A method for preparing nanocrystalline tivn coating by reactive plasma spraying

A plasma and nanocrystalline technology, applied in the coating, metal material coating process, molten spraying, etc., can solve the problems of low bonding strength, high porosity, and difficult densification of the phase interface, and achieve superior high temperature stability. Improved usability and increased bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

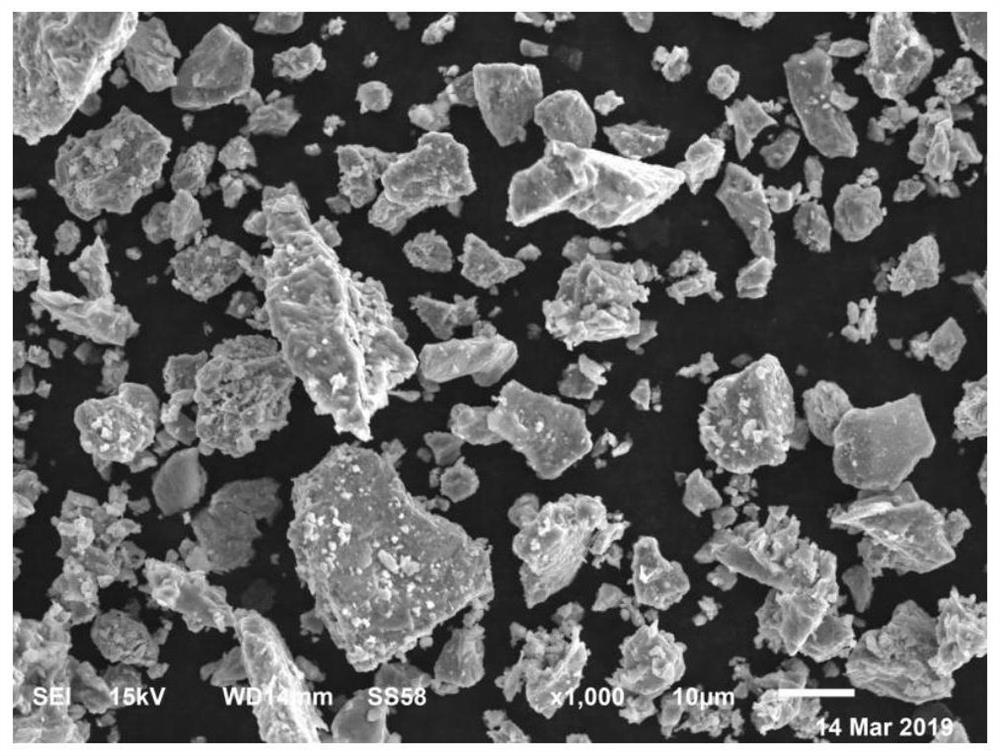

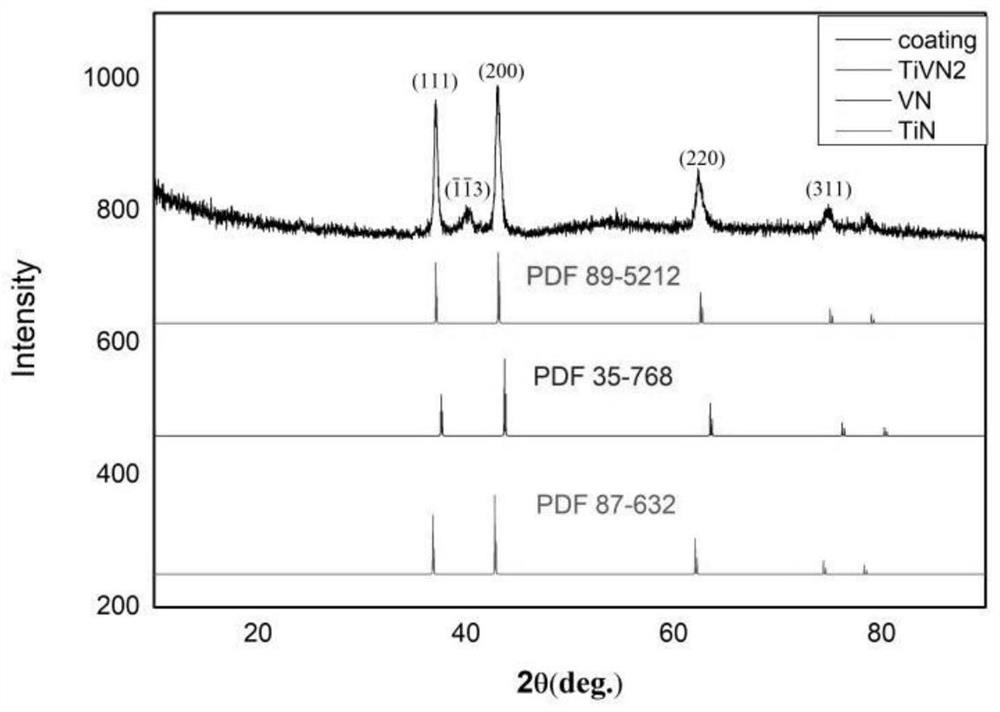

[0032] Weigh the original Ti powder and V powder with a mass ratio of 8:2 as raw materials for the preparation of the initial Ti-V mixed powder, wherein the particle size of Ti powder and V powder are both 200-500 mesh. And use stainless steel balls with diameters of 4mm, 6mm and 10mm respectively, and the mass ratio of 1:4:1 as the grinding balls, in which the mass ratio of the mixed powder to the total grinding balls is 1:8; the ball milling tank is the bottom A cylindrical mold with a diameter of 6cm and a height of 10cm.

[0033] The obtained simply mixed raw material powder and balls are mixed into the ball mill tank, vacuumed and sealed, filled with argon as an inert protective gas, and the sealed spherical tank is placed in a planetary ball mill with the speed set at 500r / min. The duration is set to 12h. After the ball milling is finished, sieving treatment is carried out to obtain Ti-V mechanical alloying powder with a particle size of 1-50 microns, which is used as a...

Embodiment 2

