NB continuous brazing core body heating method for automobile radiator brazing process

A technology of automobile radiator and brazing process, which is applied in the direction of instruments, electric heating devices, manufacturing tools, etc., and can solve problems such as inability to directly measure temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

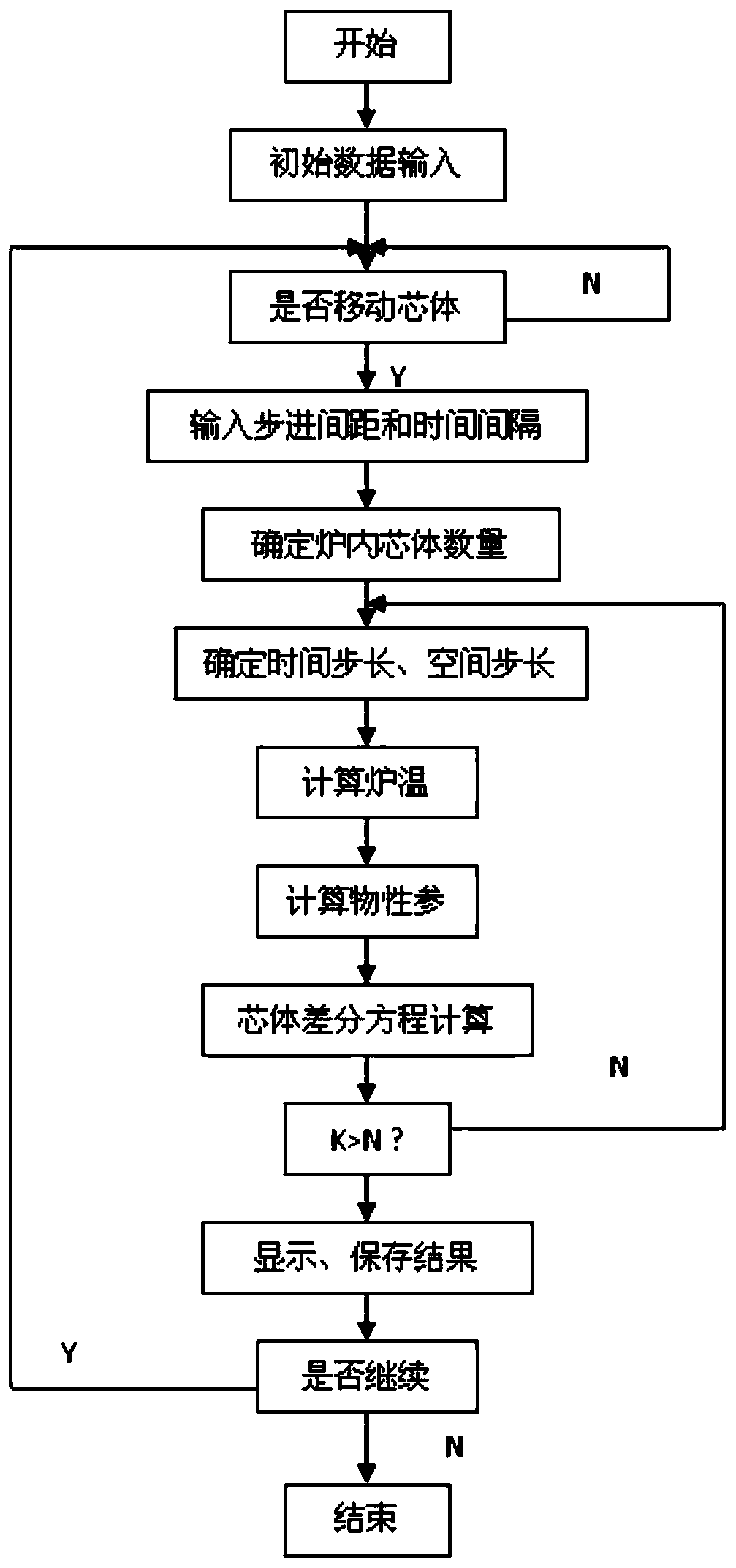

[0129] A kind of NB continuous brazing core body heating method of automobile radiator brazing process, the method comprises the following steps:

