Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Improve brazing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

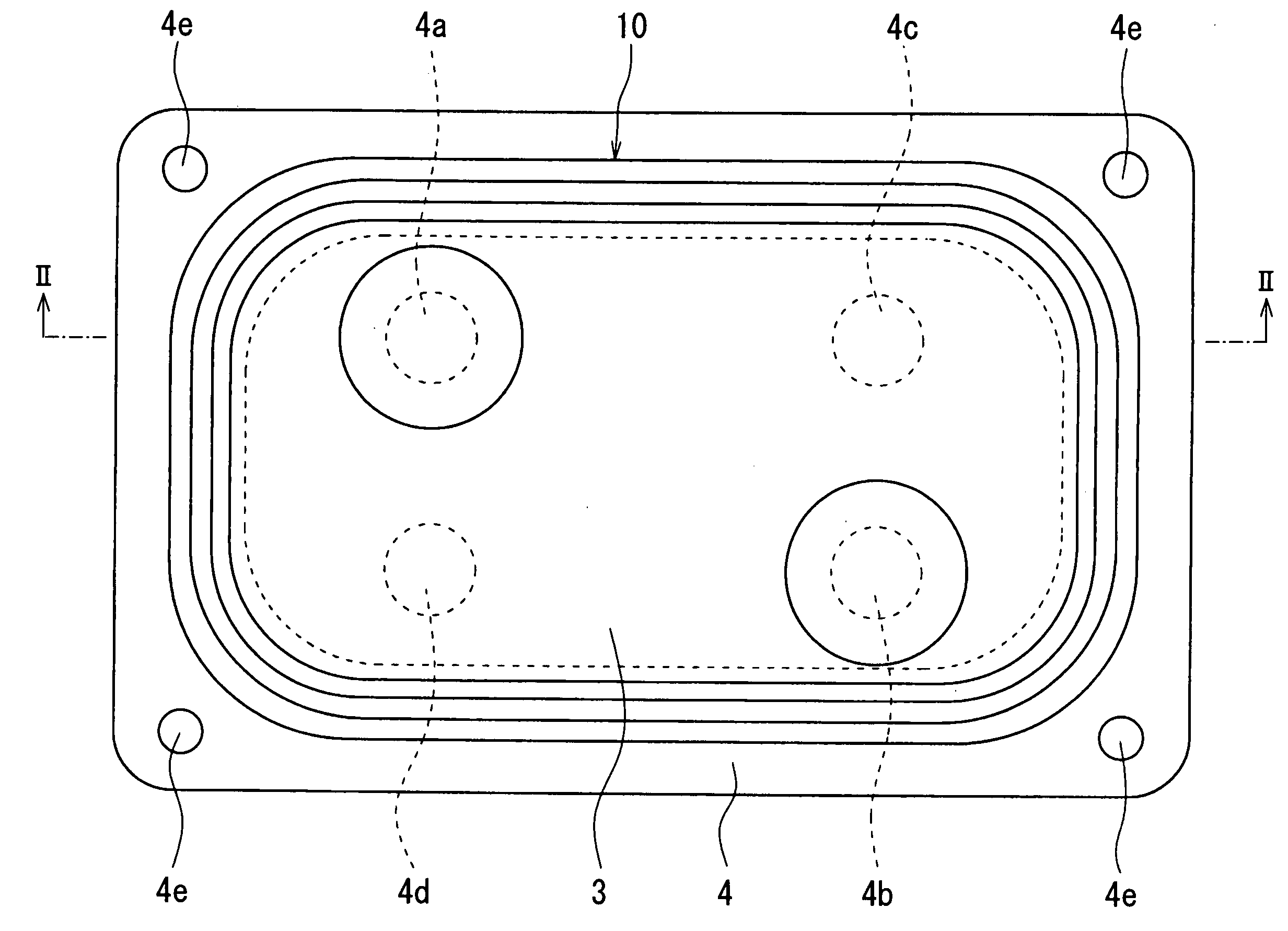

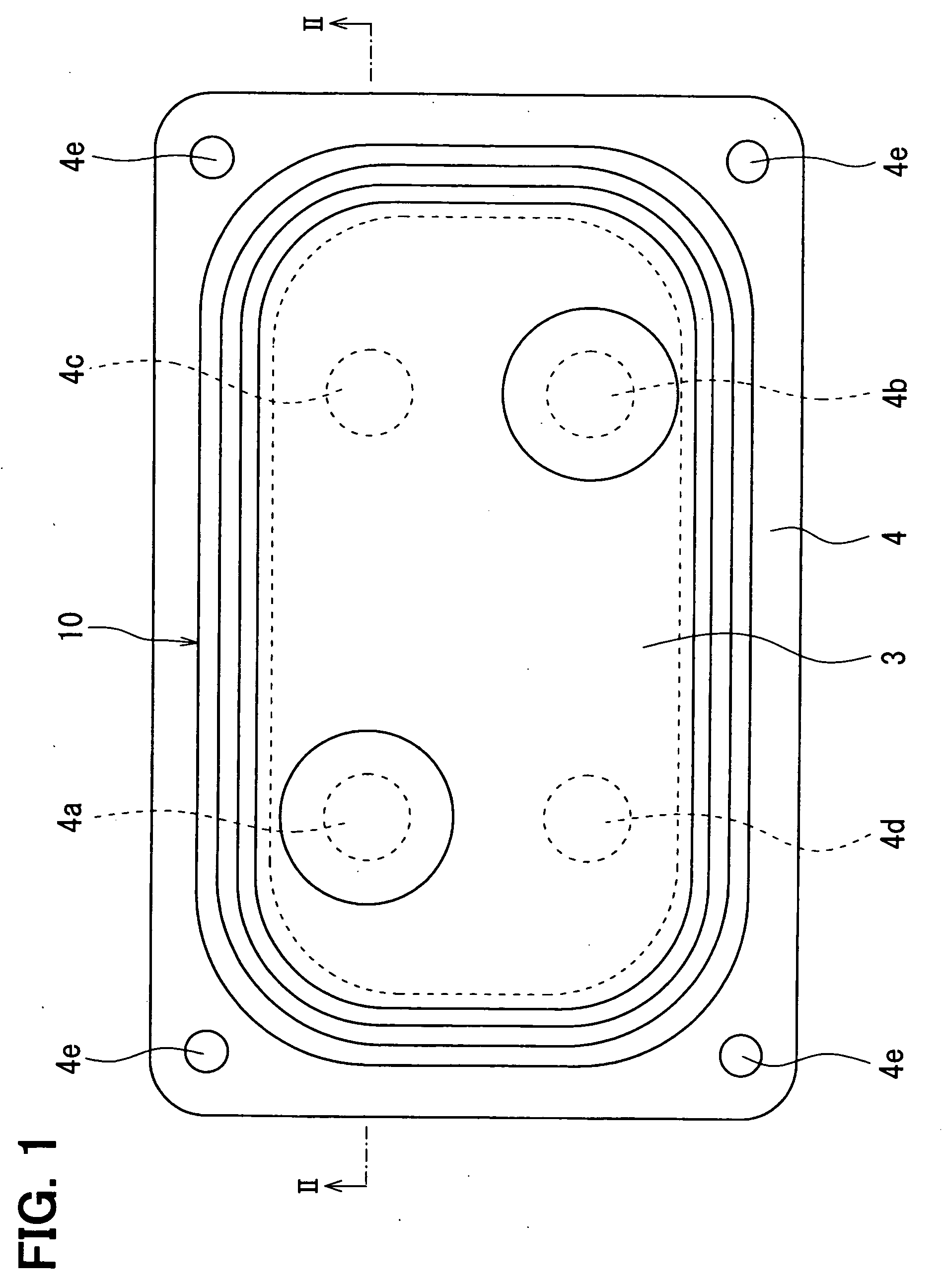

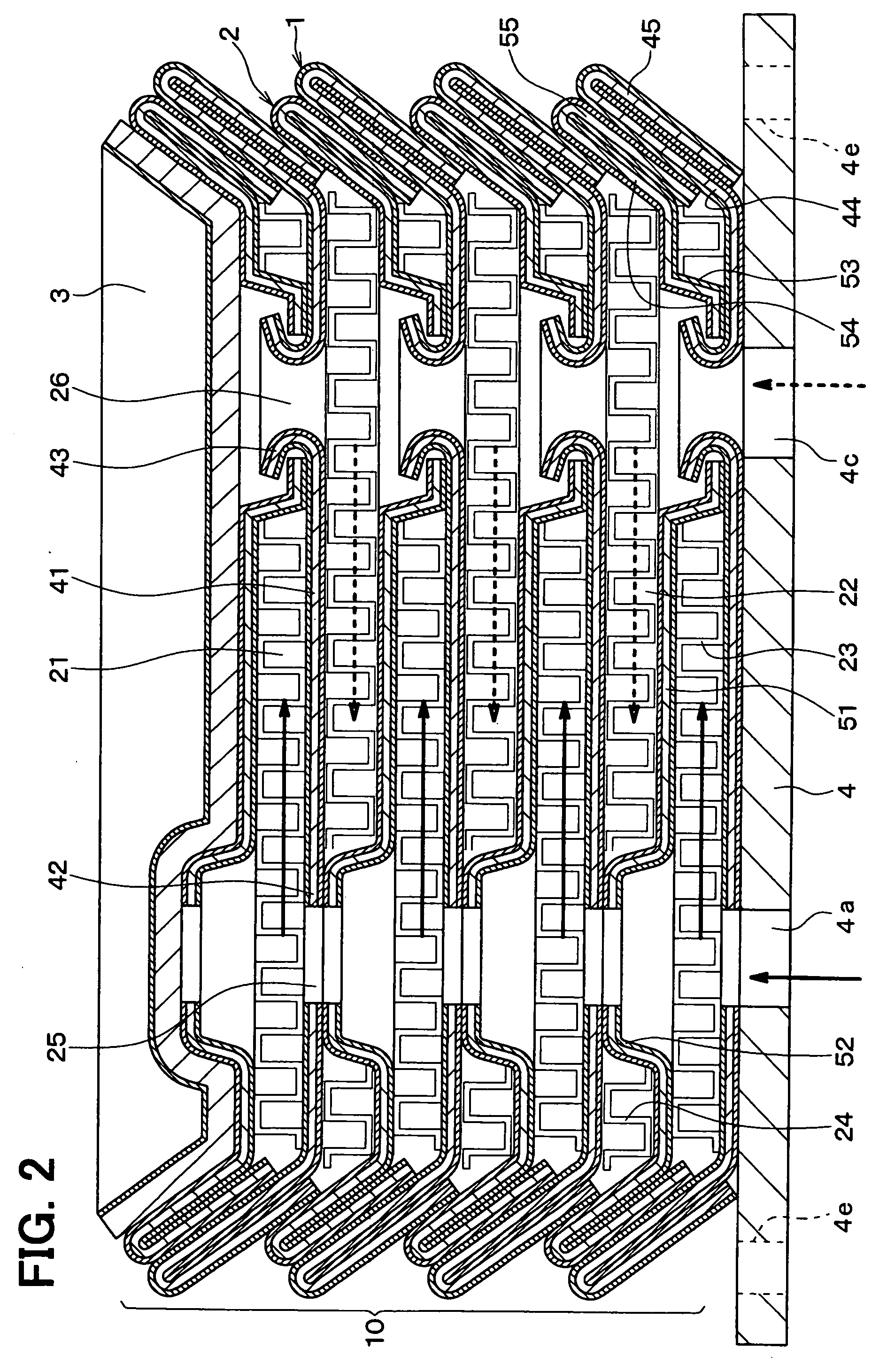

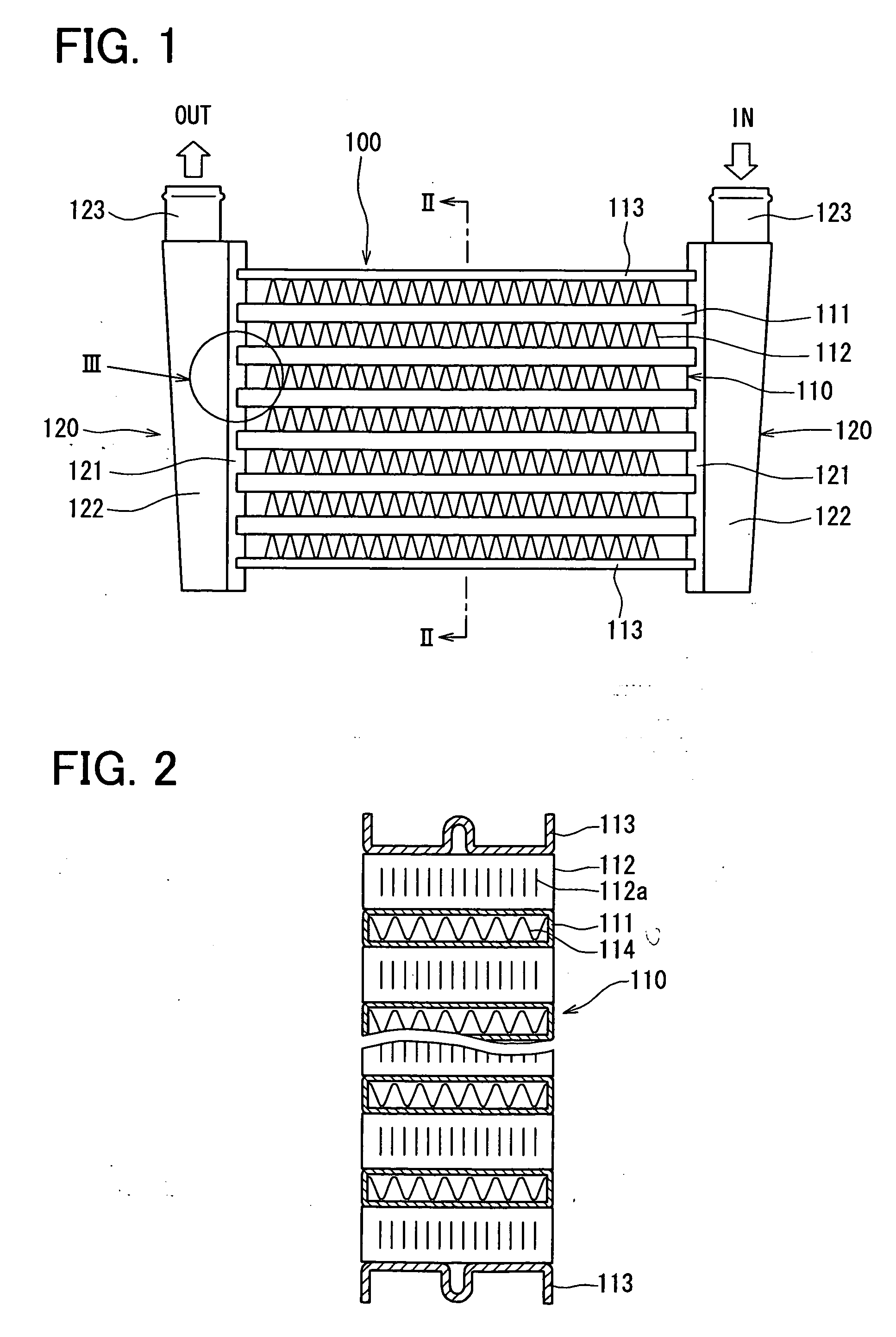

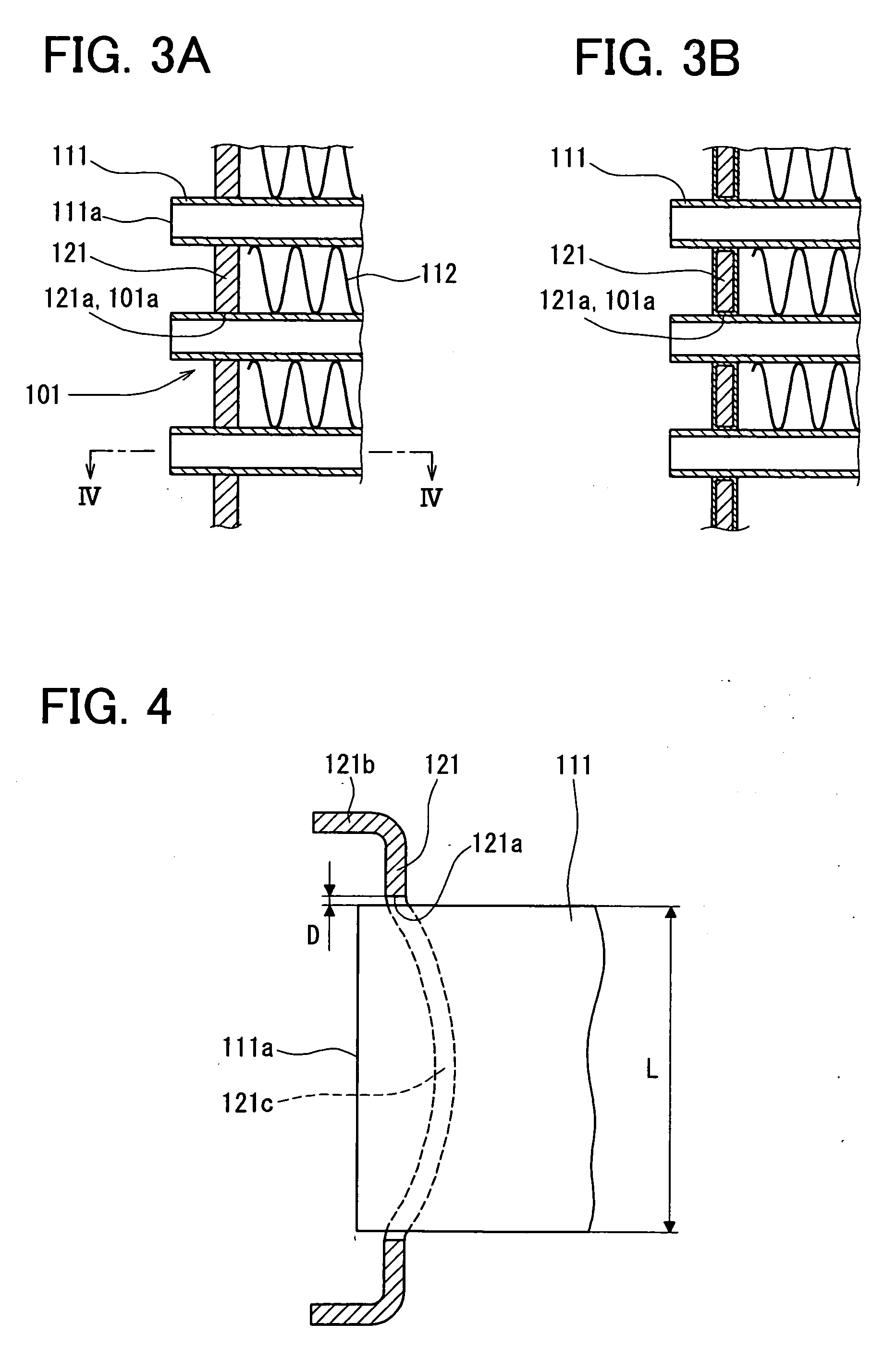

Stacked plate heat exchanger

InactiveUS20090032231A1Sufficient resistance to corrosionReliable joint of brazingCoatingsLaminated elementsPlate heat exchangerEngineering

The stacked plate oil cooler has a first plate and a second plate. Both the first plate and the second plate are made of a three-layered aluminum alloy clad sheet. The second plate is folded at an outer rim to place the brazing material layer on both sides of the second plate. The first and second plates and are stacked alternately and brazed to define a water passage between sacrificial layers and, and to define an oil passage between brazing material layers. The first plate is folded at an outer rim to place the sacrificial layer on a lateral outside of a core assembly to decrease exposure of the brazing material layer to the lateral outside.

