Paper of electrolytic capacitor and preparation method

A technology for electrolytic capacitor paper and pulp, applied in the field of paper and papermaking, can solve the problems of high short-circuit rate, single variety, unavoidable holes, etc., and achieve the effects of improving electrical performance, improving life, and low short-circuit rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

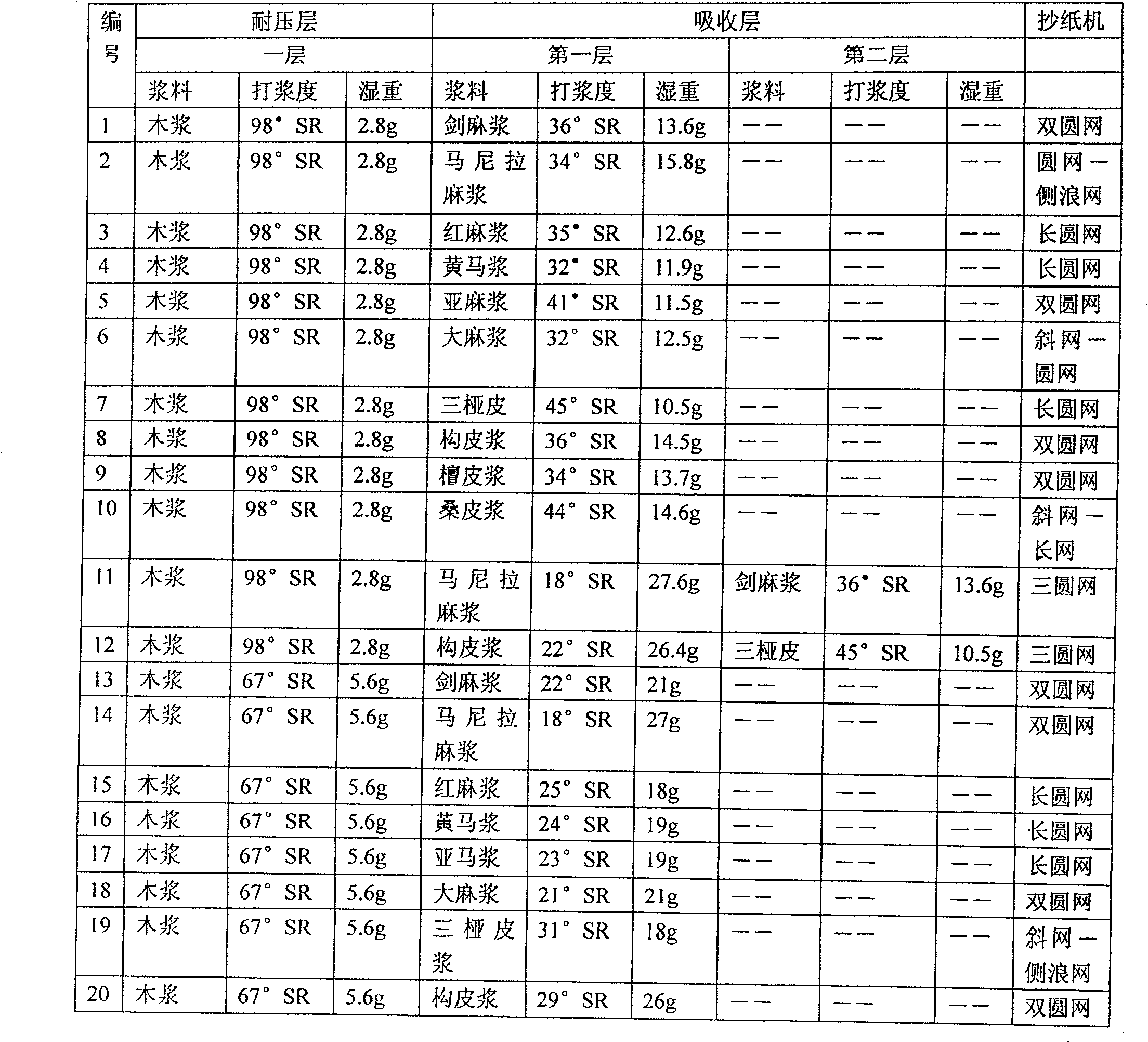

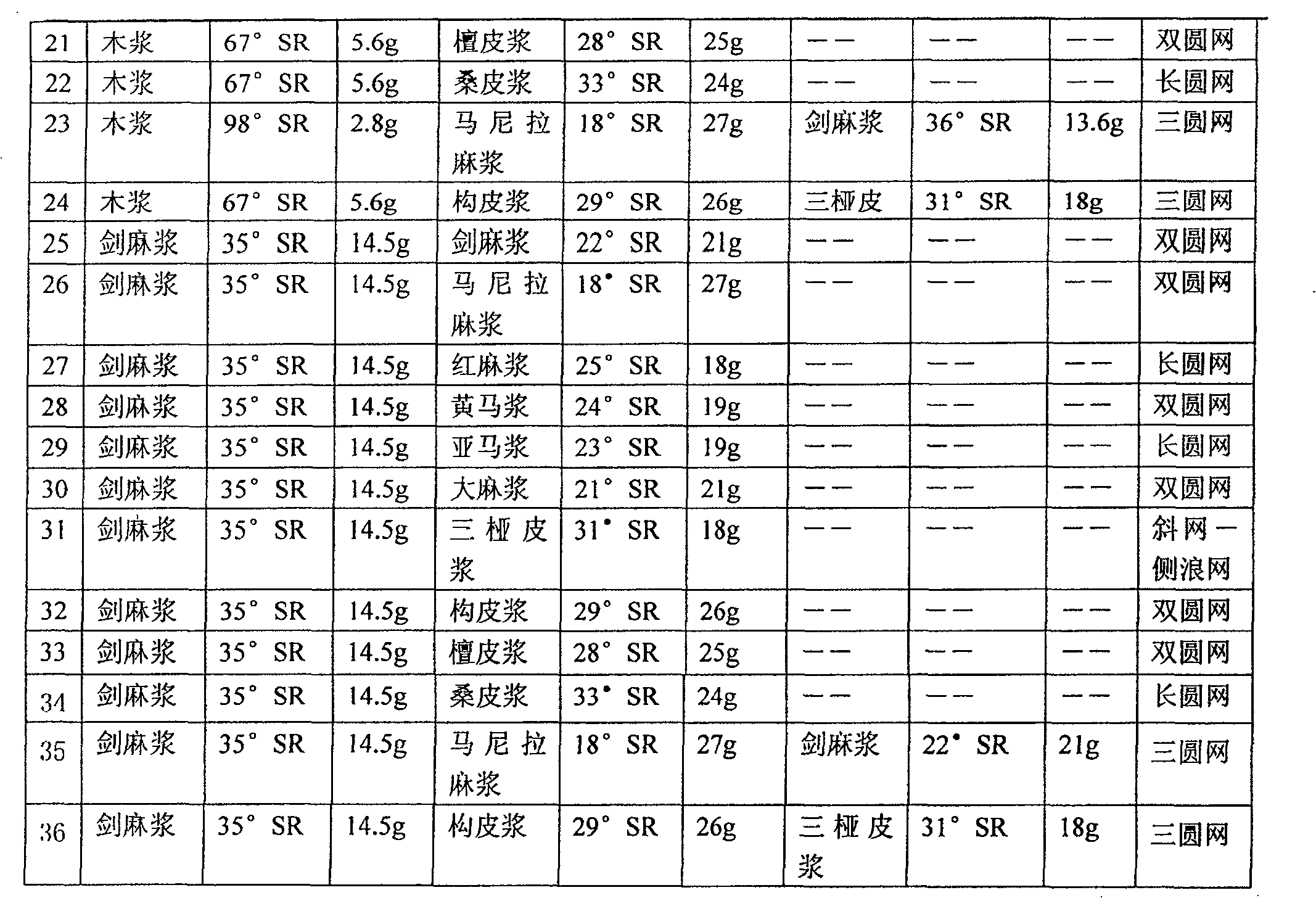

Examples

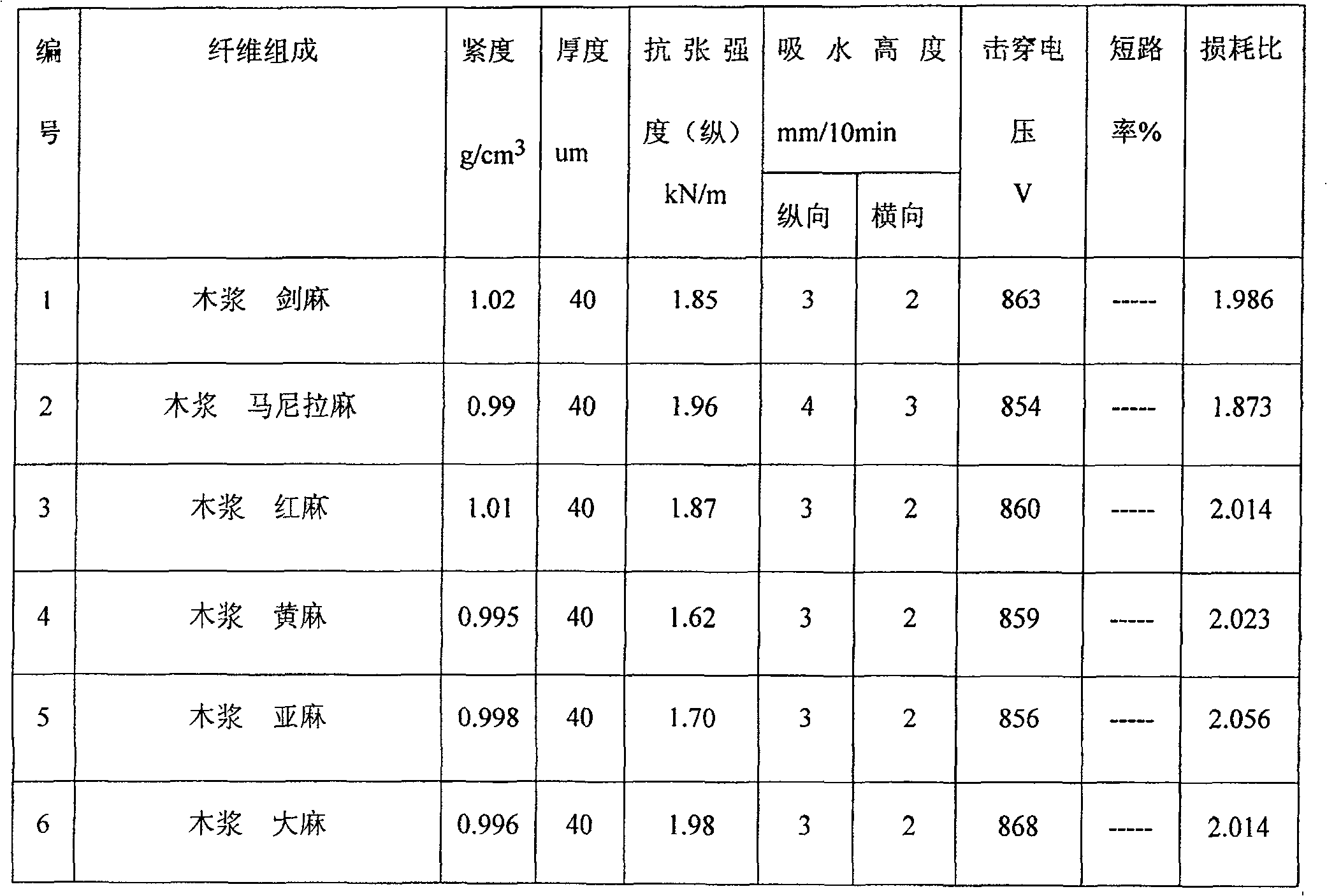

Embodiment 1

[0008] Example 1: All wood pulp is used for the paper pulp of the pressure-resistant layer, and sisal pulp is used for the paper pulp of the absorbent layer. The wood pulp was beaten by disc mill to 98°SR, and the wet weight was 2.8g; the sisal pulp was beaten to 36°SR by paddle car, and the wet weight was 13.6g. Then use a double cylinder screen to make paper, and the pressure-resistant layer paper and the absorbing layer paper are formed on a wet felt and then compounded. After compounding, they are dried with a drying cylinder. When drying, the pressure-resistant layer paper is pasted on the cylinder for drying. Electrolytic capacitor paper. After