Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "High hardness and strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

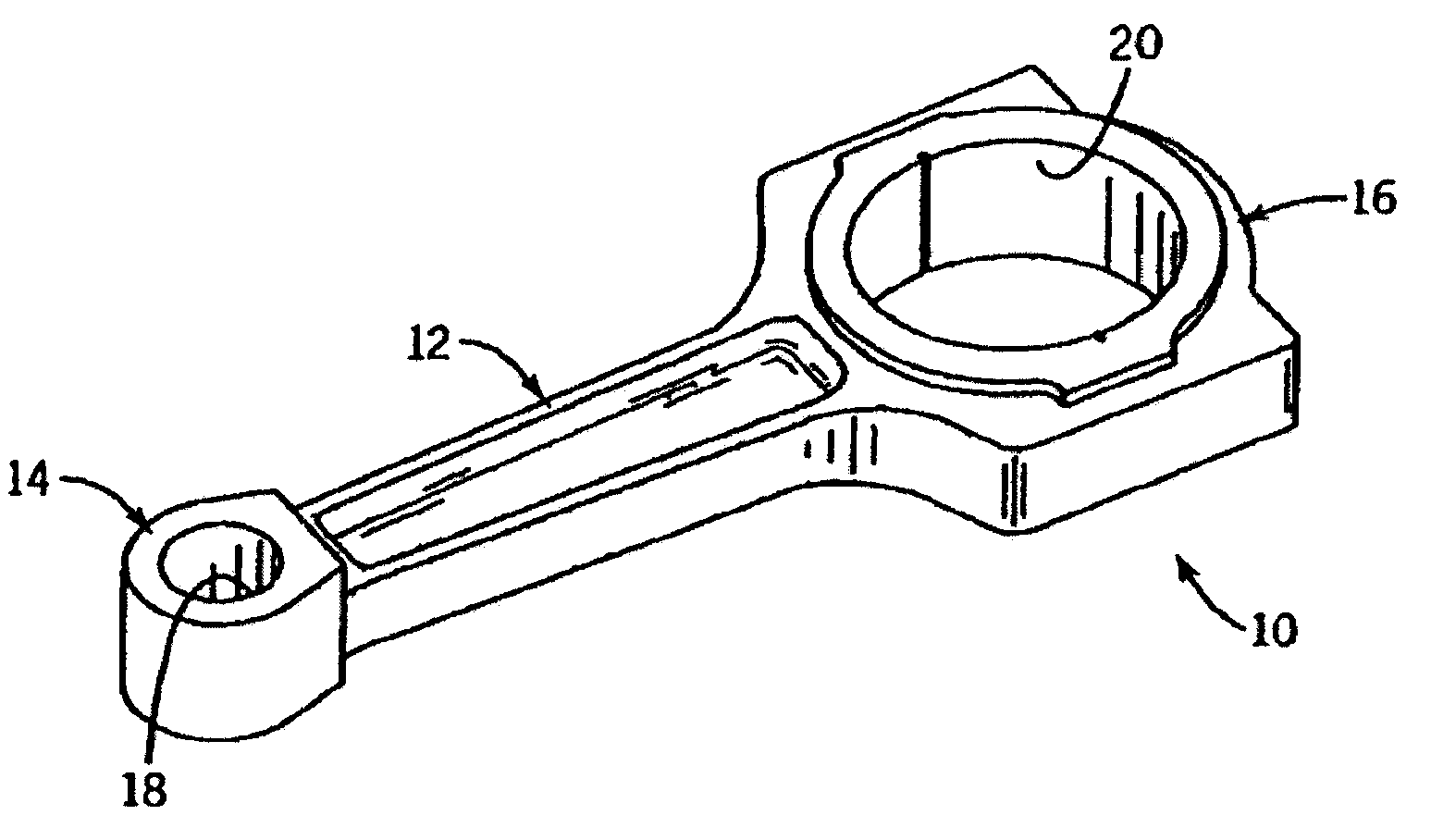

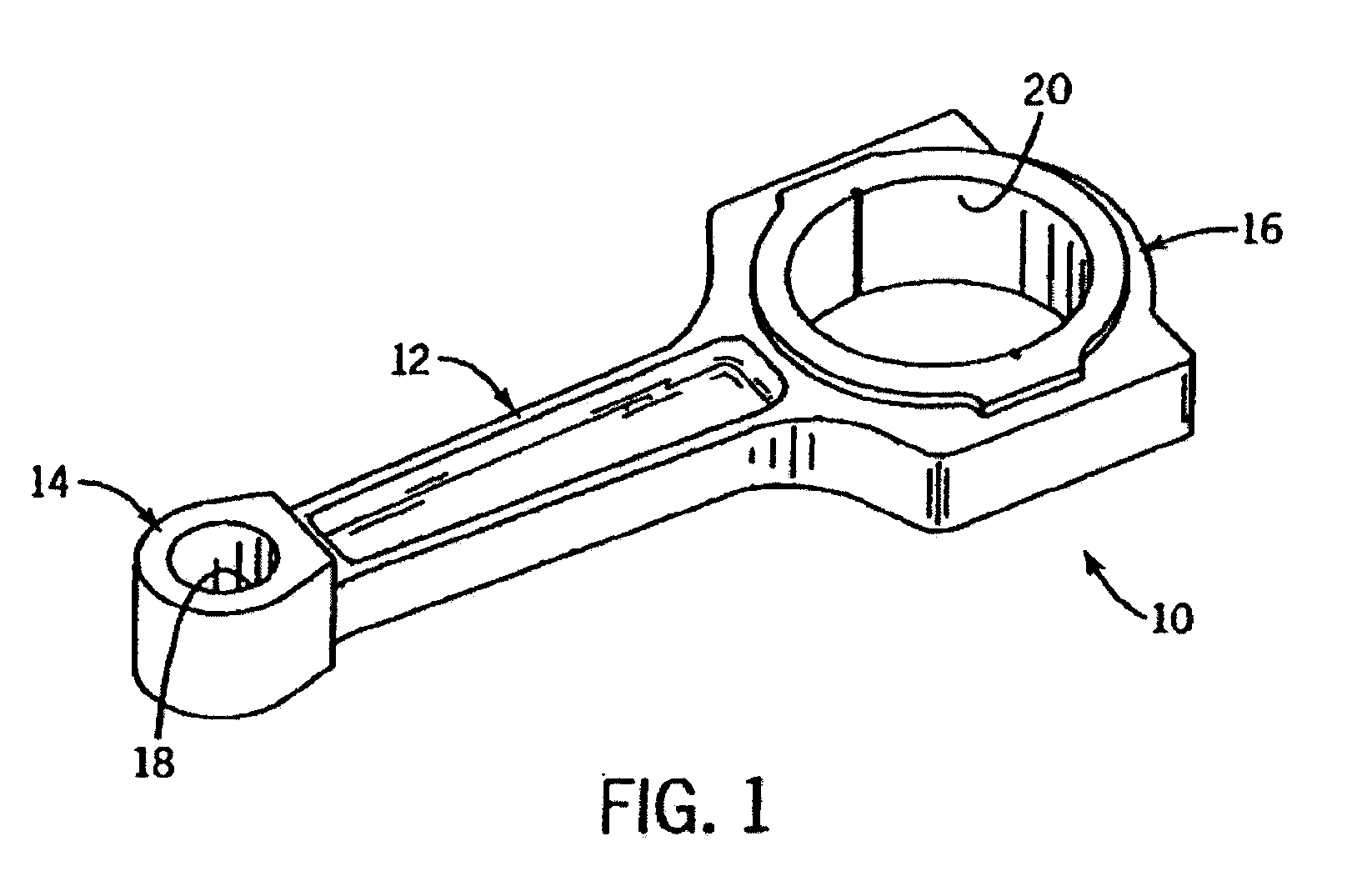

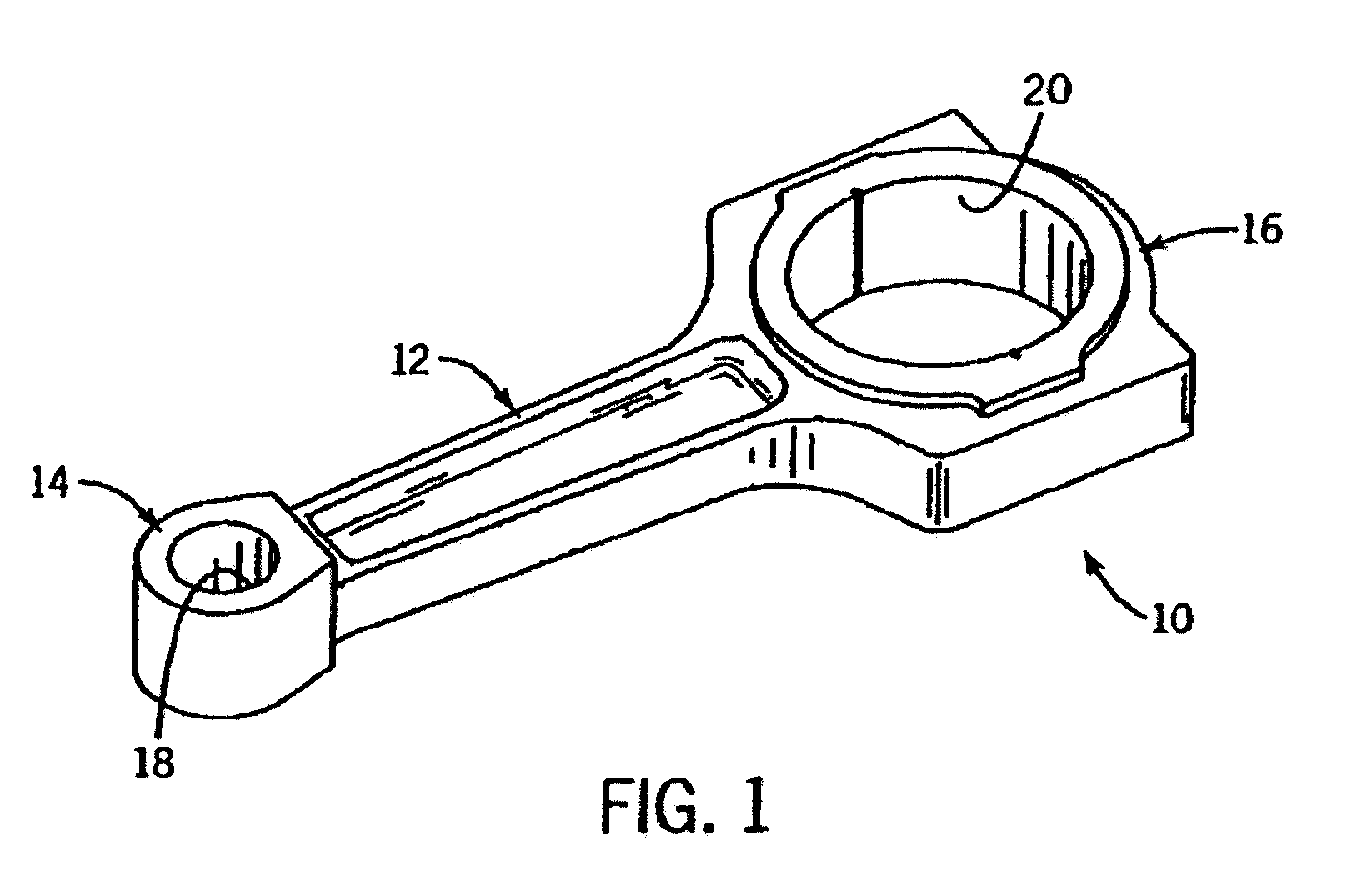

Prealloyed copper powder forged connecting rod

A process for manufacturing connecting rods is provided which comprises the steps of compacting, sintering, and powder forging a powder metal comprising a carbon source and a prealloyed powder consisting essentially of iron and copper. The connecting rods made from this process have sufficient hardness and strength to be used in an engine and do not require any additional quenching or tempering.

