Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "High metal recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

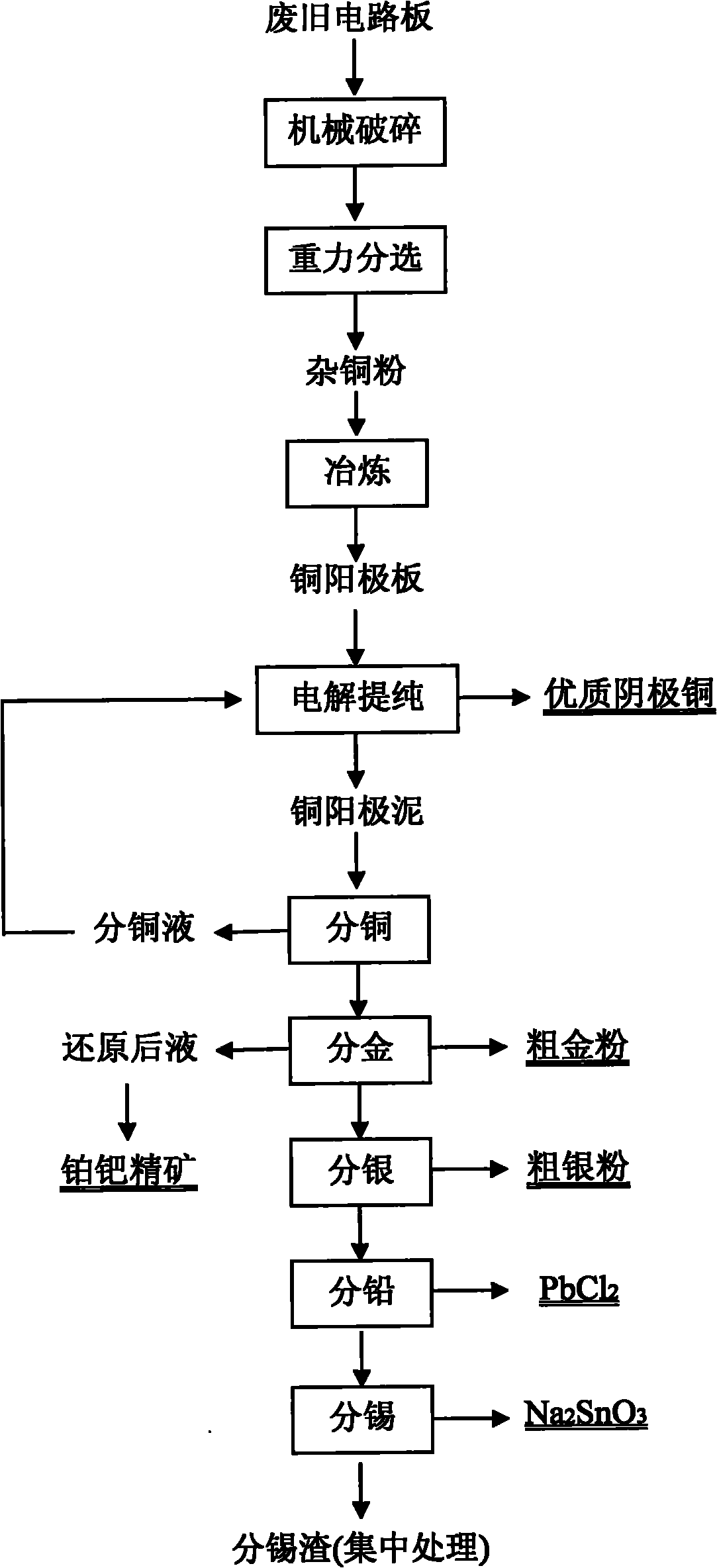

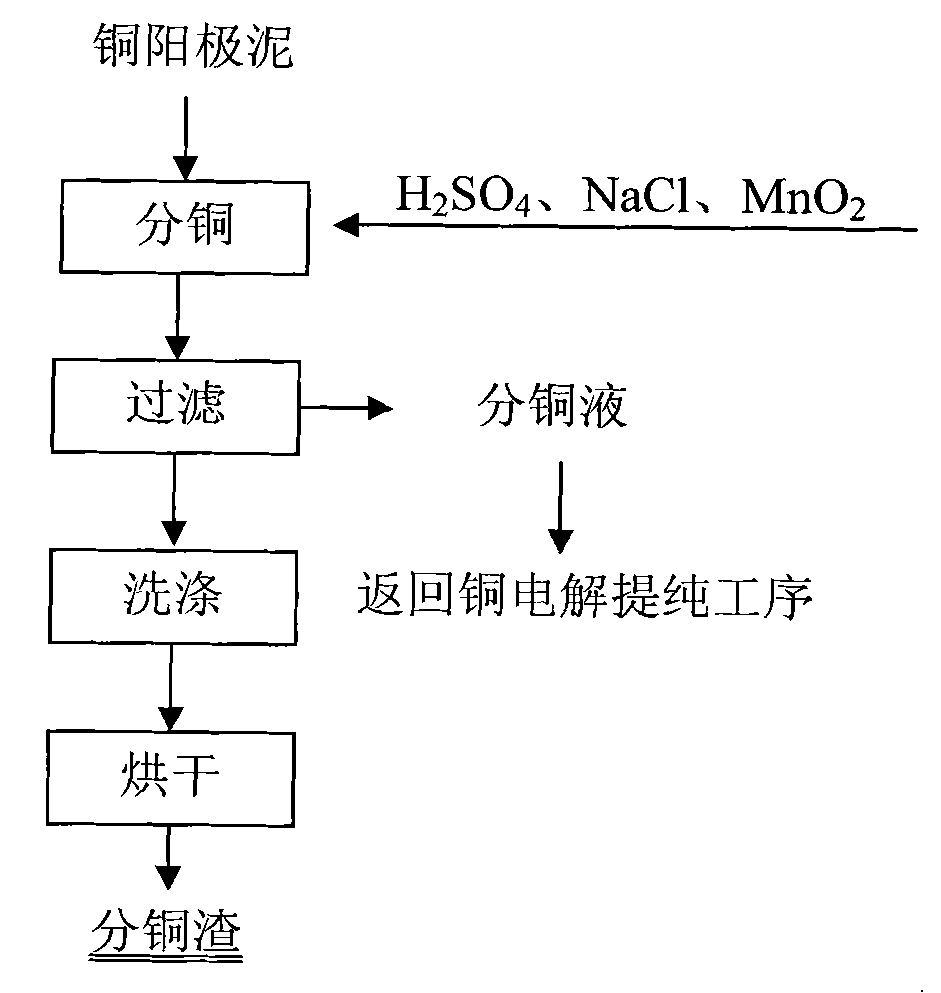

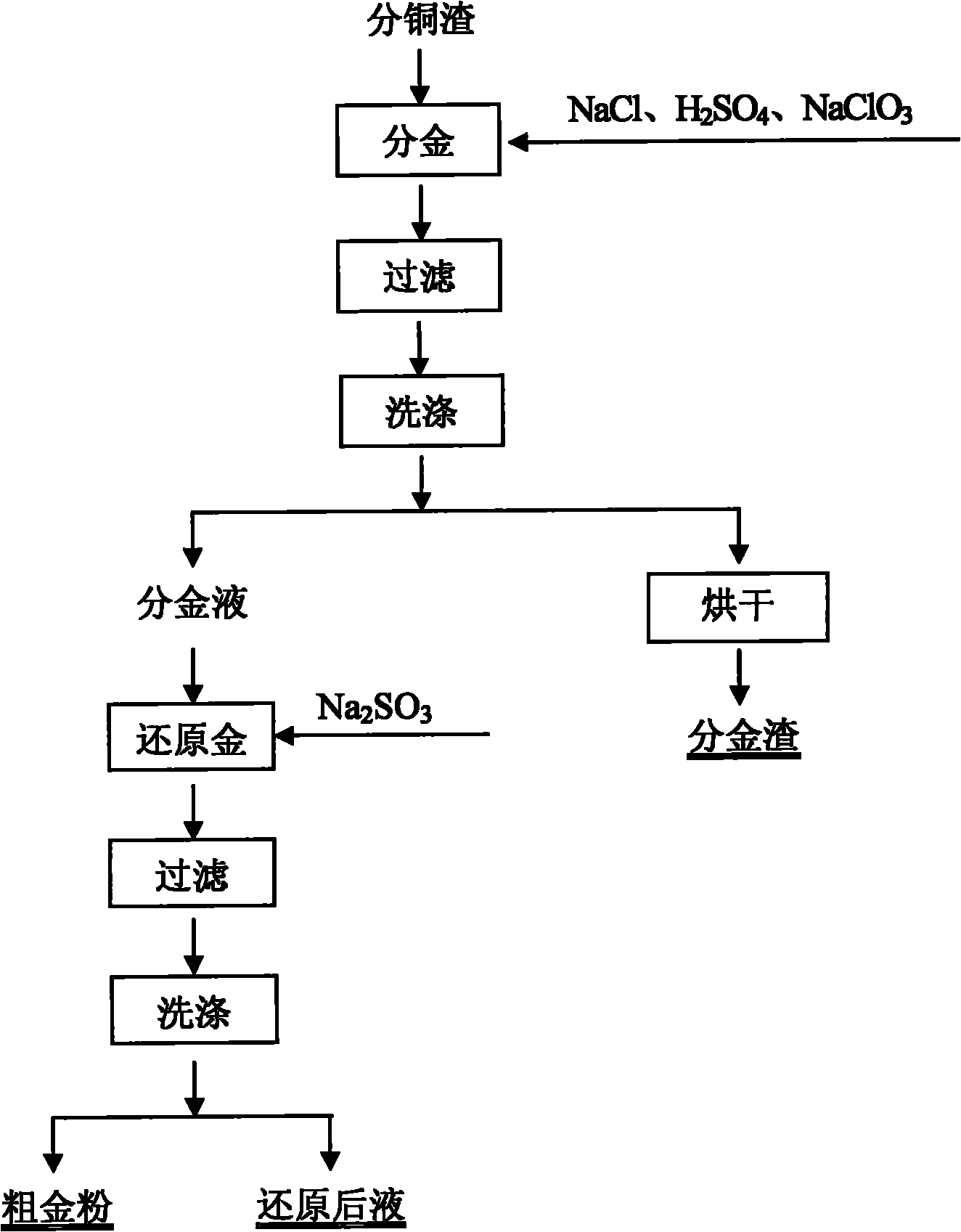

Method for green recovery of waste circuit boards by cyanide-free full-wet whole set process

InactiveCN101831553AHigh metal recovery rateSolve high energy consumptionProcess efficiency improvementPrinted circuit boardPalladium

The invention provides a method for green recovery of waste circuit boards by a cyanide-free full-wet whole set process, and belongs to the field of recycle economy. The method comprises the following steps of: mechanically crushing waste circuit boards; separating by adopting gravitational segregation to obtain impure copper powder and non-metallic powder; smelting and casting the impure copper powder to obtain a copper anode plate; and performing copper electrolytic refining on the copper anode plate; separating copper, gold, solver, platinum-palladium, lead and tin in the copper anode mud so as to recover the valuable metals of copper, gold, solver, platinum-palladium, lead and tin therein and performing wastewater recycling. The overall recovery rate of metals in the waste circuit boards reaches over 98 percent, the cathode copper obtained by the copper electrolytic refining reaches 4N level, the copper removal rate in the copper anode mud reaches over 96 percent, the recovery rate of the gold reaches over 98 percent, the recovery of the platinum-palladium reaches over 96 percent, the recovery rate of the silver and lead reaches over 95 percent, and the recovery rate of the tin reaches over 90 percent. The method for the green recovery of the waste circuit boards has the characteristics of cyanide-free full-wet property, wastewater recycling, and no secondary pollution.

Owner:UNIV OF SCI & TECH BEIJING

Beneficiation process for increasing recovery rate of gold of refractory gold ores

The invention relates to a beneficiation process for increasing the recovery rate of gold of refractory gold ores. According to the process, a reselection-floatation-reselection combined procedure is adopted to increase the recovery rate of the gold, and in other words, ores are ground till the particle size is -0.074 mm(60-80)%; a hydraulic power classifier is firstly utilized for classification, coarse gold concentrate is obtained from classified setting sand through a reselection method, and reselected tailings return to a ball mill to be ground gain; and classified overflow adopts a total-sulfur flotation method to recycle the gold, mustard gold concentrate is obtained, flotation tailings are reselected through a Nilson centrifugal ore separator, and obtained reselected concentrate returns to the ball mill to be ground gain. Early recovery and much recovery of the gold can be achieved through the process, gold which cannot be recycled because the particle size is too large or too small in total-sulfur flotation is effectively recycled, the purpose of selective ore grinding is achieved through reselection-ball mill closed cycle, the dissociation degree of the ores can be improved easily, the grade of the gold concentrate is remarkably improved, the metal recovery rate is remarkably increased, and good economic benefits can be brought to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

Method for metal heap and dump leaching coupled with metal solvent extraction

InactiveUS20060088458A1Increase heightImprove recovery rateSolvent extractionSolid sorbent liquid separationLower gradeLow graded

The disclosed invention provides a process for enhanced recovery of one or more metal values from heap and / or dump leaching of ores containing the metal values, the process comprising: (a) providing a high grade leach solution obtained by heap or dump leaching of fresh high grade ore containing a first metal value; (b) subjecting the high grade leach solution to a first solvent extraction of the first metal value and applying the resulting first aqueous raffinate to leach fresh high grade ore; (c) providing a low grade leach solution obtained by heap or dump leaching of partially leached ore or fresh low grade ore of the first metal value; and (d) subjecting the low grade leach solution to a second solvent extraction of the first metal value, separate from the first solvent extraction of the first metal value, and applying the resulting separate, second aqueous to leach partially leached ore or fresh low grade ore, wherein the first and second aqueous raffinates are not intermixed prior to being applied to their respective ores for leaching. Alternatively, the first and second raffinates may be intermixed prior to being applied to their respective ores for leaching, providing that the aqueous raffinate applied to fresh high grade ore comprises at least 60% by volume of the first aqueous raffinate and the aqueous raffinate applied to partially leached ore or fresh low grade ore comprises at least 60% by volume of the second aqueous raffinate.

Owner:COGNIS IP MANAGEMENT GMBH

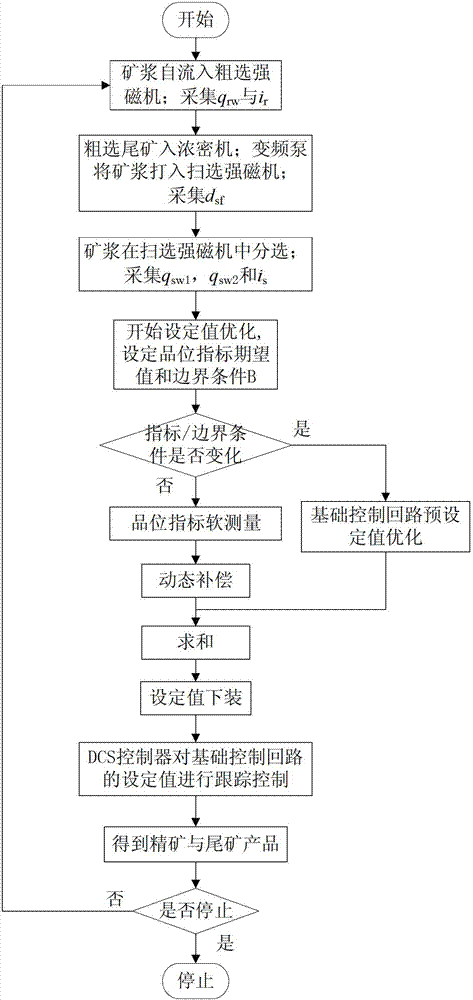

Operation control method of high magnetic grading process

ActiveCN102778843AHigh metal recovery rateMeet needsMagnetic separationAdaptive controlSystems designAutomatic control

An operation control method of a high magnetic grading process belongs to the technical field of automatic control and comprises the following steps of: performing optimal control on a set value of a basic control loop of the high magnetic grading process according to an expected value of a high magnetic grading index and an actual value of the basic control loop to improve the concentrate grade and lowering the tailing grade. With the adoption of the method, a system is ensured to run on working points corresponding to the expected value of concentrate grade and the expected value of the tailing grade, the concentrate grade and the tailing grade which cannot be measured on line are predicated in real time by a neural network, the poor effect to the grading process, caused by each unknown interference, is inhibited effectively by using a dynamic compensation method, in this way, the concrete grade is improved, meanwhile, the tailing grade is lowered, and thus the metal recovering rate of a final grading product is increased. The method can be realized by a software system; with the adoption of the software system, the separation of a software functional module and an algorithm is realized, the de-coupling degree is low, the algorithm is easy to expand and maintain, and a technical support and a running platform are provided to the research and the system design of the operation control method of the high magnetic grading process.

