Special cutter for machining small-diameter pore helical milling of composite material

A composite material, helical hole milling technology, applied in the direction of cutters, milling cutters, manufacturing tools, etc. for milling machines, can solve the problem of unsuitable helical milling for small diameter holes, not fully considering high-speed chatter, and improve tool processing. Difficulty in production and other problems, to achieve the effect of improving stiffness, improving chip removal performance, and improving anti-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

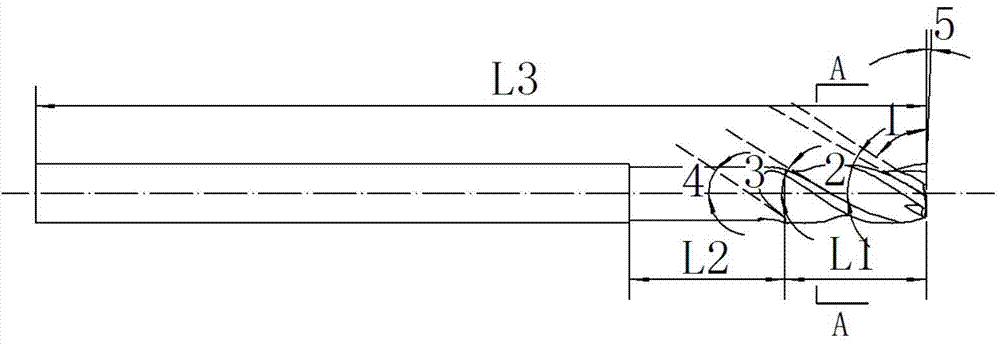

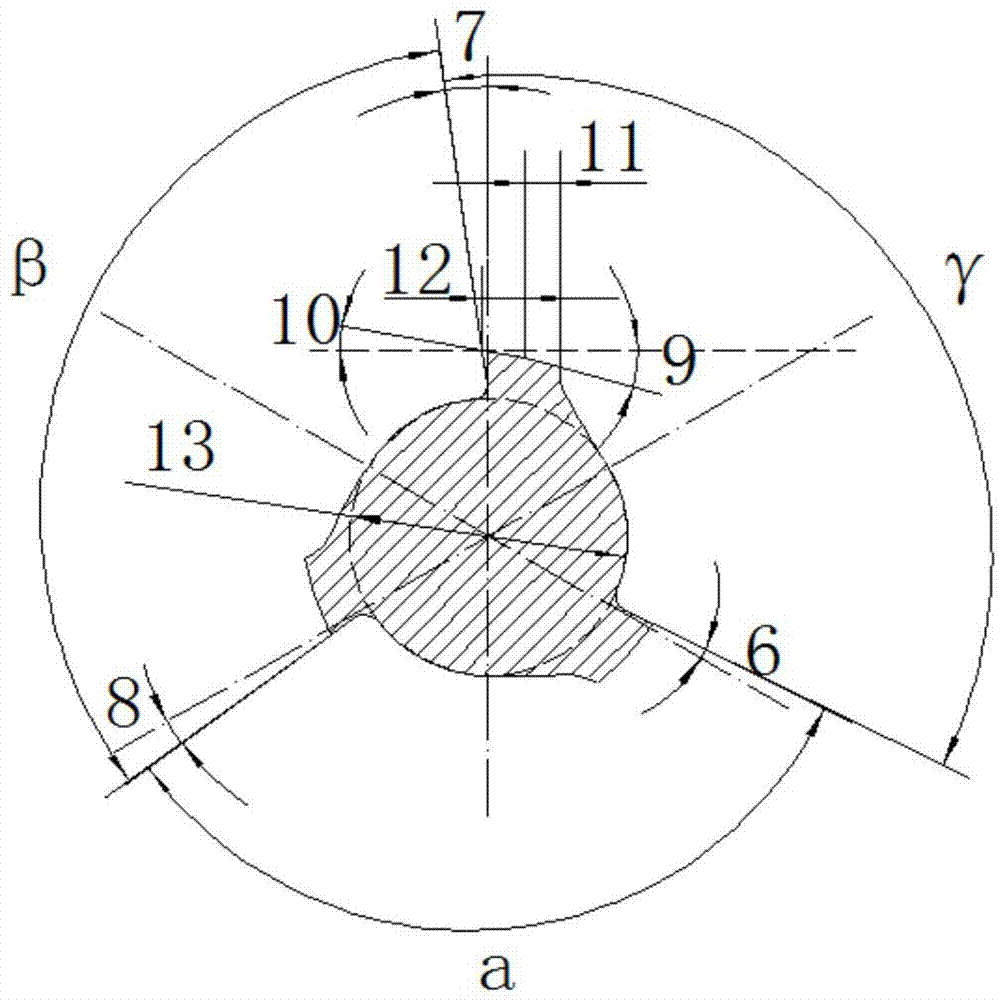

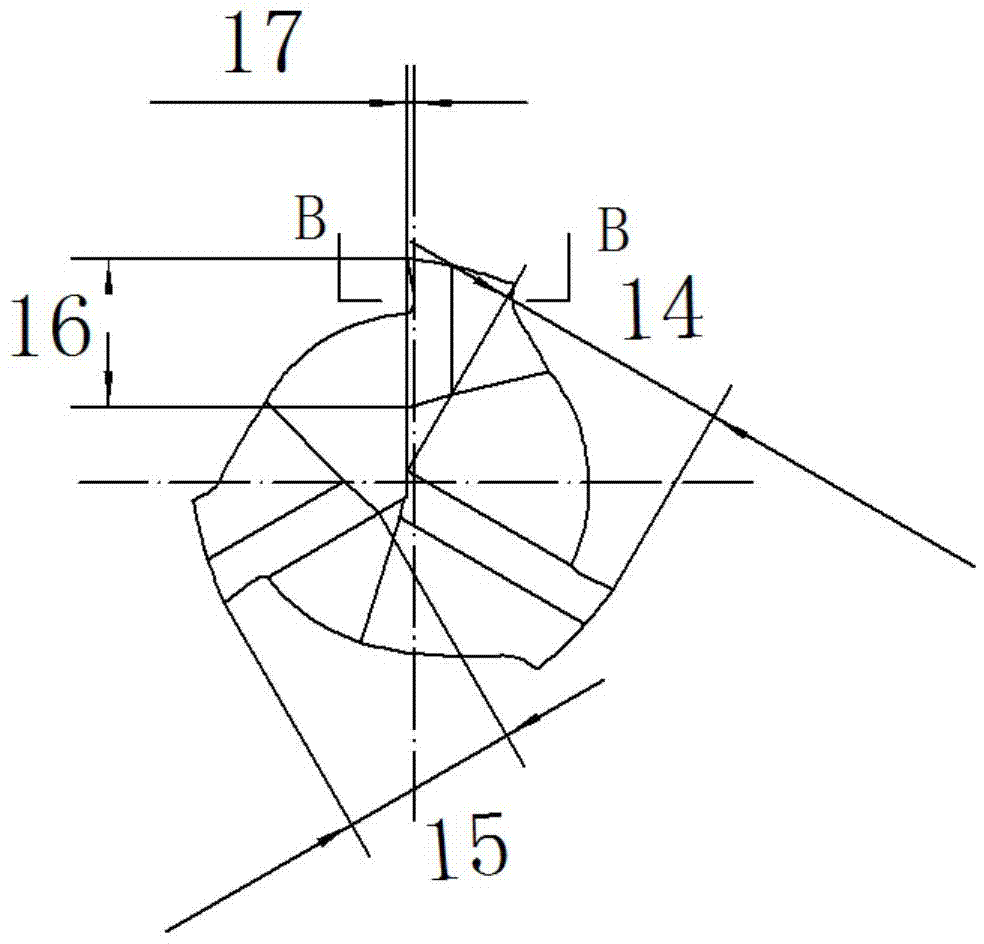

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] As shown in the accompanying drawings, the special cutting tool for processing small-diameter holes of composite materials for spiral milling of the present invention has first, second and third cutting edges on the cutting edge, and the included angles a and β between the three cutting edges , γ are not equal, wherein the angle a between the first cutting edge and the second cutting edge is 117°~119°, the angle β between the second cutting edge and the third cutting edge is 119°~121°, The included angle γ between the first cutting edge and the third cutting edge is 121°~123°, and the lengths of the three cutting edges are 14, 15, 16, and the length 14 of the first cutting edge is 1.5mm~1.6mm , the edge length 15 of the second cutting edge is 1.1 mm to 1.3 mm, the edge length 16 of the third cutting edge is 0.9 mm to 1.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com