Method for green recovery of waste circuit boards by cyanide-free full-wet whole set process

A technology for waste circuit boards and processes, applied in the direction of improving process efficiency, can solve problems such as high energy consumption, complex processes, and complex recycling methods, and achieve the effects of easy industrial production, high metal recovery rate, and reduction of secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

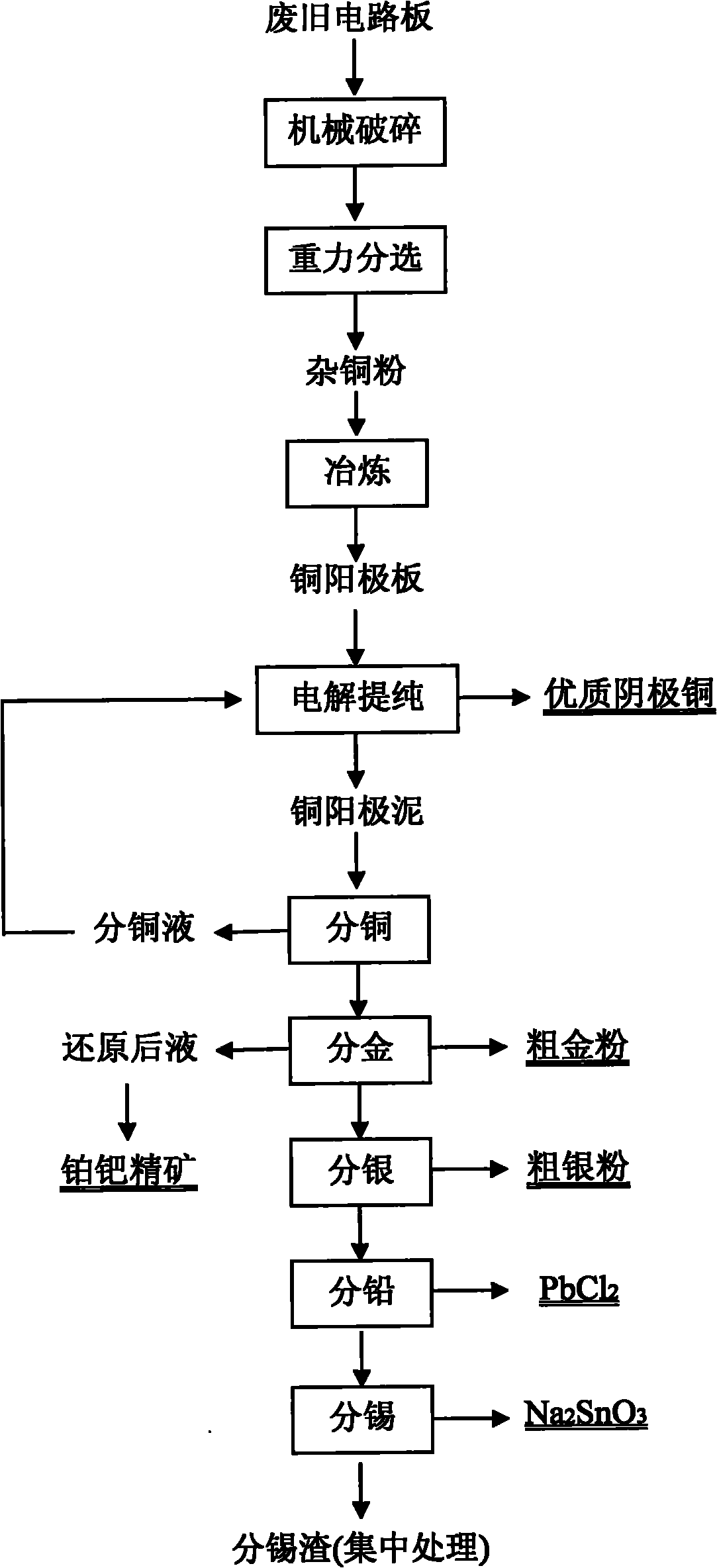

[0036] figure 1 It is the overall implementation process flow chart of the method for green recycling of waste circuit boards in the cyanide-free full-wet complete process of the present invention. As shown in the figure, the waste circuit boards are first crushed with a jaw crusher, and then separated by winnowing to obtain miscellaneous copper powder and non-metallic powder, smelting and casting miscellaneous copper powder to obtain copper anode plate.