Owner:NORTHEASTERN UNIV

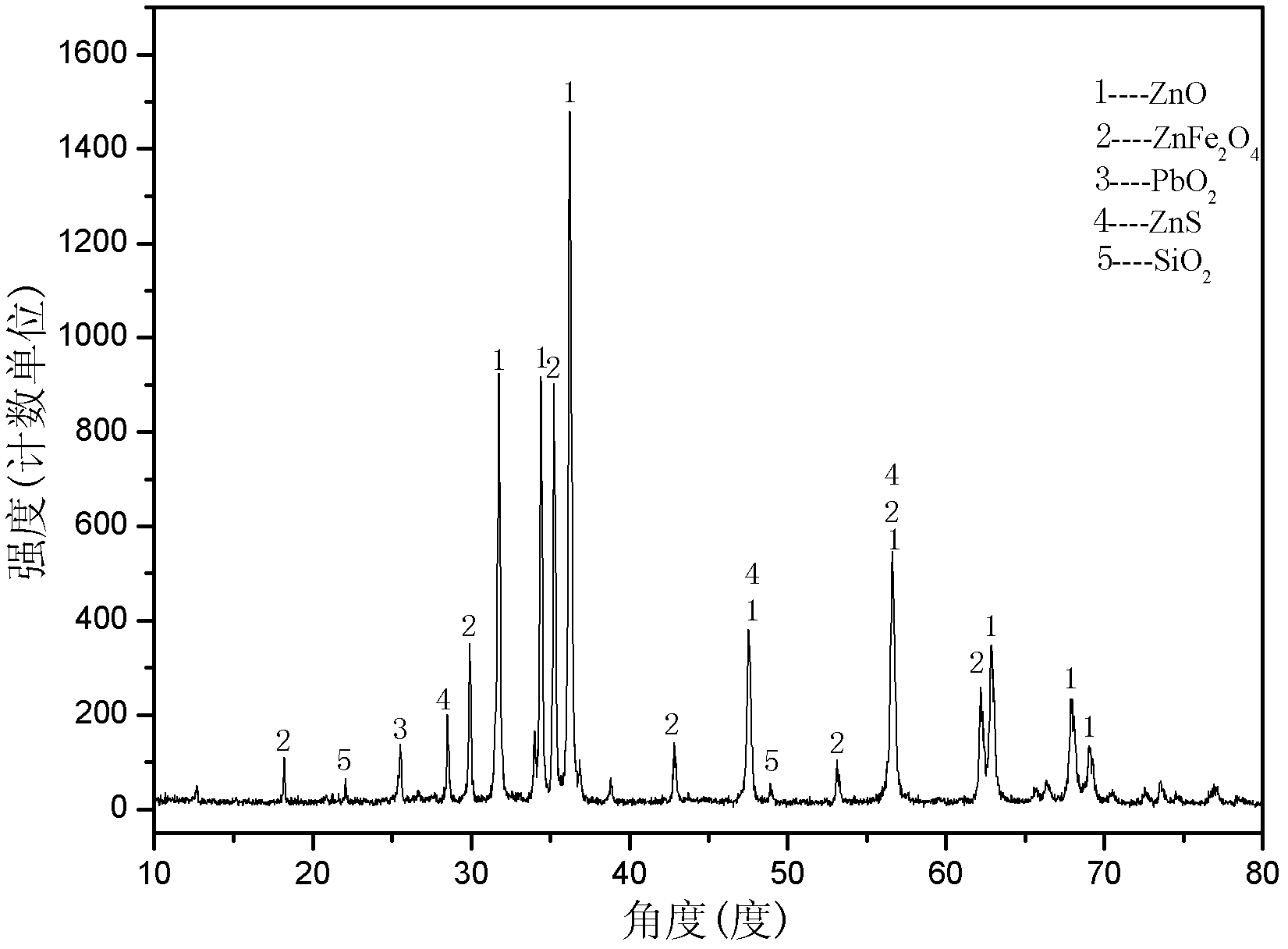

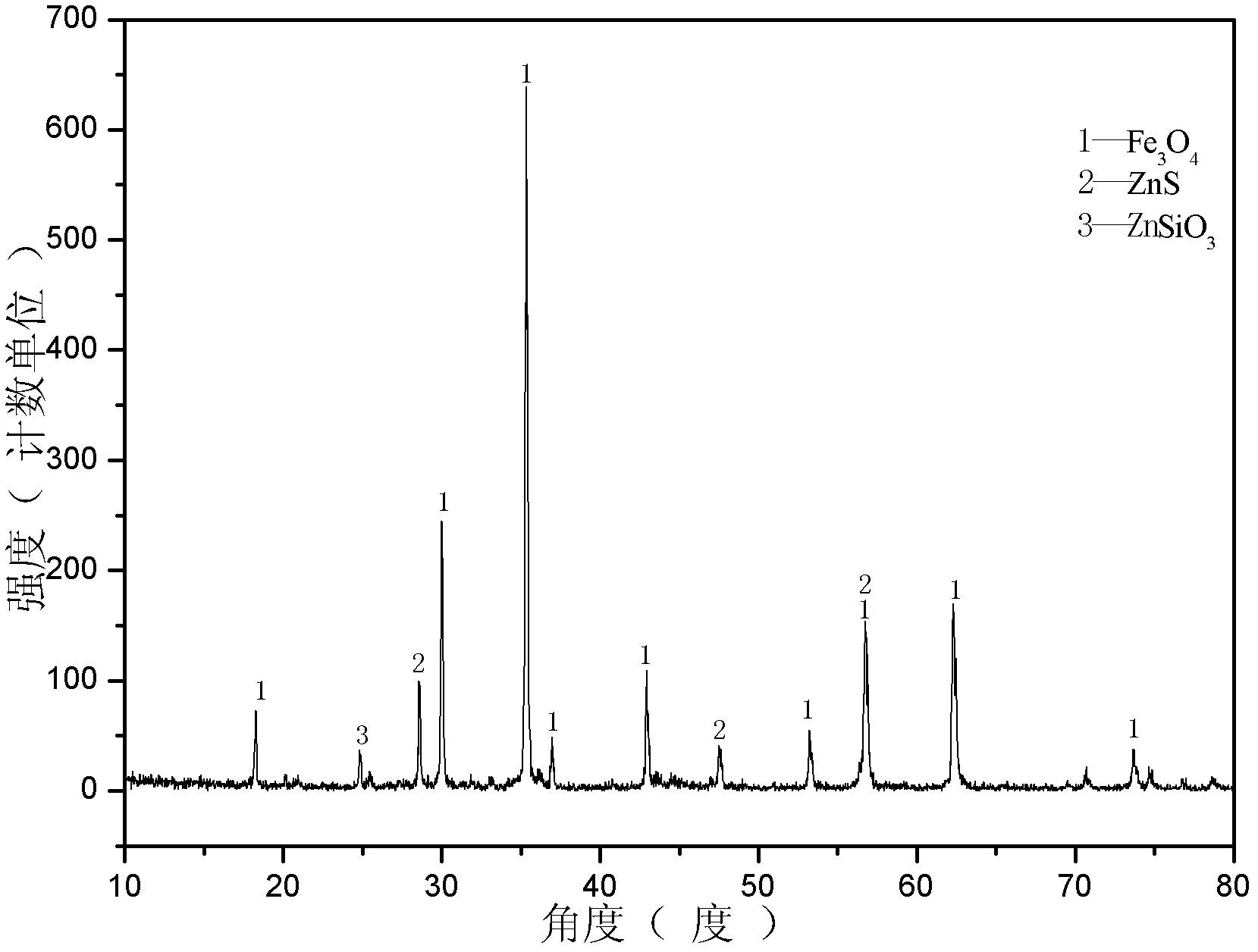

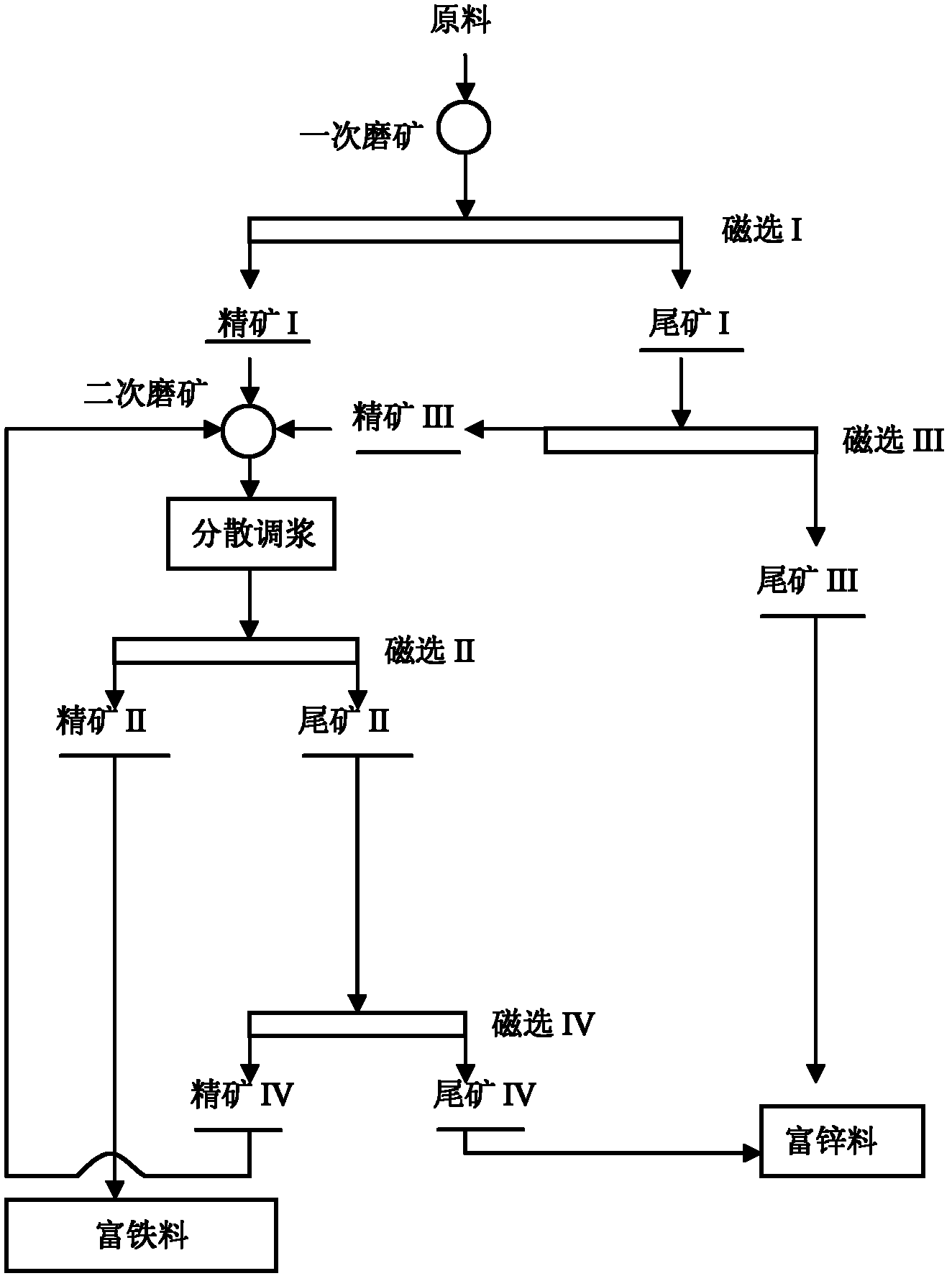

Method for recycling iron in multilevel magnetic separation mode from zinc hydrometallurgy process

ActiveCN102614979ARaise the gradeAvoid enteringMagnetic separationGrain treatmentsSlurryHydrometallurgy

The invention discloses a method for recycling iron in multilevel magnetic separation mode from a zinc hydrometallurgy process. Reduction roasting products of high iron and zinc calcine are chosen as raw materials, raw material slurry once ball milled is treated by primary magnetic separation through a magnetic field of moderate strength, and then obtained concentrate is secondary ball milled and dispersed to perform fine separation through a weak magnetic field to achieve iron enrichment ore concentrate. Primarily-separated and finely-separated tailings are magnetically separated through a strong magnetic field to obtain zinc enrichment tailings, and concentrate magnetically separated by the strong magnetic field returns to the steps of secondary ball milling, dispersing and weak magnetic separation to be separated again. The method can adjust strength of different magnetic fields according to different magnetic separation processes, reduces magnetic mixing and non-magnetic mixing in a fine separation process and greatly improves selectivity. Simultaneously, processes of ball milling and dispersing are added, thereby avoiding magnetic flocculation in a traditional single-level magnetic separation process and improving separation efficiency. The problems that a traditional zinc hydrometallurgy process is difficult in iron and zinc separation, large in environmental pollution, seriously waste in zinc and iron elements and the like are effectively resolved.

Owner:CENT SOUTH UNIV

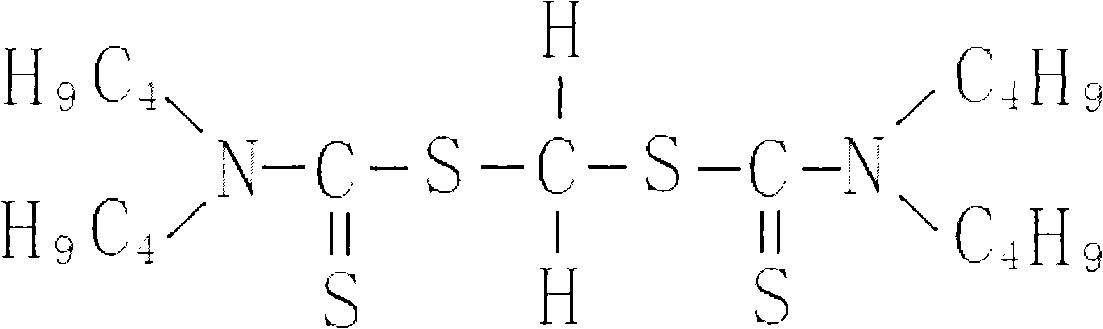

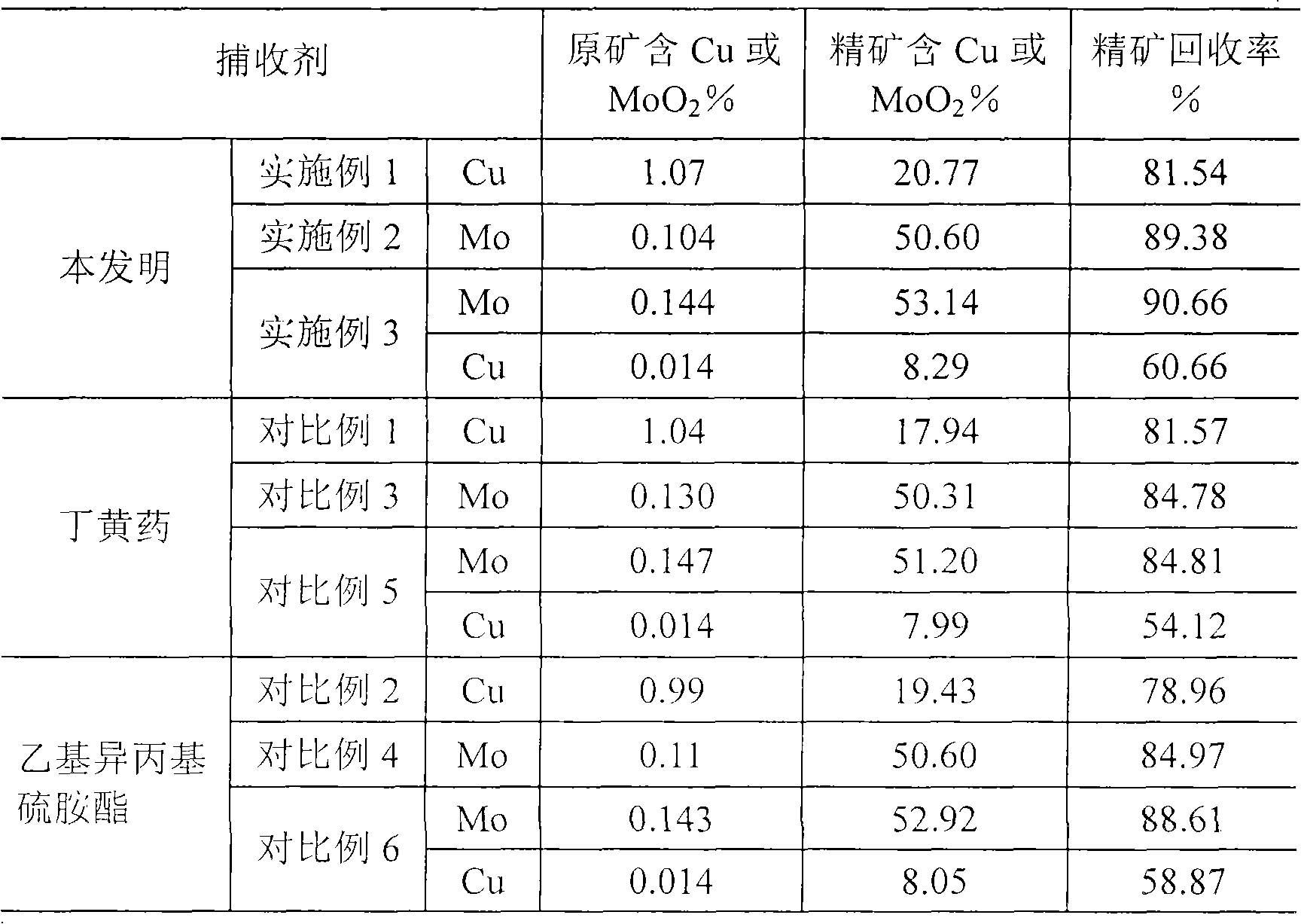

Application of methylne bis (bitutyl dithio carbamate)

The invention relates to application of methylne bis (bitutyl dithio carbamate) in flotation of copper-molybdenum ore and is characterized in that a use method is as follows: smashing and levigating sulfide ore containing copper and / or molybdenum; adding water until the solid content in ore slurry reaches 30-35%; adding 300-500 g / ton raw ore of activating agent sodium sulfide, 1000-1800g / ton raw ore of inhibitor sodium silicate and 10-20g / ton raw ore of collector methylne bis (bitutyl dithio carbamate); and carrying out primary roughing, three times of scavenging and three times of selections, and obtaining copper concentrate. Compared with the existing collector, the collector methylne bis (bitutyl dithio carbamate) provided by the invention does not block a pipeline, is convenient for operation, is used for achieving the flotation of copper-molybdenum sulfide ore in an alkaline medium, and is strong in adaptability; use amount of the collector is less, and production cost is low, so the collector methylne bis (bitutyl dithio carbamate) is beneficial to popularization and application in a dressing plant; and the metal recovery rate of the copper-molybdenum sulfide ore in the process of copper-molybdenum sulfide ore flotation is improved by using the collector in the invention.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

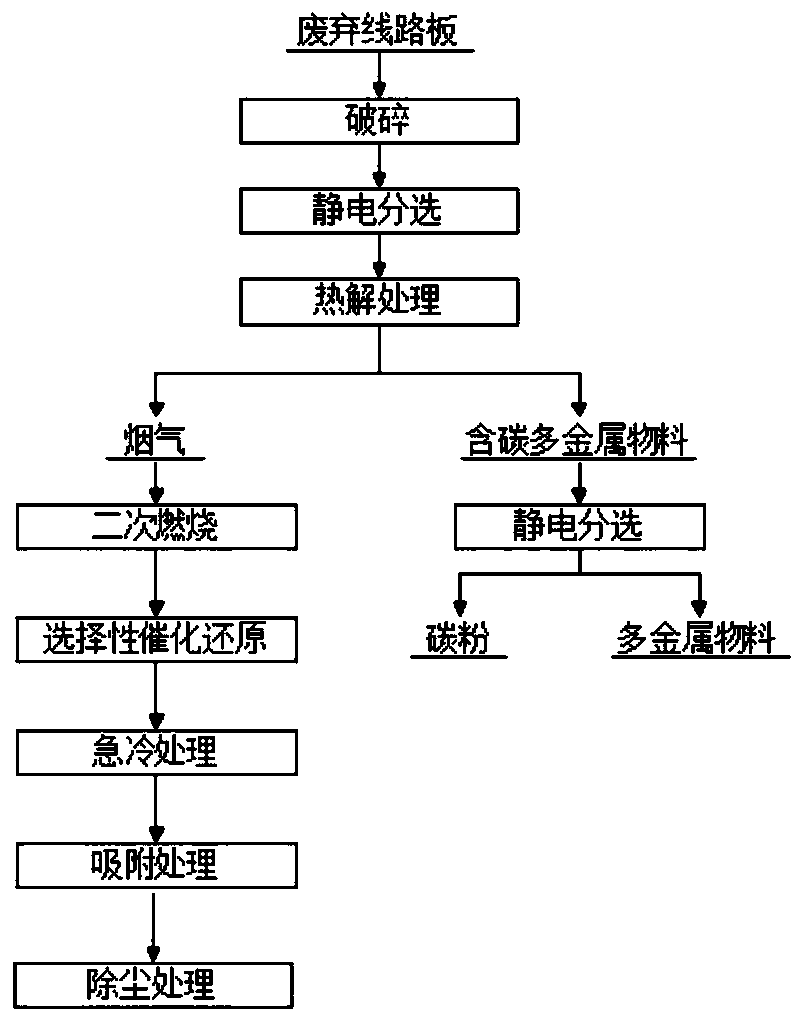

Treatment method for waste circuit board pyrolysis recovery

InactiveCN107866437AReduce productionReduce processing costsSolid waste disposalTransportation and packagingReduction treatmentCombustion

The invention discloses a treatment method for waste circuit board pyrolysis recovery. The method comprises the following steps that waste circuit boards are subjected to crushing, electrostatic separation and pyrolysis treatment to obtain flue gas and carbon-containing multi-metal materials, the carbon-containing multi-metal materials are subjected to electrostatic separation to obtain carbon powder and multi-metal materials, and the flue gas is subjected to secondary combustion, selective catalytic reduction treatment, quenching treatment, adsorption treatment and dust removal treatment to obtain the flue gas superior to the emission standard. By means of the treatment method, metal and non-metal substances in the waste circuit boards can be effectively separated, industrial continuous treatment of the waste circuit boards and recycling of resources are achieved, and the metal recovery rate reaches nearly 99.9%; besides, dioxin can be effectively prevented from being generated, and the dioxin removal efficiency is higher than 99.9%.