[0041] Weigh the original Ti powder and V powder with a mass ratio of 7.5:2.5 as the raw materials for the preparation of the initial Ti-V mixed powder. Except for the different proportions of the original powder, the methods and control parameters are the same example 1.

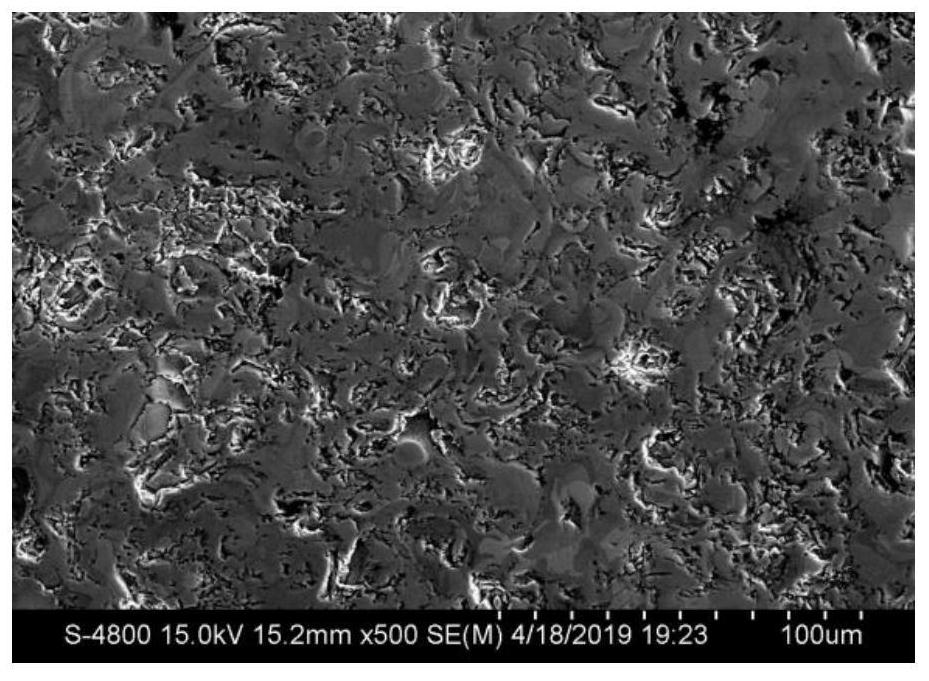

[0042] The mechanical alloy powder and TiVN coating prepared by the above method are similar to those in Example 1, and the composition and morphology analysis are relatively uniform and stable. Compared with Example 1, the surface composition will have a slightly increased white area, and its microhardness The average value of the test analysis is 1836Hv (Vickers hardness), and it can be seen that the hardness of the proportional feed powder is not much different from that of Example 1 after use.

Embodiment 3

[0044] Weigh the original Ti powder and V powder with a mass ratio of 7:3 as the raw materials for the preparation of the initial Ti-V mixed powder. Except for the different proportions of the original powder, the methods and control parameters are the same. example 1.

[0045] The mechanical alloy powder and TiVN coating prepared by the above method are similar to those in Example 1. Compared with Example 1 and Example 2, the white area distribution in its surface composition is more and uniform, and its microhardness test analyzes the average value It is 1904Hv (Vickers hardness), it can be seen that the hardness of this kind of ratio feeding powder is slightly improved compared with Examples 1 and 2 after use, which is a more reasonable proportion of ingredients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com