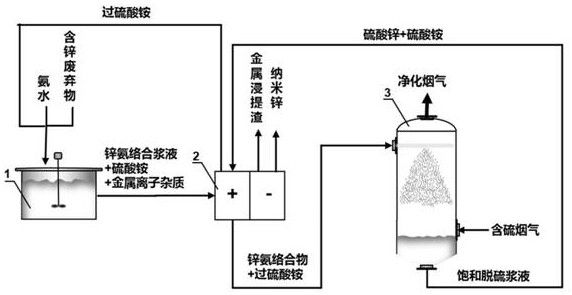

Method and system for removing sulfur dioxide in flue gas by coupling zinc-ammonia complexing with persulfate advanced oxidation technology

An advanced oxidation technology and persulfate technology are applied in the field of industrial solid waste resource utilization and flue gas desulfurization, which can solve problems such as low zinc leaching rate, limitation of desulfurization efficiency, and influence on the purity of zinc-containing products, and achieve a large metal recovery rate. , Improve the effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Use hot-dip galvanizing slag from a galvanizing plant, the zinc content of which is 20.5%, to treat SO 2 The content is 2000 mg / m 3 industrial flue gas, the following steps are adopted:

[0045] (1) Mix the zinc dross with ammonia water and ammonium persulfate evenly, the solid-to-liquid ratio of the zinc dross and the slurry is 1:4, and obtain the zinc-ammonia complex slurry, and then separate the solid and liquid, and the insoluble metal leaching residue is separated Recycled as metal smelting raw materials, liquid phase to obtain a mixed solution containing zinc ammonia complex and soluble metal ions;

[0046] (2) The solution obtained in step (1) is passed into the anode chamber of the electrolytic cell, and iron, copper, and cobalt ions enter the cathode chamber through the cation exchange membrane under the action of an electric field, and the reduction reaction occurs at the cathode and is loaded on the cathode plate Above, the impurity removal of the zinc-ammon...

Embodiment 2

[0052] Use zinc concentrate roasting fume from a zinc power plant, the dust content of which is 62% zinc, to treat SO 2 The content is 3000 mg / m 3 industrial flue gas, the following steps are adopted:

[0053] (1) Mix the zinc dross with ammonia water and ammonium persulfate evenly, the solid-to-liquid ratio of the zinc dross and the slurry is 1:5, and obtain the zinc-ammonia complex slurry, and then separate the solid and liquid, and the insoluble metal leaching residue is separated Recycled as metal smelting raw materials, liquid phase to obtain a mixed solution containing zinc ammonia complex and soluble metal ions;

[0054] (2) The solution obtained in step (1) is passed into the anode chamber of the electrolytic cell, and iron, copper, manganese, and lead ions enter the cathode chamber through the cation exchange membrane under the action of an electric field, and the reduction reaction occurs at the cathode. On the cathode plate, the impurity removal of the zinc-ammoni...

Embodiment 3

[0059] Using zinc-containing blast furnace dust from a steel plant, the dust content of which is 8% zinc, to treat SO 2 The content is 2000 mg / m 3 industrial flue gas, the following steps are adopted:

[0060] (1) Mix the zinc dross with ammonia water and ammonium persulfate evenly, the solid-to-liquid ratio of the zinc dross and the slurry is 1:5, and obtain the zinc-ammonia complex slurry, and then separate the solid and liquid, and the insoluble metal leaching residue is separated Recycled as metal smelting raw materials, liquid phase to obtain a mixed solution containing zinc ammonia complex and soluble metal ions;

[0061] (2) The solution obtained in step (1) is passed into the anode chamber of the electrolytic cell, and the lead, copper, and iron ions enter the cathode chamber through the cation exchange membrane under the action of an electric field, and the reduction reaction occurs at the cathode and is loaded on the cathode plate Above, the impurity removal of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com