measurement, the thickness of the paper is 40μm, and the tightness reaches 1.02g / cm 3 , The tensile strength is 1.85kN / m. This kind of electrolytic capacitor paper made of wood pulp as the pressure-resistant layer and sisal as the absorbing layer has a water absorption height of 3mm / 10min in the longitudinal direction and 2mm / 10...

Embodiment 2

[0009] Embodiment 2: The paper pulp of the pressure-resistant layer paper of the electrolytic capacitor paper in this embodiment adopts wood pulp, and the beating degree is 67°SR, and the wet weight is 5.6g, and the pulp of the absorbing layer paper is Manila hemp pulp, and the beating degree is 18°SR , wet weight 27g. After making paper with an oblong net paper machine, the pressure-resistant layer paper and the absorbing layer paper are formed on a wet felt and then compounded. After compounding, they are dried with a drying cylinder. When drying, the pressure-resistant layer paper is dried in a cylinder, and the roll is Electrolytic capacitor paper. After measurement, the thickness of the paper is 40μm, and the tightness reaches 0.663g / cm 3 , The tensile strength is 1.75kN / m. This kind of electrolytic capacitor paper made of wood pulp as the pressure-resistant layer and sisal as the absorbing layer has a water absorption height of 9mm / 10min in the longitudinal direction a...

Embodiment 3

[0010] Embodiment 3: The paper pulp of the pressure-resistant layer paper of the electrolytic capacitor paper in this embodiment adopts sisal pulp, the degree of beating is 40 ° SR, and the wet weight is 14.5g, and the paper pulp of the absorbing layer paper uses sambucus bark pulp, and the degree of beating is 23 °SR, wet weight 19g. Papermaking is carried out with a wave net paper machine on one side of the rotary screen. The pressure-resistant layer paper and the absorbing layer paper are formed on a wet felt and then compounded. After compounding, they are dried with a drying cylinder. When drying, the pressure-resistant layer paper is pasted on the cylinder for drying. Roll to obtain electrolytic capacitor paper. After measurement, the thickness of the paper is 40μm, and the tightness reaches 0.362g / cm 3 , The tensile strength is 1.29kN / m. This kind of electrolytic capacitor paper made of wood pulp as the pressure-resistant layer and sisal as the absorbing layer has a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com