Manufacturing method of electroplated grinding wheel of ordered structure

A technology with an ordered structure and a manufacturing method, applied in the field of grinding wheel manufacturing, can solve the problems of increasing the surface roughness of the workpiece and decreasing the distribution density of the abrasive grains of the grinding wheel, so as to reduce the grinding temperature, ensure the grinding quality, and reduce the periodicity. The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

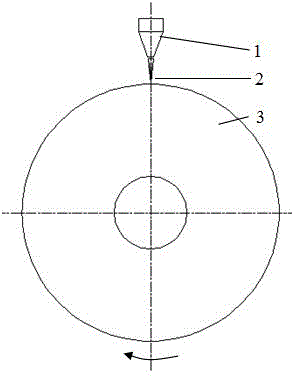

[0024] See figure 1 , figure 2 with image 3 , Ordered structure electroplating grinding wheel includes: grinding wheel base 3 and abrasive grain layer 8 with orderly arranged abrasive grains. The material of the grinding wheel base 3 is high-strength aluminum alloy with a diameter of 100-200 mm and a thickness of 12-20 mm. There is a spiral groove 5 with a fine structure on the outer circumferential working surface 4 of the grinding wheel base. The spiral groove 5 has a width of 50-80 μm, a depth of 60-100 μm, a pitch of 200-300 μm, and the spiral groove is filled with epoxy Resin 6. The material of the abrasive particles 7 is cubic boron nitride or diamond, and is fixed on the grinding wheel base 3 through a nickel-cobalt alloy coating.

[0025] When processing the grinding wheel base body, the two end faces of the grinding wheel base body 3 are firstly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com