Induction brazing equipment

A technology of induction brazing equipment and high-frequency induction heating, applied in welding equipment, metal processing equipment, electric heating devices, etc., to solve the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

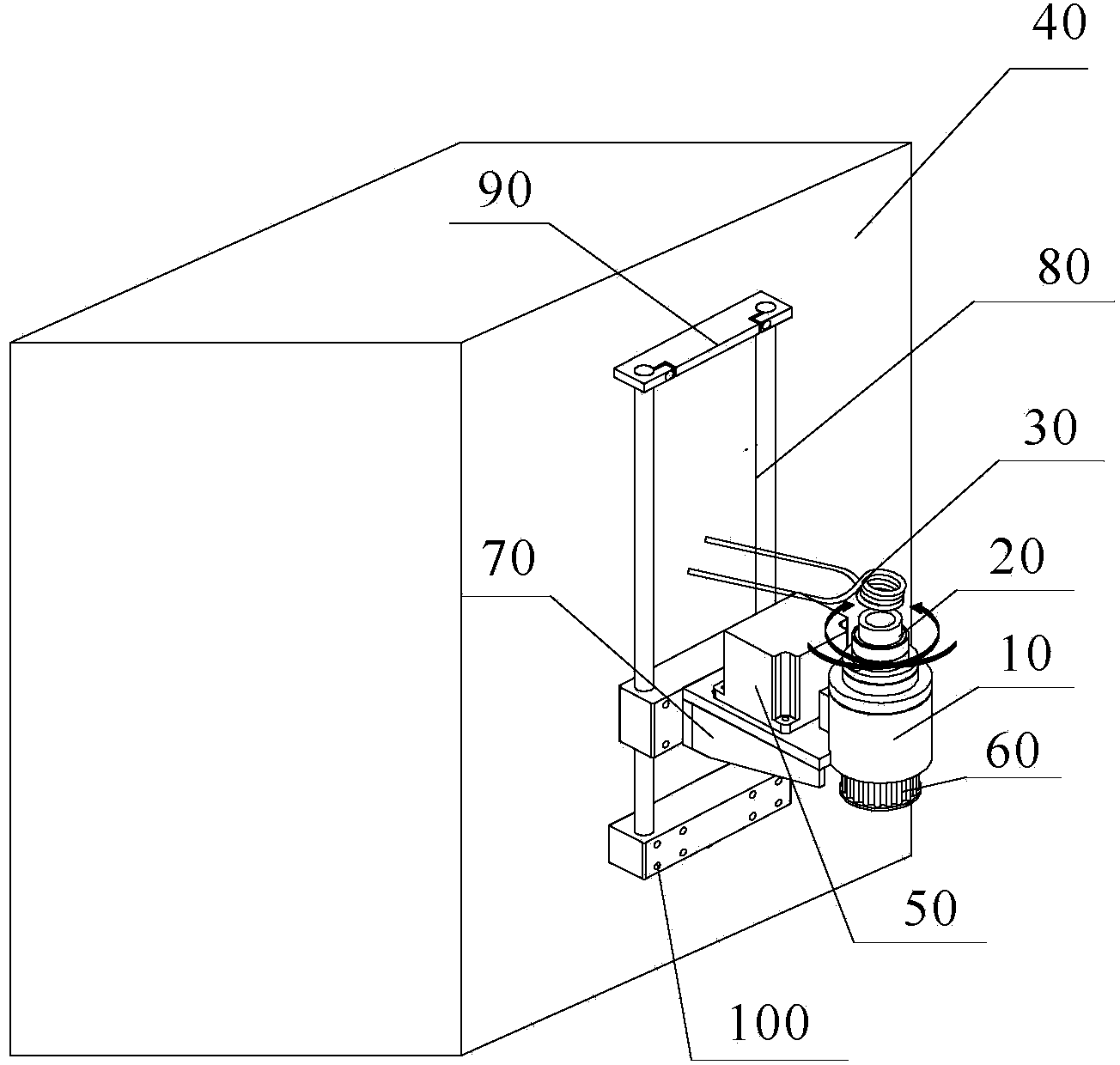

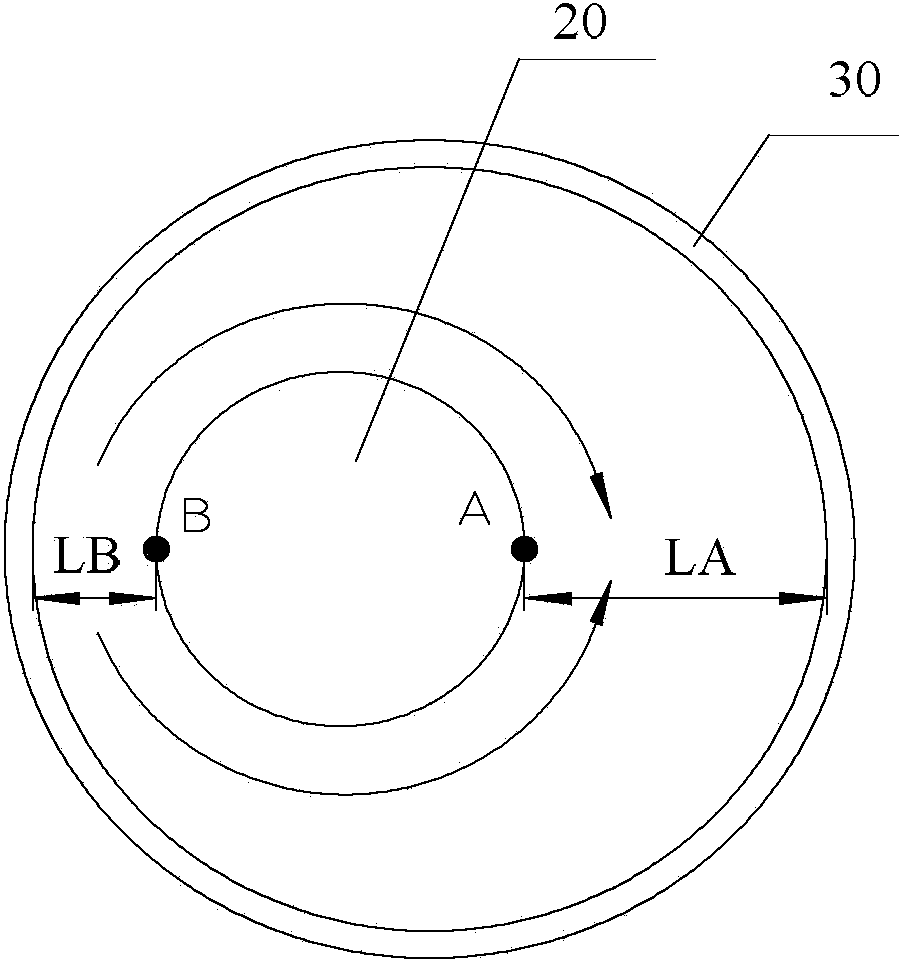

[0022] see figure 1 and figure 2 , according to the induction brazing equipment of the present invention, comprising: a rotating mechanism 10, a positioning tool 20, which is arranged on the rotating mechanism 10 and rotates concentrically with the rotating mechanism 10, and the positioning tool 20 is placed on the rotating mechanism 10 for placing workpieces to be welded , to fix the position of the workpiece; the induction heating coil 30 is sleeved outside the axis of the positioning tool 20 and forms an installation space with the positioning tool 20 .

[0023] see figure 1 and figure 2 , the induction brazing equipment further includes a high-frequency induction heating power supply 40 , and the induction heating coil 30 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com