Owner:DENSO CORP

Flux-containing brazing agent brazed at low temperature

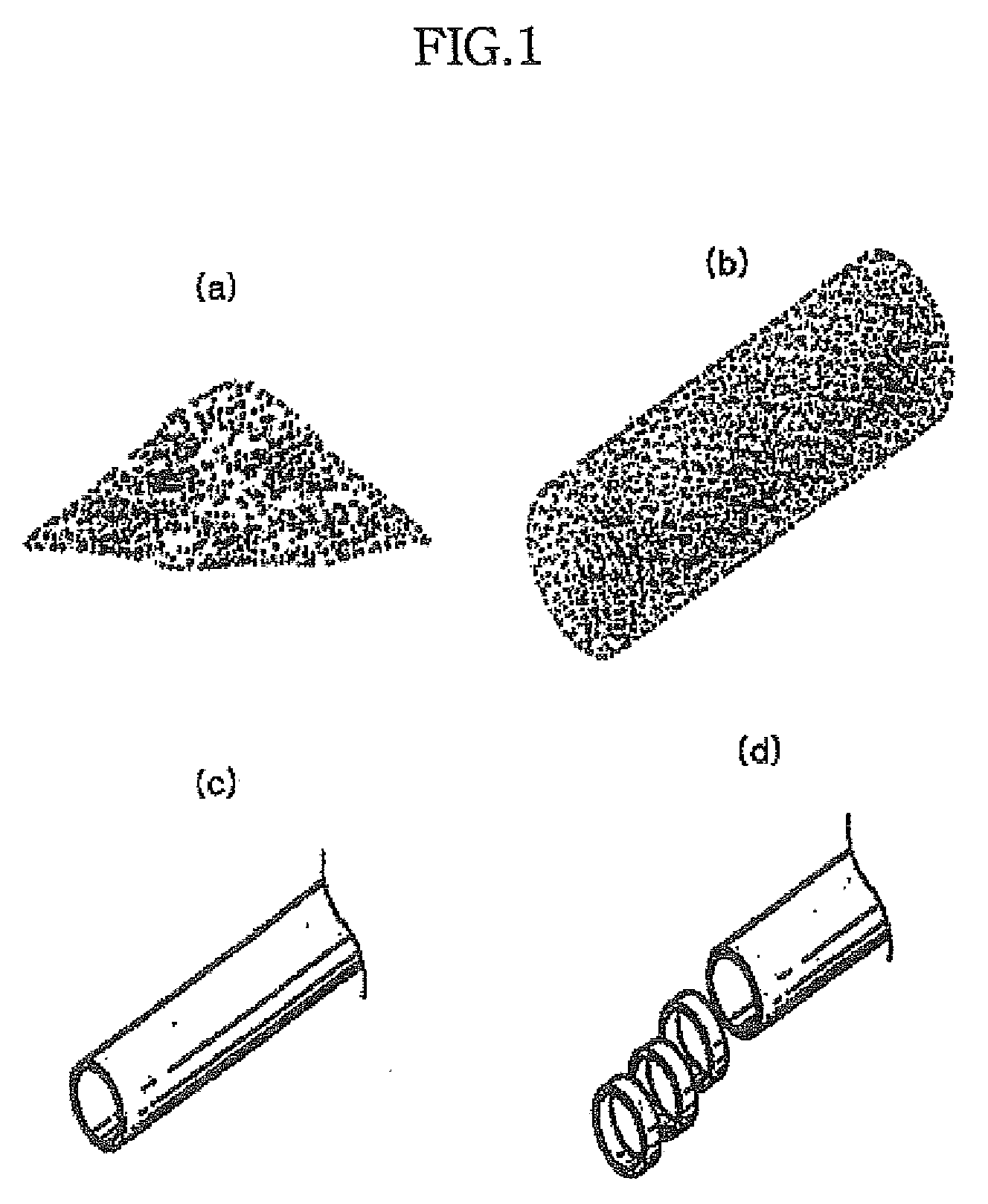

InactiveUS20080135134A1Simple processImprove brazing qualityWelding/cutting media/materialsSoldering mediaFluorideMetal

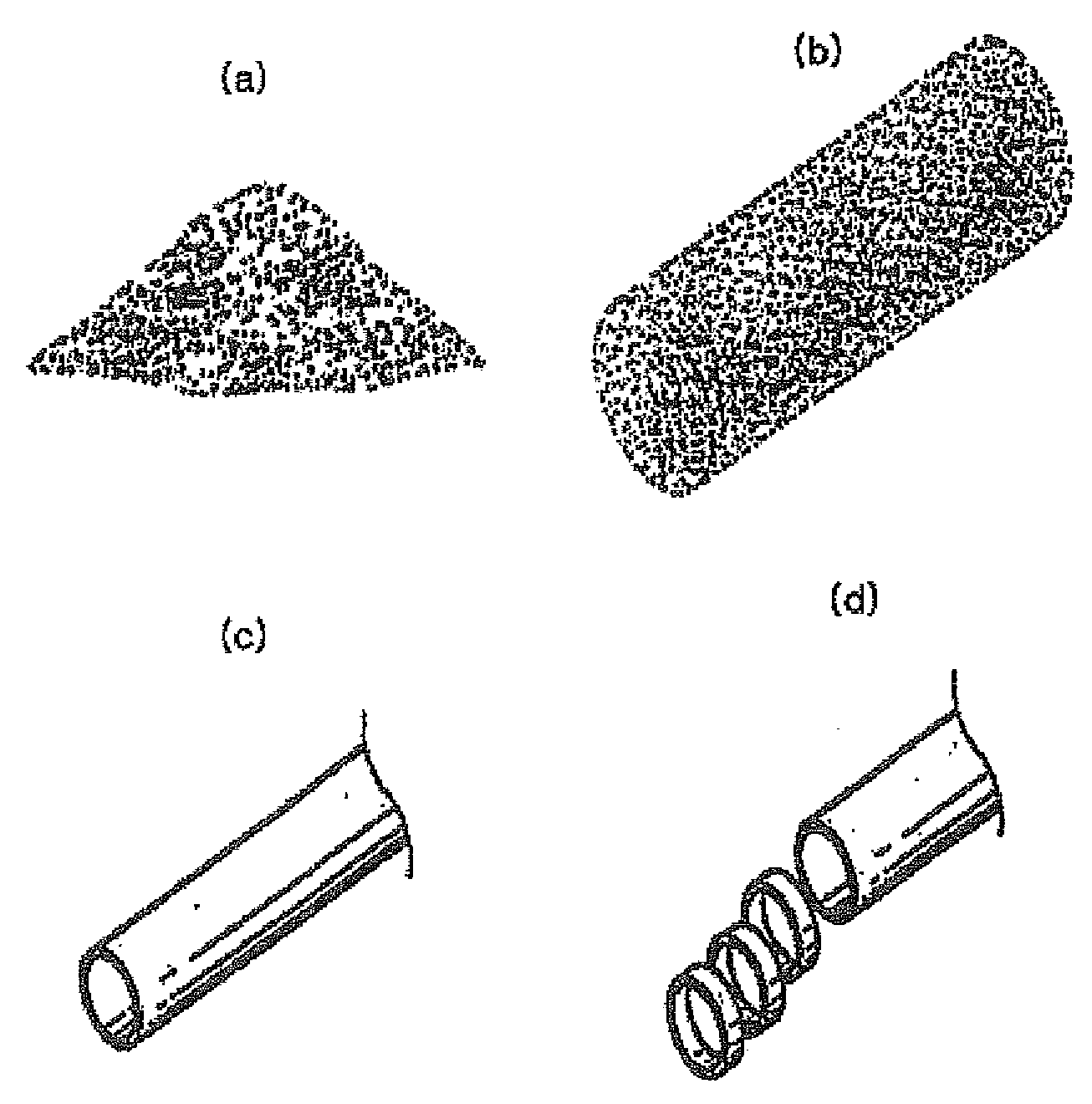

Disclosed is a flux-containing brazing material, which is used to braze the same or different kinds of metal members with each other at low temperatures. The flux-containing brazing material includes a mixed powder, comprised of Zn alloy powder, containing 10 to 40 wt % of Al or Al and Si, and remaining Zn, and 10 to 40 wt % of cesium fluoride-based flux powder on a basis of the Zn alloy powder. The mixed powder is subjected to powder forging and extruding processes to form a three-dimensional flux. The flux-containing brazing material is advantageous in that the Zn alloy and flux powders are mixed with each other and machined to form the three-dimensional flux, thereby simplifying a brazing process because a flux coating process is omitted during the brazing process. The brazing quality is improved because the flux content in the brazing material is properly controlled.

Owner:SUNKWANG BRAZING FILLER METAL

Soldering method of conducting ring of motor rotor

ActiveCN101557145AImprove brazing qualityImprove quality and performanceLine/current collector detailsSoldering apparatusSolderingEngineering

The invention relates to a soldering method of a conducting ring of a motor rotor. In the method, an end ring is heated through improving the structure of a conducting bar of a rotor and adopting a medium frequency induction way, and a super thick conducting ring of a high capacity motor rotor is soldered by the way that two brazing torches respectively assist heating the end head of the conducting bar and the excircle surface of the end ring. The soldering method of the conducting ring of the motor rotor has the advantages of good soldering quality and motor performance and quality improvement when being used for soldering the conducting ring of the high capacity motor rotor.

