Self-bonding composite board and manufacturing process thereof

A manufacturing process and composite board technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easy degumming, high temperature deformation, and unresolved problems of honeycomb boards, so as to improve brazing quality, smooth surface, and prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

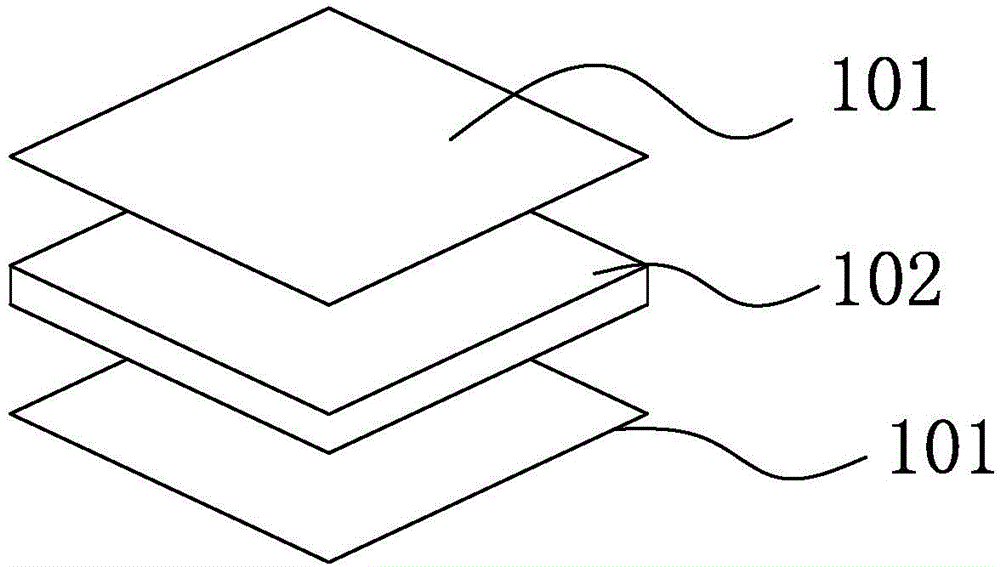

[0030] Such as Figure 1-3 Shown, a kind of manufacturing process of glue-free composite board comprises the following steps:

[0031] A. Making plates and cores: get aluminum plates and cut them into blocks for later use to obtain composite plates; take aluminum foil to make honeycomb cores and cut them into sizes corresponding to the composite plates to obtain cores;