Owner:CENT SOUTH UNIV

Method for producing electrolysis nickel from nickel-cobalt concentrate of laterite

InactiveCN101565837AWide applicabilityHigh metal recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisDecomposition

The invention relates to a method for producing electrolysis nickel from nickel-cobalt concentrate of laterite, and relates to a production method of electrolysis nickel, particularly a method for producing the electrolysis nickel by utilizing the laterite. The method is characterized by comprising the following steps of: carrying out drying and dehydration on the nickel-cobalt concentrate of the laterite, adding coke and quartz, mixing materials, producing pellet material, pre-treating at the temperature of 300 to 1000 DEG C, carrying out high-temperature treatment at the temperature of 1000 to 1600 DEG C, separating slag phase, producing electrolysis anode and producing the electrolysis nickel by electrolysis. The method utilizes the nickel-cobalt concentrate produced in the smelting processing of nickel laterite and adopts the technique of drying, pretreatment, high-temperature decomposition and electrolysis to produce the electrolysis nickel, and has the advantages of high metal recovery rate and simple process; simultaneously the process is also applicable to processing nickel-cobalt sulphide and nickel-cobalt waste; and the method has the characteristics of wider material applicability, little investment, low production cost, high nickel-cobalt recovery rate, little environmental pollution and the like.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Step recycling method for metallic aluminum in aluminum ash

ActiveCN108325738AHigh metal recovery rateHigh recovery rateSolid separationProcess efficiency improvementBall millMetal recycling

The invention discloses a step recycling method for metallic aluminum in aluminum ash. The step recycling method includes steps of 1), sieving the aluminum ash to obtain oversize aluminum ash and undersize aluminum ash; 2), smashing the oversize aluminum ash obtained at the step 1), and then sieving the oversize aluminum ash to obtain metallic aluminum particles and undersize aluminum ash; 3), carrying out wet ball-milling on the undersize aluminum ash obtained at the steps 1) and 2) to obtain ball-milled slurry; 4), carrying out wet classification on the ball-milled slurry to obtain large-particle metallic aluminum sheets and fine-particle slurry; 5), sorting the fine-particle slurry to obtain fine-particle metallic aluminum powder and tailings; 6), dehydrating the tailings to obtain filter liquor and filter residues; 7), carrying out circulation enrichment the filter liquor and then evaporating the filter liquor to recycle industrial salt; 8), mounting ammonia gas collecting and absorbing devices above all materials exposed in the air in aluminum ash treatment procedures. The step recycling method has the advantages that step recycling is carried out on the metallic aluminum, accordingly, the metal recycling rate can be greatly increased, the purity of products can be greatly improved, and a novel way can be developed for harmlessly utilizing the aluminum ash as a resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

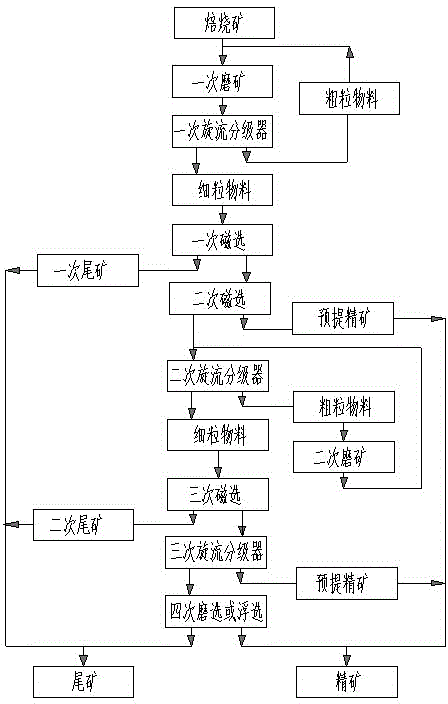

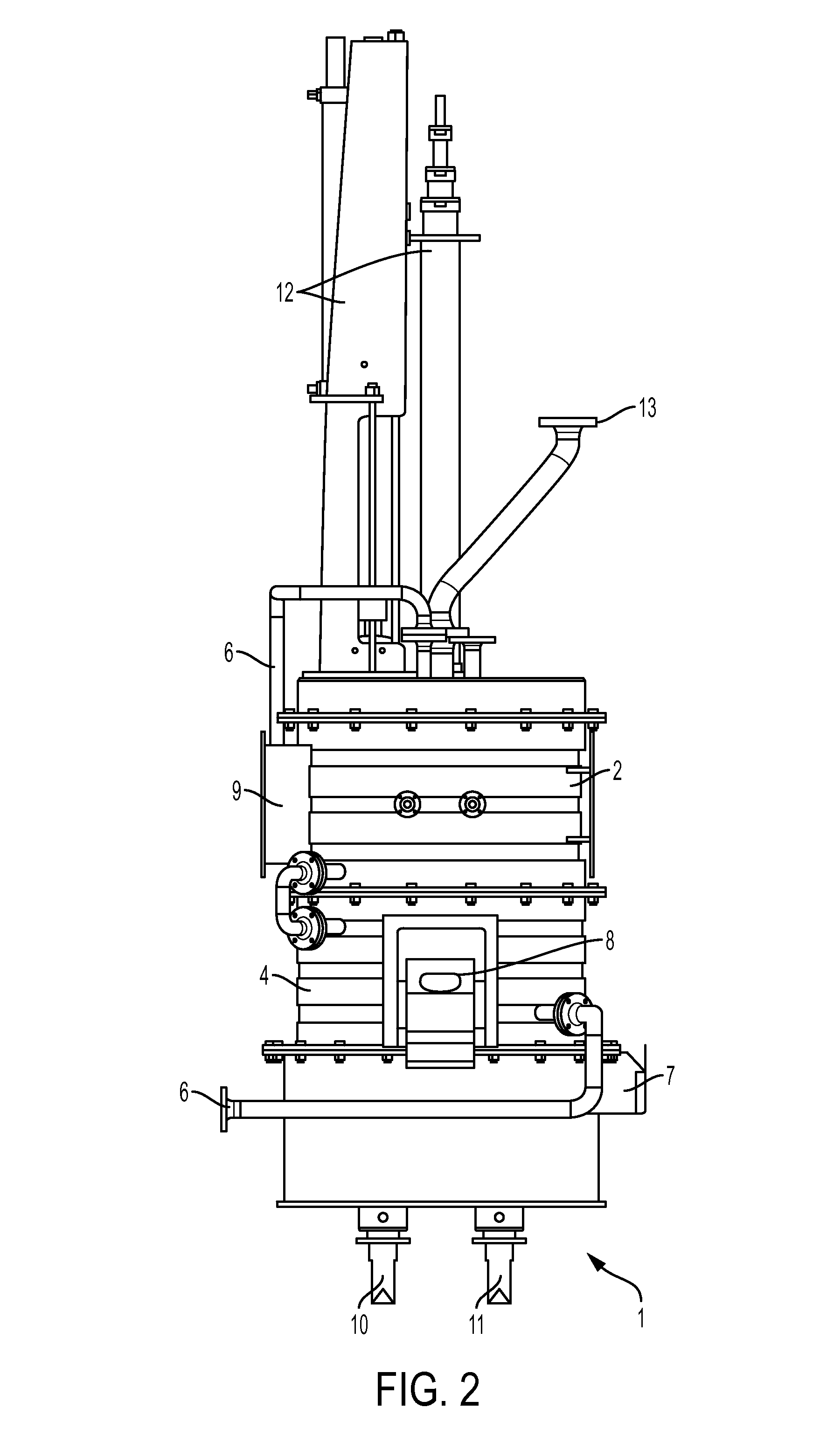

Mineral separation method for pre-extraction of concentrates from roasted iron ore

The invention relates to the technical field of metallurgy and mineral engineering and discloses a mineral separation method for pre-extraction of concentrates from roasted iron ore. According to the method, roasted ore which is uniform in size distribution and formed after magnetizing roasting of refractory low-grade iron ore with the insetting grain size of 15-120 mu m is taken as a raw material; the method comprises process steps of primary ore grinding of the roasted ore, magnetic separation of primary ore ground materials, primary ore concentrate pre-extraction of rough concentrate with a large grain size, three stages of magnetic separation of materials with fine grain sizes, secondary ore concentrate pre-extraction of rough ore concentrate with medium grain sizes and the like. The method of fractionated ore grinding and fractionated magnetic separation is adopted due to the fact that different insetting grain sizes of the roasted ore correspond to different ore grinding sizes; iron ore concentrate is extracted in a fractionated manner according to difference of grain sizes, the over-grinding phenomenon of coarse-grain iron ore is effectively prevented, the separation efficiency and the metal recovery efficiency are improved, the over-grinding phenomenon of the iron ore with larger grain sizes in the roasted ore is effectively prevented, the production cost is reduced, and the ore separation efficiency is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

