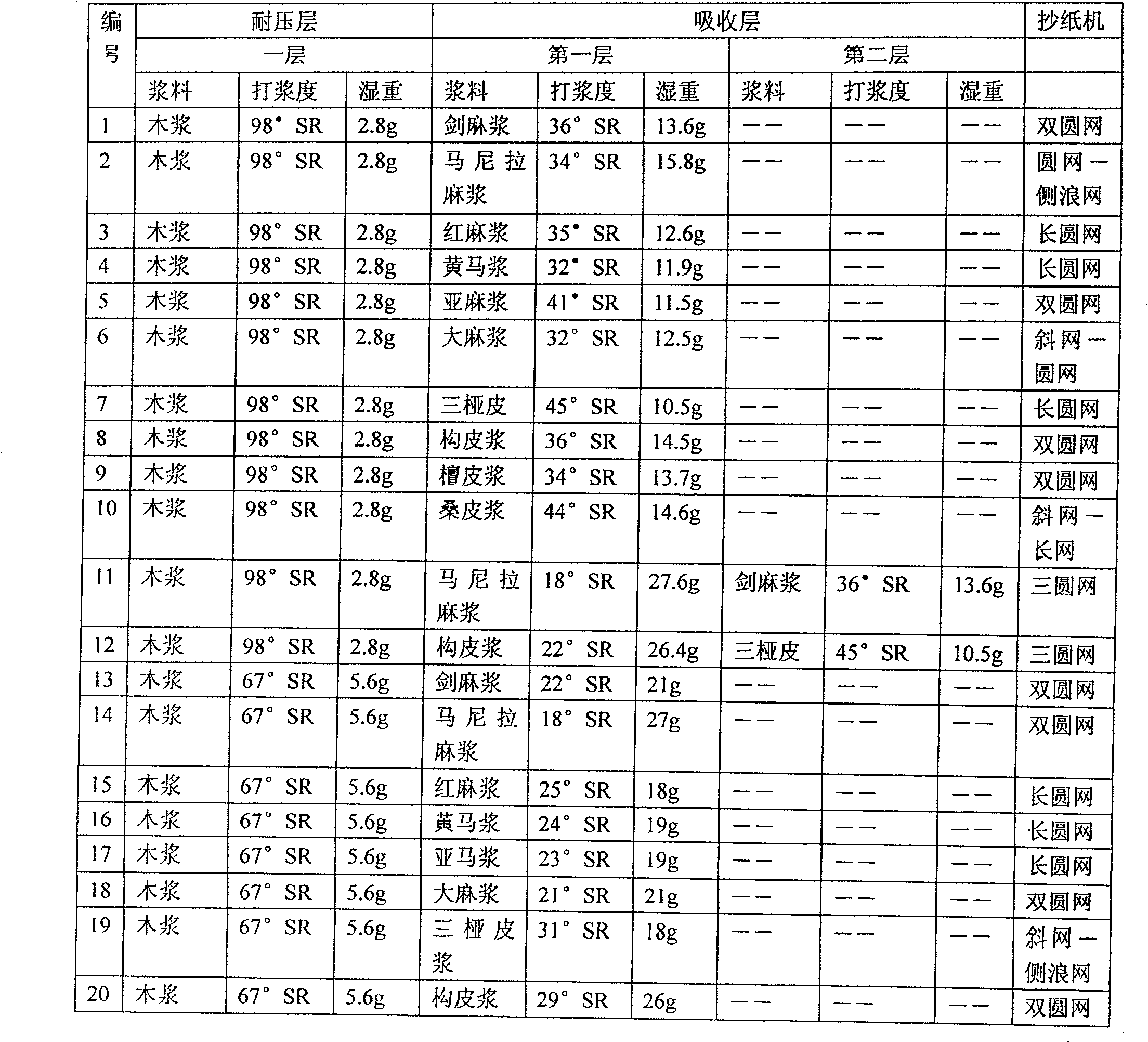

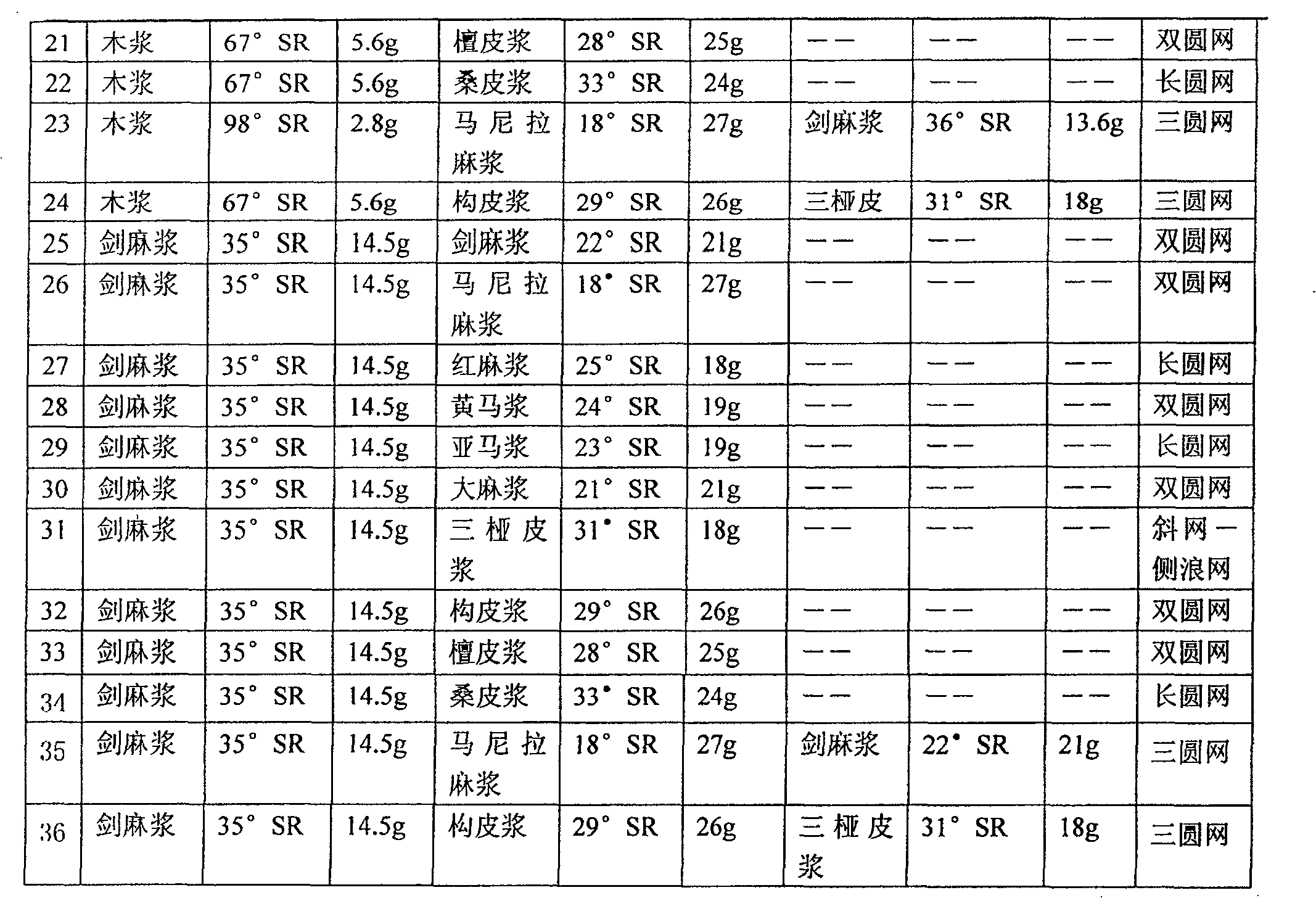

Paper of electrolytic capacitor and preparation method

InactiveCN100412270CExtend your lifeReduce energy consumptionSpecial paperPaper/cardboardElectrolysisPulp and paper industry

The invention relates to an electrolytic capacitor paper. It adopts multilayer structure formed from one layer of pressure-resisting layer and several layers of absorption layers, and the pulp of pressure-resisting layer paper is one kind selected from wood pulp, agave fiber and grass fiber or their mixture, and the absorption layer paper can be one layer or multilayer structure, and its pulp is one kind selected from fibrila, bast fibre and grass fibre or their mixture. Said invention also provides a method for preparing said electrolytic capacitor paper.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL

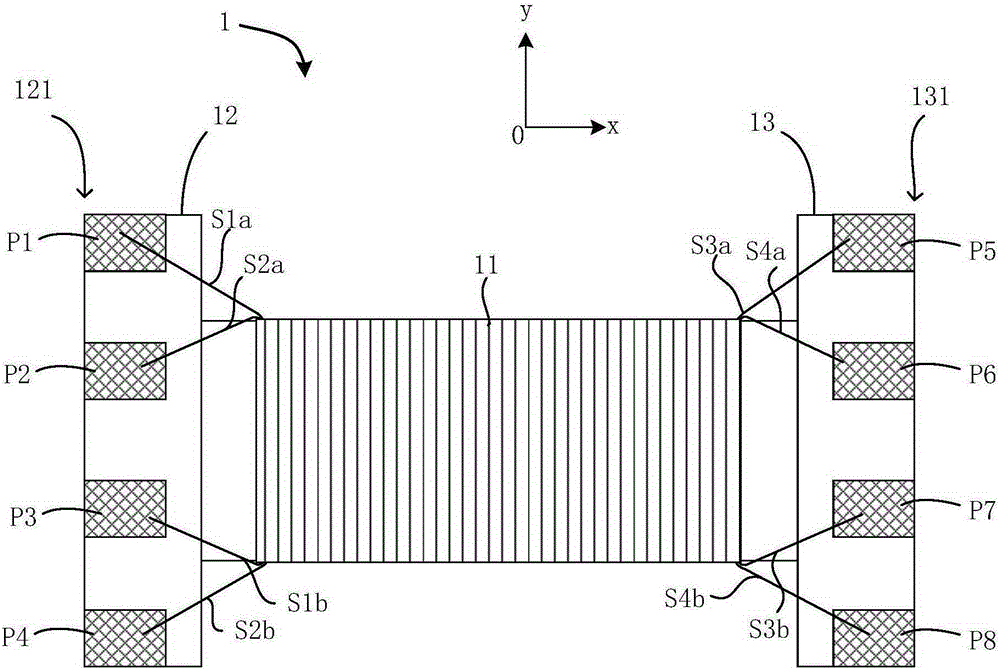

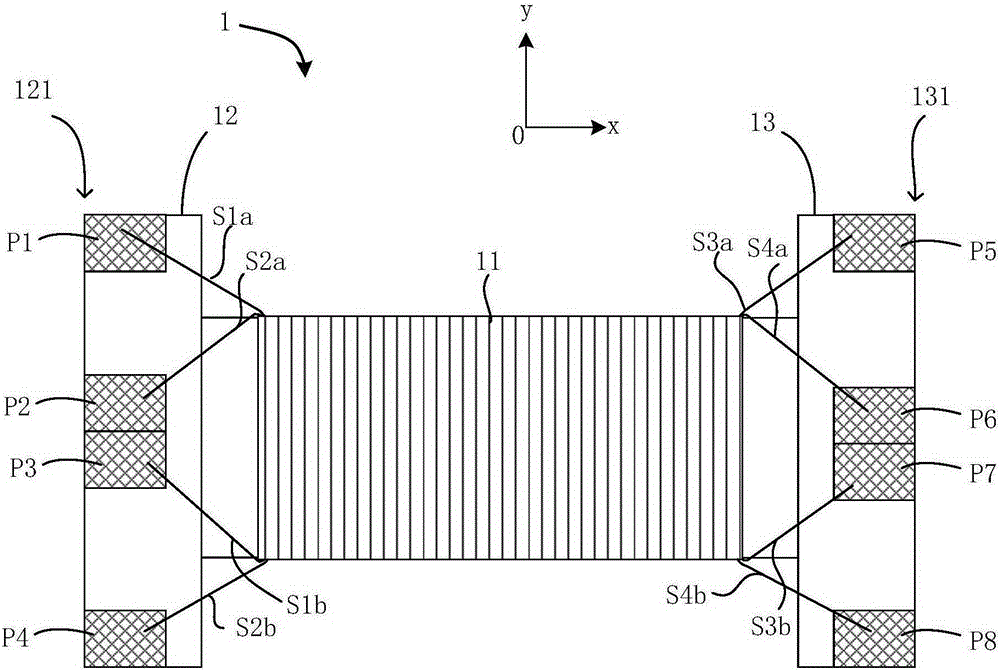

Pulse transformer

ActiveCN105304266ALower requirementNo crossoverTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresPhysicsPulse transformer

The invention provides a pulse transformer, comprising a magnetic core composed of a first magnetic core body and a second magnetic core body, wherein winding wires are wound on the first magnetic core body in advance to form a corresponding winding coil, and then the first magnetic core body is mounted on the second magnetic core body so that the first magnetic core body and the second magnetic core body form a closed magnetic circuit, the winding coil comprises a first winding and a second winding, the first winding comprises two first winding wires, the first ends of the two first winding wires are respectively connected with a first electrode and a second electrode, the second ends of the two first winding wires are respectively connected with a third electrode and a fourth electrode, the second winding comprises two second winding wires, the first ends of the two second winding wires are respectively connected with fifth and sixth electrodes, the second ends of the two second winding wires are respectively connected with seventh and eighth electrodes. The start and tail ends of the two windings are both arranged on the same side of the first magnetic core body, and thus the insulation capability of primary and secondary windings can be improved and the requirement on magnetic core material can be reduced further.

Owner:深圳市普扬技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com