Owner:上海电气集团上海电机厂有限公司

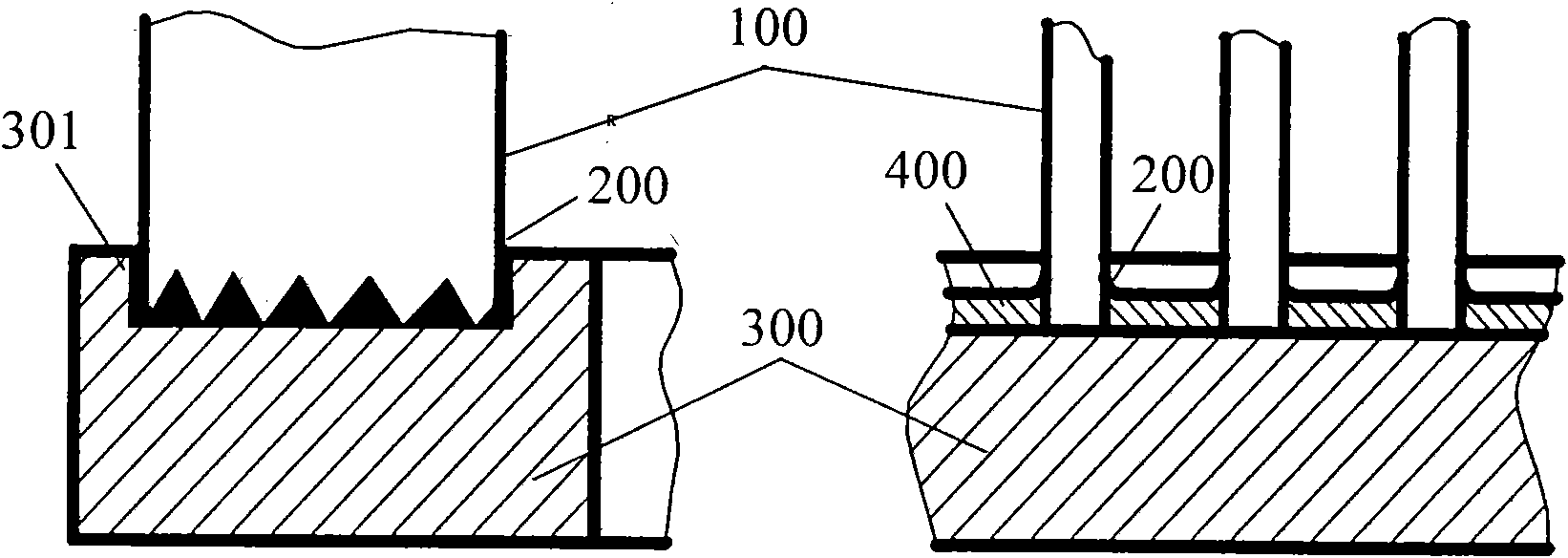

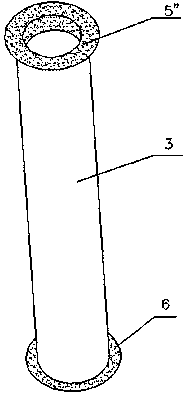

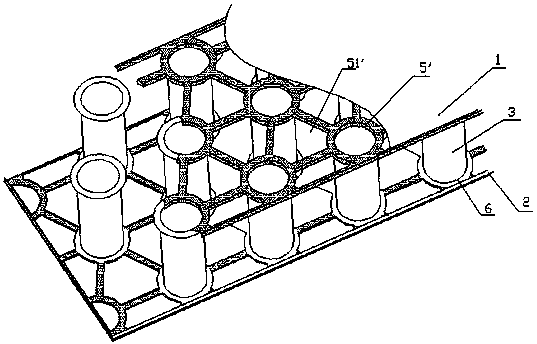

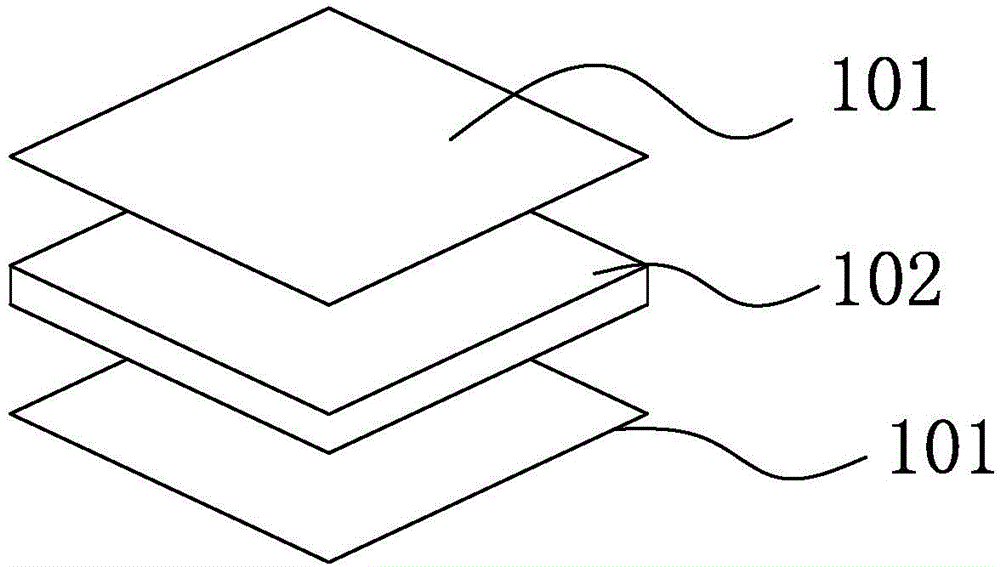

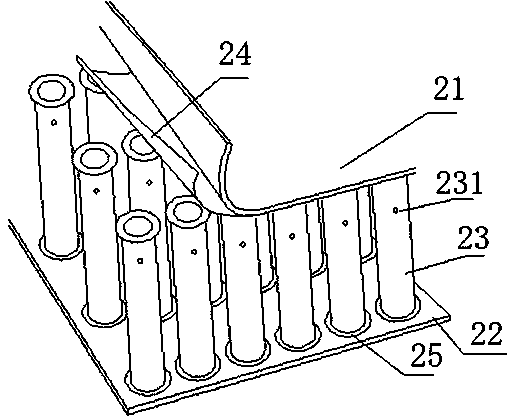

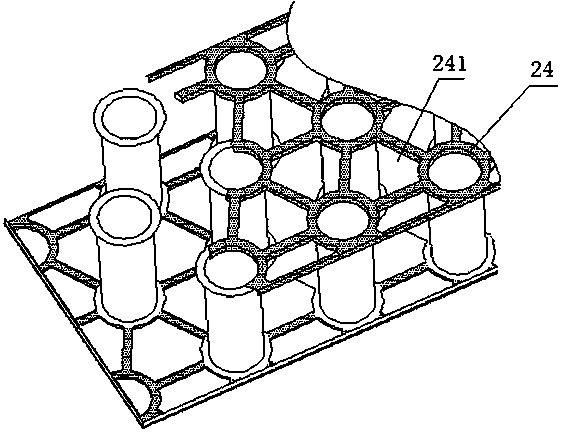

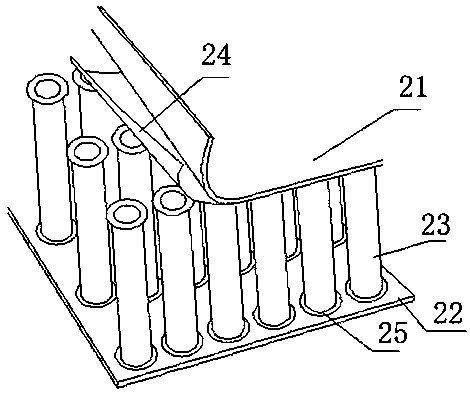

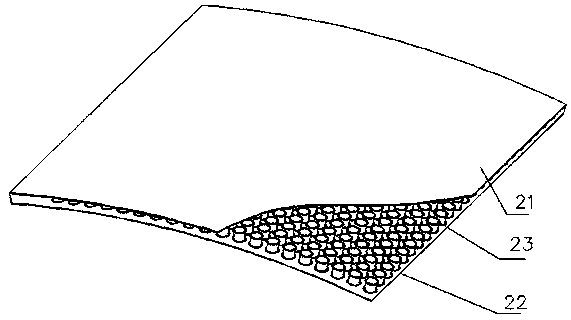

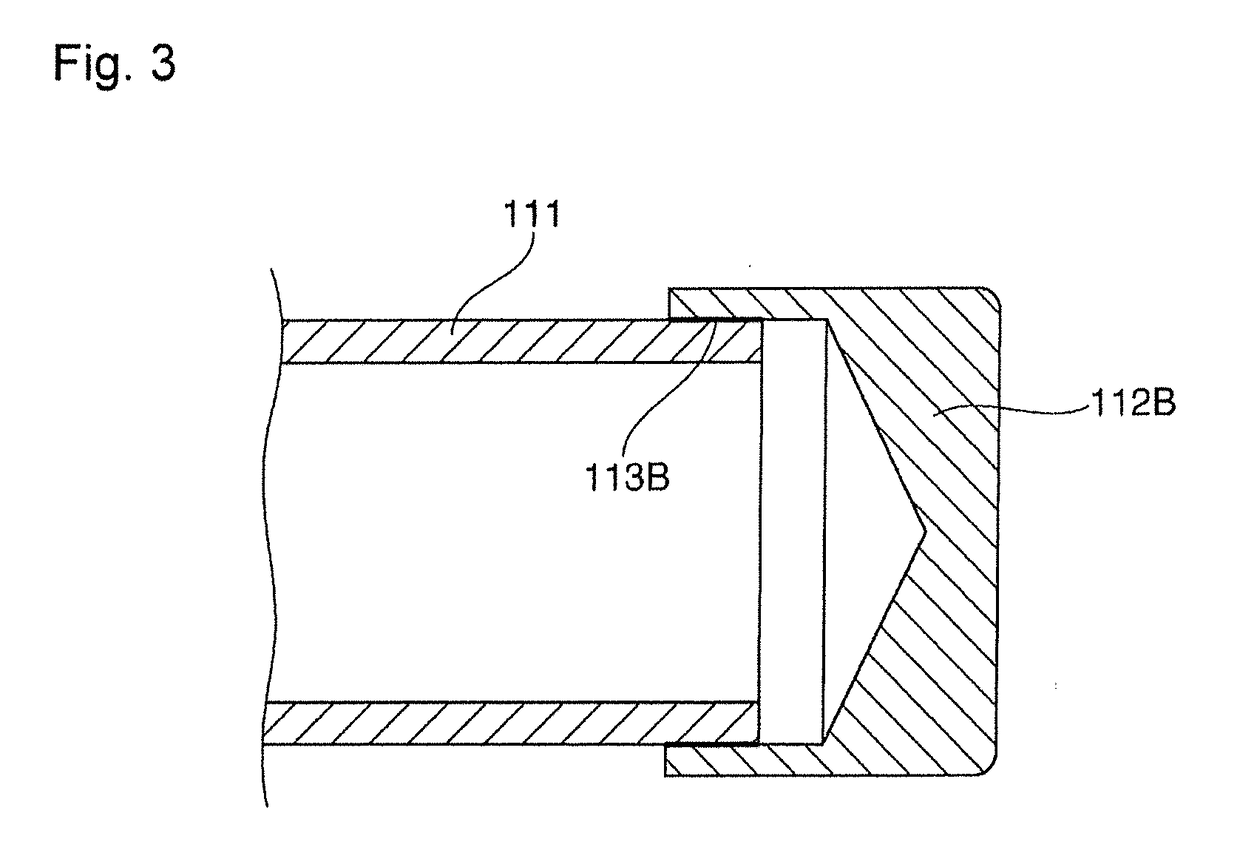

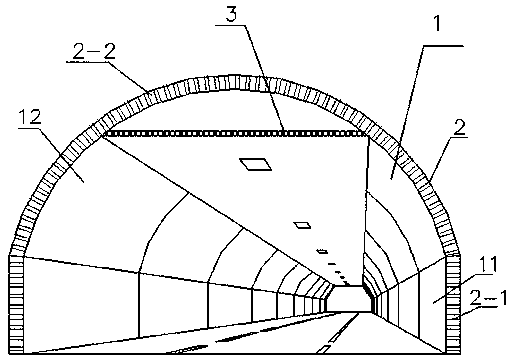

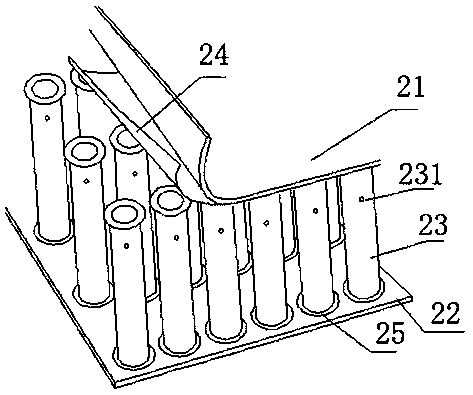

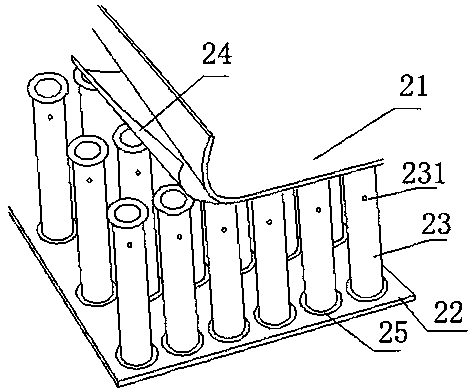

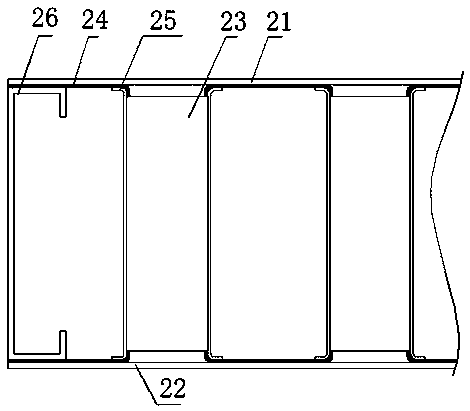

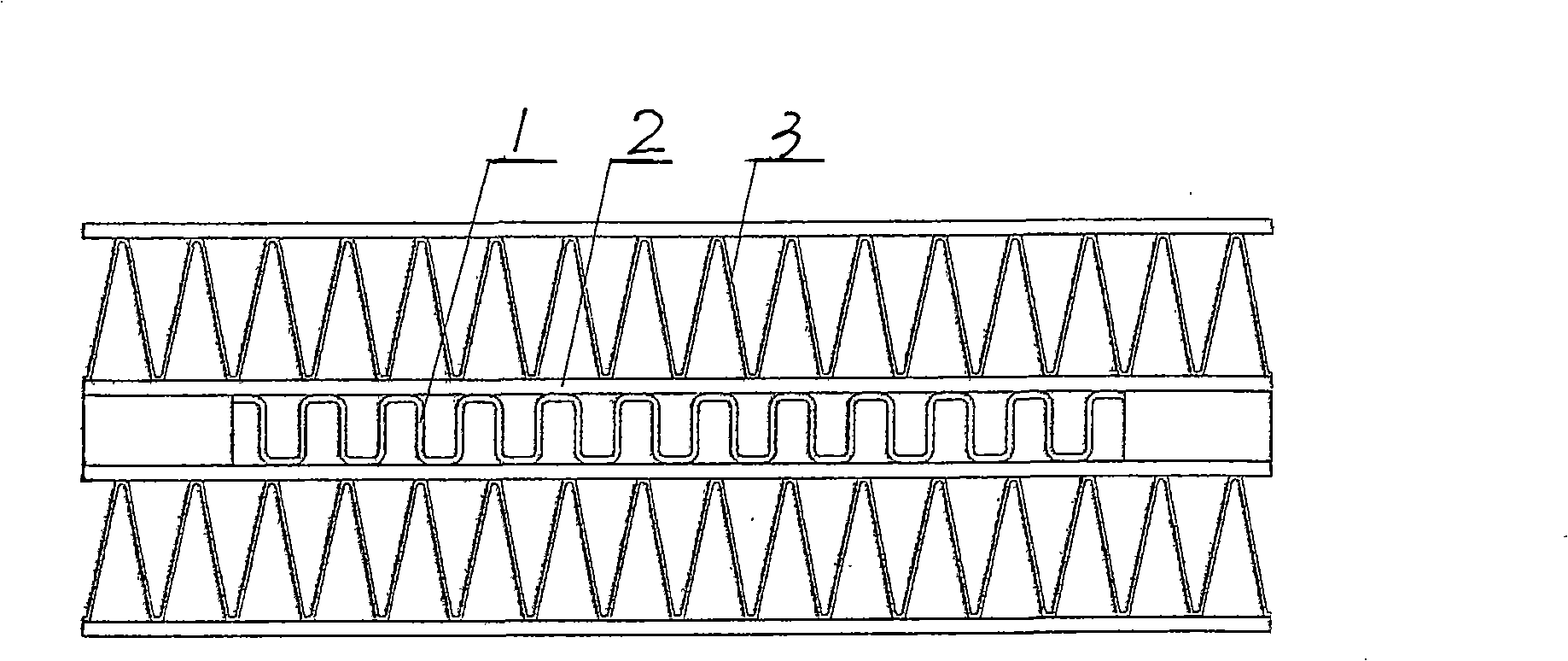

Sandwich metal plate

ActiveCN108397679APermanent service lifeLow intensitySheets/panelsMetal layered productsThermal insulationEngineering

The invention relates to a sandwich metal plate. The sandwich metal plate comprises an upper panel, a lower panel and a plurality of core tubes, wherein the multiple core tubes are arranged between the upper panel and the lower panel, penetrating air passages are arranged among the multiple core tubes, and the core tubes as well as the upper panel and the lower panel are brazed through fore-and-aft and / or left-and-right circulating heating by utilizing high-temperature gas through the air passages. On one hand, the sandwich metal plate has the advantages of light weight, high strength, heat insulation and the like, and on the other hand, the sandwich metal plate cannot be deformed by heat difference, so that the permanent service life of the sandwich metal plate is guaranteed.

Owner:张跃

Brazing technology for diamond

InactiveCN101524779AImprove brazing qualitySuitable for industrial operationWelding/cutting media/materialsSoldering mediaArgon gasWelding torch

The invention relates to brazing technology for diamond. Firstly, a flame spraying method (an oxyacetylene welding torch) is used to plate solder alloy on a tool steel substrate, the diamond is arranged on the surface of a solder layer, then the high-frequency induction brazing is performed under the protection of argon at a temperature of 1,080 DEG C for 30 seconds to realize the combination of the diamond and the steel substrate, and main components of the solder alloy in percentage by mass comprise 72 percent of Ni, 14.4 percent of Cr, 3.5 percent of Fe, 3.5 percent of Si, 3.35 percent of B and 0.5 percent of O2. The technical proposal is adopted, so the brazing technology has high brazing quality and is suitable for industrialized operation.

Owner:JIANGSU YOUHE TOOLS CO LTD

Brazed structure and method of manufacturing the same

InactiveUS20060254761A1Improve qualityImprove brazing qualitySoldering apparatusStationary conduit assembliesEngineeringCopper

In a brazed structure, a first member has a first portion defined by one of a recessed portion and a hole, and a second member has a second portion brazed to the first portion with a copper brazing material. The first member has a coefficient of thermal expansion that is smaller than that of the second member.

Owner:DENSO CORP

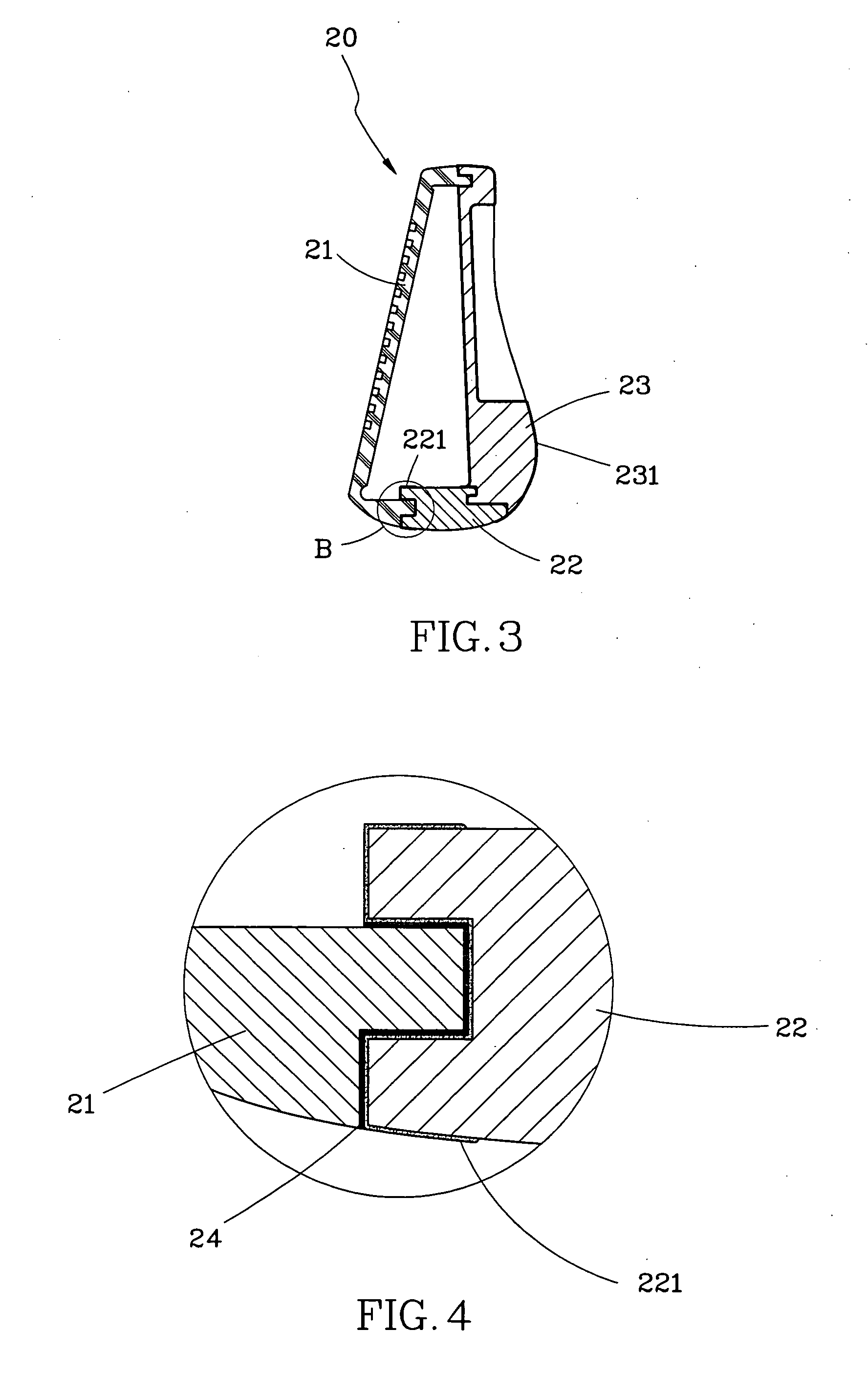

Method of bonding golf club head by brazing

InactiveUS20080009364A1Improve qualityImprove brazing qualitySoldering apparatusGolf clubsGolf clubMetallurgy

A method of making a golf club head, which the golf club includes a plurality of components, includes the steps of: coating a brazing solder on the components, then heating the components for solidification of the brazing solder to form a metal skin layer on each component, then bonding the components together by brazing.

Owner:CHEN ARCHER C C

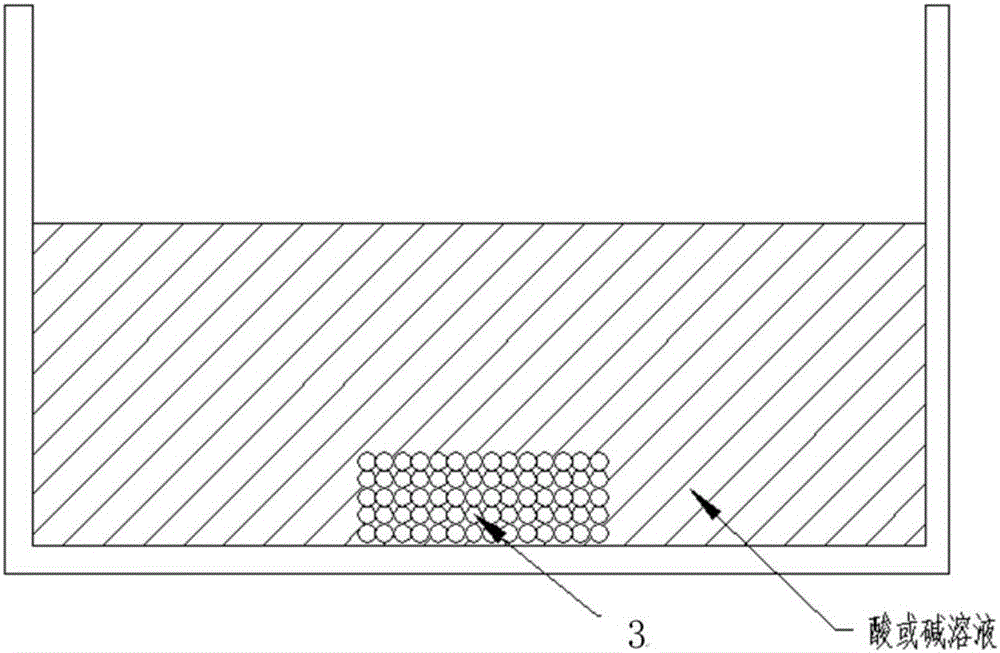

Self-bonding composite board and manufacturing process thereof

InactiveCN104607746AAvoid deformationQuality improvementSoldering apparatusMetal working apparatusHoneycombEngineering

The invention provides a self-bonding composite board and a manufacturing process thereof and belongs to the technical field of soldering. The manufacturing process comprises the steps of A, manufacturing board bodies and board cores, wherein an aluminum board is cut into blocks so that the board bodies for composition can be obtained, honeycomb cores are manufactured with aluminum foil and cut into a size corresponding to that of the board bodies for composition so that the board cores can be obtained, and the board bodies for composition and the board cores can be machined with corresponding dies manufactured according to different specification requirements; B, conducting assembly, wherein the upper surface and lower surface of each board core are smeared with soldering flux and covered with the corresponding board bodies for composition to obtain a blocky composite cellular board, and the composite cellular boards are clamped to be shaped with a clamp; C, conducting soldering, wherein the composite cellular boards are dried and fed into a soldering furnace to be soldered so that the self-bonding composite board can be obtained. According to the self-bonding composite board and the manufacturing process thereof, deformation of the composite board during high-temperature soldering can be prevented, so that soldering quality is improved, production cost is reduced and the high-quality self-bonding composite board is obtained.

Owner:JIANGSU LONGHE LIGHT MATERIAL CO LTD

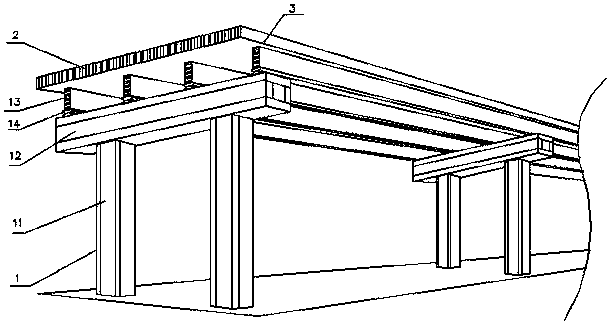

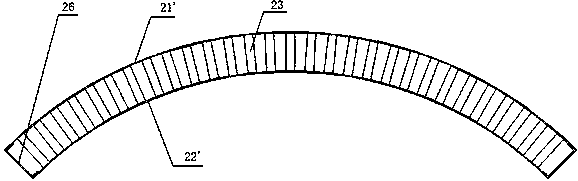

Viaduct structure

InactiveCN109403210AReduce stressIncrease the welding areaBallastwayDoors/windowsEngineeringTemperature resistance

A viaduct structure comprises a deck and a supporting body used for supporting the deck. The viaduct structure is characterized in that the deck and / or the supporting body is made of a metal plate; the metal plate comprises a first panel, a second panel and multiple hollow pipes, wherein the multiple hollow pipes are arranged between the first panel and the second panel; brazing layers are arranged between the hollow pipe and the first panel and between the hollow pipe and the second panels; and a turned-up edge is arranged at at least one end of each hollow pipe. The viaduct structure has theadvantages of light deadweight, high strength, stable structure, high pressure bearing capacity, sound insulation and noise reduction, high temperature resistance, vibration resistance, long servicelife and the like, and the viaduct structure can also be conveyed and spliced.

Owner:张跃

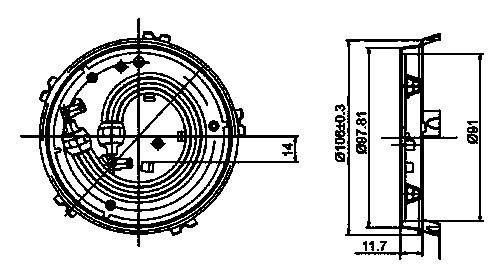

Induction brazing equipment

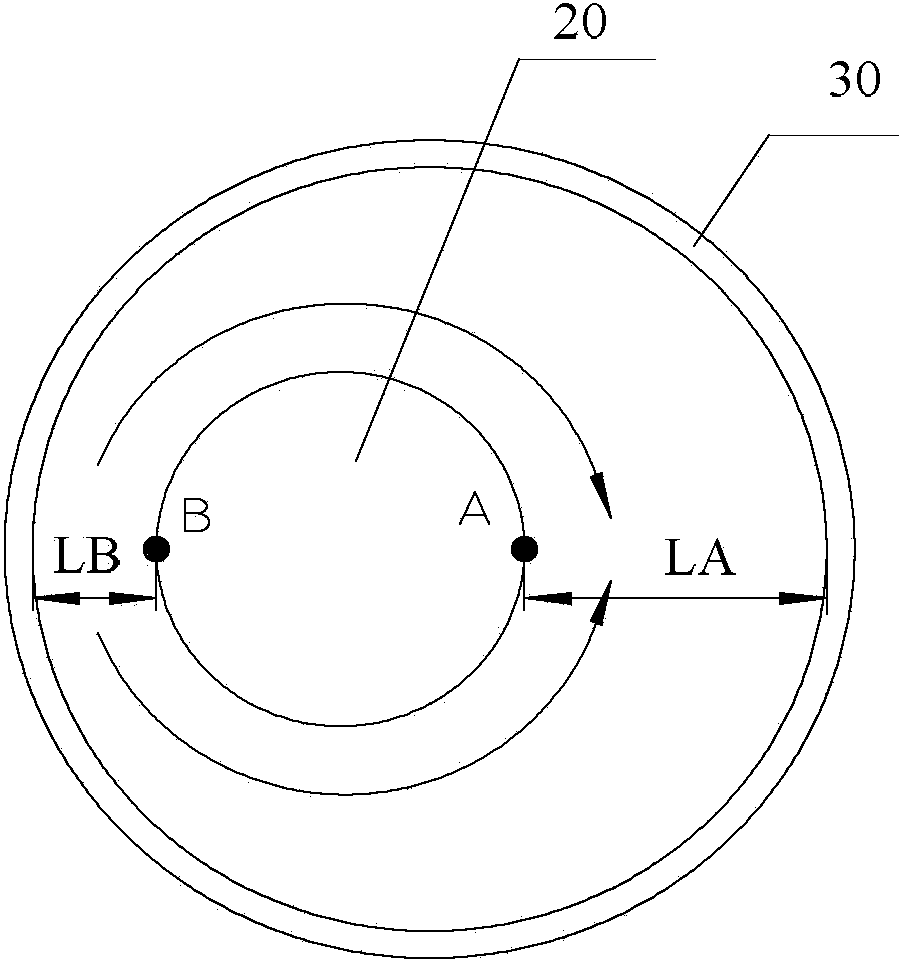

ActiveCN103909316AImprove brazing qualitySolve the phenomenon of uneven heatingHeating appliancesMetal working apparatusEngineeringElectrical and Electronics engineering

The invention provides induction brazing equipment which comprises a rotating mechanism, a positioning tool and an induction heating coil. The positioning tool is disposed on the rotating mechanism and concentrically rotates along with the rotating mechanism. The induction heating coil sleeves the outer side of the axis of the positioning tool. A mounting space is formed between the induction heating coil and the positioning tool. The induction brazing equipment has the advantages that a to-be-welded part is heated evenly through the induction heating coil, the problems of traditional flame brazing are solved, uneven heating caused by position deviation of tradition induction brazing is avoided, and brazing quality of workpieces is increased.

Owner:GREE ELECTRIC APPLIANCES INC

Rareearth-silver solder and producing method thereof

InactiveCN1435294AEliminate the phenomenon of \"precipitation\"Eliminate the \"cofferdam effect\"Welding/cutting media/materialsSoldering mediaRare earthAcid washing

An RE-silver solder based on a silver solder series including Ag-Cu-Zn, Ag-Cu-Zn-Sn, Ag-Cu-Zn-Cd, and Ag-Cu-P is prepared through adding RE mixture whose main components are Ce and La, mixing, smelting, casting, sawing, acid washing, squeezing and drawing. Its advantages are high purity and plasticity, and good spreading nature on metal surface.

Owner:金华市金钟焊接材料有限公司

Aerial vehicle structure

An air vehicle structure comprises a framework structure and a skin connected with the framework structure, wherein at least one of the framework structure and the skin is made of plate metal; the plate metal comprises a first panel, a second panel as well as a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubesand the first panel as well as between the hollow tubes and the second panel; a turning edge is arranged at at least one end of the hollow tubes. The aerial vehicle structure has the advantages of being small in self-weight, high in strength, stable in structure, high in impact resistance, capable of insulating sound and reducing noise, resistant to high temperature, corrosion and vibration, longin service life, capable of being carried and spliced and the like.