Owner:SKN SINTER METALS LLC (US)

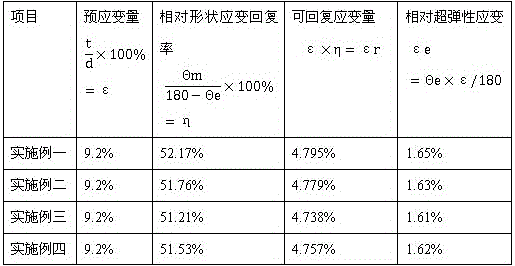

High-hardness, high-strength and high-toughness aluminium alloy, preparation method of aluminium alloy, and preparation method of synchronizer toothed ring

The invention discloses a high-hardness, high-strength and high-toughness aluminium alloy which comprises the components: 7.36-10.21wt% of zinc, 2.18-3.56wt% of magnesium, 1.9-2.8wt% of copper, 0.15-0.40wt% of zirconium, 0.12-0.36wt% of iron, 0.05-0.45wt% of silicon, 0.01-0.03wt% of erbium / lanthanum / cerium, and the balance aluminum and unavoidable impurities. The invention also relates to a preparation method of the high-hardness, high-strength and high-toughness aluminium alloy and a preparation method of a high-hardness, high-strength and high-toughness synchronizer toothed ring. Through the improvement on smelting and heat treatment technologies, the prepared aluminium alloy has excellent mechanical properties such as high hardness, high tensile strength and high yield strength; and when the aluminium alloy is used to prepare the synchronizer toothed ring, the surface strength and the abrasive resistance of the prepared synchronizer toothed ring are improved greatly, and the quality and service life of the synchronizer toothed ring can be improved and increased.

Owner:FUJIAN DEYEXI LIGHT ALLOY TECH CO LTD

High-strength wear-resistant nonmagnetic stainless steel and preparation method thereof

The invention discloses a high-strength wear-resistant nonmagnetic stainless steel and a preparation method thereof. The high-strength wear-resistant nonmagnetic stainless steel is composed of the following components in percentage by weight: 0.1%-0.18% of carbon, 8%-11% of nickel, 19%-21% of chromium, 1%-2% of manganese, 0.5%-1% of silicon, 0.48%-0.65% of niobium, 0.11%-0.14% of vanadium, 1.2%-2.0% of molybdenum, 0.021%-0.03% of titanium, 0.01%-0.1% of aluminum, 0.8%-2% of nitrogen, 0.2%-0.3% of rare earth, not more than 0.035% of phosphorus and sulfur, and the balance of iron thereof inevitable impurities. The high-strength wear-resistant nonmagnetic stainless steel has the advantages of favorable corrosion resistance, favorable intercrystalline corrosion resistance, favorable oxidation resistance, favorable acid / alkali resistance, high strength and high hardness.

Owner:何鹏

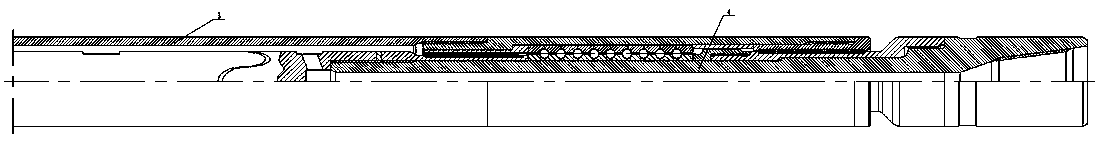

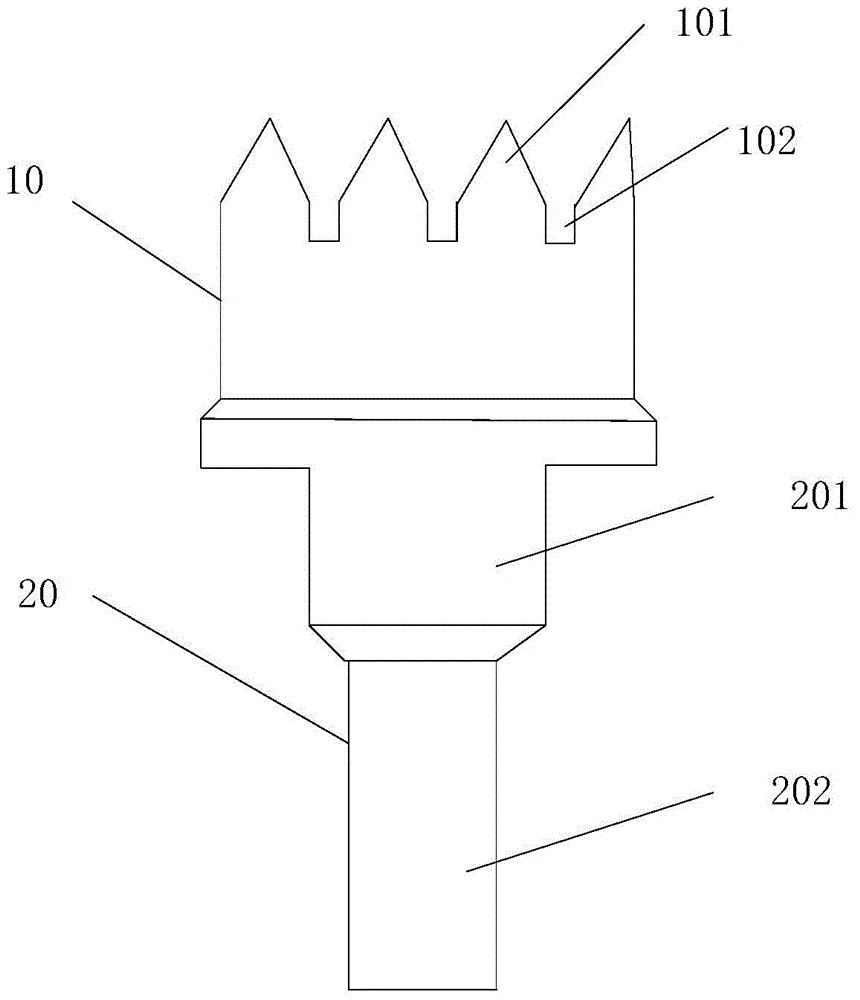

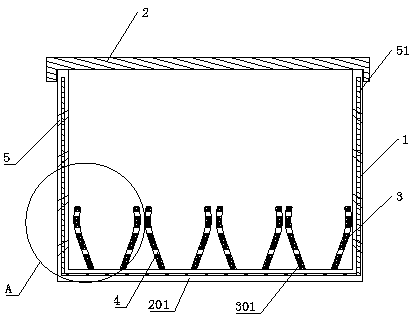

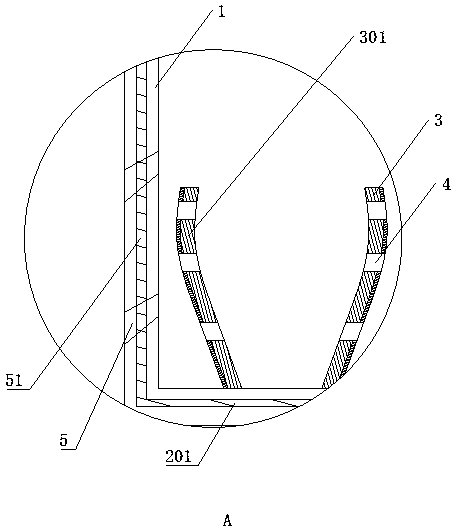

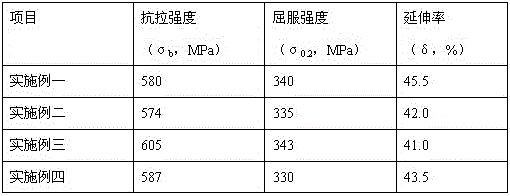

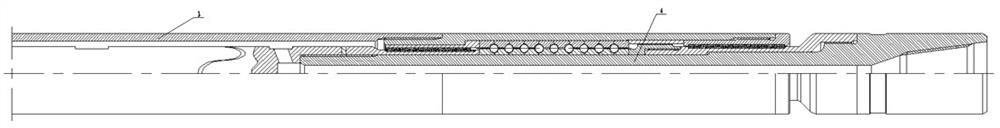

Anticorrosion and anti-degumming screw drill special for high-sulfur-content oil-gas well and machining process of anticorrosion and anti-degumming screw drill

ActiveCN110107222AHigh tensile strengthIncrease elasticityBorehole drivesAnti-corrosive paintsHydraulic motorDrive shaft

The invention discloses an anticorrosion and anti-degumming screw drill special for a high-sulfur-content oil-gas well and a machining process of the anticorrosion and anti-degumming screw drill, wherein the anticorrosion and anti-degumming screw drill is resistant to oil, acid, sulfur and high-corrosion media such as H2S. The anticorrosion and anti-degumming screw drill mainly comprises a bypassvalve assembly, a hydraulic motor assembly, a cardan shaft assembly and a transmission shaft assembly; the hydraulic motor assembly comprises a motor stator metal shell, a motor rotor, and a motor stator rubber bushing arranged between the motor stator metal shell and the motor rotor; a plurality of 90-degree V-shaped taper holes are formed in the motor stator metal shell, and plugs are arranged in the 90-degree V-shaped taper holes; and synthetic gum of the motor stator rubber bushing is injected into a cavity between the motor stator metal shell and a motor rotor mold core, and part of molten gum is injected into the 90-degree V-shaped taper holes.