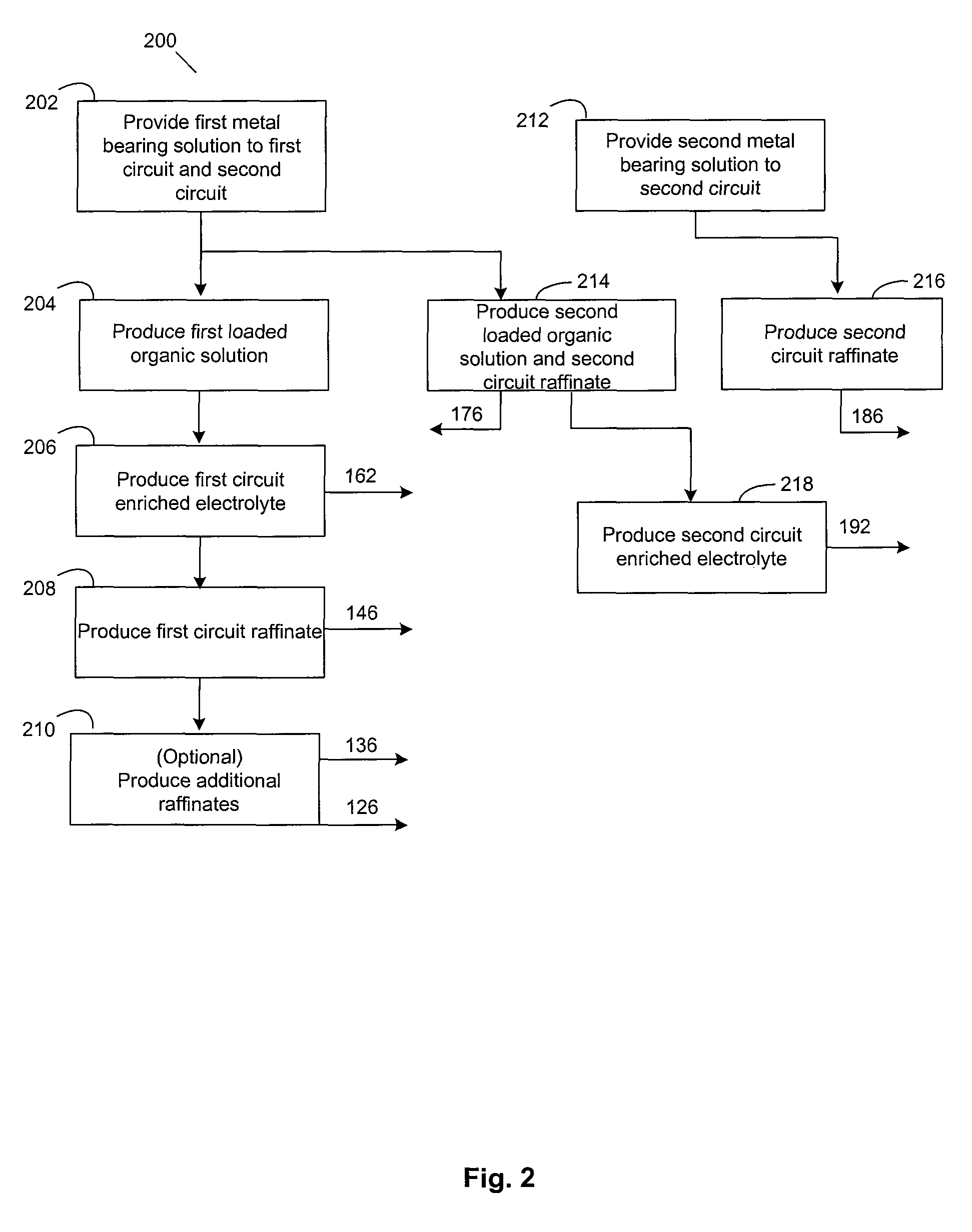

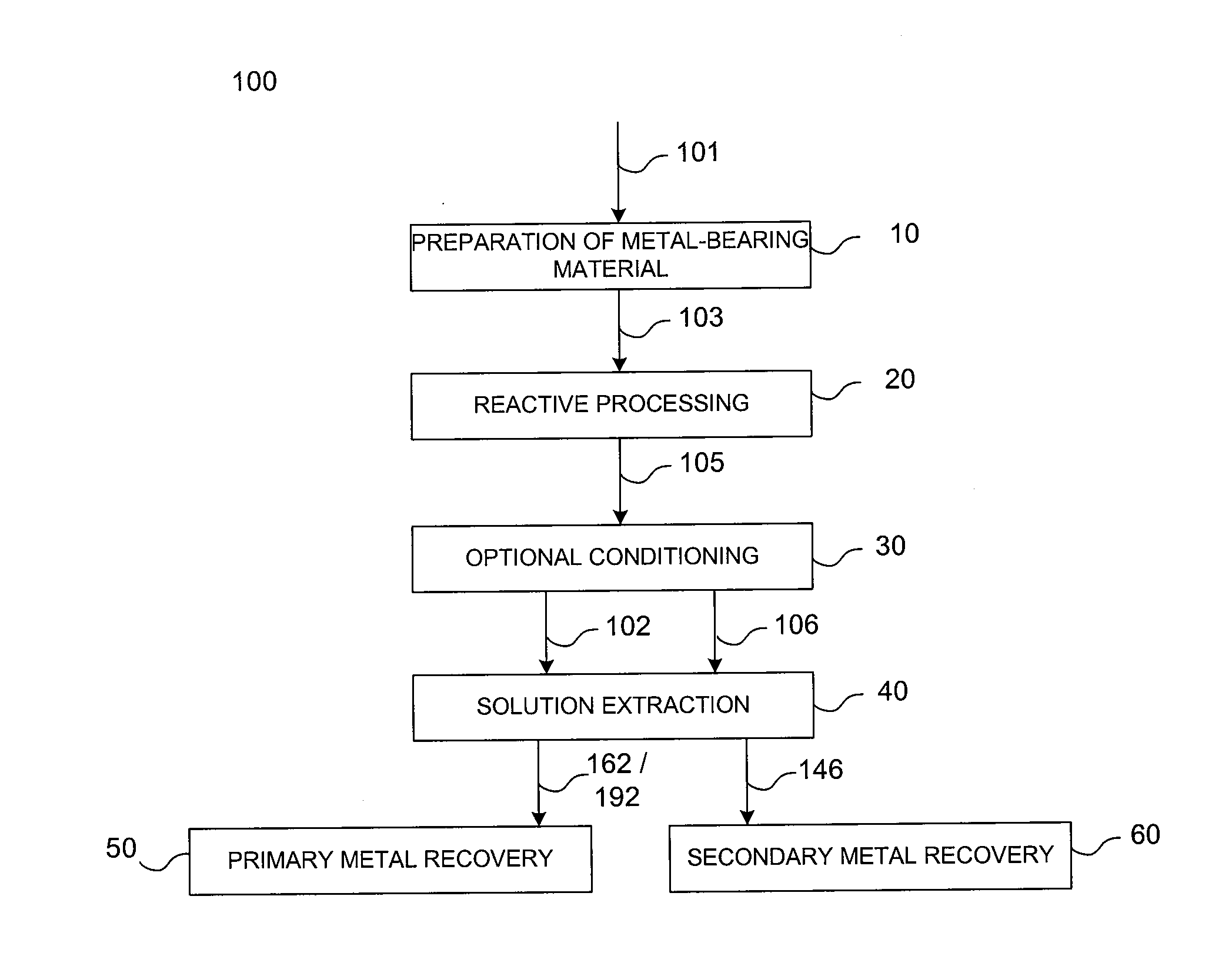

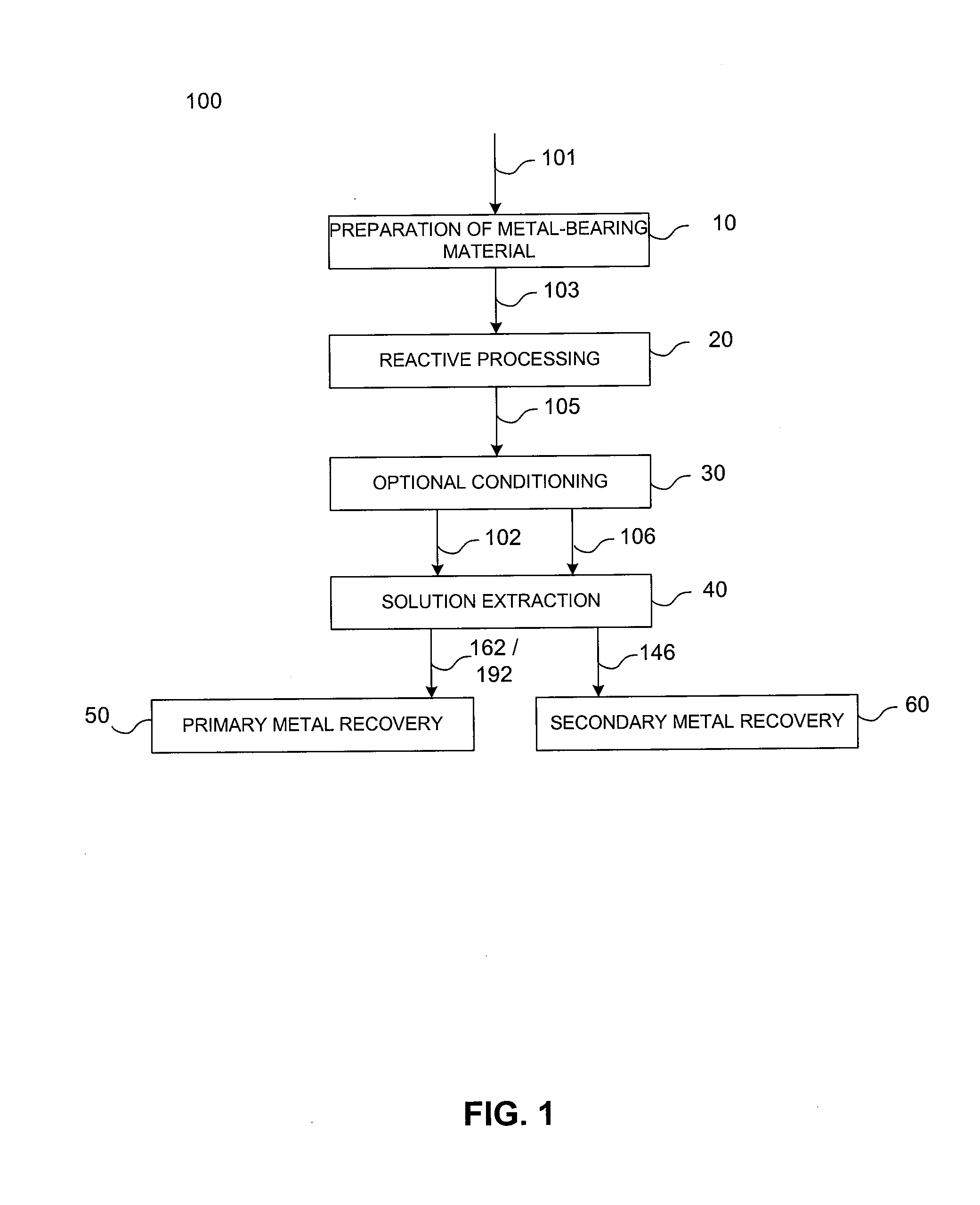

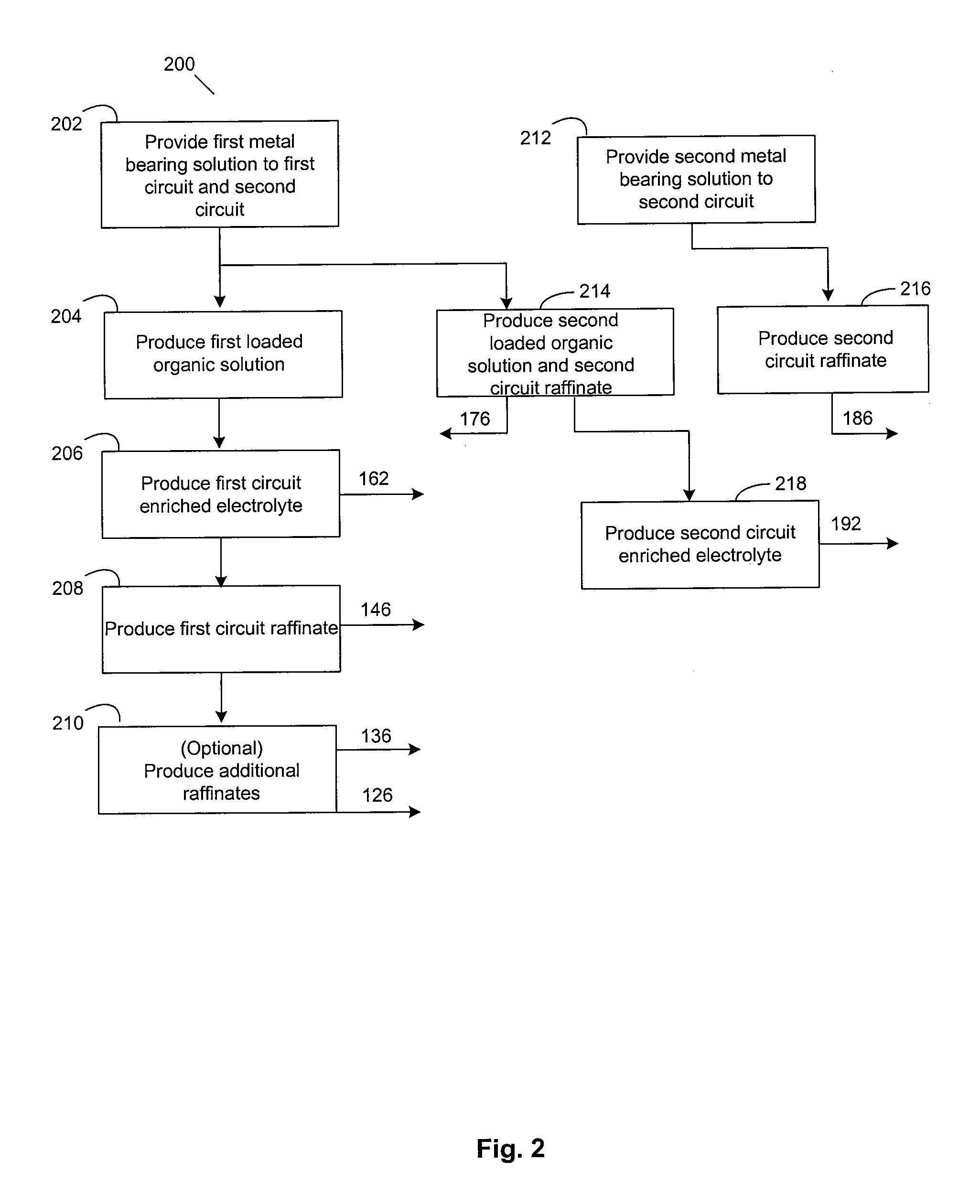

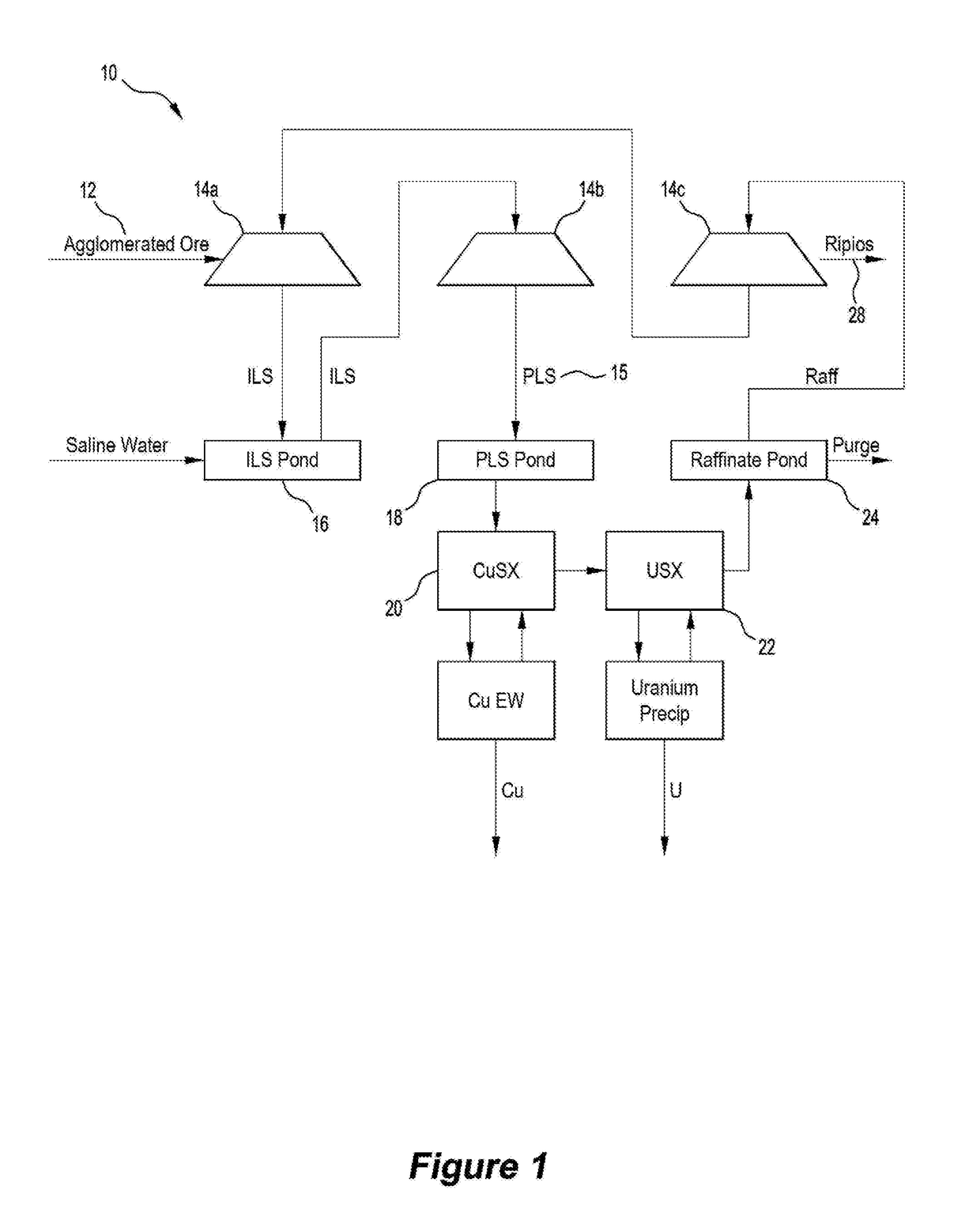

System and method including multi-circuit solution extraction for recovery of metal values from metal-bearing materials

ActiveUS9169533B2High metal recovery rateIncrease profitLiquid solutions solvent extractionProcess efficiency improvementPregnant leach solutionLower grade

Owner:FREEPORT MCMORAN COPPER & GOLD INC

System and method including multi-circuit solution extraction for recovery of metal values from metal-bearing materials

ActiveUS20130152741A1High metal recovery rateIncrease profitCellsSolvent extractionPregnant leach solutionMetallic materials

The present disclosure relates to a metal recovery process comprising a solvent extraction process. In an exemplary embodiment, the solution extraction system comprises a plant with a first and second circuit. A high-grade pregnant leach solution (“HGPLS”) is provided to the first and second circuit, and a low-grade pregnant leach solution (“LGPLS”) is provided to the second circuit. The first circuit produces a rich electrolyte, which can be forwarded to a primary metal recovery, and a low-grade raffinate, which can be forwarded to a secondary metal recovery process. The second circuit produces a rich electrolyte, which can also be forwarded to the primary metal recovery process. The first and second circuits are in fluid communication with each other.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

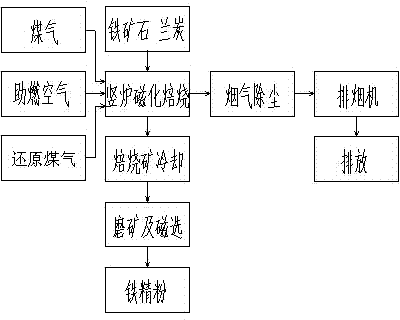

Refractory low-grade iron ore shaft furnace semi-coke added magnetizing roast process

ActiveCN104745806AHigh metal recovery rateIncrease the concentration of reducing mediumLow gradedMagnetic separation

The invention relates to the technical fields of metallurgy and mineral engineering and discloses a refractory low-grade iron ore shaft furnace coal-based magnetizing roast process. The process disclosed by the invention comprises the following steps: dosing iron ore with the granularity of 15-50mm and semi-coke with the granularity of 15-30mm according to a ratio of 100:(2-5), uniformly mixing, and adding the mixture from the top of the shaft furnace; and allowing the mixed material flow to pass through a preheating zone of the shaft furnace and enter a heating zone, allowing one part of the semi-coke to participate in combustion in the shaft furnace, and allowing the mixed materials comprising the iron ore of which the temperature rises to 900-950 DEG C and the residual semi-coke to enter a reducing zone. At the reducing zone of the shaft furnace, reducing gas is introduced from the bottom of the furnace chamber, H2 and CO in the gas participate in iron ore reduction so as to generate water vapor and CO2, the water vapor and CO2 are contacted with the semi-coke to carry out a carbon gasification reaction in the iron ore in the rising process in the furnace chamber so as to produce H2 and CO, the reducing medium concentration in the shaft furnace is improved, and the amount of the reducing gas is reduced, so that the iron ore is fully reduced. After the iron ore is completely roasted at the reducing zone of the shaft furnace, fine iron ore concentrate with the iron grade of 56-60 percent is obtained by virtue of oxygen-free cooling, ore grinding and magnetic separation.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

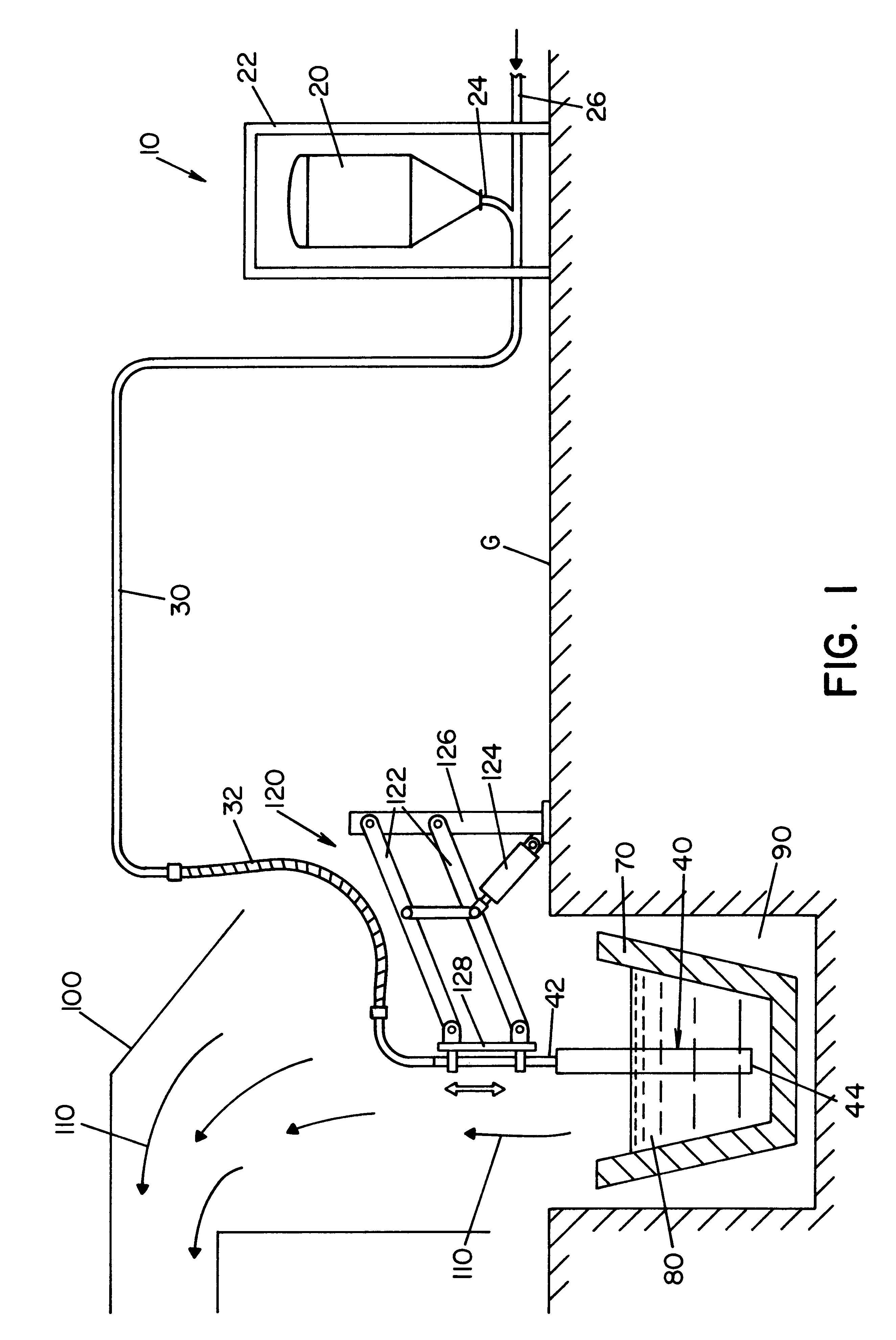

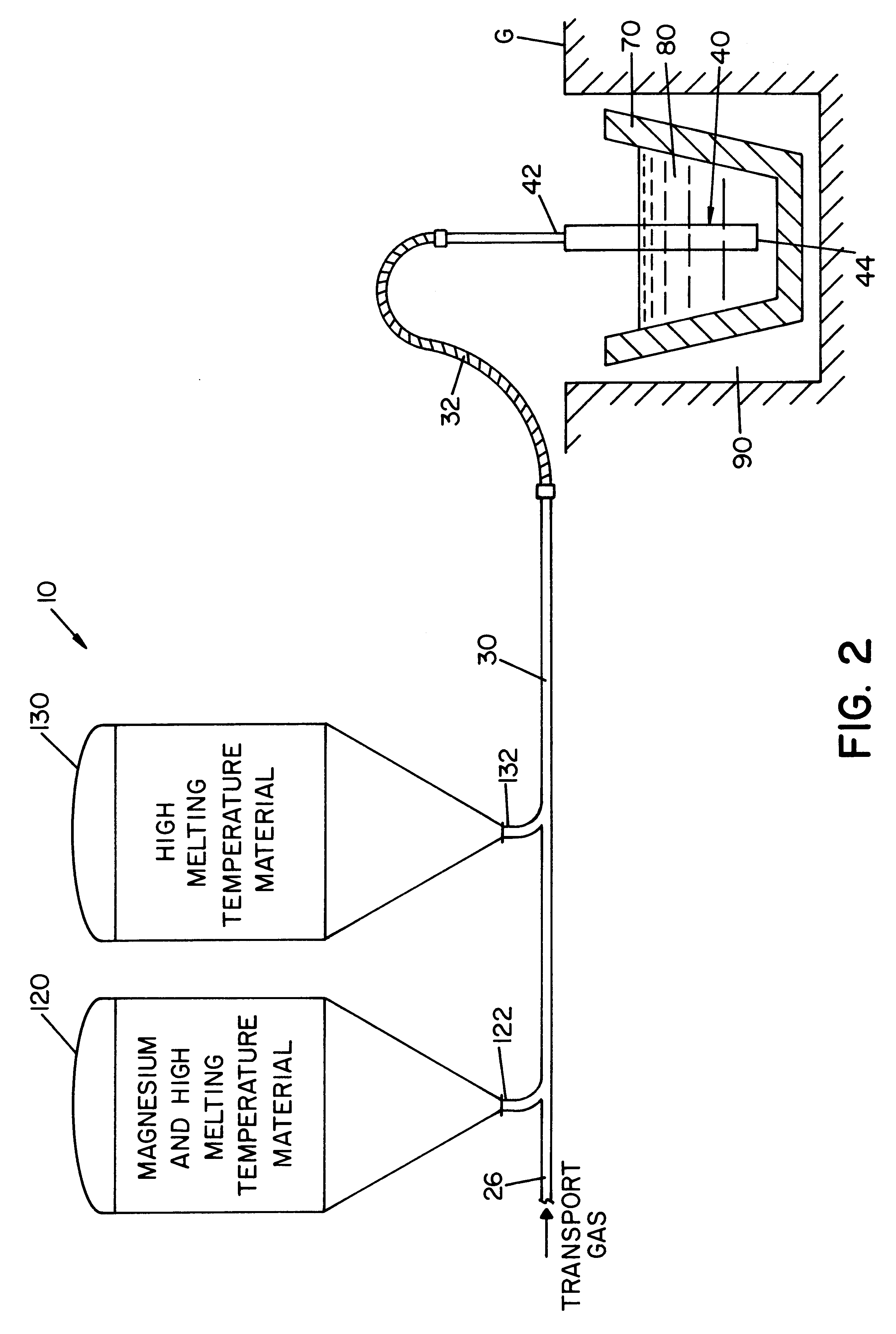

Magnesium injection agent for ferrous metal

InactiveUS6372014B1Improves amount of alloyingSimple processBlast furnace componentsBlast furnace detailsMelting temperatureMetal

