Stacked plate heat exchanger

a heat exchanger and stacked plate technology, applied in the direction of coatings, lighting and heating apparatus, laminated elements, etc., can solve the problems of oil coolers having leak holes on the plates, and it is difficult to braze such a support plate on the core, so as to achieve reliable joint brazing and sufficient corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0028]A first embodiment of the invention is described below with the drawings. The first embodiment is an oil cooler also called as a housingless oil cooler for cooling oil lubricating an internal combustion engine mounted on a vehicle. The oil cooler is attached on a side wall of an engine cylinder block and performs heat exchange between oil and engine cooling water.

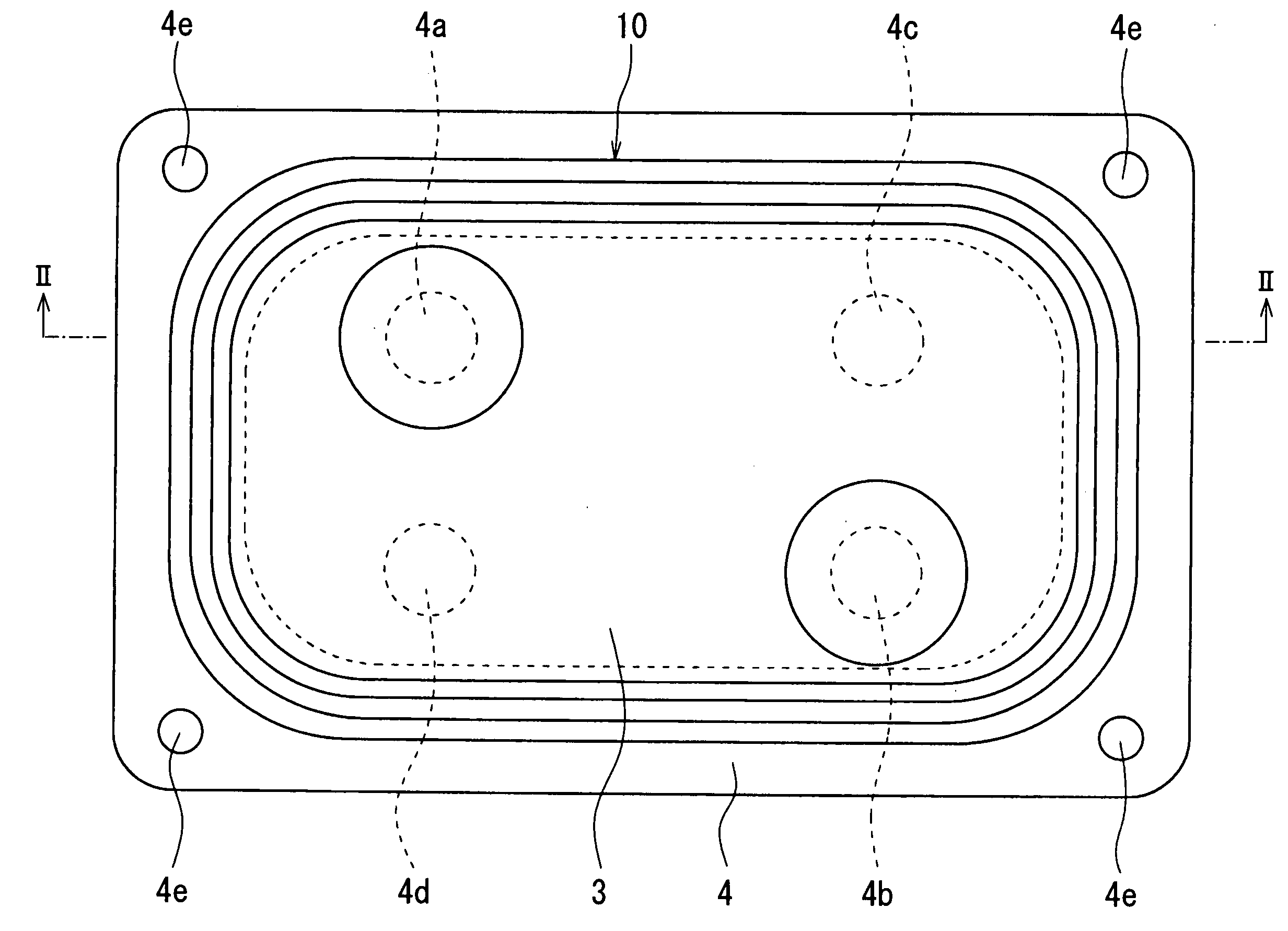

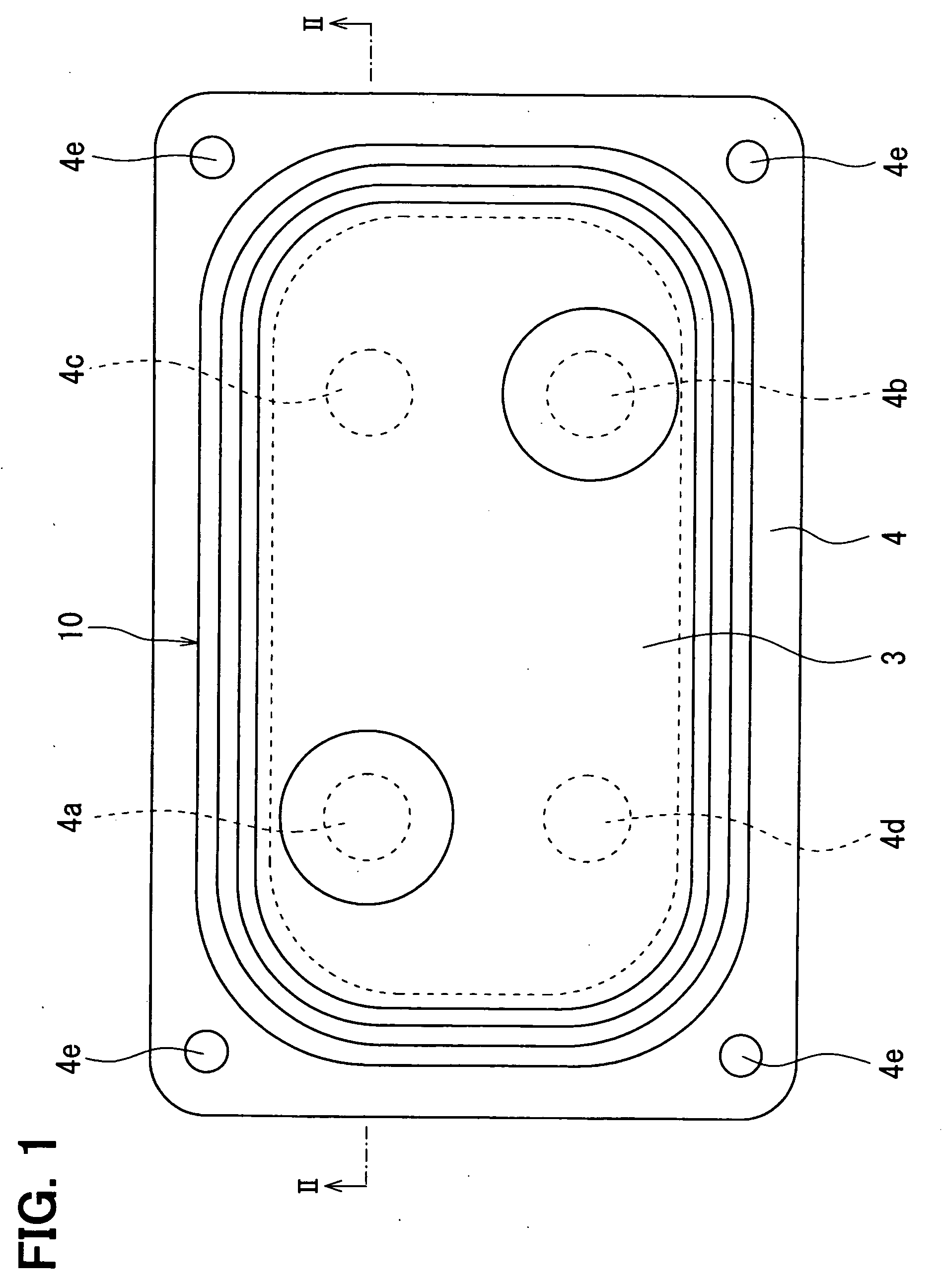

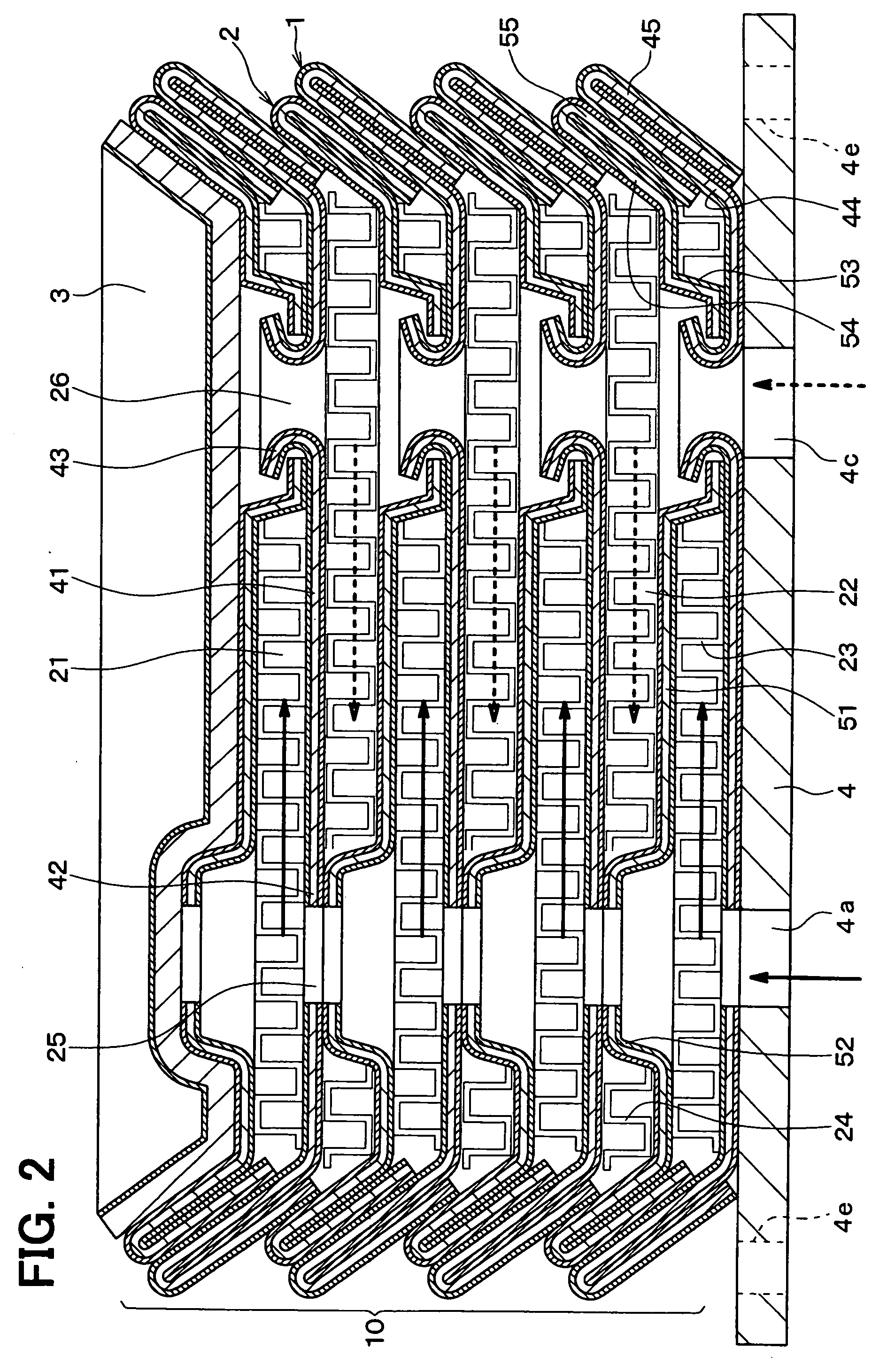

[0029]Referring to FIGS. 1 and 2, the oil cooler has a core 10 formed by stacking a plurality of plates for performing heat exchange between oil and cooling water. The core 10 has alternately stacked first plates 1 and second plates 2. The first plates 1 and second plates 2 are formed to have a predetermined shape