TiAl alloy and preparation method thereof

An alloy and intermediate alloy technology, applied in the field of TiAl alloy and its preparation, can solve the problems of increased manufacturing cost, poor comprehensive mechanical properties, inherent brittleness of TiAl alloy and difficulty in use, etc., and achieves good plasticity and good high temperature creep resistance. The effect of variable performance and excellent hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation process of the present embodiment TiAl alloy is as follows:

[0022] Take the raw material sponge titanium, aluminum beans, AlV master alloy, AlTiB, carbon powder, and prepare it by vacuum consumable melting + induction suspension melting The actual composition of the TiAl alloy ingot is Ti-41.5Al-8.0V-0.1B-0.1C (at.%), which contains unavoidable impurities.

[0023] The ingot is subjected to hot isostatic pressing to eliminate keyhole shrinkage, and then a test rod is cut from the ingot.

[0024] Put each test rod into a resistance furnace and raise the temperature to 1320°C. The heating rate of the resistance furnace is 10°C / min. When the temperature reaches 1320°C, it is kept for 40 minutes, and then the test rod is oil-quenched to room temperature.

[0025] Put the quenched sample into the resistance furnace and raise the temperature to 1000°C. The heating rate of the resistance furnace is 10°C / min. When the temperature reaches 1000°C, keep it warm...

Embodiment 2

[0029] The preparation process of the present embodiment TiAl alloy is as follows:

[0030] Using the same ingot as in Example 1, cut the test rod, put it into the resistance furnace and raise the temperature to 1320 ° C, the heating rate of the resistance furnace is 10 ° C / min, when the temperature reaches 1320 ° C, keep it warm for 1 hour, and then oil quench the test rod to room temperature.

[0031] Put the quenched sample into the electric resistance furnace and raise the temperature to 850°C. The heating rate of the electric resistance furnace is 10°C / min.

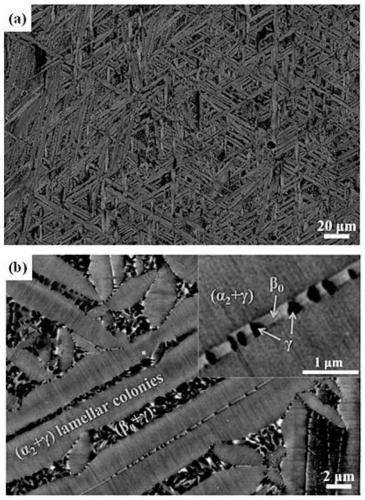

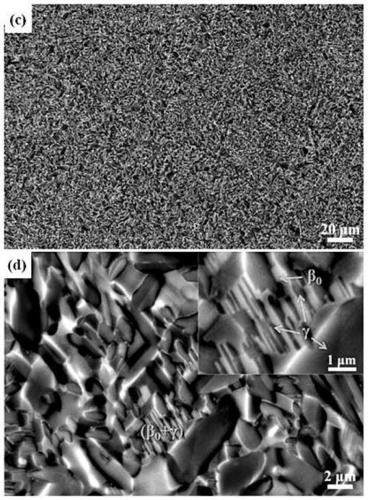

[0032] figure 2 It is the microstructure of TiAl alloy 1300℃ / 0.5h oil quenching, followed by 850℃ / 1500min tempering. It can be observed that the quenched martensite transforms into fine α 2 / γ lamellar structure, and ultrafine γ grains are precipitated in the residual β phase.

[0033] The mechanical properties of the tissue were tested. The test results show that the tensile strength of the alloy reaches abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com