Owner:YANCHENG HUAYA GASOLINEEUM MACHINERY MFG

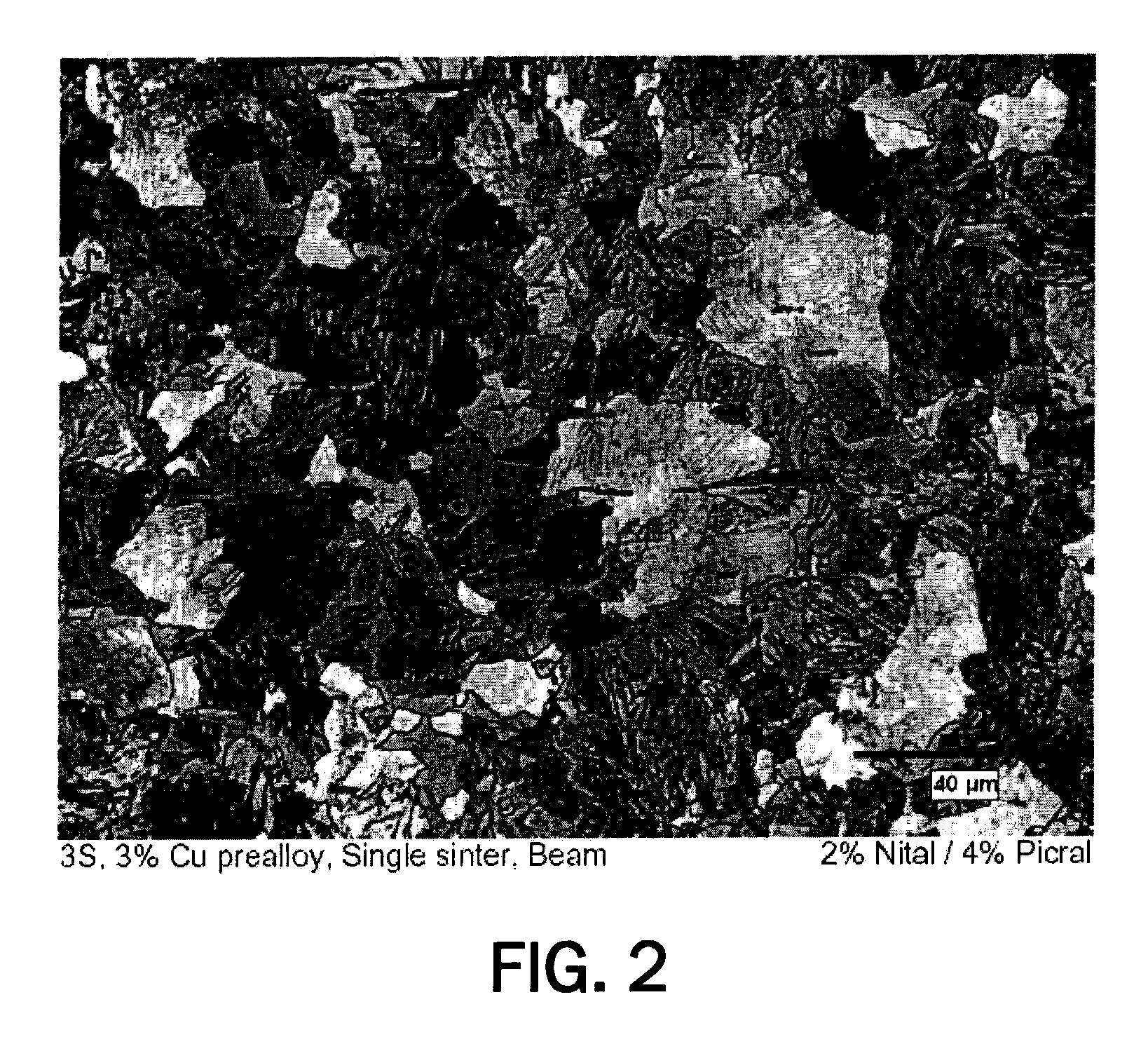

Prealloyed copper powder forged connecting rod

ActiveUS8935852B2Reduce in quantityDimensional precision can be increasedConnecting rodsMetal-working apparatusHardnessCopper

A process for manufacturing connecting rods is provided which comprises the steps of compacting, sintering, and powder forging a powder metal comprising a carbon source and a prealloyed powder consisting essentially of iron and copper. The connecting rods made from this process have sufficient hardness and strength to be used in an engine and do not require any additional quenching or tempering.

Owner:SKN SINTER METALS LLC (US)

Dry powder coating added with attapulgite mineral and preparation method thereof

InactiveCN105753401AHigh hardness and strengthImprove weather resistanceAluminium saltsPortland cement

The invention discloses dry powder coating added with attapulgite mineral and a preparation method thereof. On the basis that the total weight of the dry powder coating is 1000 parts, the dry powder coating is prepared from the following raw material components in parts by weight: 150 to 400 parts of portland cement, 50 to 500 parts of attapulgite, 5 to 50 parts of soluble aluminium salt, 2 to 7 parts of thickening water-retaining agent, 1 to 3 parts of retarder; 0 to 30 parts of color paste, and 450 to 550 parts of filler. The dry powder coating added with the attapulgite mineral adopts the attapulgite as a new-style internal filler, and the attapulgite has better adsorption capacity, and unique dispersibility, plasticity and viscous force, is heat-resistant and low in shrinkage rate after drying, and has no flocculation and no precipitation during suspension.

Owner:GUANGZHOU SHENGJING ENVIRONMENTAL BUILDING MATERIALS CO LTD

Good-liquidity harmful-gas-free environmentally-friendly hot melt adhesive

InactiveCN105038645ACompounding is reasonableGood liquidityNon-macromolecular adhesive additivesStarch adhesivesSodium polyacrylateDibenzoyl Peroxide

The invention discloses a good-liquidity harmful-gas-free environmentally-friendly hot melt adhesive which is prepared from the following raw materials in parts by weight: 35-45 parts of EVA, 1-2 parts of dodecyl trimethyl ammonium chloride, 10-15 parts of nano fly ash, 10-20 parts of kieselguhr, 1-3 parts of tetraethylenepentamine, 4-8 parts of polycarbonate, 5-8 parts of starch, 0.1-0.5 part of benzoyl peroxide, 10-15 parts of octyl-phenolic curing resin, 1-2 parts of an anti-aging agent NBC, 1-2 parts of sodium polyacrylate, 10-18 parts of silicone rubber, 3-9 parts of phenolic resin and 10-20 parts of modified tackifying resin. According to the invention, resin and additives are reasonably compounded, so that the hot melt adhesive is good in liquidity, and high in softness and viscidity; through intercalated modifying, the mechanical property of rubber can be improved, thermal deformation temperature is increased, and water absorption is low, and thus when the rubber is used for preparing the hot melt adhesive, compatibility of all raw materials of the hot melt adhesive can be increased and viscosity and water resistance are improved.

Owner:QUANJIAO HAIFENG PRINTING PACKAGING

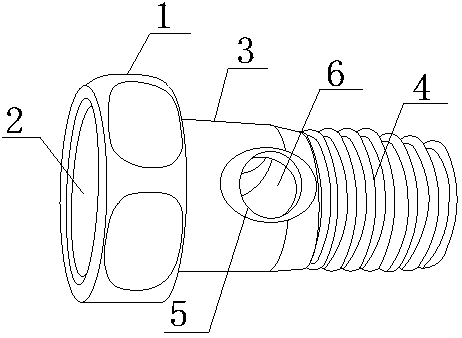

Hollow bolt and machining process thereof

The invention discloses a hollow bolt machining process. The hollow bolt machining process comprises the following steps of (1), preparing raw material; (2), cold drawing; (3), cold heading; (4), automatic drilling; (5), cleaning; (6) thread rolling; and (7), heat treatment (tempering). The machining process has the advantages that surface smoothness of material is good, the automatic machining production efficiency is high, the strength of a thread rolling surface is good, and the strength of a finished product is high. Meanwhile, the hollow bolt comprises a screw cap and a screw rod, one side of the screw cap is provided with a round concave surface, a screw rod is integrally arranged at the center of the other side of the screw cap, a threaded part is arranged at one end of the screw rod, three round holes are annularly arrayed on the side, close to the screw cap, of the screw rod, and an inner hole is formed in one side of the screw rod. The hollow bolt has the advantages of beinggood in using effect and good in oil passing effect.

Owner:浙江国盛汽车科技股份有限公司

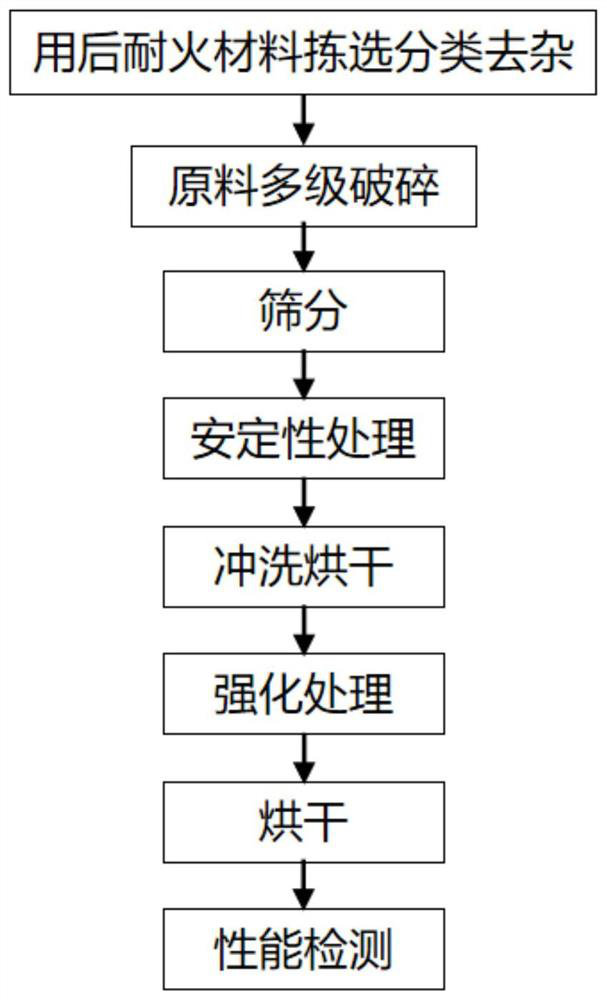

High-wear-resistance anti-skid pavement aggregate, pavement and preparation method