Owner:张跃

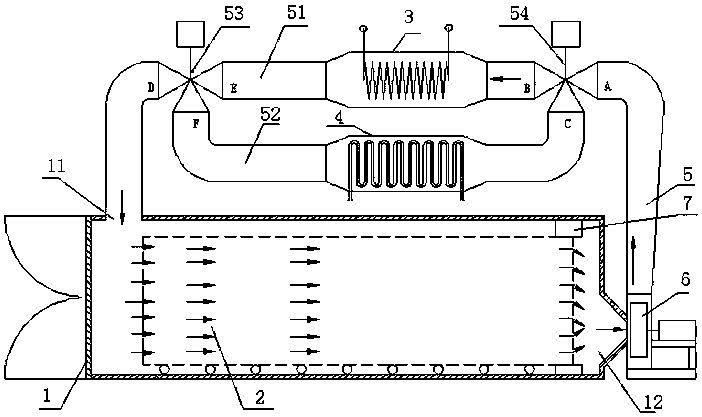

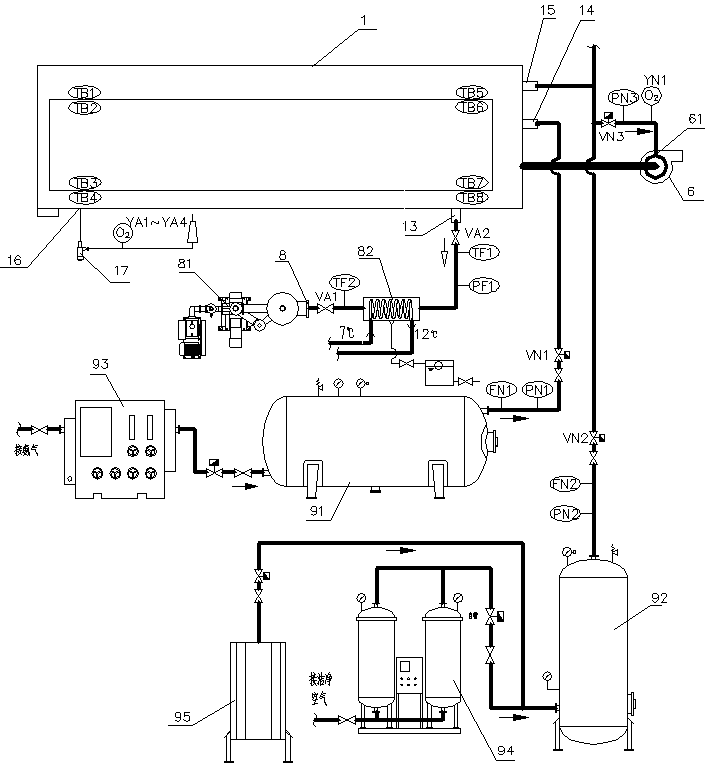

Brazing system carrying out heating/cooling by using gas as medium

InactiveCN108213630AReduce processing timeImprove efficiencySoldering apparatusMetal working apparatusVacuum pumpingShielding gas

A brazing system carrying out heating / cooling by using gas as a medium comprises a furnace body, a vacuum pumping system and a gas supply system, wherein a workpiece is arranged in a furnace chamber of the furnace body, a gas inlet and a gas outlet are arranged on the furnace body, and the outer part of the furnace body is provided with a circulating pipeline which is connected between the gas inlet and the gas outlet of the furnace body; a heating part and / or a cooling part are / is arranged on the circulating pipeline, and the heating part and / or the cooling part guides hot gas or cold gas into an inner cavity of the workpiece via the circulating pipeline through a power device so as to carry out circulating heating or cooling on the workpiece; a vacuum opening and a protective gas input opening are further arranged on the furnace body; the vacuum pumping system is connected with the vacuum opening and used for enabling the workpiece to be in an oxygen-free environment; and the gas supply system comprises a protective gas storage tank, and is connected with the protective gas input opening and used for conveying protective gas for the furnace body. The brazing system has the advantages of high efficiency, light weight, high safety, uniform workpiece heating or cooling, wide application range and the like.

Owner:张跃

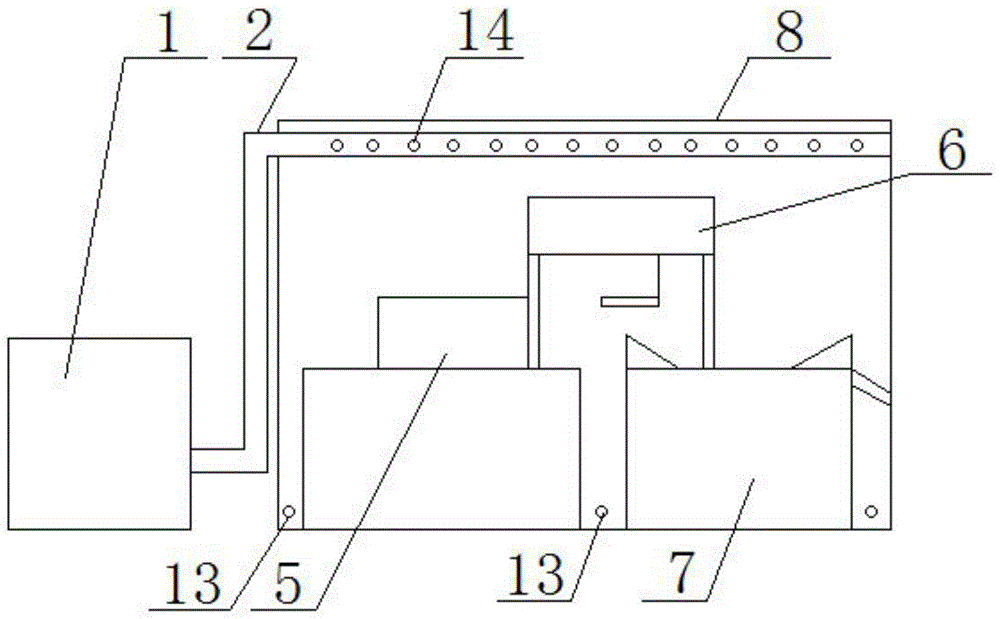

Non-oxidation brazing and thermal treatment device of hard alloy cutting teeth

ActiveCN104400172AAchieving brazing qualityExtend your lifeFurnace typesMetal working apparatusQuenchingManipulator

The invention provides a non-oxidation brazing and thermal treatment device of hard alloy cutting teeth, belongs to the technical field of cutting tools, and mainly solves the problems of the prior art of poor welding quality and thermal treatment effect. The non-oxidation brazing and thermal treatment device comprises a cryogenic box, a nitrogen transporting pipeline, a heating furnace, a quenching tank and a manipulator. The non-oxidation brazing and thermal treatment device is characterized in that the nitrogen transporting pipeline is arranged between the cryogenic box and a working bin, one part of the nitrogen transporting pipeline in the working bin is close to the top wall of the working bin, and oxidation discharge holes formed on the nitrogen transporting pipeline. The heating furnace, the quenching tank and the manipulator are located in the working bin of a sealed structure. A heating operation hole, a heating observation hole, a quenching operation hole and a quenching observation hole are formed at the top of the working bin. A waste gas discharge hole is formed on the lower portion of the working bin or on the side wall close to the bottom. A material inlet is formed on the side wall of one side of the working bin close to the heating furnace, a material outlet is arranged on the side wall of one side of the working bin close to the quenching tank, and a movable sealed device is arranged in the material outlet. The non-oxidation brazing and thermal treatment device reduces energy consumption and saves materials.

Owner:SHANXI LI PU LI TUO COAL PARTS MFG CO LTD

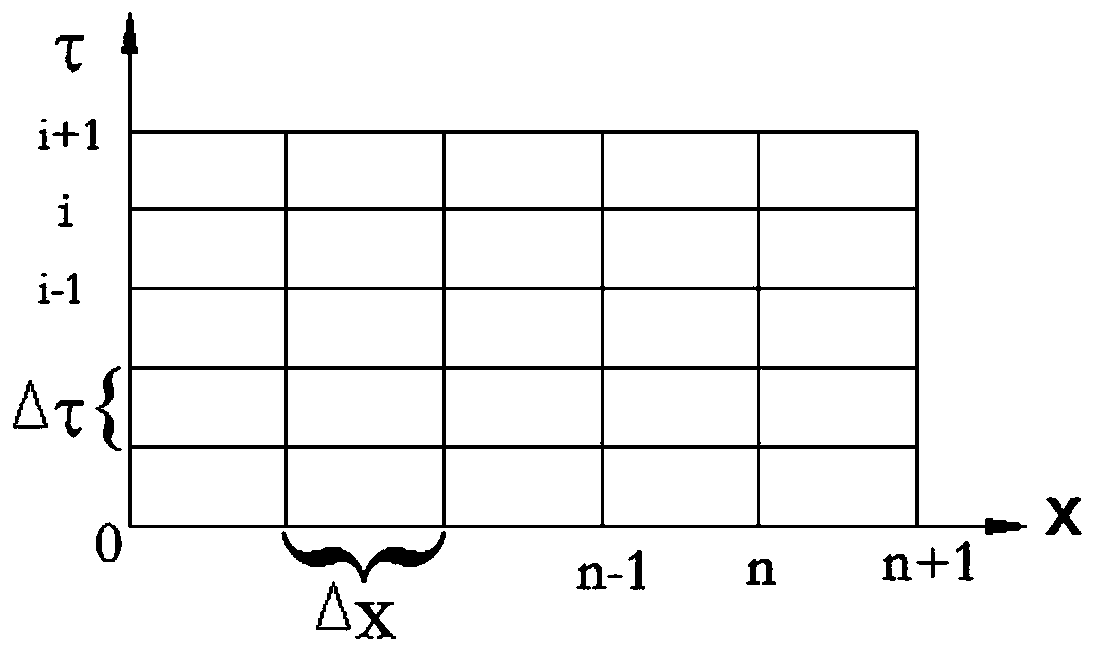

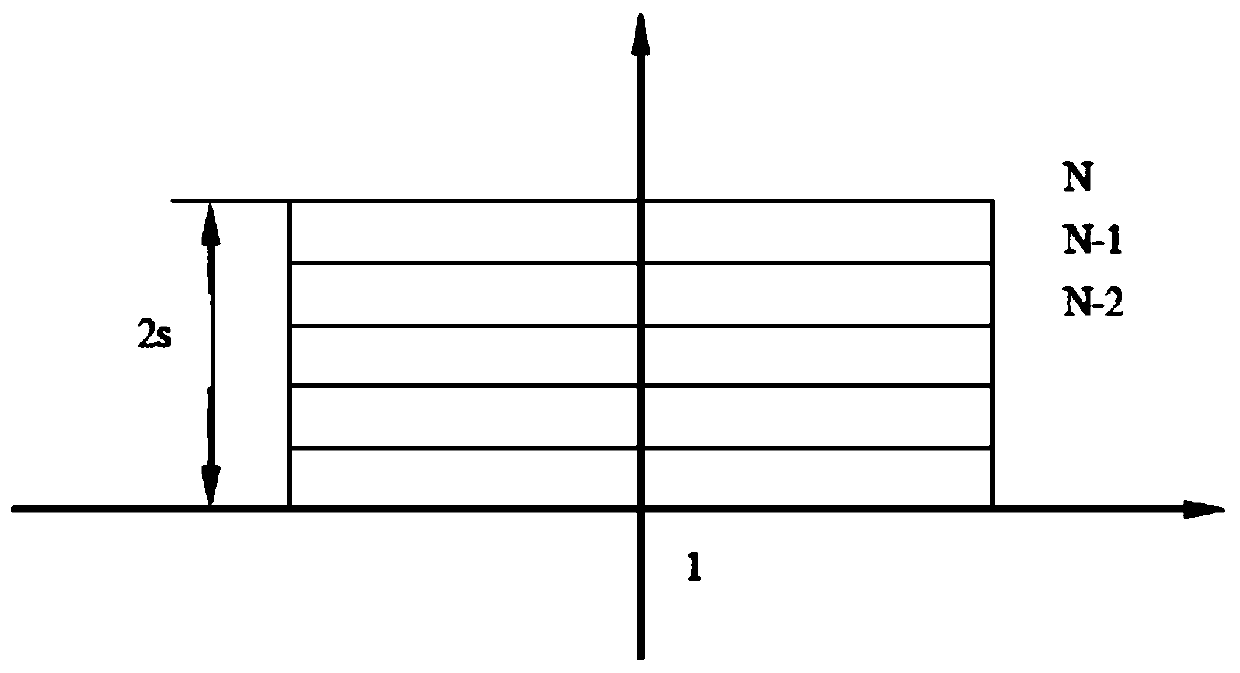

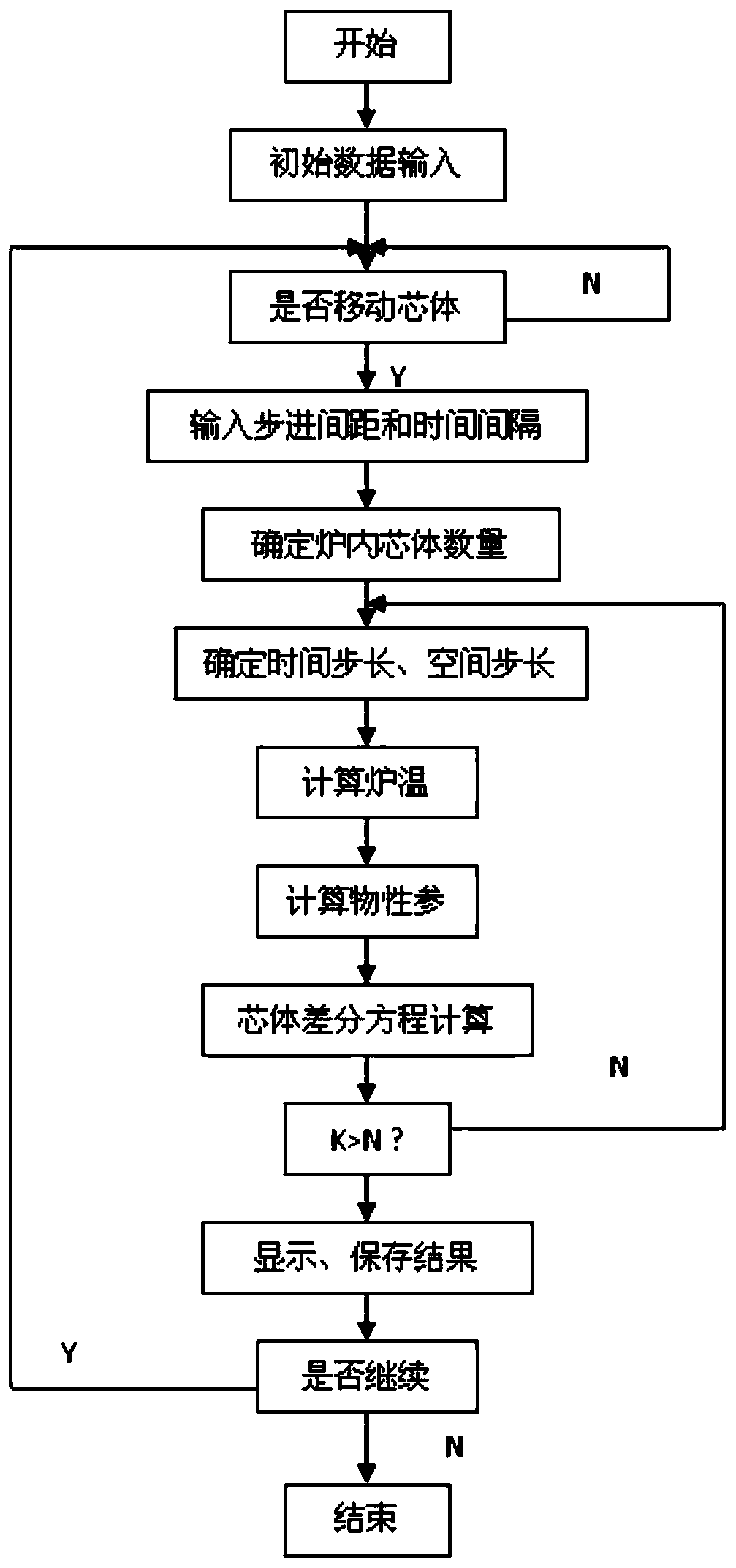

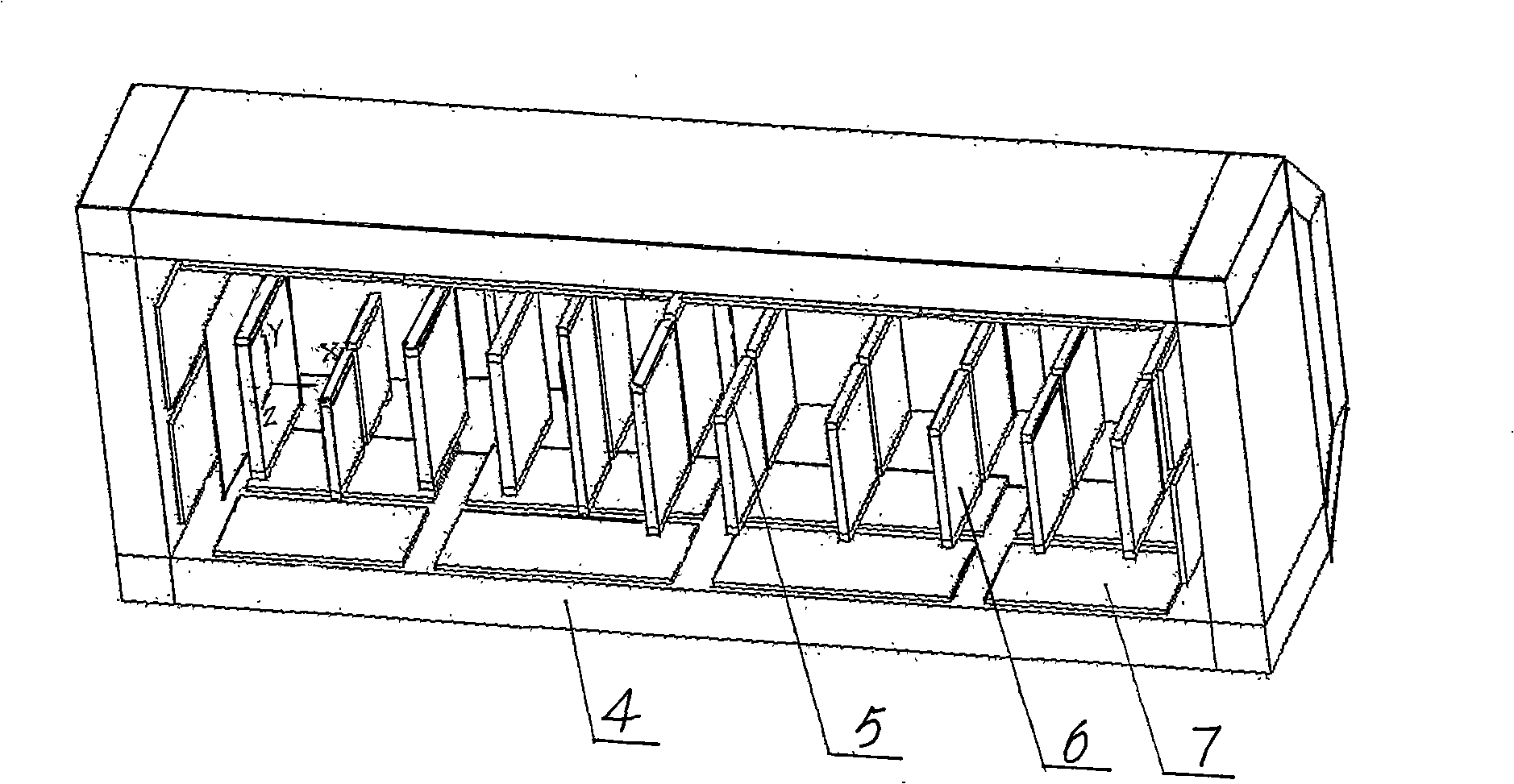

NB continuous brazing core body heating method for automobile radiator brazing process

InactiveCN109926675AImprove brazing qualityOptimum brazing heating regimeHeating appliancesSpecial data processing applicationsElement modelMathematical model

The invention provides a NB continuous brazing core body heating method for an automobile radiator brazing process. The heating method comprises the following steps of establishing a core heating model, calculating boundary heat flow of the core surface by the model; solving a total heat absorption rate by adopting a test method, obtaining the total heat absorption rate of each position inside a hearth according to a position corresponding to a central position of a core body in the furnace, and realizing a mathematical model control for a heating furnace. According to the method, states of products in the furnace is controlled in real time through the model, the brazing quality is improved, according to the heat transfer principle, a three-dimensional transient thermal analysis model is constructed, a simulation and test combination method is adopted, the product states in the furnace is monitored, a core heating model is established, a simulated thermal cycle curve is basically matched with a measured thermal cycle curve, so that the correctness of the finite element model is proved, parameters of the brazing process are preliminarily determined through the simulation method, initial parameters of the model are changed by utilizing the model, and an optimal brazing heating system is found out.

