Cutting insert, cutting tool, and method for manufacturing cut product using cutting tool

A technology for cutting inserts and cutting tools, used in milling cutting inserts, manufacturing tools, accessories of tool holders, etc., can solve the problems of long elongation and surface quality degradation, and achieve the effect of excellent chip discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

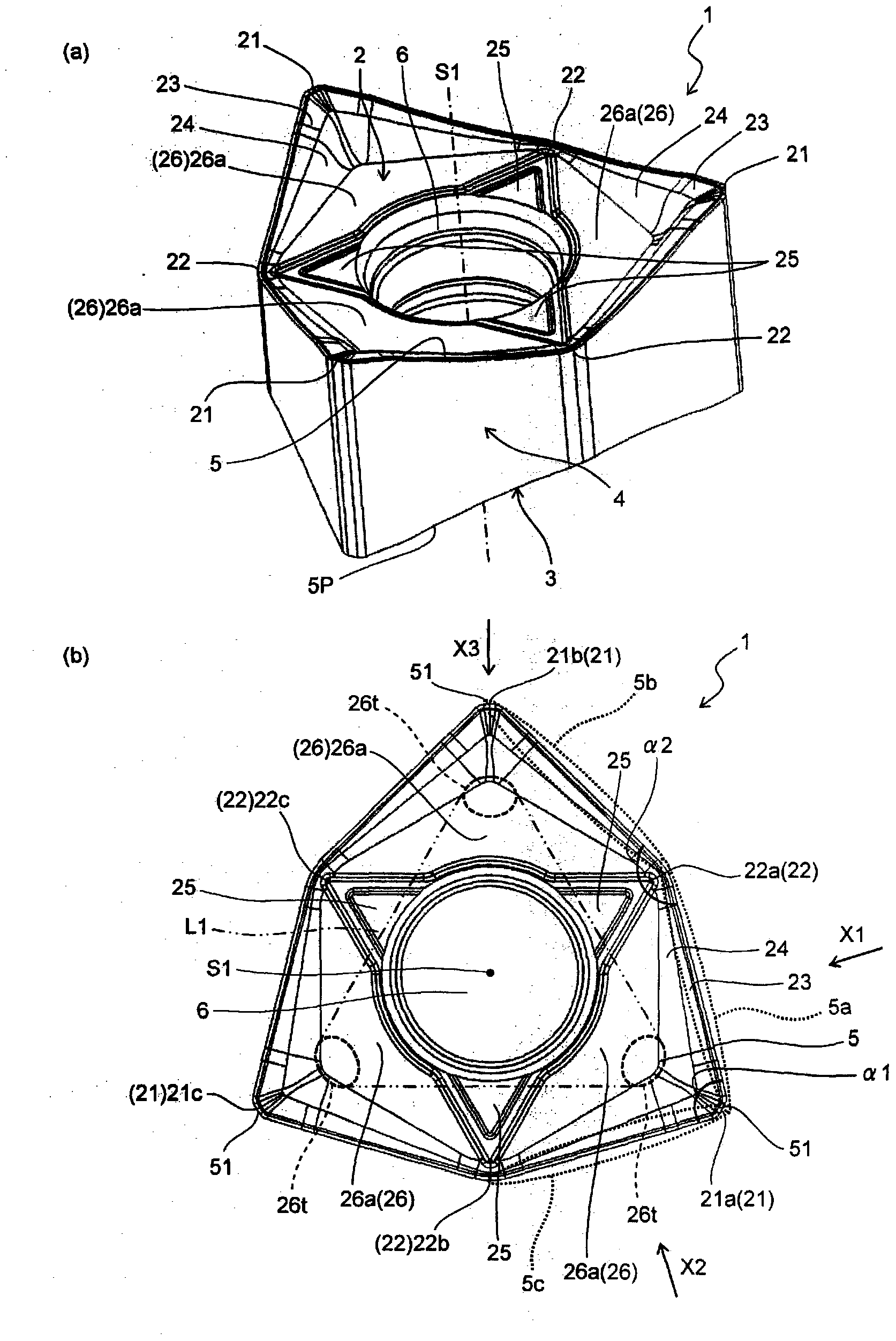

[0025] Hereinafter, regarding the cutting insert according to the first embodiment of the present invention, the insert 1 having a hexagonal shape in a plan view is taken as an example, referring to Figure 1 ~ Figure 4 Explain in detail.