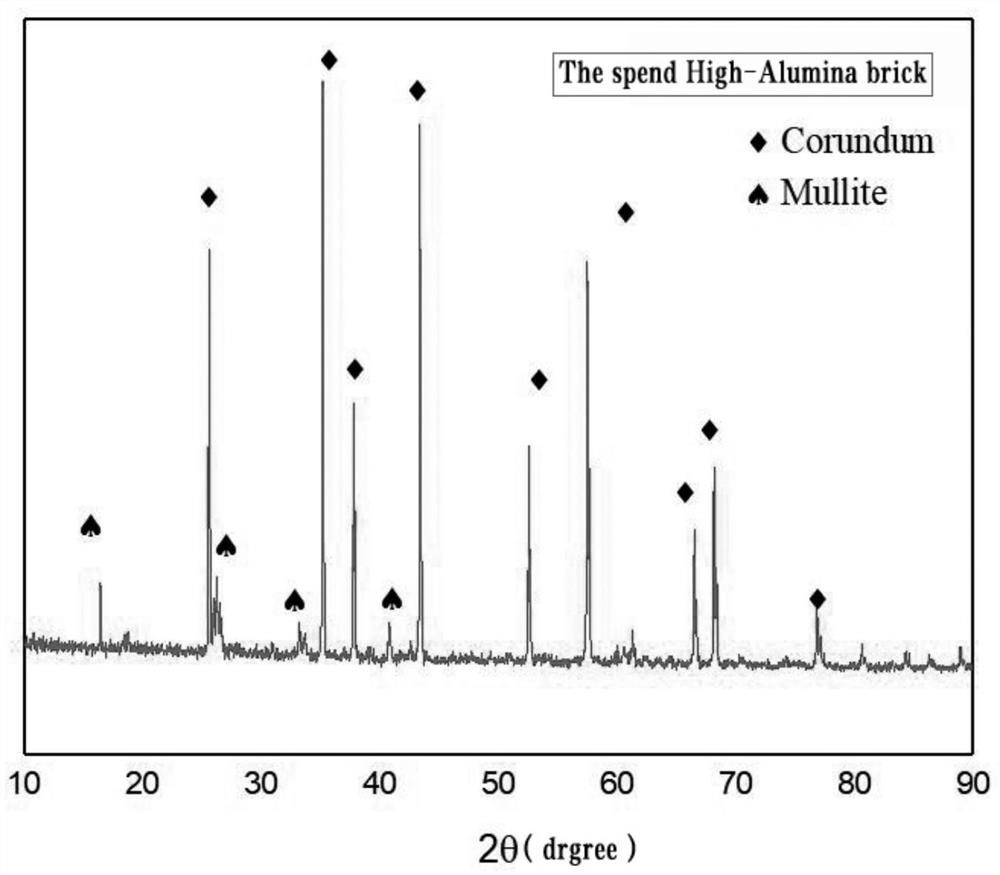

InactiveCN111718143AIncrease added valueAchieve protectionSolid waste managementCarbide siliconBrick

The invention discloses a high-wear-resistance anti-skid pavement aggregate, a pavement and a preparation method. The high-wear-resistance anti-skid pavement aggregate is obtained by taking a waste refractory material as a raw material and carrying out sorting, crushing, screening, soaking and strengthening treatment on the waste refractory material, and the waste refractory material comprises a waste high-alumina refractory material and a waste silicon mullite brick. Main phases in the waste high-alumina refractory material are corundum, mullite and quartz, wherein the mass percentage of Al2O3 is greater than or equal to 60%; main phases in the waste silicon mullite brick are corundum, mullite, silicon carbide and quartz, wherein the mass percentage of Al2O3 is greater than or equal to 55%. The waste is high in alumina content, high in hardness and strength and good in wear resistance, and compared with a process of treating the waste to prepare a refractory material, the process is simple and low in cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-hardness pneumatic vehicle high-pressure steel cylinder production process

InactiveCN106270265AAvoid shortened service lifeHigh precisionShaping toolsHollow articlesHardnessHigh pressure

The invention discloses a high-hardness pneumatic vehicle high-pressure steel cylinder production process. The production process comprises such steps as material selection, annealing, polishing, deep drawing, opening closing, cleaning and painting; the first time of cold drawing is performed for the polished blank; the annealing step is performed after the first time of cold drawing; then, the second time of cold drawing is performed; after the second time of cold drawing, the third time of thermal drawing shape correction is performed for the blank; and the pressure keeping treatment is performed in the third time of thermal drawing shape correction. The overall quality of steel cylinders is guaranteed by multiple times of drawing and annealing treatments.

Owner:成都科创诺商贸有限公司

Capacitor shell insulating coating

InactiveCN107805431AHigh hardness and strengthGood weather resistanceCoatingsSodium stearateMechanical property

The invention discloses a capacitor shell insulating coating which is prepared from cinnamyl aldehyde derivative modified waterborne acrylic acid emulsion, calcium carbonate, pentaerythritol, wood flour, rubber powder, talcum powder, pigments, glass fibers, soybean starch, lauryl sodium sulfate, zeolite powder, sodium stearate, lauroyl diethanolamide, rosin resin and deionized water. The preparedcapacitor shell insulating coating is nontoxic and environmentally friendly. After the insulating coating is sprayed on the surface of a capacitor shell, a coating film is high in hardness and strength, good in abrasion resistance, weather resistance and ageing resistance, tough and tensile and high in flexibility, and the insulating performance of the coating film can be greatly improved withoutreduction of mechanical properties of the coating film.

Owner:蚌埠市嘉实机电设备制造有限公司

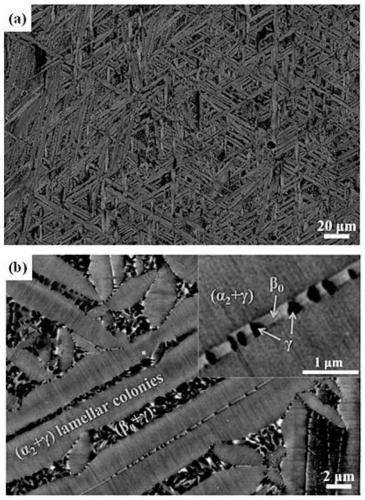

TiAl alloy and preparation method thereof

The invention belongs to the technical field of alloy material thermal treatment and particularly relates to TiAl alloy and a preparation method thereof. The TiAl alloy comprises the following components in atom percentage: 38.0-42.0 at.% of Al, 5.0-10.0 at.% of V, 0.1-0.5 at.% of B, 0.1-0.5 at.% of C and the balance of Ti and unavoidable impurity elements. According to TiAl alloy, high hardenability is obtained through increasing V content and reducing Al content, so that the TiAl alloy can generate martensite transformation at a medium cooling rate from a beta phase area to optimize the usability and processability of TiAl alloy through adjusting the tempering technology.