Owner:安徽双桦智能技术有限公司

Adhesive system for brazing flux, coating composition for brazing filler metal and flux coated brazing rod

ActiveCN106271226AImprove bindingGood moisture-proof and anti-shedding effectWelding/cutting media/materialsSoldering mediaPolysulfide rubberSulfur

The invention relates to an adhesive system for brazing flux, a coating composition for brazing filler metal and a flux coated brazing rod, and belongs to the field of flux coated brazing rods. The adhesive system for the brazing flux comprises a main agent and a curing agent; the main agent is composed of, by weight, 18-23 parts of epoxy resin, 15-20 parts of polysulfide rubber, 7-14 parts of dibutyl phthalate and 3-8 parts of diluent; the curing agent is composed of, by weight, 70%-80% of diethylenetriamine and 20%-30% of phthalic anhydride. The adhesive system for the brazing flux is composed of epoxy resin and polysulfide rubber and can be used on the brazing filler metal surface for preparing dampproof and anti-drop coating after adding and mixing brazing flux evenly. The coating can be adhered to the inner core of brazing filler metal well and good in dampproof and anti-drop effect; the flux coated brazing rod cured and prepared by the coating composition is low in organic content, capable of decomposing under the brazing temperature, less in residues and small in influence on brazing.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

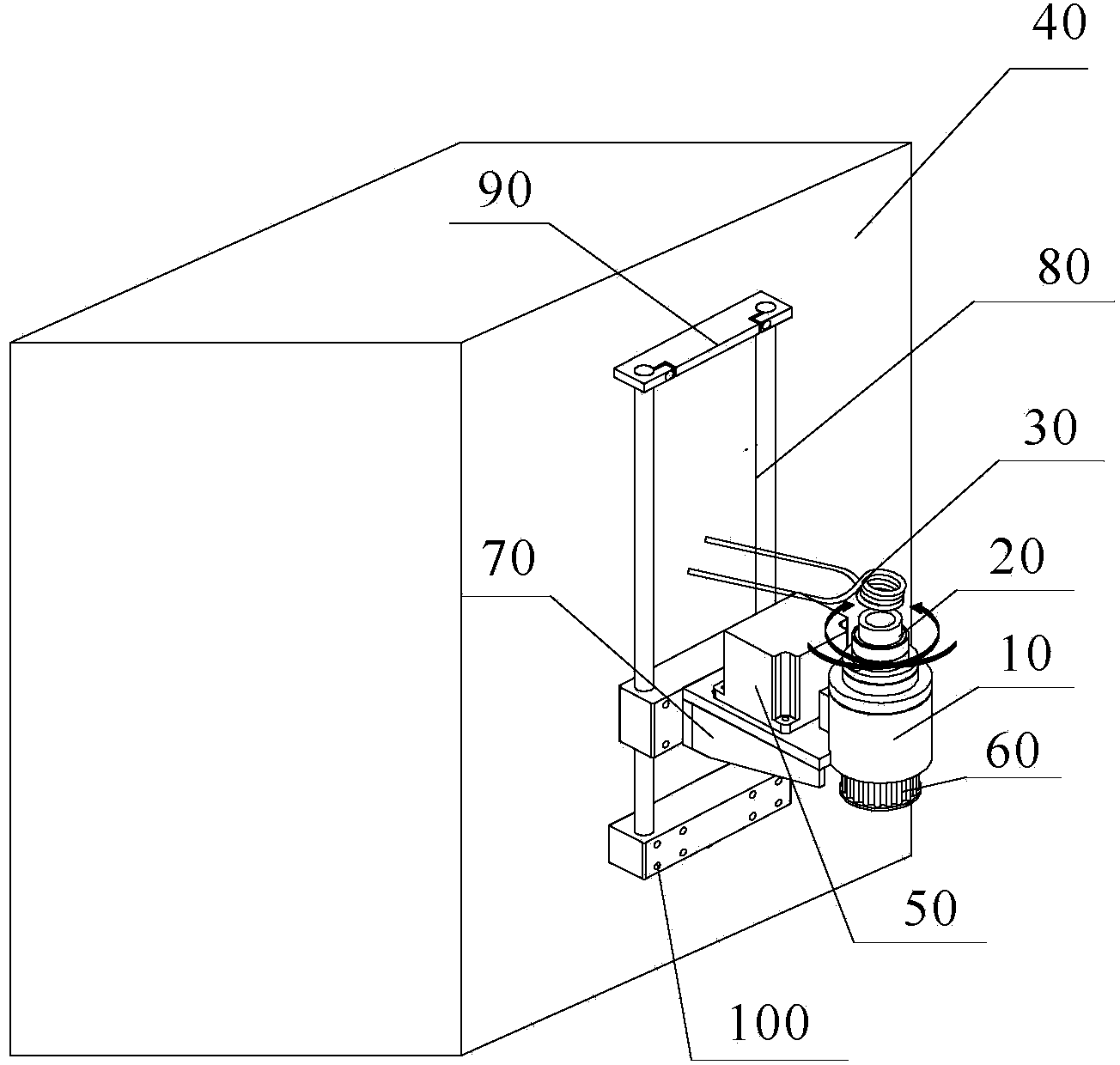

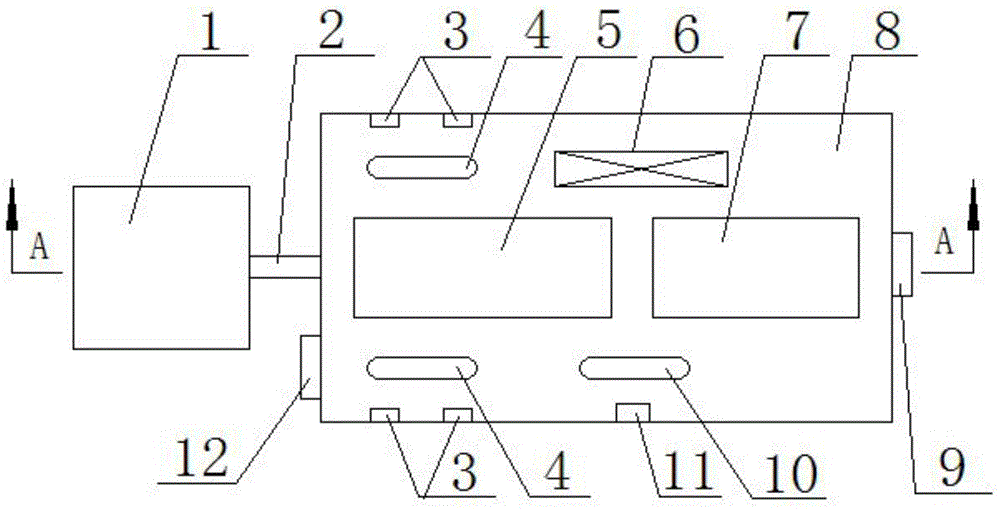

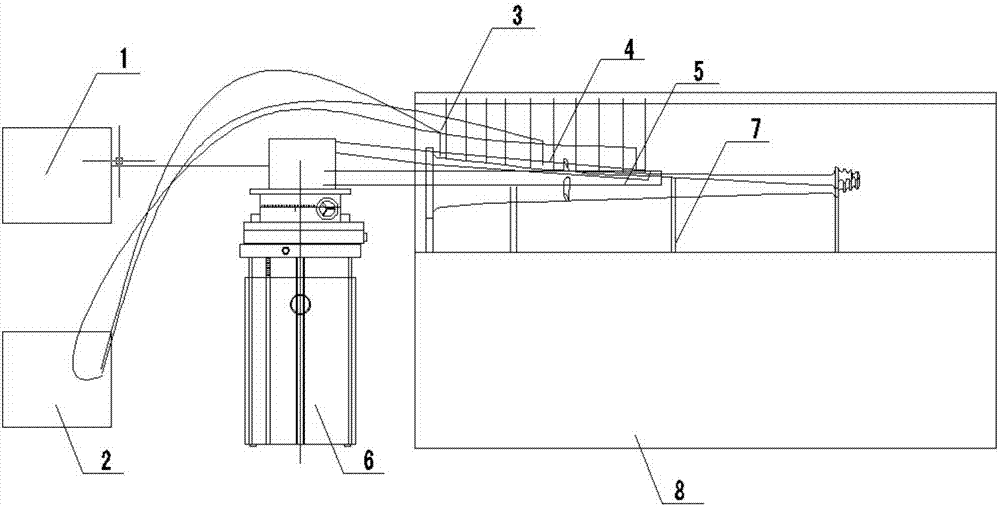

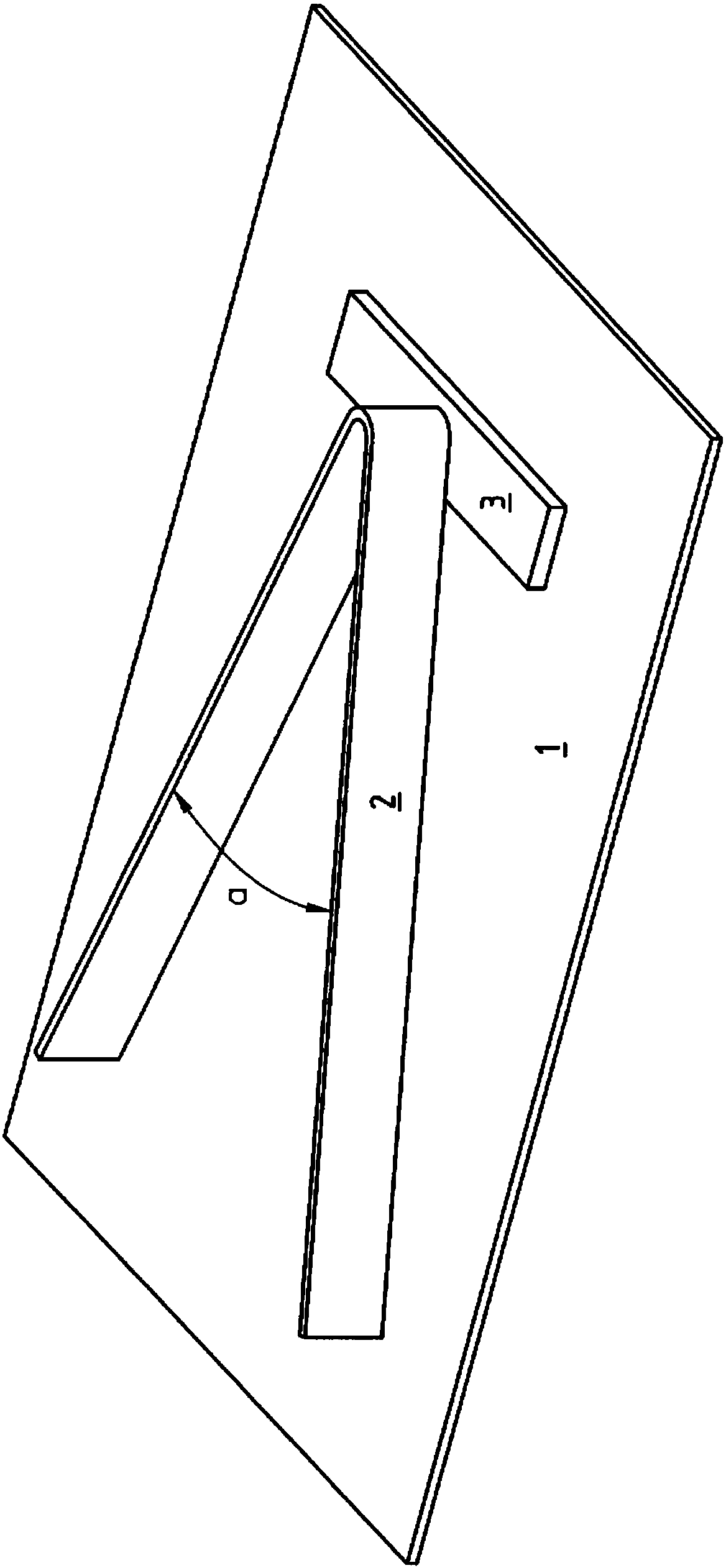

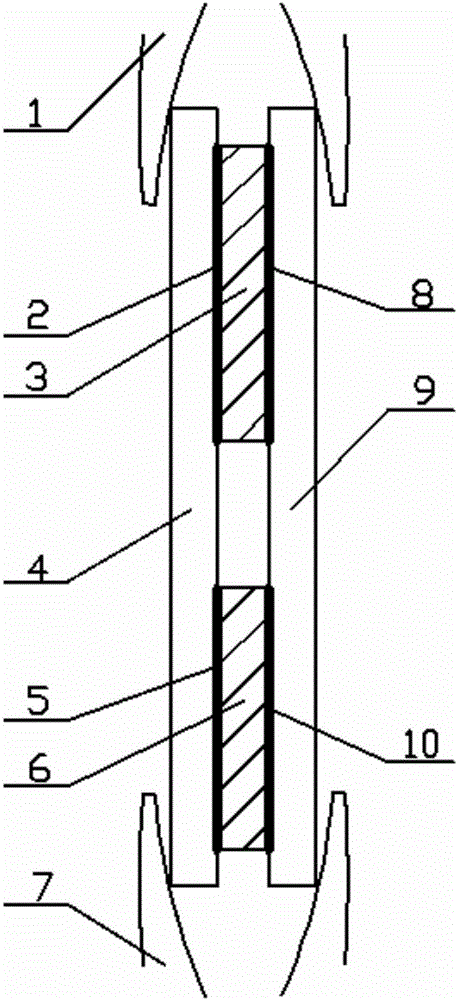

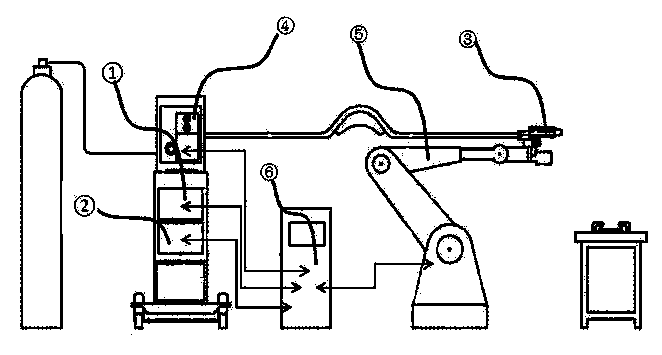

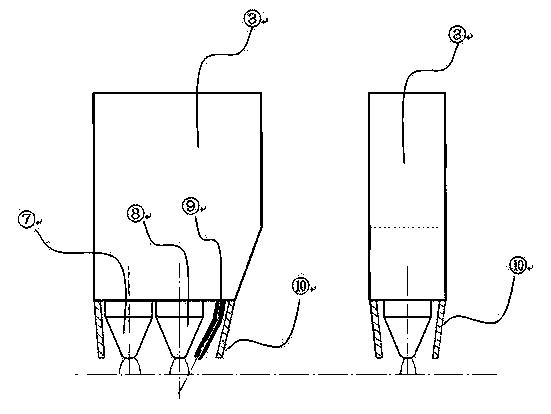

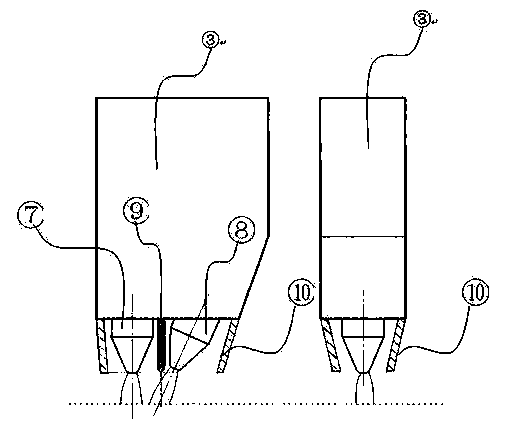

System and method applied to automatic brazing of stellite alloy long blades

ActiveCN106984880AImprove qualified rate and brazing qualityEasy to useMetal working apparatusSoldering auxillary devicesStellite alloyInductor

The invention discloses a system and a method applied to automatic brazing of stellite alloy long blades, relates to a system and a method applied to automatic brazing of stellite alloy long blades and aims to solve the defects that manual high-frequency brazing manner is used for operating in the prior art, the brazing operation is limited by the skills of the welders, the brazing qualification rate is low and each blade is low in consistency of brazing quality. The system applied to automatic brazing of the stellite alloy long blades comprises an IGBT high-frequency induction heating power supply device (1), a PLC control system (2), an infrared thermometer (3), an inductor with blade profile, a rigid inductor bracket (5), a four-axis transformer lifting and rotating platform (6), a blade anti-deformation supporting tool (7) and brazing operation platform tool (8). The system and the method are applied to the field of automatic brazing of the stellite alloy long blades.

Owner:HARBIN TURBINE +1

Method for avoiding flexure deformation of radial diffuser center plate of aeroengine

InactiveCN102172791ASolve the problem of excessive deflectionAvoid warpingFurnace typesWelding/cutting media/materialsX-rayCopper

The invention relates to a method for avoiding the flexure deformation of a radial diffuser center plate of an aeroengine, which comprises the steps: firstly, No.20 steel plates which are originally used in the diffuser center plate are replaced by 1Cr13 plates; meanwhile, brazing quality is improved, and brazing is carried out by high-temperature copper brazing with a brazing temperature of 1050 DEG C; after the brazing is finished, an X-ray is used to test brazing joints so as to ensure that brazing filler metal evenly and fully flows into the brazing joints; after the copper brazing is finished, radial diffuser parts are protected on a tray, and are heated to 930 to 950 DEG C so as to be subjected to oil quenching; and after the oil quenching process is finished, the radial diffuser parts are processed by high temperature tempering, and the tempering temperature is 650 to 670 DEG C.