having protrusions and depressions by pressing processes. The oil cooler has a cover plate 3 made of aluminum alloy, and attached on one end of the core 10. The oil cooler further has a support plate 4 made of aluminum alloy, and attached on the other end of the core 10. In FIG. 2, the core 10 has the cover ...

second embodiment

[0057]A second embodiment of the invention is described below with the drawings. Referring to FIG. 7, the same or corresponding structures are indicated by the same reference numbers as described in the first embodiment. In this embodiment, a first plate 201 has a first tapered portion 244 apparently longer than that of the second plate 202 and that of the first plate 1 in the first embodiment. The first tapered portion 244 is higher formed from the partitioning portion 41 than the second tapered portion 254. The first plate 201 has a folded portion 245 having a distal end that does not reach the boundary between the partitioning portion 51 and the tapered portion 244. As a result, the folded portion 245 only covers an outer end region of the lateral outside surface of the tapered portion 244. The first plate 201 and the second plate 202 are stacked so that the first sacrificial layer 32 comes in contact with the second brazing material layer 35, and that the first brazing material ...

third embodiment

[0058]A third embodiment of the invention is described below with the drawings. Referring to FIG. 8, the same or corresponding structures are indicated by the same reference numbers as described in the first embodiment. In this embodiment, a first plate 301 has a first tapered portion 344 apparently longer than that of the second plate 302 and that of the first plate 1 in the first embodiment. The first tapered portion 344 is higher formed from the partitioning portion 41 than the second tapered portion 354. The first plate 301 has a folded portion 345 having a distal end that does not reach the boundary between the partitioning portion 51 and the tapered portion 344. As a result, the folded portion 345 only covers an outer end region of the lateral outside surface of the tapered portion 344. The folded portion 345 is much longer than the folded portion 355. The first plate 301 and the second plate 302 are stacked alternately. The first sacrificial layer 32 is brazed with the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Exposure limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com