A special anti-corrosion and anti-degumming screw drilling tool for high-sulfur oil and gas wells and its processing technology

A technology for screw drilling tools and oil and gas wells, which is applied in anti-corrosion coatings, driving devices for drilling in boreholes, and earth square drilling, etc., and can solve problems such as high cost, corrosion, and reduced toughness of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

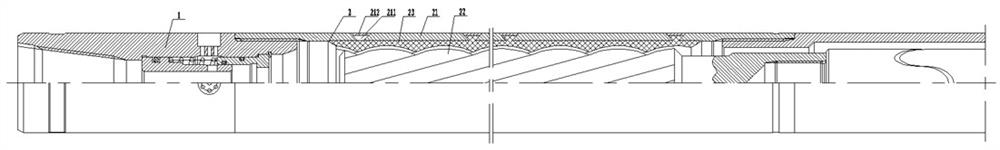

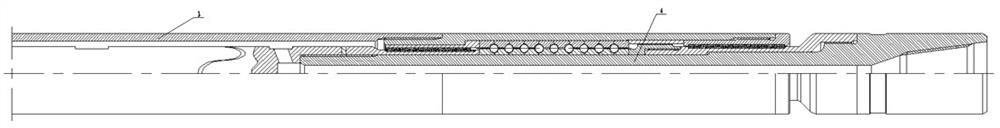

Image

Examples

Embodiment 1

[0032] A processing technology for anti-corrosion and anti-degumming screw drilling tools specially used for high-sulfur oil and gas wells, including the following process steps:

[0033] (1) Making motor stator rubber bushing:

[0034] 15% neoprene rubber, 20% acrylic ester, 3% fluorine rubber 246, 20% chlorohydrin rubber, 10% 6μm modified ultrafine carbon fiber powder, the average length of the fiber is 10mm, and 15% polymer poly Ethylene is uniformly mixed and co-refined;

[0035] (2), add 3% dibenzothiazole disulfide, 2% zinc oxide activator, 2% dibutyl phthalate softening agent in the sizing material that mixing co-refining step (1) obtains, 3% % anti-aging agent A, adding 3% nano-silica reinforcing agent, 2% cobalt salt coagulant, and 2% triazine adhesive in batches to make synthetic rubber for motor stator rubber bushing;

[0036] (3) To make the motor stator metal shell, the inner wall of the motor stator metal shell is driven by high-pressure fluid, and the quartz s...

Embodiment 2

[0043] A processing technology for anti-corrosion and anti-degumming screw drilling tools specially used for high-sulfur oil and gas wells, including the following process steps:

[0044] (1) Making motor stator rubber bushing:

[0045] 20% neoprene rubber, 10% acrylic ester, 5% fluorine rubber 246, 10% chlorohydrin rubber, 12% 5μm modified ultrafine carbon fiber powder, the average fiber length is 13mm, 20% polymer poly Ethylene is uniformly mixed and co-refined;

[0046] (2), add 4% dibenzothiazole disulfide, 3% zinc oxide activator, 3% dibutyl phthalate softening agent, 4% in the sizing material that mixing co-refining step (1) obtains, % anti-aging agent A, adding 5% nano-silica reinforcing agent, 3% cobalt salt coagulant, and 1% triazine adhesive in batches to make synthetic rubber for motor stator rubber bushing;

[0047] (3) To make the motor stator metal shell, the inner wall of the motor stator metal shell is driven by high-pressure fluid, and the quartz sand is use...

Embodiment 3

[0054] A processing technology for anti-corrosion and anti-degumming screw drilling tools specially used for high-sulfur oil and gas wells, including the following process steps:

[0055] (1) Making motor stator rubber bushing:

[0056] 218% neoprene rubber, 18% acrylic ester, 4% fluorine rubber 246, 16% chlorohydrin rubber, 11% 4μm modified ultrafine carbon fiber powder, the average length of the fiber is 15mm, and 16% polymer poly Ethylene is uniformly mixed and co-refined;

[0057] (2), add 3% dibenzothiazole disulfide, 2% zinc oxide activator, 2% dibutyl phthalate softening agent in the sizing material that mixing co-refining step (1) obtains, 3% % anti-aging agent A, add 4% nano-silica reinforcing agent in batches, 1% cobalt salt coagulant, and 1% triazine adhesive to make motor stator rubber bushing synthetic rubber;

[0058] (3) To make the motor stator metal shell, the inner wall of the motor stator metal shell is driven by high-pressure fluid, and the quartz sand is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com