Owner:MAGNESIUM TECH CORP

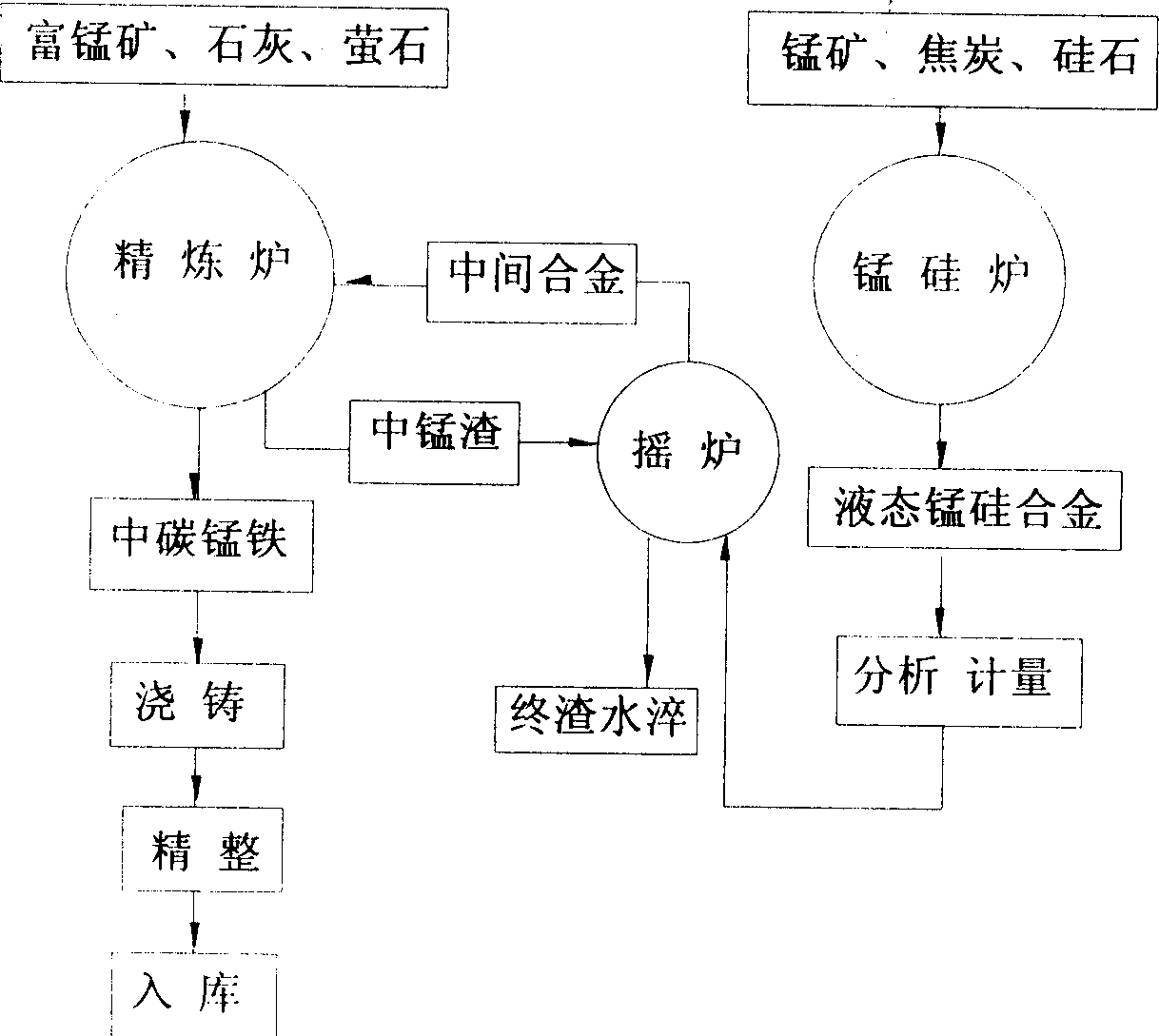

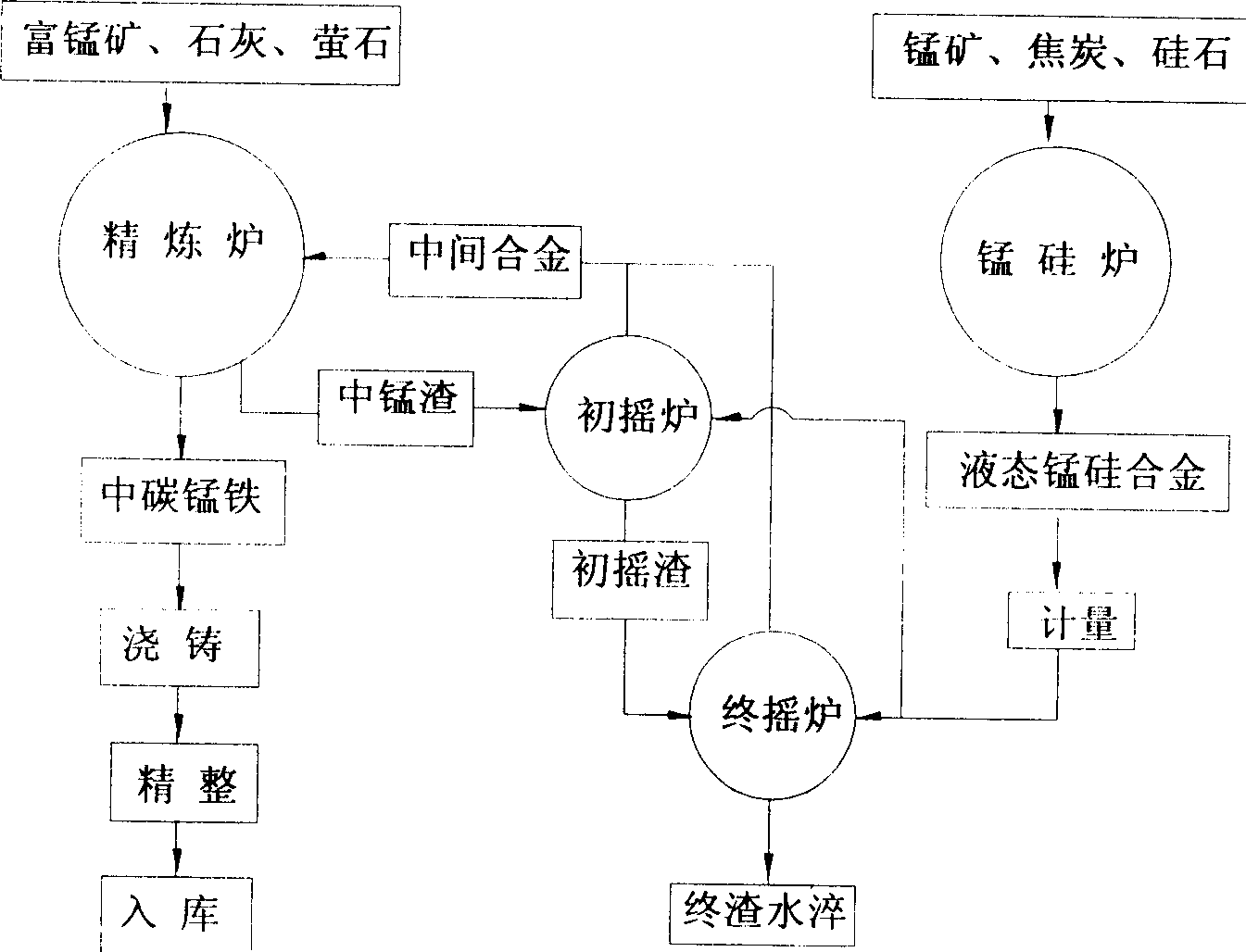

Producing medium carbon magnganese iron by duplexing rocking furnace method

The invention relates to a duplex rocking furnace method used to produce carbon ferromanganese. It includes the following steps: leading manganese slag thermal fluid to start rocking furnace; adding 1 / 2 liquid state manganese-silicon by weight; swing; leading the formed start rocking slag into final rocking furnace; adding the rest 1 / 2 liquid stage manganese-silicon; rocking; the fining procedure is as follows: adding rich manganese ore with not less than 40% manganese content; charging quantity is the 3 / 4 of the proportioning by weight; adding liquid state middle alloy into fining furnace; adding the rest 1 / 4 rich manganese ore; their ratio by weight is 1.1-0.85:1. The invention adopts four furnaces linkage to increase manganese recovery rate. Compared with fining carbon ferromanganese by single rocking furnace method, it can reduce 2-4 percent of final slag manganese containing, and reach under 7% to further increase manganese recovery rate.

Owner:云南文山斗南锰业股份有限公司

Continuous Ore Process and Apparatus Using Plasma

InactiveUS20160186291A1Prevent escapeSpeed up coolingCharge manipulationHeat treatment process controlReagentMaterials science

A method of processing ore using a plasma arc reactor includes the steps of first determining the content of the ore, modeling the plasma arc reaction for different stoichiometric ratios of ore to candidate reagents, selecting one or more of candidate reagents pre-mixing the selected reagents with the ore at corresponding stoichiometric ratios, and continuously feeding the pre-mixed ore into a plasma arc reactor, and controlling the plasma arc reaction according to the previously modeled conditions.

Owner:MILLS MICHAEL J +1

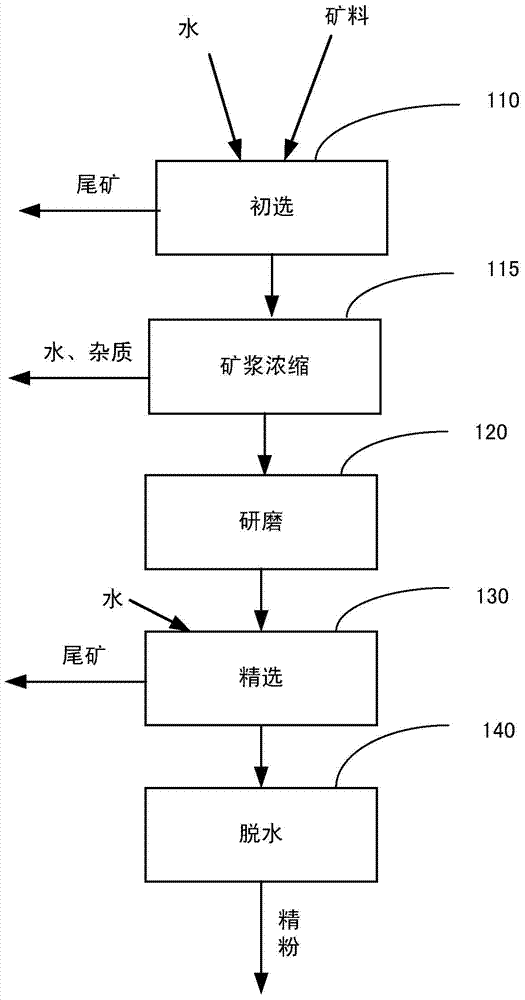

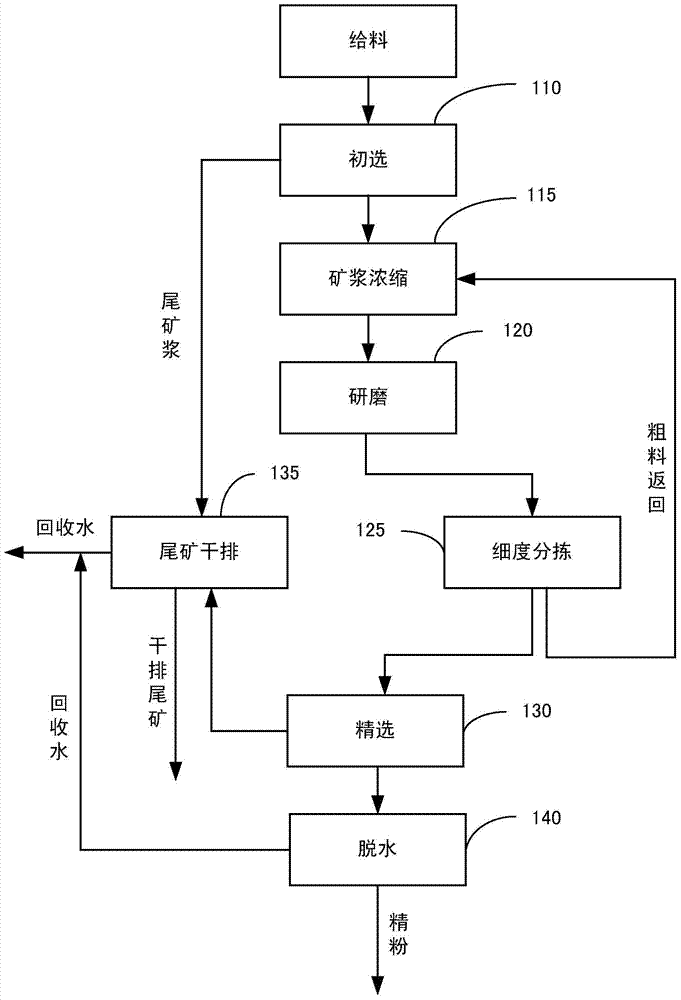

Tailings resource recovery technology

ActiveCN104841550AReduce energy consumptionHigh metal recovery rateSolid separationMechanical material recoveryEngineeringResource recovery

The invention discloses a tailings recovery technology. The tailings recovery technology includes feeding ore pulp into a concentrating cylinder of a concentrating machine; driving the concentrating cylinder to rotate around own central axis to enable the ore pulp to stir and tumble in an inner chamber of the concentrating cylinder incessantly while the ore pulp flows; applying a magnetic field on the ore pulp by a magnetic field generator, and subjecting the ore pulp to precise separation by a separator to enable separated ores in the ore pulp to be attached to the inner wall of the concentrating cylinder to move upwards during ascent and descent under the action of the magnetic field so as to arrive at an ore discharging area; in the discharging area, enabling the separated ores to fall into a receiving groove of the concentrating machine and enabling other substances, except for the separated ores, in the ore pulp to enter a tailings trough of the concentrating machine from the bottom of the inner chamber of the concentrating cylinder and then enter a tailings conveying system.

Owner:西安特瑞钒环保科技有限公司

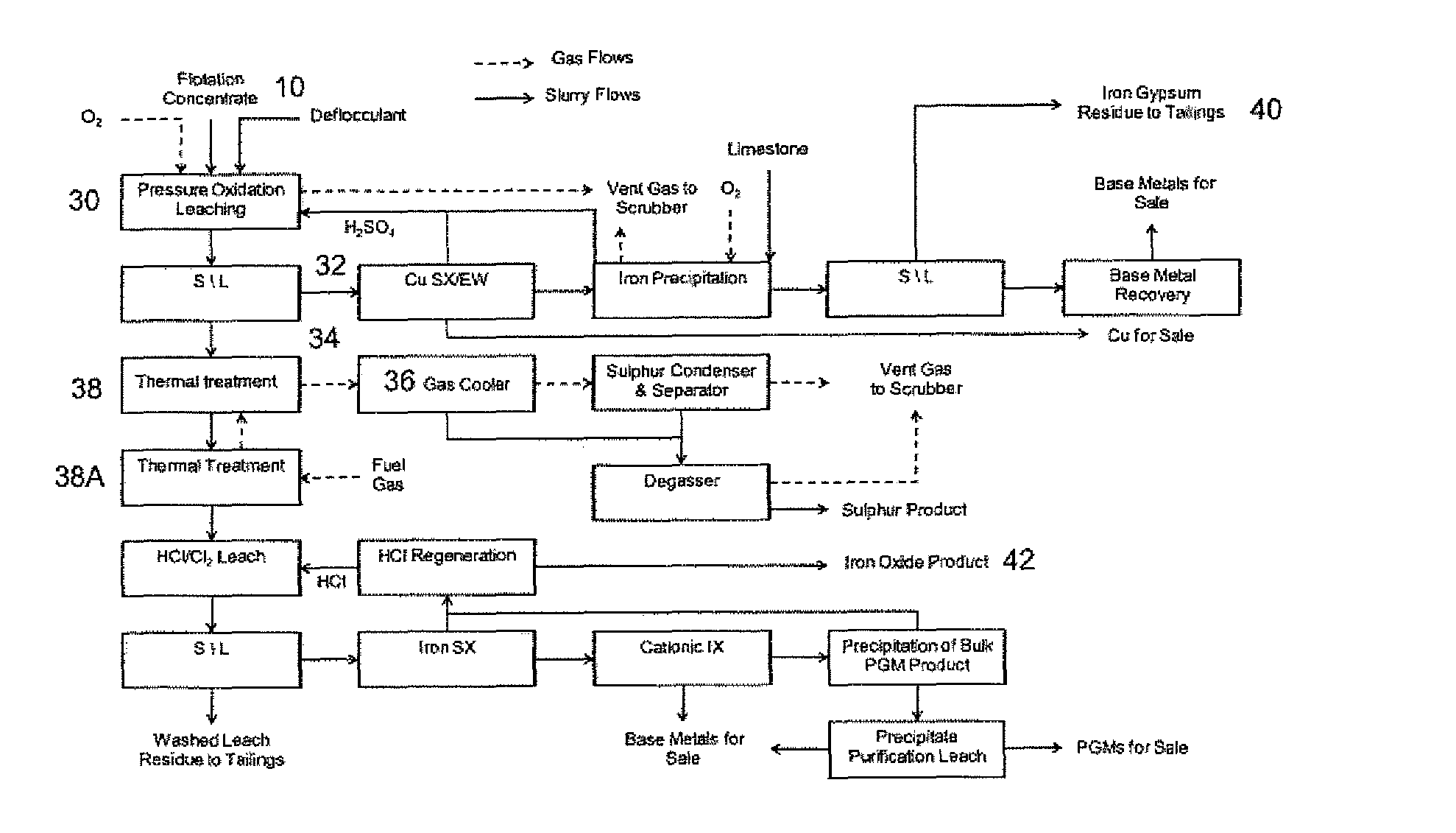

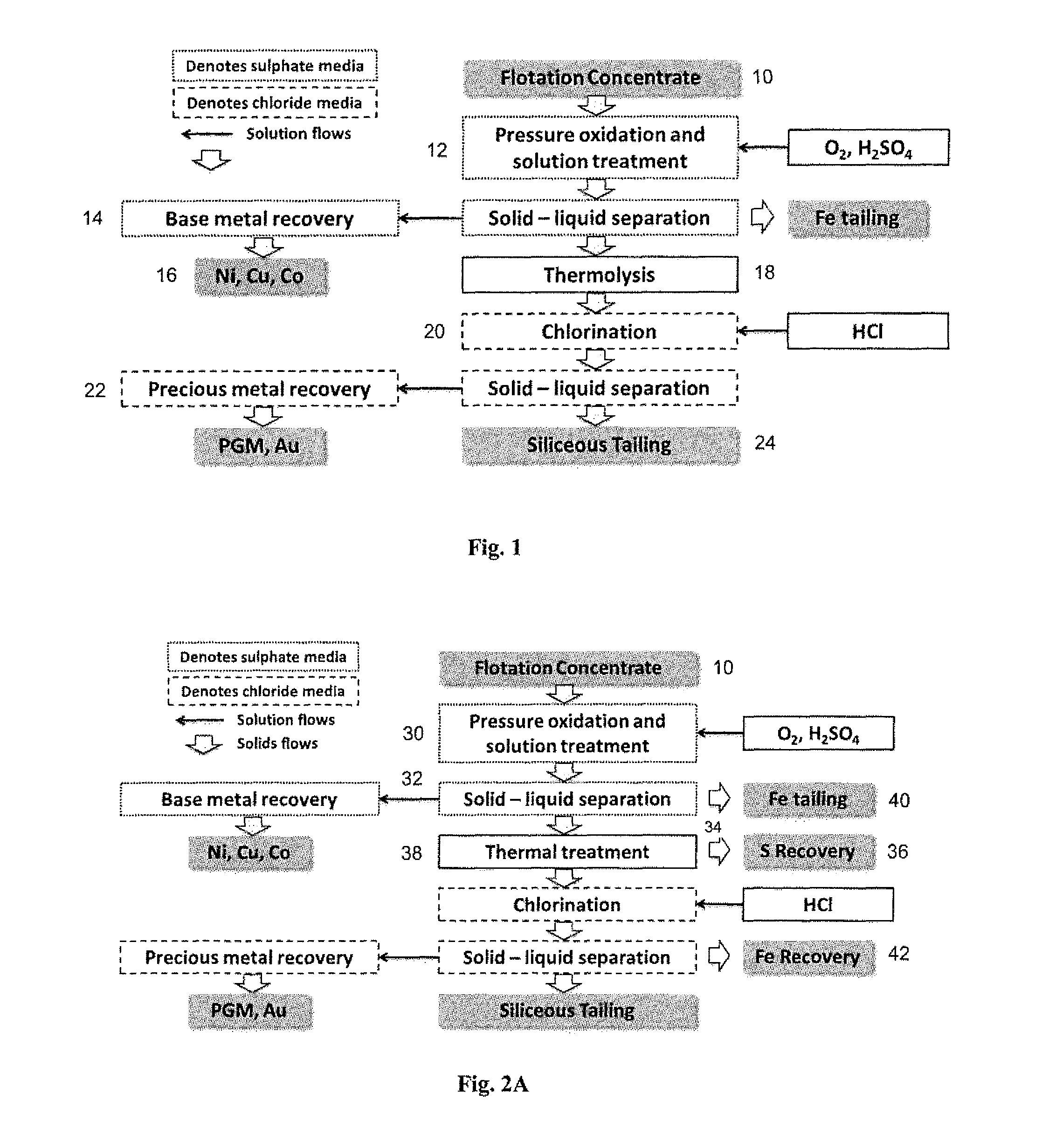

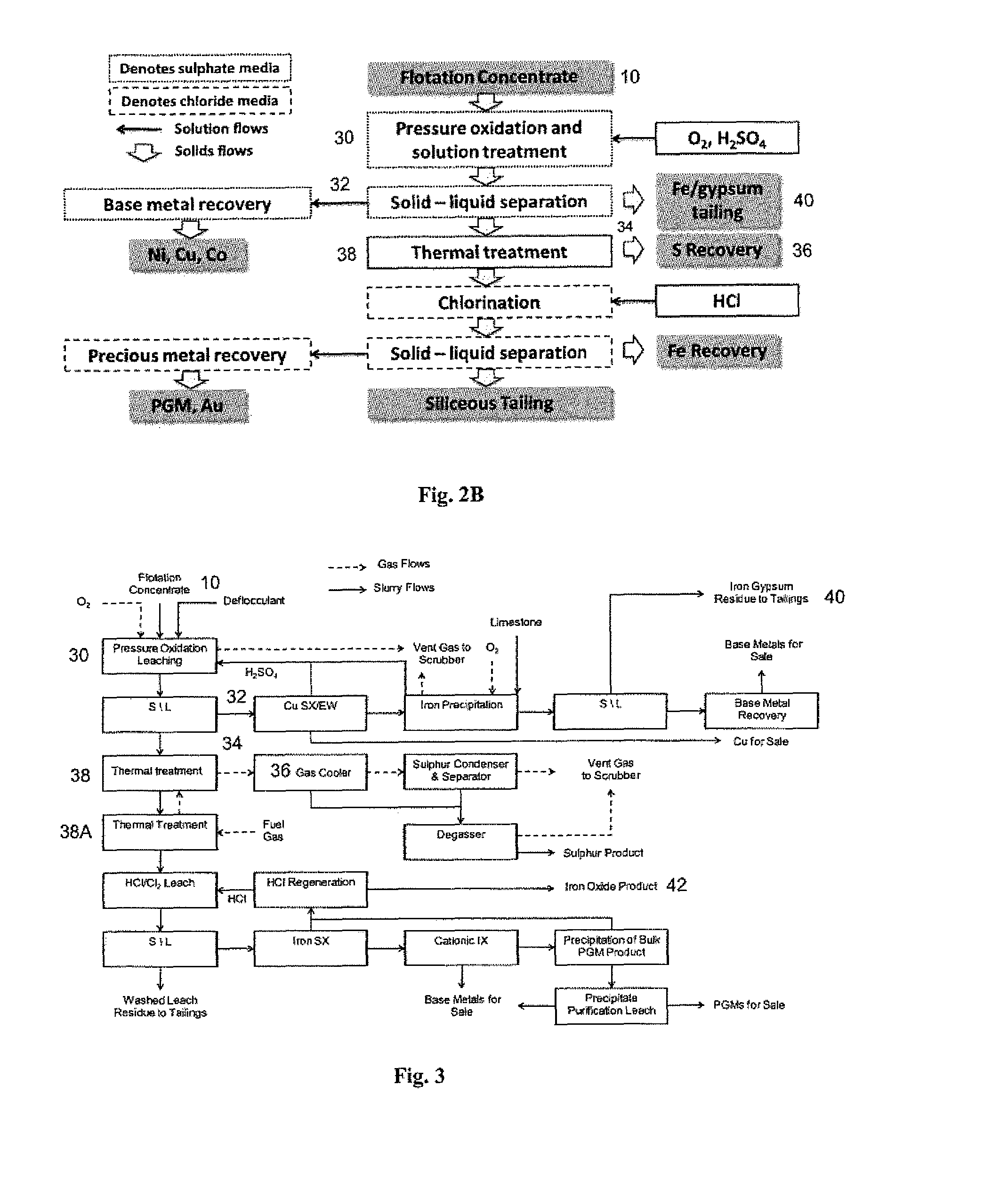

Hydrometallurgical treatment process for extraction of metals from concentrates

ActiveUS9540706B2Minimize consumptionQuality improvementRecovering materialsHydrometallurgySulfide minerals

Owner:LIFEZONE

Method for recycling cobalt nickel from tungsten waste recycling slag

The invention discloses a method for recycling cobalt nickel from tungsten waste recycling slag. The method comprises the steps that firstly, the tungsten waste recycling slag and water mixed to be subjected to size mixing, and a sizing mixture is conveniently obtained; secondly, the sizing mixture is mixed with acid liquor and a reducing agent to be subjected to a reduction reaction, and liquor after reduction is conveniently obtained; and thirdly, the reduced liquor is subjected to solid and liquid separation treatment, and a solution containing cobalt nickel is conveniently obtained. The method is adopted to effectively recycle metal elements like metal cobalt nickel in the tungsten waste recycling slag, the process is simple, and the metal recycling rate is high.