[0026] like figure 1 and figure 2 As shown, the insert 1 of this embodiment generally includes a polygonal (hexagonal) upper surface 2, a lower surface 3 having the same shape as the upper surface 2, side surfaces 4 respectively connected to the upper surface 2 and the lower surface 3, The through hole 6 (installation hole) penetrating from the upper surface 2 to the lower surface 3 , the upper cutting edge 5 located at the intersection of the upper surface 2 and the side surface 4 , and the lower cutting edge 5 located at the intersection of the lower surface 3 and the side surface 4 Cutting edge 5P. For the insert 1, for example, one side of the upper surface 2 may be 5 mm to 100 mm, and the thickness of the upper and lower surfaces ...

no. 2 approach )

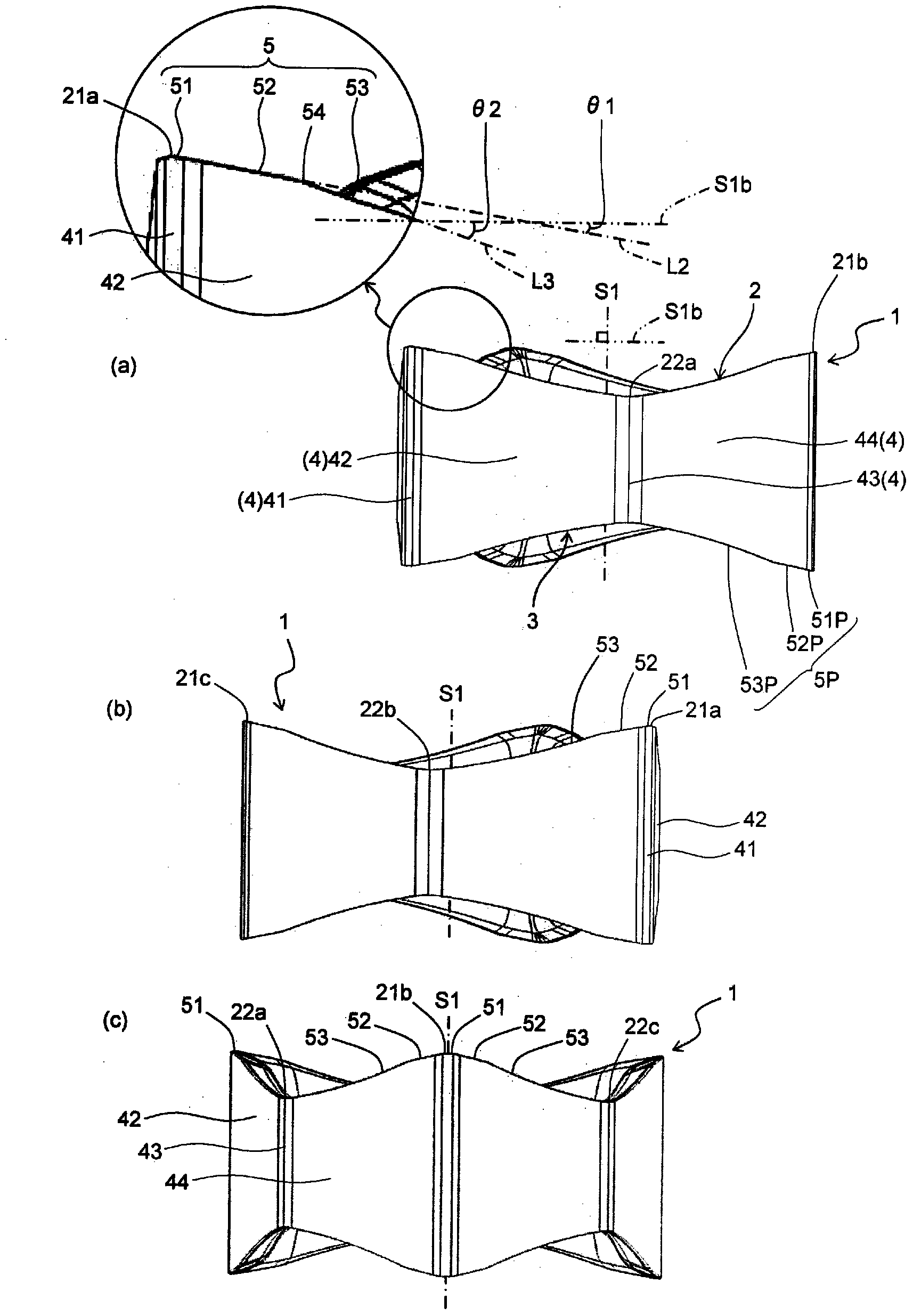

[0072] Below, refer to Figure 5 and Image 6 An insert according to a second embodiment of the present invention will be described in detail. In addition, the basic structure of the insert of this embodiment is the same as that of the insert of the said 1st embodiment. Therefore, in the drawings, the same reference numerals are assigned to the same components as those of the insert of the first embodiment, and description thereof will be omitted. Hereinafter, the description will focus on parts having structural differences.