Owner:JIANGSU UNIV OF TECH

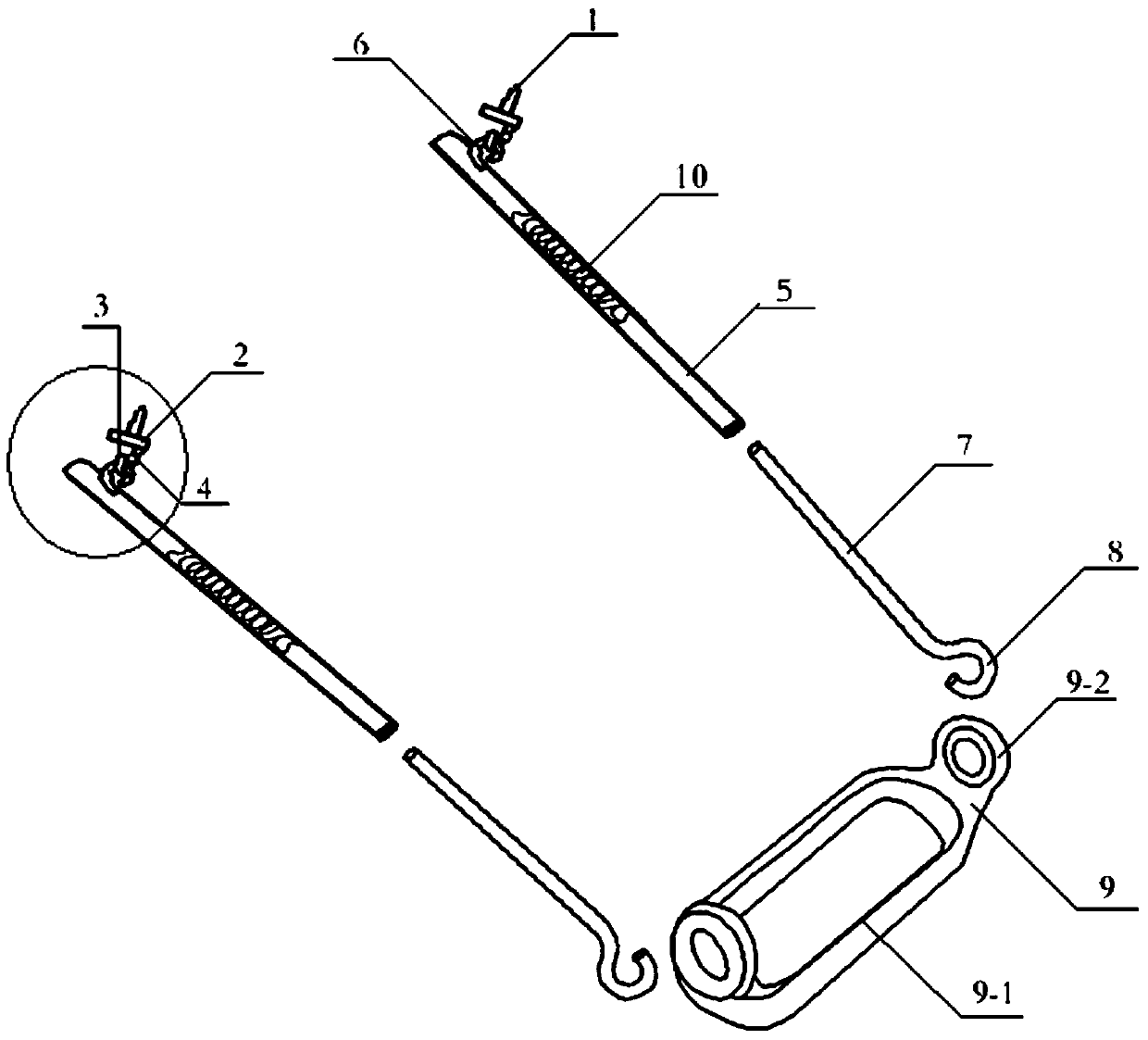

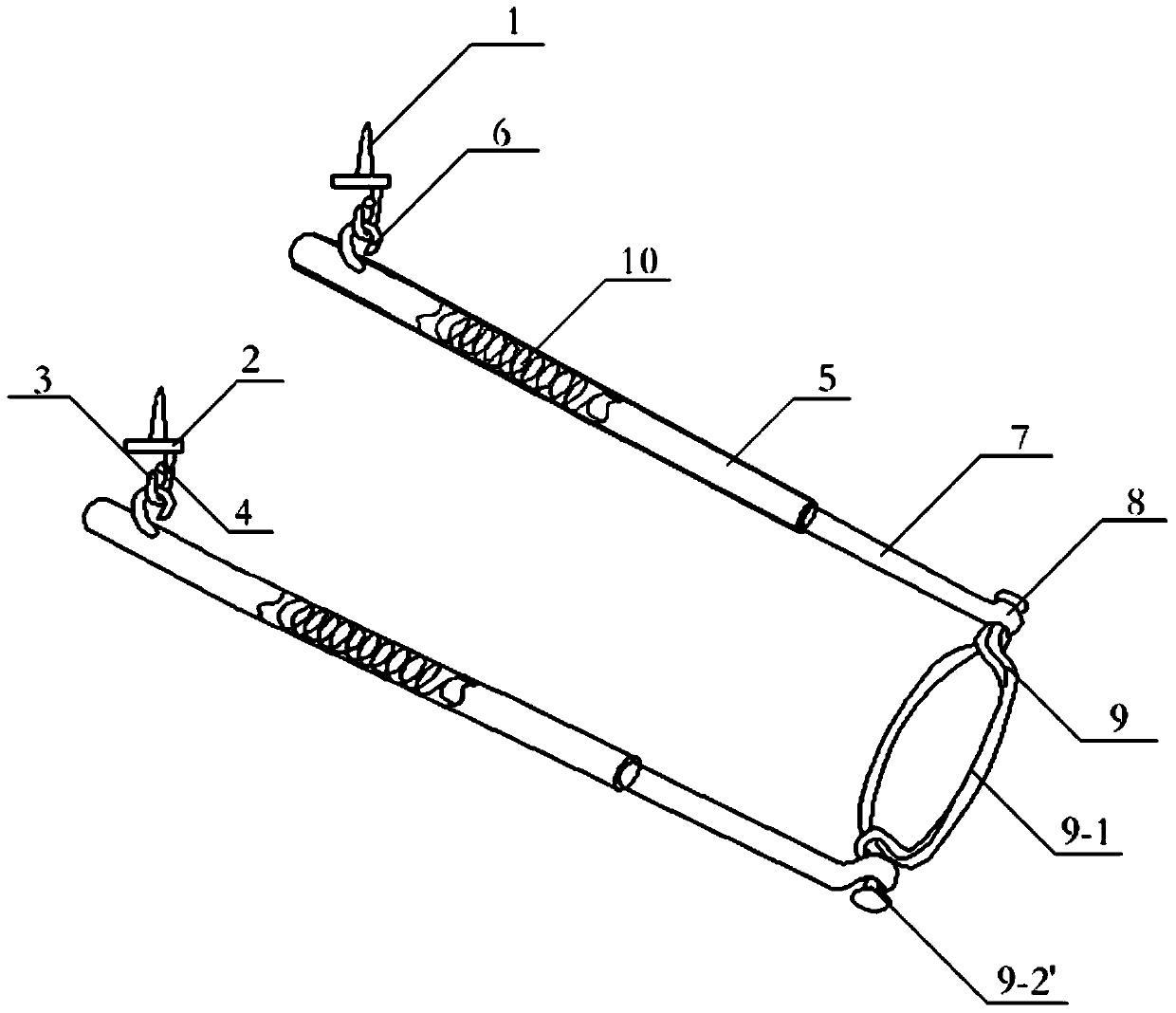

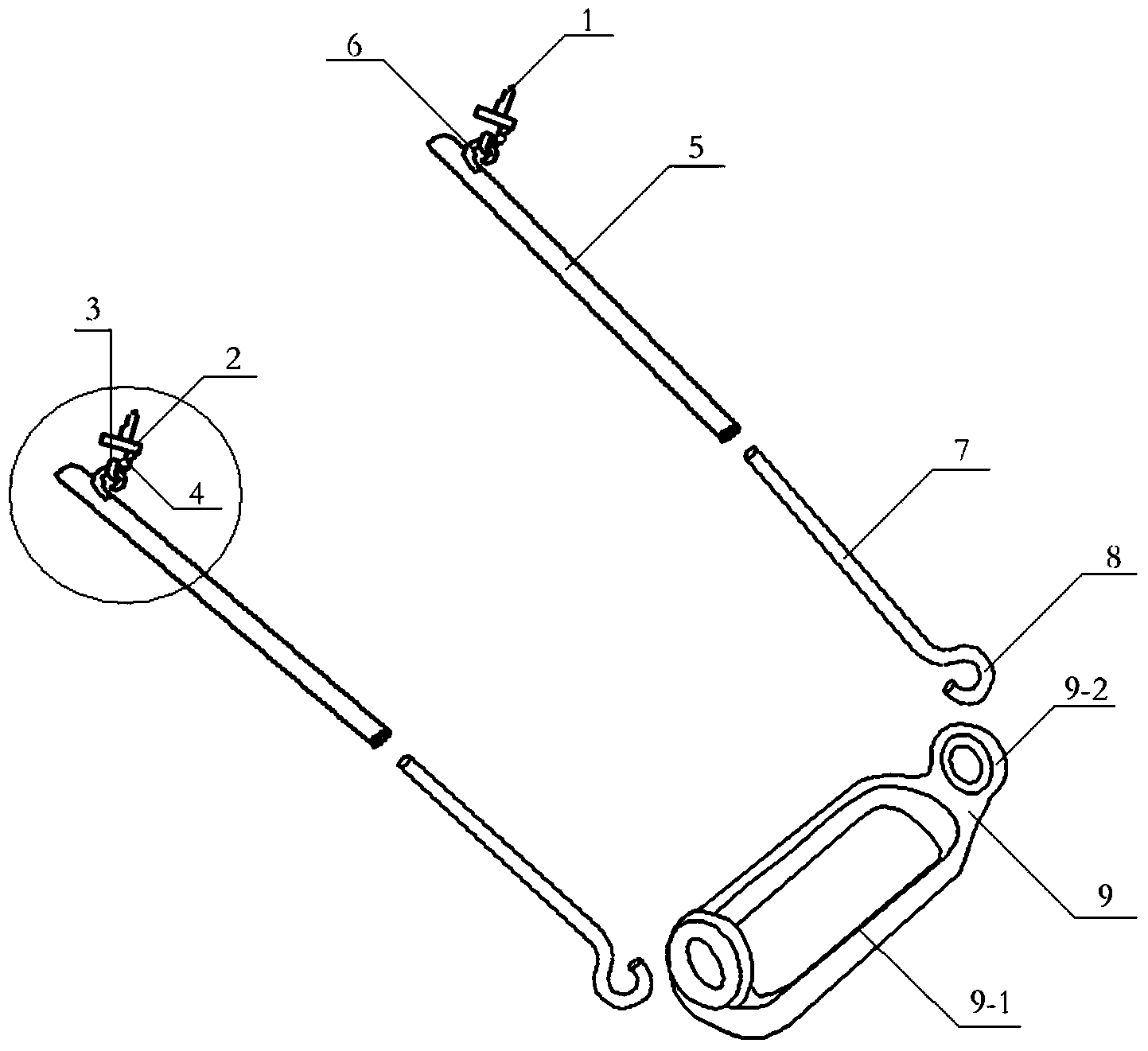

Isotonic contraction forcing device

The invention provides an isotonic contraction forcing device which comprises a supporting component and a fixing device. The supporting component is composed of a connecting component, a sleeve, a pushing spring and an inner rod, the pushing spring is arranged inside the sleeve, the inner rod is nested into the sleeve, the pushing spring arranged in the sleeve has the elastic supporting effect on the inner rod, the supporting component is fixed on the outer side of the sleeve, and the fixing device is connected with the inner rod of the supporting component; the isotonic contraction forcing device is small in size, simple in structure, wide in application range and capable of being applied to tissues and organs such as skin, skeletal muscles and smooth muscles, isotonic contraction of the tissues and the organs is achieved through ingenious design, and applicable tools are provided for controllable growth of the tissues and the organs such as the skin, the skeletal muscles and the smooth muscles.

Owner:高辉 +1

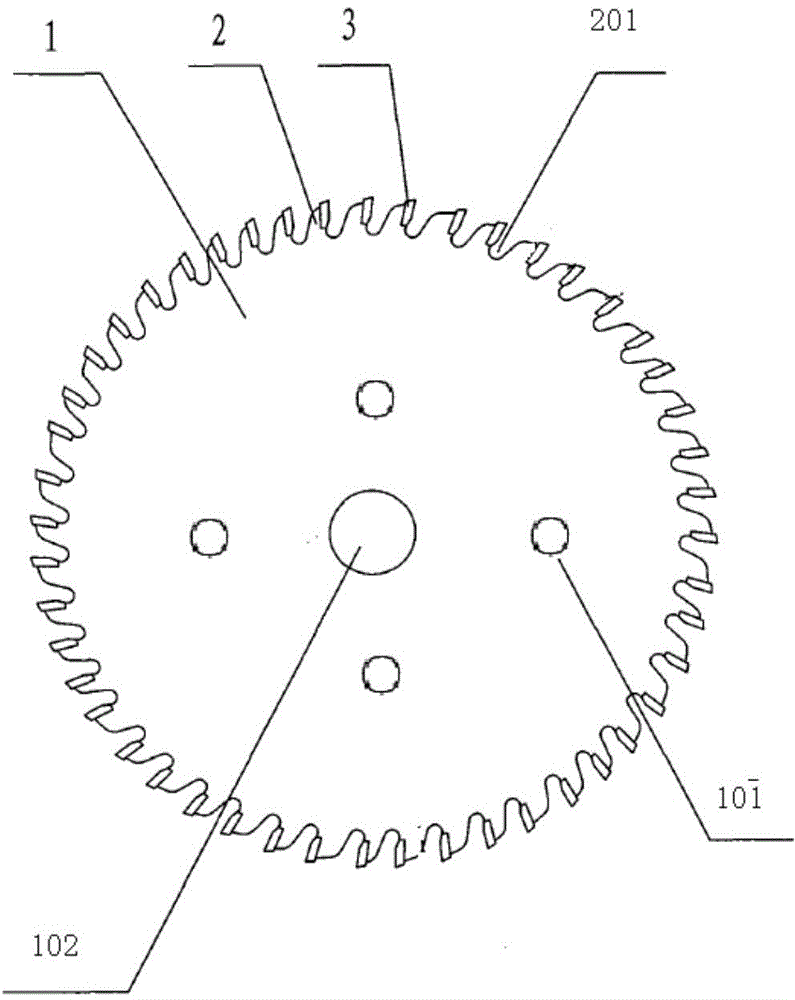

Heat-resistant and abrasion-resistant alloy saw blade

The invention discloses a heat-resistant and abrasion-resistant alloy saw blade which comprises an alloy saw blade substrate and a plurality of alloy sawteeth. The alloy sawteeth are annularly arranged around the alloy saw blade substrate, a plurality of radiating and silencing holes are formed in positions around the center of the alloy saw blade substrate, heat-resistant layers and abrasion-resistant layers respectively cover the alloy saw blade substrate and the alloy sawteeth, and a chip pocket is arranged between each two adjacent alloy sawteeth. The heat-resistant and abrasion-resistant alloy saw blade has the advantages of radiating and silencing functions, excellent abrasion-resistant performance and long service life.