[0037] Put the copper anode plate in H 2 SO 4 and CuSO 4 Copper electrolytic purification is carried out in the mixed solution to obtain cathode copper and copper anode slime. Copper electrolytically purified H 2 SO 4 The concentration is 0.5mol / L, CuSO 4 The concentration is 1.5mol / L, the gelatin concentration is 100mg / L, the thiourea concentration is 120mg / L, and the current density is 130A / m 2 , the electrolysis temperature is 60°C. The purity of the obtained cathode copper reaches 4N level.

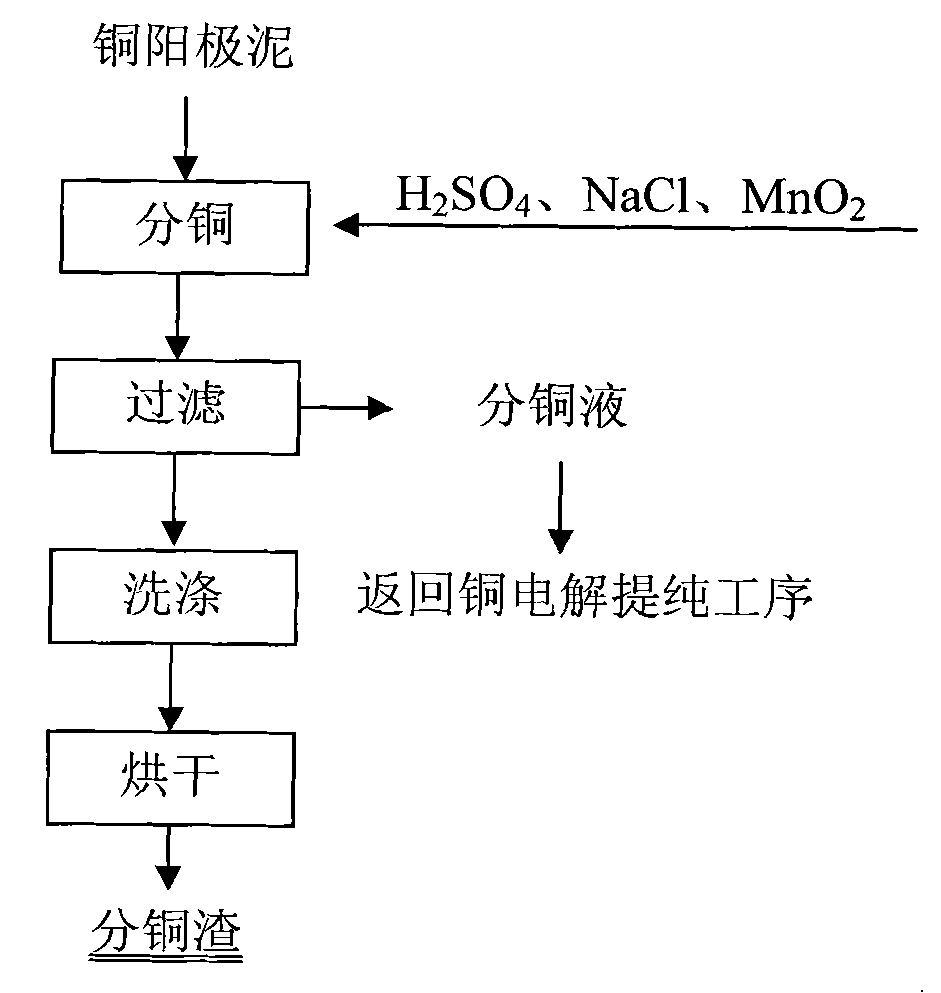

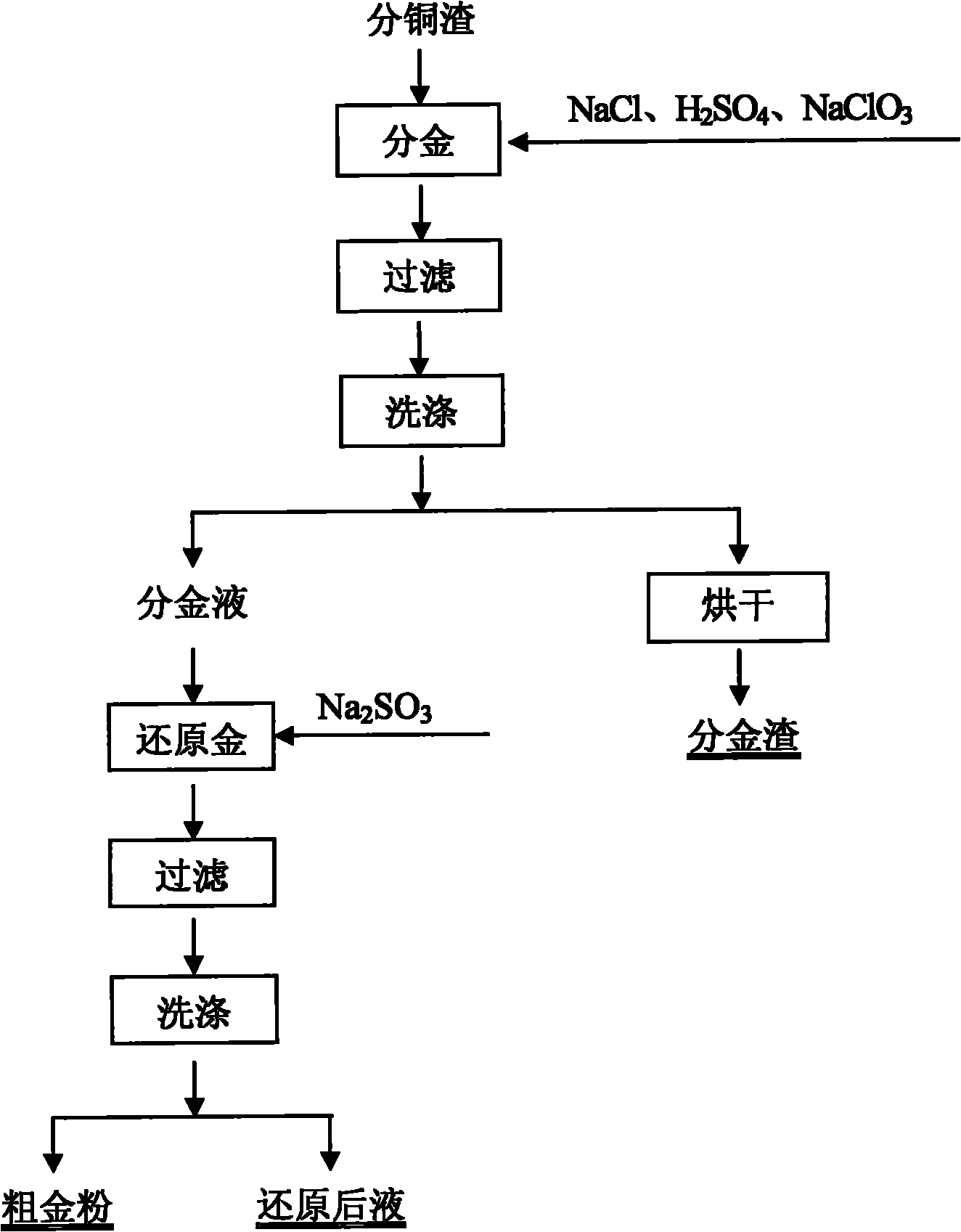

[0038] figure 2 I...

Embodiment 2

[0045] Firstly, the waste circuit board is crushed with a hammer crusher, and then miscellaneous copper powder and non-metallic powder are obtained by water separation, and the miscellaneous copper powder is smelted and cast to obtain a copper anode plate.

[0046] Put the copper anode plate in H 2 SO 4 and CuSO 4 Copper electrolytic purification is carried out in the mixed solution to obtain cathode copper and copper anode slime. Copper electrolytically purified H 2 SO 4 The concentration is 2mol / L, CuSO 4 The concentration is 1mol / L, the gelatin concentration is 50mg / L, the thiourea concentration is 100mg / L, and the current density is 100A / m 2 , The electrolysis temperature is 40°C. The purity of the obtained cathode copper reaches 4N level.

[0047] Copper anode slime and H 2 SO 4 , NaCl solution mixed, adding MnO 2 Carry out copper separation, filter to obtain copper separation liquid and copper separation slag. The copper separating solution is returned to the ...

Embodiment 3

[0054] First, the waste circuit boards are crushed with an impact crusher, and then miscellaneous copper powder and non-metallic powder are obtained by air separation, and the miscellaneous copper powder is smelted and cast to obtain a copper anode plate.

[0055] Put the copper anode plate in H 2 SO 4 and CuSO 4 Copper electrolytic purification is carried out in the mixed solution to obtain cathode copper and copper anode slime. Copper electrolytically purified H 2 SO 4 The concentration is 1mol / L, CuSO 4 The concentration is 0.5mol / L, the gelatin concentration is 300mg / L, the thiourea concentration is 300mg / L, and the current density is 250A / m 2 , The electrolysis temperature is 80°C. The purity of the obtained cathode copper reaches 4N level.

[0056] Copper anode slime and H 2 SO 4 , NaCl solution mixed, adding MnO 2 Carry out copper separation, filter to obtain copper separation liquid and copper separation slag. The copper separating solution is returned to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com