Owner:BEIHANG UNIV

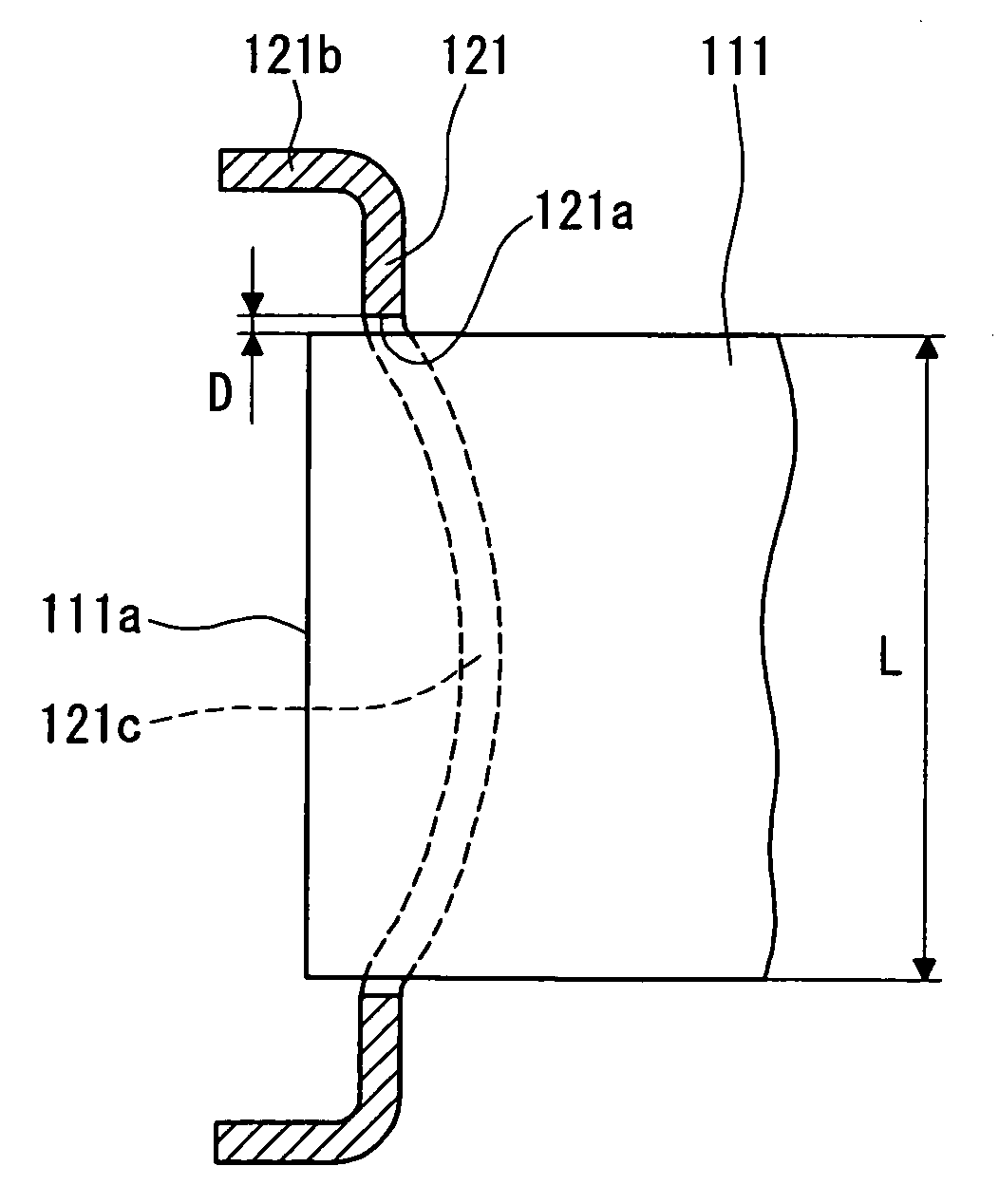

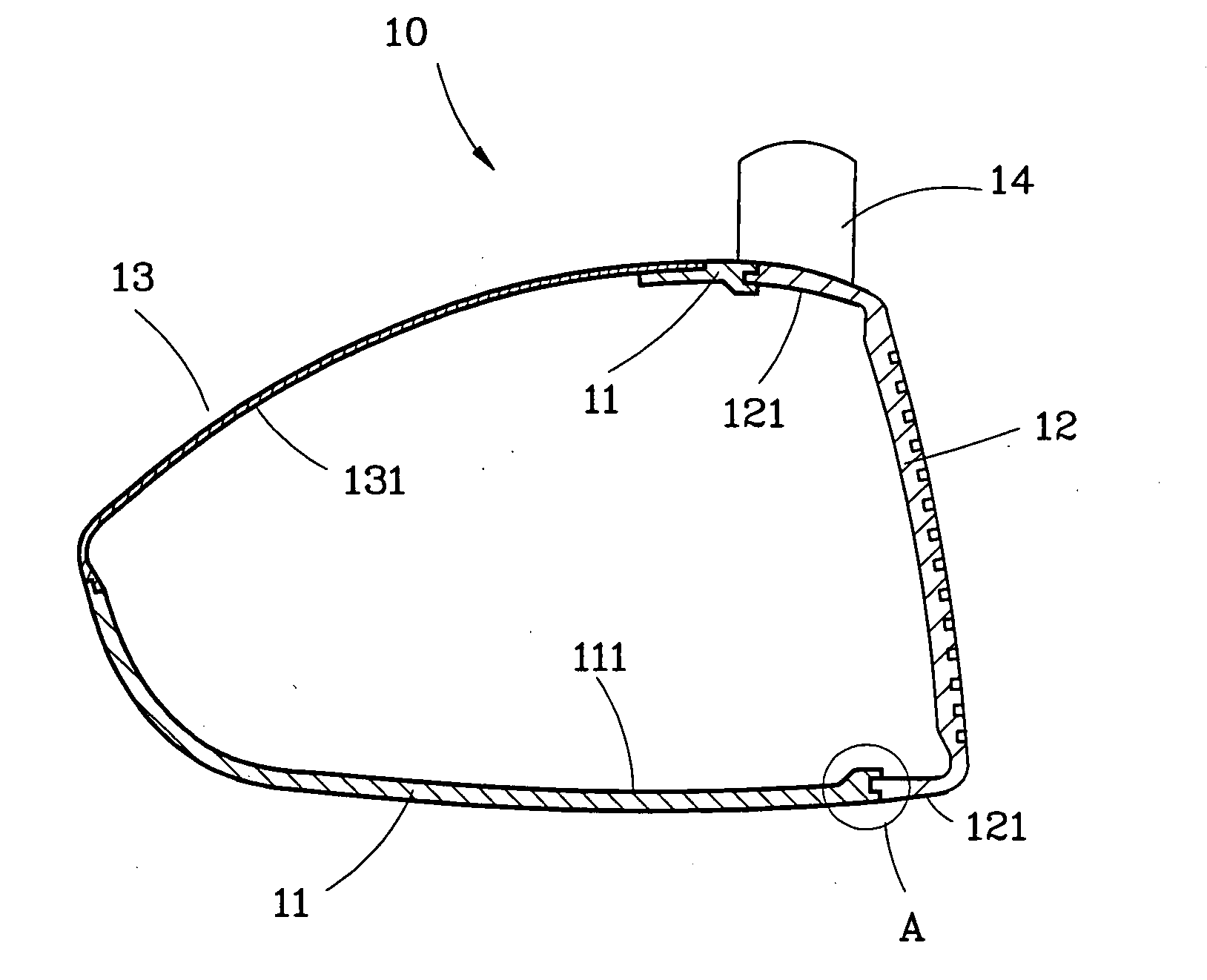

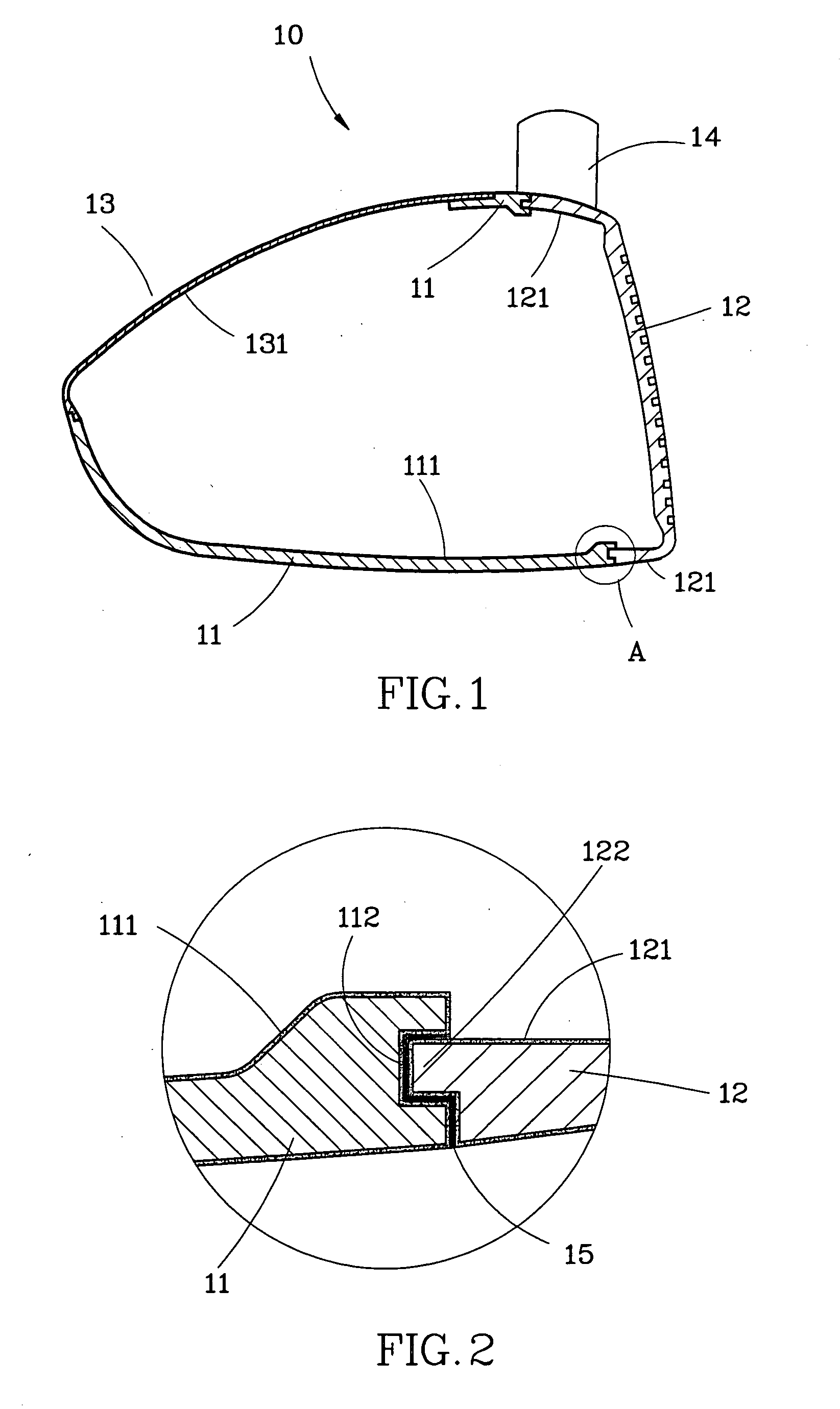

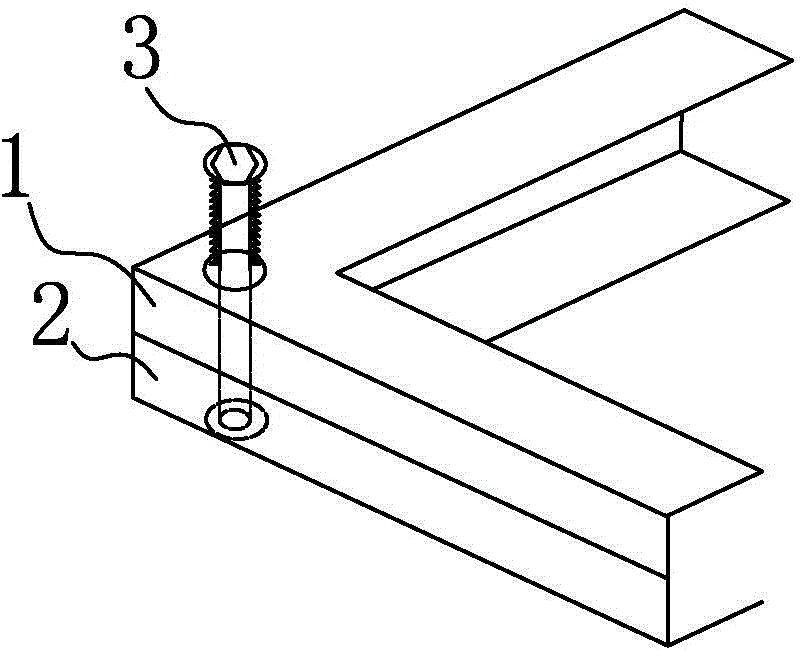

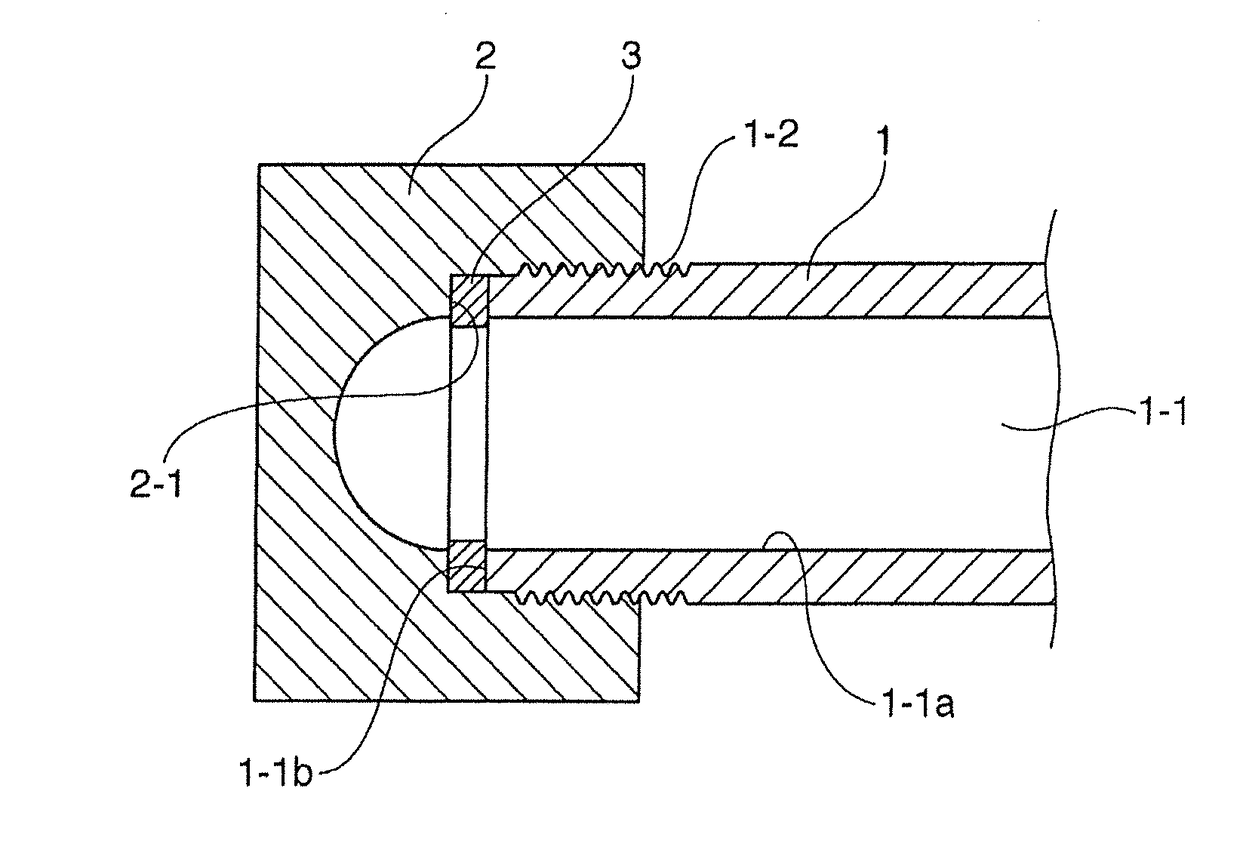

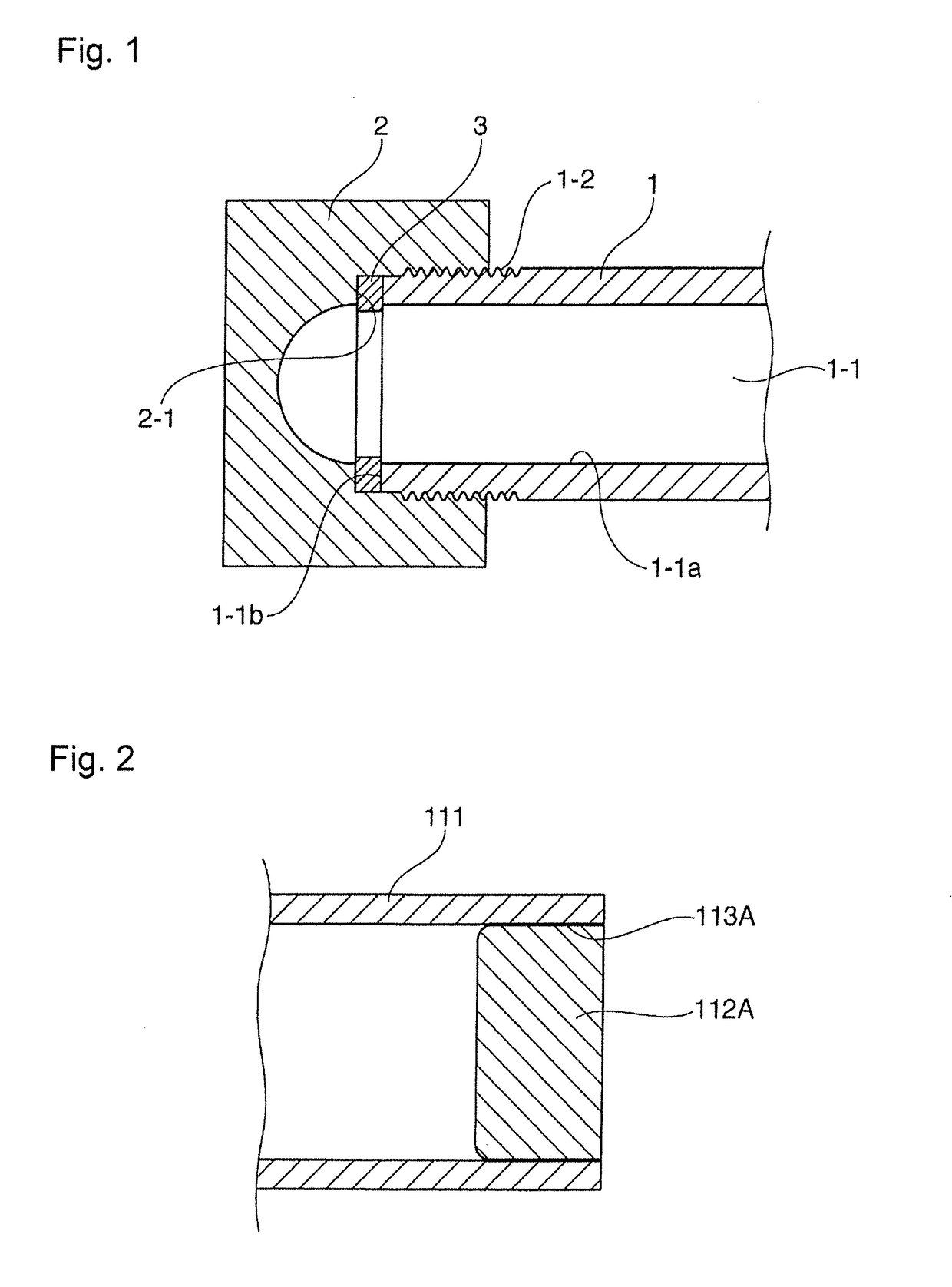

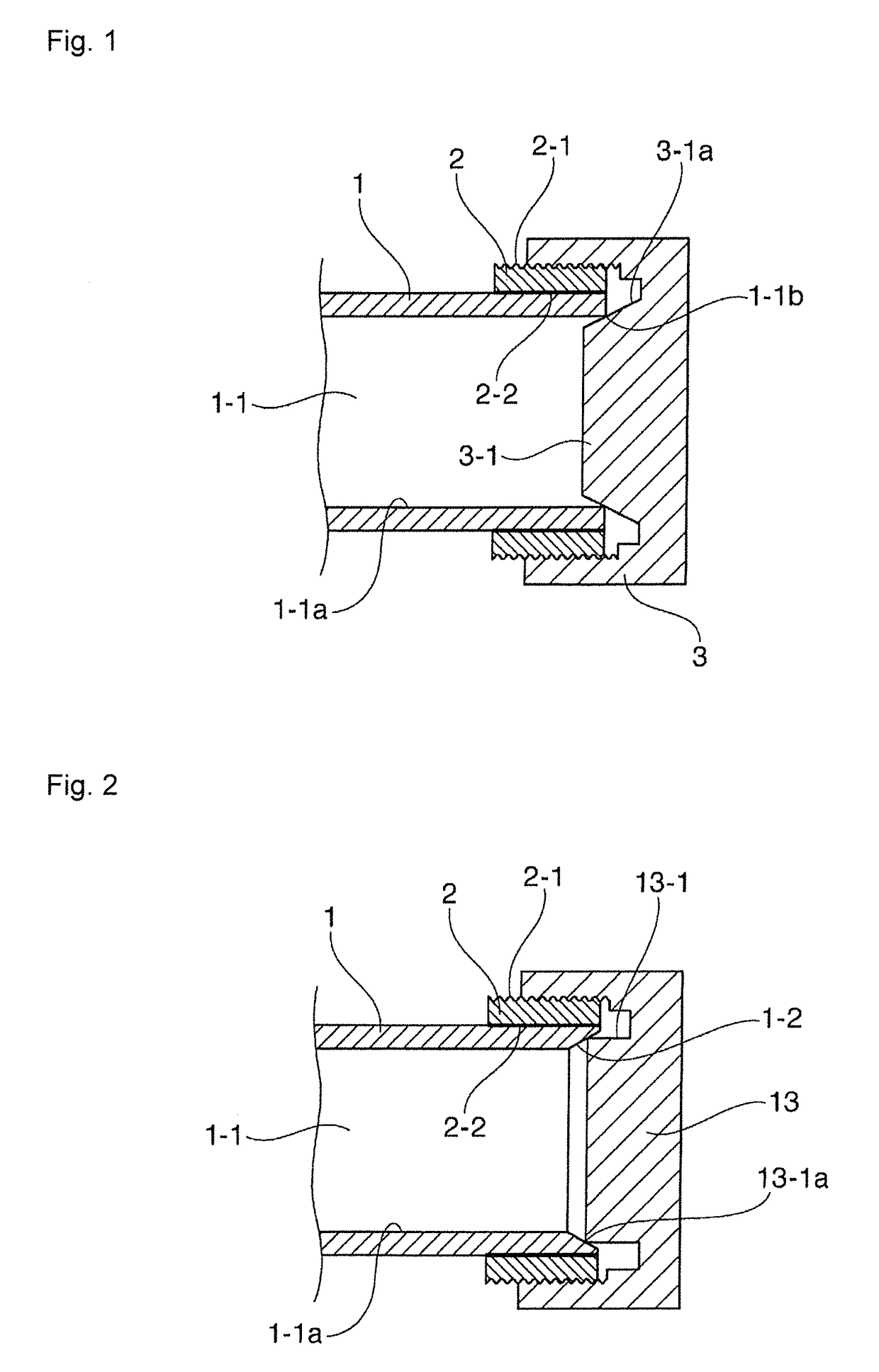

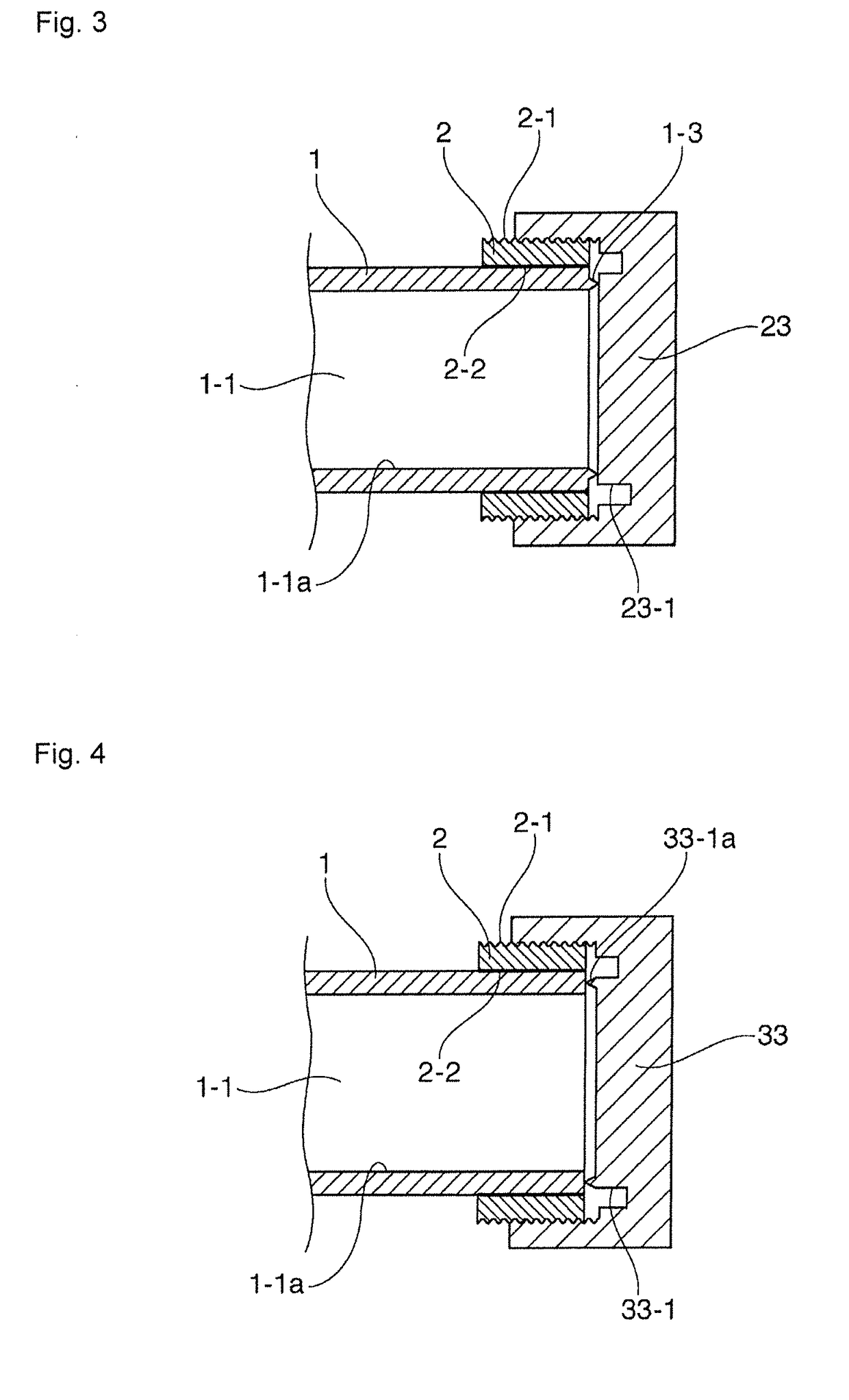

End seal structure of fuel rail for gasoline direct-injection engine

ActiveUS20170159626A1Ensure reliabilityEnsure stabilityFuel injection apparatusMachines/enginesGasoline direct injectionEngineering

Provided is an end seal structure of a fuel rail for a gasoline direct injection engine, in which an end or both ends of a rail body composed of a pipe is / are closed by a thread fastening type of an end cap or end caps having a cap-nut shape, is characterized in that a metallic gasket is provided between an inner wall surface of the end cap having the cap-nut shape and an end section of the rail body, the end cap having the cap-nut shape is screwed and fixed to the rail body, and the gasket is tightened by an axial force created by tightening of the end cap having the cap-nut shape so that the end of the rail body is sealed.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Tunnel structure

The invention discloses a tunnel structure. The tunnel structure comprises a tunnel body, and the tunnel body is formed by spicing a plurality of metal plates. The metal plates comprise first panels,second panels and a plurality of hollow pipes, wherein the hollow pipes are arranged between the first panels and the second panels. Brazing layers are arranged between the hollow pipes and the firstpanels as well as the second panels, and flangings are arranged at least one ends of the hollow pipes. The tunnel structure has the advantages of light self-weight, high strength, stable structure, sound insulation and noise reduction, high temperature resistance, vibration resistance, long service life, capability to be carried and assembled, short building period and the like.