Owner:XIAMEN TUNGSTEN +1

Heap Leaching Method

ActiveUS20170349972A1High solution redox potentialSolve highProcess efficiency improvementPregnant leach solutionHeap leaching

A method for recovering one or more of copper, uranium and a precious metal from an ore material, including: (a) forming a heap of the ore material; (b) during active heap irrigation, contacting the heap of the ore material with an iron containing acidic leach liquor having a high chloride content in the presence of an oxygen containing gas, and producing a pregnant leach solution; and (c) recovering one or more of copper, uranium and a precious metal from the pregnant leach solution.

Owner:BHP OLYMPIC DAM CORP PTY LTD

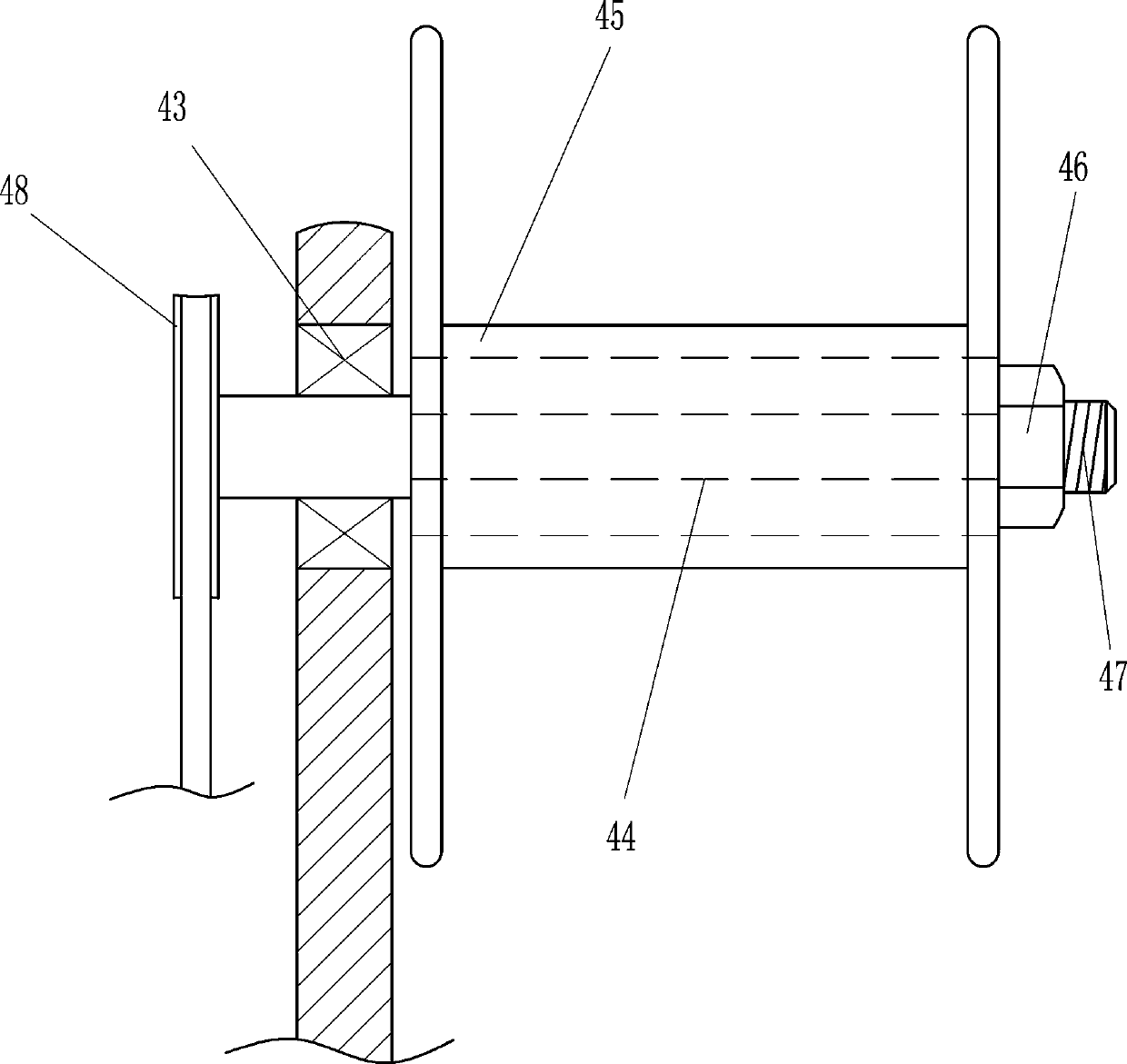

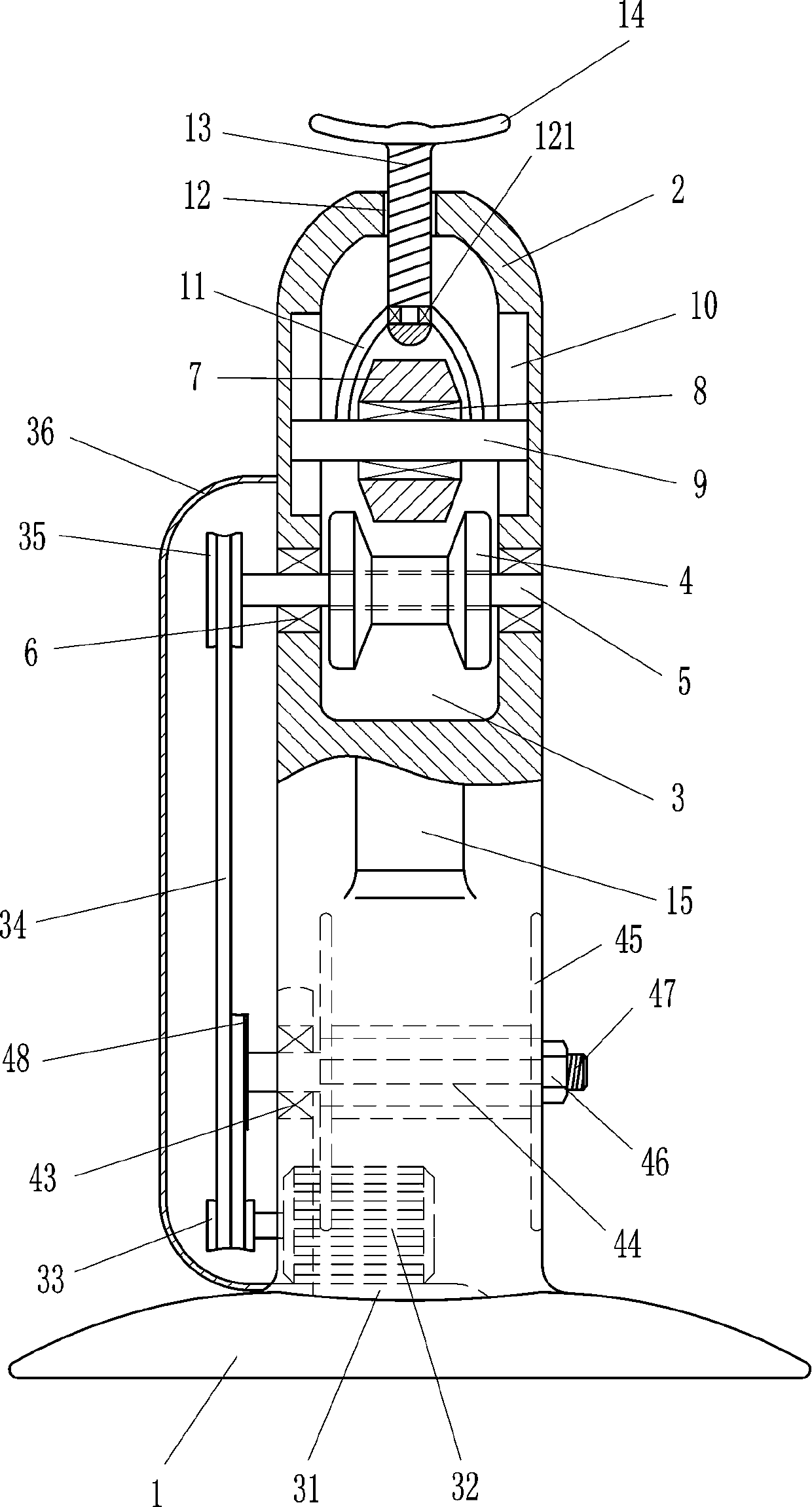

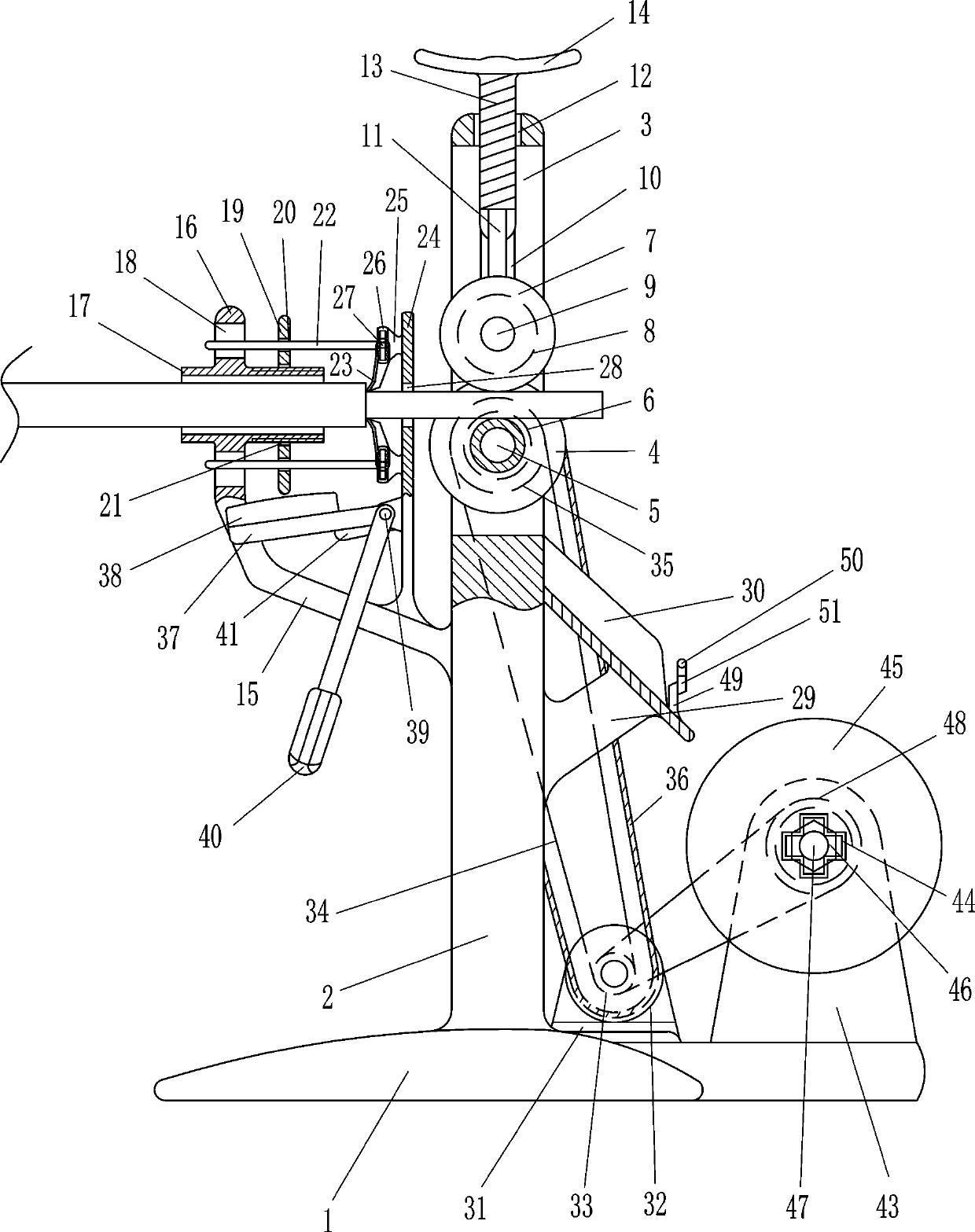

Cable core recovery device

ActiveCN110211749ASave the hassle of recyclingEasy to organizeBasic electric elementsElectronic waste recyclingElectrical and Electronics engineeringEngineering

The invention relates to a recovery device, in particular to a cable core recovery device. The invention aims to provide the cable core recovery device which is high in stripping efficiency, low in labor intensity and relatively environment-friendly. According to the technical scheme, the cable core recovery device comprises a base, a bracket, a groove rotating wheel, a rotating shaft, first bearings, a convex head rotating wheel, a second bearing, a first mandrel, a first connecting rod, a first bolt, a rotating handle and the like; the top of the base is connected with the bracket; the upperpart of the bracket is provided with a first through hole; and the upper parts of the front side and the rear side of the bracket are embedded with the first bearings. According to the cable core recovery device, an operator penetrates a cable between cutters on the upper and lower sides, and a rotary motor is started to rotate clockwise, so that the cutters can well cut cable sheath; the cable core recovery device is high in stripping efficiency, low in labor intensity and relatively environment-friendly; the damage to a cable core can be prevented; and relatively high metal recovery rate can be ensured.