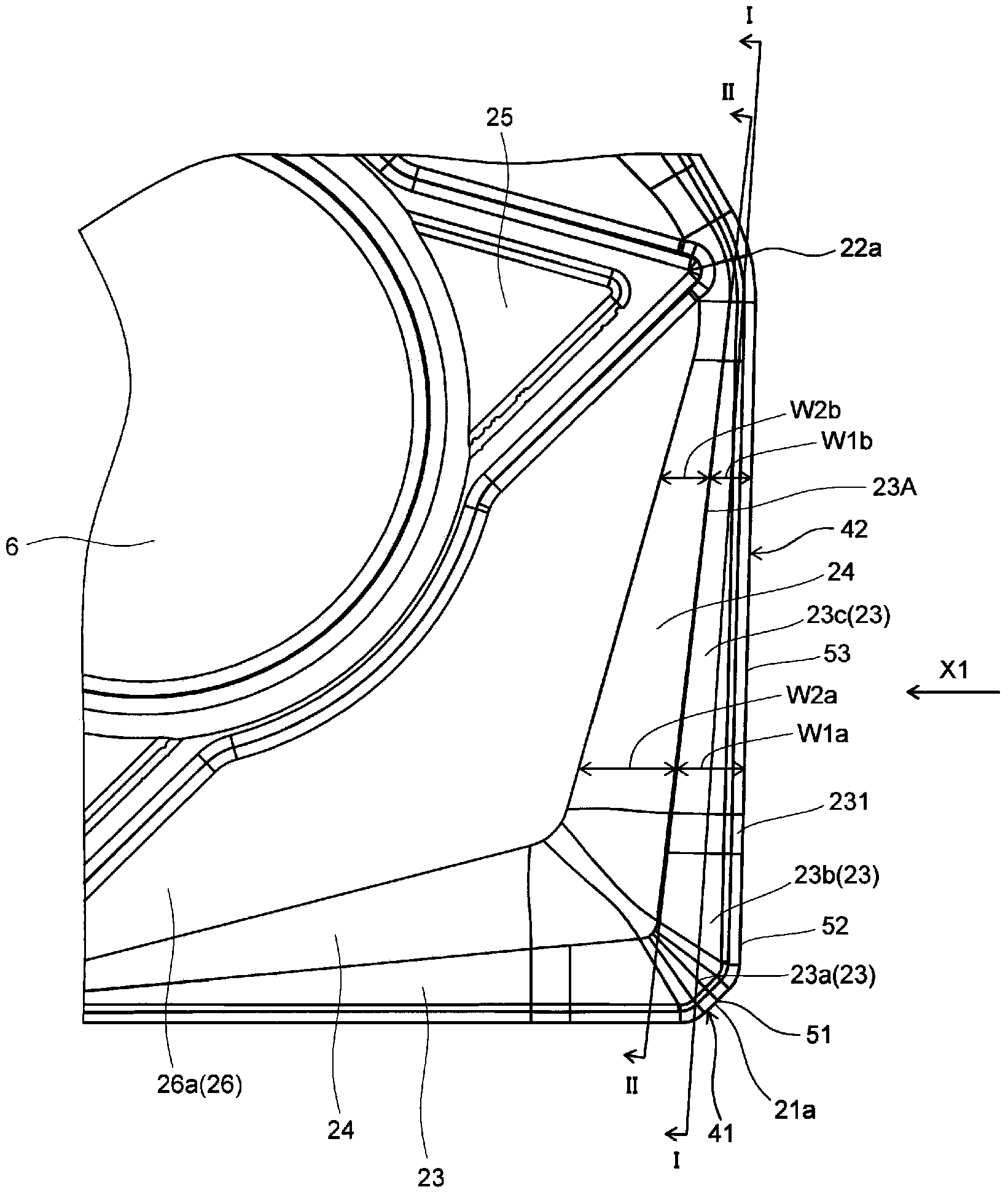

[0073] In the insert 1 of the present embodiment, as Figure 5 and Image 6 As shown, the rake surface 23 has a sub-rake surface 23b and a main rake surface 23c similarly to the first embodiment. The main rake surface 23c is continuous with the main cutting edge 53 and is inclined toward the lower surface 3 by the second rake angle β1 on the basis of the vertical plane S1b as it goes inward. The rake angle β2 is inclined.

[0074] In addition, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com