Tailings resource recovery technology

A resource recovery and process technology, applied in recycling technology, mechanical material recovery, solid separation and other directions, can solve problems such as encroaching on large land, hidden dangers, and forming safety, achieving high metal recovery grade, high metal recovery rate, and environmental protection. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

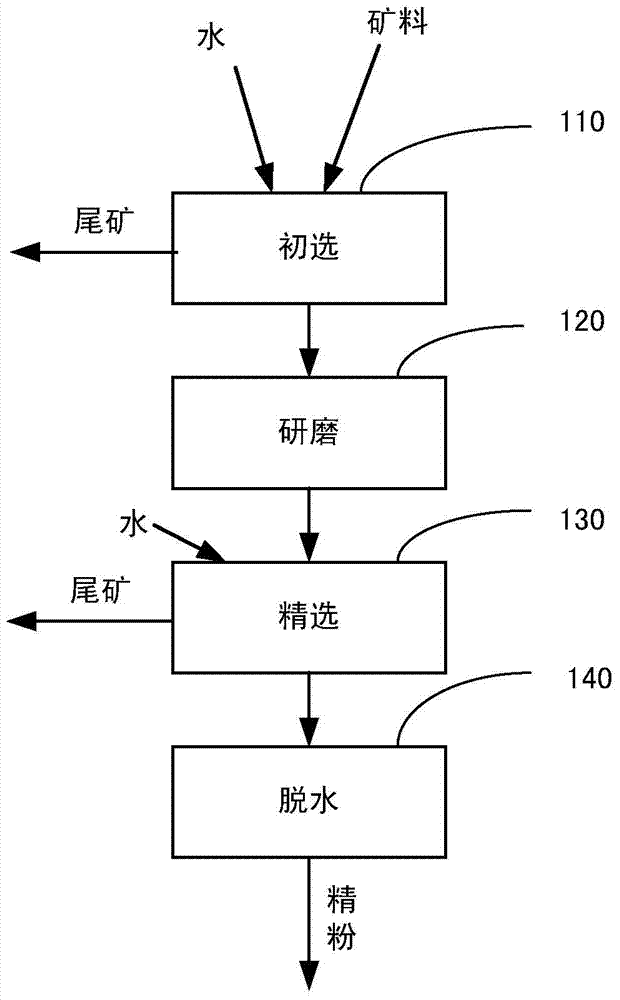

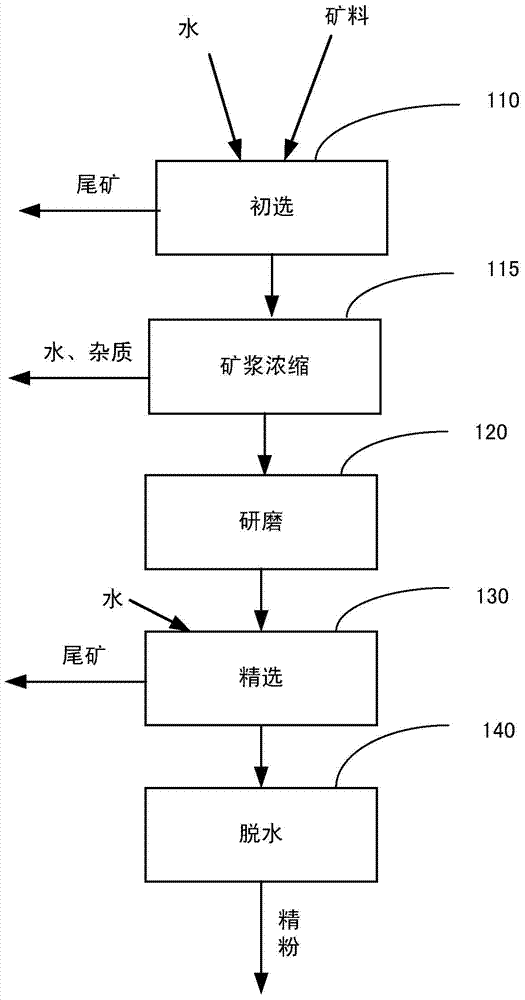

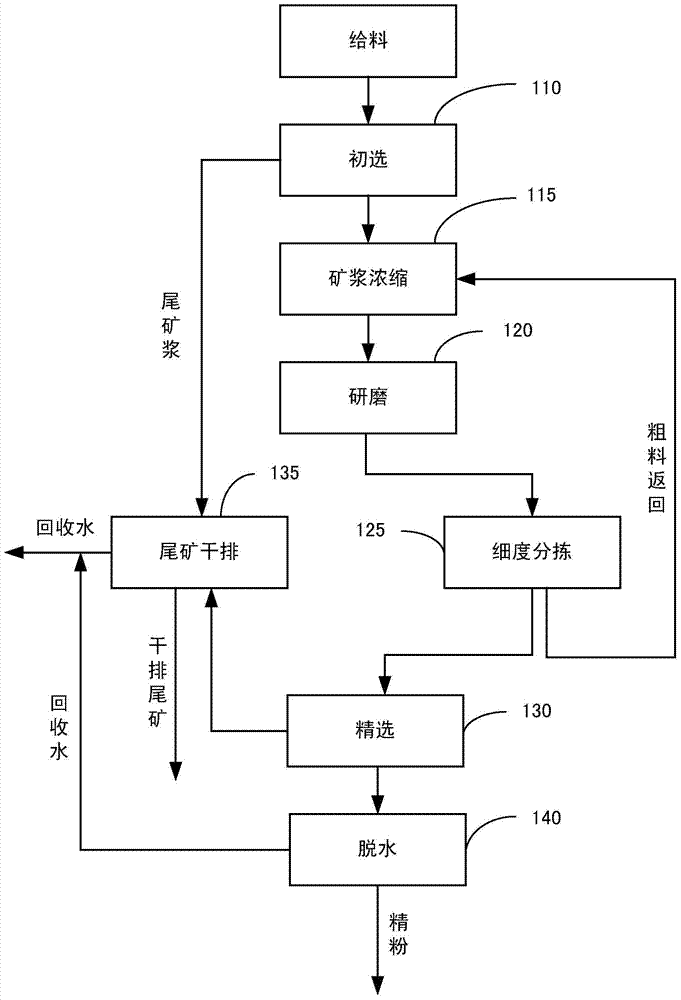

Method used

Image

Examples

example 1

[0120] The method according to the present invention is used to screen the tailings of the ultra-poor vanadium-titanium magnetite from an ultrabasic rock mass in a certain place in Hebei Province.

[0121] According to the test report of the testing department: the mineral content of the above mine tailings sand is as follows (100% in total): pyroxene minerals account for 47.59% of the tailings sand, amphibole minerals account for 18.53%, feldspar minerals account for 14.51%, ilmenite minerals Accounting for 5.87%, montmorillonite minerals accounted for 5.19%, chlorite minerals accounted for 1.75%, illite minerals accounted for 6.55%. It can be seen that there is no single mineral of magnetite in the tailings sand.

[0122]In the tailings treatment process of the prior art, there is almost no way to select iron fine powder that meets the requirements of industrial indicators from the above-mentioned ultra-poor vanadium-titanium magnetite tailings sand. Because based on common...

example 2

[0126] Sampling 32 tons of tailings in a mine for mineral processing test.

[0127] Utilize tailings recycling process according to the present invention, (the tailings sand of the same ore deposit industry type) beneficiation test result is:

[0128] The Tfe content is 8.52%; the refined powder grade is 65.67%; the tailings Tfe grade is 3.61%; the metal recovery rate of the beneficiation is 60.98%, and the yield is 7.9%.

[0129] In contrast: with the same tailings sand, the best indicators obtained by the tailings recovery process in the prior art are:

[0130] The Tfe grade of the tailings sand is 7.91%; the fine powder grade is also 65.76%, but the metal recovery rate of the beneficiation is 21.23%, and the yield rate is 2.46%.

[0131] It can be seen that the recovery rate of beneficiation metal obtained by the tailings recovery process of the present invention is 39.75% higher than the best index of 21.23%, and the yield is 5.44% higher than the current national best in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com