Owner:无锡市兆亨线缆有限公司

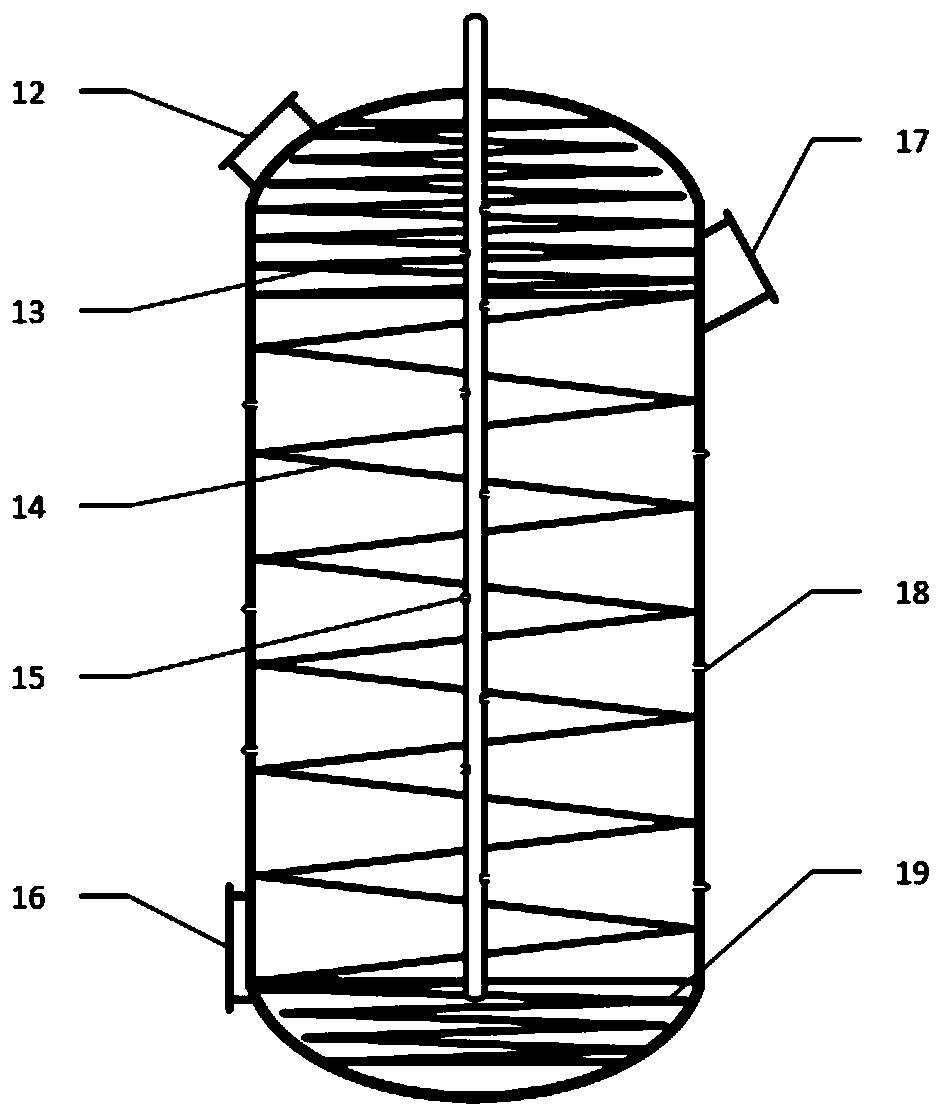

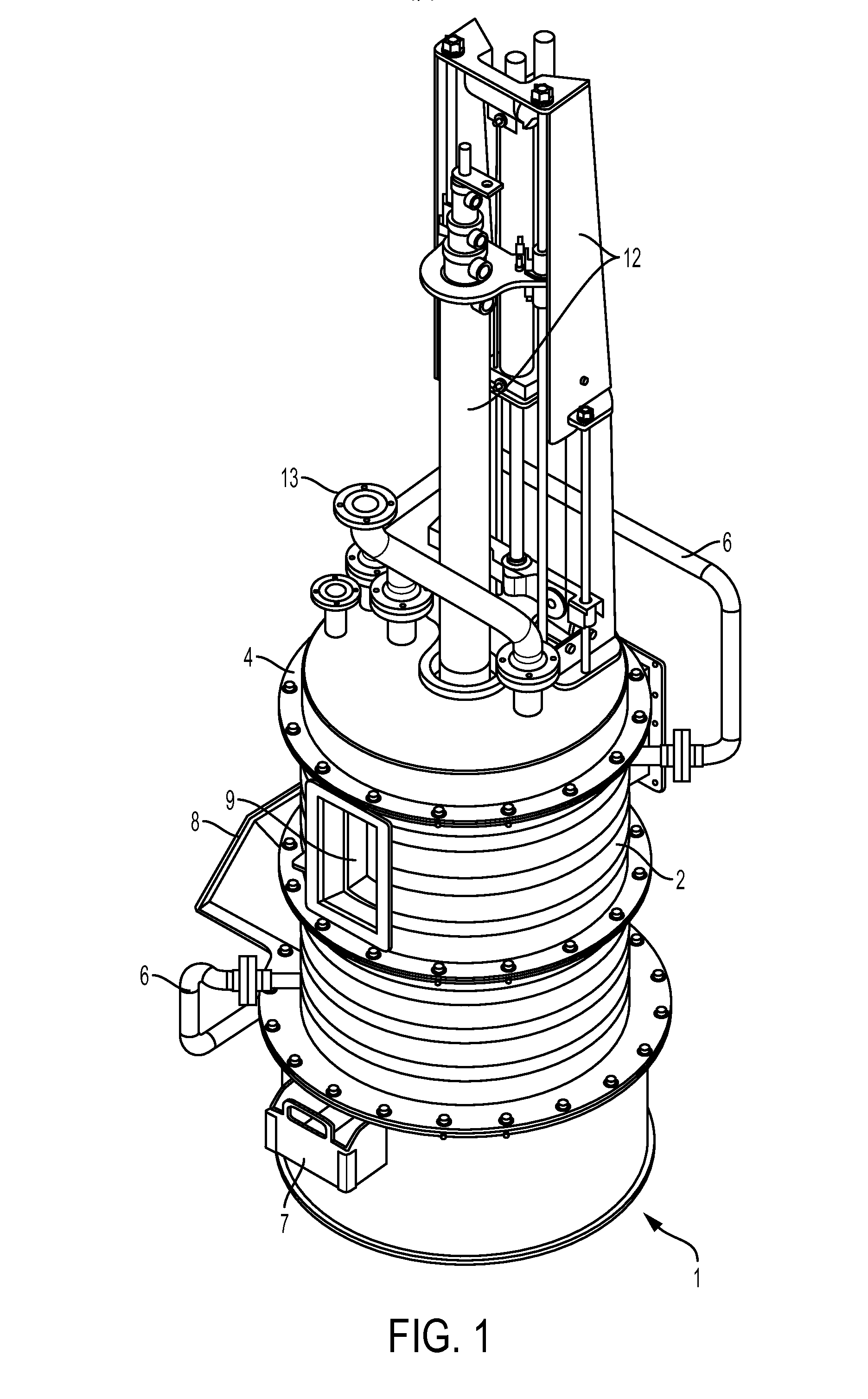

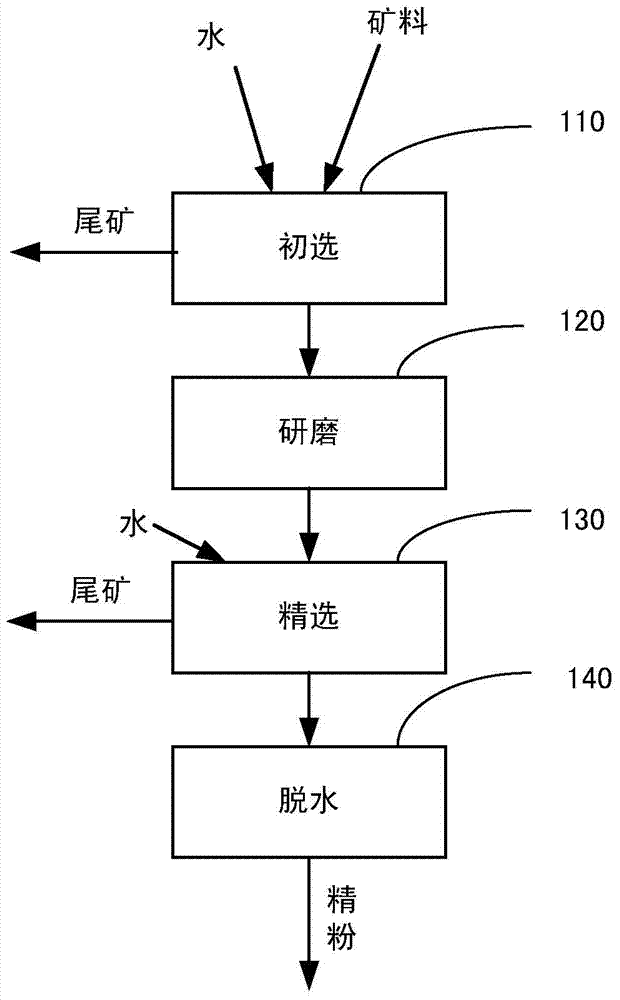

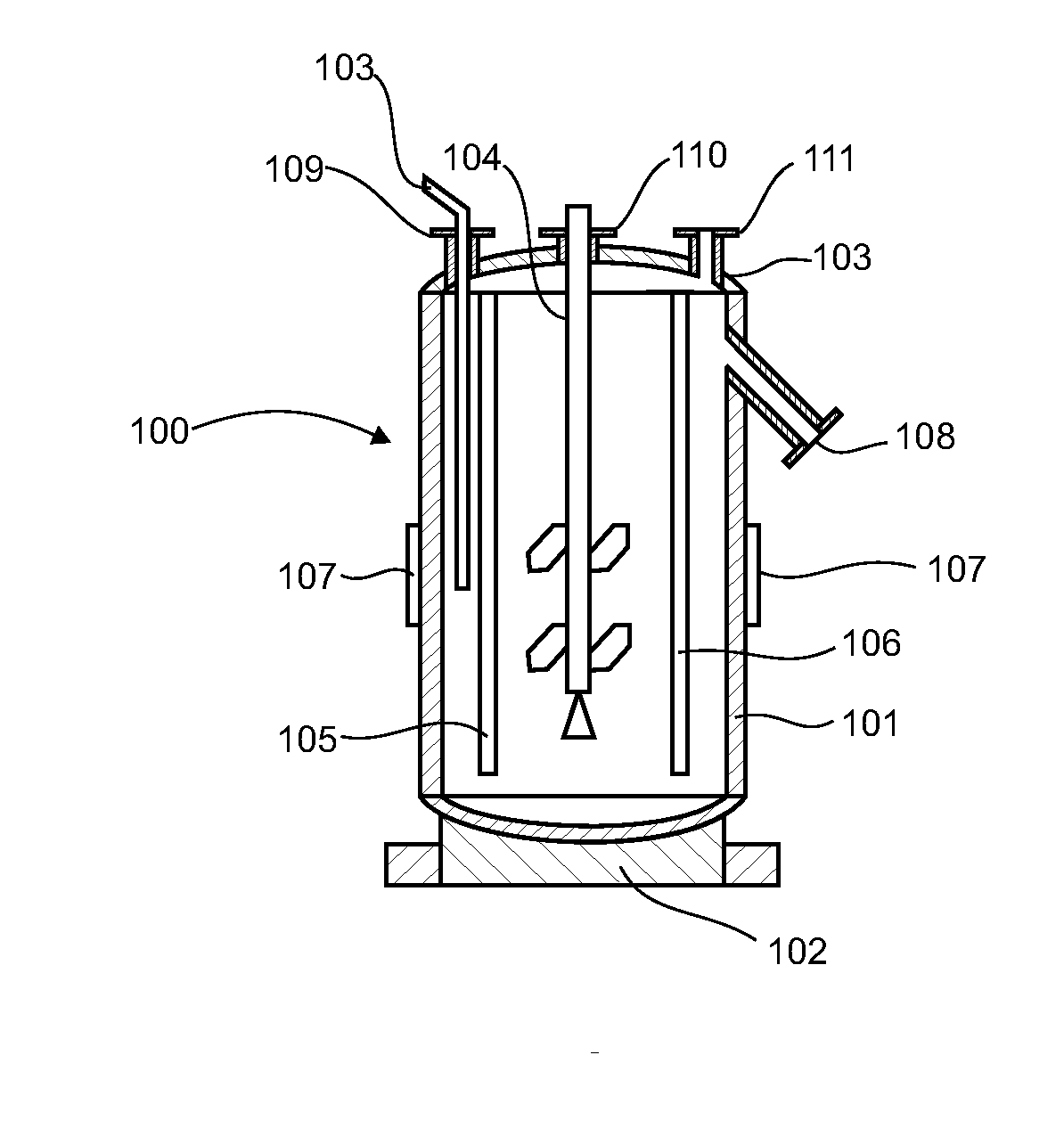

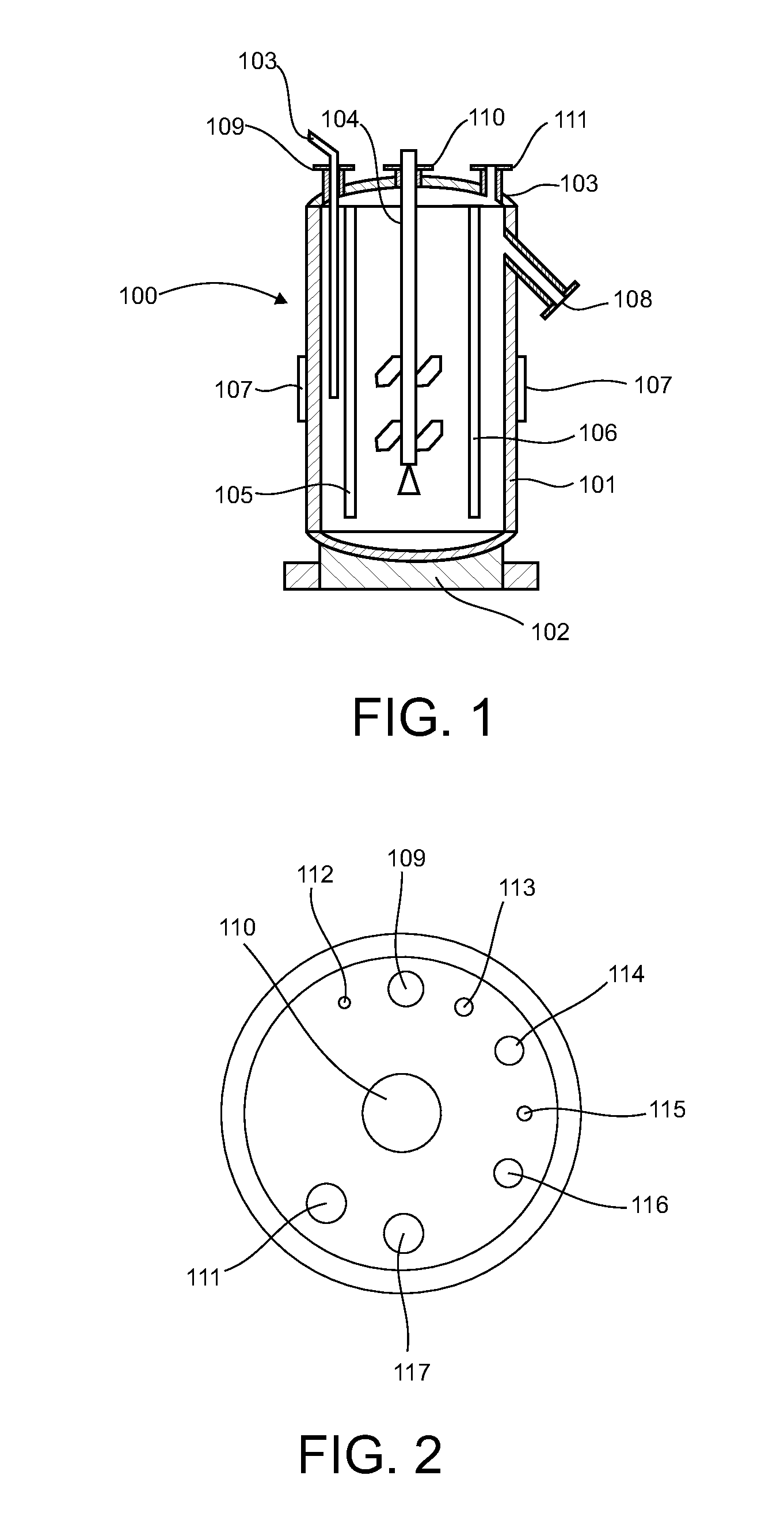

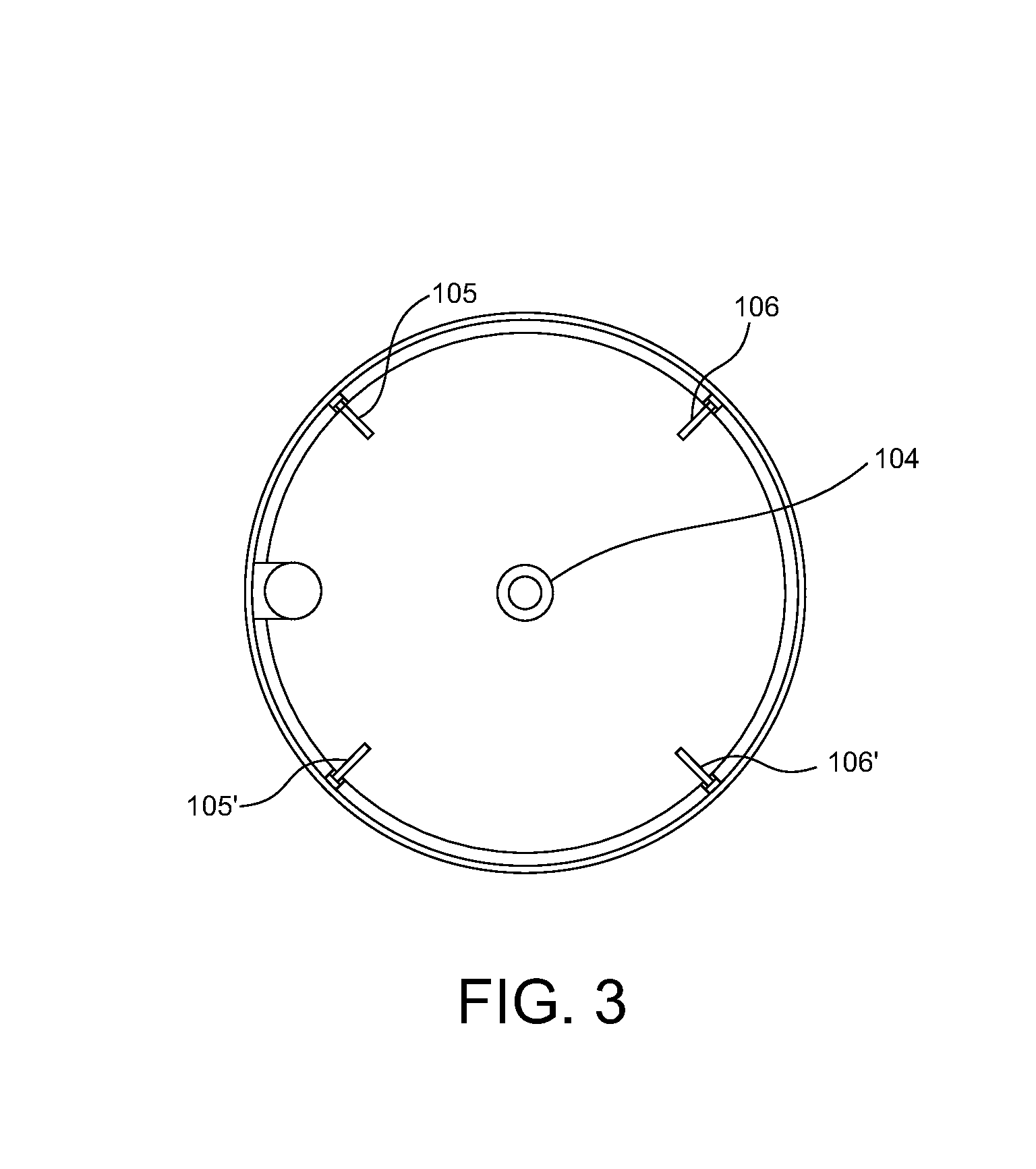

Bioleaching bioreactor with a system for injection and diffusion of air

ActiveUS20140239561A1Improve oxygen and carbon dioxide distributionControl sizeRotary stirring mixersTransportation and packagingCarbon dioxideEngineering

The present invention is related to a bioleaching bioreactor having an air injection and diffusion system, which allows to control the air bubble fine size, improving the oxygen and carbon dioxide distribution required by the microorganisms promoting the bioleaching process, in order to maintain the cellular concentration during the process. The bioleaching bioreactor comprises a reactor body to contain the pulp to be processed and to allow the reaction to proceed; a support base to secure the reactor body; a pulp feeding device, protruding inwards the reactor body; an air injection and diffusion system to mix and to supply the air required by the reaction process; at least four vortex breaking elements located inside the reactor body; at least a heating element surrounding the reactor body to maintain the reaction temperature; a pulp outlet port to deliver the pulp already processed; an inlet port for the pulp to be processed; an air inlet port, located at the upper end of the reactor body; and, a vapor outlet port, located at the upper end of the reactor body.

Owner:SERVICIOS CONDUMEX DE C V

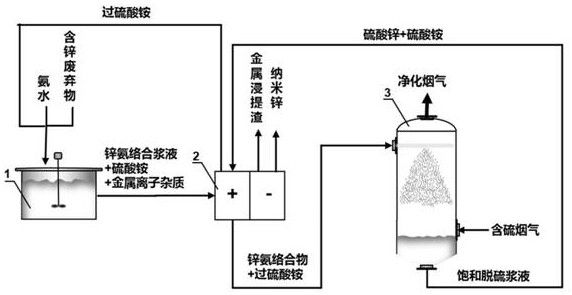

Method and system for removing sulfur dioxide in flue gas by coupling zinc-ammonia complexing with persulfate advanced oxidation technology

PendingCN112323097AHigh metal recovery rateImprove leaching rateGas treatmentPhotography auxillary processesAmmonium sulfateFlue gas

The invention discloses a method and system for removing sulfur dioxide in flue gas by coupling zinc-ammonia complexing with persulfate advanced oxidation technology. The method comprises the following steps of firstly, uniformly mixing zinc-containing waste with ammonia water and an ammonium persulfate solution, carrying out solid-liquid separation to obtain a zinc-ammonia complexing solution, then introducing the zinc-ammonia complexing solution into an electrolysis device to remove impurities and prepare a mixed solution containing ammonium persulfate, spraying the mixed solution into a flue gas desulfurization tower, activating the ammonium persulfate in waste heat provided by flue gas to generate SO4.-with a strong oxidizing property, and absorbing SO2 in the flue gas by the zinc-ammonia complexing solution under oxidation strengthening to achieve the purpose of efficient desulfurization of the flue gas; and introducing desulfurization slurry into an electrolytic cell again, carrying out cyclic electrolysis for multiple times to obtain pure nano-zinc, recycling an ammonium sulfate and ammonium persulfate mixed solution generated by electrolysis, and participating in the zinc-ammonia complexing reaction again. The method has the advantages of coupling of flue gas desulfurization and secondary zinc resource recovery processes, high flue gas desulfurization efficiency, high recovery rate of metal in waste, multi-path cyclic utilization of ammonium sulfate and the like.

Owner:KUNMING UNIV OF SCI & TECH

Stainless steel intelligent smelting system

InactiveCN102534121AEasy to operateHigh metal recovery rateIncreasing energy efficiencyProgrammable logic controllerHuman–machine interface

The invention discloses a stainless steel intelligent smelting system, which comprises a stainless steel argon-oxygen decarburization (AOD) smelting furnace and an intelligent smelting system connected with the stainless steel AOD smelting furnace, wherein the intelligent smelting system consists of a gas control system, an AOD operating workstation and an AOD automation system; the AOD operating workstation consists of a human machine interface (HMI) system, a personal computer (PC) server and a programmable logic controller (PLC) module; and the AOD automation system consists of a database and an intelligent smelting model. The stainless steel intelligent smelting system is provided with the human machine interface for a user, and operation is convenient and intuitive; and the database calculates and displays chemical compositions in molten steel and the temperature of the molten steel in the furnace by a picture in real time according to the consumption of the gas. The stainless steel intelligent smelting system is suitable for small, medium as well as large steel mills and solves the problem of the complicated steelmaking process for the user because the operation is convenient; and because of reasonable price, the smelting cost can be greatly reduced for the user, and the stainless steel intelligent smelting system is easy to promote.