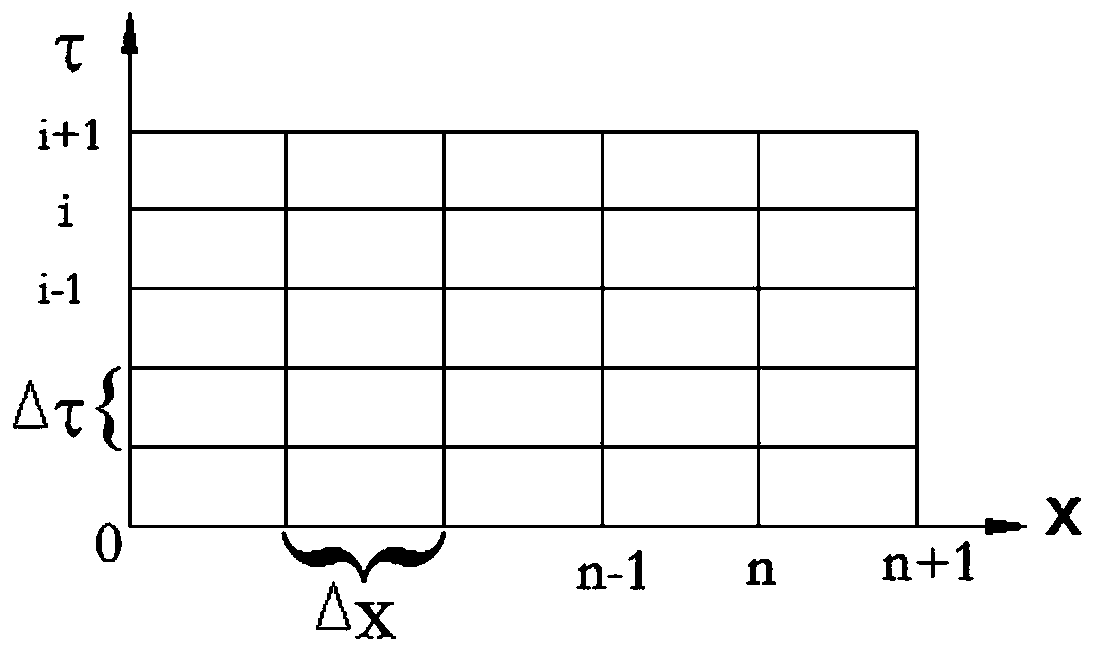

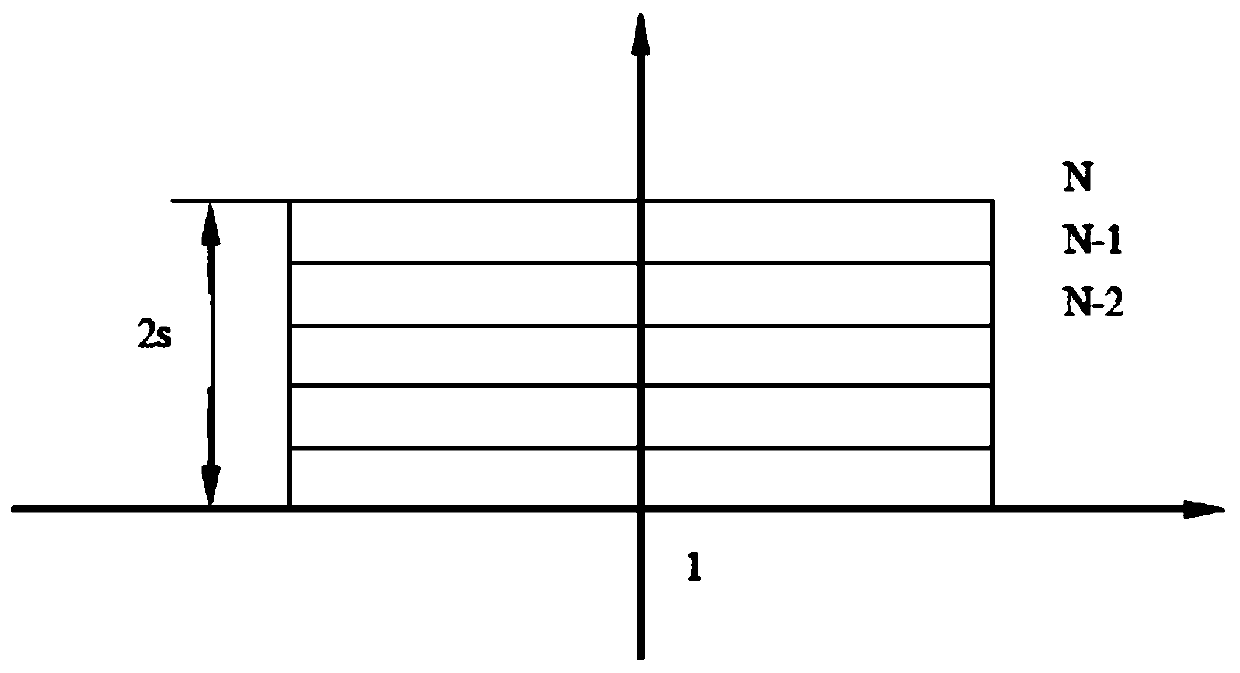

[0130] S1: Establish a core heating model, which calculates the heat flow at the core surface boundary as follows:

[0131] (1) The effective heat flow per unit of radiation heat exchange between the furnace and the core is:

[0132] q 1 = σ 0 ·C gwm ·(T f 4 -T s 4 ) (3-1)

[0133] The unit effective heat obtained by convection on the surface of the core is:

[0134] q 2 =a·(T f -T s ) (3-2)

[0135] Then the total effective heat flow obtained by the core in the furnace is:

[0136]

[0137] In the formula:

[0138] T f , T s --------Respectively represent furnace gas and core body surface temperature, K;

[0139] a----------Convective heat transfer coefficient of furnace gas to core body, W / (m2·℃)

[0140] C gwm -------The conduction radiation coefficient of the furnace gas and the furnace wall to the radiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com