Owner:SUZHOU OUMEIKE CARBIDE TOOL

Environment-friendly paint for chemical pump housing

InactiveCN107641403AHigh hardness and strengthGood weather resistanceCoatingsWeather resistanceEmulsion

The invention discloses environment-friendly paint for a chemical pump housing. The environment-friendly paint is prepared from the following components: waterborne acrylic emulsion, abietate, polyvinyl alcohol, pentaerythritol, carboxymethylcellulose, propanediol, talcum powder, pigments, aluminum silicate fibers, corn stalk powder, lauryl sodium sulfate, inositol hexaphosphate, nano particles, lauroyl diethanolamide, rhus verniciflua folium alcohol extract and deionized water. The chemical pump housing paint prepared by the invention is nontoxic and environmentally friendly; after being smeared on the surface of a capacitor housing, a paint film is high in hardness and strength, good in wear resistance, weather resistance and aging resistance and high in toughness and flexibility.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

Alloy hole opener

InactiveCN104551113AIncrease the opening speedNot easy to wearTransportation and packagingTrepanning drillsAlloyPyramid

The invention discloses an alloy hole opener. The alloy hole opener comprises a head part and a handle part connected with the head part, wherein hard alloy blades are arranged at the end of the head part; each hard alloy blade is in a rectangular pyramid shape; one rectangular face in each rectangular pyramid is connected with the head part; a chip discharging groove is further formed between the adjacent hard alloy blades. According to the alloy hole opener, a blade tooth opening is not easy to abrade, the service life is longer and the hole opening speed is rapid.

Owner:滁州用朴合金工具有限公司

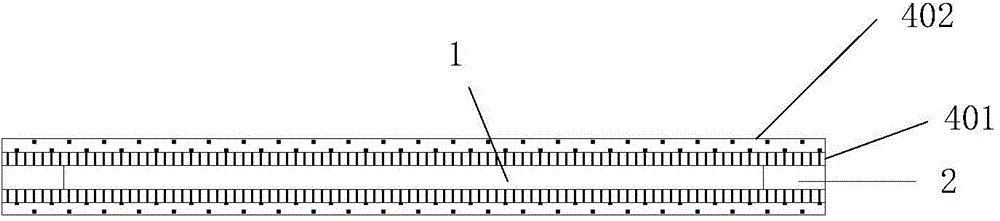

Self-cooling cable tray with good cable gathering convenience

InactiveCN107565473AAchieve fixationArrange neatlyElectrical apparatusCable trayPetroleum engineering

The invention discloses a self-cooling cable tray with good cable gathering convenience and relates to the technical field of cable trays. The self-cooling cable tray with good cable gathering convenience comprises a tray body; the tray body includes a cable receiving chamber composed of a pair of side plates and a pair of cover plates, the cover plates include an upper cover plate and a lower cover plate, the lower cover plate is evenly provided with a plurality of cable tie units along its length, each cable tie unit includes a plurality of cable ties that are distributed evenly along the length of each lower cover plate, each cable tie includes a set of hook and loop fasteners mating with each other, each set of hook and loop fasteners includes a loop part and a hook part, one end of each loop part and one end of the hook part are fixedly connected with the lower cover plate, and the other ends of the corresponding loop part and hook part are free ends.

Owner:江苏鼎荣电气集团有限公司

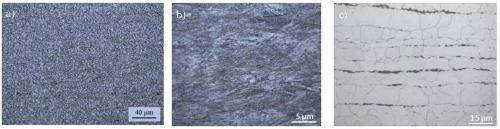

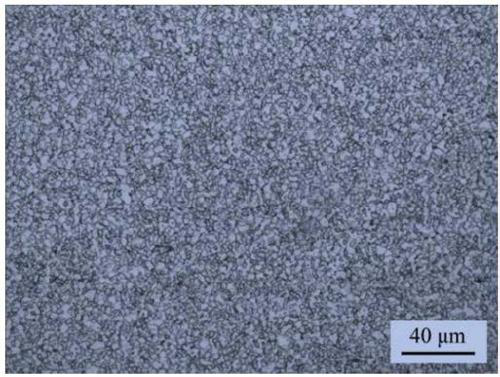

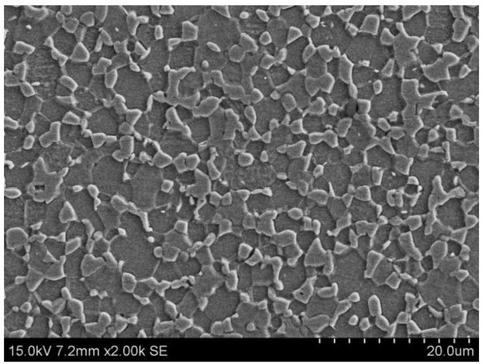

Preparation method of ferrite-twin-crystal martensite low-carbon steel

The invention relates to a preparation method of ferrite-twin-crystal martensite low-carbon steel. The method mainly comprises the following steps that common low-carbon steel with the carbon contentof 0.13% or 0.20% is adopted, quenching is carried out to obtain low-carbon martensite, 75% rolling deformation at the room temperature is carried out, then deformation is carried out at the temperature of 700 DEG C or 710 DEG C for recrystallization, elastic stress of 210 MPa or 220 MPa is applied at the same temperature, ageing is for 40 minutes so as to obtain the ferrite-twin-crystal martensite low-carbon steel ferrite, wherein ferrite is ultrafine isometric crystal, and the grain size of the twin-crystal martensite is about 2 micrometers. The twin-crystal martensite low-carbon steel. According to the prepared ultrafine isometric crystal ferrite + twin-crystal martensite low-carbon steel, the hardness strength is higher than that in the normalizing state, the toughness plasticity is higher than that in the quenching state, the comprehensive mechanical property is greatly improved, the hardness of the low-carbon steel reaches 1.8 times that in the annealing state, and the elongationrate is 2.1 times that in the quenching state.

Owner:YANSHAN UNIV

Corrosion-resisting tensile type alloy steel and production technology thereof

InactiveCN108048750AStrong wear resistanceImprove hardness and wear resistanceSolid state diffusion coatingCompound (substance)Corrosion

The invention discloses corrosion-resisting tensile type alloy steel, and relates to the technical field of metal smelting. The corrosion-resisting tensile type alloy steel comprises the chemical compositions of, by mass, 0.22-0.31% of C, 4.36-5.24% of Cr, 0.71-0.74% of Al, 0.33-0.46% of Zn, 0.41-0.58% of Cu, 0.45-0.49% of Ti, 0.11-0.19% of Si, 0.12-0.15% of W, 0.12-0.14% of Nb, 0.14-0.17% of Mn,and the balance Fe and unavoidable impurities. The invention further discloses a preparation method of the corrosion-resisting tensile type alloy steel. The hardness and tensile strength of the alloysteel can be improved, meanwhile, the corrosion resisting property of the alloy steel can further be improved, and the service life of the alloy steel is effectively prolonged.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

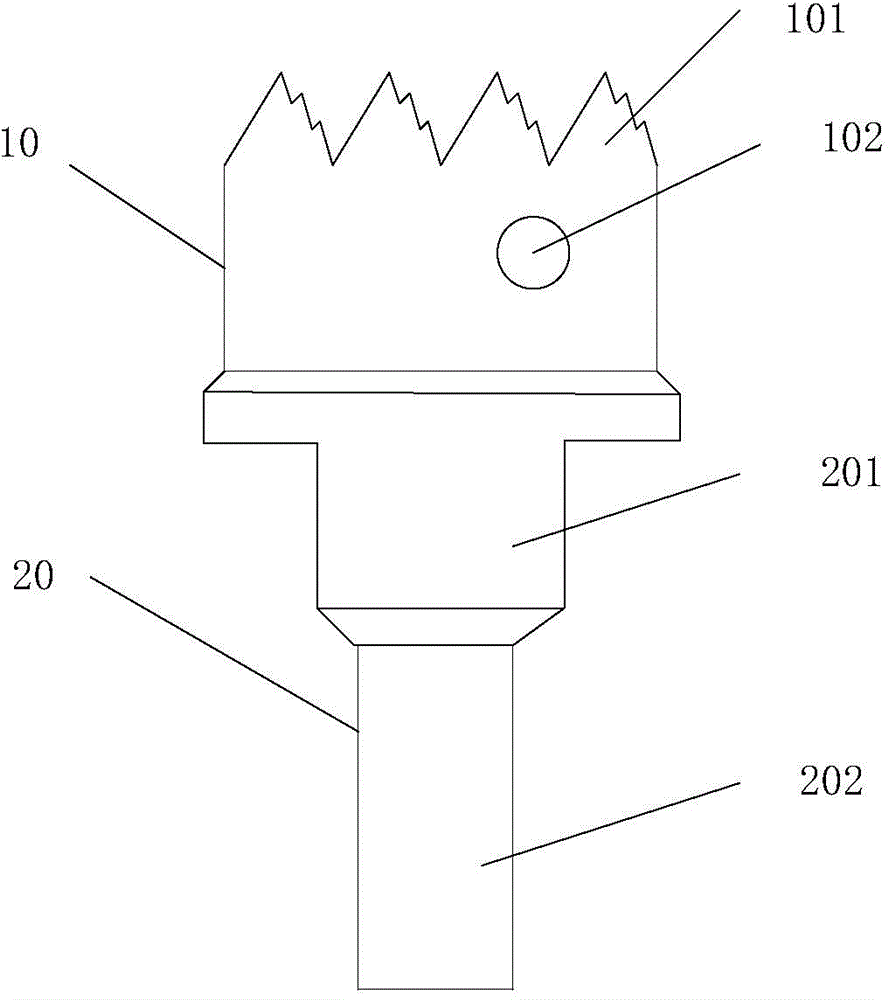

Hard alloy tapper

InactiveCN104551123ANot easy to wearIncrease the opening speedTransportation and packagingTrepanning drillsAlloy

The invention discloses a hard alloy tapper which comprises a head part and a handle part connected with the head part, wherein a sawtooth-shaped hard alloy blade is arranged at an end of the head part; one side of the sawtooth-shaped hard alloy blade is in a straight form; two peaks extend to the bottom of the sawtooth on the other side of the sawtooth-shaped hard alloy blade; a chip outlet is formed in the head part. The hard alloy tapper has the advantages that the blade and the tooth edge are difficult to be abraded and the service life is longer.