Owner:张跃

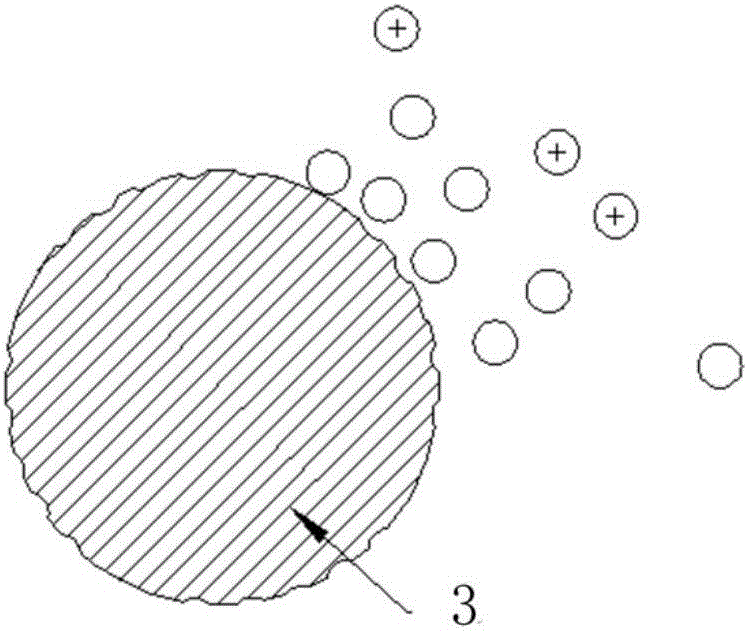

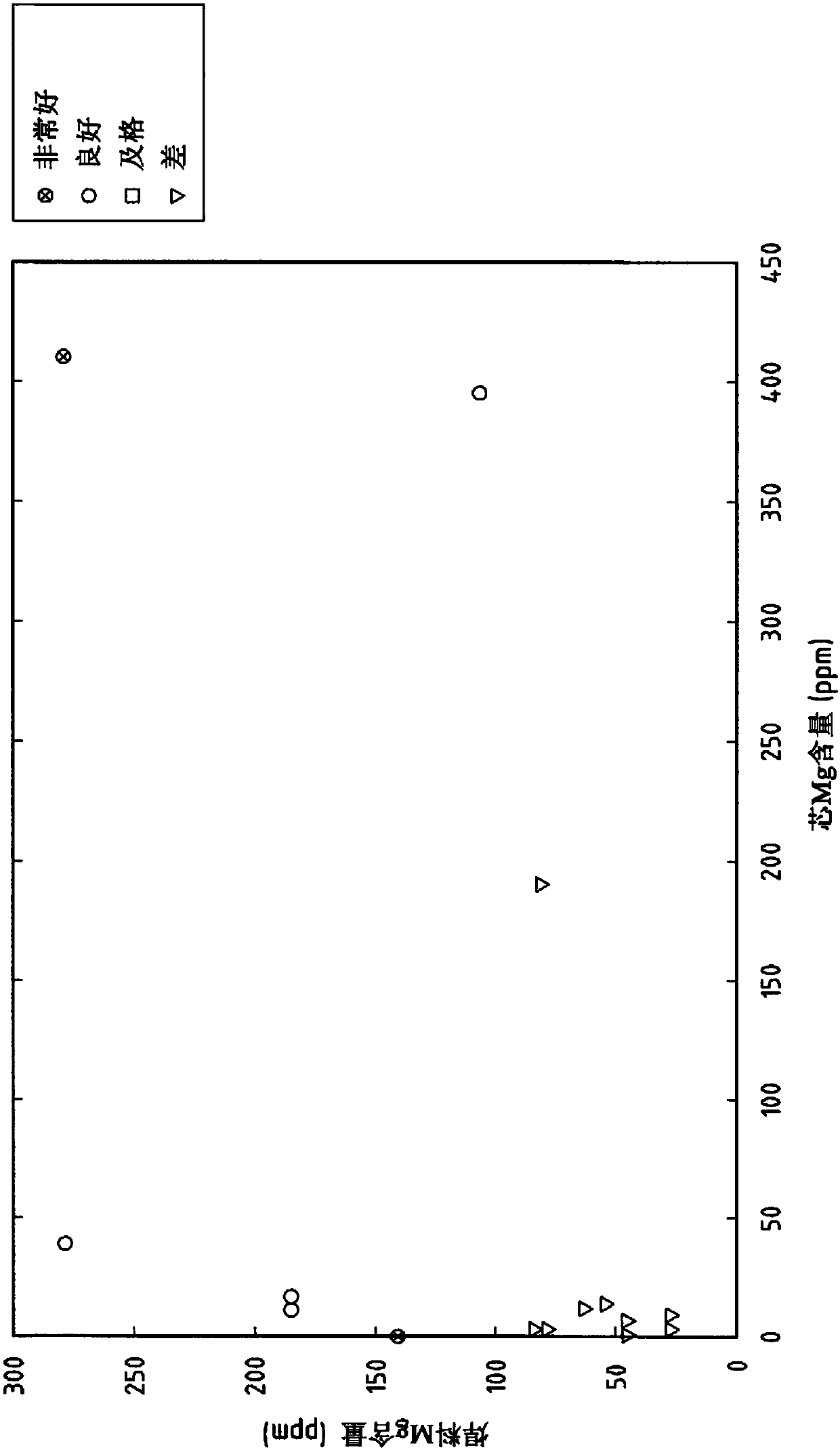

Aluminum composite material for use in thermal flux-free joining methods and method for producing same

ActiveCN108136545AImprove brazing qualityPrevent surface discolorationWelding/cutting media/materialsWelding/soldering/cutting articlesCarbon Dioxide / HeliumShielding gas

The invention relates to an aluminum composite material for use in thermal flux-free joining methods, comprising at least one core layer, which consists of an aluminum core alloy, and at least one outer solder layer, which is provided on one side or both sides of the core layer and which consists of an aluminum solder alloy. The aim of proposing an aluminum composite material for use in a thermalflux-free joining method by means of which the soldering properties can be further optimized both in a vacuum and under shielding gas without the use of fluxes while avoiding the disadvantages known from the prior art is achieved in that the aluminum solder alloy has the following composition in wt%: 6.5%<=Si<=13%, Fe<=1%, 90 ppm<=Mg<=300 ppm, Bi<500 ppm, Mn<=0.15%, Cu<=0.3%, Zn<=3%, Ti<=0.3%, theremainder Al and unavoidable impurities of at most 0.05% individually and at most 0.15% in total, and the aluminum solder layer has a surface that has been pickled in an alkaline or acidic manner. The invention further relates to a method for producing an aluminum composite material, in particular an aluminum composite material according to the invention, wherein at least one core layer consisting of an aluminum core alloy is provided and at least one outer solder layer consisting of an aluminum solder alloy is applied to one side or both sides of the core layer. The invention further relatesto a method for thermally joining components and to a thermally joined construction.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

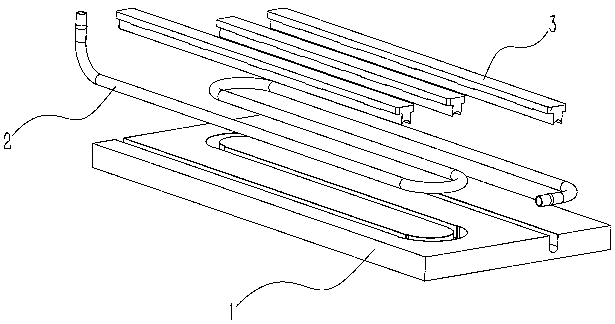

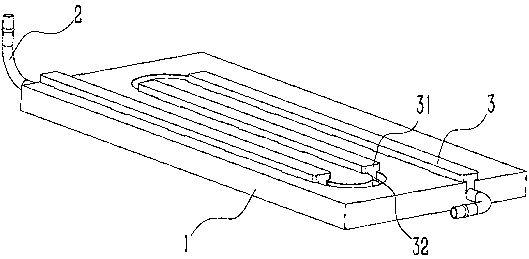

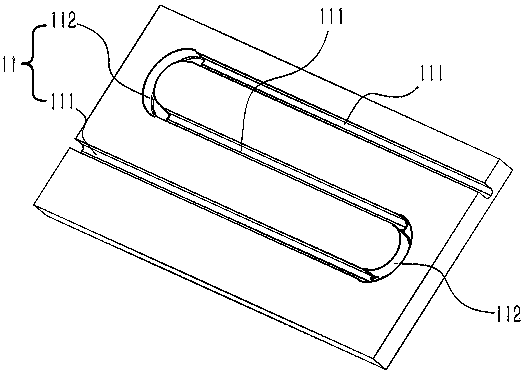

Manufacturing method of water-cooled plate

The invention discloses a manufacturing method of a water-cooled plate. The manufacturing method comprises the following steps: step one, processing a groove in a substrate, wherein the groove comprises a plurality of linear sections and a plurality of semi-circular sections by which the linear sections communicate with one another, processing a water-cooled tube, bending the middle of the water-cooled tube according to the shape of the groove, and processing a plurality of pressing blocks for covering the linear sections, wherein each pressing block comprises an auxiliary section arranged onthe upper portion and a groove-shaped section arranged on the lower portion, each auxiliary section comprises a supporting portion and a ventilating portion, and the ventilating portions and the supporting portions are alternately arranged; step two, embedding the water-cooled tube into the groove; step three, placing the pressing blocks in the corresponding linear sections, attaching the groove-shaped sections to the surface of the water-cooled tube, and erecting the supporting portions to the two sides of the linear sections; and step four, fixedly connecting the substrate, the water-cooledtube and the pressing blocks by braze welding. The manufacturing method of the water-cooled plate has the beneficial effects that the yield of products is improved, and the production cost is reduced.

Owner:AAVID SHANGHAI SYST

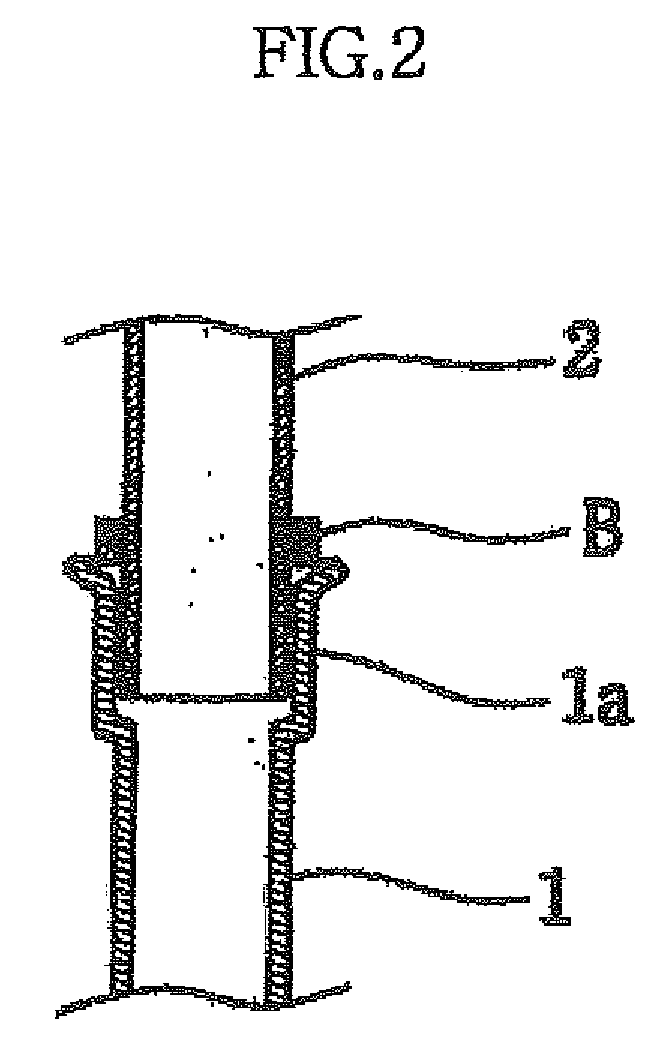

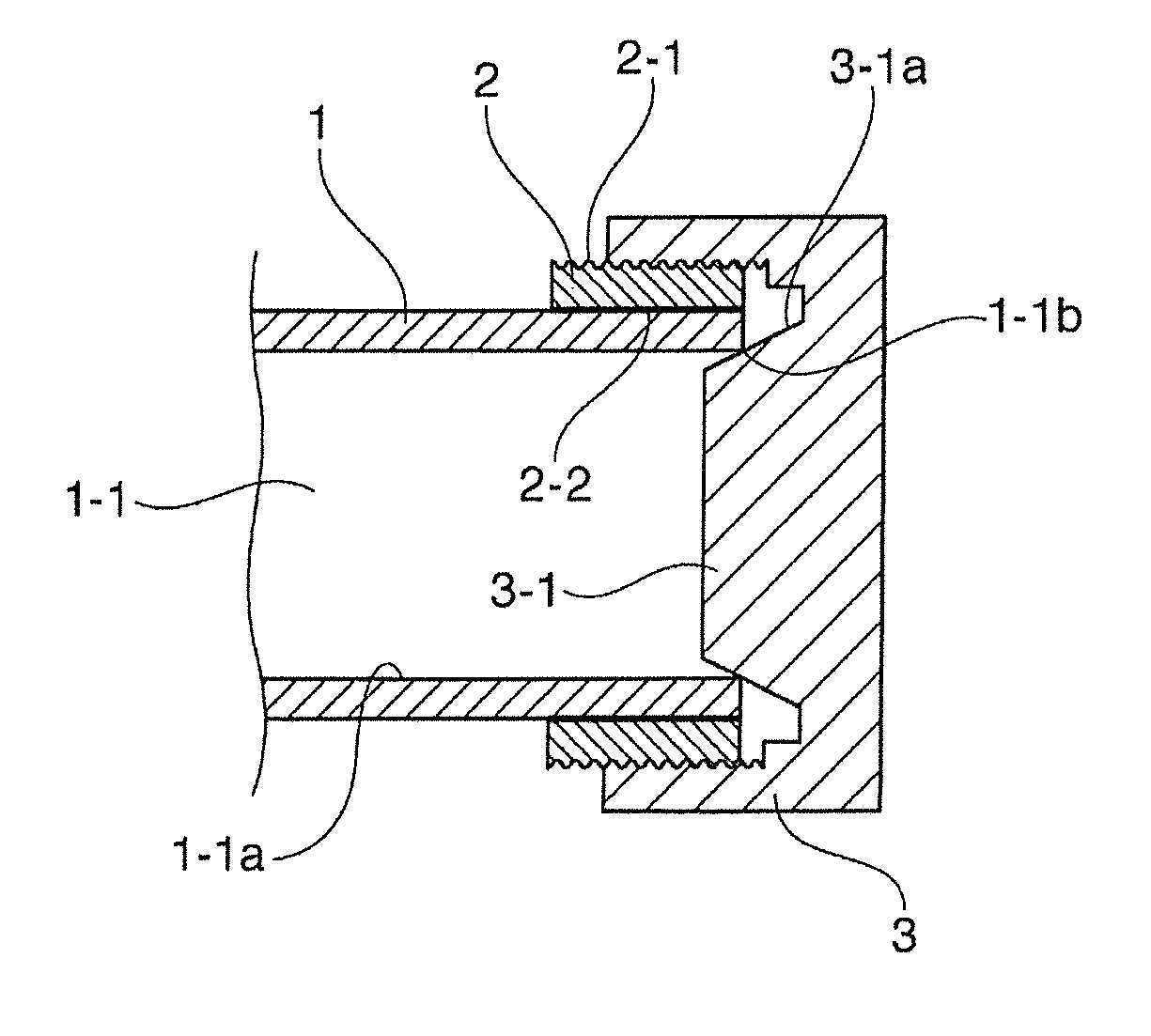

End seal structure of a fuel rail for a gasoline direct injection engine

ActiveUS20170122277A1Improve sealingImprove brazing qualityCombustion enginesLow pressure fuel injectionGasoline direct injectionEngineering

Provided is an end seal structure of a fuel rail for a gasoline direct injection engine, the end seal structure being characterized in that: a collar is joined by brazing to an outer circumference of an end of a pipe of the rail body including a pipe; the end cap having a cap-nut shape and including a sealing projection on an surface thereof facing the opening at the end of the pipe of the rail body, is screwed and fixed to the collar; and the sealing projection of the end cap brings into pressure contact with the end of the opening of the rail body by an axial force created by tightening of the end cap having the cap-nut shape to seal the end of the opening of the rail body.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

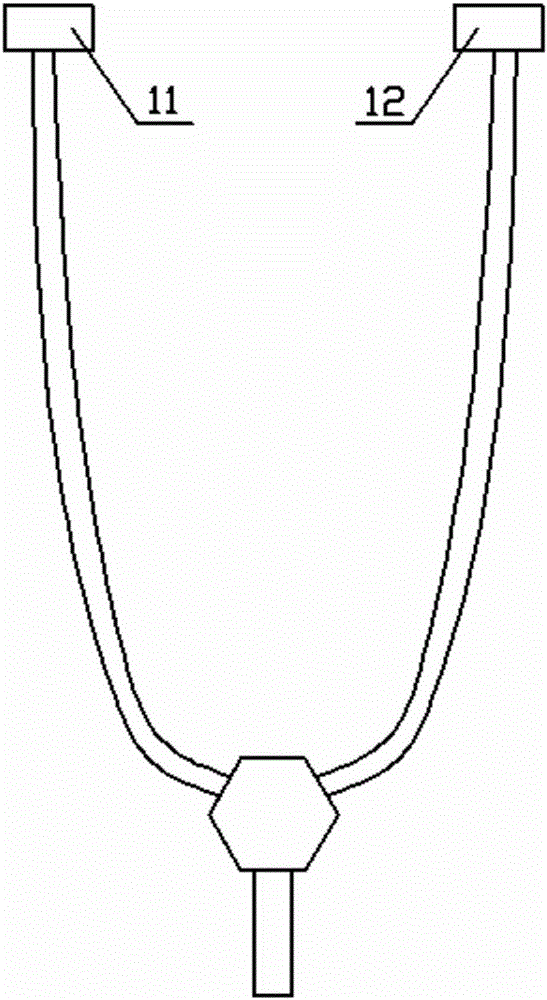

Flame brazing process method for stator coil bars and connector plates of power generator

InactiveCN105215496APer capita labor productivity increasedReduce labor costsSoldering apparatusOrganic solventStator coil

The invention discloses a flame brazing process method for stator coil bars and connector plates of a power generator. The flame brazing process method comprises the following steps: removing oxides and pollutants in a brazing area and the surfaces of brazing materials through mechanical cleaning and organic solvent cleaning; wrapping insulation parts of the coil bars with water-soaked fireproof cloths; placing brazing pieces between the end parts of the coil bars and the connector plates, and clamping and fixing the brazing pieces by clamping tools; heating a brazed joint by a double-end welding torch, aligning two air nozzles of the welding torch with the connector plates at the two sides of the joint respectively, adjusting the welding torch to heat by virtue of a flame, enabling the double-end welding torch to move back and forth at a constant speed along the connector plates at the two sides during the heating process, and meanwhile, uniformly heating connection plates at the two sides, starting to fill with brazing wires when an area to be brazed is heat to dark red, and stopping heating after surrounding brazing seams are fully filled; and after the joint is cooled, mechanically removing oxides and redundant brazing materials on the surface of the joint. The flame brazing process method disclosed by the invention is simple, convenient and practicable, high in applicability, and capable of remarkably improving heating efficiency, temperature uniformity and joint brazing quality relative to a conventional flame brazing process.

