Brazed structure and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

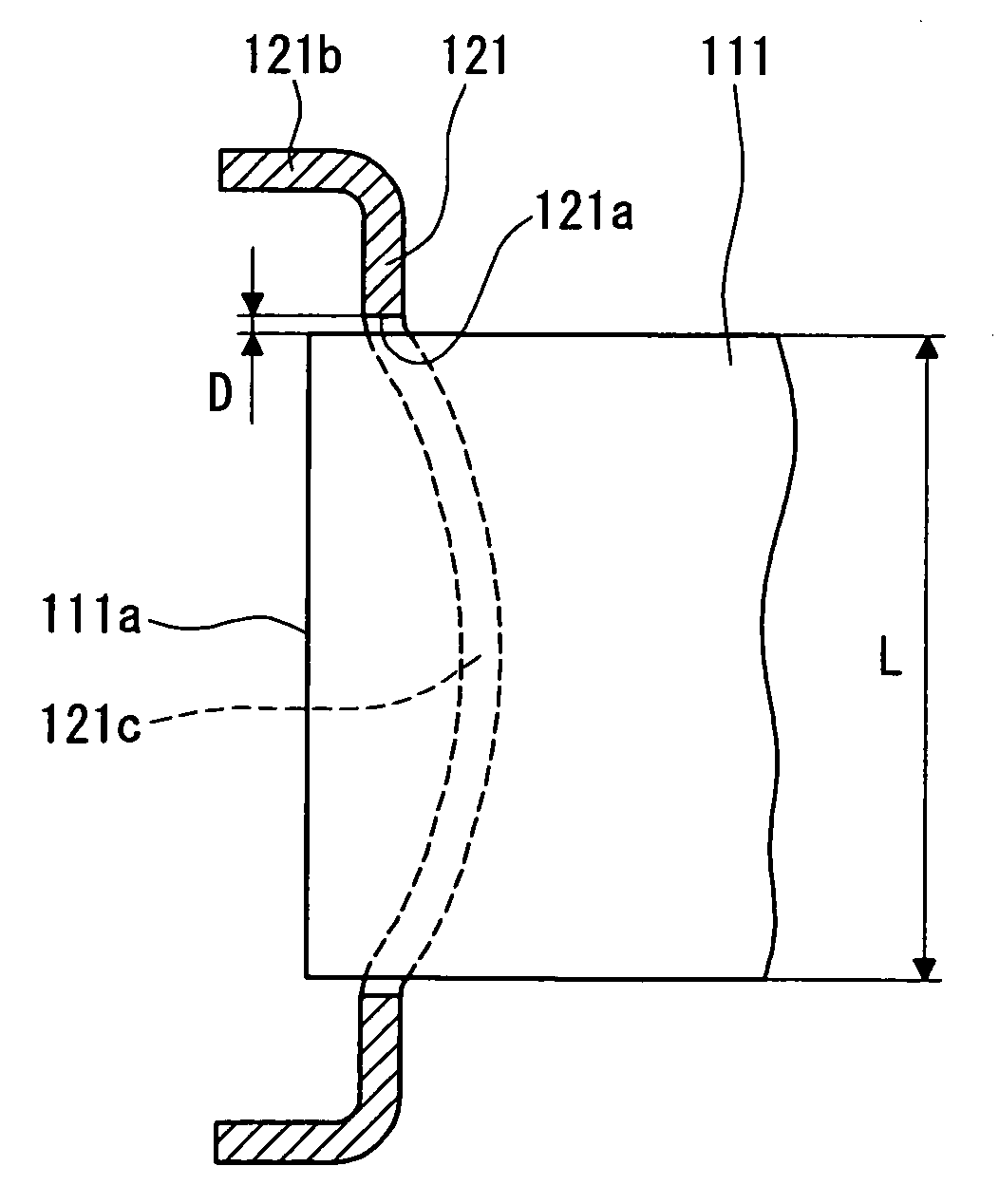

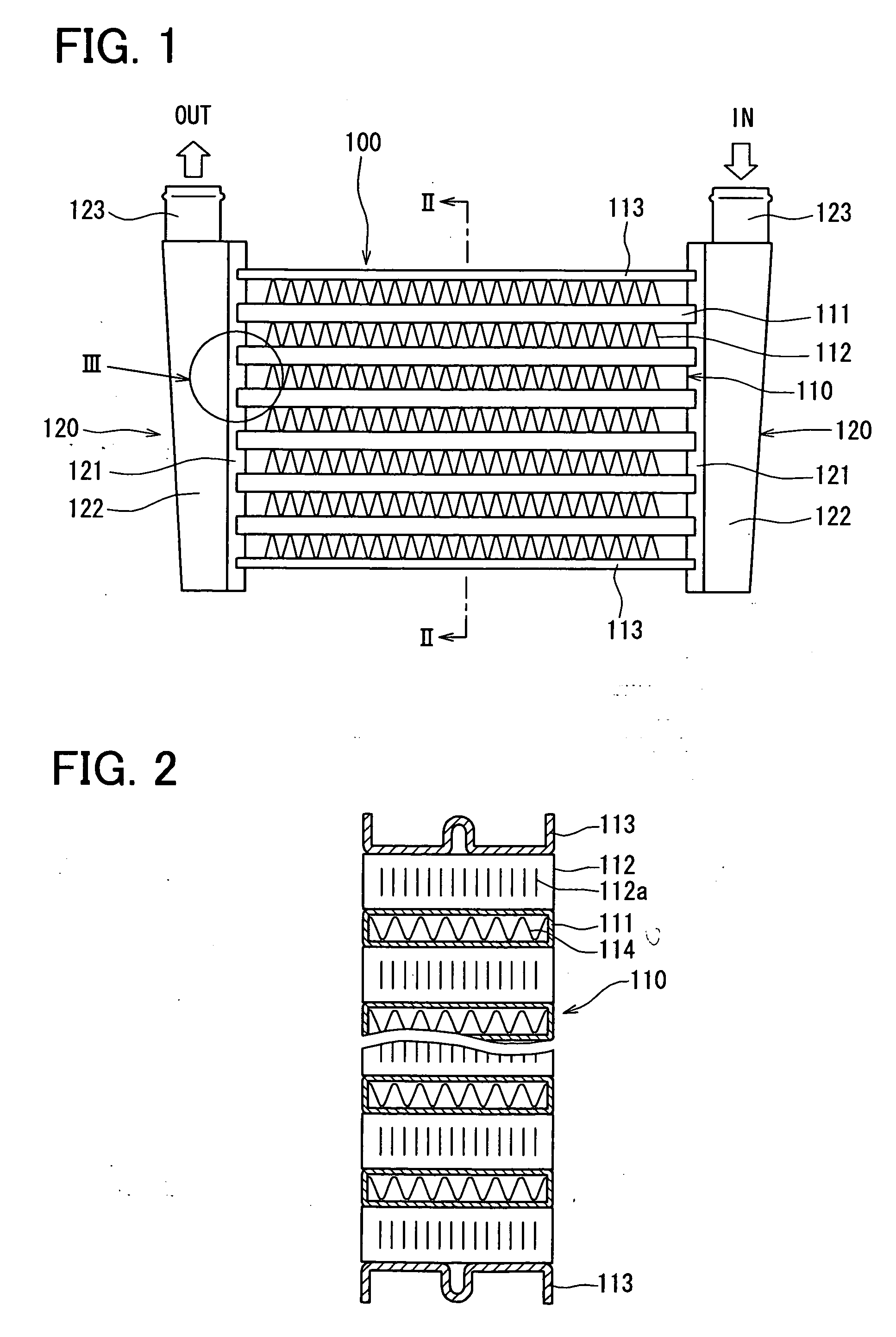

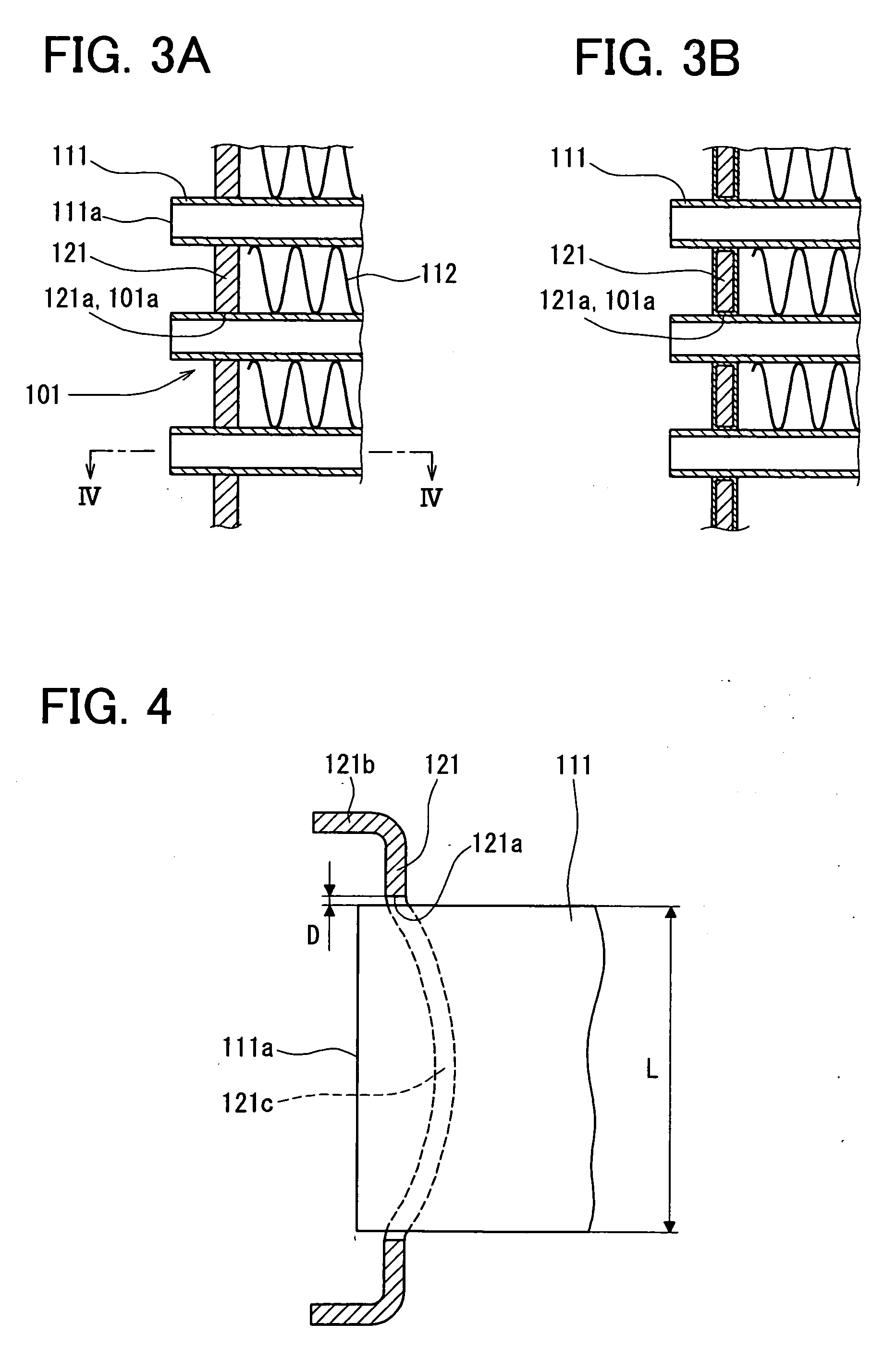

[0019] A first example embodiment of the present invention will now be described with reference to FIGS. 1 to 4. In the first example embodiment, a brazed structure of the present invention is for example employed to a base portion (connecting portion) 101 of an air cooling type intercooler 100.

[0020] The intercooler 100 is a heat exchanger for performing heat exchange between an intake air to be sucked in an engine of a vehicle for combustion and an external cooling air for cooling the intake air. The intercooler 100 has a core portion 110 and a pair of header tanks 120. The intercooler 100 is a large heat exchanger and is for example mounted on a large vehicle such as trucks. Respective parts of the intercooler 100, which will be described later, are made of materials such as copper, copper alloy, or iron to have sufficient thermal conduction and durability.

[0021] Further, connecting portions between respective parts are connected by brazing or welding. For example, a copper bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com