Owner:SUZHOU OUMEIKE CARBIDE TOOL

Preparation method of ceramic grinding body for gypsum grinding

The invention discloses a preparation method of a ceramic grinding body for gypsum grinding. The preparation method comprises the following steps of a, selecting the powder, using BaO (barium oxide),TiC (titanium carbide), Mo2C (molybdenum carbide), ZrO2 (zirconium dioxide), Cr2C3 (Chromium carbide) and TaC (tantalum carbide) as the raw materials, preparing acetic acid with concentration of 80% to 90% as a solvent, pouring into the raw materials, mixing with the raw materials, fully impregnating for 3 to 6h, mixing, and controlling the time within 0.5h, so as to obtain a grinding medium; b, drying the raw materials in step a, mixing with coke, selecting spheres, and fully grinding, wherein the ratio of spheres to material is 3:5, the rotation speed of sphere grinding is 300 to 450rpm, andthe duration of sphere grinding is 30 to 48h; c, screening the mixture after sphere grinding, wherein the sieve hole is 50 to 150 meshes; d, putting the screened mixture into a die, and pressing intothe blank at the pressure of 350 to 550MPa; e, heating the fetched blank, cooling the heated and formed blank, cutting after cooling, grinding and polishing. The prepared grinding body has higher hardness and longer service life.

Owner:FOSHAN HUAQIANG XIEXING CERAMIC CO LTD

Inner container coating used for lightweight submersible pump, and preparation method thereof

InactiveCN107353736AIncreased rust resistance and hardness strengthPrevent liner damageAnti-corrosive paintsPolyamideRosin

The invention discloses to an inner container coating for a lightweight submersible pump, and relates to the technical field of production and processing of pumps. The coating comprises acrylic resin, isocyanate, lithopone, polyamide, aluminum nitrate, magnesium chloride, carbon fiber powder, triethanolamine, rosin, cyclohexanol, polyethylene wax, toluene, EVA resin, calcium bentonite, silica powder, calamine powder, wood glue powder, deionized water, an antirust agent, a composite reinforcing agent, an antifoaming agent and a thickener. The antirust agent and the composite reinforcing agent are used to modify a coating in order to increase the antirust property and the hardness of the coating, and antirust powder-containing components in the antirust agent added to the coating can help the coating to form a film on an inner container in order to improve the antirust ability of the inner container, so the pump body of the water pump is protected, the resistance of the submersible pump to low-oxygen humid environment is effectively improved, and the service life of the submersible pump is prolonged.

Owner:张黎明

Soft hot melt adhesive containing rosin

InactiveCN105038641AImprove mechanical propertiesGood compatibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterThermal deformation

The invention discloses a soft hot melt adhesive containing rosin. The hot melt adhesive is prepared from the following raw materials in parts by weight: 45-50 parts of EVA, 10-20 parts of modified tackifying resin, 1-2 parts of dodecyl trimethyl ammonium chloride, 40-55 parts of hydrotalcite powder, 1-2 parts of an antioxidant RD, 1-5 parts of dimethyl aminopropyl amine, 3-5 parts of polypropylene adipate, 5-10 parts of diatomite, 10-13 parts of rosin, 20-30 parts of alkyl phenolic resin, 1-2 parts of methyl methacrylate and 1-2 parts of n-octyl acrylate. The hot melt adhesive contains intercalated modified rosin, so that the mechanical property of rosin can be improved, the thermal deformation temperature can be increased, and the water absorptivity is low; when the intercalated modified rosin is utilized for preparation of the hot melt adhesive, the compatibility of all the raw materials can be improved, the viscosity and water resistance of the hot melt adhesive can be improved, and thus the prepared hot melt adhesive can be soft.

Owner:QUANJIAO HAIFENG PRINTING PACKAGING

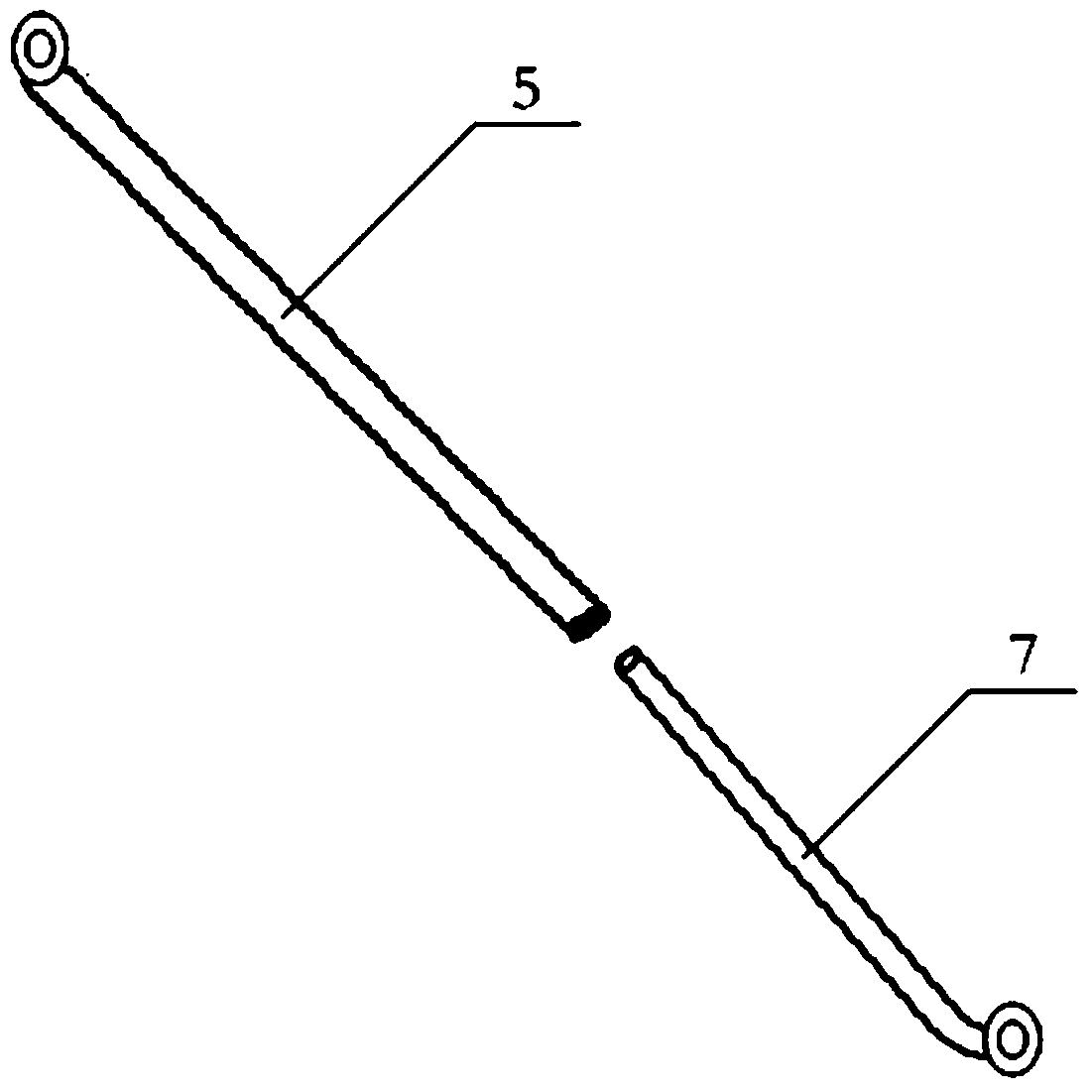

Isometric contraction force-applying device

InactiveCN104027183AReduce volumeSimple structureSurgical veterinarySkeletal muscleBiomedical engineering

The invention provides an isometric contraction force-applying device which comprises a supporting component and a fixing device. The supporting component is composed of a connecting component, a sleeve and an inner rod. The inner rod is embedded inside the sleeve. The connecting component is fixed to the outer side of the sleeve. The fixing device is connected with the inner rod of the supporting component. The isometric contraction force-applying device is small in size, simple in structure and wide in application range; due to the ingenious design of the sleeve, the isometric contraction force-applying device can be applied to all tissue and organs such as skin, skeletal muscles and smooth muscles; isometric contraction of the tissue and organs is achieved through the ingenious design, and an applicable tool is provided for controlled growth of all the tissue and organs such as the skin, the skeletal muscles and the smooth muscles.

Owner:高辉 +1

A kind of novel non-magnetic stainless steel and preparation method thereof

The invention discloses novel non-magnetic stainless steel which consists of the following components in percentage by weight (% hereinafter being percentage by weight): 0.15%-0.21% of carbon, 3%-5% of nickel, 8%-13% of chromium, 8%-11% of manganese, 4%-5% of silicon, 0.48%-0.65% of niobium, 0.13%-0.47% of vanadium, 1.2%-1.7% of molybdenum, 3%-4% of titanium, 0.27%-0.33% of rare earth, less than or equal to 0.035% of phosphor and sulfur, and the balance of iron and other inevitable impurities. Based on the original non-magnetic stainless steel, the novel non-magnetic stainless steel has highly improved mechanical performance by changing alloy components and adding a novel component; meanwhile, the structural texture of steel is changed by changing a preparation process and controlling the parameters in the process, so that the obtained steel is good in various performances, high in corrosion resistance, good in shape memory effect and especially suitable for pipeline connection on ships and warships.

Owner:东莞市雅鲁实业有限公司

A special anti-corrosion and anti-degumming screw drilling tool for high-sulfur oil and gas wells and its processing technology

ActiveCN110107222BHigh tensile strengthIncrease elasticityBorehole drivesAnti-corrosive paintsHydraulic motorDrive shaft

The invention discloses an oil-resistant, acid-resistant, sulfur-resistant, H-resistant 2 A special anti-corrosion and anti-degumming screw drilling tool and processing technology for high-sulfur oil and gas wells in highly corrosive media such as S. Including: bypass valve assembly, hydraulic motor assembly, cardan shaft assembly and transmission shaft assembly, the hydraulic motor assembly includes: motor stator metal casing, motor rotor and the motor stator metal casing and motor rotor The rubber bushing of the motor stator between them; several 90° inverted splayed tapered holes are arranged on the metal casing of the motor stator, and plugs are arranged in the 90° inverted splayed tapered holes, and the motor stator The synthetic glue of the rubber bushing is injected into the cavity between the metal casing of the motor stator and the core of the motor rotor, and part of the synthetic glue is injected into the 90° inverted figure-eight tapered hole.