Owner:SHANGHAI YOUCHENG IRON & STEEL EQUIP TECH

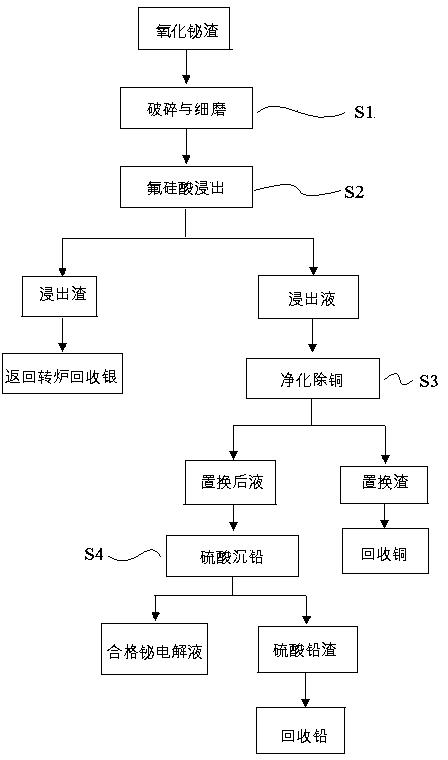

Method for preparing bismuth electrolyte with bismuth oxide slag

ActiveCN104099480AShort processHigh metal recovery ratePhotography auxillary processesProcess efficiency improvementSlagMetal leaching

The invention provides a method for preparing bismuth electrolyte with bismuth oxide slag. The method is characterized by comprising the following steps: leaching fine-grained bismuth oxide slag in a fluosilicic acid system, and filtering; returning leaching slag back into a silver revolving furnace for blowing; adding lead powder into leach liquor to replace copper in a solution; adding sulfuric acid into the copper-removed solution to recover lead; precipitating lead in sulfuric acid for purifying to obtain a solution which is qualified bismuth electrolyte. By leaching through the fluosilicic acid system, separation of bismuth-lead-copper and silver is realized, piling of precious metals is reduced, and the metal leaching rate is high.

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

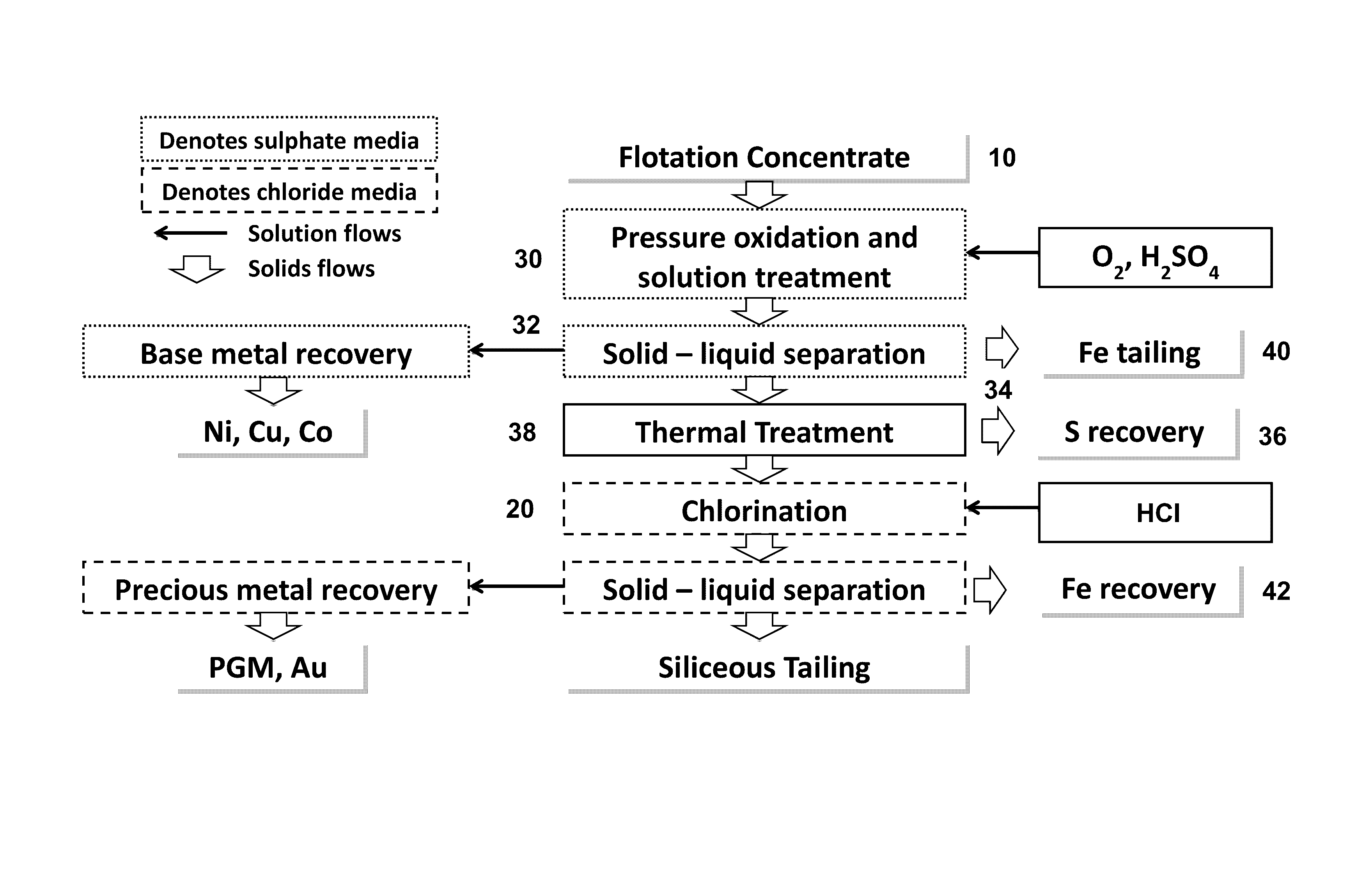

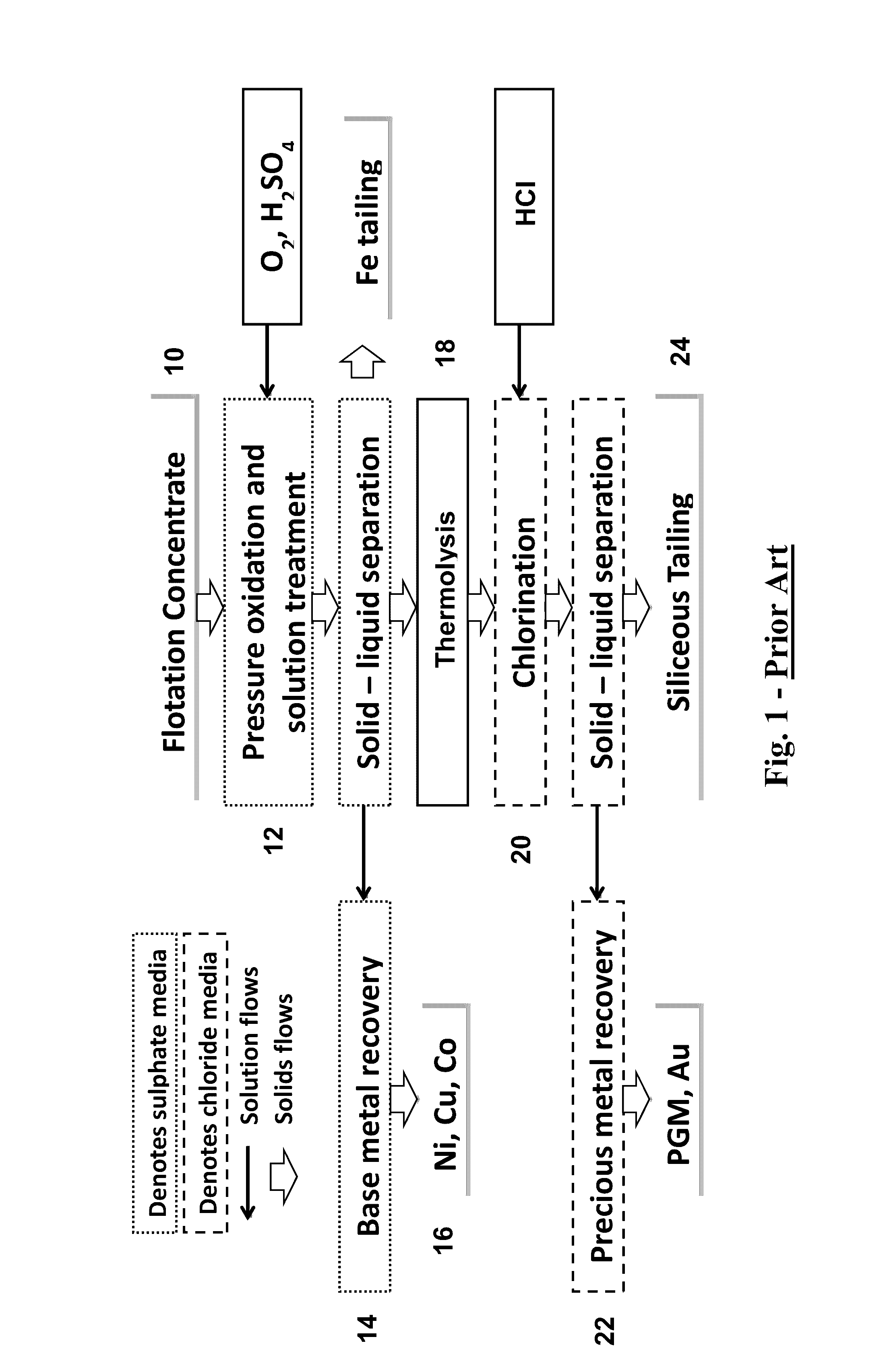

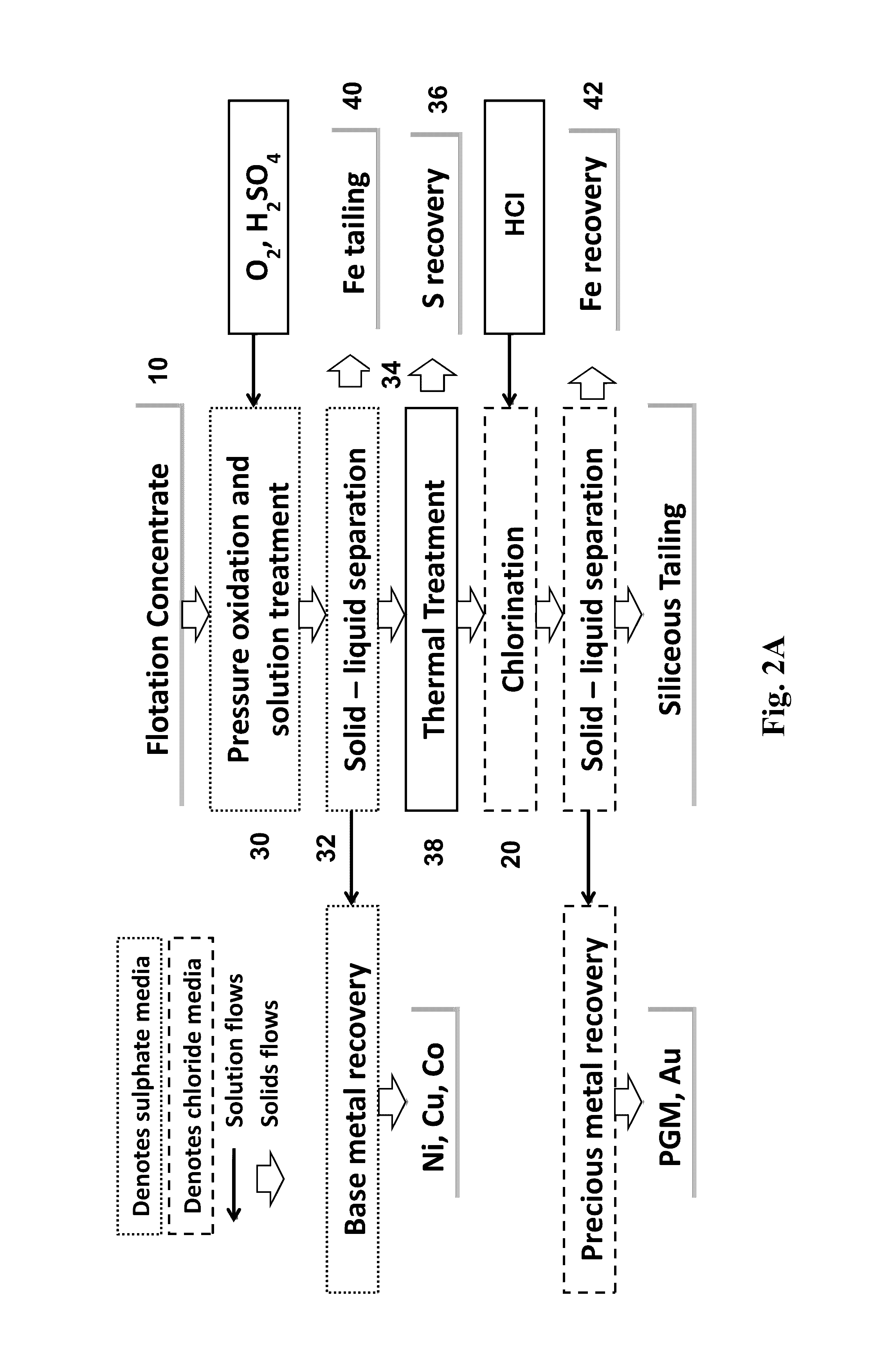

Hydrometallurgical treatment process for extraction of metals from concentrates

ActiveUS20150344990A1Minimize water consumptionQuality improvementProcess efficiency improvementSulfide mineralsSlurry

This invention relates to a hydrometallurgical process for extracting platinum group metals (PGMs), gold, silver and base metals from a flotation concentrate (10) containing sulphide minerals such as pentlandite and chalcopyrite, along with pyrite and pyrrhotite. The process includes a modified pressure oxidation step (12) to selectively separate base metals into sulphate medium (14), from the PGMs. The modified pressure oxidation step (12) partially or completely oxidizes sulphide minerals to produce a N product slurry (14) containing base metal sulphates in solution and a solid residue containing PGMs along with sulphate and elemental sulphur. The solid residue is subjected to a thermal treatment (18) to remove sulphate and elemental sulphur from the solid residue, and to condition the PGMs to be soluble in chloride medium. The treated solid residue is the subjected to PGM recovery by leaching in chloride leaching medium (20) to recover the PGMs.

Owner:LIFEZONE

Technology and system for producing iron ore concentrate by iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy

InactiveCN111748684AHigh strengthImproving the quality of magnetization roastingRoastingMetal recycling

The invention relates to a technology and a system for producing an iron ore concentrate by an iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy. Iron ore of which the granularity is 40 mm or below is divided into three granular classes, wherein coarse-grain iron ore is dried and preheated through the chain grate machine to be added from the material adding end of the rotary kiln, high-volatility lignite is evenly sprayed and blown to be distributed in the length direction of the whole rotary kiln, middle-grain iron ore is sprayed and blown to the front section and the middle section of the shallow hydrogen metallurgy roasting area of the rotary kiln, and fine-grain iron ore is added into the rear section of the shallow hydrogen metallurgy roasting area and is processed through a shallow hydrogen metallurgy process to obtain iron ore concentrate. The chain grate machine is connected in front of a magnetization roasting rotary kiln in series, an early stage oxidizing roasting method and a later-stage reduction roasting method are adopted to further improve hydrogen utilization efficiency, roasting time is shortened, and the roasting quantity of the iron ore, the yield of the iron ore concentrate and a metal recovery rate can be greatly improved.

Owner:JIUQUAN IRON & STEEL GRP

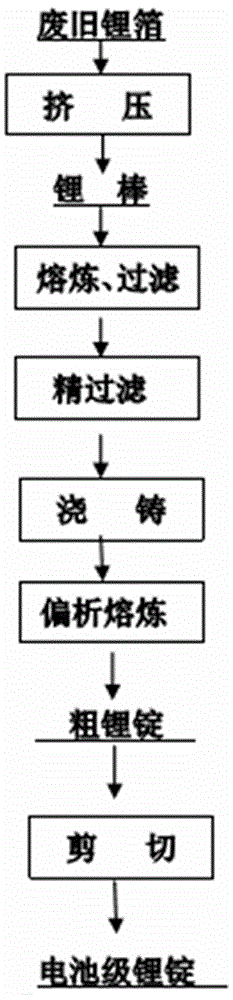

Method for recovering waste battery lithium foil

ActiveCN104862486AHigh purityHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementRecovery methodLithium

The invention relates to recovery of a lithium foil and particularly relates to a method for recovering a waste battery lithium foil. The method for recovering the waste battery lithium foil comprises the following steps: (1) performing extrusion forming; (2) performing coarse filtration; (3) performing fine filtration; (4) casting; (5) performing segregation melting; and (6) cutting. The metal lithium product recovered by the invention is high in product purity and is stable and further the metal recovery rate is high. The filtering and melting process is performed under a high vacuum condition, the casting and segregation melting process are performed under an argon protection condition, and the oxygen content and nitrogen content in the metal lithium product can be stably controlled. The recovery method is safe and reasonable. The recovery method is processed in a fully closed device, the filtering and melting process and the segregation melting process are continuously finished at a step and the production efficiency is high.

Owner:南通盛能新材料科技有限公司

Resource recovery processing method of waste circuit board

InactiveCN112139201AHigh metal recovery rateSpeed up heat transferSolid waste disposalTransportation and packagingCalcium hydroxideResource recovery

The invention discloses a resource recovery processing method of a waste circuit board. The resource recovery processing method comprises the following steps of crushing the waste circuit board into particles, mixing the particles with an additive, and carrying out anaerobic pyrolysis treatment to obtain pyrolysis gas and a pyrolysis solid product; screening the pyrolysis solid product to obtain calcium bromide, calcium carbonate, calcium oxide, carbon powder, glass cloth, copper foil and the like; adding water into the calcium bromide, the calcium carbonate, the calcium oxide and the carbon powder, dissolving and filtering the mixture to obtain a calcium bromide aqueous solution and calcium carbonate-calcium hydroxide-carbon powder; evaporating the calcium bromide aqueous solution to obtain a calcium bromide product; drying and screening the calcium carbonate-calcium hydroxide-carbon powder to obtain a carbon powder product and the calcium carbonate and the calcium hydroxide; inorganic bromine in pyrolysis gas generated by catalytic cracking of the thermal gas is absorbed by calcium oxide, then dissolved, filtered, evaporated and concentrated, bromine in the pyrolysis gas is recycled, the pyrolysis gas is combusted after absorption by calcium oxide, and smoke generated by combustion and fusion casting is treated to reach the standard and then discharged. According to the method, the waste circuit board can be recycled, dioxin is prevented from being generated, the recovery rate is high, and industrial application is facilitated.

Owner:GUANGZHOU WEIGANG ENVIRONMENT TECH CO LTD

Method for extracting nickel from chemically-deposited nickel sulfide materials

ActiveCN108441649AHigh purityPromote environmental protectionProcess efficiency improvementNickel sulfideSulfur dioxide

The invention discloses a method for extracting nickel from chemically-deposited nickel sulfide materials. In an alkalescence system, the nickel sulfide in nickel sulfide material pulp and sodium hypochlorite have a reaction to generate nickel chloride; nickel hydroxide generated by nickel sulfate in the nickel sulfide material pulp and the sodium hypochlorite react to generate nickelic hydroxide,and the nickelic hydroxide has strong oxidability and can accelerate the nickel sulfide oxidization effect. After alkaline oxidation is finished, the pulp is subjected to acid dissolving through sulfuric acid or hydrochloric acid, the incompletely-reacting vulcanized materials and the nickelic hydroxide react, and nickel is leached; after leachate is subjected to chemical and extraction impurityremoval, a high-purity nickel sulfate solution is obtained, and after oil removal, through evaporative crystallization, a nickel sulfate product can be obtained or the high-purity nickel sulfate solution is conveyed to be subjected to nickel electrolyzing . According to method, generation of sulfur dioxide, hydrogen sulfide gas and other harmful gases is avoided, environment protection and production operation are better facilitated, the cost is low, pollution is little, and the comprehensive recycling effect is good.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com