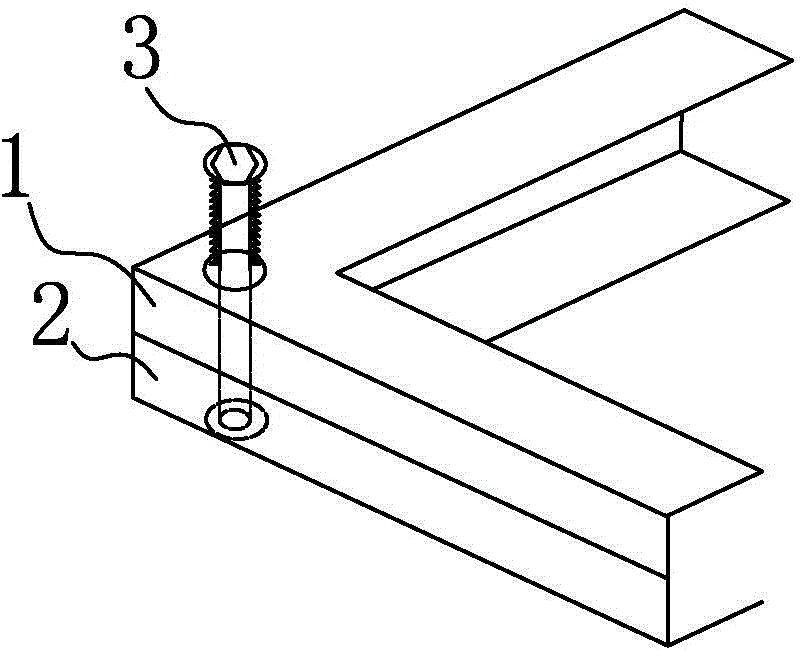

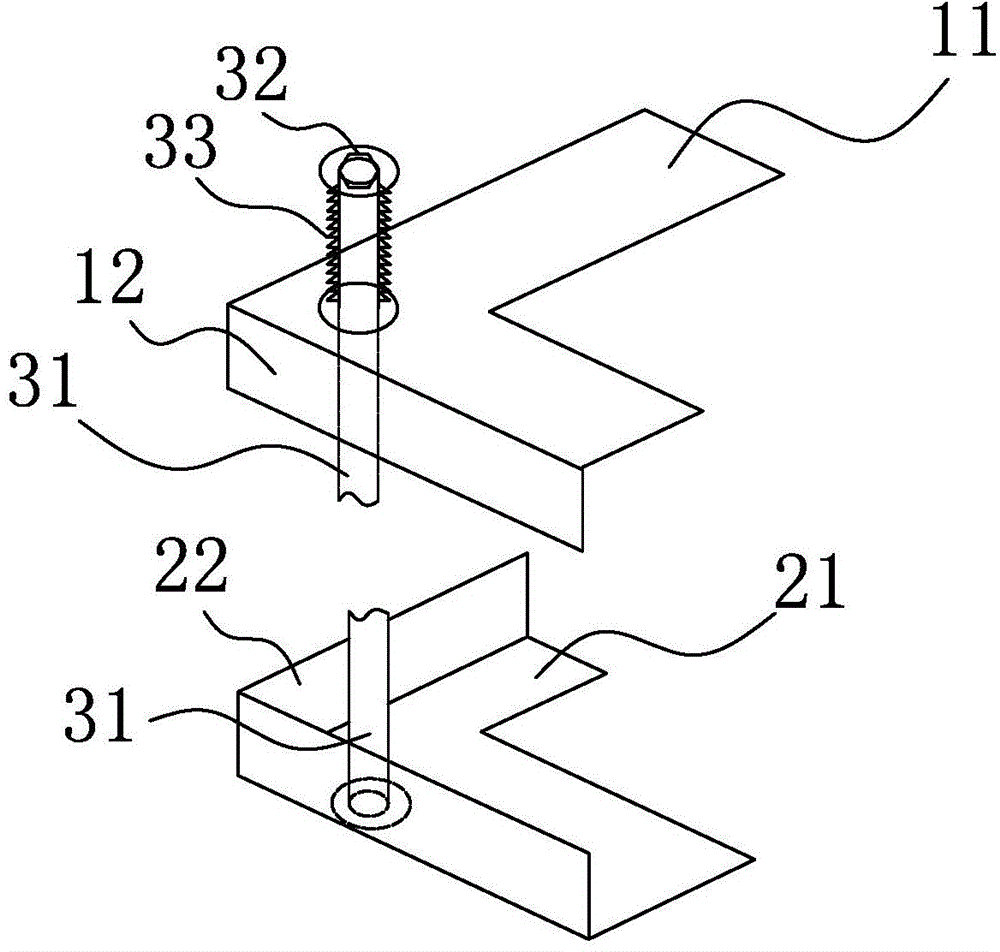

[0032] B. Assembly: smear flux on the upper and lower surfaces of the core, and cover the upper and lower surfaces of the core with composite plates to obtain a block-shaped composite honeycomb panel, and clamp the composite honeycomb panel with a fixture;

[0033] C. Brazing: Dry the composite honeycomb panel and put it into a brazing furnace for brazing to obtain a glue-free composite panel.

[0034] Because the composite honeycomb board is clamped by the fixture, the composite board and the board core will not be deformed during high-temperature brazing, thereby improving the manufacturing quality. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com