Owner:YANCHENG HUAYA GASOLINEEUM MACHINERY MFG

Heat-resistant styrene resin-containing hot melt glue

InactiveCN105038650AImprove mechanical propertiesGood compatibilityNon-macromolecular adhesive additivesHydrocarbon polymer adhesivesPotassiumMechanical property

The invention discloses heat-resistant styrene resin-containing hot melt glue. The hot melt glue is prepared from the following raw materials in parts by weight: 65-70 parts of EVA, 10-20 parts of modified tackifying resin, 1-3 parts of cetyl trimethyl ammonium bromide, 5-10 parts of styrene resin, 10-15 parts of xylene formaldehyde resin, 1.3-1.5 parts of a crosslinking agent TAC, 15-20 parts of neoprene, 1-2 parts of paraffin oil, 0.5-0.8 part of sodium carboxymethylcellulose, 2-5 parts of epoxidized soybean oil, 25-30 parts of nano potassium feldspar powder, 1.3-1.9 parts of casein and 1.5-1.9 parts of citric acid. According to the heat-resistant styrene resin-containing hot melt glue, the heat resistance of the hot melt glue can be improved through the usage of nano potassium feldspar powder and casein; styrene resin and neoprene are subjected to intercalation modification, so that the mechanical property of the resin can be improved, the heat deflection temperature is increased, the water-absorbing property is low, and when the resin subjected to intercalation modification is used to prepare the hot melt glue, the compatibility among the raw materials of the hot melt glue is strengthened, and the viscosity, heat resistance and waterpfoofness of the hot melt glue are improved.

Owner:QUANJIAO HAIFENG PRINTING PACKAGING

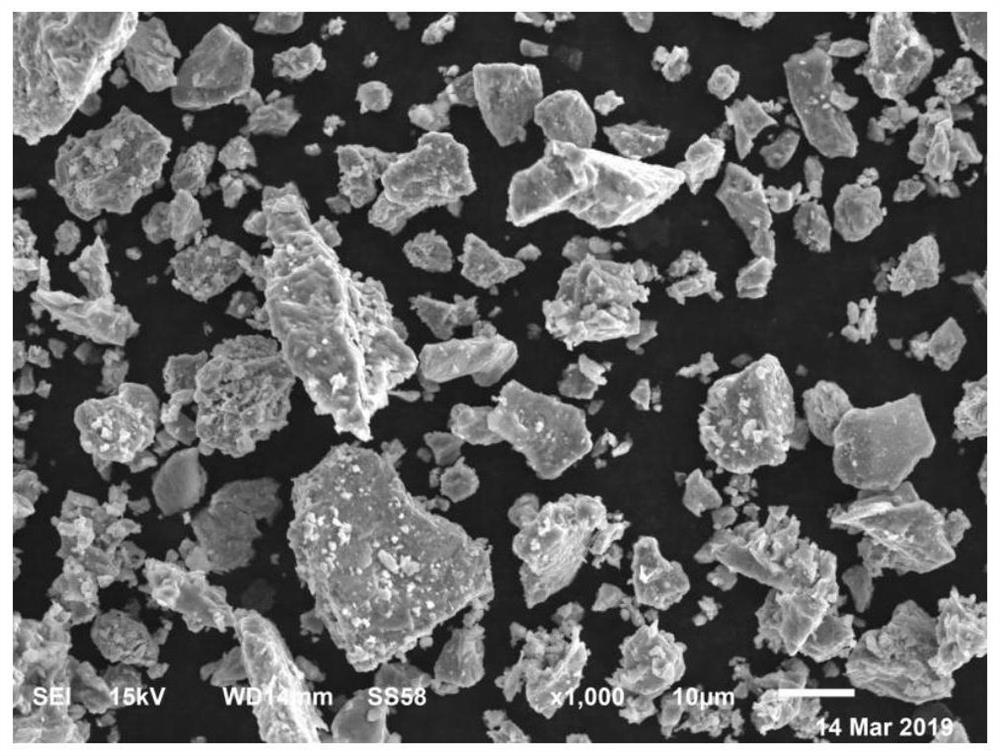

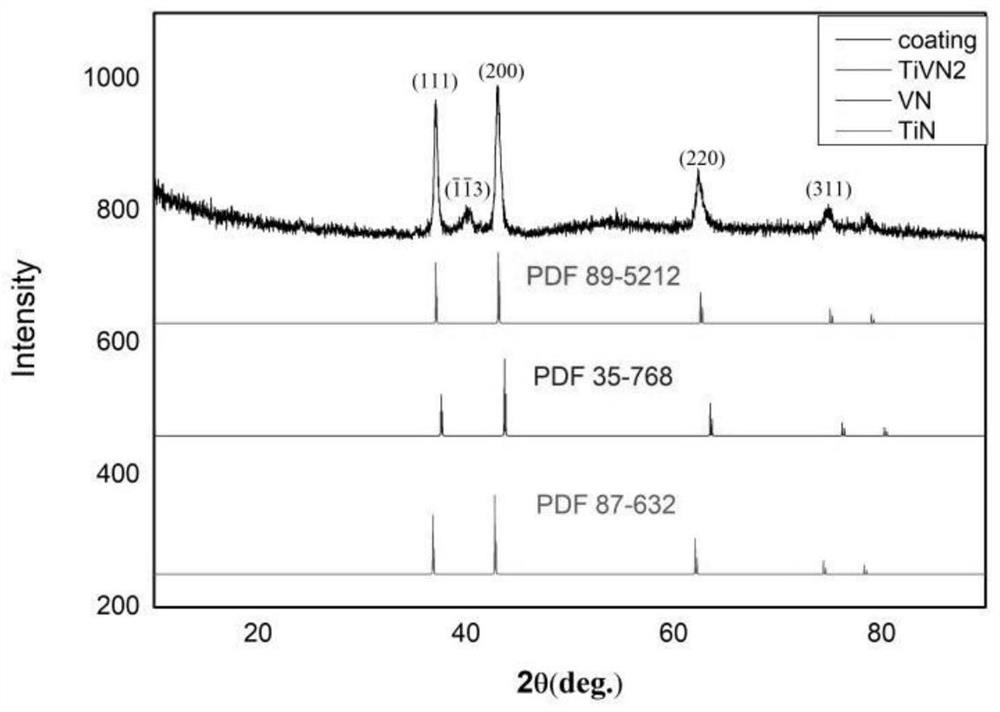

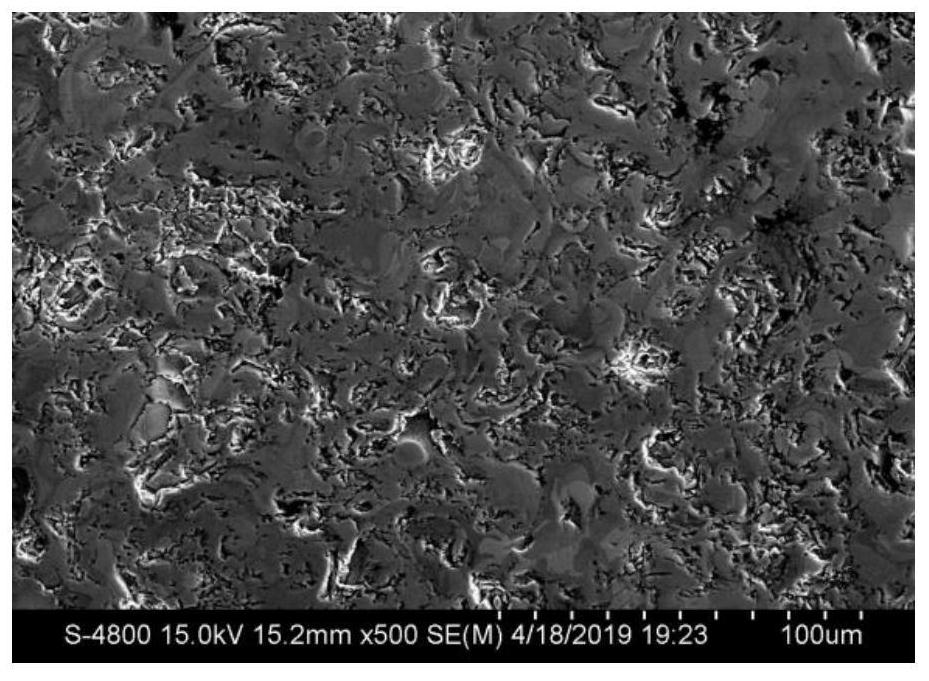

A method for preparing nanocrystalline tivn coating by reactive plasma spraying

The invention relates to a method for preparing a nanocrystalline TiVN coating by reactive plasma spraying. The method comprises the following steps: sand blasting is carried out on the surface of the required coating base material, followed by spraying a bonding primer on the surface of the metal base material after the sand blasting treatment; the Ti-V alloy powder obtained by mechanical ball milling is sprayed on the previous step The surface of the bonded base layer is formed to prepare a nanocrystalline TiVN coating with a thickness of 200-500 microns. The invention can effectively overcome the brittleness of nitride ceramics, improve the toughness, wear resistance and high temperature stability of the coating, and realize the TiN and VN solid solution composite nitride coating efficiently formed in reactive plasma spraying.

Owner:HEBEI UNIV OF TECH

High-hardness Cu-based material containing interface layers and preparation method thereof

PendingCN112323032ASimple processLow priceVacuum evaporation coatingSputtering coatingInterface layerLayer thickness

The invention discloses a high-hardness Cu-based material containing interface layers and a preparation method thereof. The material comprises Cu matrix layers and the interface layers, wherein the Cumatrix layers and the interface layers are alternately superposed; an initial layer and a final layer are Cu layers; the interlayer modulation ratio is 10:1-50:1; the interface layers are Nd, Zr, Ag,CuZr amorphous and CuNb amorphous; the thicknesses of the Cu layers are the same; the thickness range of the single Cu layer is 5-50 nm; the thicknesses of the interface layers are the same; and thethickness range of the single interface layer is 0.5-2 nm. The prepared high-hardness Cu-based material has such mechanical properties as higher hardness; and the interface layers generate no side effect on the matrix Cu. The preparation method of the Cu-based material is simple in production process, low in cost and suitable for industrial application and automatic batch production, and has unique structure and performance advantages in such fields as microelectronic components, power transmission devices, integrated circuits and printed circuits.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com