Owner:HARBIN ELECTRIC MASCH CO LTD

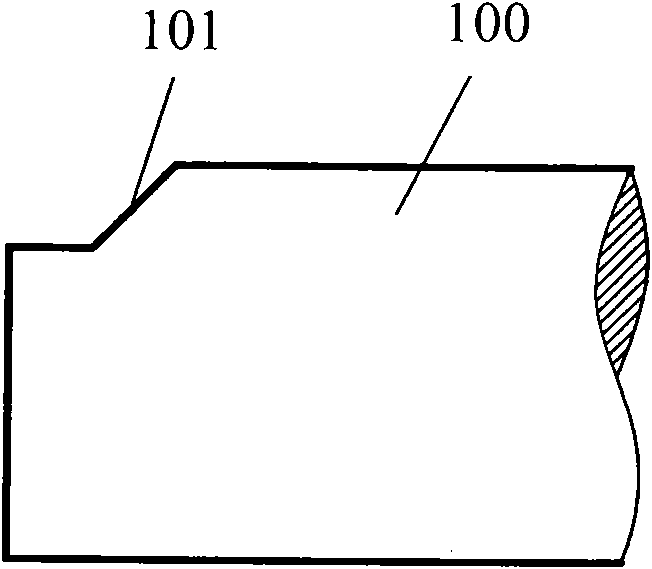

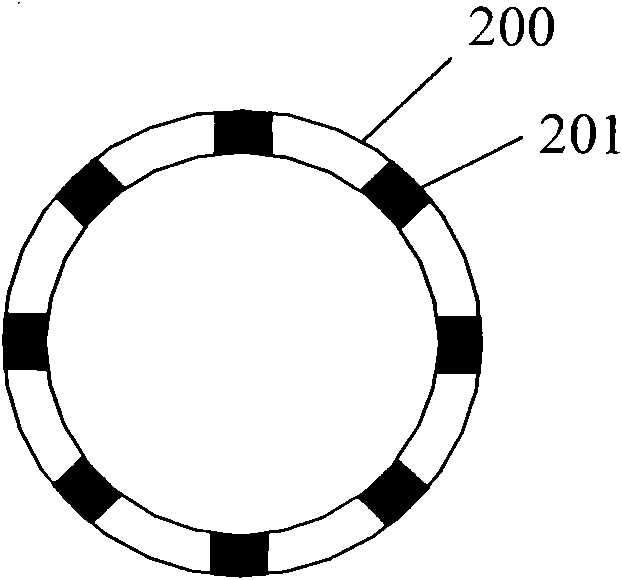

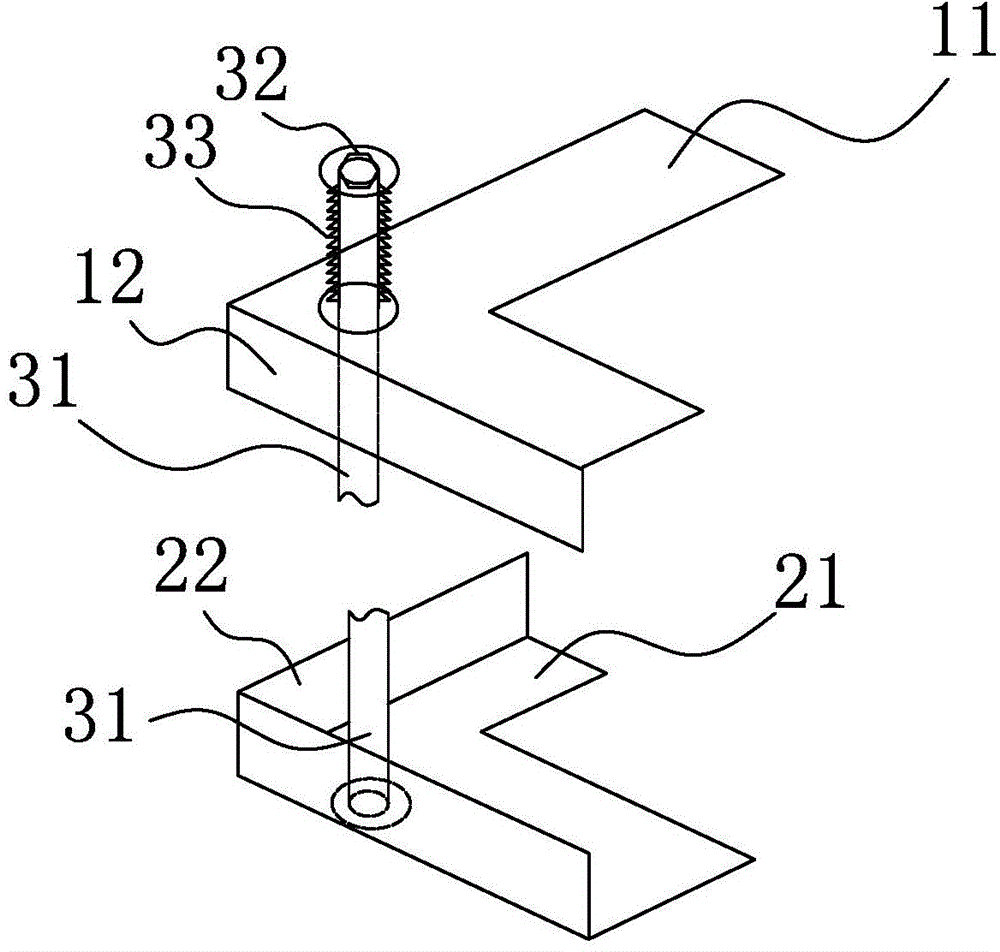

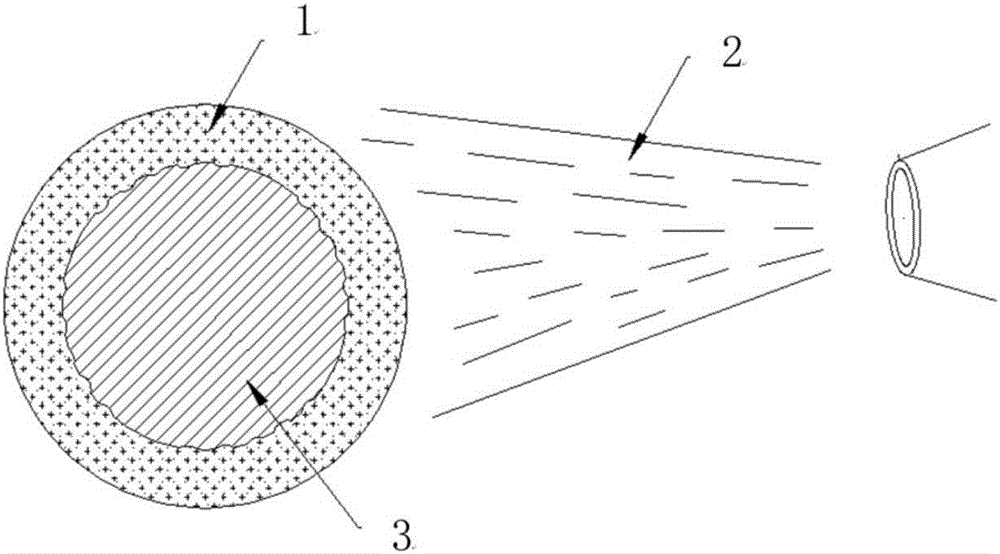

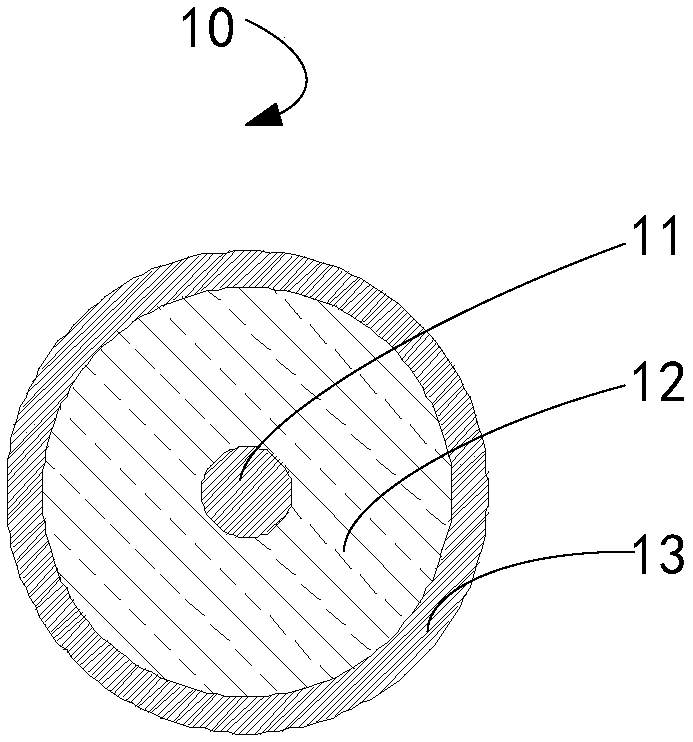

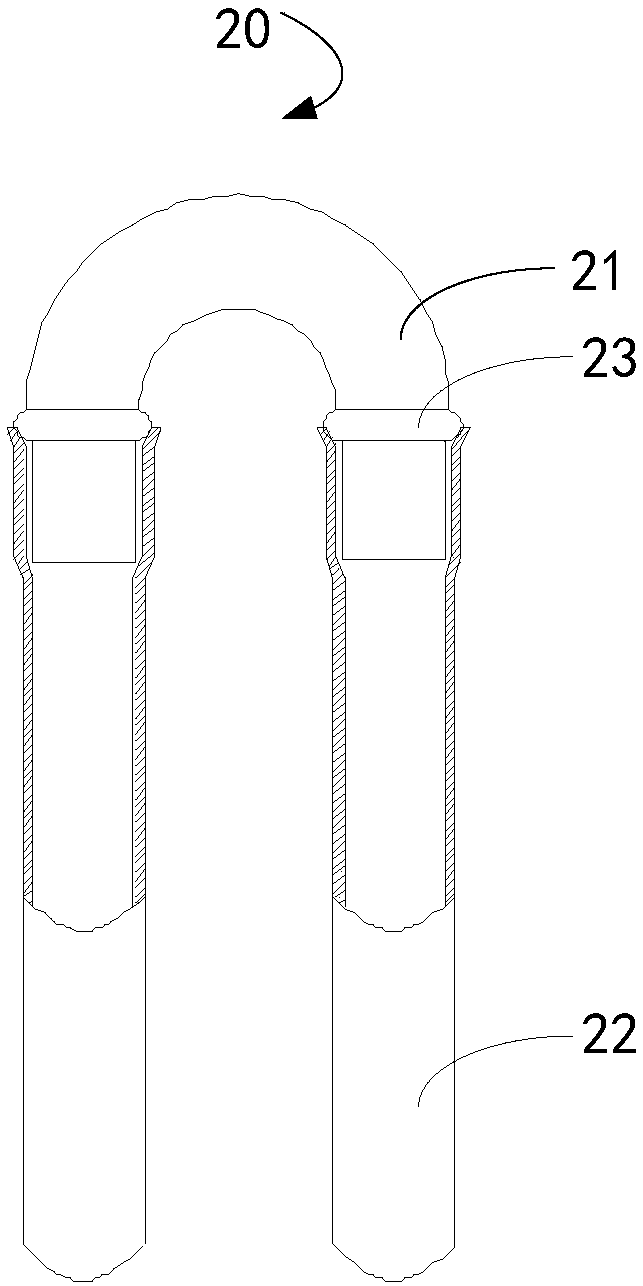

Brazing ring and brazing system

PendingCN107617829AExtended flow timeImprove brazing qualityWelding/cutting media/materialsSoldering mediaMetallurgyLiquid state

The invention relates to the technical field of welding ring manufacture, in particular to a brazing ring and a brazing system. The brazing ring comprises brazing filler metal. The brazing filler metal comprises an inner brazing filler metal layer and an outer brazing filler metal layer, wherein the inner brazing filler metal layer has a first melting point, the inner brazing filler metal layer iswrapped by the outer brazing filler metal layer, the outer brazing filler metal layer has a second melting point, and the second melting point is higher than the first melting point. According to theimplementation manner, the brazing ring is designed into the composite structure comprising the inner brazing filler metal layer and the outer brazing filler metal layer, in the later period of brazing, when the outer brazing filler metal layer is solidified, the inner brazing filler metal layer is still in the liquid state, pores and small gaps between welded pipes can be further filled, the flow time of the brazing filler metal is prolonged, and the brazing quality is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Integrated technique of hard alloy brazing and heat treatment for cutting pick

The invention discloses an integrated technique for hard alloy brazing and heat treatment for a cutting pick. The technique is characterized by including the steps of A, feeding; B, die forging; C, machining; D, hard alloy brazing; E, heat treatment; F, surface treatment. The technique has the advantages that brazing quality is improved greatly, technical indexes of heat treatment meet the condition requirements, productivity is improved effectively, production cost is reduced, work environment is improved, and environmental pollution is reduced greatly.

Owner:SHAANXI AOBANG FORGING

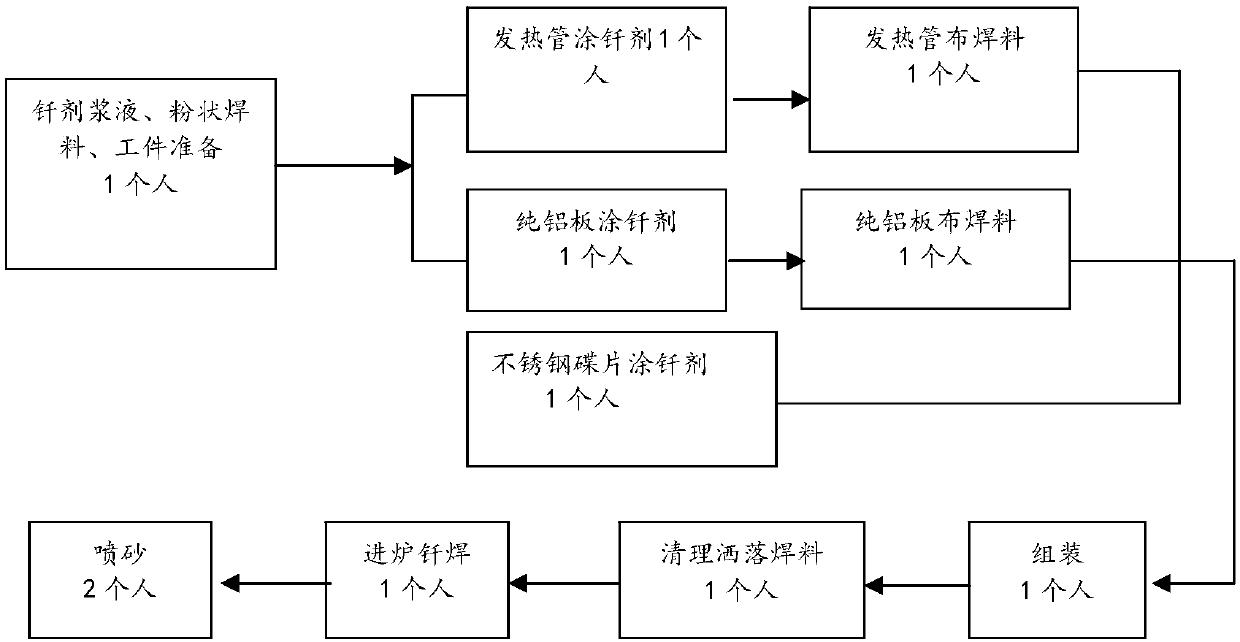

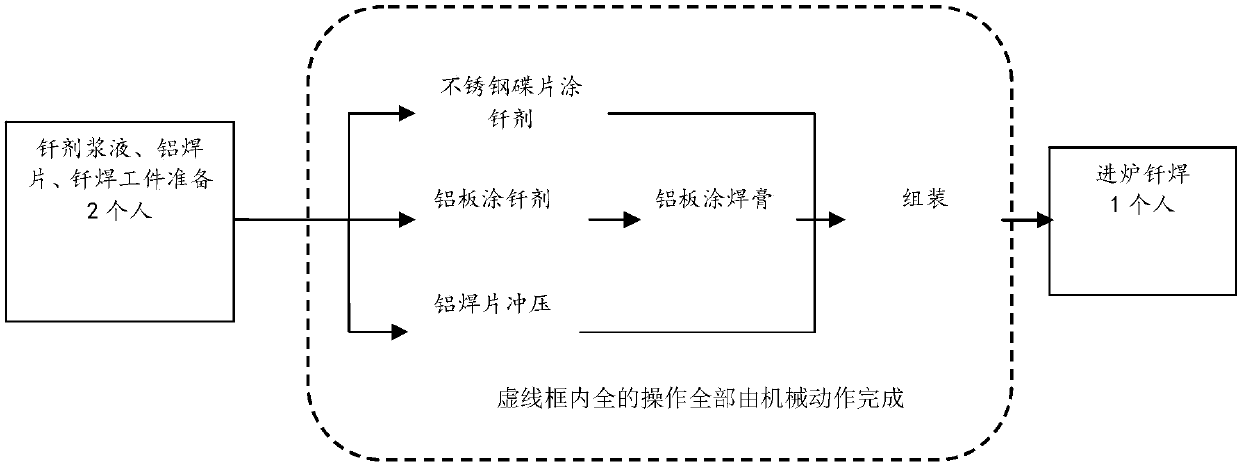

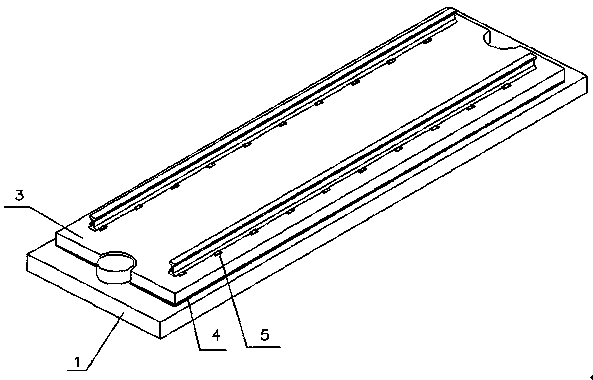

Automatic brazing process for heating disc production

ActiveCN107695473AAutomate the brazing processTo achieve the purpose of substitutionSoldering apparatusMetal working apparatusManufacturing cost reductionHeat conducting

The invention discloses an automatic brazing process for heating disc production. The process comprises the following steps: (1) aluminum brazing flux pulp is prepared, and is brushed on the surfacesof a heat conducting aluminum plate and a stainless steel disc; (2) aluminum welding paste is injected in a to-be-brazed position of the heat conducting aluminum plate by adopting a glue dispensing mode; (3) an aluminum welding piece roll is punched to prepare a welding piece with a preset shape; and then, the welding piece is automatically fed to the stainless steel disc coated with an aluminum brazing flux for assembly; and (4) the heat conducting aluminum plate and an aluminum heating pipe are assembled for the first time; then, the heat conducting aluminum plate and the stainless steel disc to which the welding piece is attached are assembled for the second time; and then brazing is performed. Automatic and intelligent novel welding materials are obtained through the process, and the welding paste and the aluminum welding piece are used in the process, automatic and intelligent elements are embodied, and the process is green in operating environment, improves the brazing quality and the brazing efficiency, reduces the manufacturing cost, and really achieves the purpose of replacing workers with machines.

Owner:广州有研焊接材料科技有限公司

Ballastless track structure

A ballastless track structure includes a foundation and a track slab. The foundation and / or the track slab is made of metal plates; each metal plate comprises a first panel, a second panel and a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubes and the first and second panels correspondingly; and at least one end of each hollow tube is provided with a flange. On the one hand, the ballastless track structure has the advantages of light dead weight, large strength, stable structure, high bearing capacity, sound insulation and noise reduction, high temperature resistance, vibration resistance, long service life, portability, assembly and the like; and on the other hand, the ballastless track structure canincrease the speed of rail vehicles such as high-speed trains and bullet trains.

Owner:张跃

Aluminum plate fin type radiator vacuum brazing furnace temperature field equilibrium method

ActiveCN101339579AImprove temperature uniformityImprove brazing qualitySpecial data processing applicationsFurnace temperatureMathematical model

The invention discloses a temperature equalization method for the temperature field of an aluminum plate-fin typed radiator vacuum brazing furnace, which belongs to a temperature equalization method for the temperature field of a vacuum brazing furnace and aims at providing a method for guaranteeing a more uniform product temperature at varied positions in the vacuum furnace. The invention has specific methods that: 1) a furnace body mathematical model is established; 2) a product mathematical model is established according to a heat conduction formula; 3) a simulation heating curve is set and a simulation temperature field is established on a computer according to an actual art heating curve and a thermal radiation formula; 4) the simulation heating curve is modified according to the actual temperature; 5) the putting position of the product mathematical model in the furnace body mathematical model is adjusted according to the distribution of the high temperature and low temperature areas of simulation temperature fields; 6) the putting of the products in actual production is guided according to rules for putting products and the correctness of the simulation heating curve is validated according to the actual temperature. The temperature equalization method provided by the invention can effectively improve the uniform temperature of products in the vacuum furnace, thus being an ideal method for improving the vacuum brazing quality of the aluminum plate-fin typed radiator.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Vehicle brazing method and vehicle brazing device

ActiveCN103785917AImprove melting efficiencyImprove brazing qualityVehicle componentsHeating appliancesGuide wiresAutomotive engineering

The invention provides a vehicle brazing method and a vehicle brazing device. The brazing device comprises a brazing heat source, a brazing torch, a wire feeder, a robot and a controller. The brazing torch is arranged on the robot, and the controller is connected with the brazing heat source, the brazing torch, the wire feeder and the robot respectively and controls the same to operate. The brazing heat source comprises a front-end plasma power supply and a rear-end plasma power supply. A front-end plasma nozzle, a rear-end plasma nozzle and a wire guiding nozzle are arranged in the top of the brazing torch, the front-end plasma nozzle is connected with the front-end plasma power supply through a cable, the rear-end plasma nozzle is connected with the rear-end plasma power supply through another cable, the wire guiding nozzle is connected with the wire feeder, and a brazing wire discharged from the wire feeder extends out of the wire guiding nozzle. The vehicle brazing device has the advantages of high seam strength, narrow seams, freeness of spattering, high brazing efficiency and the like; compared to laser brazing manufacturing, brazing manufacturing can greatly lower investment, use cost can be lowered, and wide application can be achieved.

Owner:成都天启万峰机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com